Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "No ablation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

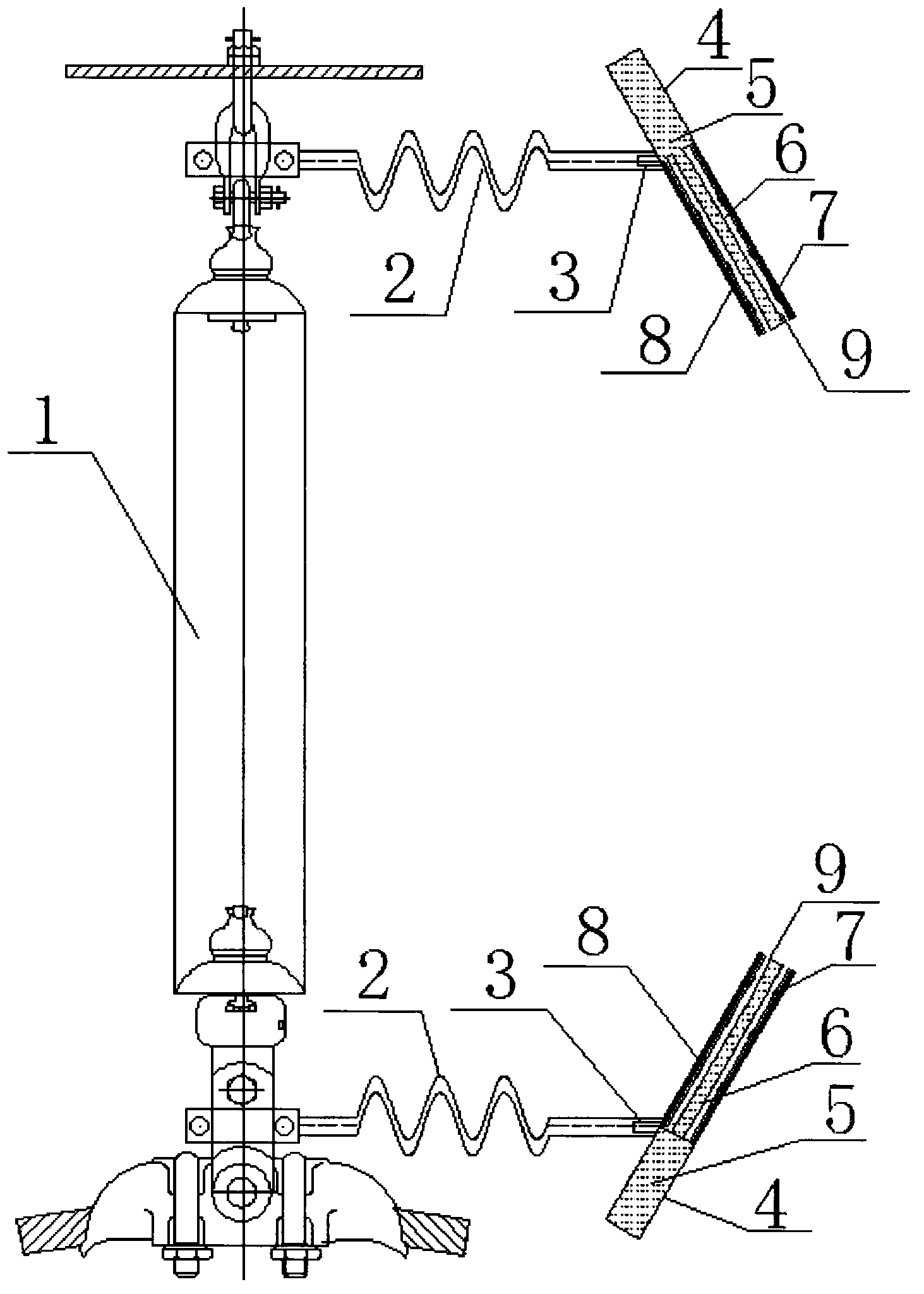

10-35kv overhead transmission line constraint space injection gas arc extinguishing lightning protection gap apparatus

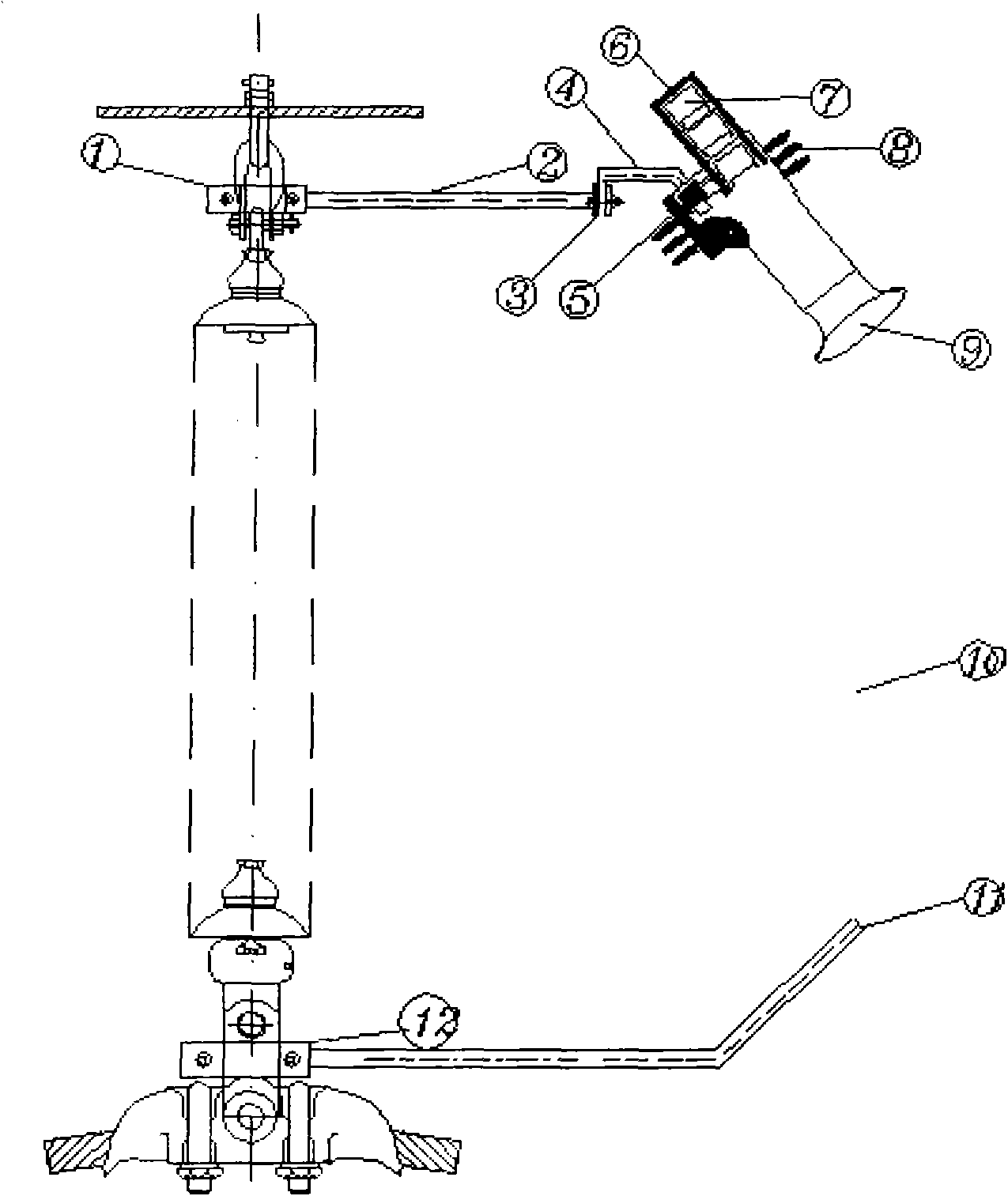

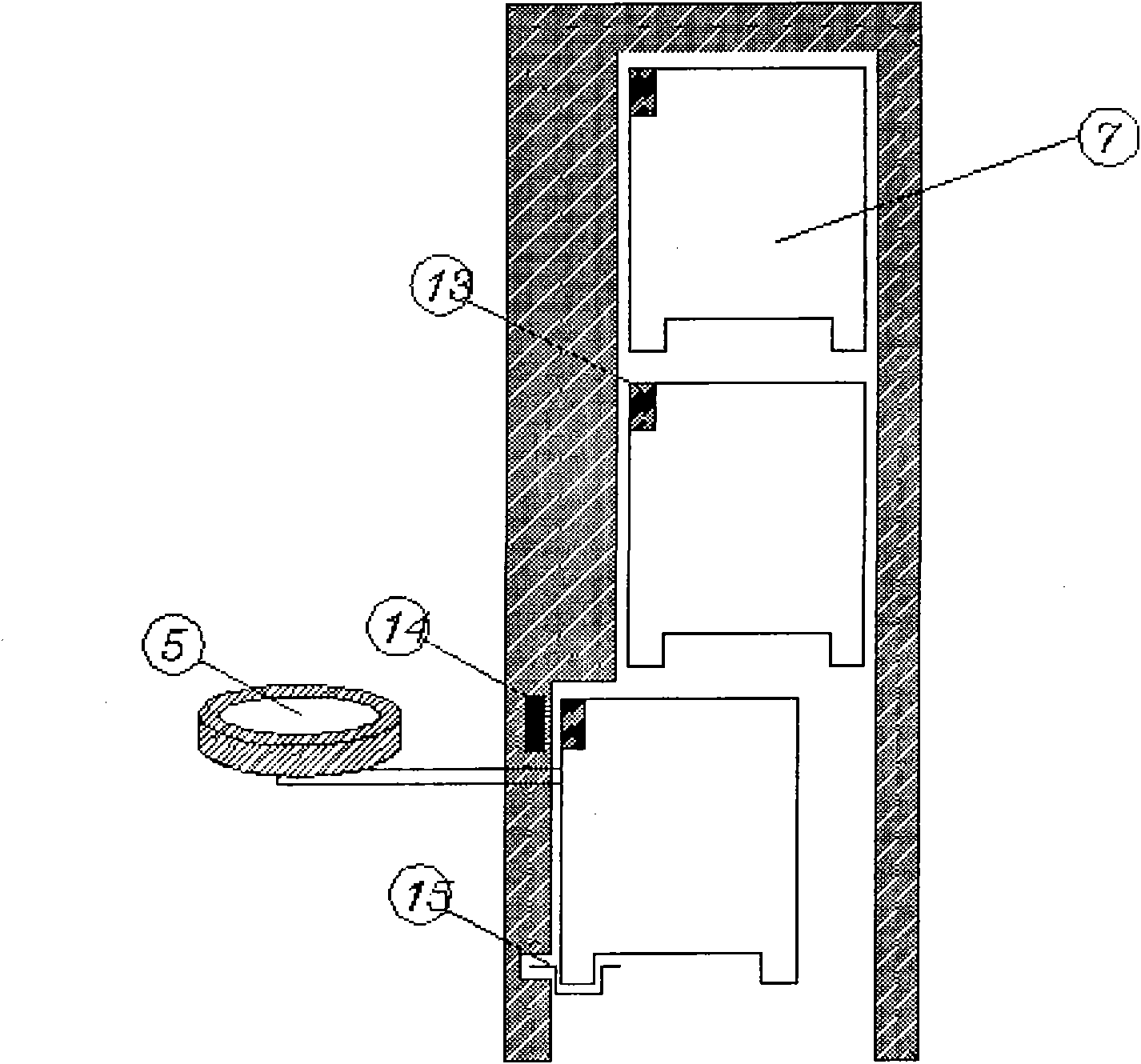

The invention relates to a lightning protection and especially relates to a 10-35kV overhead transmission line constraint space injection gas arc extinguishing lightning protection gap apparatus which is suitable for a 10-35kV overhead transmission line. The apparatus is installed in parallel on two ends of a line insulator string to protect a flash-over voltage between gaps to be less than the voltage of a protected insulator string so that the apparatus is punctured prior to the protected insulator string when the power transmission line is suffered from lightning stroke. During disruptive discharging, a signal acquisition device automatically senses a lightning current signal and triggers a high speed injection gas generation apparatus. A high speed injection air flow is instantly generated so as to carry out great impact on a follow current arc in a constraint space along a vertical direction, and carry out cooling till the arc is quenched. According to the invention, a structure is simple, installation and maintenance are convenient. Through using the apparatus of the invention, when the line is suffered from the lightning stroke, a lightning current can be rapidly led to the ground and simultaneously a high speed airflow quenching power frequency follow current is generated so that electric equipment can be effectively protected and power supply reliability is increased.

Owner:云南电力试验研究院(集团)有限公司

Multi-interspace self-expanding strong-airflow arc extinguishing lightning protection device

The invention relates to a lightning protection device and especially relates to a multi-interspace self-expanding strong-airflow arc extinguishing lightning protection device used in power transmission lines with different voltage grades. The device is installed in parallel on one side of a line insulator substring. Insulation strength of a main discharge protection gap and an auxiliary discharge gap is less than the insulation strength of the protected insulator substring so that an overvoltage generated when lightning stroke is generated on the line punctures the protection gap preferentially. When the protection gap is punctured so as to discharge, high temperature arc is generated in the auxiliary discharge gap, air is rapidly heated and expanded in a semi-closed space of the auxiliary discharge gap so that the arc is elongated and is erupted along a gas guidance hole. Simultaneously, a signal acquisition device automatically collects signals and starts a gas generation apparatusso as to instantly generate high speed airflow to extinguish the arc. The protection device of the invention has a simple structure. Installation is convenient. When the lightning stroke is generatedon the line, the lightning current can be rapidly leaked to the ground and simultaneously the high speed airflow is generated to extinguish the arc. Therefore, electric power equipment can be effectively protected and power supply reliability can be increased.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU

