Mold elements for tire molds including removable inserts

A technology for tire molds and inserts, which is applied in the field of baking molds or vulcanization molds, and can solve cumbersome problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

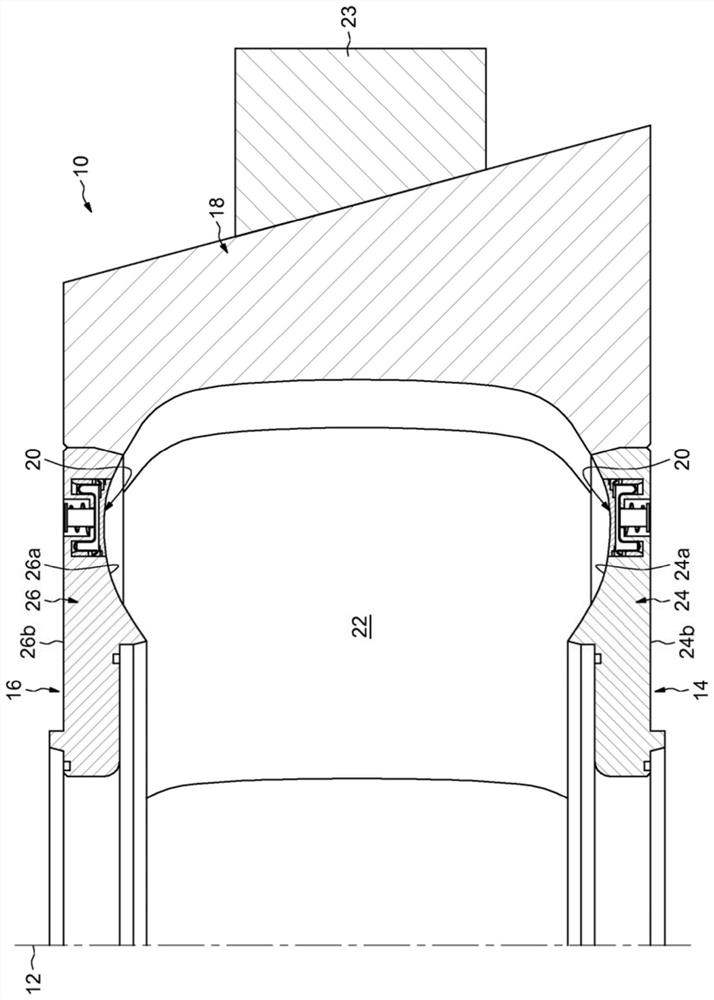

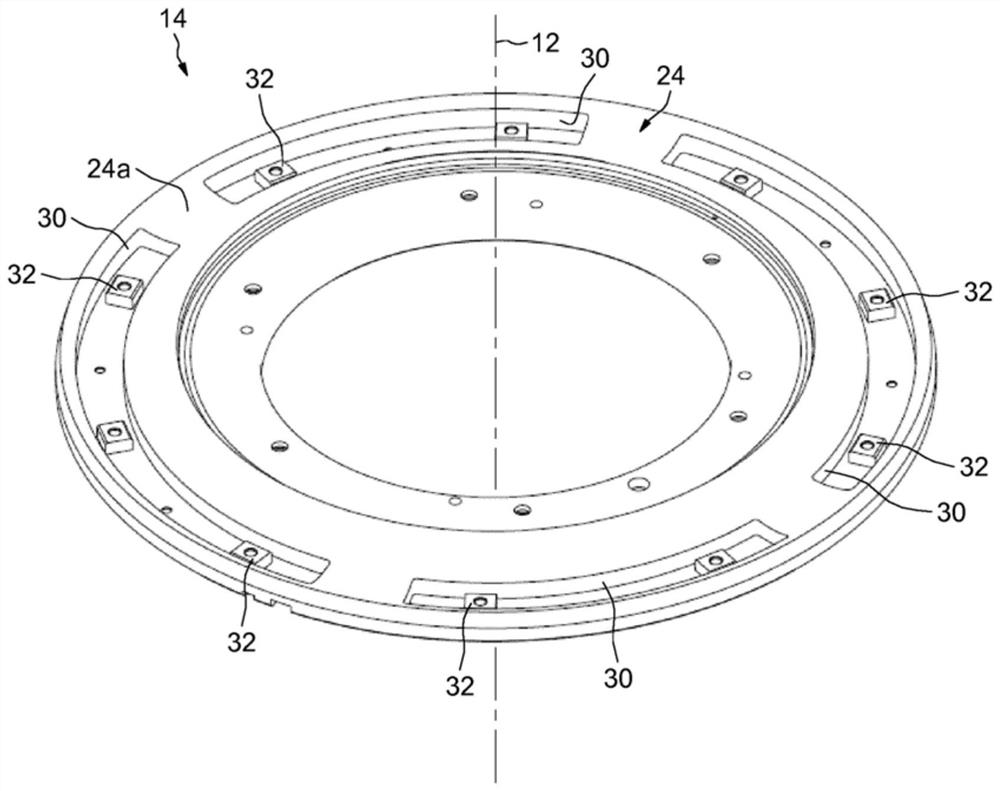

[0052] exist figure 1 In , an exemplary embodiment of a mold is shown, generally designated 10, for the baking or vulcanization of tyres. The mold 10 has an axis of symmetry 12 , here assumed to be vertical, which coincides with the axis of rotation of the tyre.

[0053] The mold 10 comprises two annular shells 14 , 16 facing each other axially above and below, and a crown ring of a segment 18 radially surrounding the shells 14 , 16 .

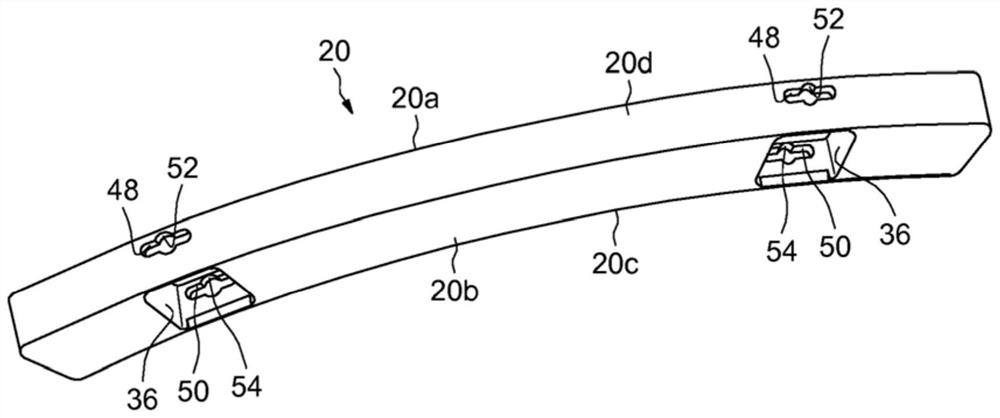

[0054] As will be described in more detail below, the housing 14, 16 of the mold comprises an insert 20 which is removably secured and which comprises marking means for molding a pattern on the sidewall of the tyre.

[0055] As known per se, the section 18 of the mold is in figure 1 The mold 10 shown in FIG. 10 moves radially between a closed position (corresponding to the tire molding position) and an open position. In the closed position, the housings 14, 16 and the plurality of segments 18 collectively define a mold cavity 22 for the tir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com