[0009] The fundamental

advantage of the invention is the ability to industrialise the construction of a large part of the dike and to optimise the logistical aspects of dike construction on land or sea. By being able to construct a large variety of dikes with a few basic modules, it is possible to optimise and industrialise the module manufacturing process in places suitably prepared for the purpose (pre-manufacturing plants), avoiding the environmental impact and cost increments involved in on-site and / or tailored to the site construction. The dismantling of a modular dike allows the modules to be reutilised in the construction of other dikes, reutilising and avoiding the production of residues, with the ensuing economic and long-term environmental

advantage. Furthermore, as the basic modules have certain standardised weights and dimensions similar to or compatible with those of the containers (section of 8×8 feet and lengths of 20 and 40 feet) and can be transported by the intermodal container

transport network, it is possible to efficiently manage large centralised stores of basic modules, to be transported in a short space of time, with a large degree of flexibility and at little cost, to the place on the shoreline requiring the construction of a groyne or protection dike. In this way, reductions are achieved in environmental impacts,

prefabrication costs, installation and dike

operability times. In addition, the elements resulting from the dismantling may be reutilised, minimising the impact on the global environment.

[0010] The invention permits change in the manner in which shoreline protection is currently managed. The ability to construct different types and sizes of dike for shoreline protection using few basic elements makes large-scale industrialised production of basic modules possible, to be stored in determined deposits prior to distribution. Industrial production, transport and storage would be very efficient processes from an economic and environmental stance, since it would be a matter of executing scheduled, repetitive tasks, continuous over time, and unconstrained by space. Once the need for rapid intervention has been established (for example, following a large

storm), a construction project would be swiftly drawn up, adapted to the site (

floor type, depth and maritime climate), the necessary modules would then be transported from the distribution deposits. The on-site construction would be simple, and at a later stage, the structure could be easily modified or dismantled, and the basic elements reutilised. The logistical, economic and environmental advantages of the invention are evident.

[0011] In addition to the clear logical, economic and environmental advantages (if

mass produced), the invention affords flexible shoreline management, reduced global environmental risks and shorter intervention times for shoreline protection. Furthermore, modular dikes permit a total separation, in time and space, of the

prefabrication and installation processes; accumulated reserve modules may be used in situations of crisis (large storms simultaneously affecting extensive areas of shoreline). And furthermore, shoreline intervention times are clearly reduced, as the only requirements are for modules to be transported from the deposits to the dike site using the efficient intermodal container network and for maritime equipment to be available for the mounting and stabilisation of the dike. Lastly, the dike, made up of reutilisable basic modules of

reinforced concrete, in addition to being easy to dismantle, has a

residual value which underpins the economic interest in dismantling and reversing the end works; this means the environmental impact would be small, and a guarantee thereof would be offered, which does not accompany non-modular prefabrications.

[0012] The invention permits the construction of emerged or submerged modular dikes, with numerous gaps, to be used in all likelihood by abundant

marine species, as occurs in

artificial reefs. These modular dikes will generally be installed within the breaker zone (up to 7 metres deep) to support beaches or diminish

waves reaching the shores. In their wave-reducing function, these dikes may be used to

signal the limit of the

bathing area, utilising the danger signals for boats to protect bathers. In this breaker zone, the gaps, with different levels of light as defined by the modular dike, allow different

marine species to settle and shelter, and therefore to benefit from the new ecological space. Thus, in addition to contributing to beach and shoreline protection, these dikes may serve to heighten the productivity and stability of marine ecosystems.