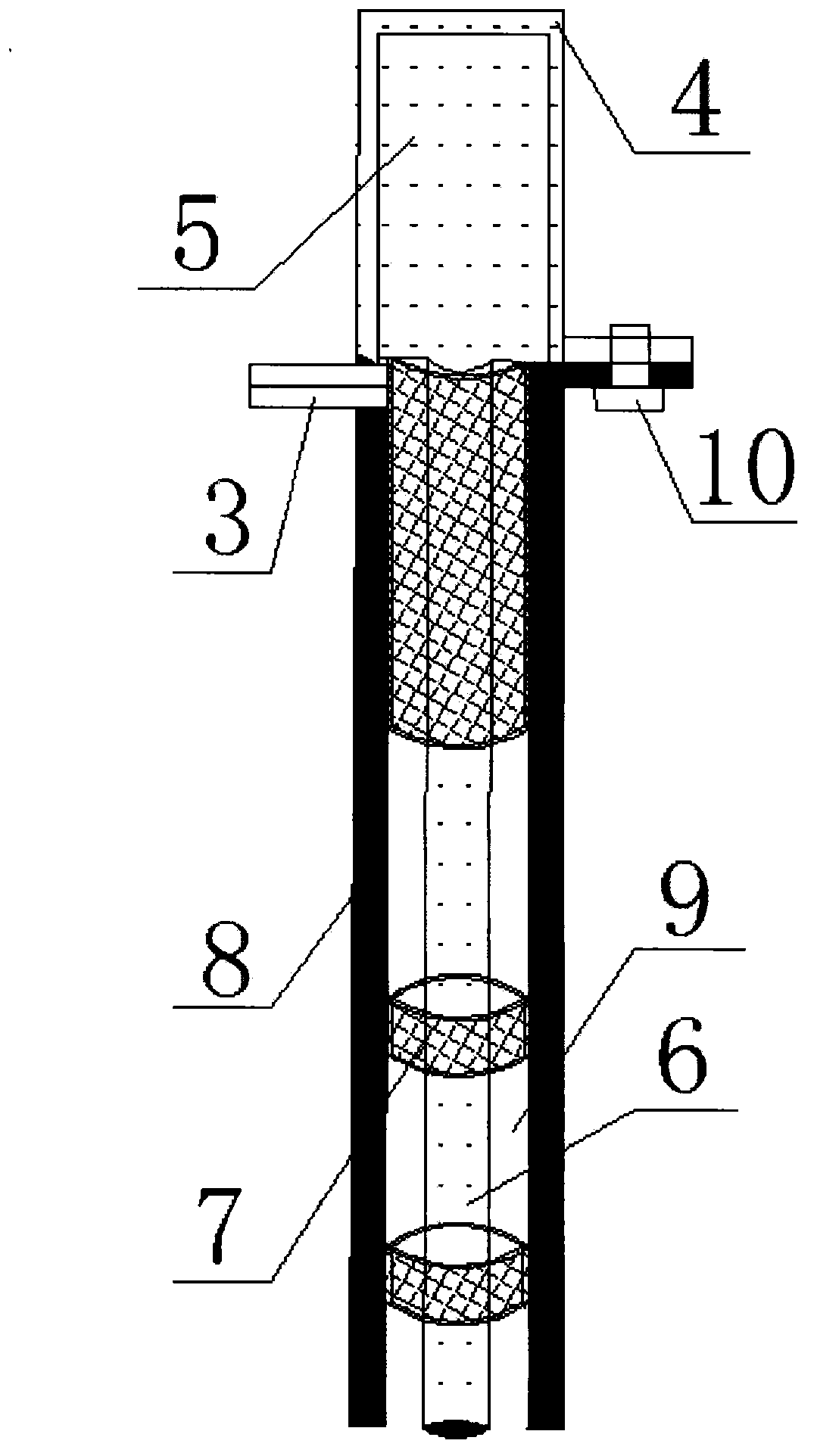

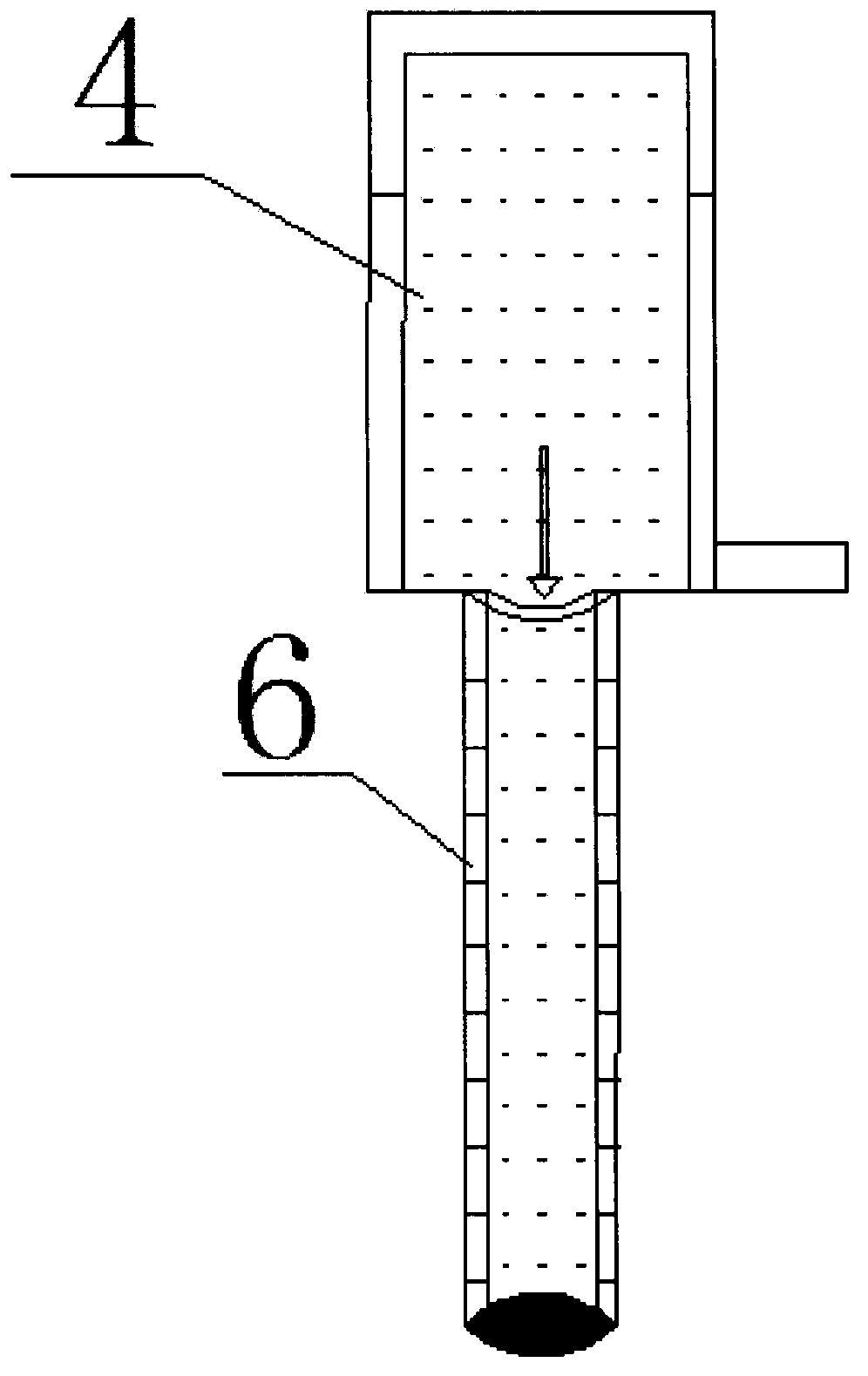

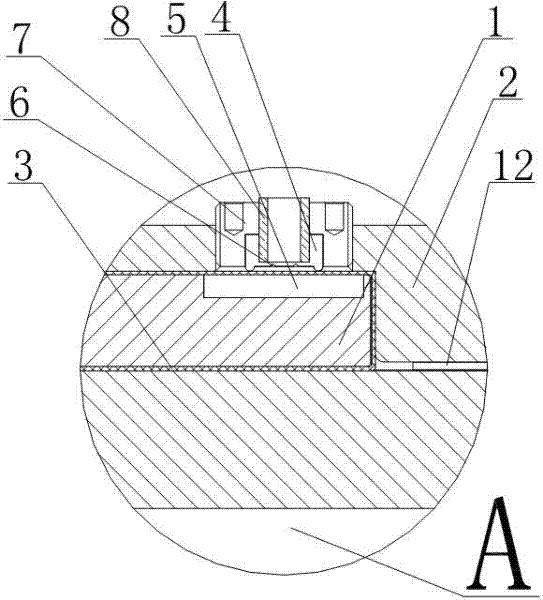

Gas injection type parallel gap device

InactiveCN103730834APrevent trippingEffective protectionSpark gap detailsInsulatorsTransformerElectric power system

The invention discloses a gas injection type parallel gap device. The protection device belongs to the field of lightening protection gap for power transmission lines of alternating-current and direct-current electric power systems. The device is connected with the two ends of a power transmission line insulator chain in parallel, under a lightening stroke, the device is broken down before the insulator chain can be broken down, and thus the insulator chain and the corresponding power transmission line can be protected; moreover, a high-speed high-voltage gas flow can be generated fast and acts on arcs to restrain formation and development of the arcs, the arcs are extinguished in a transient state, and thus the lightning trip-out rate and the lightening accident rate of an electric power system are reduced. The gas injection type parallel gap device comprises arc-control devices on the grounding side and the wire side, fixing devices and parallel spiral fittings installed at the two ends of the insulator train of the line. The arc-control device on the grounding side and the arc-control device on the wire side respectively comprise an arc extinguishing powder storage chamber, an arc air-termination ring, an insulating gas generation chamber, an arc spray channel and the like. With the device, the stability of the electric power system is improved, the on-load action frequency of a breaker is effectively reduced, the service life of electric power equipment such as a transformer is prolonged, and production, operation and maintenance cost is very low.

Owner:闫仁宝 +1

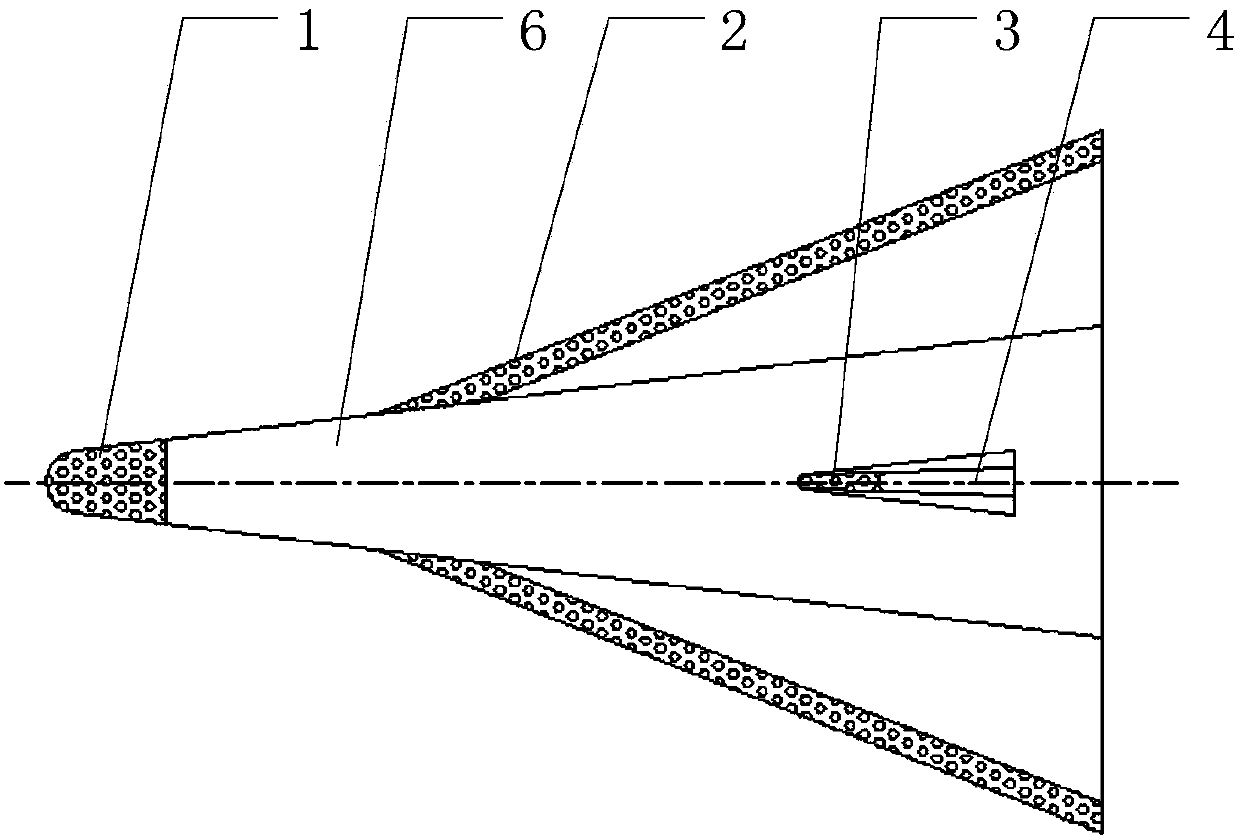

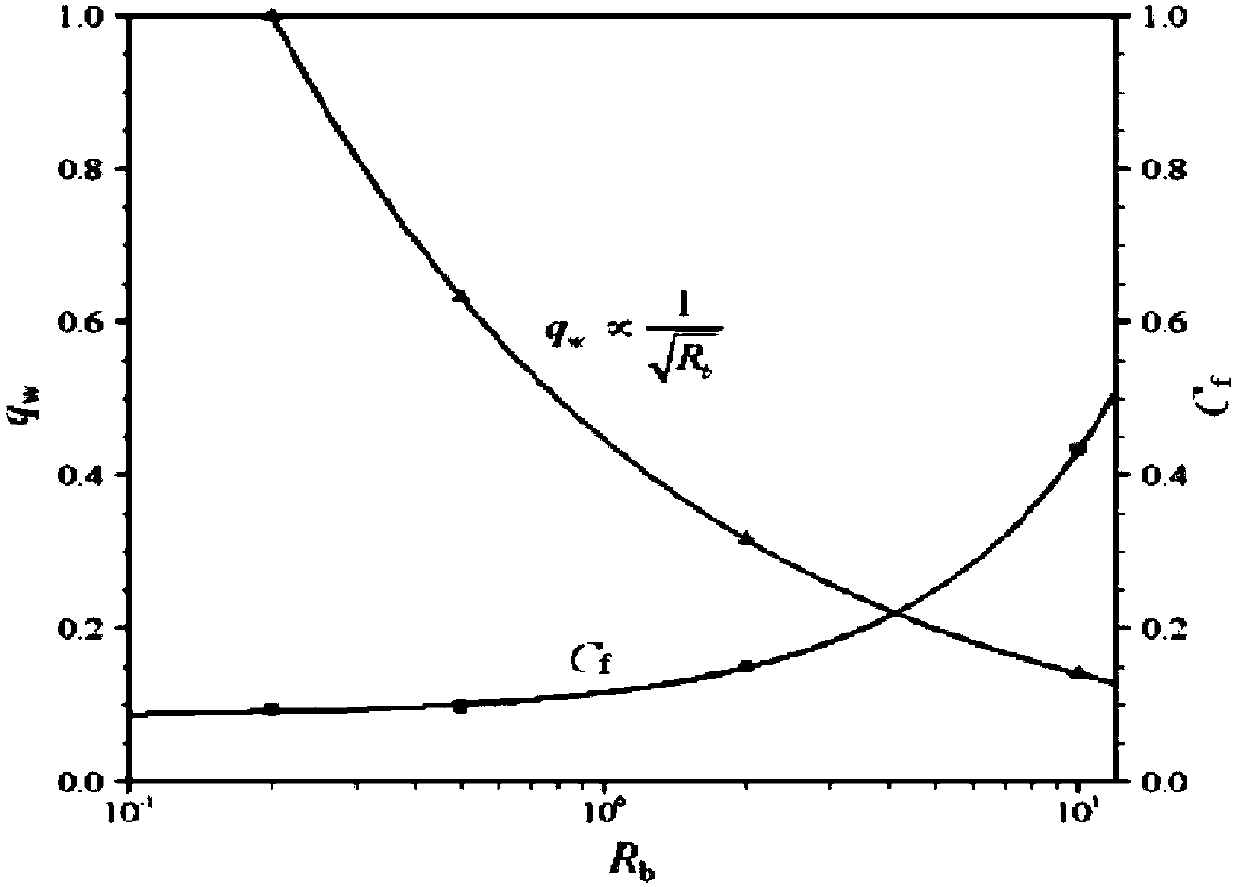

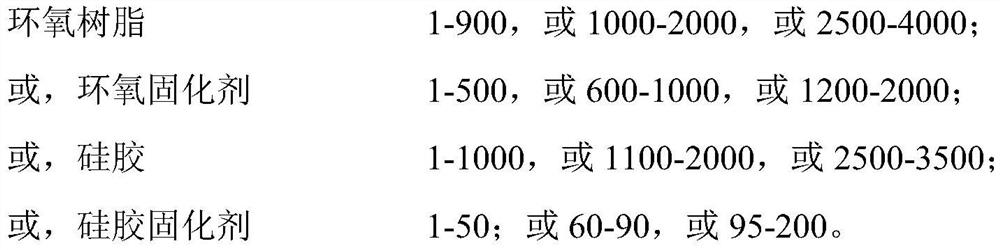

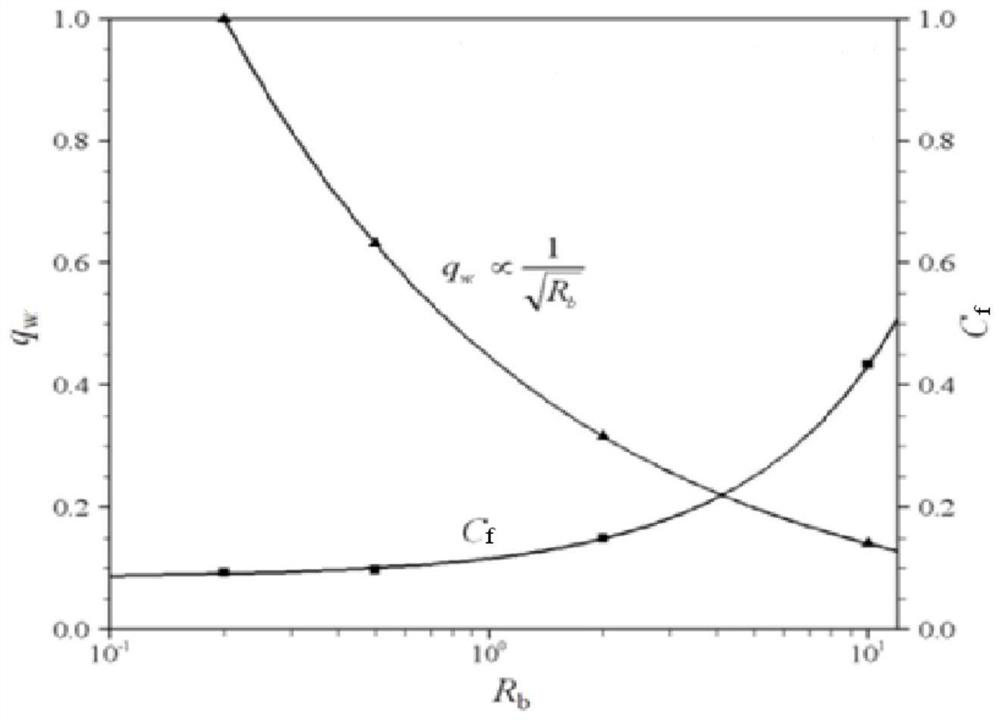

Full-active cooling hypersonic flight vehicle

ActiveCN107914862AAvoid thermal structural thermal matching problemsGuaranteed aerodynamic shapeBoundary layer controlsFuselage insulationFlight vehicleTranspiration

