Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Not difficult to operate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strain aging method for improving mechanical properties of aluminum alloy

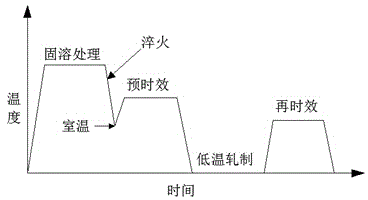

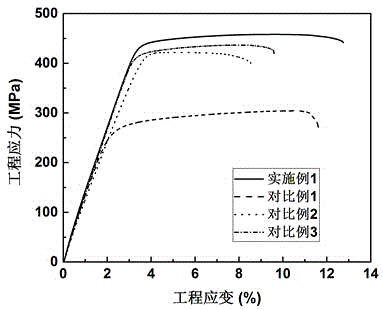

The invention discloses a strain aging method for improving the mechanical properties of aluminum alloy. The strain aging method comprises the following steps: the aluminum alloy is subjected to the solution treatment for 20-60 min at 520-560 DEG C; the aluminum alloy material after the solution treatment is water-cooled and quenched to room temperature; the aluminum alloy is subjected to the pre-aging treatment for 10-30 min at 150-180 DEG C so that the aluminum alloy material is in an underaged state; the aluminum alloy material after the pre-aging treatment is immersed in liquid nitrogen for 20-30 min and then is subjected to the multi-pass low-temperature rolling; finally, the rolled aluminum alloy material is subjected to the low-temperature reaging treatment for 85-100 hours at 100-130 DEG C so as to further strengthen the aluminum alloy. According to the invention, the strain aging method effectively improves the tensile strength and yield strength of aluminum alloy, is simple in process, easy to operate and low in cost, and has good generalizability.

Owner:CHONGQING UNIV

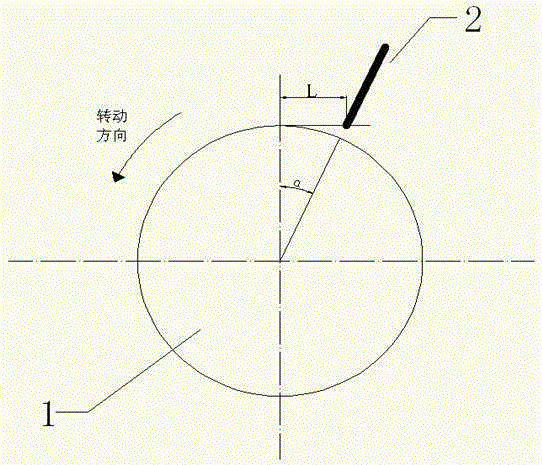

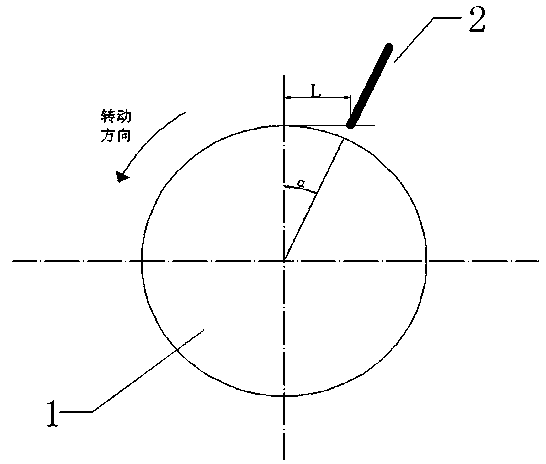

Surfacing welding method for abraded large roll shaft

ActiveCN105382378AReduce defectsImprove forming qualityArc welding apparatusWelding/cutting media/materialsFatigue damageSlag

The invention discloses a surfacing welding method for an abraded large roll shaft. The surfacing welding method is characterized by comprising the following steps that 1, preweld material analysis is carried out, preweld cleaning is carried out on the roll shaft, and preweld preparation is carried out; 2, after preweld preparation is finished, preweld preheating is carried out; 3, after preweld preheating is finished, automatic submerged arc welding is adopted for surfacing welding; 4, after surfacing welding is finished, welding slag is broken down, and postweld heat treatment is carried out; and 5, after heat treatment is finished, finally machining is carried out according to requirements. After the surfacing welding method is adopted, surfacing welding layer defects at the surfacing welding position are few, and the forming quality of a welding channel is good; the hardness of the surfacing welding position is distributed in a ladder manner from low to high from inside to outside, and the hardness of the outermost layer even ranges from 55 HRC to 60 HRC; the impact toughness and strength of the surfacing welding position are equal to those of the roll shaft and even exceed those of a base material by 1-2 times; the capacity for resisting spalling fatigue damage is high, the surfacing welding effect is remarkable, and the welding quality requirement can be completely met; and the whole surfacing welding process is easy to master and control, and good economical efficiency is achieved.

Owner:JIANGSU JINHANG MACHINERY MFG CO LTD

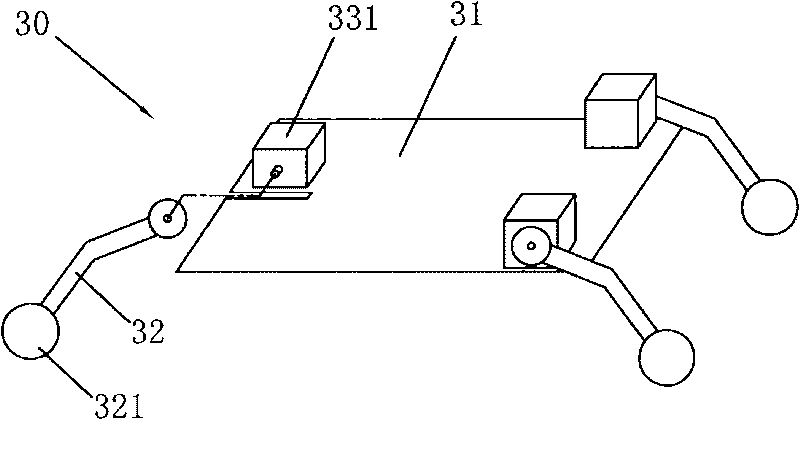

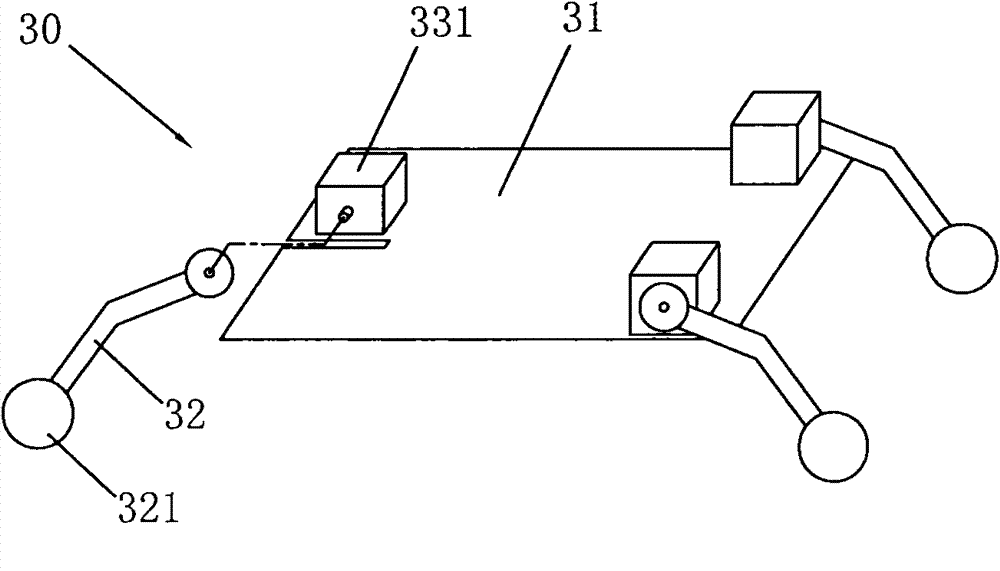

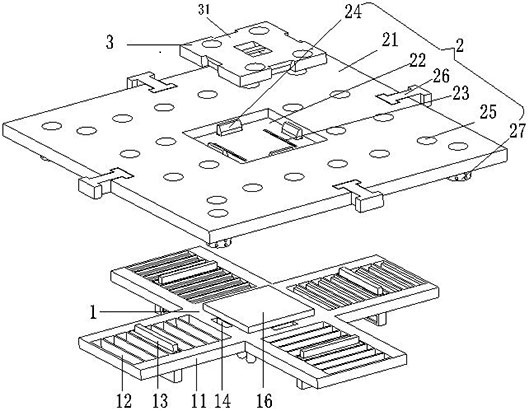

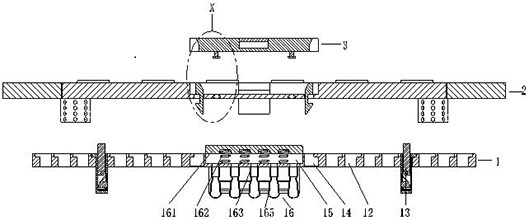

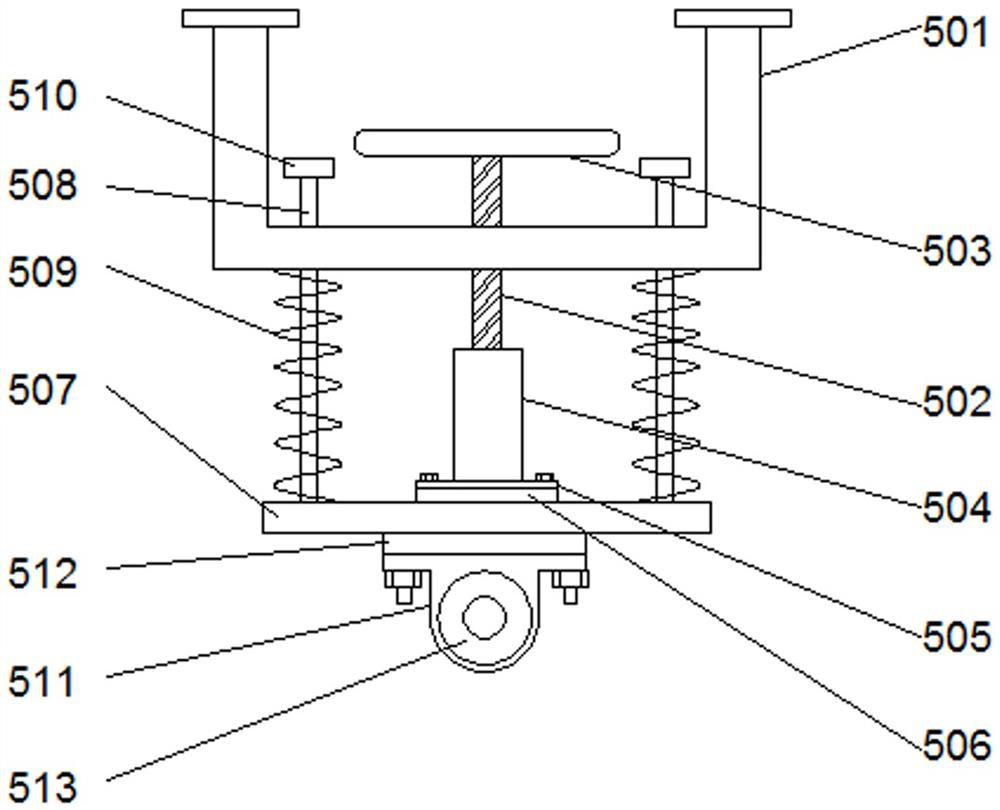

Device for compensating the difference of height by which a helicopter lands on a non-horizontal ground and the method thereof

InactiveCN101746500AIncrease flexibilityReduce the risk factor of rolloverUndercarriagesElectricityLeg type

The invention provides a device for compensating the difference of height by which a helicopter lands on a non-horizontal ground and the method thereof, which aim at addressing the problem that the helicopter lands on the non-horizontal ground. The device comprises three ranging sensors used for testing the pitch angle and spinning angle of the non-horizontal ground, three leg-type landing gears comprising a landing platform fixedly connected with the body of the helicopter and three landing supporting legs fixed on the landing platform and a control device respectively electrically connected with three ranging sensors and three power output devices; power output devices independent of each other are arranged between each landing supporting leg and the landing platform. When the helicopter lands, the measurement results of the ranging sensors are used for calculating the pitch angle and spinning angle of the non-horizontal ground and then controlling the pitch angle and spinning angle of the plane on which three landing ends of three landing supporting legs to be equal to the pitch angle and spinning angle of the non-horizontal ground so that the helicopter can be controlled to land vertically.

