Electrical etching machine of metal cutter template

An electrolytic etching and metal knife technology, applied in the direction of electrolytic process, electrolytic components, metal processing equipment, etc., can solve the problems of accurate positioning, roughness, and increased production cost of difficult-to-etch metal products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

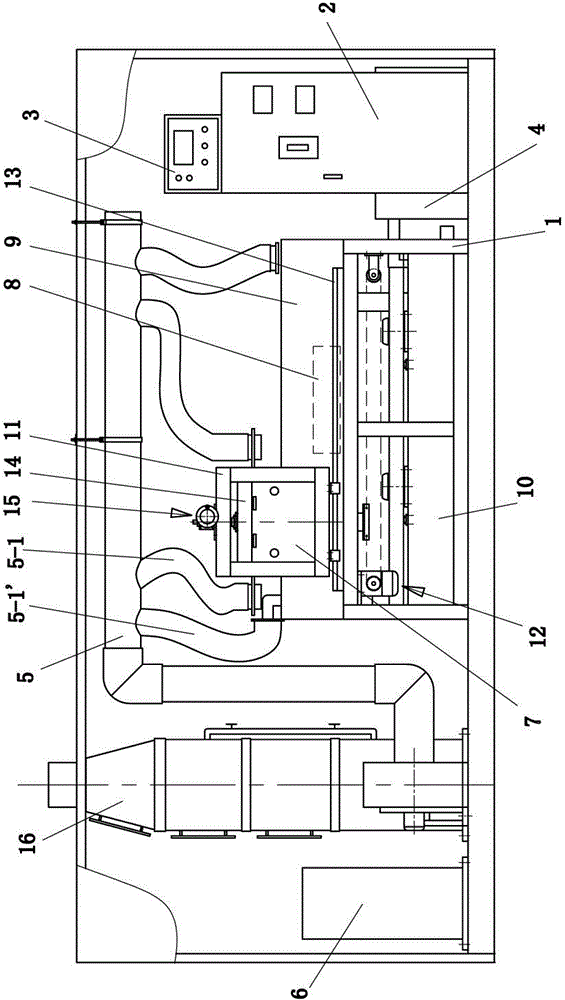

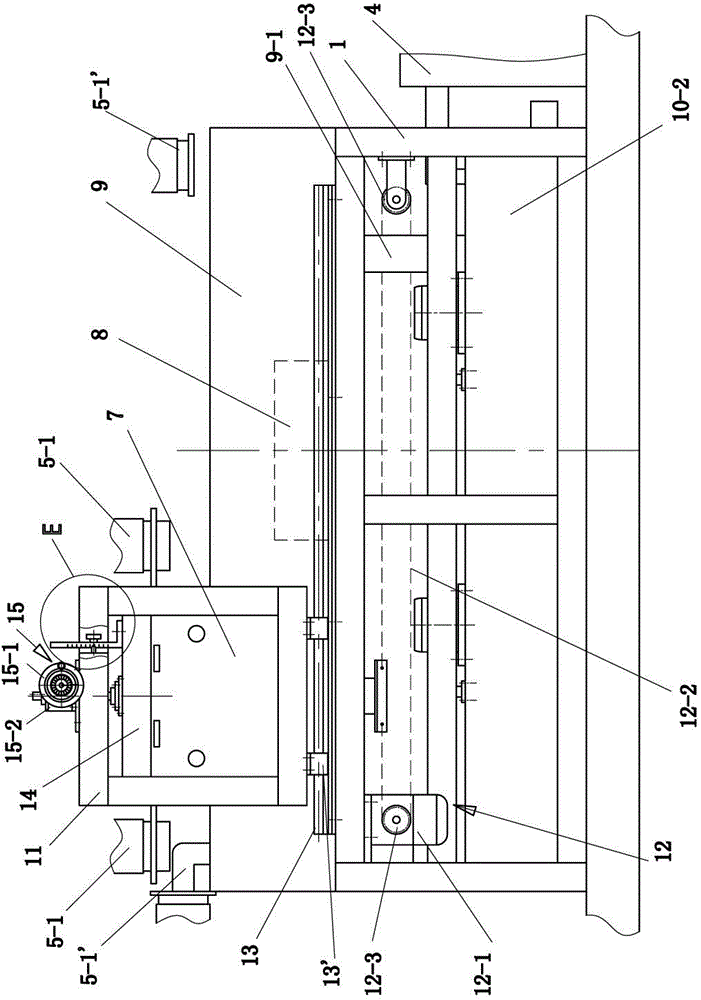

[0049] like Figure 1~12 , 22, 23, and 24, a metal knife template electrolytic etching machine includes a frame 1, an upper electrode 7, a lower electrode 8 and an electrolyte collection tank 9, wherein the electrolyte collection tank 9 is located on the frame 1 , the lower electrode 8 is located in the electrolyte collection tank 9, the frame 1 is also moved with a translation frame 11, the upper electrode 7 is mounted on the translation frame 11, and the translation frame 11 is located on the upper There are at least two liquid outlets 7-1 next to the electrode 7, and the liquid outlets of the liquid outlets 7-1 are all facing the bottom of the upper electrode 7 and the space below the bottom surface. When the translation frame 11 moves, the upper electrode 7 and the outlet The liquid container 7-1 can pass above the lower electrode 8, the upper surface of the lower electrode 8 is provided with an insulating workpiece support 8-1, and the workpiece support 8-1 has a liquid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com