The invention discloses a full-active cooling hypersonic flight vehicle which comprises a transpiration cooling end, a transpiration cooling wing front edge, a transpiration cooling rudder front edge,a regenerative cooling rudder surface, a regenerative cooling windward side and a flight vehicle leeside, wherein porous structures are formed in the transpiration cooling end, the transpiration cooling wing front edge and the transpiration cooling rudder front edge, and the interiors of the porous structures are filled with liquid cooling media; the liquid cooling media can be supplied outwardsfrom the porous structures, flow through the porous structures to perform heat exchange, are heated and then flow out of the outer surface of the end in a gaseous form; and the regenerative cooling rudder surface and the regenerative cooling windward side are respectively used for cooling the rudder surface and the windward side of the flight vehicle in a regenerative cooling manner, and the liquid cooling media carried inside the flight vehicle are used for blocking, cooling and taking away pneumatic heating volume of the flight vehicle transferred into the flight vehicle in the hypersonic flight process, so that thermal protection requirements of the flight vehicle on high-speed, long-term and long-distance flight in the atmosphere are met.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

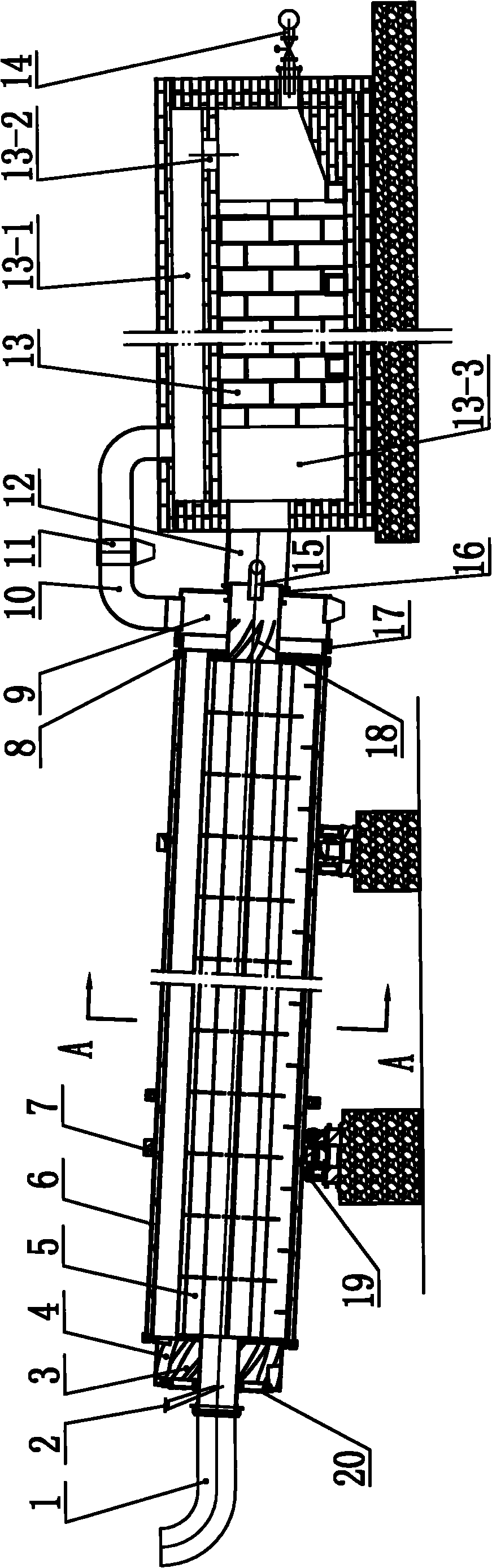

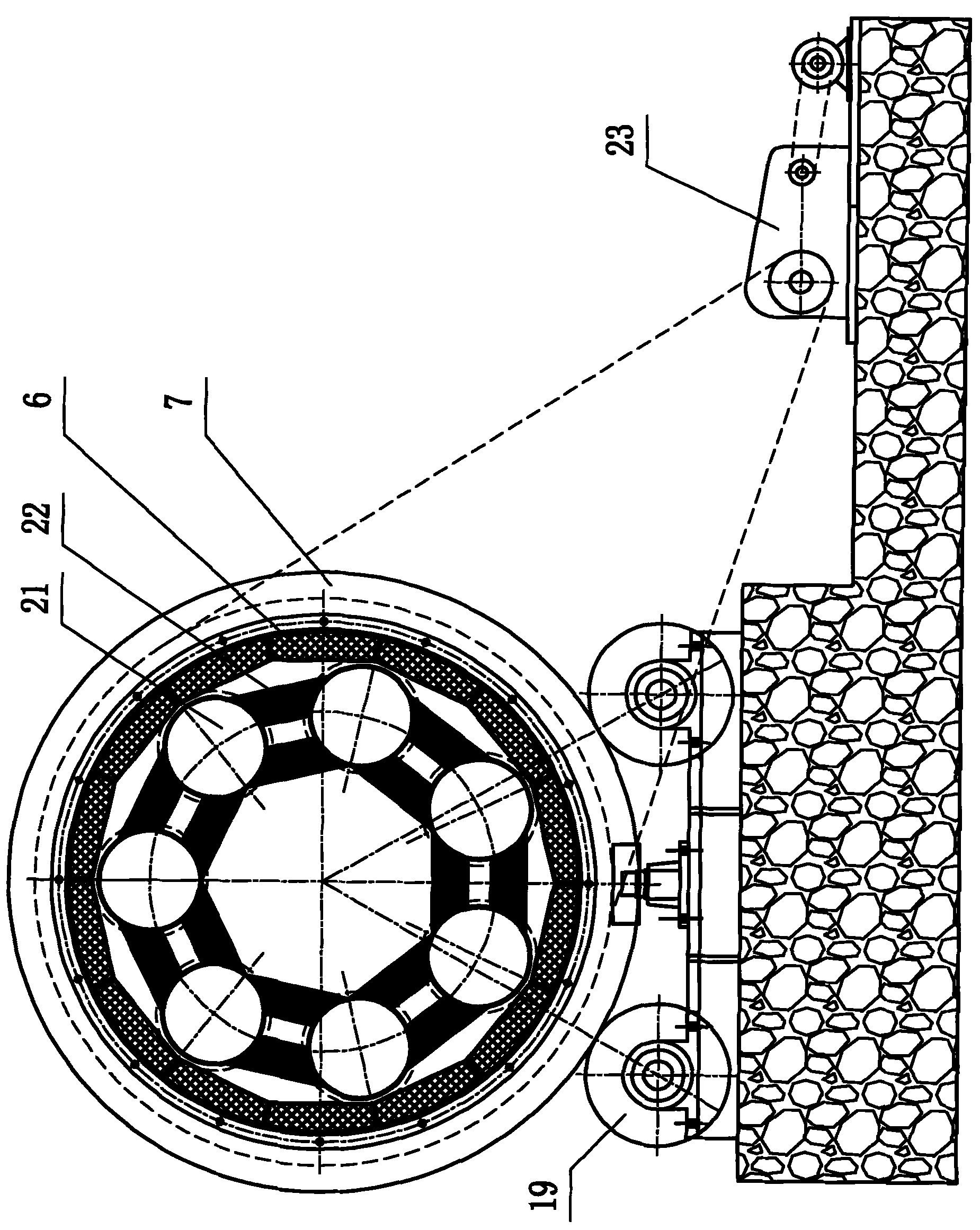

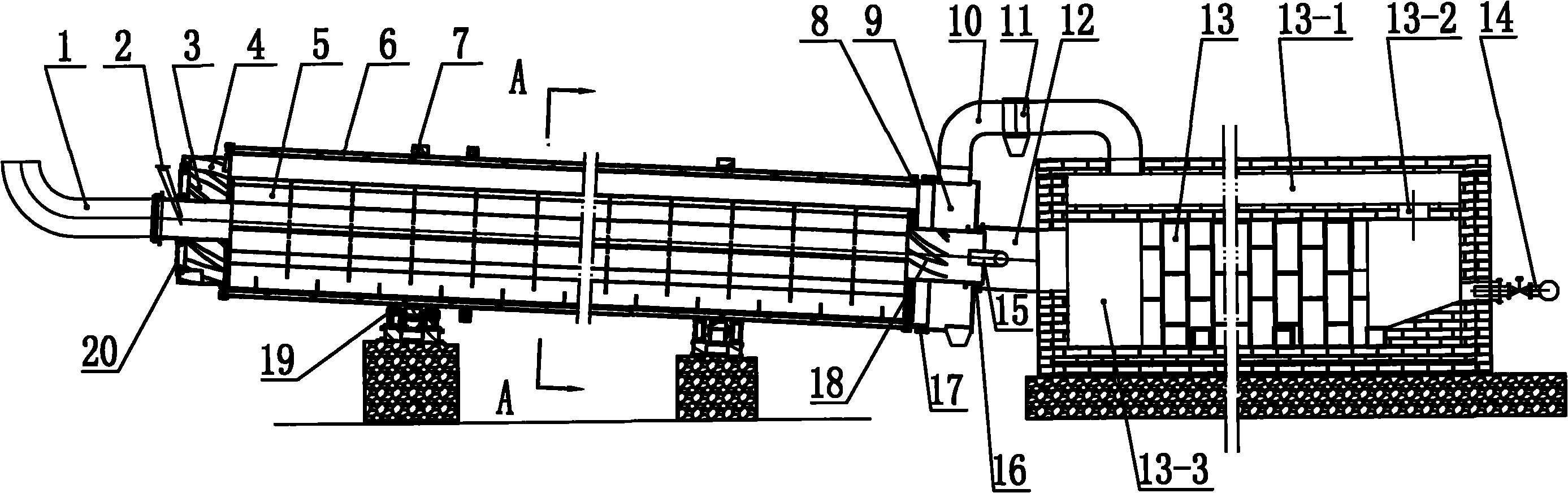

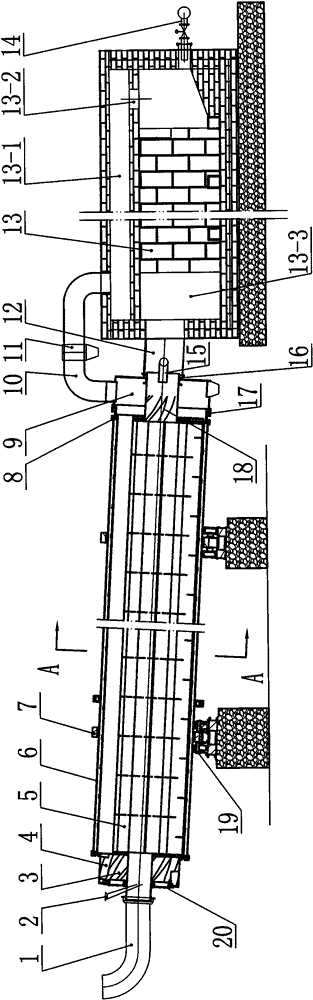

External-heating energy-saving and environment friendly rotary carbonization furnace

InactiveCN102092706AImprove qualityHigh mechanical strengthChemical industryCombustion chamberCarbonization