Owner:李子赫

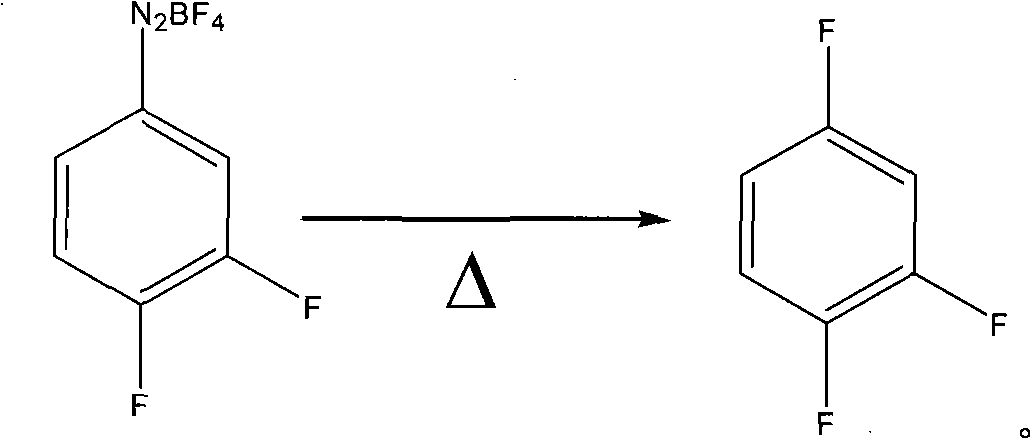

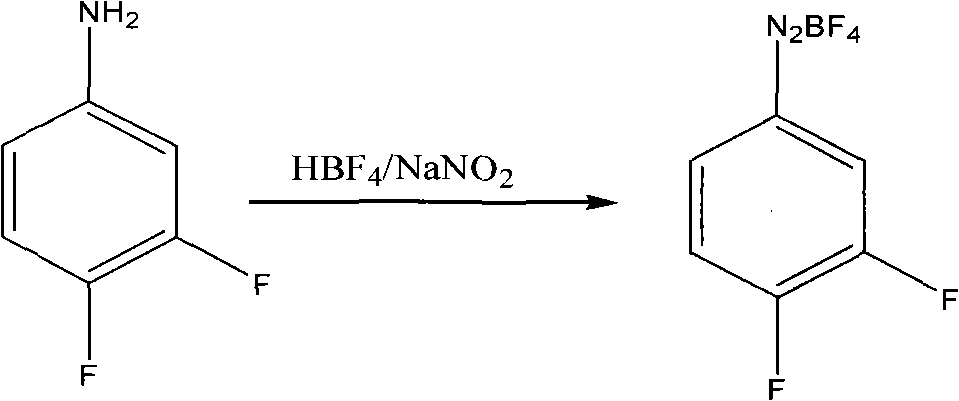

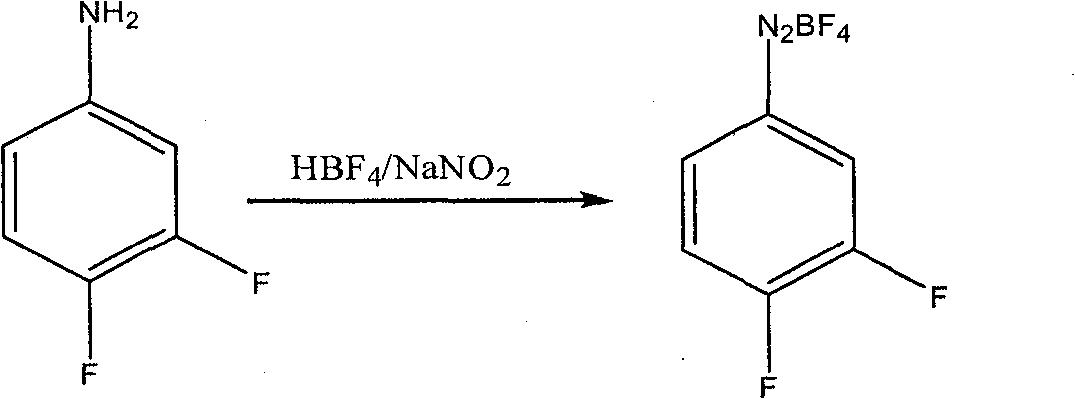

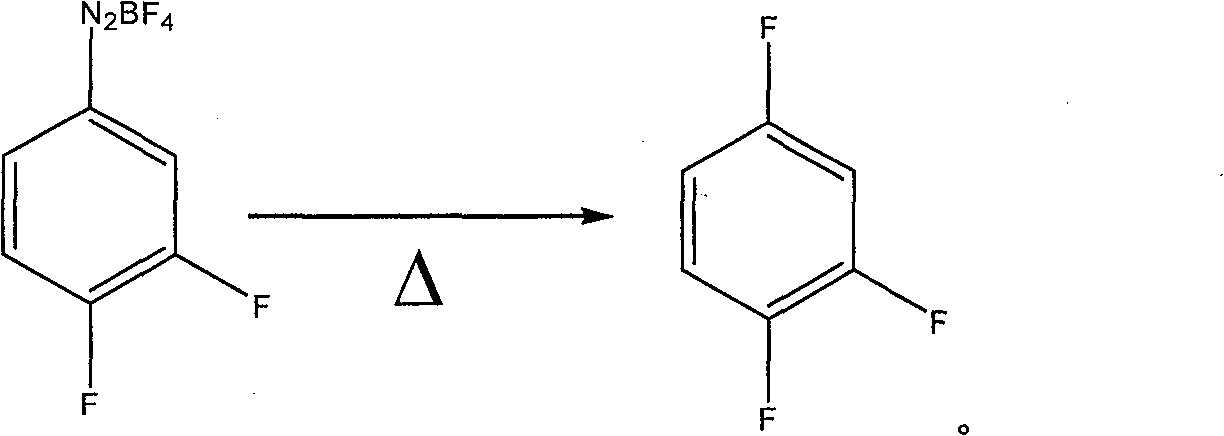

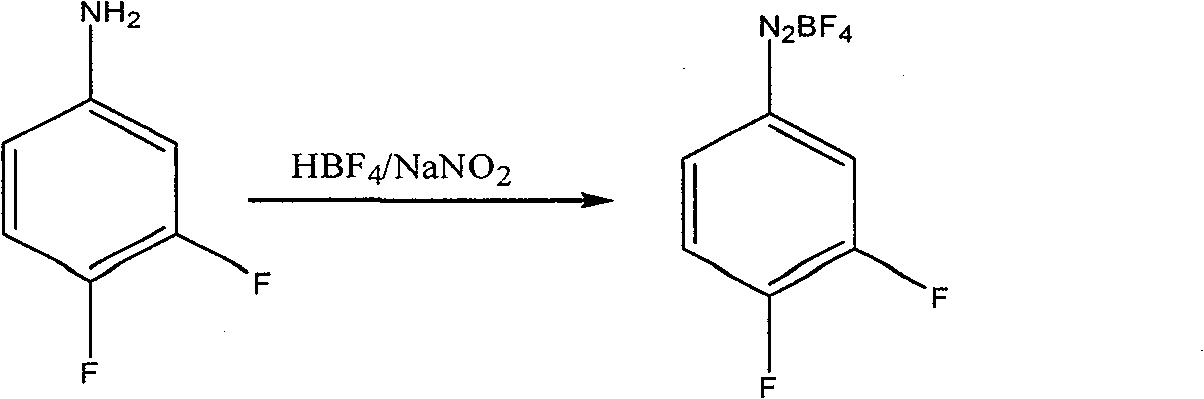

Preparation method of 1,2,4-trifluoro-benzene

ActiveCN101817724ALow costReduce manufacturing costHalogenated hydrocarbon preparationBenzeneSolvent free

The invention relates to a preparation method of 1,2,4-trifluoro-benzene, belonging to the technical field of preparation methods of chemical drug intermediates. The preparation method comprises the following steps of: (1) generating salifying reaction on 3,4-difluoroaniline and fluoboric acid, and then generating diazotization reaction with sodium nitrite to obtain fluoboric acid diazonium salt;and (2) under the solvent-free condition, carrying out high-temperature cracking reaction on the fluoboric acid diazonium salt at the temperature of 80-300 DEG C to obtain 1,2,4-trifluoro-benzene. The preparation method has the advantages of cost saving of raw materials, relatively simple process flow, mild reaction condition, low operation difficulty, operability and convenient aftertreatment; and the prepared products have the purity increased to 98 percent or more now from 80 percent or less originally, are stable in quality, and are suitable for large-scale industrial production.

Owner:ZHEJIANG TIANYU PHARMA

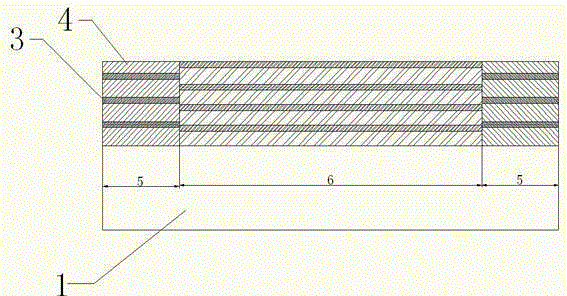

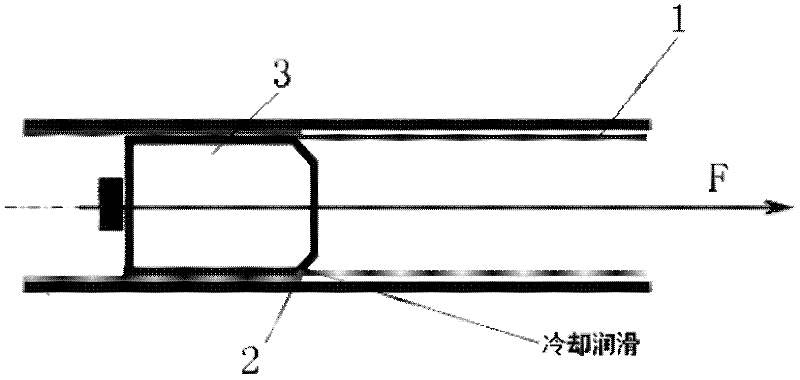

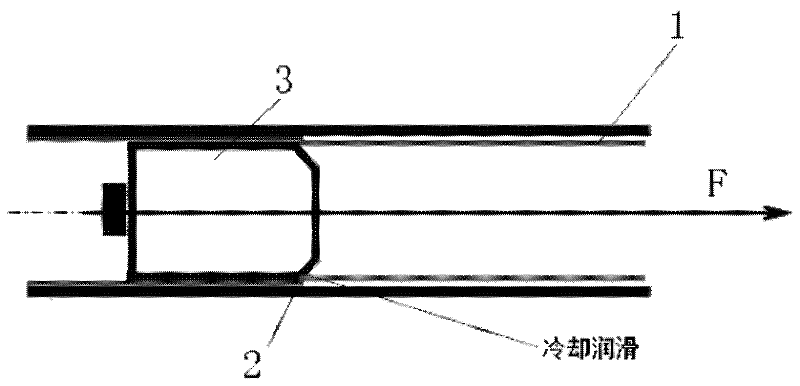

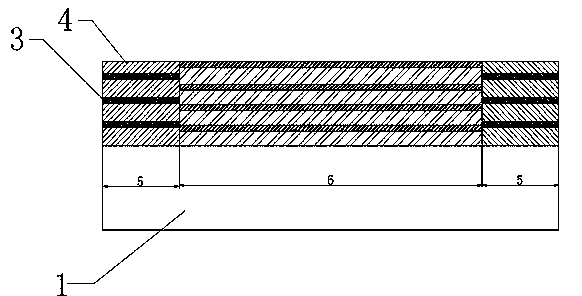

Method for combining carbon steel-based stainless steel internal composited tube

The invention discloses a compounding method of a carbon steel-based stainless steel inside clad tube, which belongs to the technical field of fluid transmission pipe manufacturing. The invention aims to provide a compounding method which is capable of maintaining the advantages and overcoming the disadvantages of stainless steel tubes and significantly reducing the cost. The technical proposal includes the following steps that: one end of a stainless steel tube is inserted into a carbon steel tube, wherein, the outside diameter of the stainless steel tube is slightly smaller than the inside diameter of the carbon steel tube, the stainless steel tube is longer than the carbon steel tube, and the diameter of the other end of the stainless steel tube is expanded by a hydraulic flaring machine; the carbon steel tube is gripped by a hydraulic gripper; the cold drawbench is started up to push the internal mold, whose largest working outside diameter is a slightly larger than the inside diameter of the carbon steel tube, into the stainless steel tube from the expanded end, and the internal mold is towed by the mandrel in the cold drawbench to execute spiral beeline movement of forward rotary extrusion until coming out of the other end of the stainless steel tube; here, the carbon steel-based stainless steel inside clad tube is produced. The compounding technique of the invention has the characteristics of easy operations, good compounding effect, low power consumption and high speed.

Owner:汪正友

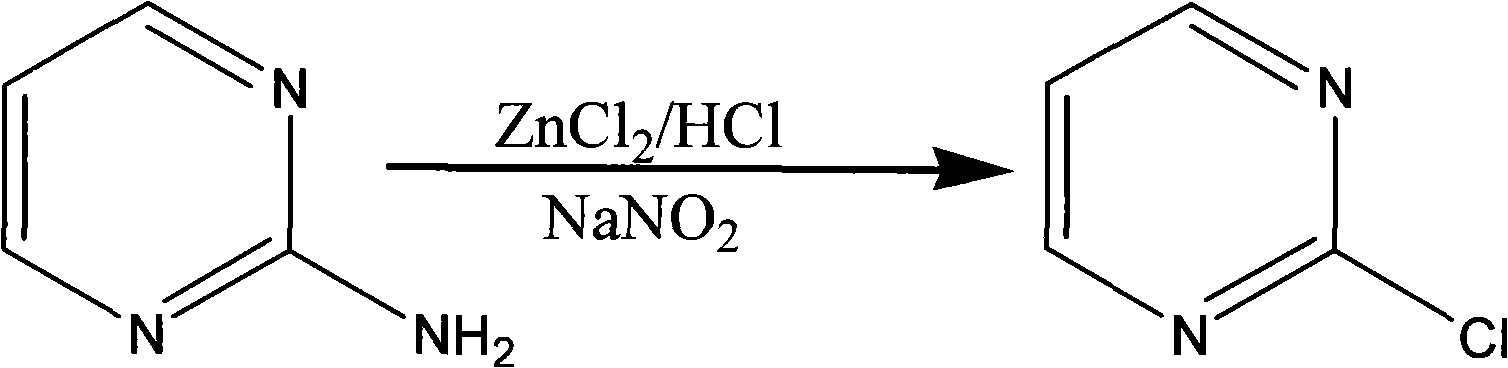

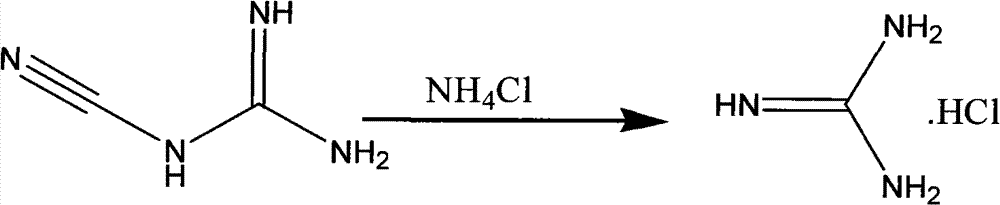

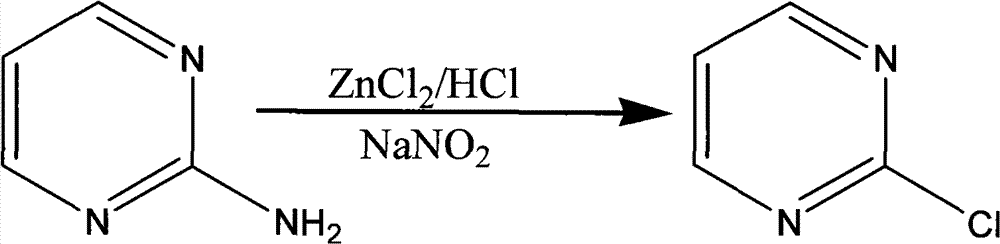

Method for preparing 2-chloropyrimidine

The invention discloses a method for preparing 2-chloropyrimidine, belonging to the technical field of methods for preparing chemical medicine intermediates. The method for preparing the 2-chloropyrimidine comprises the following steps of: (1) reacting dicyandiamide with ammonium chloride at high temperature, and obtaining guanidine hydrochloride; (2) reacting the guanidine hydrochloride with 1.1.3.3-tetramethoxypropane by refluxing under the condition of taking industrial hydrochloric acid as a solvent to obtain 2-amino pyrimidine; and (3) reacting the 2-amino pyrimidine with sodium nitrate at low temperature for producing the 2-chloropyrimidine by taking zinc chloride as a catalyst and taking the industrial hydrochloric acid as the solvent. The preparation method disclosed by the invention has the advantages of lower cost of raw materials, relatively simple technical process, mild reaction conditions, low operation difficulty, excellent maneuverability; convenience for post-treatment; and largely improved yield stable quality and applicability of large-scale industrial production of prepared products,.

