Seamless splicing method for circular metal mould tape with optical micro structure aggregate on surface

An optical microstructure and seamless splicing technology, applied in the field of optical mold manufacturing, can solve the problems of sub-board seam burrs, the inability to ensure the absolute fit of the seam, and the inability of the weld to be completely filled and filled. Ablation, strong and not easy to crack, the effect of mechanical strength guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] The peelable single-sided tape used in the embodiment is 3M898 fiber tape of 3M Company in the United States; the A / B structural conductive adhesive is TD-8813 high-strength electronic conductive adhesive produced by Dongguan Yantai Adhesive Co., Ltd.; the two-component structural adhesive It is Wuhan double bond DB8011 two-component epoxy structure AB glue.

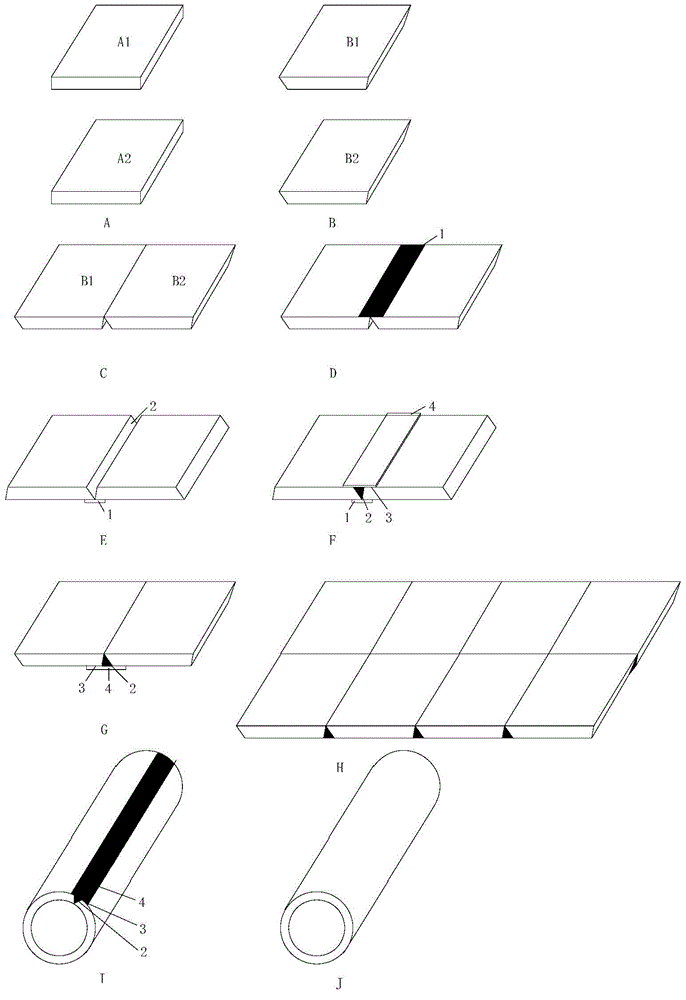

[0023] 1. Make two unit small-area flat metal master templates A1 and A2, the size of which is not less than 500mm×500mm. Cut, polish, and corner the two flat metal master templates to ensure smooth end faces and good straightness . The processed metal plates are B1 and B2, the size is 480mm×480mm, and the inclination angle of the corresponding edge is 30 degrees.

[0024] 2. Put the well-polished metal plates B1 and B2 side by side on a plane according to the required size and grain structure direction, so that the edges with inclined angles are close to each other, and match until there is no gap in the eyes, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com