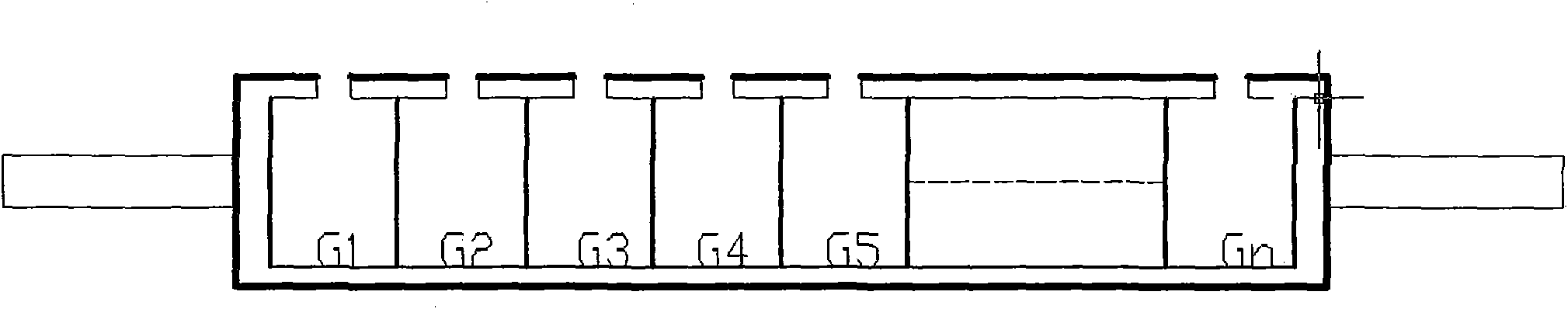

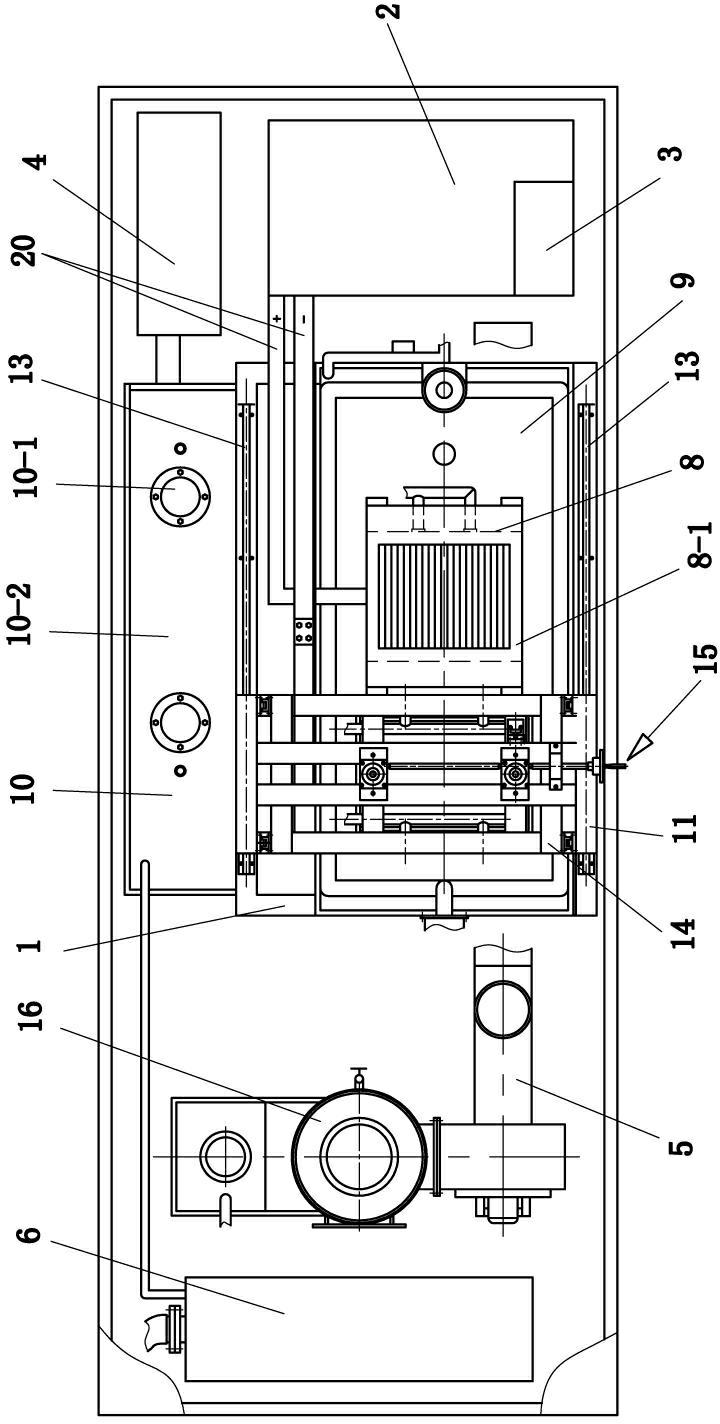

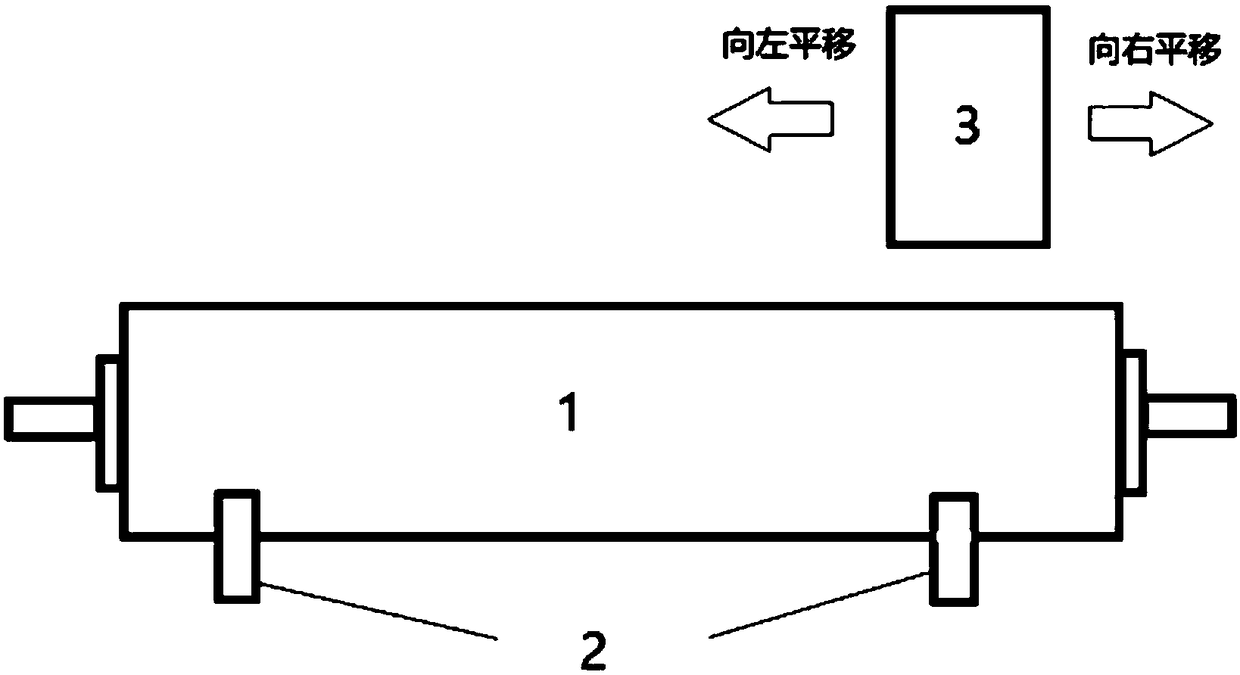

The invention relates to an external-heating energy-saving and environment friendly rotary carbonization furnace; a furnace body (5) consists of at least three independent material passages (21) that are connected with each other through reinforcing plates (22); the left feed end of the furnace body is sealed with a sealing flange (20), and the right feed end of the furnace body is sealed with a material passage expansion sealing device (8); the left and the right ends of a discharge warehouse are sealed with sealing flanges (16, 17); a feeding warehouse (3), the sealing passage (21), the discharge warehouse (9), a fugitive constituent pipeline (10), a combustion chamber (13), a high-temperature smoke gas pipe (12), a space between the inner part of a furnace housing (6) and the outer part of the material passage (21) and a tail gas exhaust pipe (1) are communicated with each other in sequence; and the temperature of the high-temperature smoke gas of heated material is adjusted through an air distributing pipe (15). In the invention, the temperature and heating rate are easy to control when the material is carbonized, and the material is capable of uniformly and sufficiently absorbing heat with low material ablation, high yield and few energy consumption; and the produced carbonized material has good quality.

Owner:淮北市协力重型机器有限责任公司 +1

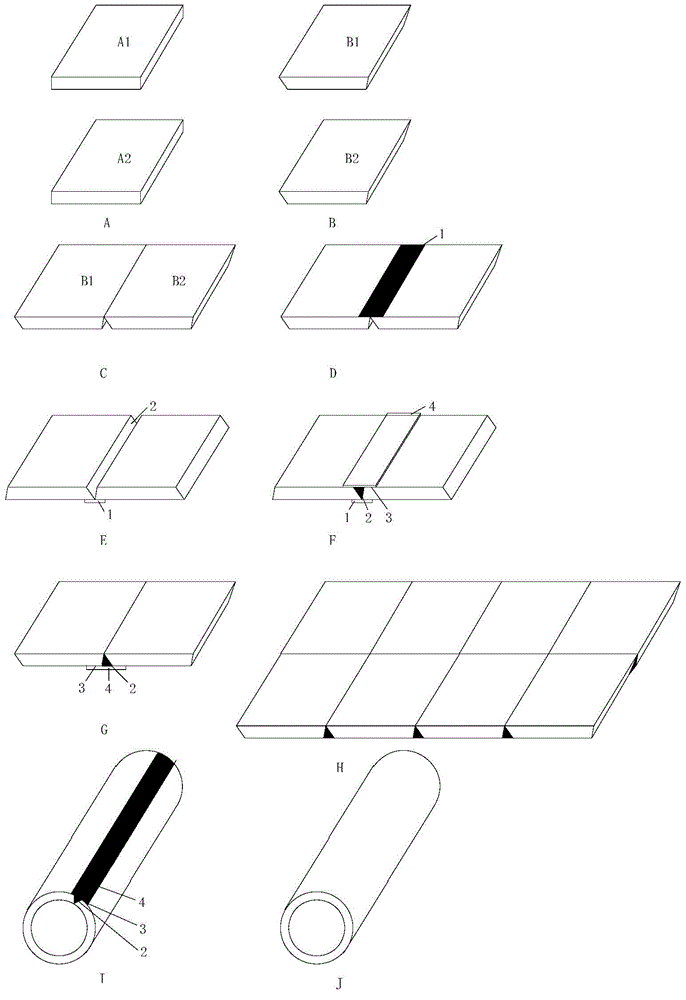

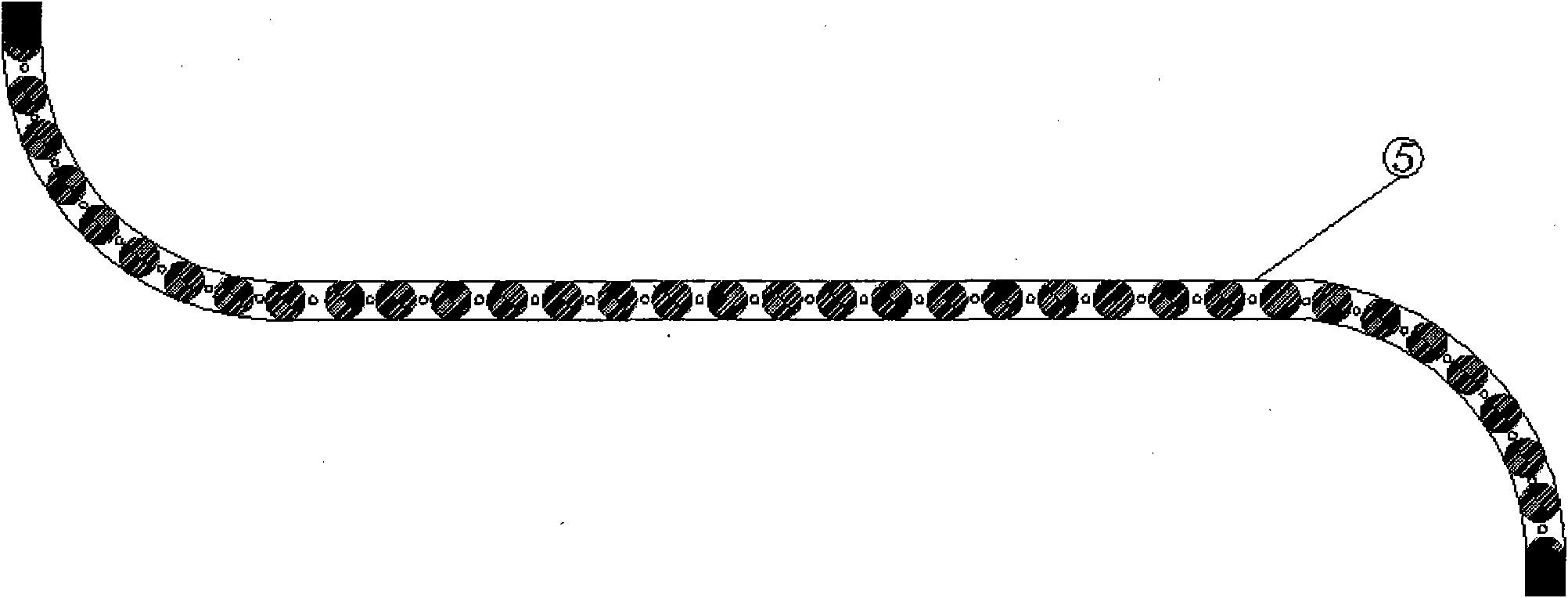

Seamless splicing method for circular metal mould tape with optical micro structure aggregate on surface

The invention discloses a seamless splicing method for a circular metal mould tape with an optical micro structure aggregate on the surface. The seamless splicing method for the circular metal mould tape with the optical micro structure aggregate on the surface is characterized in that a peelable adhesive tape is adopted for sealing and pasting a seam in the front, a room temperature cured A / B structure conductive adhesive is used for packing the back of the seam, and a method that the seam is fixed by metal sheet and two-component structural adhesive from the back is adopted for treating the seam; meanwhile, an electroforming process is combined, and finally a super large circular tape metal template is formed. The seamless splicing method for the circular metal mould tape with the optical micro structure aggregate on the surface has the advantages that the seam is smooth and ablation-free and mechanical strength can be guaranteed.

Owner:田武学 +1

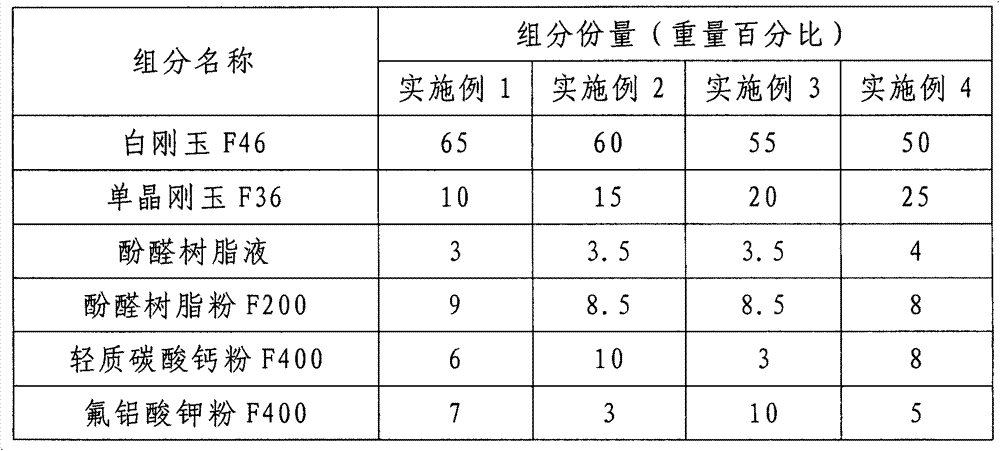

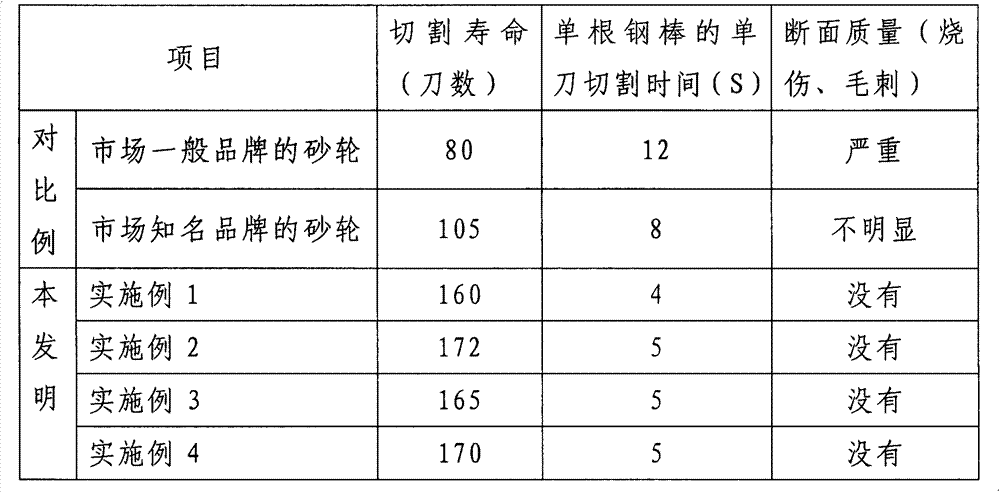

Thin resin wheel

InactiveCN103042476AImprove cutting effectReduce cutting heat generationBonded abrasive wheelsPotassiumGrinding wheel

The invention discloses a thin resin wheel. The thin resin wheel is 105mm to 125mm in diameter and 0.8mm to 1.0mm in thickness. The components of the thin resin wheel comprise white corundum, monocrystalline corundum, phenolic resin powder, resorcin-formalin, light calcium carbonate powder and potassium fluoroaluminate powder, are simple and easy to allocate, have no special requirements for forming process and can be produced by conventional process. The thin resin wheel manufactured is narrow in cuts, long in cutting service life, quick to cut and low in generated cutting heat, so that cut section has no defects such as erosion, burrs and flanges.

Owner:泰州苏蒙砂轮有限公司

Electrical etching machine of metal cutter template

ActiveCN102628177APrecise positioningThere is no bad contactElectrolysis componentsElectrochemical machining apparatusElectrolyteMetal

The invention discloses an electrical etching machine of a metal cutter template, which comprises a machine frame, an upper electrode, a lower electrode and an electrolyte collecting tank. A translation frame is further matched on the machine frame in moving mode, the upper electrode is installed and connected onto the translation frame, at least two liquid outlet devices communicated with a liquid supplying device are arranged on the translation frame and beside the upper electrode, a liquid outlet of each liquid outlet device faces toward the bottom of the upper electrode and toward a space under the bottom face of the upper electrode, an insulating workpiece support piece is arranged on the upper surface of the lower electrode and provided with a liquid passageway, or a plurality of insulating workpiece support strips are arranged on the upper surface of the lower electrode, the gaps between adjacent workpiece support strips form the liquid passageway, a liquid flow passage communicated with the upper surface of the lower electrode is arranged inside the lower electrode or on the lateral face of the lower electrode, and the liquid flow passage is communicated with the liquid passageway. The electrical etching machine generates no erosion and can meet the metal cutter template etching requirements for large etching depth, high evenness and high accuracy.