Owner:LINHAI TIANYU PHARMA

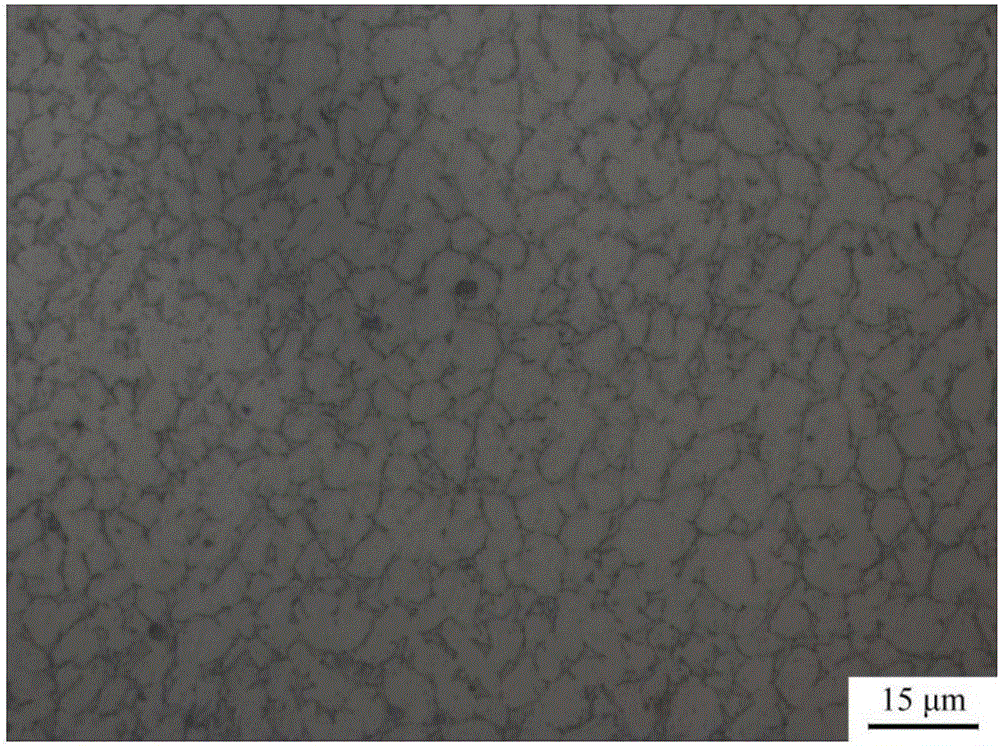

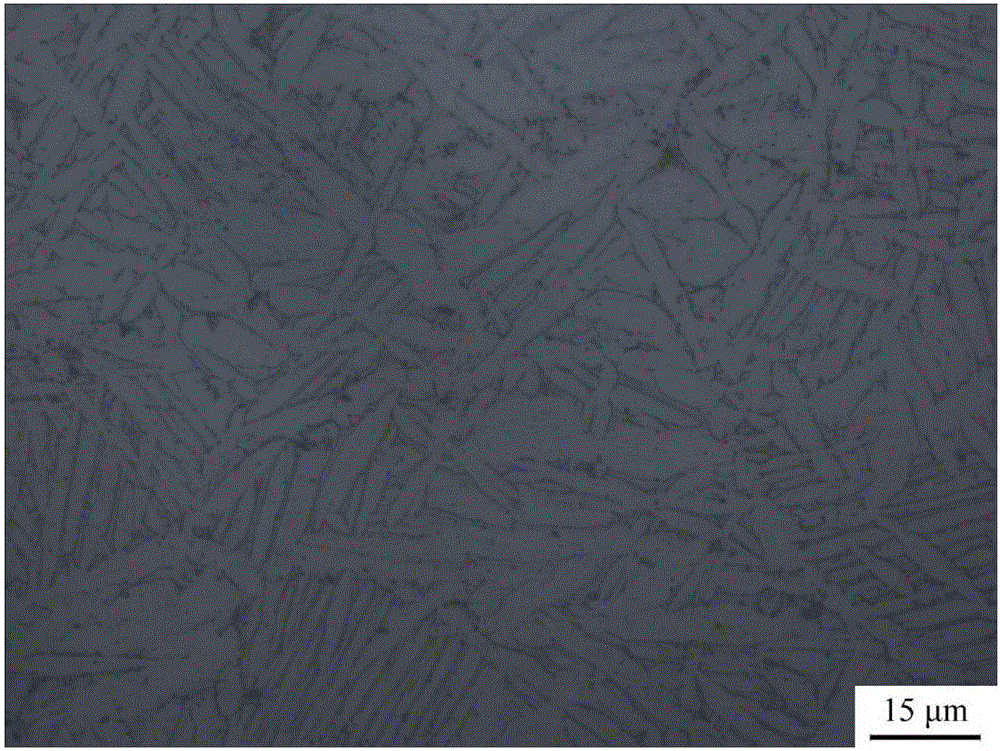

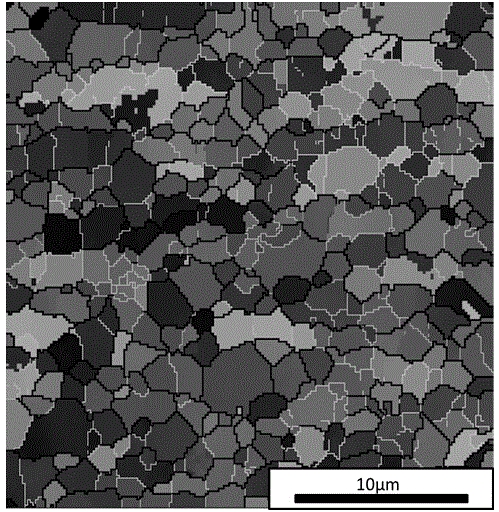

Method for controlling grain equi-axiation to improve plasticity of Ti20Zr6.5Al4V alloy

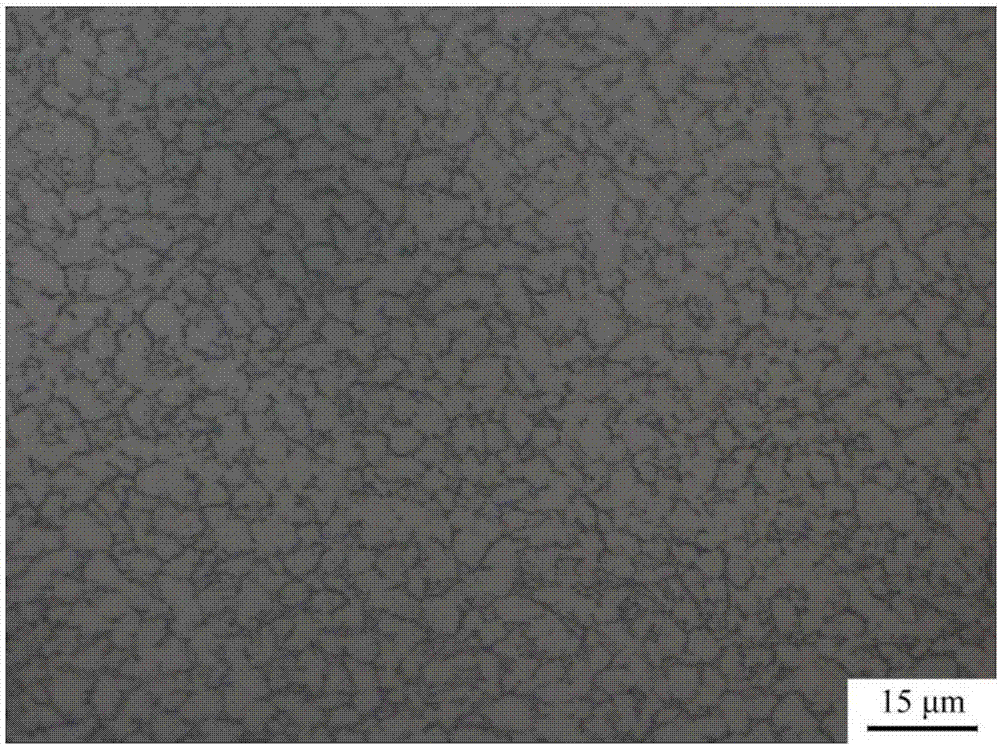

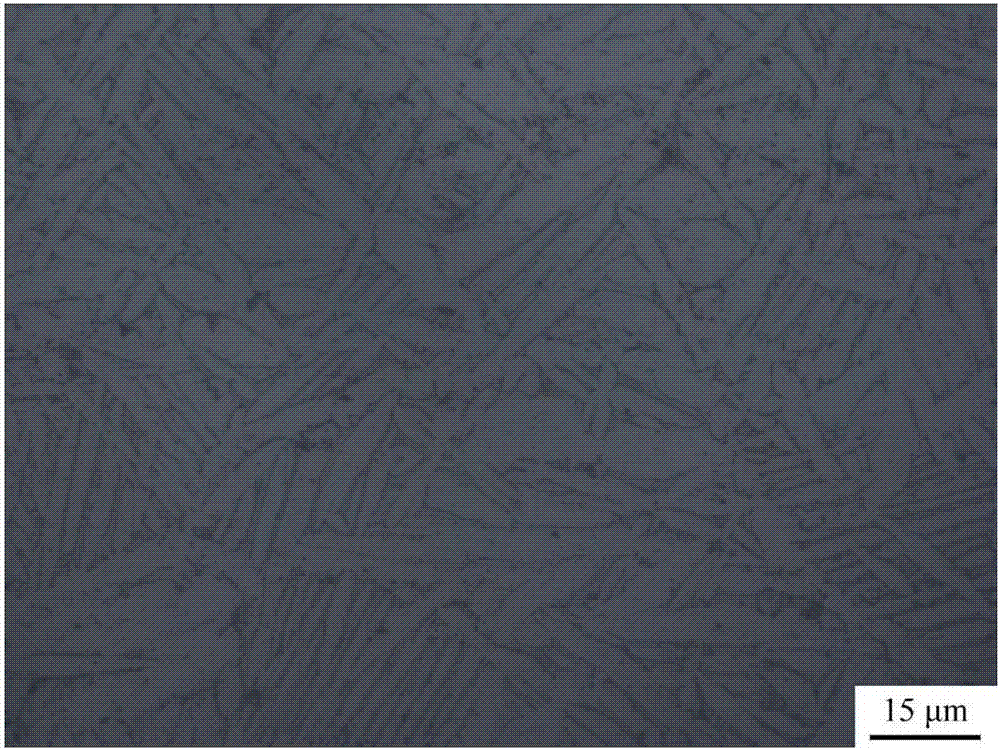

The invention relates to a method for controlling grain equi-axiation to improve plasticity of a Ti20Zr6.5Al4V alloy. The method mainly comprises the steps that a Ti20Zr6.5Al4V alloy bar is cut into a round ingot with the thickness being 16 mm, and the round ingot is cleaned up; the round ingot is put into a resistance furnace to be heated till the temperature ranges from 950 DEG C to 1,050 DEG C, heat preservation is carried out for 20 min to 40 min, and the round ingot is quickly placed in water for quenching after being taken out; then the alloy ingot is heated till the temperature ranges from 750 DEG C to 900 DEG C at the speed being 10 DEG C / min, the heat preservation time is shorter than 5 min, the alloy ingot is subjected to rolling deformation through a dual-roller mill after being taken out, the rolling speed ranges from 0.3 m / s to 0.6 m / s, and the reduction in single pass ranges from 0.5 mm to 2 mm; heating-rolling is repeated 5-20 times in the same way till deformation reaches 60% or above, and air cooling is carried out until the room temperature is obtained; and then the alloy is subjected to annealing treatment after being heated, the annealing temperature ranges from 750 DEG C to 850 DEG C, and furnace cooling is carried out until the room temperature is obtained after heat preservation is carried out for 1 h to 12 h. According to the method, operation is easy, and the production cost is low; and the plasticity of the alloy is remarkably improved while strength is guaranteed.

Owner:YANSHAN UNIV

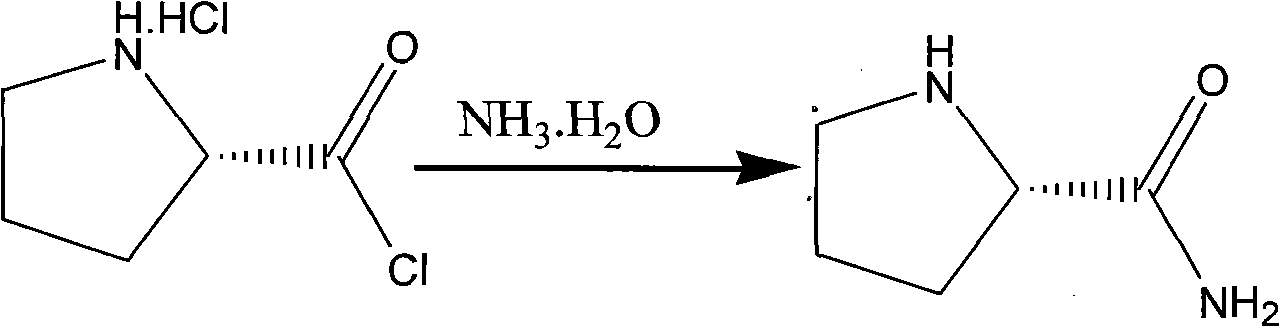

Method for preparing (2S)-N-chloracetyl-2-cyano-group pyrrolidine

The invention provides a method for preparing (2S)-N-chloracetyl-2-cyano-group pyrrolidine, which belongs to the technical field of chemical medicine midbody preparation methods. The preparation method comprises the steps: (1) L-proline and thionyl chloride generate acylation reaction to obtain L-proline chloride; (2) the L-proline chloride and ammonia water generate reaction to produce L-proline amide; (3) the L-proline amide and chloroacetyl chloride generate reaction to obtain (2S)-N-chloracetyl-2-carbamoyl pyrrole; and (4) (2S)-N-chloracetyl-2-carbamoyl pyrrolidine and phosphorus oxychloride generate dehydration reaction under low temperature condition to obtain the (2S)-N-chloracetyl-2-cyano-group pyrrolidine. The method has the advantages of saving material cost, being simple in technological process, moderate in reaction condition, low in operation difficulty, convenient in aftertreatment, stable in quality and suitable for mass industrial production, having operability, and improving yield of prepared products by a large margin.

Owner:LINHAI TIANYU PHARMA

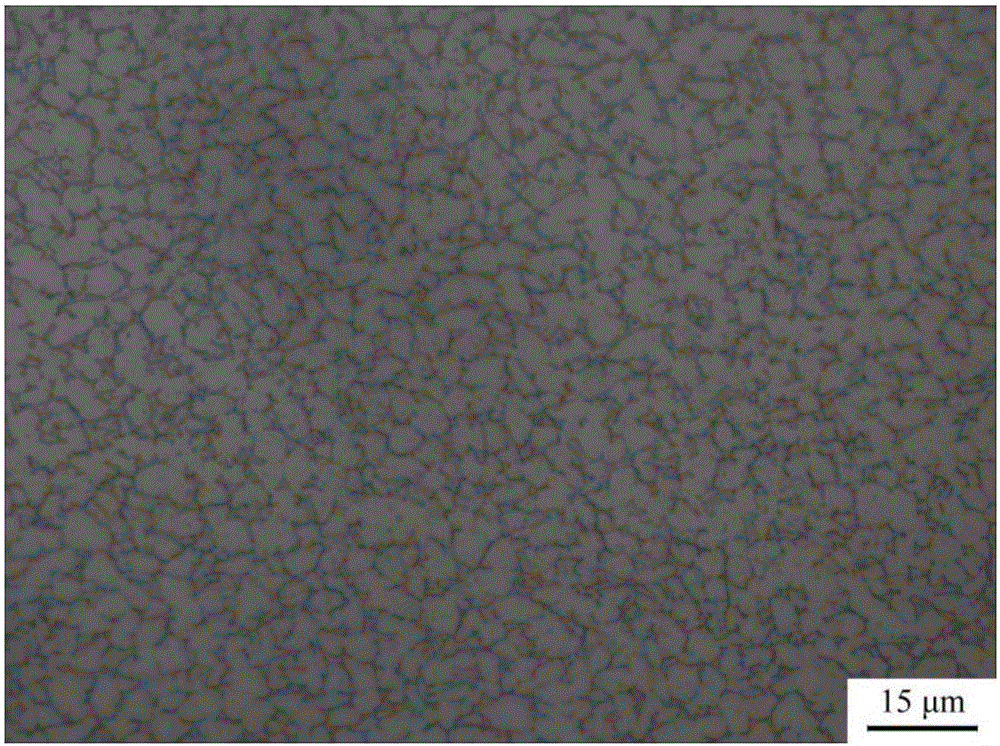

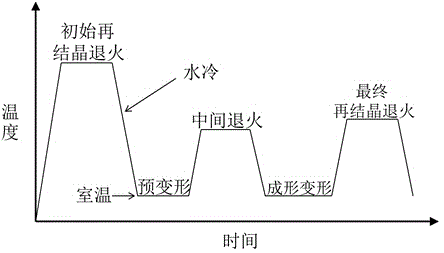

Thermomechanical treatment method for aluminium alloy grain refinement

The invention discloses a thermomechanical treatment method for aluminium alloy grain refinement. The method comprises the following steps: insulating an aluminium alloy for 30-60min for 360-460 DEG C, then cooling the aluminium alloy material to room temperature and then carrying out rolling deformation with a rolling deformation amount of 18-30%, then carrying out low-temperature annealing treatment on the pre-deformed aluminium alloy material for 24-168h at 260-290 DEG C, cooling the aluminium alloy material subjected to the low-temperature annealing to room temperature and then carrying out rolling deformation with a total rolling deformation amount of 80-96%, and finally carrying out recrystallization annealing on the rolled-formed aluminium alloy for 0.5-24h at 260-310 DEG C. The structural state of an aluminium alloy plate treated by the method disclosed by the invention is uniform and fine isometric crystals, thus 1-2[mu]m fine-grain structural state is realized; and moreover, the method disclosed by the invention has the characteristic of no limits on machining equipment, and dimensions of machined workpieces.

