Thin resin wheel

A resin grinding wheel and sheet technology, applied in the field of abrasives, can solve the problems of increased cutting volume, high cutting heat, and difficulty in achieving cutting accuracy, and achieve the effects of reducing cutting heat temperature, improving cutting performance, and reducing cutting heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

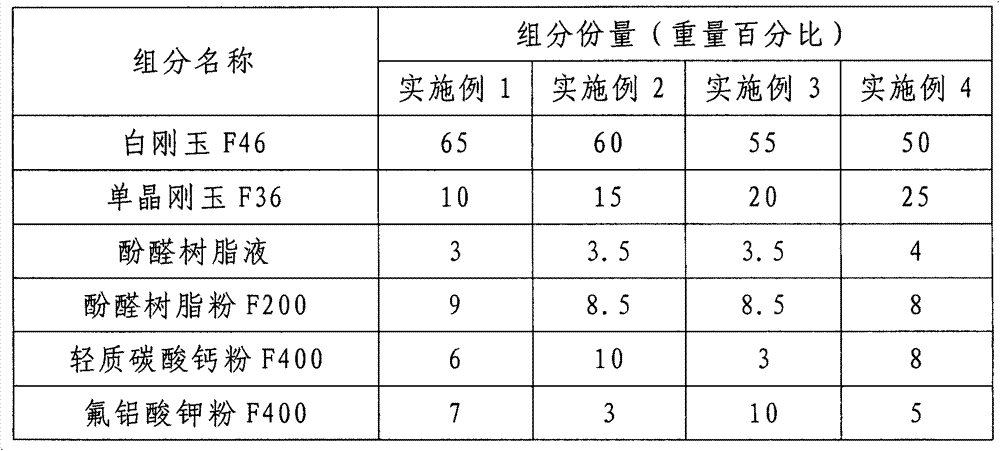

[0018] The sheet resin grinding wheel produced by the present invention has a diameter of 105 mm to 125 mm and a thickness of 0.8 mm to 1.0 mm. The components are measured by weight percentage as follows: white corundum 50% to 65%, single crystal corundum 10% to 25%, phenolic resin powder 8 % to 9%, phenolic resin solution 3% to 5%, light calcium carbonate powder 3% to 10%, and potassium fluoroaluminate powder 3% to 10%. The particle sizes of the granular materials in the above components are white corundum F46-F60, single crystal corundum F36-F40, phenolic resin powder F200-F220, light calcium carbonate powder and potassium fluoroaluminate powder F380-F400.

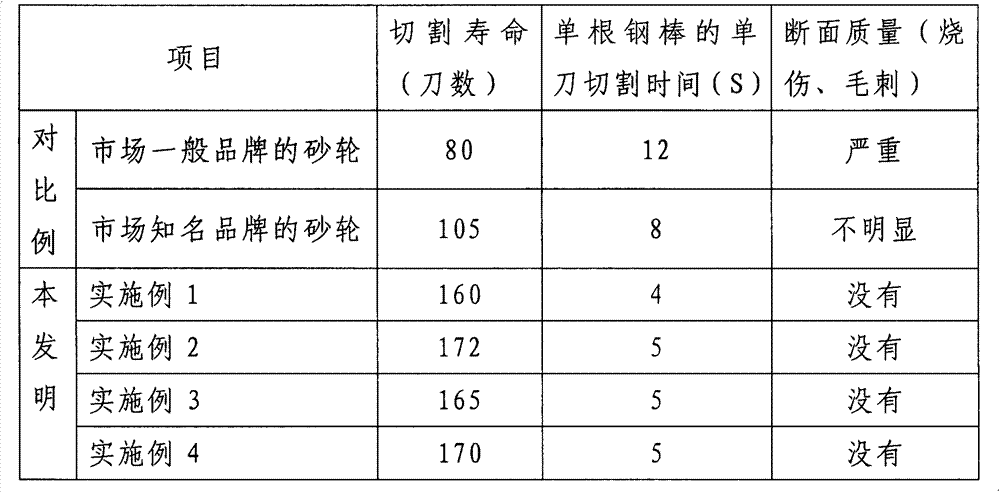

[0019] Further verify the present invention by the following examples, the embodiment component weight table (seeing table 1), the sheet resin emery wheel of the present invention is the same as the comparative example emery wheel size, is unified as 105 * 1.0 * 16, is made under the same working condition Cutting compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com