External-heating energy-saving and environment friendly rotary carbonization furnace

A rotary carbonization furnace, energy-saving and environmental protection technology, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve the problem of high wear and breakage rate, difficult to control the final temperature of carbonization, serious material surface ablation, etc. problems, to achieve the effects of easy control of the heating rate, environmental protection, and low material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

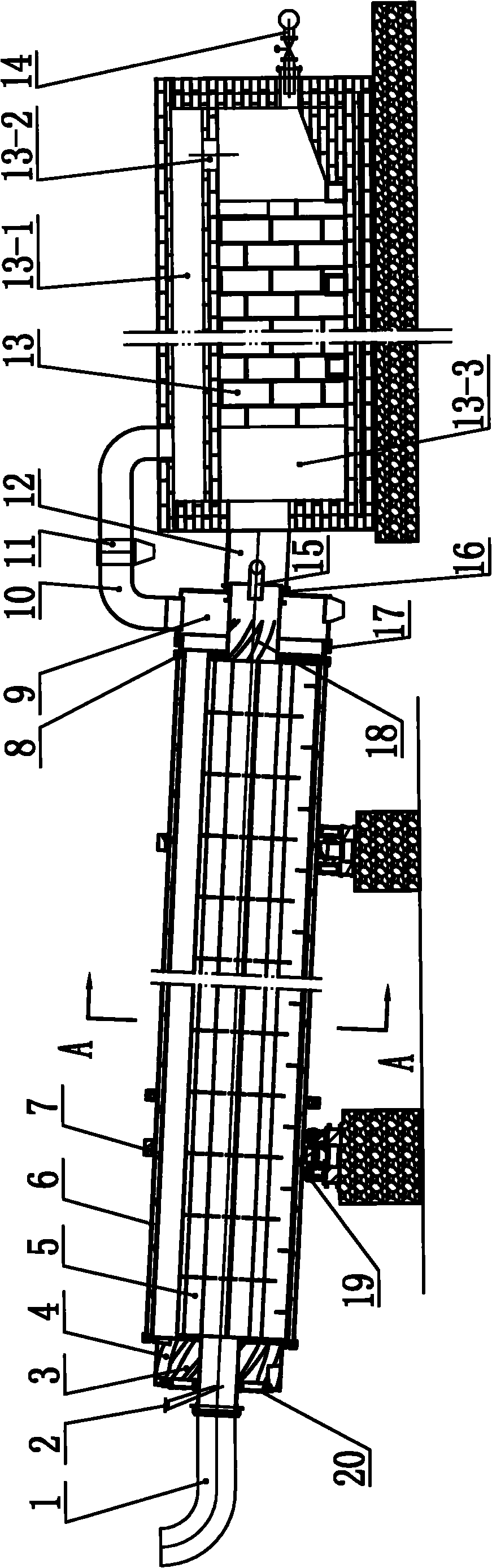

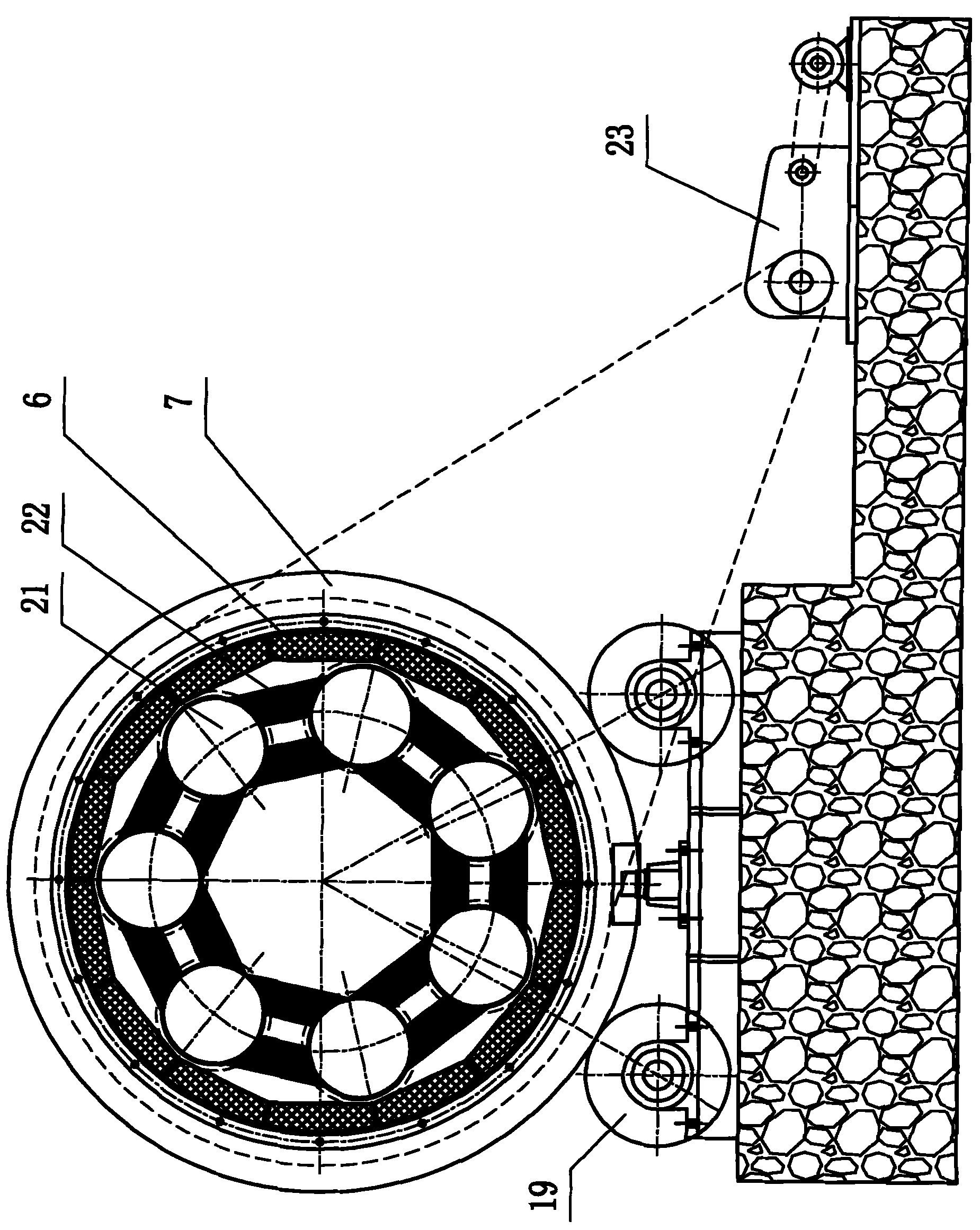

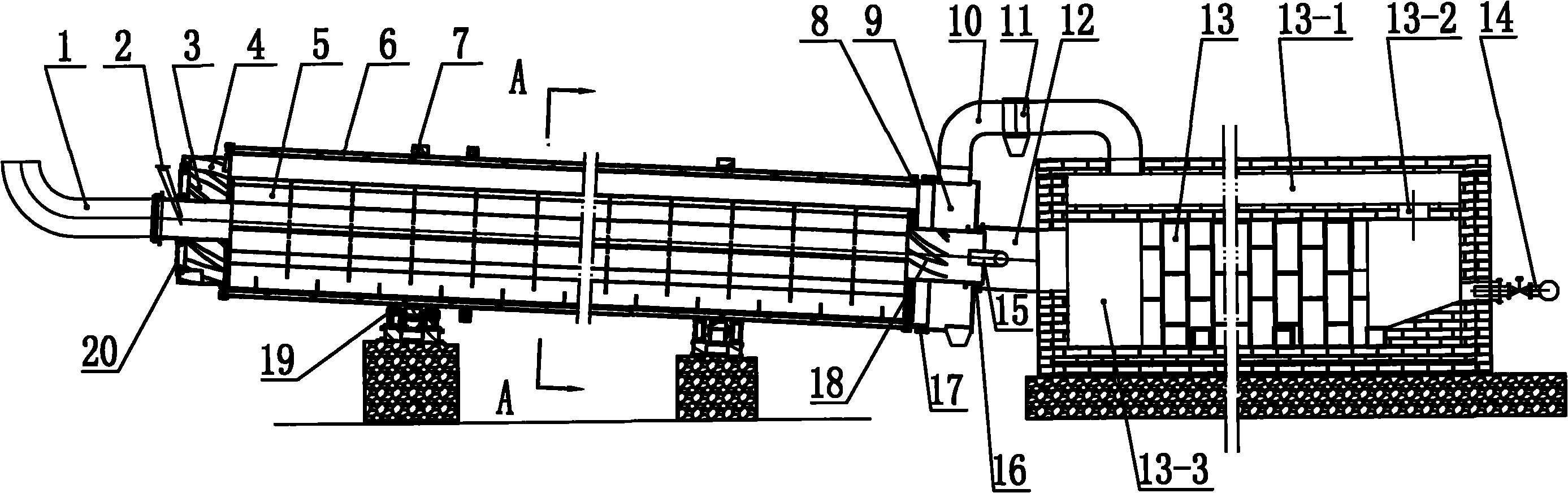

[0012] like figure 1 , figure 2 As shown, the present invention comprises feeding bin 3, furnace body 5, furnace shell 6, discharging bin 9, volatile matter pipeline 10, combustion chamber 13, high temperature flue gas pipe 12, tail gas exhaust pipe 1, driving mechanism 23; Furnace Body 5 is made up of at least three independent material passages 21 (commonly referred to as product passages in the industry), and the cross section of material passage 21 is a closed annular section, and the annular section can be circular, elliptical, with rounded corners or without circles. The circular sections such as the polygon of corner, are connected with rib plate 22 between material channel 21. The furnace body 5 is placed in the furnace shell 6, and the end is fixed on the furnace shell 6 to form a rotating body with the furnace shell 6. The furnace shell 6 is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com