Owner:CHONGQING UNIV

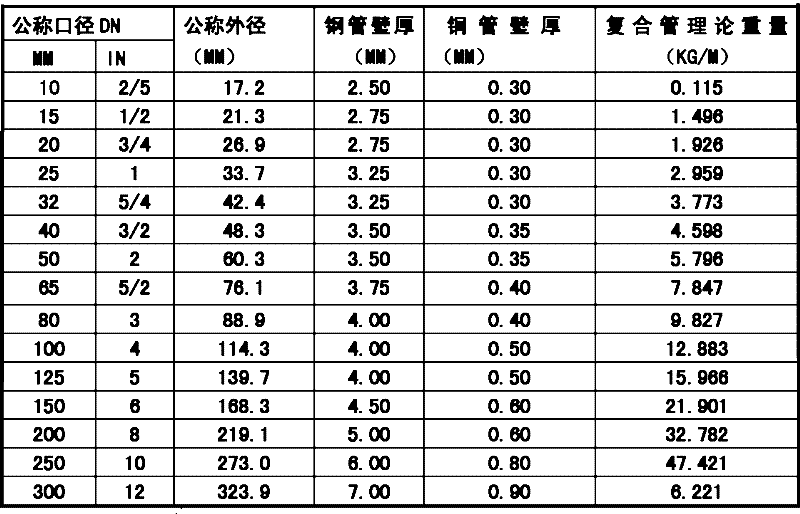

Method and special die for manufacturing composite pipeline

InactiveCN102284546AImprove flexural strengthImprove impact resistanceExtrusion diesCopperUltimate tensile strength

The invention discloses a method and a special die for manufacturing a composite pipeline. In the method for manufacturing the composite pipeline, axial cold extrusion is performed along the inner wall of a copper pipe by a cold-drawing machine and the special die to ensure that the copper pipe reaches a critical temperature and is subjected to plastic deformation, so that the copper pipe is tightly attached to a carbon steel pipe. The special die for manufacturing the composite pipeline comprises a die body made of a nylon 1010 material, wherein the die body is provided with a connecting hole connected with a core rod of the cold-drawing machine; and the front end face of the die body is provided with a transition fillet. After the copper pipe is compounded with the carbon steel pipe, the advantages of the copper pipe are kept, the defects that the copper pipe is expensive, easy to dent and deform, and the like are overcome, and the bending strength and impact resistance of the composite pipeline are greatly improved; in addition, the adopted cold extrusion composite technology is low in equipment requirement, operation difficulty and energy consumption, high in speed, quality and efficiency, concise and practical, and suitable for large-scale industrial production.

Owner:汪正友

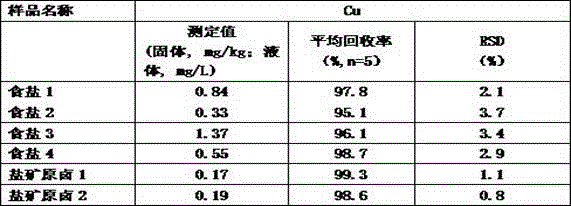

Method using static adsorption ion exchange technology to separate and measure copper ions in salt

InactiveCN106053359AAvoid interferenceEasy to separatePreparing sample for investigationColor/spectral properties measurementsIminodiacetic acidIon exchange

The invention discloses a method using a static adsorption ion exchange technology to separate and measure copper ions in salt. According to the method, an iminodiacetic acid type chelate resin is used to adsorb copper ions in a sodium chloride water solution through static adsorption; then a diluted nitric acid solution is used to wash copper ions from the resin; and after copper ions and the high salinity matrix are separated, the copper ions can be detected by atomic absorption spectrum. The static adsorption is realized through a cage shaped adsorption device; the artificial filtering is not needed, the separation is simplified, a large amount of spectrum interference caused by sodium chloride is eliminated, the subsequent detection is very simple, the results are accurate and reliable, the sensitivity is high, the selectivity is good, and the recovery rate and precision are both good.

Owner:中华人民共和国淮安出入境检验检疫局 +1

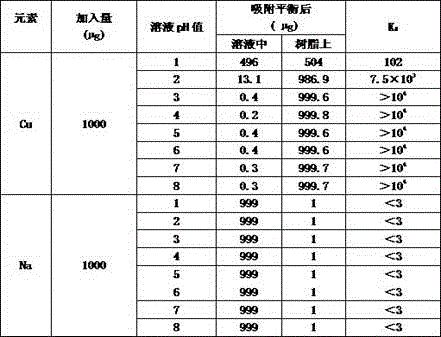

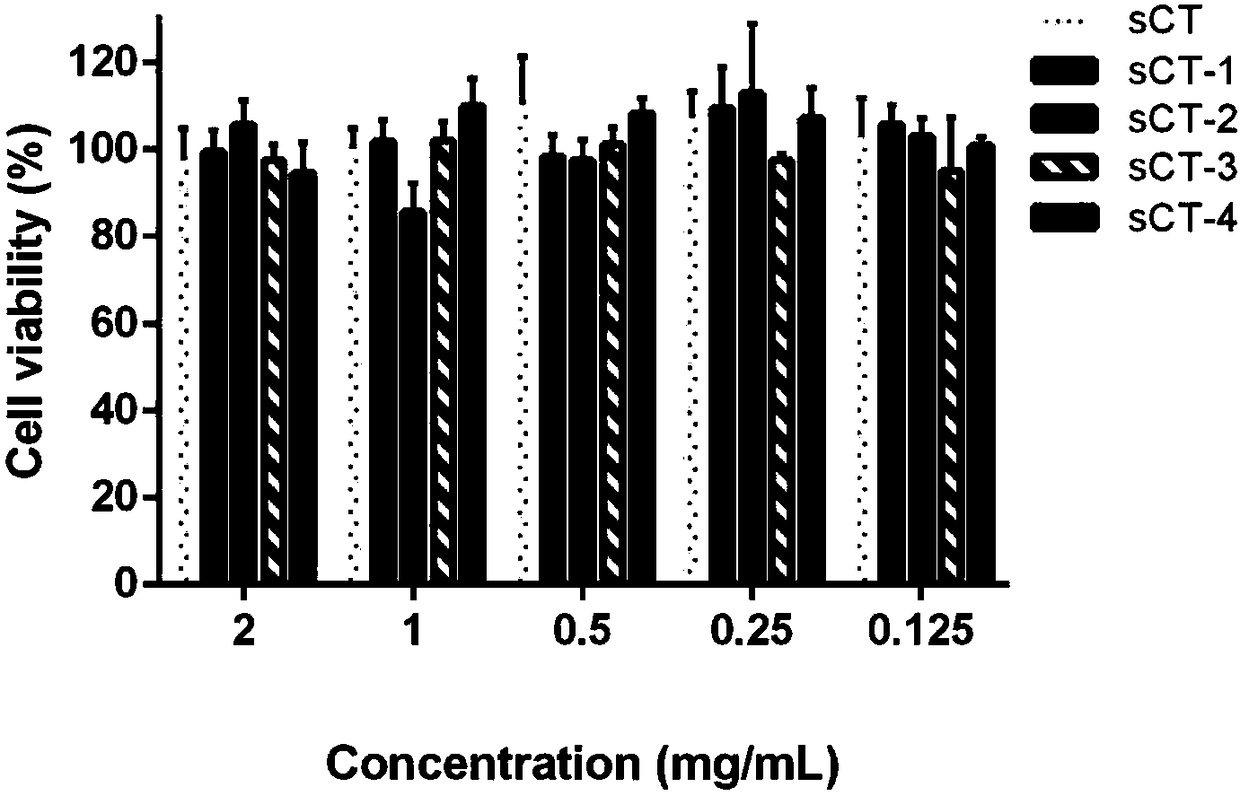

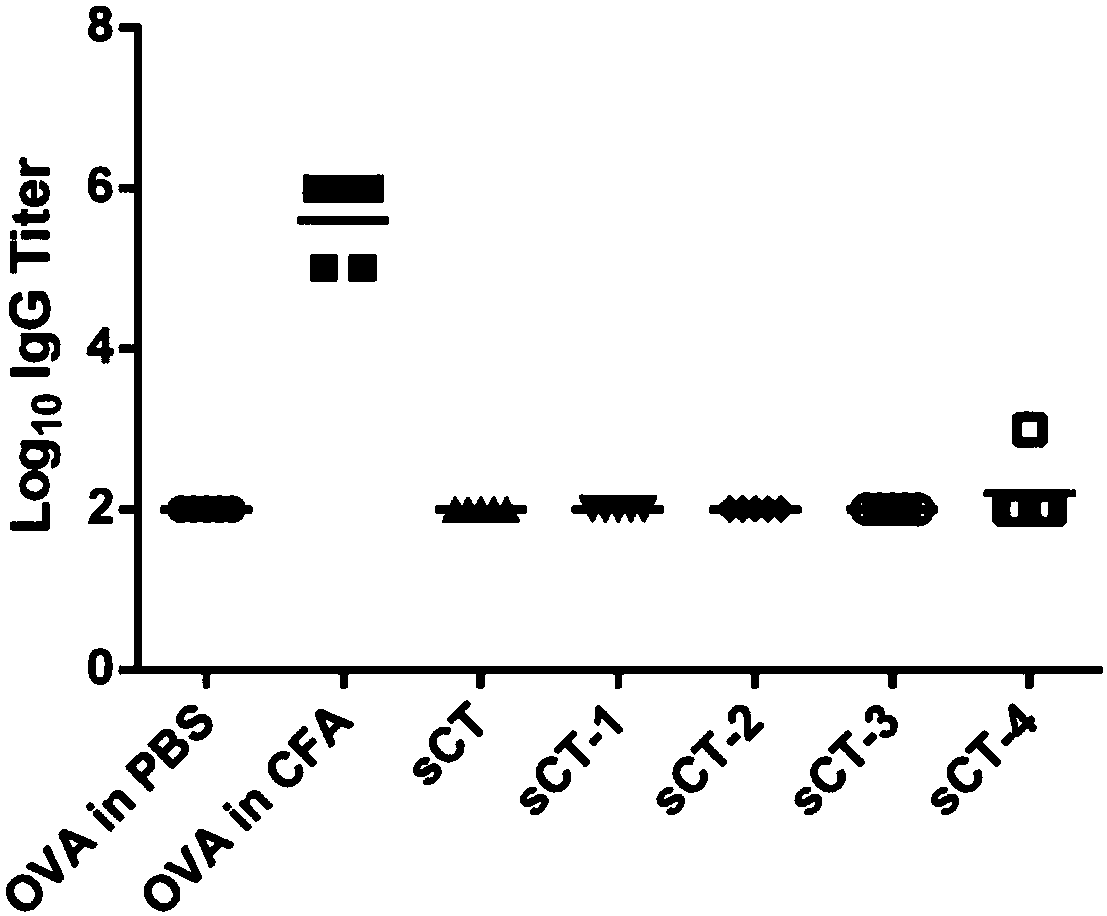

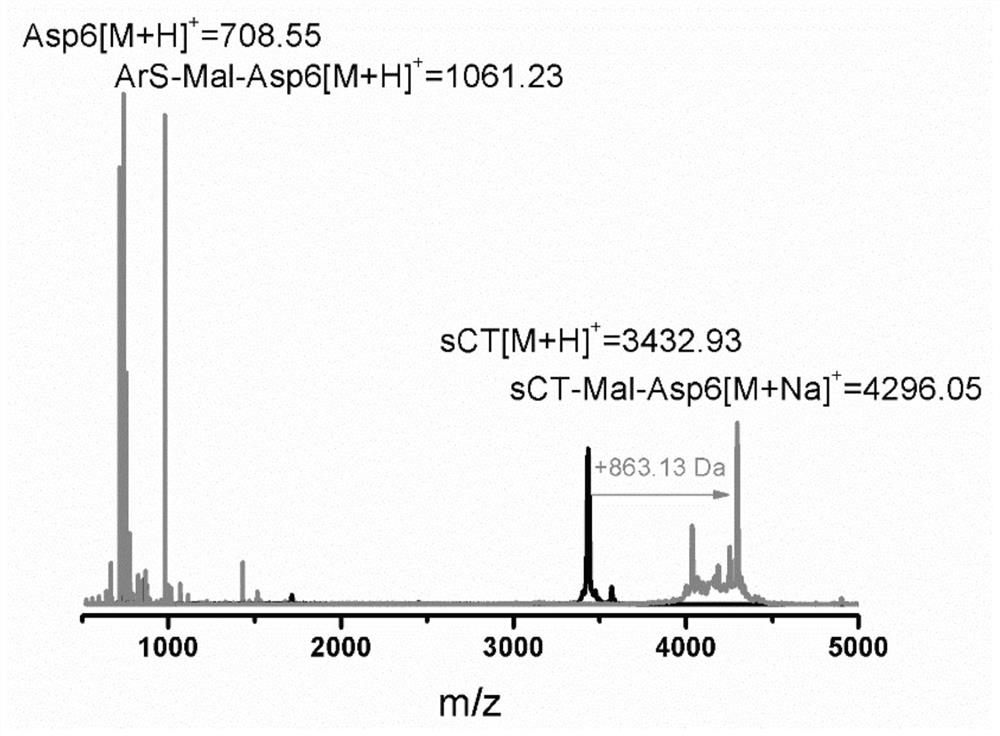

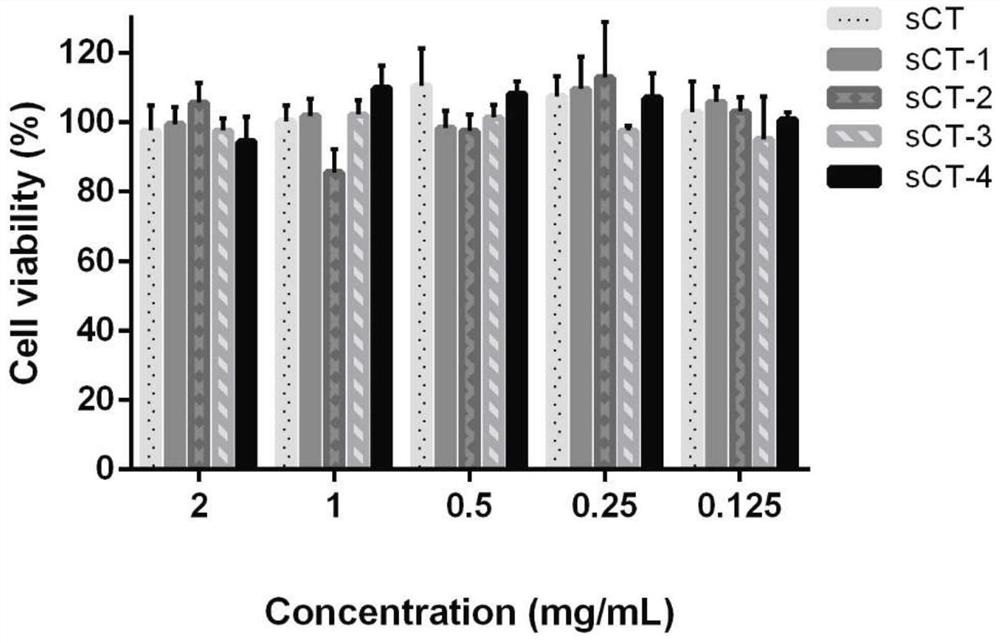

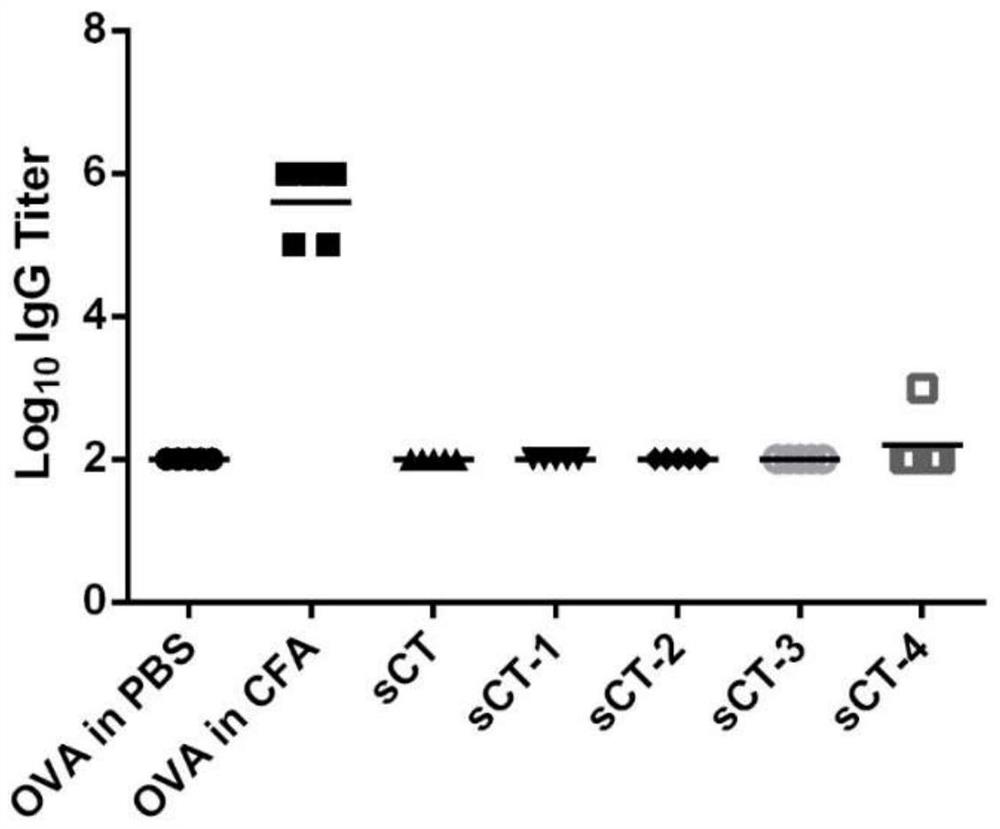

Bone targeting salmon calcitonin and preparation method thereof

ActiveCN108586601AImprove bioavailabilityImprove the effect of treatmentCalcitoninsPeptide preparation methodsSolventChemistry

The invention provides bone targeting salmon calcitonin. Disulfide bonds in salmon calcitonin molecules are opened and covalently coupled with bone targeting coupling molecules to form the bone targeting salmon calcitonin. A preparation method includes the steps: (1) preparing the bone targeting coupling molecules; (2) dissolving the salmon calcitonin in water-soluble solvents with the pH (potential of hydrogen) value of 5-7, adding reducing agents for reducing the disulfide bonds in the salmon calcitonin to form free sulfydryl, adding the bone targeting coupling molecules, performing stirringreaction for 0.5-12 hours at the temperature of 0-40 DEG C, separating crude products and preparative liquid chromatography purification to obtain the bone targeting salmon calcitonin. The bone targeting salmon calcitonin is free from cytotoxicity and immunogenicity, the bone tissue enrichment capacity of the calcitonin can be improved, bone tissues can be effectively repaired, and the bone targeting salmon calcitonin has a wide application prospect.