Owner:常州正成机电科技有限公司

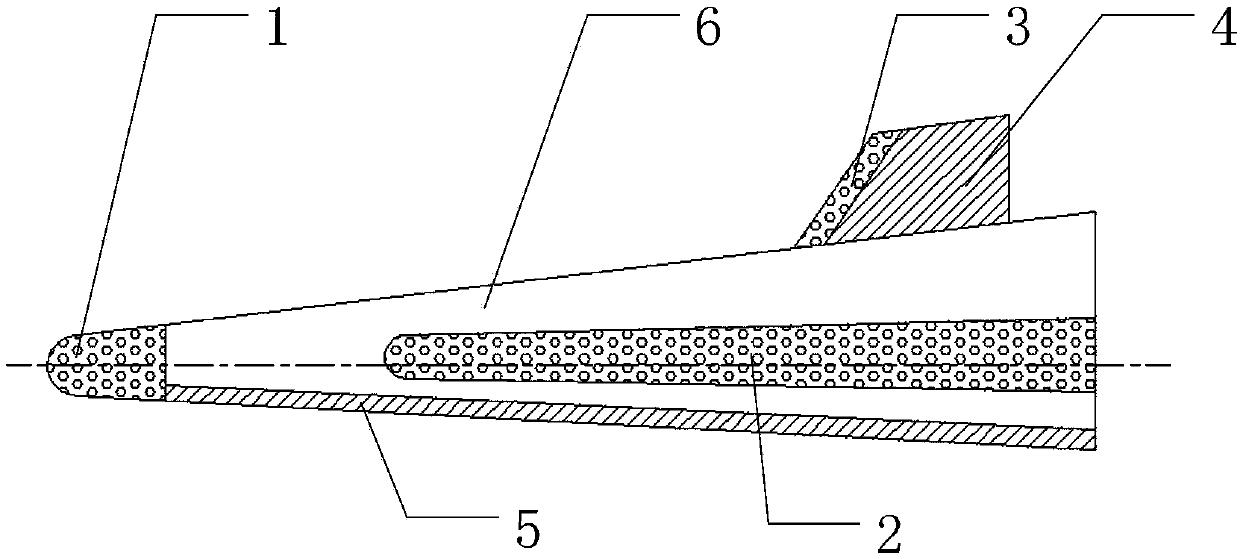

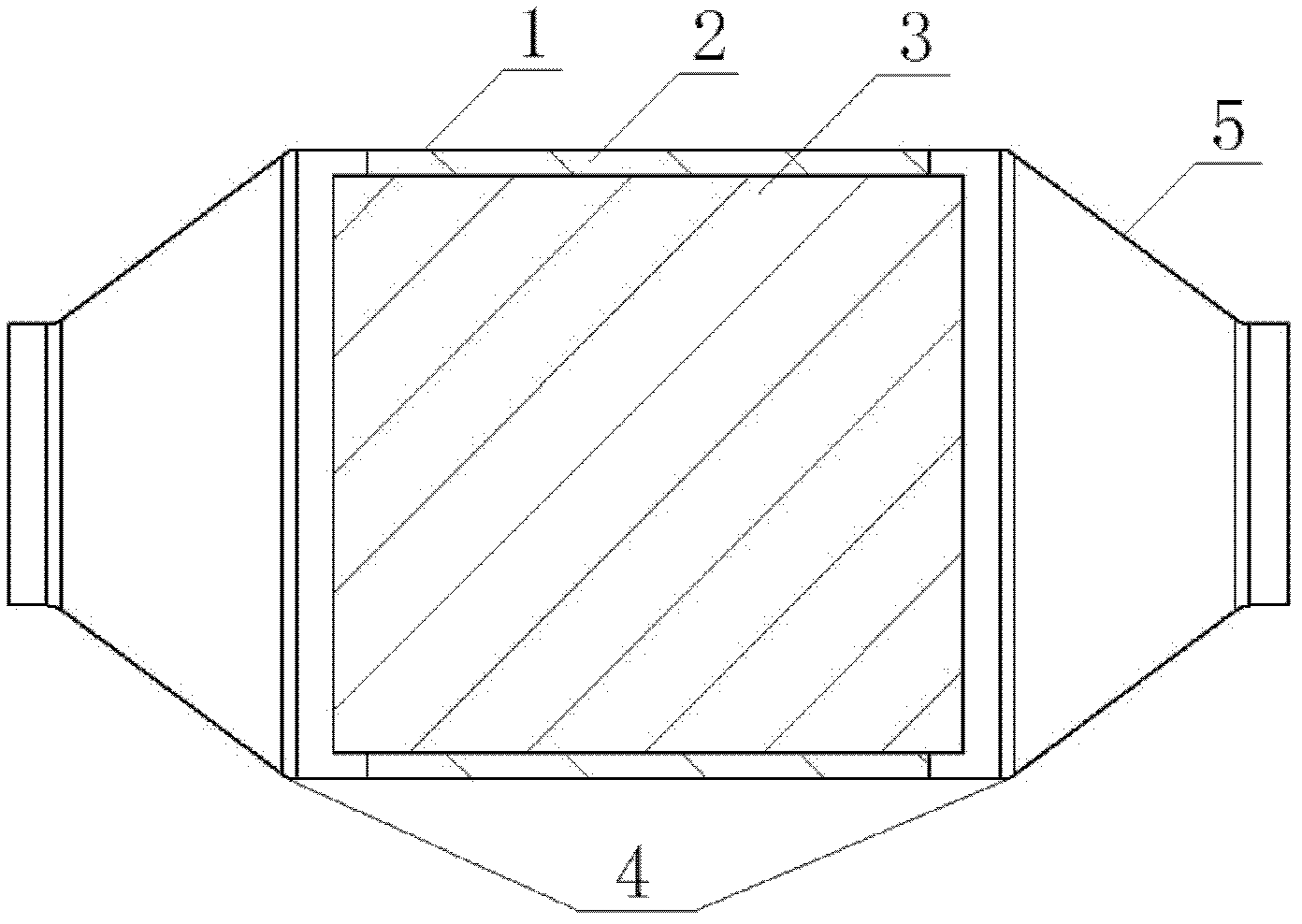

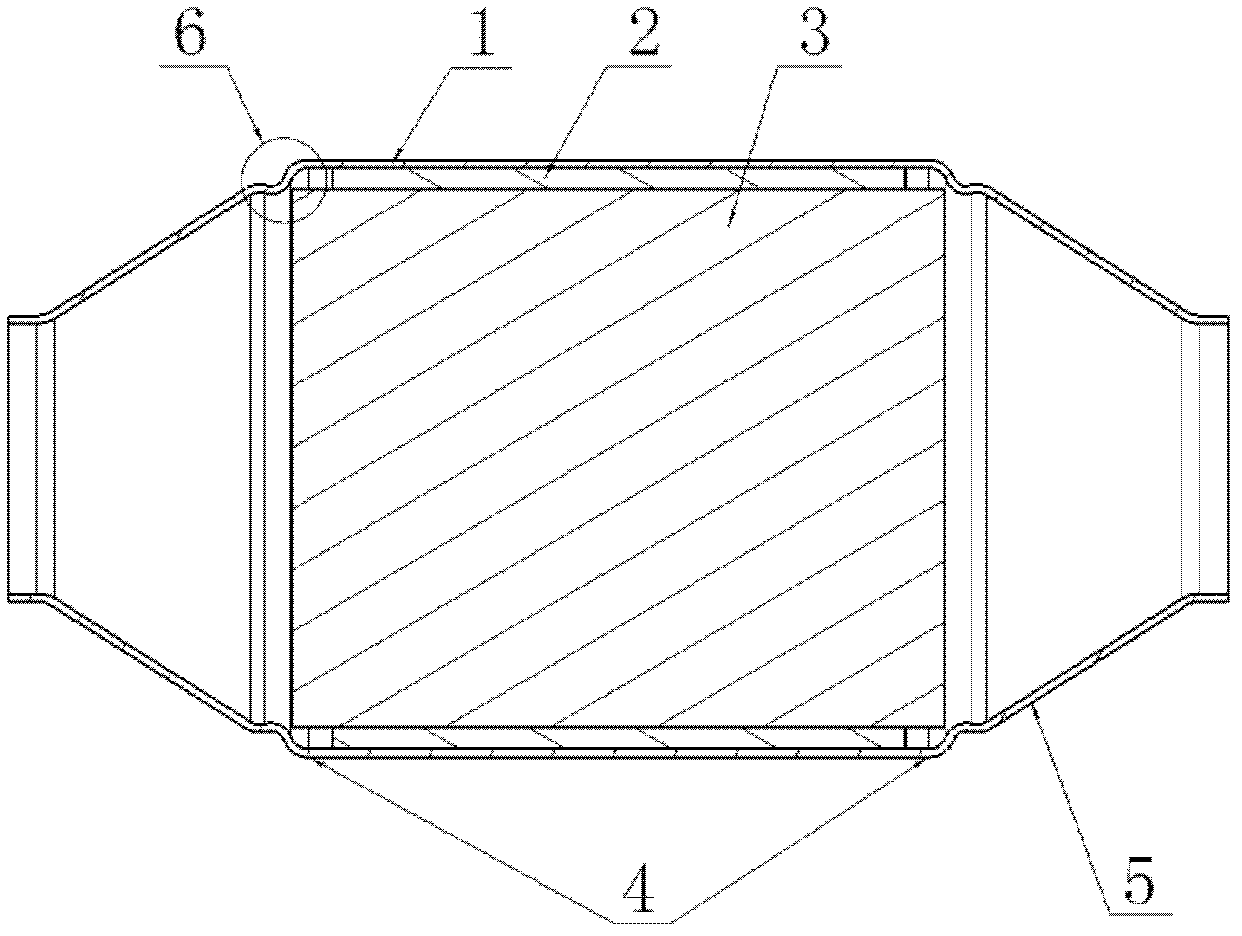

Method for processing catalytic converter for automobile

The invention discloses a method for processing a catalytic converter for an automobile. The method comprises the following steps: 1) rolling a cylindrical plate sheet according to the shape of the shell of the catalytic converter and rounding; 2) fixing the rolled cylinder (1) in the manner of direct seam welding; 3) cutting two ends of the welded cylinder to appointed length, and meanwhile, removing welding joints with flaws from two ends; 4) wrapping a gasket (2) onto a carrier (3) by using an adhesive tape; 5) pressing the wrapped carrier (3) into the cylinder (1); 6) performing flow forming on the cylinder (1) by using a spinning fixture; and 7) performing a thrust displacement test on a formed catalytic converter assembly subjected to flow forming. The catalytic converter of the specific structure has the beneficial effects that flow forming end conical forming is performed on the two ends of the shell after the carrier and the gasket are pressed into the shell, thereby reducing the cost increase caused by end conical design and mould opening, omitting an end conical girth welding process and a necking down process in process aspect; and by the adoption of the catalytic converter, a compression gap of the gasket can be well ensured, the risk of carrier breaking is reduced, and mechanical durability of the catalytic converter is improved..

Owner:JAPHL POWERTRAIN SYST

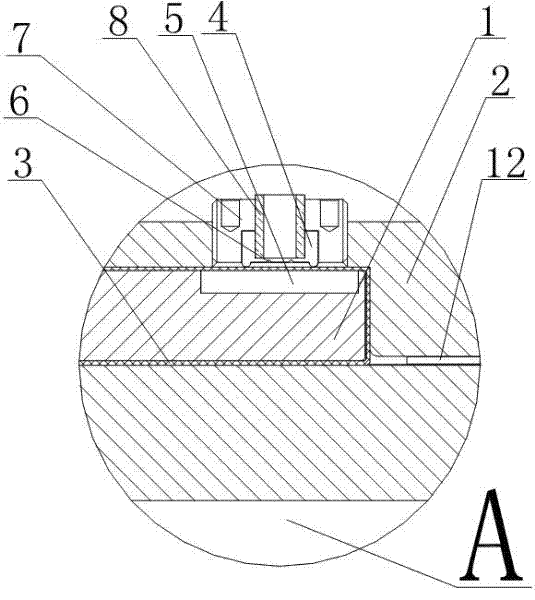

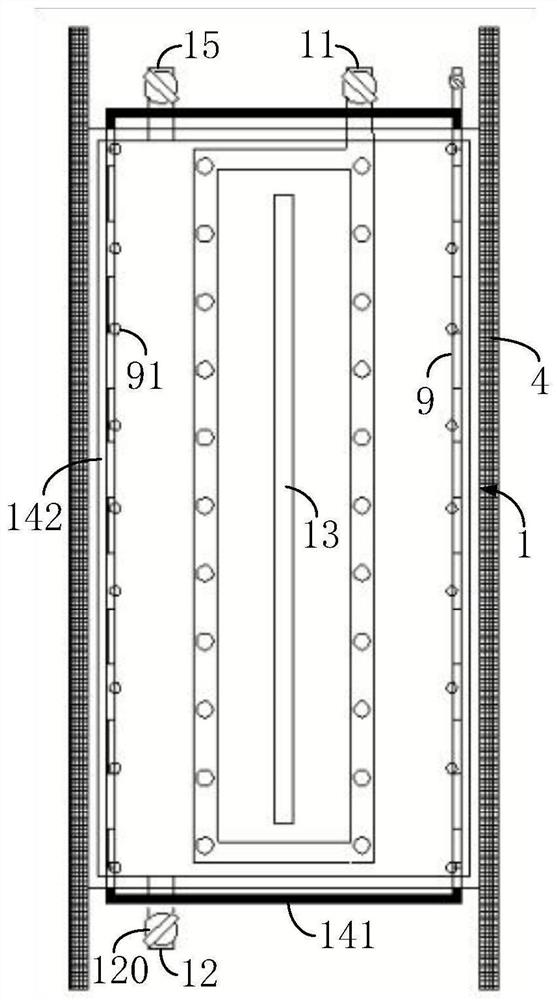

Jet stream arc extinguishing and lightning protection gap device in constraint space

The invention relates to a lightning protection device, in particular to a jet stream arc extinguishing and lightning protection gap device in a constraint space of transmission lines with various voltage levels. The device is installed on the two ends of a circuit insulator chain in parallel to ensure that the flash over voltage between gaps is smaller than that of the protected insulator chain, so as to be punctured prior to the protected insulator chain when the transmission lines are subjected to lightning stroke, a gas generation material in the constraint space is severely heated by high temperature electric arcs to generate high pressure gas in the case of disruptive discharge, and meanwhile, a signal collecting device automatically collects a signal and starts a jet gas generating device to instantaneously generate high speed gas flow so as to impact, cool and extinguish the electric arcs along the longitudinal direction. The device disclosed by the invention is simple in structure and convenient in installation, and the device can quickly discharge the lightning current to the ground and simultaneously generate high speed gas flow to extinguish the power-flow current when the transmission lines are subjected to lightening shock, so that the power equipment is effectively protected and the power supply reliability is improved.

Owner:南宁超伏电气科技有限公司

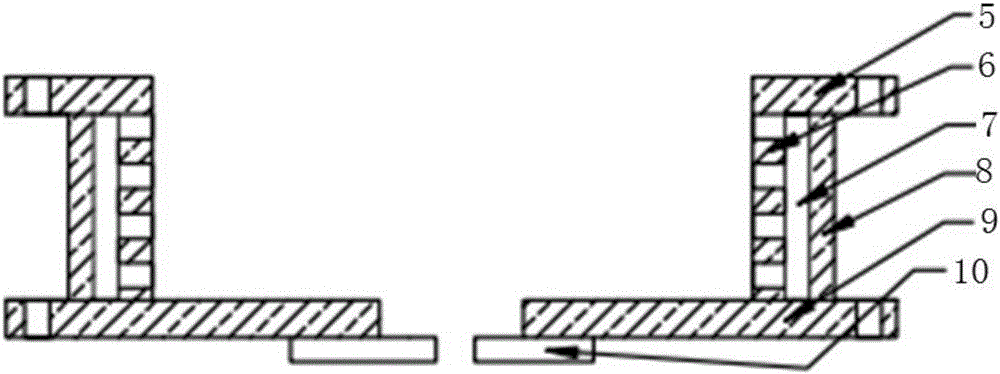

Lightning protection device with combination of multigap driven arc extinguishing and driving arc extinguishing by multipoint strong airflow

The invention relates to a lightning protection device, in particular to a lightning protection device with combination of multigap driven arc extinguishing and driving arc extinguishing by multipoint strong airflow, which is used for power transmission lines with all voltage grades. The lightning protection device is arranged on all iron caps of a line insulator string in parallel, a main discharging gap and a multigap driven arc extinguishing unit are connected in series, and the total flashover voltage is less than that of the protected insulator string, so that when the lines are struck by lightning, a product is punctured prior to the protected insulator string. A signal acquisition device acquires lightning current signals automatically and starts a gas generation device, so that high-speed air flow is generated instantaneously in a semi-enclosed space and extinguishes the arcs; and in the multigap driven arc extinguishing unit, air is rapidly heated by high-temperature arcs andexpands, lengthens the arcs quickly and sprays out the arcs from air-guiding holes so as to extinguish the arcs. According to the lightning protection device, the structure is simple, the installation is convenient, and when the line is struck by the lightning, lightning current can be leaked into the ground quickly, and simultaneously the high-speed airflow is generated to extinguish power-flow current, so that electrical equipment is effectively protected and the power supply reliability is improved.