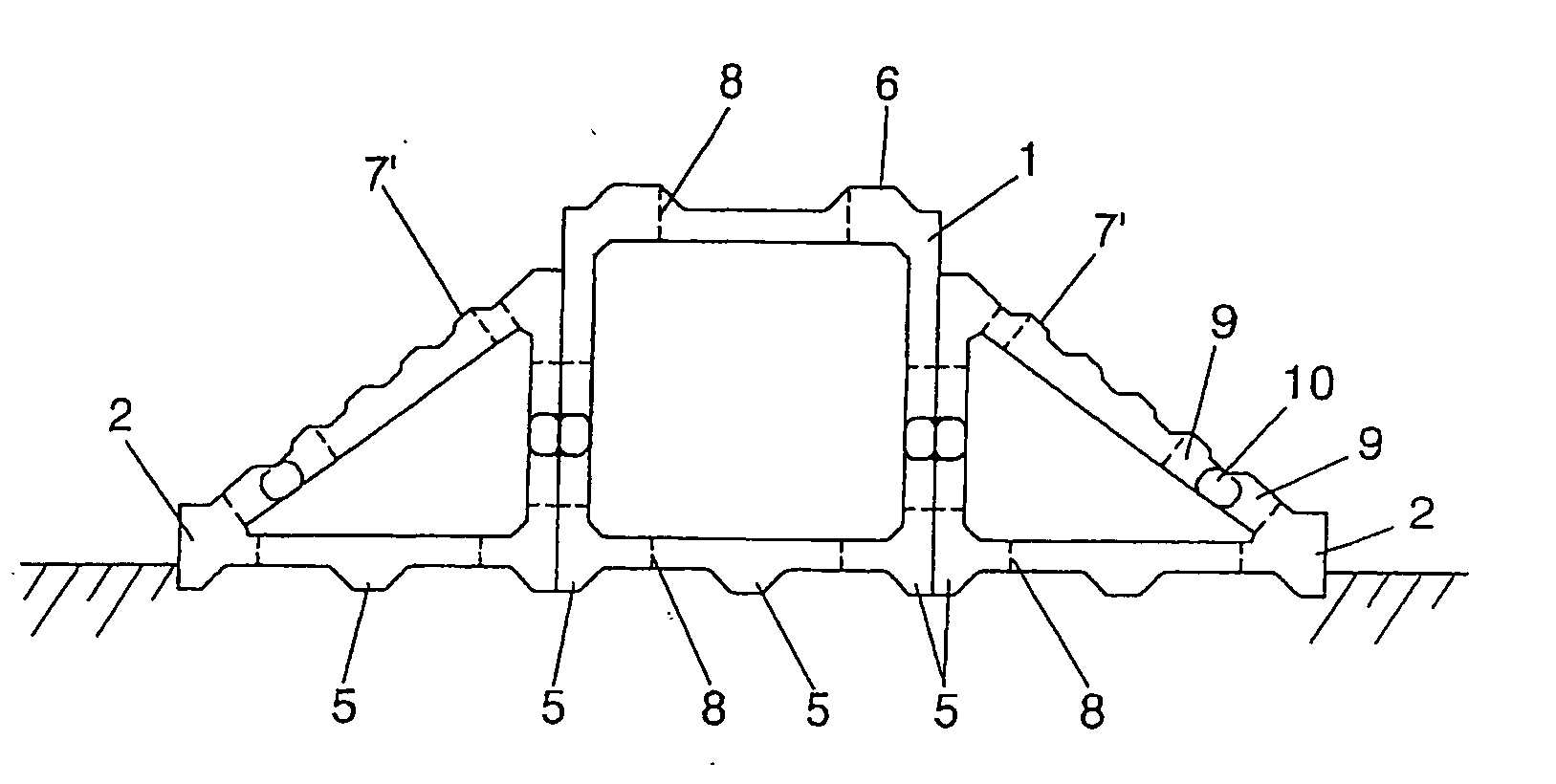

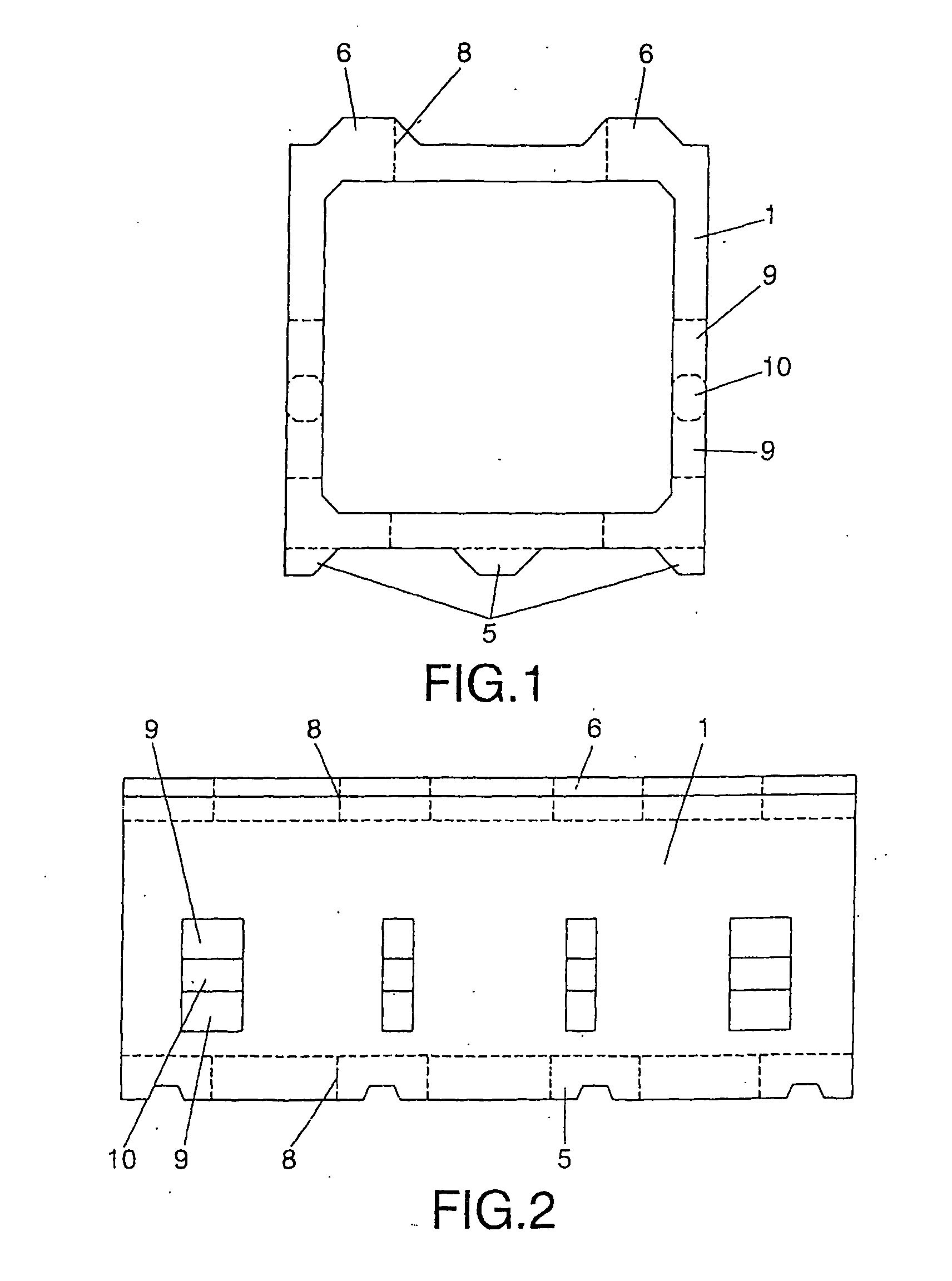

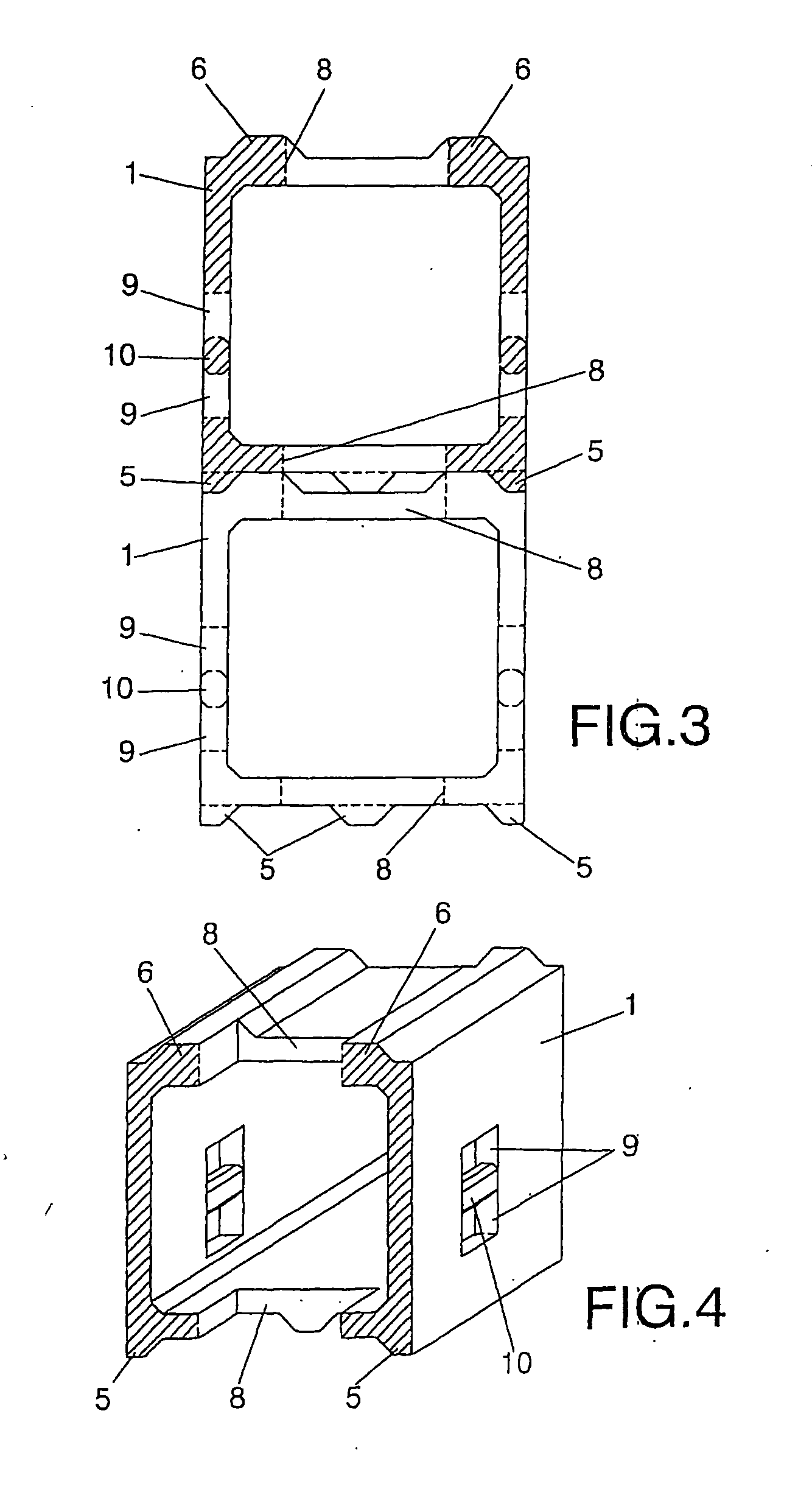

[0013] More concretely, the invention advances the construction of dikes based on a series of basic modules, which are essentially prismatic and have varying sections. For illustrative purposes, four prisms of different sections have been defined, namely, a quadrangular

prism, a rectangular

triangular prism with little difference between catheti, a straight trapezoidal rectangular

prism with considerable difference between catheti and a straight trapezoidal

prism. All these modules have a width comparable to that of a conventional container (8 feet), and a direct or combined height roughly similar to that of a conventional container, for transport by semi-trailer, free from clearance issues. The length of the modules may vary, but would ideally be as long as the most usual conventional container length, to facilitate transport by the usual means for such containers.

[0014] For easy dock crane manipulation, the weight of the basic module must not exceed 30 tons. Using these basic modules, modular dikes can be constructed from 4 up to 24 feet high with inclined vertical batters from 1 / 1 to 2 / 1, which covers the bulk of requirements of works for shoreline protection.

Login to View More

Login to View More  Login to View More

Login to View More