Owner:SICHUAN UNIV

Semiconductor glaze layer sintering method for improving matching degree of semiconductor part and central electrode

ActiveCN112615261AHighly corporatedImprove ignition performanceSpark gap detailsSparking plugs manufactureMetallurgySemiconductor

The invention relates to the technical field of sintering, and particularly discloses a semiconductor glaze layer sintering method for improving the matching degree of a semiconductor part and a central electrode, which is used for sintering a semiconductor glaze layer on a porcelain tube, and is characterized by comprising the following steps of: manufacturing a central electrode wax mold according to the shape and size of the central electrode, and matching the porcelain tube with the central electrode wax mold; and injecting pre-prepared semiconductor enamel into a contact gap between the outer conical surface of the central electrode and the inner conical surface of the porcelain tube, and after the semiconductor enamel is naturally cooled, putting the semiconductor enamel into a furnace for heating and sintering. According to the semiconductor glaze layer sintered by the semiconductor glaze layer sintering method, the matching degree of the semiconductor part and the central electrode can be improved, so that the increase of insulation resistance between the central electrode and the semiconductor part due to poor matching degree of the central electrode and the semiconductor part is avoided, and the ignition performance of the sparking plug is improved.

Owner:四川泛华航空仪表电器有限公司

Method for preparing 2-chloropyrimidine

The invention discloses a method for preparing 2-chloropyrimidine, belonging to the technical field of methods for preparing chemical medicine intermediates. The method for preparing the 2-chloropyrimidine comprises the following steps of: (1) reacting dicyandiamide with ammonium chloride at high temperature, and obtaining guanidine hydrochloride; (2) reacting the guanidine hydrochloride with 1.1.3.3-tetramethoxypropane by refluxing under the condition of taking industrial hydrochloric acid as a solvent to obtain 2-amino pyrimidine; and (3) reacting the 2-amino pyrimidine with sodium nitrate at low temperature for producing the 2-chloropyrimidine by taking zinc chloride as a catalyst and taking the industrial hydrochloric acid as the solvent. The preparation method disclosed by the invention has the advantages of lower cost of raw materials, relatively simple technical process, mild reaction conditions, low operation difficulty, excellent maneuverability; convenience for post-treatment; and largely improved yield stable quality and applicability of large-scale industrial production of prepared products,.

Owner:LINHAI TIANYU PHARMA

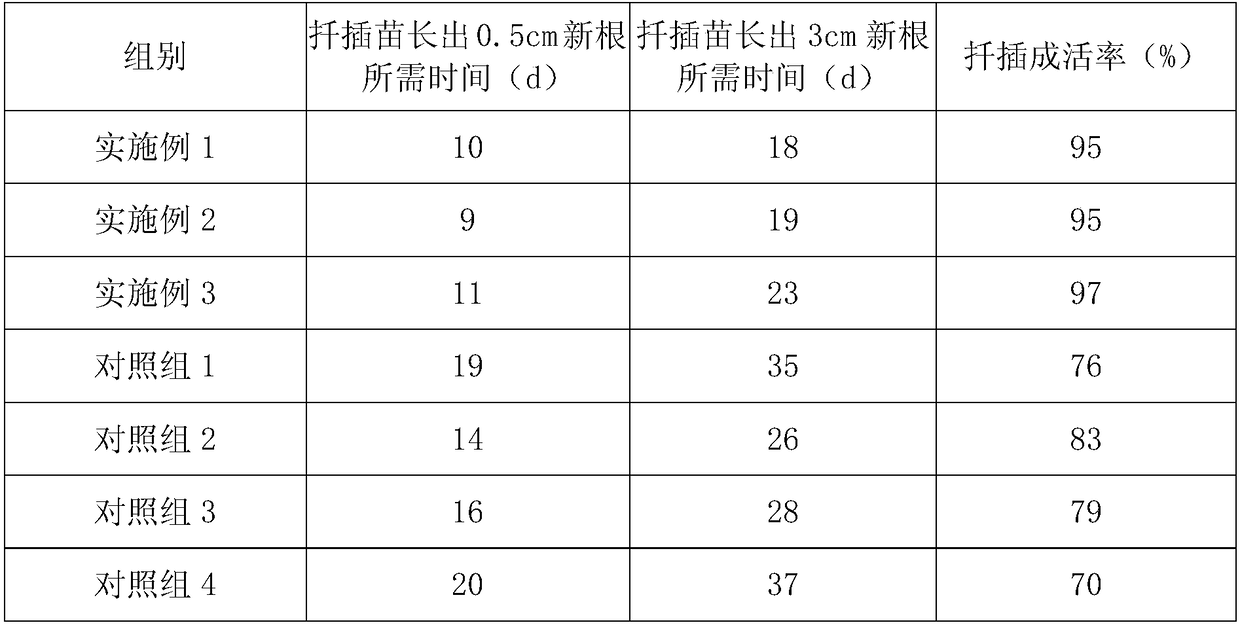

Method for promoting quick rooting of cuttage of rose seedlings

InactiveCN109463145AEasy to getImprove the survival rate of cuttingsVegetative propogationObserved SurvivalTransplanting

The invention relates to the field of planting of flowers and nursery stocks, in particular to a method for promoting quick rooting of cuttage of rose seedlings. The method comprises the steps of (1)preparation before cuttage, (2) cuttage of rose cutting slips, (3) rooting culturing and (4) seedling hardening and transplanting. The cuttage method can effectively increase the survival rate of cuttings of rose seedlings, effectively shortens rooting time, and is large in application value.

Owner:JINGXI XIUMEI BIANCHENG AGRI SCI & TECH CO LTD

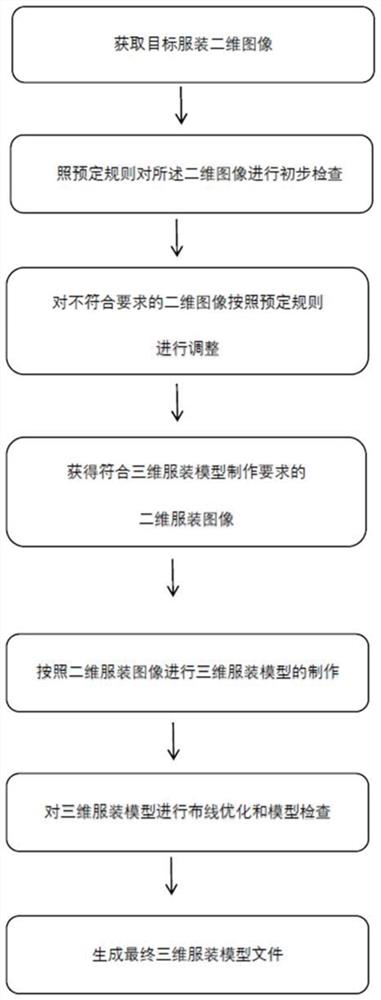

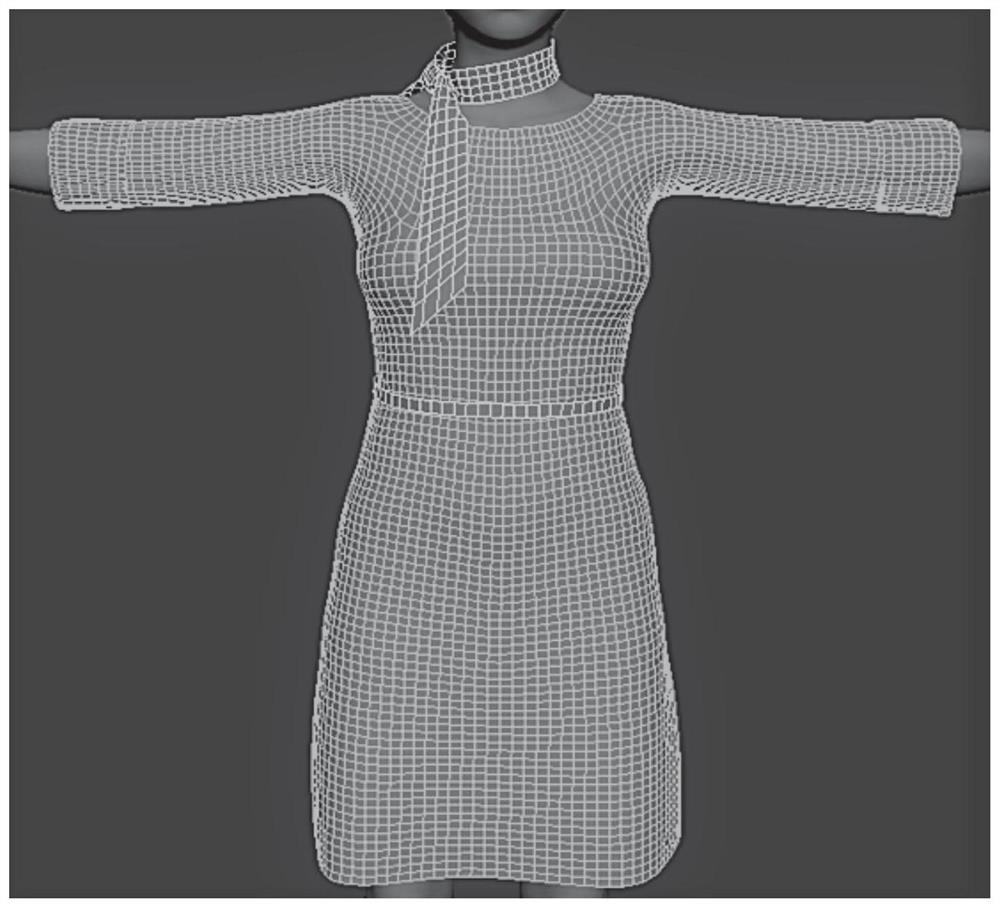

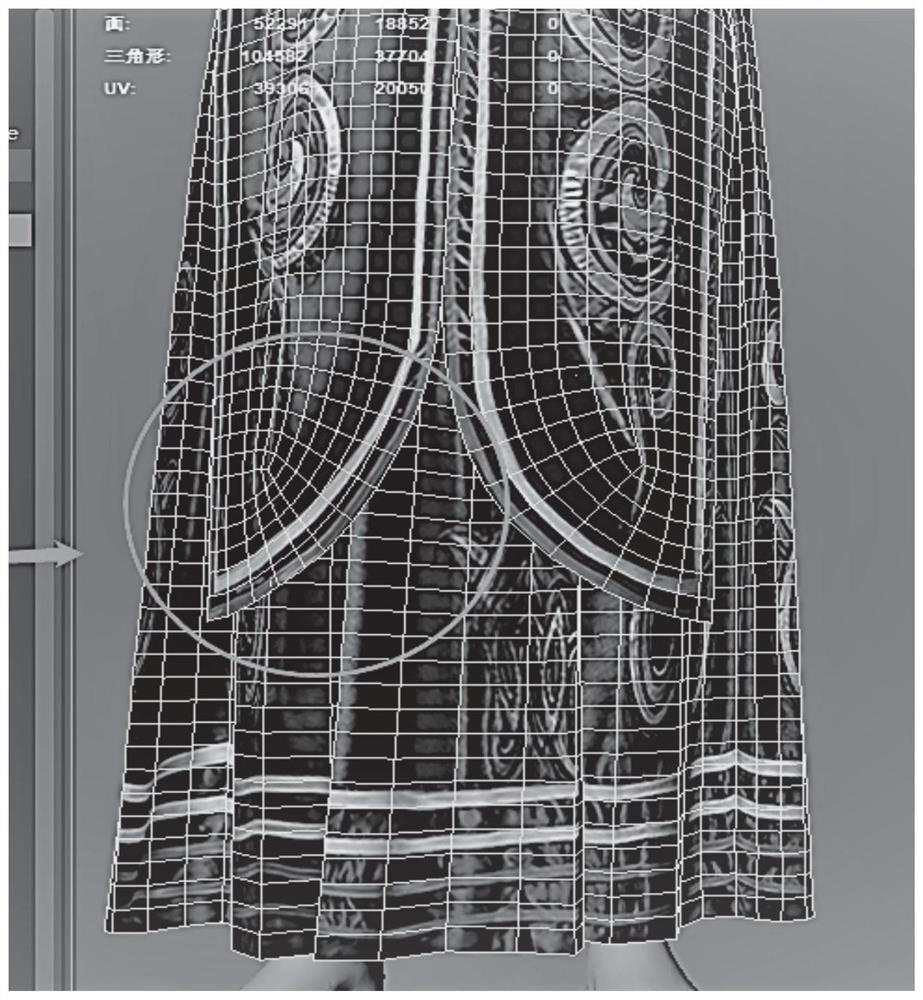

Three-dimensional garment model manufacturing quality control method and device and storage medium

PendingCN114758044AImprove product qualityIncrease authenticityGeometric image transformationCharacter and pattern recognitionQuality controlProcess engineering

The invention discloses a three-dimensional clothing model manufacturing quality control method. The method comprises the following steps: (1) acquiring a two-dimensional image of target clothing; (2) carrying out preliminary inspection on the two-dimensional image according to a preset rule; (3) adjusting the two-dimensional image which does not meet the requirement according to a preset rule; (4) obtaining a two-dimensional garment image meeting the three-dimensional garment model manufacturing requirement; (5) making a three-dimensional clothing model according to the two-dimensional clothing image; (6) performing wiring optimization and model inspection on the three-dimensional clothing model; and (7) generating a final three-dimensional clothing model file. According to the method, the manufacturing quality of the three-dimensional garment model is kept through a series of methods, the influence of all links on the quality is fully considered in the garment model manufacturing process, the whole-process quality control measures and rules are set in advance, the rules and operation are simple and controllable, the processing speed is kept high, and the production efficiency is improved. And the overall quality of the clothes model is kept.