Owner:王巨丰

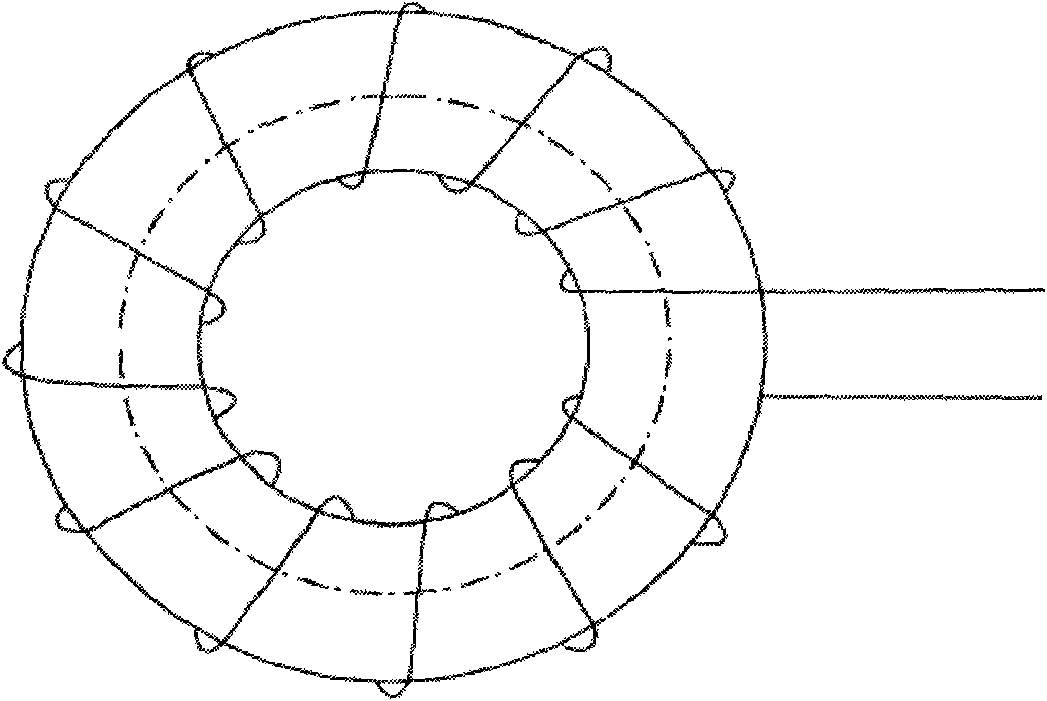

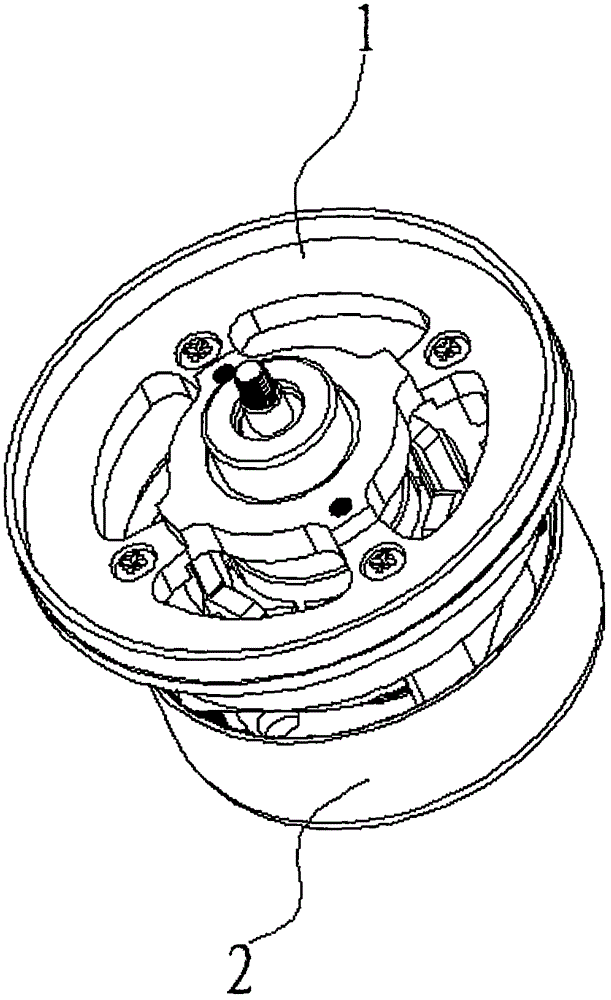

Dust collector motor

InactiveCN106130217AImprove cooling effectNo ablationMagnetic circuit rotating partsManufacturing dynamo-electric machinesPunchingConductor Coil

The invention relates to a motor, especially a vacuum cleaner motor. The motor includes a housing, a stator assembly and a rotor assembly. The housing includes a front end cover and a rear end cover, and the front end cover and the rear end cover are fixed by screwing; The rotor assembly includes the rotor shaft, permanent magnetic steel, fixed magnetic steel sleeve, rotor punch and bearings. The two ends of the rotor shaft are equipped with bearings, the middle of the rotor shaft is equipped with rotor punch, and the side of the rotor punch is bonded with permanent Magnetic steel, fixed magnetic steel sleeves are provided at both ends of the rotor punching sheet; the stator assembly includes stator core, stator winding and Hall induction plate, the stator winding is wound on the stator iron core, and the Hall induction plate is fixedly installed at the rear end On the inner wall of the cover; the stator assembly and the rotor assembly are installed in the housing; the invention not only has a good heat dissipation effect, but also has no sparks and no ablation during the working process, can work in relatively harsh and dangerous environments, and has small friction and Low noise, long life, low energy consumption, performance is superior to ordinary DC motors.

Owner:宁波市镇海净典环境治理服务有限公司

Laser processing control method and device, and computer storage medium

InactiveCN111813042AUniform processingGuarantee processing qualityNumerical controlLaser beam welding apparatusComputer hardwareGraphics

The invention relates to the field of laser processing, and concretely relates to a laser processing control method and device, and a computer storage medium. The method comprises the following steps:setting extension tracks for processing tracks forming corners in a to-be-processed pattern; and controlling a laser to move along the extension tracks to make the laser start to move along a processing track according to a preset processing speed. Extension type motion processing is carried out on the inflection point of the processing track, so that the problem of poor processing quality causedby sudden change of the motion speed of laser light at the inflection point of the graph in the laser processing process is solved.

Owner:XIAN MICROMACH TECH CO LTD

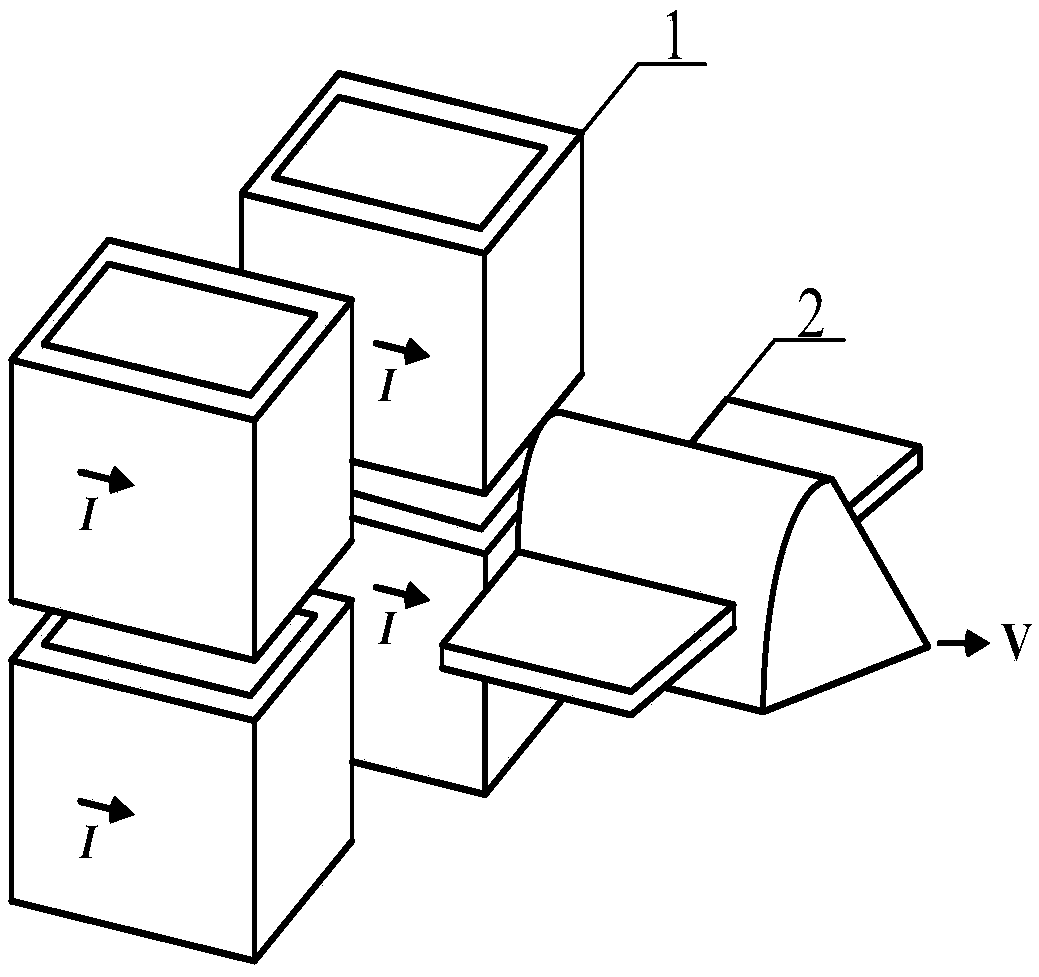

Multi-layer multi-wing reconnection type electromagnetic emission device

PendingCN108680058AReduce ohmic lossLarge axial acceleration forceElectromagnetic launchersEmission efficiencyElectrical and Electronics engineering

Owner:SOUTHWEST JIAOTONG UNIV

External-heating energy-saving and environment friendly rotary carbonization furnace

InactiveCN102092706BImprove qualityHigh mechanical strengthChemical industryCombustion chamberCarbonization

The invention relates to an external-heating energy-saving and environment friendly rotary carbonization furnace; a furnace body (5) consists of at least three independent material passages (21) that are connected with each other through reinforcing plates (22); the left feed end of the furnace body is sealed with a sealing flange (20), and the right feed end of the furnace body is sealed with a material passage expansion sealing device (8); the left and the right ends of a discharge warehouse are sealed with sealing flanges (16, 17); a feeding warehouse (3), the sealing passage (21), the discharge warehouse (9), a fugitive constituent pipeline (10), a combustion chamber (13), a high-temperature smoke gas pipe (12), a space between the inner part of a furnace housing (6) and the outer part of the material passage (21) and a tail gas exhaust pipe (1) are communicated with each other in sequence; and the temperature of the high-temperature smoke gas of heated material is adjusted through an air distributing pipe (15). In the invention, the temperature and heating rate are easy to control when the material is carbonized, and the material is capable of uniformly and sufficiently absorbing heat with low material ablation, high yield and few energy consumption; and the produced carbonized material has good quality.

Owner:淮北市协力重型机器有限责任公司 +1

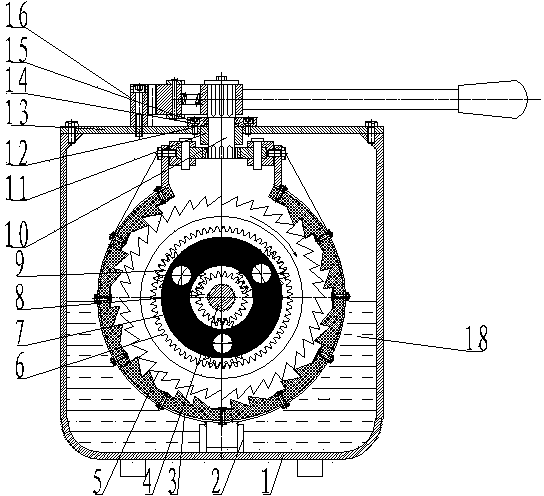

Elastic-resistance mechanical braking device

InactiveCN103486235AHigh power is easy to achieveGood explosion-proofToothed gearingsGear lubrication/coolingPower balancingEngineering

The invention provides an elastic-resistance mechanical braking device which comprises a casing, a ratchet gear, a ratchet ring, a planet transmission system and a controlling device. The planet transmission system is assembled in the casing, the ratchet gear is assembled on a planet inner gear ring of the planet transmission system, a ratchet combined ring is wrapped on a gear edge of the ratchet gear and connected with the controlling device, and lubricating oil is filled in a cavity of the casing. The elastic-resistance mechanical braking device has the advantage that the mechanical braking device can generate linear resistance to a running locomotive and can realize stepless speed adjusting, soft starting, soft parking, overload protecting and multipoint driving power balancing.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

Cylindrical surface hardening and strengthening treatment method for ultra-large piston of large oil press

InactiveCN102031514AReach sizeAchieve precisionMaterial nanotechnologyMetallic material coating processesMicron scaleEffective power

The invention relates to a cylindrical surface hardening and strengthening treatment method for an ultra-large piston of a large oil press, comprising the steps of: (1) cleaning the running surface of an ultra-large working cylinder piston of an oil press, and then mixing micron-scale powder and nanoscale powder, which respectively comprise TiO2, SiO2, graphite and Ae2O2 according to the proportion of 1:1:0.3:0.1, wherein the weight ratio of various materials in the micron-scale powder to the various materials in the nanoscale powder is 4:1; uniformly blending the mixed powder with a methylcellulose solution, and presetting the blended mixed powder on the piston running surface to be strengthened by adopting a spraying method; and forming a uniform coating to be hardened, deepened and strengthened by laser, with the thickness of 0.05-0.15mm; (2) carrying out densely covering type deep-layer hardening and strengthening by using a TFL (Thin Film Laser)-H6000CO2 high-power laser processing machine set with the wide laser beam of 30*2mm and the effective power of 4300-5200W to realize laser hardening and strengthening to reach the effective depth of 2.2-3.0mm and the hardened layer hardness of HRC55-60; and (3) after the treatment of laser deep-layer hardening and strengthening, carrying out ground finish on the running surface of the piston to reach the machine size tolerance and precision of design paper. In the invention, the process is simple and the effect is very obvious.

Owner:四川新吉隆环保科技有限公司

Ablation-resistant polyphenylene sulfide composite material and preparation method thereof

The invention discloses an ablation-resistant polyphenylene sulfide composite material and a preparation method thereof, and belongs to the technical field of ablation-resistant materials. The polyphenylene sulfide composite material mainly comprises the following components: polyphenylene sulfide resin, alkali-free glass fibers and polyadipoyl m-xylylenediamine. The preparation method comprises the following steps: firstly melting and mixing polyphenylene sulfide resin and alkali-free glass fibers, then adding polyadipoyl m-xylylenediamine for secondary melting and mixing, cooling, curing anddicing to obtain a target product. The polyphenylene sulfide composite material obtained by the preparation method can bear high-temperature and high-pressure effects generated in a micro-arc oxidation process, has good ablation resistance, and is simple in preparation process.

