Method for tamping bottom of embedded steel plate of support

A pre-embedded steel plate and bottom filling technology, which is applied in the processing of building materials, construction, infrastructure engineering, etc., can solve the problems of difficulty in ensuring the flatness of the pre-embedded steel plate, lack of steel plate surface, and the impact of equipment connection, etc., so as to facilitate popularization and use , The operation is not difficult, and the construction quality is controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

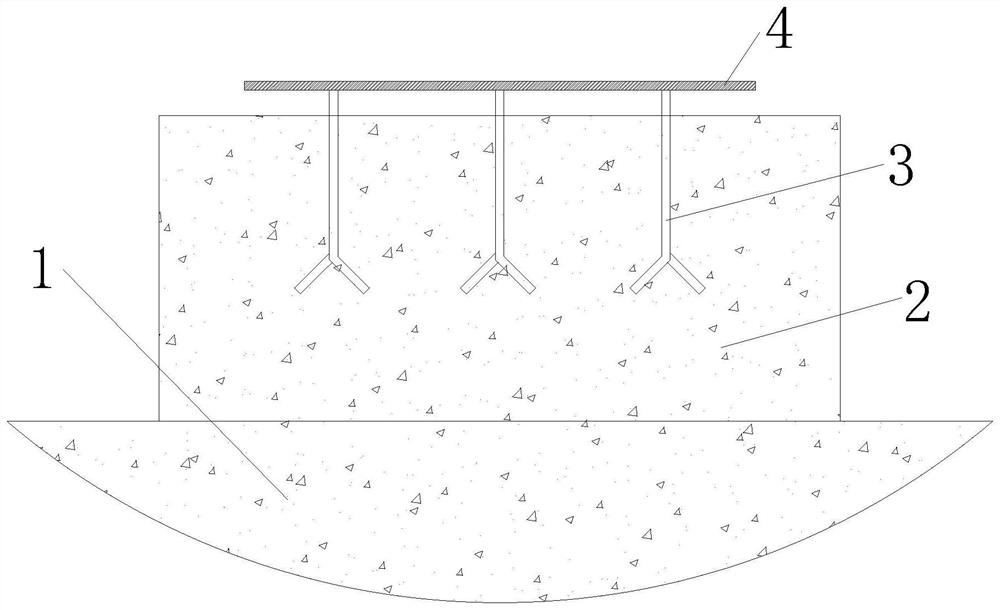

[0036] like Figure 1 to Figure 8 As shown, a method for filling the bottom of a support pre-embedded steel plate of the present invention includes the following steps:

[0037] Step 1, pouring the concrete bearing base layer: pouring the concrete bearing base layer 2 on the concrete base 1, at the same time, a plurality of tie members 3 are integrally poured in the concrete bearing base layer 2, and the plurality of tie members 3 protrude On the top of the base layer 2 of the concrete support, the tops of the plurality of tie members 3 are welded with embedded steel plates 4;

[0038] Step 2. Install the template and the primer strip, the process is as follows:

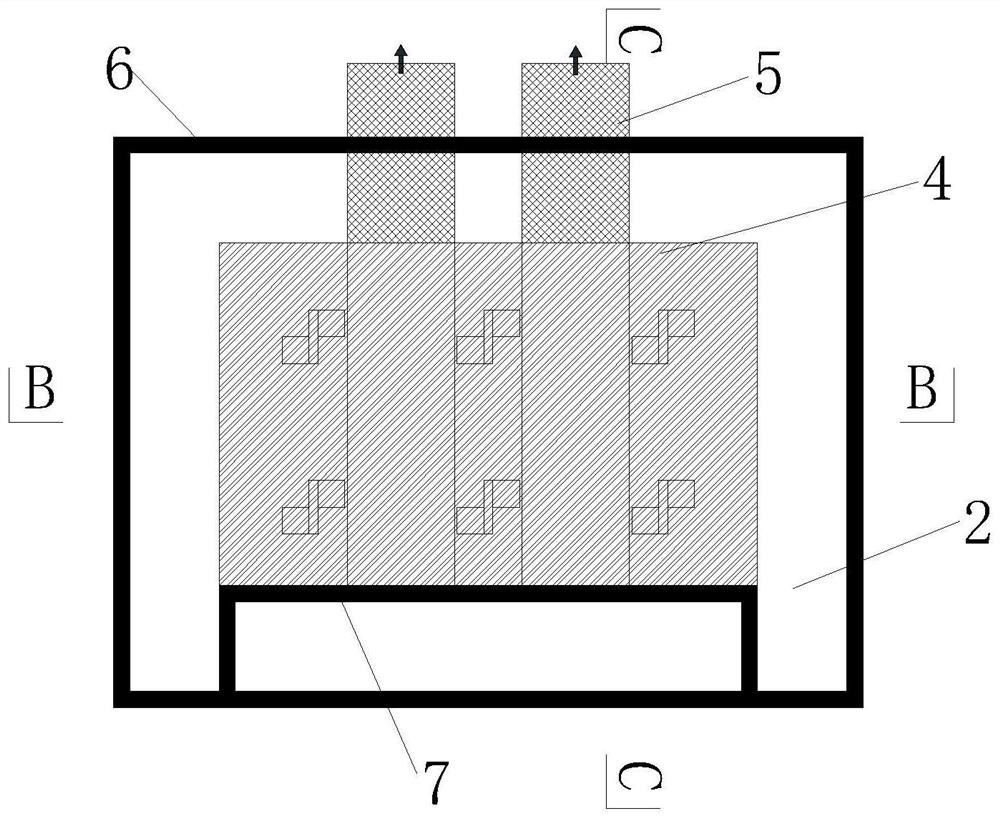

[0039] Step 201: After the concrete bearing base layer 2 reaches the design age, install the bearing peripheral formwork 6 on the upper peripheral side of the concrete bearing base layer 2;

[0040] Step 202: Install the U-shaped structure of the feed formwork 7 between the top of one end of the embedded steel plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com