Method and special die for manufacturing composite pipeline

A technology for composite pipes and manufacturing methods, which is applied in the field of pipes, can solve the problems of poor impact resistance, single performance, anti-corrosion and anti-aging, etc., achieves improved bending strength and impact resistance, less difficult operation, and less equipment requirements high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

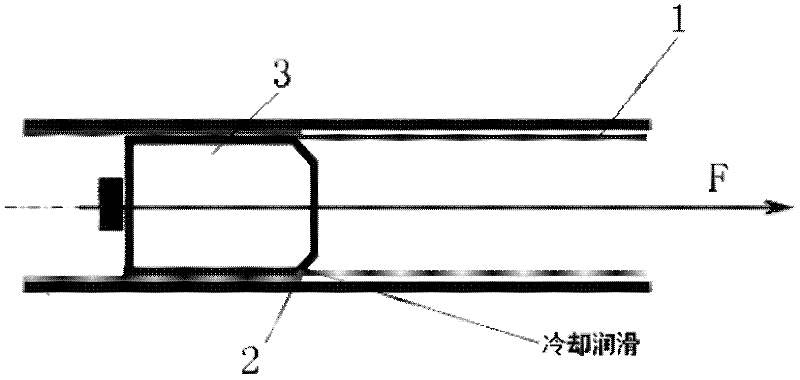

[0028] The manufacturing method of described composite pipeline, such as figure 1 As shown, the composite pipe is sequentially composed of copper or copper alloy layer 1 and carbon steel layer 2 from inside to outside, and the manufacturing method of the composite pipe includes the following steps:

[0029] A: Select copper or copper alloy pipes and carbon steel pipes. According to the plastic deformation coefficient of carbon steel and copper alloy pipes, the outer diameter of copper pipes is 4MM smaller than the inner diameter of carbon steel pipes, and then put the copper pipes into carbon steel pipes. One end needs to protrude from the carbon steel pipe 100MM;

[0030] B: Use a flaring machine to flaring the end of the copper pipe. The outer diameter of the copper pipe after flaring is 8MM larger than the outer diameter of the carbon steel pipe. The flaring length of the copper pipe is 50MM. Edge welding of carbon steel pipe mouth;

[0031] C: Composite copper pipe and c...

Embodiment 2

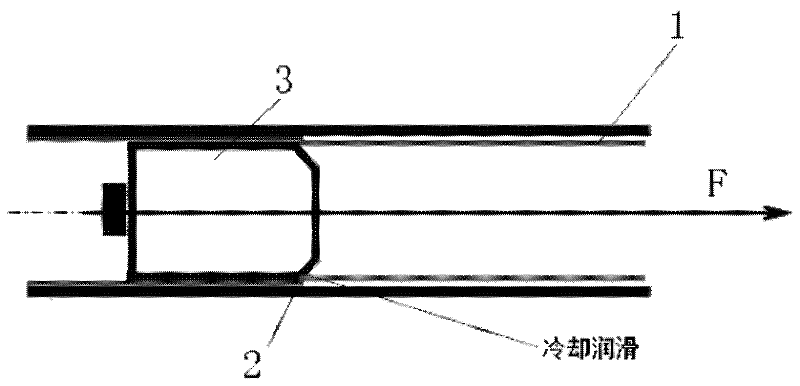

[0037] The manufacturing method of the composite pipe, the composite pipe is sequentially composed of a copper or copper alloy layer and a carbon steel layer from the inside to the outside, and the manufacturing method of the composite pipe includes the following steps:

[0038] A: Select copper or copper alloy pipes and carbon steel pipes. According to the plastic deformation coefficient of carbon steel and copper alloy pipes, the outer diameter of copper pipes is 8MM smaller than the inner diameter of carbon steel pipes, and then put the copper pipes into carbon steel pipes. One end needs to protrude from the carbon steel pipe 150MM;

[0039] B: Use a flaring machine to flaring the end of the copper pipe. The outer diameter of the copper pipe after flaring is 3MM larger than the outer diameter of the carbon steel pipe. The flaring length of the copper pipe is 20MM. Edge welding of carbon steel pipe mouth;

[0040] C: Composite copper pipe and carbon steel pipe using cold dr...

Embodiment 3

[0046] The manufacturing method of the composite pipe, the composite pipe is sequentially composed of a copper or copper alloy layer and a carbon steel layer from the inside to the outside, and the manufacturing method of the composite pipe includes the following steps:

[0047] A: Select copper or copper alloy pipes and carbon steel pipes. According to the plastic deformation coefficient of carbon steel and copper alloy pipes, the outer diameter of copper pipes is 5MM smaller than the inner diameter of carbon steel pipes, and then put the copper pipes into carbon steel pipes. One end needs to protrude from the carbon steel pipe 120MM;

[0048] B: Use a flaring machine to flaring the end of the copper pipe. The outer diameter of the copper pipe after flaring is 6MM larger than that of the carbon steel pipe, and the flaring length of the copper pipe is 30MM. Edge welding of carbon steel pipe mouth;

[0049] C: Composite copper pipe and carbon steel pipe using cold drawing compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com