Owner:SUZHOU NAPO ADVANCED MATERIAL TECH CO LTD

Method for destroying waste airbag gas generator

ActiveCN110281165ALarge areaHigh construction and operating costsBlast gunsAbrasive machine appurtenancesSmall footprintMetal

The invention relates to a method for destroying a waste automobile airbag gas generator. The method adopts a water knife cutting process, namely by using high-pressure water jet flow to carry out cold-state cutting so as to destroy the airbag gas generator, and involves a water knife cutting machine, wherein the water knife cutting machine is mainly composed of a high-pressure pump, a numerical control machining platform, an injection cutting head, a sand supply system and a cooling system; and meanwhile, a waste water pretreatment system is also provided. The airbag gas generator is divided into two halves after being cut by a water knife, wherein sodium azide (NaN3 ) and potassium nitrate (KNO3) and the like of the airbag gas generator are completely dissolved in water, and an igniter is completely destroyed to lose the detonation function, so that only a metal shell capable of being recycled of the whole gas generator remains, and the metal shell is separately treated after being collected. Compared with the prior art, the method for destroying a waste airbag gas generator has the advantages of being safe and reliable in process, clean and environment-friendly, small in occupied area, low in operation cost, high in treatment efficiency and capable of running for 24 hours continuously; and meanwhile, the recycling application of the gas generator outer shell after treatment is wide.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

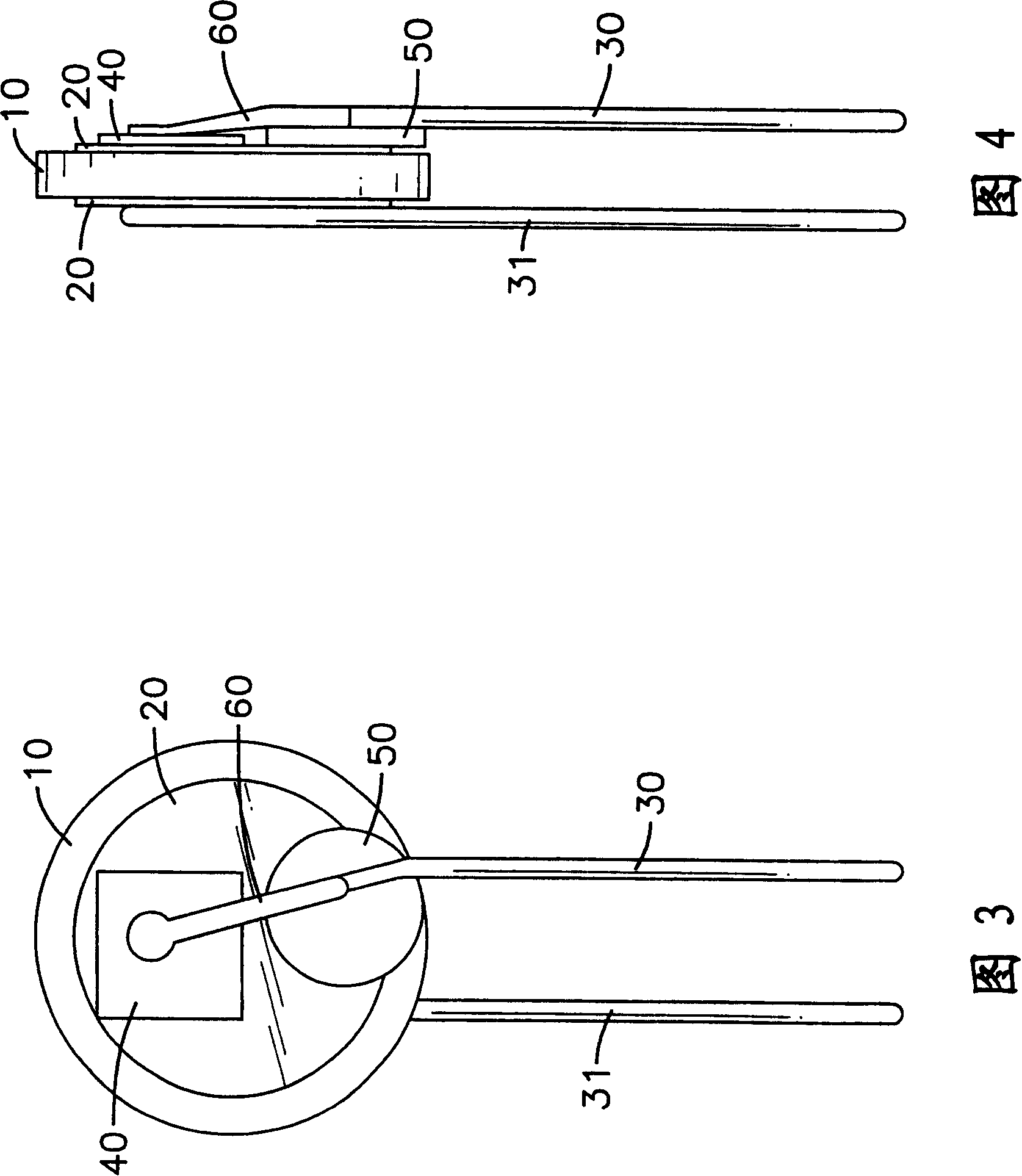

Detonator explosion closing switch and electric gun composed of same

The invention discloses a detonator explosion closing switch, comprising a firing positive plate and a firing negative plate, wherein a high-voltage insulating layer is arranged between the firing positive plate and the firing negative plate; a detonator seat is installed on the firing negative plate; the detonator seat is circular-barrel-shaped, and the bottom of the detonator seat is sealed and sunk inwards to form a firing plane; the firing plane is sunk inwards to form a firing groove with an arc cross section; and the firing groove forms a circular ring. The detonator explosion closing switch disclosed by the invention has the advantages of being simple in structure, low in inductance, resistant to high voltage, high in current-withstanding capacity, free from electrode ablation, and stable and reliable in operation; and due to a parallel plate structure, the detonator explosion closing switch is easily connected with a pulse power device of parallel plate transmission, applied to the device and the like, and compact in structure, and the low-inductance requirement of the device can be met easily, a peak value of discharge current of the device is increased, the rise time of the discharge current is shortened, and the discharge performance of the device is improved.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

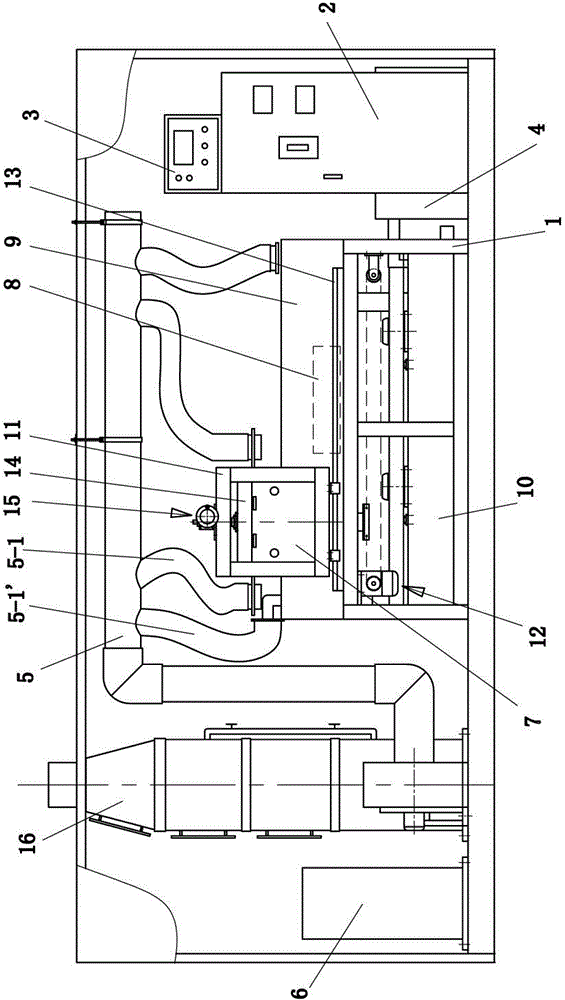

Titanium alloy component print-free micro-arc oxidation treatment device

ActiveCN106498479ASimple compositionReduce maintenance costsSurface reaction electrolytic coatingMicro arc oxidationTitanium alloy

The invention provides a titanium alloy component print-free micro-arc oxidation treatment device. The device comprises an electrolytic cell, a lifter and a cathode assembly. The cathode assembly comprises cathodes, a guard plate assembly and flexible sealing rubber plates. The cathodes are mounted in the guard plate assembly and located on the two sides of a titanium alloy component descending path. Upper guard plates, rear guard plates and lower guard plates close the upper surfaces, the lower surfaces and the side faces, back to the titanium alloy component descending path, of the cathodes. Hollowed-out front guard plates are fixed to the side faces, facing the titanium alloy component descending path, of the cathodes. Hollowed-out holes are uniformly formed in the hollowed-out front guard plates. The hollowed-out area is set according to the requirement for the electric field intensity. The flexible sealing rubber plates are fixed to the front ends of the two lower guard plates. When the lifter can drive a titanium alloy component to descend, the flexible sealing rubber plates are attached to the titanium alloy component to enable the oxidized titanium alloy component to be partially separated from the electric field. According to the titanium alloy component print-free micro-arc oxidation treatment device, sheet-like open type cathodes are changed into the cathodes with the closed lower portions, and oxidized titanium alloy is made to be separated from the electric field. Consequently, energy is saved, and erosion of titanium alloy can be effectively prevented.

Owner:CHINA SPECIAL TYPE FLIER RES INST

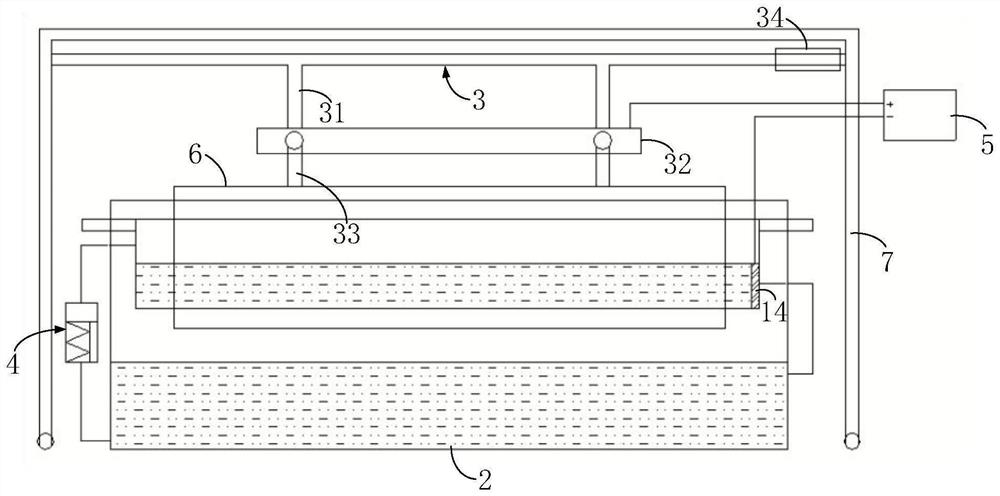

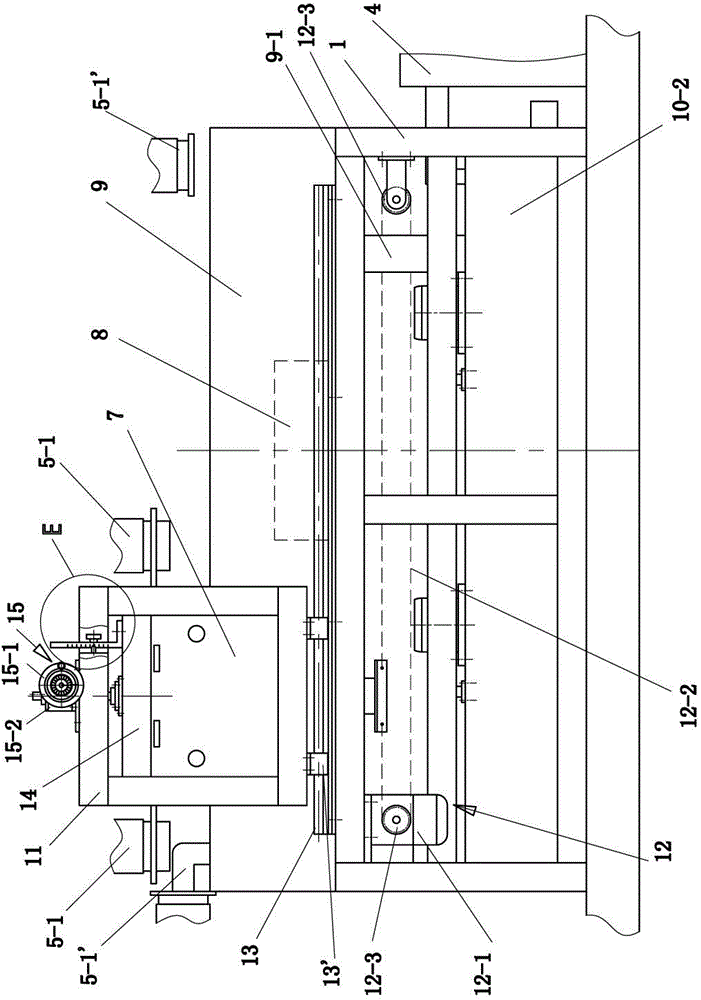

Micro-arc oxidation device with variable cathode area and surface treatment method

The invention discloses a micro-arc oxidation device with a variable cathode area and a surface treatment method, and belongs to the technical field of surface treatment. The micro-arc oxidation device comprises a micro-arc oxidation tank, a circulating tank, a lifting mechanism, a cooling circulating mechanism and a power supply mechanism, an injection port and an outflow port are formed in the side part of the micro-arc oxidation tank, a liquid level control piece is arranged at the end of the outflow port, and a workpiece channel is formed in the bottom of the micro-arc oxidation tank; a cathode part in the micro-arc oxidation tank is connected with the cathode of the power supply mechanism; the lifting mechanism is arranged above the micro-arc oxidation tank, and an anode part connected with the anode of the power supply mechanism is arranged on the lifting mechanism; and the circulating tank is arranged below the micro-arc oxidation tank, and the micro-arc oxidation tank is connected with the circulating tank and can cool the electrolyte flowing to the injection port. According to the micro-arc oxidation device with the variable cathode area, the growth rate of a micro-arc oxidation film layer is increased, the processing period is shortened, the production efficiency of the micro-arc oxidation film layer is improved, the electrolyte can be recycled, and the production energy consumption is reduced.