Owner:北京陌陌信息技术有限公司

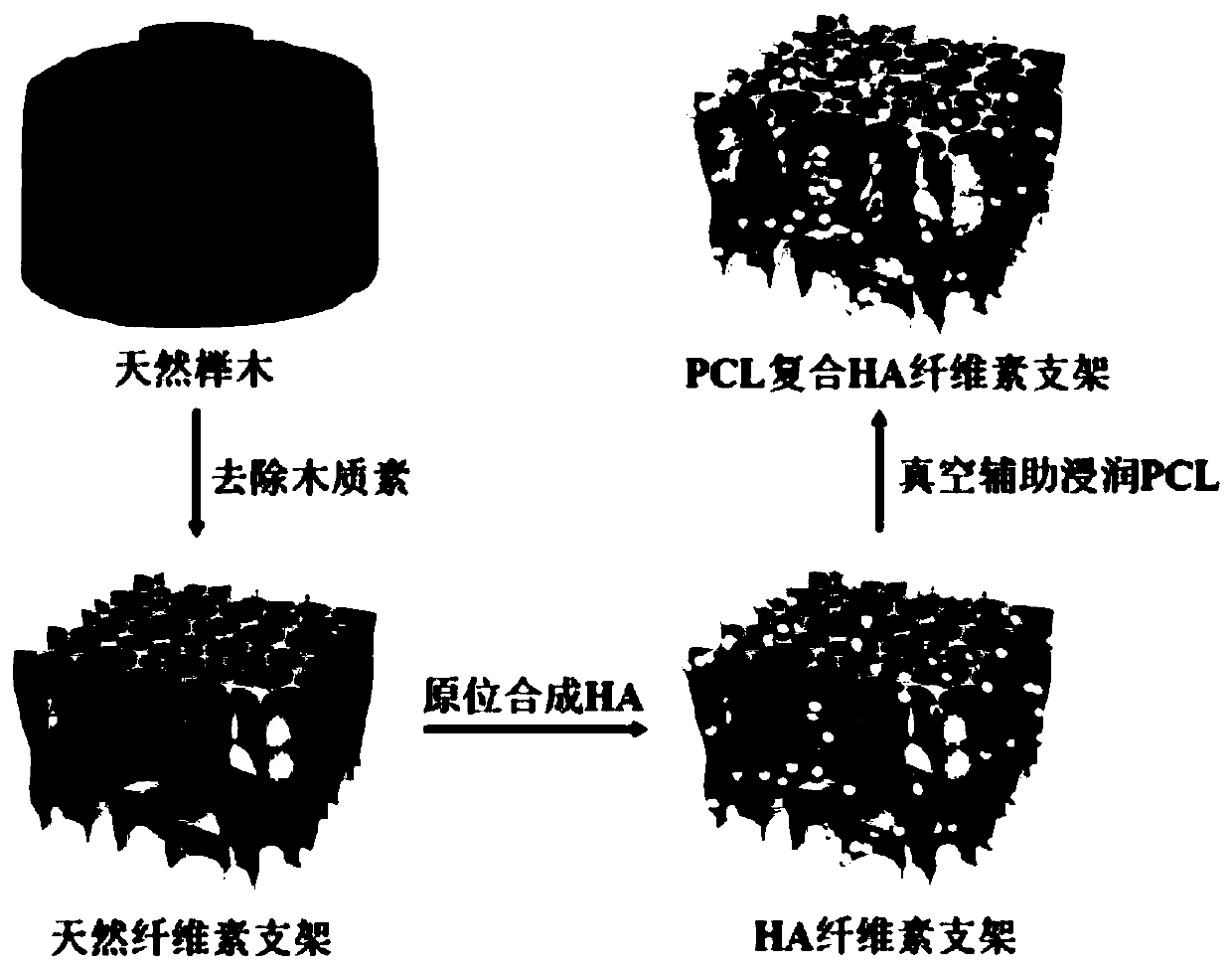

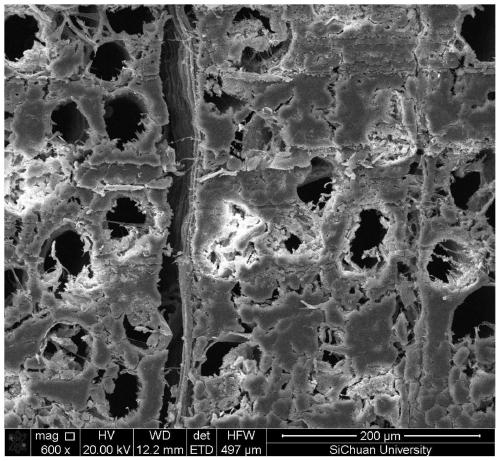

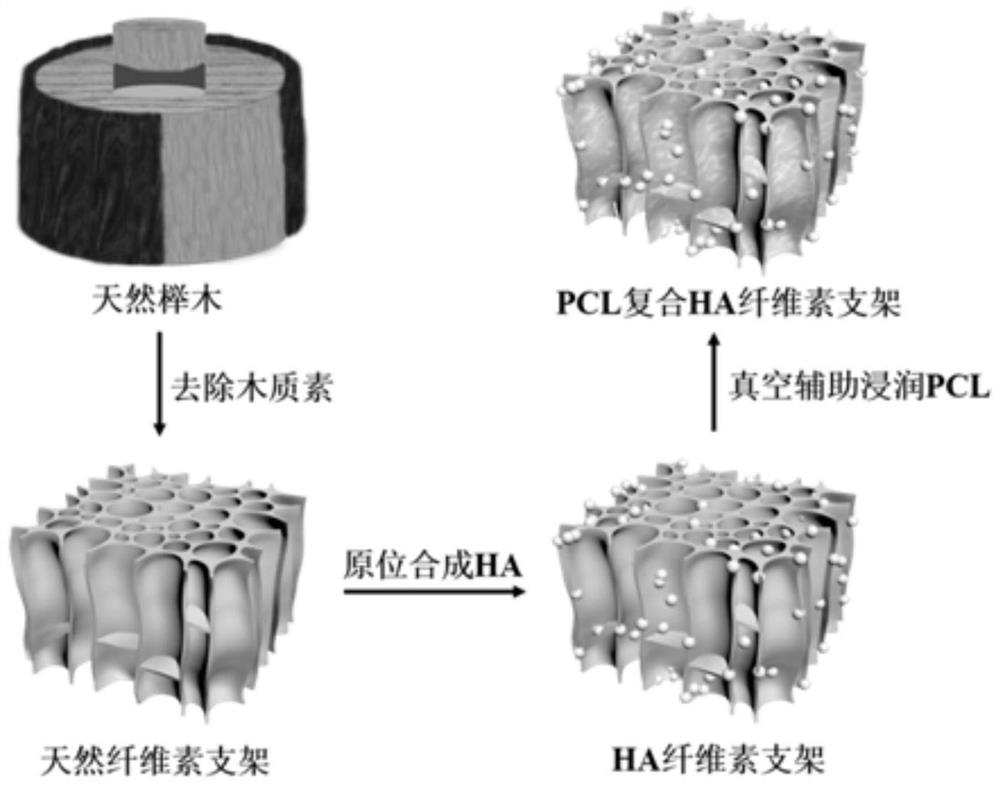

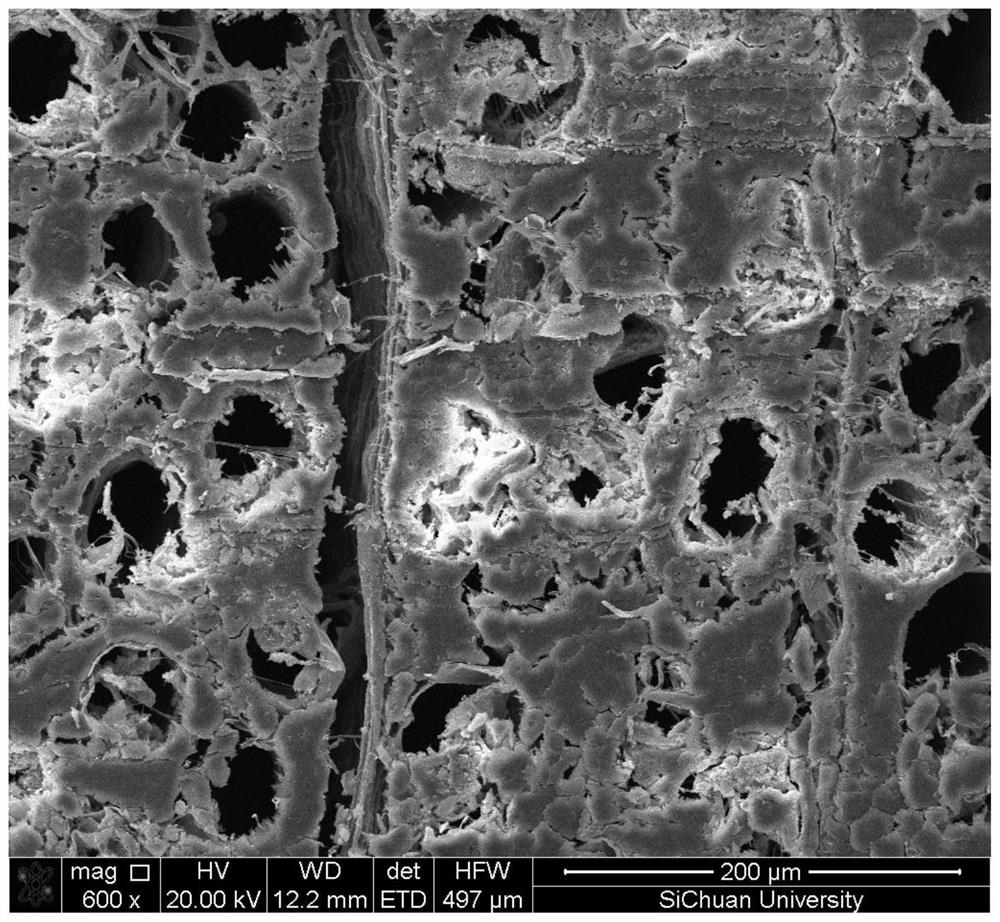

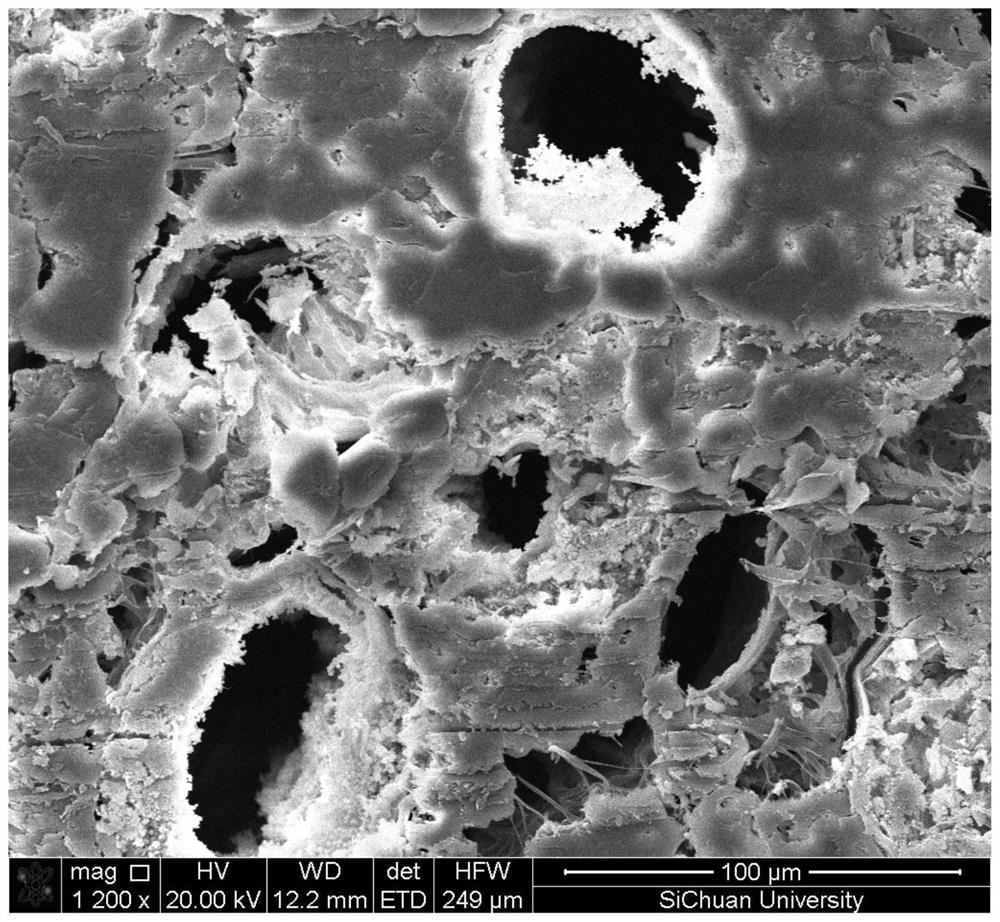

Bone-imitation composite material scaffold and preparation method thereof

ActiveCN111249523AAvoid disadvantagesMeet strength requirementsTissue regenerationProsthesisExtracellular ground substancePorous scaffold

The invention provides a bone-imitation composite material scaffold and a preparation method thereof. The method comprises the following steps: performing delignification treatment on natural wood, performing compounding by using hydroxyapatite to obtain a bone-inducible scaffold material, and performing infiltration by using polycaprolactone to simulate an extracellular matrix to obtain the bone-imitation composite material scaffold. The method obtains the highly anisotropic porous scaffold, the three-dimensional pore structure provides channels for nutrient substance transportation and intracellular growth and regeneration, the shortcomings of traditional isotropic scaffold materials are overcome, and the strength and stability requirements of bone tissue regeneration are met; and the method does not need to use special reagents or equipment, is not difficult to operate and mild in process conditions, and has the characteristics of easy realization of production, promotion and application.

