Micro-arc oxidation device with variable cathode area and surface treatment method

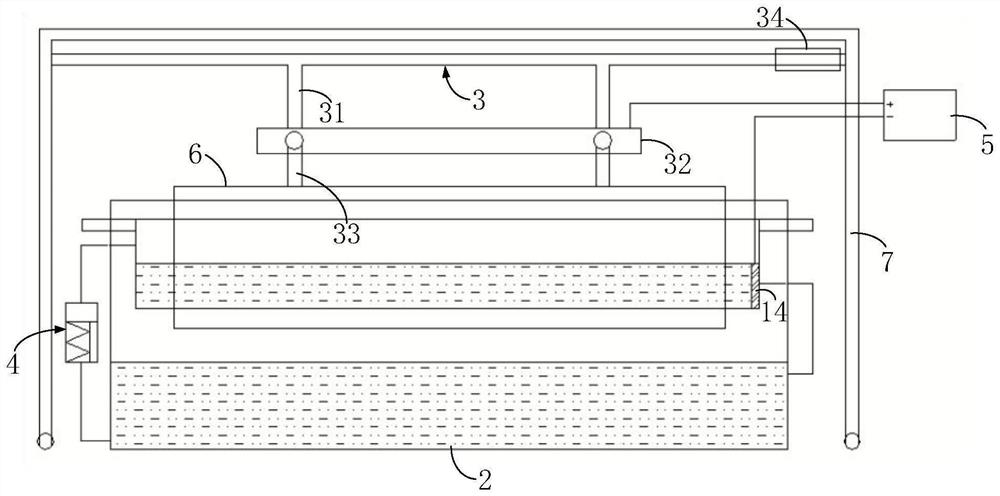

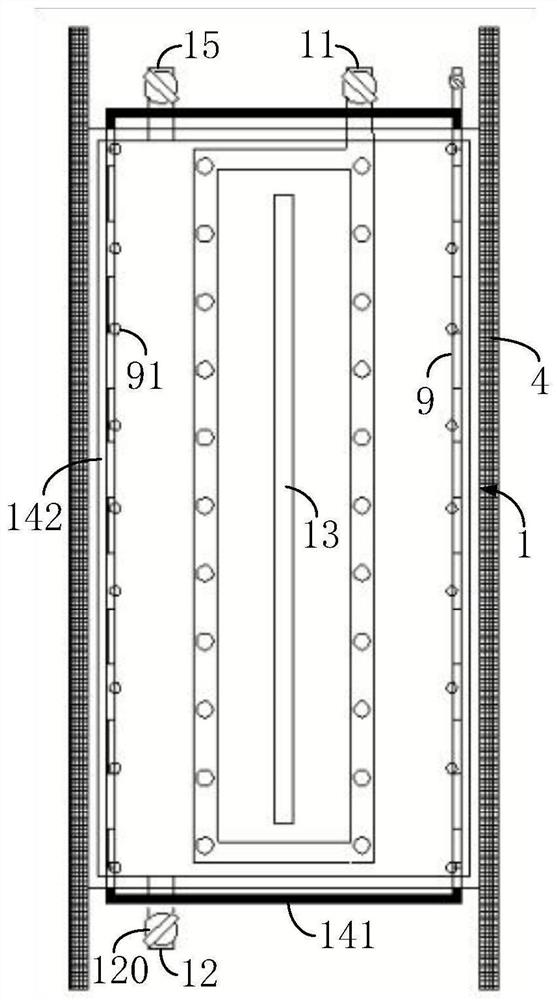

A technology of micro-arc oxidation and cathode area, applied in anodic oxidation, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of high production equipment requirements, low production efficiency, poor film quality, etc., and achieve low production cost, Improvement of production efficiency, effect of no oxidation transition zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The present embodiment 1 provides a kind of preparation method of ceramic oxide film layer of plate material for industrial use or building, specifically comprises the following steps:

[0065] Step 1 - Prepare raw materials: select aluminum alloy plates for industrial use or construction with a size of 2000mm×2000mm×1mm;

[0066] Step 2-preparation of cleaning mixture: use metal surface cleaning agent CY-10, add 5% mass ratio into cleaning tank 1, start gas stirring and ultrasonic cleaning (20-130KHZ);

[0067] Step 3-preparation of micro-arc oxidation electrolyte: fully stir sodium silicate 10g / L, sodium fluoride 10g / L, sodium hydroxide 10g / L and water to obtain an electrolyte, and add the electrolyte to the micro-arc oxidation tank 1;

[0068] Step 4 - Set the power supply parameters: voltage 600V, frequency 500HZ, duty cycle 20%; output pressure of the air compressor is 1-1.2Mpa; cooling temperature is set to 25-35°C;

[0069] Step 5 - Micro-arc oxidation: hang the...

Embodiment 2

[0072] This embodiment 2 provides a kind of preparation method of ceramic oxide film layer of plate material for industrial use or building, specifically comprises the following steps:

[0073] Step 1 - Prepare raw materials: select aluminum alloy plates for industrial use or construction with a size of 2000mm×2000mm×1mm;

[0074] Step 2-preparation of cleaning mixture: use metal surface cleaning agent CY-10, add 5% mass ratio into cleaning tank 1, start gas stirring and ultrasonic cleaning (20-130KHZ);

[0075] Step 3-preparation of micro-arc oxidation electrolyte: fully stir sodium silicate 10g / L, sodium fluoride 10g / L, sodium hydroxide 10g / L and water to obtain an electrolyte, and add the electrolyte to the micro-arc oxidation tank 1;

[0076] Step 4 - Set the power supply parameters: voltage 620V, frequency 500HZ, duty cycle 22%; output pressure of the air compressor is 1-1.2Mpa; refrigeration temperature is set to 25-35°C;

[0077] Step 5 - Micro-arc oxidation: hang the ...

Embodiment 3

[0080] The present embodiment 3 provides a kind of preparation method of the plate ceramic oxide film layer for industrial use or construction, specifically comprises the following steps:

[0081] Step 1 - Prepare raw materials: select aluminum alloy plates for industrial use or construction with a size specification of 2500mm×2500mm×4mm;

[0082] Step 2-preparation of cleaning mixture: use metal surface cleaning agent CY-10, add 5% mass ratio into cleaning tank 1, start gas stirring and ultrasonic cleaning (20-130KHZ);

[0083] Step 3-preparation of micro-arc oxidation electrolyte: fully stir sodium silicate 10g / L, sodium fluoride 10g / L, sodium hydroxide 10g / L and water to obtain an electrolyte, and add the electrolyte to the micro-arc oxidation tank 1;

[0084] Step 4 - Set the power supply parameters: voltage 630V, frequency 600HZ, duty cycle 22%; the output pressure of the air compressor is 1-1.2Mpa; the cooling temperature is set at 25-35°C;

[0085] Step 5 - Micro-arc o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com