Owner:西安庄信新材料科技有限公司

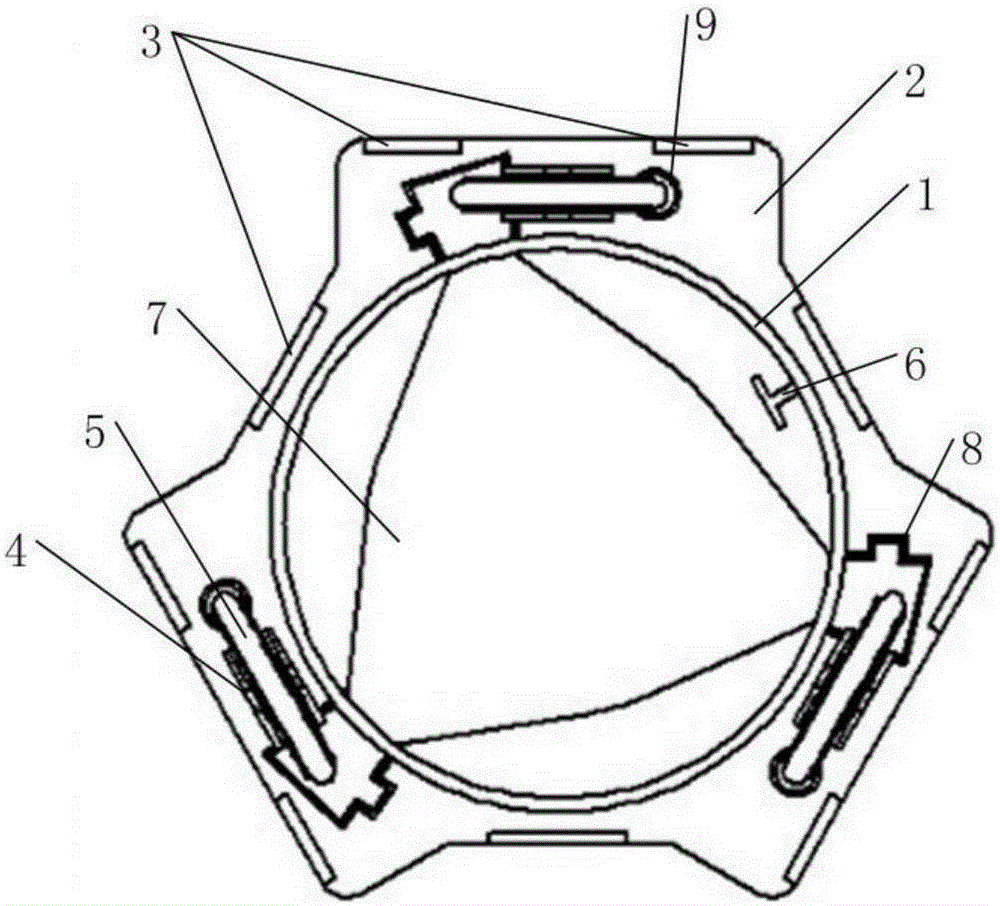

Passive element with high surge current tolerance and method for advancing tolerance thereof

InactiveCN101206938AIncrease contact areaNo ablationCurrent responsive resistorsNegative temperature coefficient thermistorsSilver electrodeMetal sheet

The invention relates to a passive element with high surge and current withstanding characteristic. A metal sheet is arranged in the current loop of the passive element, to cause the current to pass through the metal sheet to be evenly dispersed, the passive element is generally provided with a silver electrode arranged on a ceramic chip, the silver electrode is led out from two terminals, through the arrangement of the metal sheet, the contact area of the terminals and the silver electrode can be increased, and the uniformity degree of the surge current passing through the silver electrode is improved, to cause no ablation phenomenon of a silver layer to be produced, to ensure that the operation of the invention is stable. The invention also discloses a method for improving the withstanding characteristic of the passive element to the surge current.

Owner:THINKING ELECTRONIC IND CO LTD

Micro-arc oxidation synchronous auxiliary electromagnetic field device

The invention discloses a micro-arc oxidation synchronous auxiliary electromagnetic field device, and belongs to the technical field of micro-arc oxidation devices. The device aims to solve the technical problems that an existing micro-arc oxidation device is low in machining efficiency, and sometimes ablation is prone to happening in the micro-arc oxidation film growing process. The device further comprises an electromagnetic field assembly. The electromagnetic field assembly is composed of a hollow pipe and N turns of coils wound around the outer wall of the hollow pipe. The electromagnetic field assembly is arranged in a micro-arc oxidation tank. A workpiece is mounted in the electromagnetic field assembly and serves as an anode to be connected with the output positive pole of a power box. The micro-arc oxidation tank and the hollow pipe serve as a cathode to be connected with the output negative pole of the power box. The power box controls on-off of the hollow pipe and the coils. According to the device, an auxiliary synchronous electromagnetic field is additionally mounted to act on electrolyte micro-plasma, the growing rate of a micro-arc oxidation film layer can be further increased, and meanwhile the ablation defect appearing during film layer growing in the micro-arc oxidation process is avoided.

Owner:哈尔滨佰倍科技有限公司

Electrical etching machine of metal cutter template

ActiveCN102628177BPrecise positioningThere is no bad contactElectrolysis componentsElectrochemical machining apparatusMetalElectrolyte

Owner:常州正成机电科技有限公司

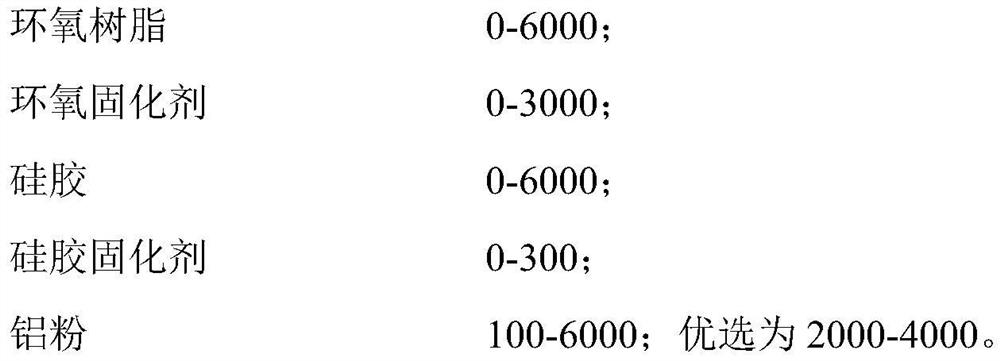

Composition for preparing earthquake physical model, earthquake physical model and preparation and construction method

The invention belongs to the field of earthquake physical models, and particularly relates to a geophysical reservoir model. The model is mainly made of epoxy resin, silica gel, aluminum powder and other compositions, the longitudinal and transverse wave speed of a model material is controlled by changing the contents of the components, the longitudinal wave speed can be controlled to be graduallychanged between 2800m / s and 4900m / s, and the transverse wave speed can be controlled to be gradually changed between 1500m / s and 2600m / s. The reservoir model manufactured by adopting a geophysical reservoir model composition and a manufacturing method has good penetrability under strong pulse excitation of laser ultrasound, good seismic wave reflection data can be obtained when the model is applied to physical simulation test, and a new method is provided for reservoir geologic body and laser ultrasound research.

Owner:CHINA PETROLEUM & CHEM CORP +1

A fully actively cooled hypersonic vehicle

ActiveCN107914862BAvoid thermal structural thermal matching problemsGuaranteed aerodynamic shapeBoundary layer controlsFuselage insulationThermodynamicsFlight vehicle

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

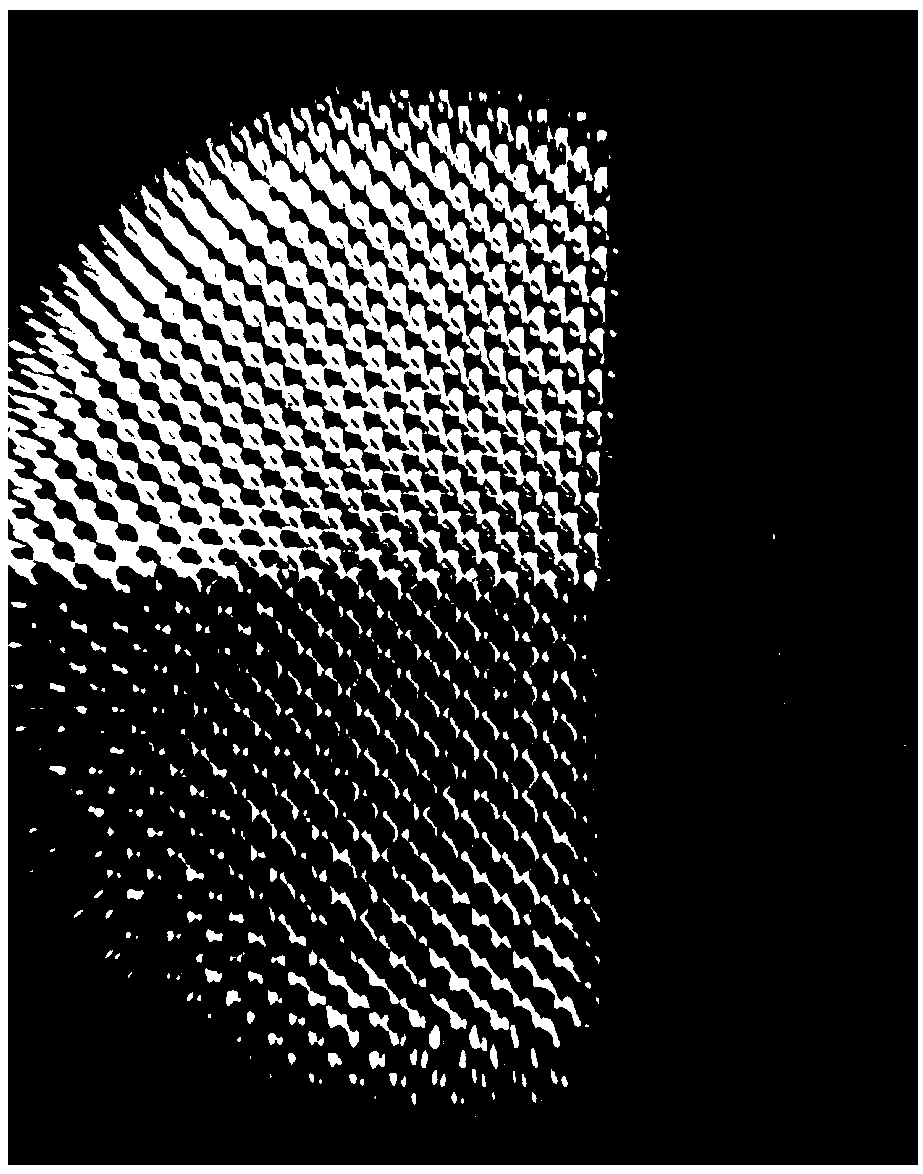

Anilox roller cleaning method

The invention belongs to the technical field of flexography printing, and relates to an anilox roller cleaning method. The anilox roller cleaning method comprises the steps that an anilox roller is cleaned through pulse laser, the wavelength of the pulse laser is 1064 nm, the pulse frequency is 20-30 kHz, and the power is 180-220 W. According to the anilox roller cleaning method, a laser cleaninglight source is controlled accurately, and thus the effects of high cleaning speed, thorough cleaning effect and no chemical reagent participation are achieved.

Owner:矫矫

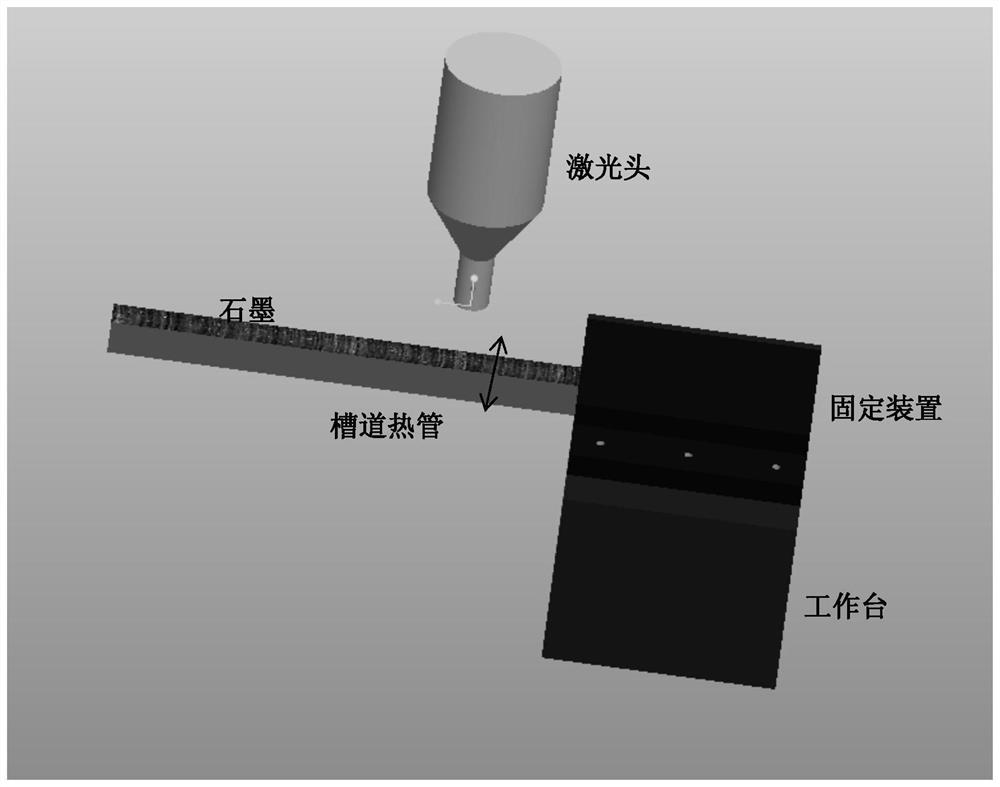

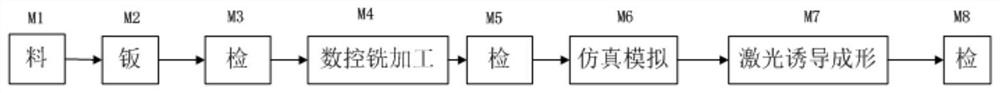

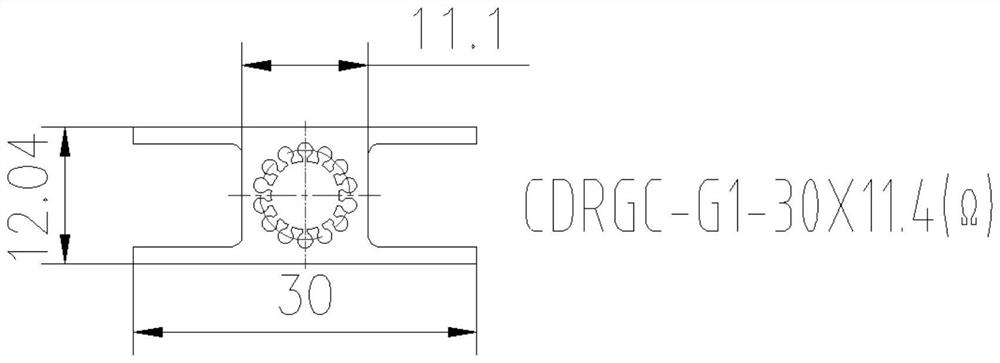

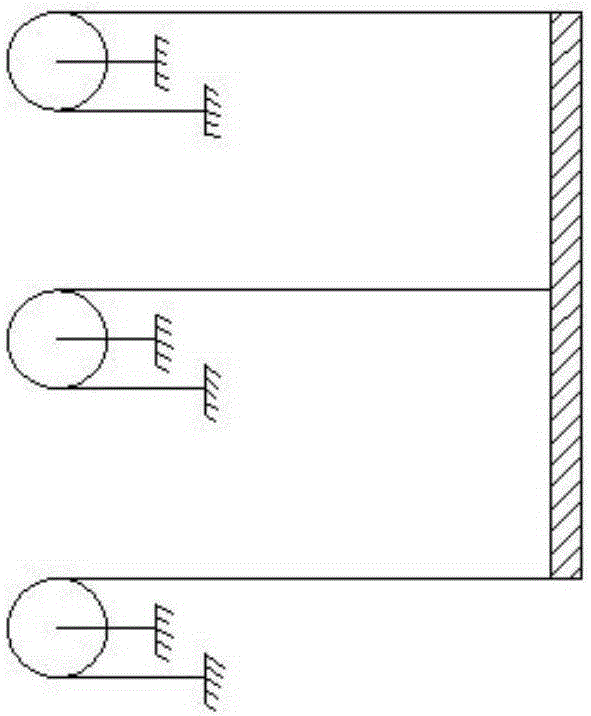

Bending and forming ammonia axial channel heat pipe based on laser induction

The invention relates to a method for bending and forming an ammonia axial channel heat pipe based on laser induction. The method comprises the following steps of blanking an ammonia axial channel heat pipe raw material in a laser cutting manner, and milling a product notch, a hole site and a bending section fin according to a process drawing to obtain an ammonia axial channel heat pipe test piece; the surface of the test piece is coated with an ablation heat-proof material; and simulation is conducted on the laser-induced bending forming parameters of the test piece, the bending forming angle, the temperature distribution cloud picture and the stress-strain cloud picture of the test piece under the laser-induced bending forming parameters are determined, and the laser-induced bending forming parameters with the surface quality and the forming angle meeting the requirements of the test piece are determined through simulation. The ammonia axial channel heat pipe test piece is tested according to the determined laser-induced bending forming parameters, whether bending forming of the ammonia axial channel heat pipe meets the requirements or not after testing is judged, and if not, the laser-induced bending forming parameters are optimized, and the ammonia axial channel heat pipe test piece is tested again till the requirements are met.

Owner:BEIJING SATELLITE MFG FACTORY

Small flexible wing drone launcher

InactiveCN103552692BReduce manufacturing costExtended service lifeLaunching/towing gearLocking mechanismCentral symmetry

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com