Owner:SICHUAN UNIV

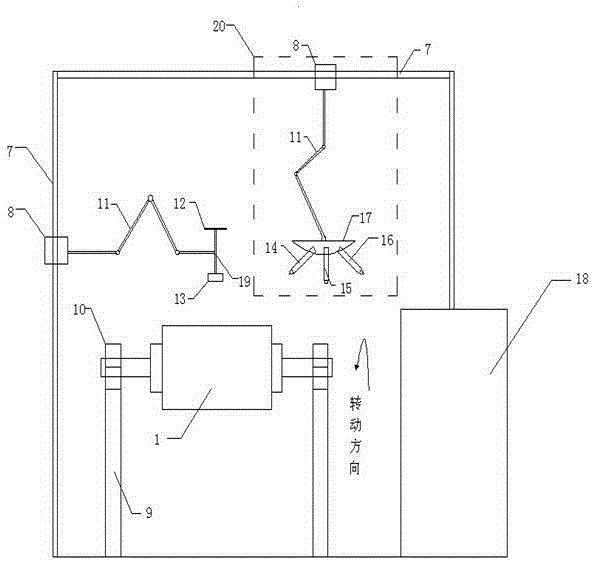

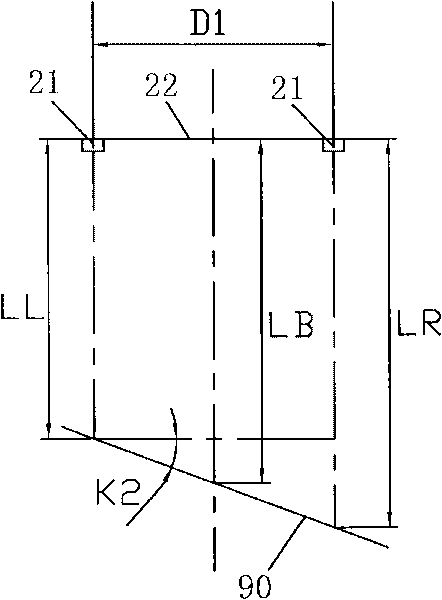

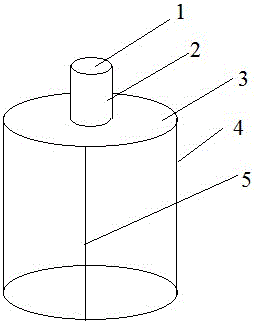

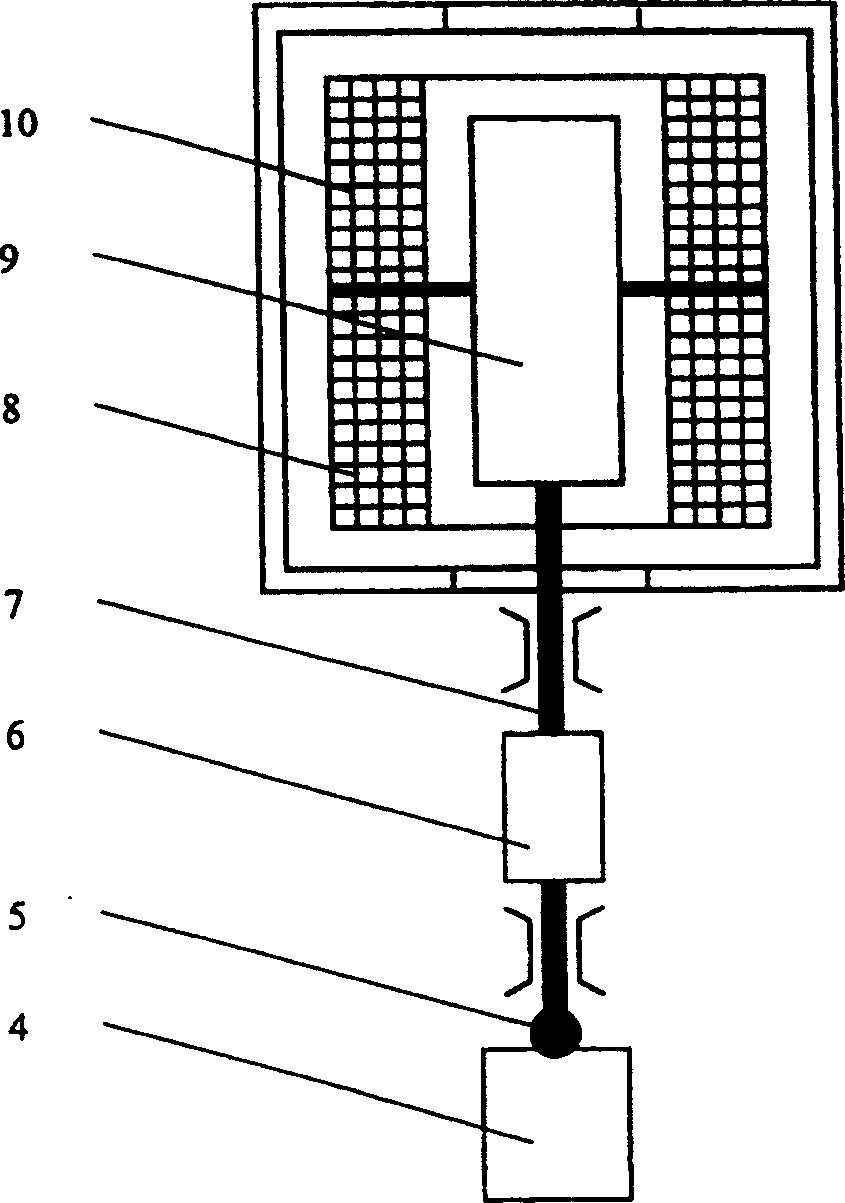

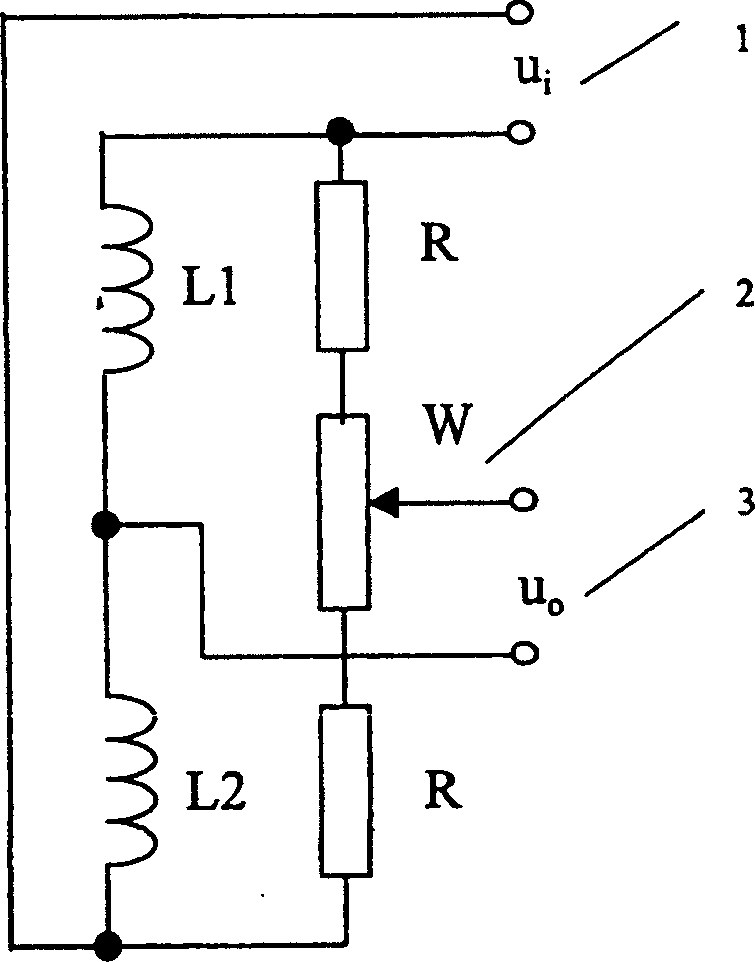

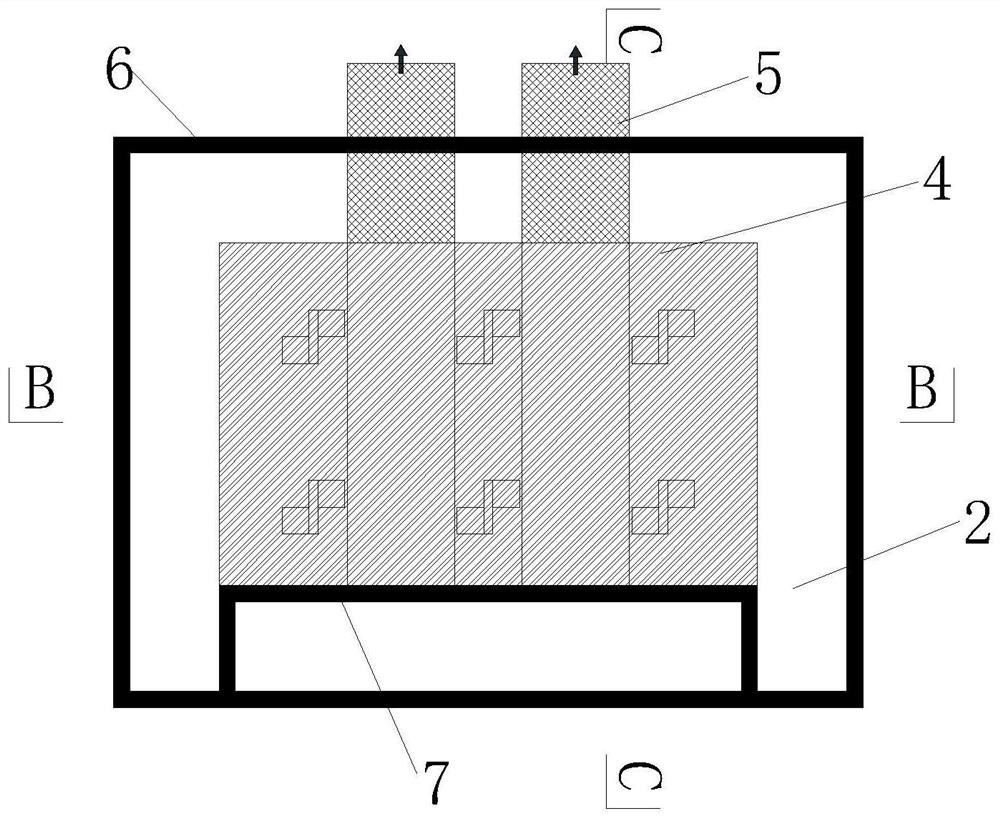

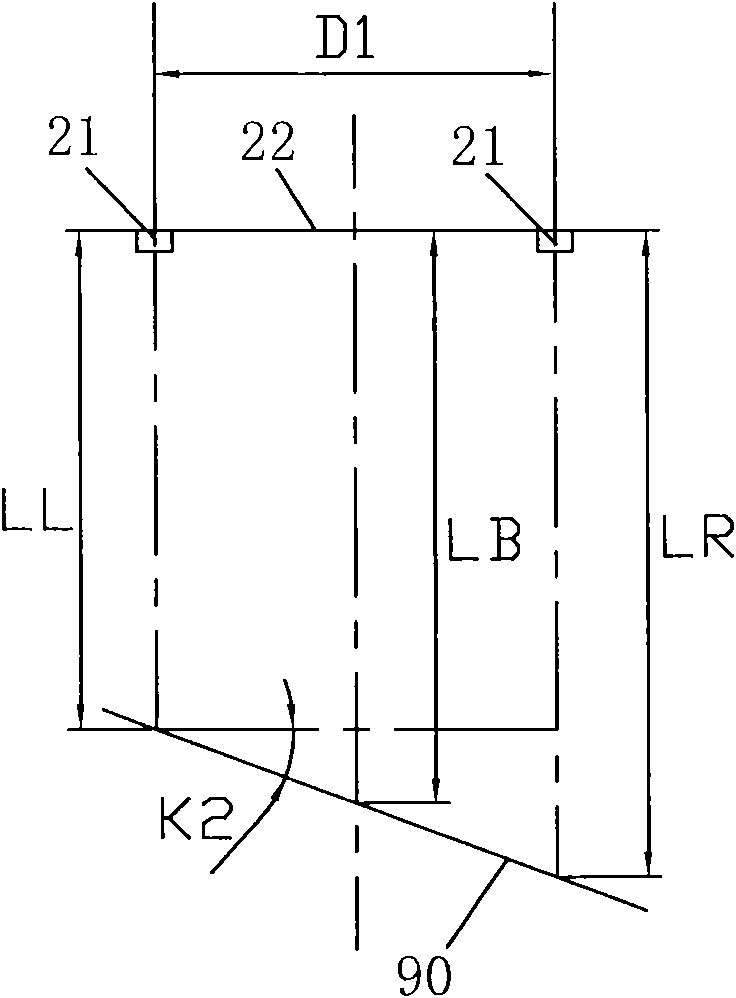

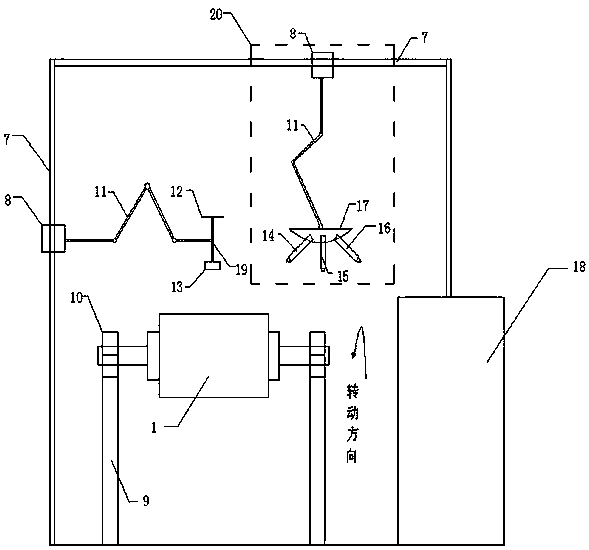

Step-recursion nano-level measuring system based on high-precision inductive probe

InactiveCN1258071CLarge measuring rangeReduce precisionElectrical measurement instrument detailsElectrical testingDisplacement controlStatic displacement

A step-by-step recursive nanoscale measurement system based on a high-precision electric probe, including a control part, an iron core (9) placed between a first coil (10) and a second coil (8); a measuring rod (7 ), one end of which is connected to the iron core (9), and the other end is connected to the measuring rod contact (5); the upper and lower ends of the nano-scale micro-feeding device (6) are fixed on the measuring rod (7). The micro-displacement of the object (4) provides the feed amount; the control part controls the micro-feeding device (6) with nanometer-level precision according to the displacement of the object to be sided. The present invention adopts a step-by-step recursive method for micro-displacement measurement, on the one hand, the nano-level measurement is easy to realize, and on the other hand, the whole measurement system has a larger measurement range. Therefore, the nanoscale feeding device determines that the measurement system has high measurement accuracy. The measurement system adopts contact measurement, so this system is suitable for quasi-static micro-displacement measurement.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Bone-mimetic composite scaffold and preparation method thereof

ActiveCN111249523BAvoid disadvantagesGuaranteed normal transportationTissue regenerationProsthesisBone tissueComposite scaffold

The invention provides a bone-imitative composite material scaffold and a preparation method thereof. The natural wood is de-lignified, and then compounded with hydroxyapatite to obtain an osteoinductive scaffold material, and the extracellular The matrix is simulated to obtain the bone-mimetic composite scaffold. The invention obtains a highly anisotropic porous scaffold, and the three-dimensional pore structure provides channels for the transport of nutrients and intracellular growth and regeneration, overcomes the shortcomings of traditional isotropic scaffold materials and meets the strength and stability requirements of bone tissue regeneration. The method does not need to use special reagents and equipment, the operation is not difficult, the process conditions are mild, and it has the characteristics of easy production and popularization and application.

Owner:SICHUAN UNIV

A Method of Controlling Grain Equiaxation to Improve the Plasticity of Ti20zr6.5al4v Alloy

The invention relates to a method for controlling grain equi-axiation to improve plasticity of a Ti20Zr6.5Al4V alloy. The method mainly comprises the steps that a Ti20Zr6.5Al4V alloy bar is cut into a round ingot with the thickness being 16 mm, and the round ingot is cleaned up; the round ingot is put into a resistance furnace to be heated till the temperature ranges from 950 DEG C to 1,050 DEG C, heat preservation is carried out for 20 min to 40 min, and the round ingot is quickly placed in water for quenching after being taken out; then the alloy ingot is heated till the temperature ranges from 750 DEG C to 900 DEG C at the speed being 10 DEG C / min, the heat preservation time is shorter than 5 min, the alloy ingot is subjected to rolling deformation through a dual-roller mill after being taken out, the rolling speed ranges from 0.3 m / s to 0.6 m / s, and the reduction in single pass ranges from 0.5 mm to 2 mm; heating-rolling is repeated 5-20 times in the same way till deformation reaches 60% or above, and air cooling is carried out until the room temperature is obtained; and then the alloy is subjected to annealing treatment after being heated, the annealing temperature ranges from 750 DEG C to 850 DEG C, and furnace cooling is carried out until the room temperature is obtained after heat preservation is carried out for 1 h to 12 h. According to the method, operation is easy, and the production cost is low; and the plasticity of the alloy is remarkably improved while strength is guaranteed.

Owner:YANSHAN UNIV

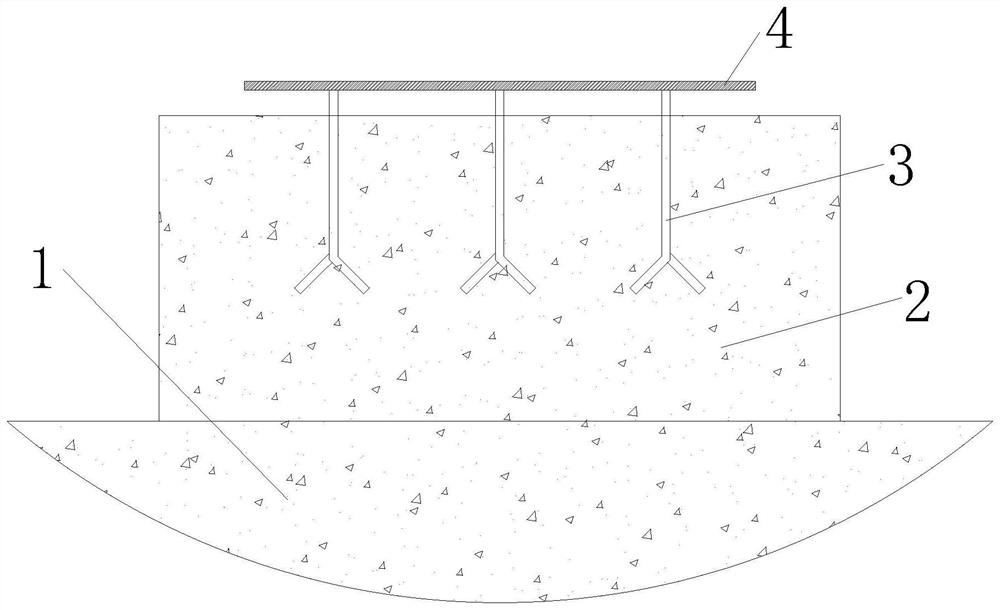

Method for tamping bottom of embedded steel plate of support

PendingCN114687376AEasy to useEfficient dischargeFoundation engineeringBuilding material handlingArchitectural engineeringDrill hole

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

Preparation method of 1,2,4-trifluoro-benzene

ActiveCN101817724BLow costReduce manufacturing costHalogenated hydrocarbon preparationBenzeneSolvent free

The invention relates to a preparation method of 1,2,4-trifluoro-benzene, belonging to the technical field of preparation methods of chemical drug intermediates. The preparation method comprises the following steps of: (1) generating salifying reaction on 3,4-difluoroaniline and fluoboric acid, and then generating diazotization reaction with sodium nitrite to obtain fluoboric acid diazonium salt;and (2) under the solvent-free condition, carrying out high-temperature cracking reaction on the fluoboric acid diazonium salt at the temperature of 80-300 DEG C to obtain 1,2,4-trifluoro-benzene. The preparation method has the advantages of cost saving of raw materials, relatively simple process flow, mild reaction condition, low operation difficulty, operability and convenient aftertreatment; and the prepared products have the purity increased to 98 percent or more now from 80 percent or less originally, are stable in quality, and are suitable for large-scale industrial production.

