Step-recursion nano-level measuring system based on high-precision inductive probe

An inductive probe, nano-scale technology, applied to the components of electrical measuring instruments, measuring electronics, measuring devices, etc., can solve the problems of complex structure of the measurement system, difficult adjustment, limited accuracy, etc., and achieve high measurement accuracy, Large measuring range, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

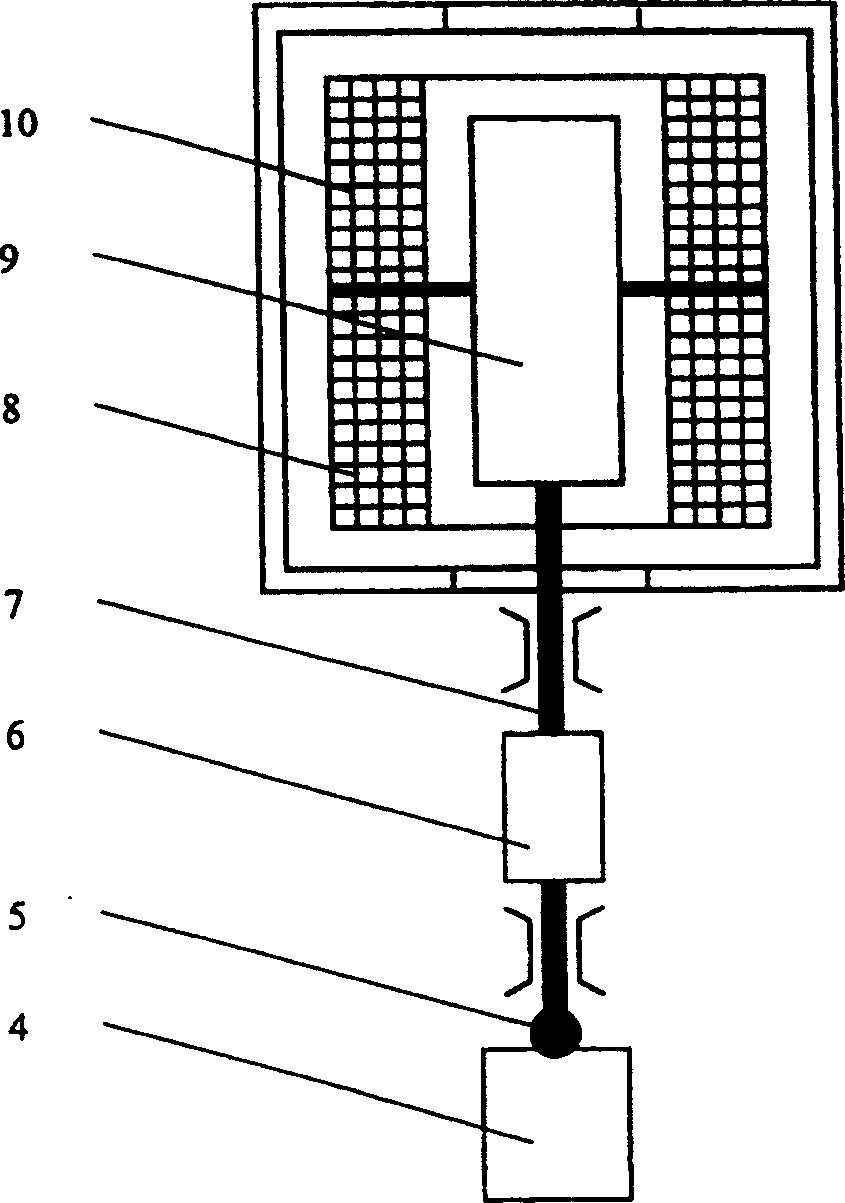

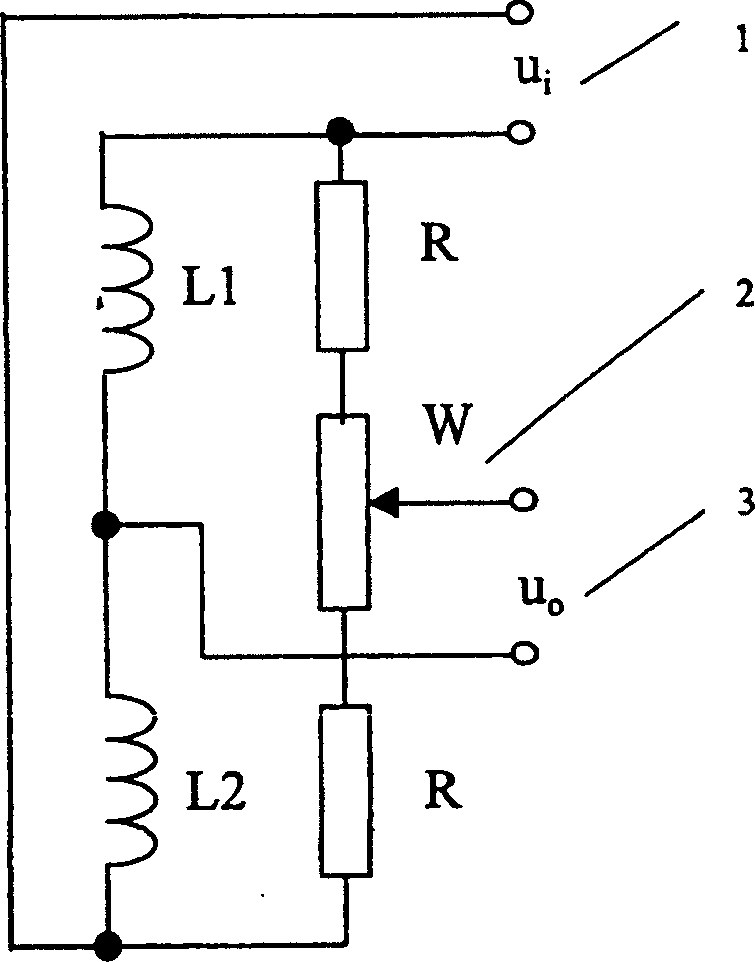

[0015] Such as figure 2 and image 3 As shown, the high-precision inductive probe adopts a differential method, and there are two coils 10 and 8 in the probe, that is, L1 and L2, and the iron core 9 is placed between the two coils. The iron core 9, the measuring rod 7, the micro-feeding device 6, and the measuring rod contact 5 are connected into one body, and it is ensured that the object 4 to be measured is in good contact with the inductive probe 5. If the slight change of the micro-feeding device 6 is not considered, when the displacement of the object 4 to be measured changes slightly, the iron core 9 will move up and down. Because the magnetic field distribution between the coils L1 and L2 is uniform, the iron core 9 moves Will cause the inductance of the two coils L1 and L2 to change by equal amounts but opposite signs. Under the excitation of the standard sine wave 1 with stable frequency and amplitude, the bridge circuit converts the inductance change into a voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com