Owner:ZHEJIANG TIANYU PHARMA

Method for promoting quick rooting of cuttage of babysbreath seedlings

The invention relates to the field of seedling growing of plants, in particular to a method for promoting quick rooting of cuttage of babysbreath seedlings. The method comprises the steps of (1) preparation before cuttage, (2) cuttage of the babysbreath seedlings, (3) rooting culturing and (4) seedling hardening and transplanting. The method is simple in operation, cannot be limited by seasons, can be completed in the room, can effectively increase the survival rate of cutting seedlings of babysbreath, shortens rooting time of cuttage, and is large in application value.

Owner:JINGXI XIUMEI BIANCHENG AGRI SCI & TECH CO LTD

Device for compensating the difference of height by which a helicopter lands on a non-horizontal ground and the method thereof

InactiveCN101746500BIncrease flexibilityReduce the risk factor of rolloverUndercarriagesElectricityFuselage

The invention provides a device for compensating the difference of height by which a helicopter lands on a non-horizontal ground and the method thereof, which aim at addressing the problem that the helicopter lands on the non-horizontal ground. The device comprises three ranging sensors used for testing the pitch angle and spinning angle of the non-horizontal ground, three leg-type landing gears comprising a landing platform fixedly connected with the body of the helicopter and three landing supporting legs fixed on the landing platform and a control device respectively electrically connectedwith three ranging sensors and three power output devices; power output devices independent of each other are arranged between each landing supporting leg and the landing platform. When the helicopter lands, the measurement results of the ranging sensors are used for calculating the pitch angle and spinning angle of the non-horizontal ground and then controlling the pitch angle and spinning angleof the plane on which three landing ends of three landing supporting legs to be equal to the pitch angle and spinning angle of the non-horizontal ground so that the helicopter can be controlled to land vertically.

Owner:李子赫

A kind of bone targeting salmon calcitonin and its preparation method

ActiveCN108586601BAchieve targeted enrichmentDoes not affect conformationCalcitoninsPeptide preparation methodsRecombinant salmon calcitoninDisulfide bonding

The invention provides a bone-targeted salmon calcitonin, which is formed by opening the disulfide bond in the salmon calcitonin molecule and covalently coupling it with a bone-targeted coupling molecule. The preparation method is as follows: (1) To prepare bone-targeting coupling molecules, (2) dissolving salmon calcitonin in a water-soluble solvent with a pH value of 5 to 7, adding a reducing agent to reduce the disulfide bonds of salmon calcitonin to form free sulfhydryl groups, and then adding The bone-targeting coupling molecule is stirred and reacted at 0-40° C. for 0.5-12 hours, the crude product is separated, and purified by preparative liquid chromatography to obtain the bone-targeting salmon calcitonin. The bone-targeted salmon calcitonin provided by the invention has no cytotoxicity and immunogenicity, can improve the bone tissue enrichment ability of the calcitonin, can effectively repair the bone tissue, and has broad application prospects.

Owner:SICHUAN UNIV

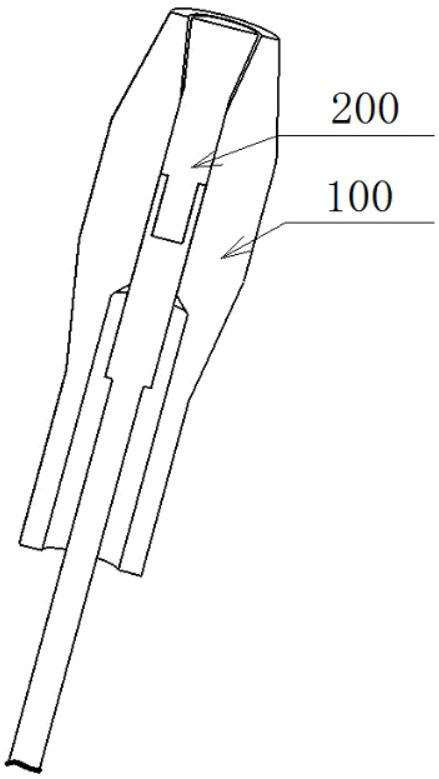

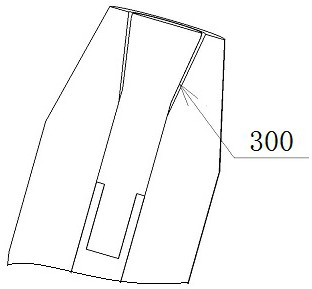

High-strength steel bar floor construction anti-trampling device

ActiveCN113463935AReduce the risk of working at heightsAvoid misalignmentBuilding material handlingFloor slabArchitectural engineering

The invention relates to a high-strength steel bar floor construction anti-trampling device which comprises a positioning base, a pedal and an embedded positioning mechanism. The pedal is installed at the upper end of the positioning base, and the embedded positioning mechanism is installed at the upper end of the pedal. The high-strength steel bar floor construction anti-trampling device can solve the problems that a flat plate and a reinforcing mesh are directly laid and are not in any positioning connection, the flat plate and the reinforcing mesh are prone to happening position dislocation and deviation when people step on the flat plate and the reinforcing mesh, friction force between the flat plate and the reinforcing mesh is smaller in rainy weather, slipping is prone to occurring, when a person falls down on the reinforcing mesh due to slipping of the flat plate, the danger degree of high-altitude operation of the person is increased, the deformation degree of the reinforcing mesh is increased due to direct contact between the person and the reinforcing mesh, and the quality of a floor slab is seriously influenced.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

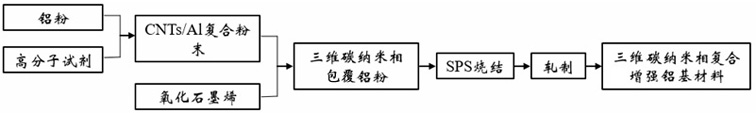

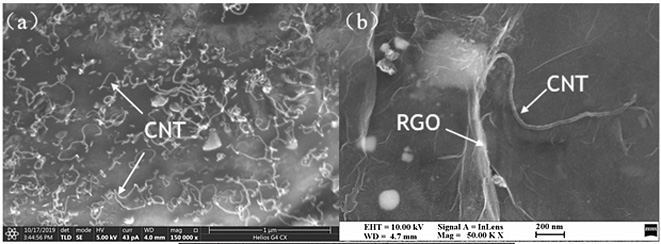

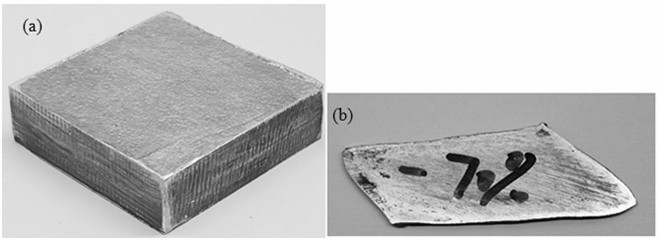

A three-dimensional carbon nanophase composite reinforced aluminum-based material and its preparation method

ActiveCN111996418BGuaranteed decentralizationAvoid degradation of mechanical propertiesTransportation and packagingMetal-working apparatusGlycidyl ethersAluminium powder

Owner:FUZHOU UNIV

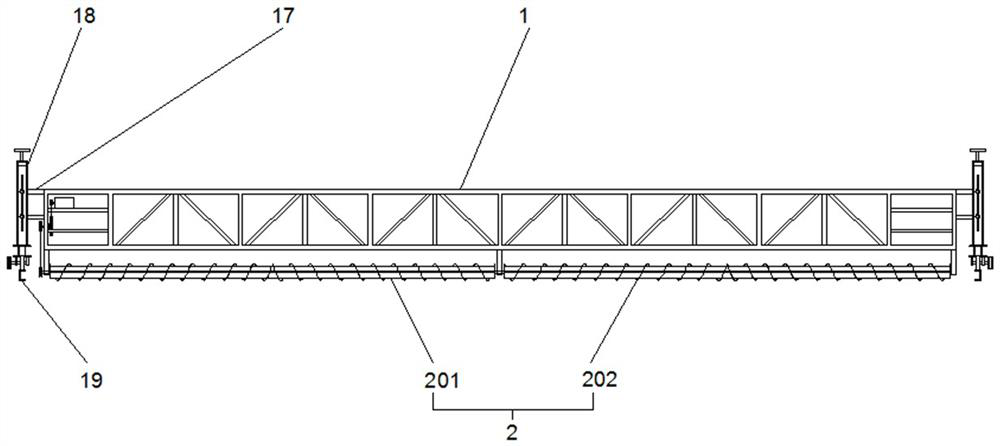

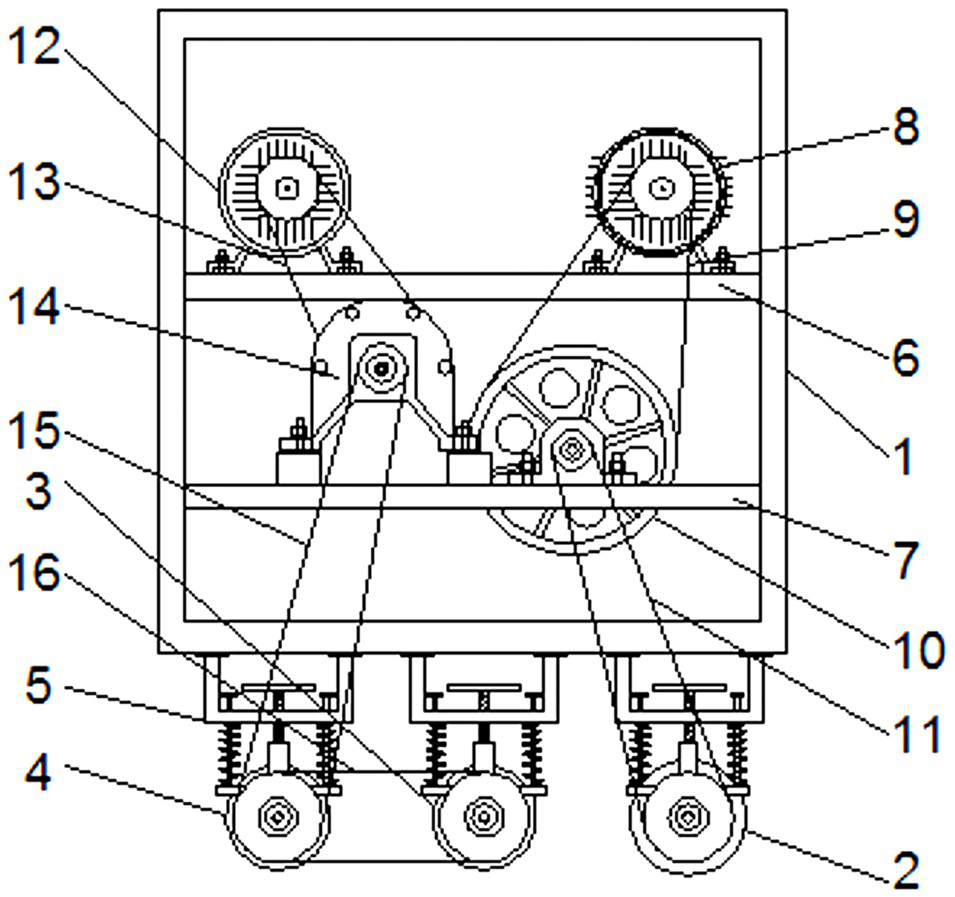

Equipment for leveling large-span light truss bridge surface

InactiveCN113047132AShrink evenlyNo loose unevennessBridge erection/assemblyRoads maintainenceBridge deckSlurry

The invention discloses equipment for leveling a large-span light truss bridge surface. The equipment comprises a truss body, wherein the front part, the middle part and the rear part of a lower end of the truss body are respectively provided with a main spiral roll shaft, a first main leveling roll shaft and a second main leveling roll shaft, and the main spiral roll shaft comprises a first spiral roll shaft and a second spiral roll shaft. Truss type suspended walking is adopted, walking devices are arranged at a left end and a right end, and overall lifting is achieved through the thread transmission effect of a second lead screw and a second inner thread sleeve; the paving and leveling system is composed of a main spiral roller shaft and two main leveling roller shafts; the spiral roll shaft adopts positive and negative spirals and a scraping plate to distribute materials, and stirring is carried out again in the paving process, so gravel materials in the concrete are more uniform, and surface shrinkage of the bridge floor after final setting is more uniform. The two leveling roll shafts are subjected to rotary excitation, so density of concrete on the bridge floor meets the requirement, and slurry is extracted after accurate leveling, so flatness of the bridge floor meets the design requirement.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

Overlay welding method after large roller shaft wear

ActiveCN105382378BReduce defectsImprove forming qualityArc welding apparatusWelding/cutting media/materialsFatigue damageSlag

The invention discloses a surfacing welding method for an abraded large roll shaft. The surfacing welding method is characterized by comprising the following steps that 1, preweld material analysis is carried out, preweld cleaning is carried out on the roll shaft, and preweld preparation is carried out; 2, after preweld preparation is finished, preweld preheating is carried out; 3, after preweld preheating is finished, automatic submerged arc welding is adopted for surfacing welding; 4, after surfacing welding is finished, welding slag is broken down, and postweld heat treatment is carried out; and 5, after heat treatment is finished, finally machining is carried out according to requirements. After the surfacing welding method is adopted, surfacing welding layer defects at the surfacing welding position are few, and the forming quality of a welding channel is good; the hardness of the surfacing welding position is distributed in a ladder manner from low to high from inside to outside, and the hardness of the outermost layer even ranges from 55 HRC to 60 HRC; the impact toughness and strength of the surfacing welding position are equal to those of the roll shaft and even exceed those of a base material by 1-2 times; the capacity for resisting spalling fatigue damage is high, the surfacing welding effect is remarkable, and the welding quality requirement can be completely met; and the whole surfacing welding process is easy to master and control, and good economical efficiency is achieved.

Owner:JIANGSU JINHANG MACHINERY MFG CO LTD

Sintering method of semi-conductor glaze layer for improving cooperation between semi-conductor components and central electrode

ActiveCN112615261BHighly corporatedImprove ignition performanceSpark gap detailsSparking plugs manufactureMetallurgyMaterials science

The invention relates to the field of sintering technology, and specifically discloses a semiconductor glaze layer sintering method for improving the matching degree of semiconductor components and a central electrode, which is used for sintering a semiconductor glaze layer on a porcelain tube, and is characterized in that: firstly, the center electrode wax is made according to the shape and size of the center electrode Then fit the porcelain tube with the wax mold of the center electrode, inject the pre-configured semiconductor enamel into the gap between the outer cone surface of the center electrode and the inner cone surface of the porcelain tube, and put it into the furnace for heating after the semiconductor enamel cools naturally sintering. The semiconductor glaze layer sintered by the method for sintering the semiconductor glaze layer can improve the matching degree between the semiconductor component and the central electrode, thereby avoiding the increase of the insulation resistance between the central electrode and the semiconductor component due to the poor coordination between the central electrode and the semiconductor component, and improving the electric resistance. Mouth pyrogenicity.

Owner:四川泛华航空仪表电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com