Bending and forming ammonia axial channel heat pipe based on laser induction

A channel heat pipe, bending forming technology, applied in the field of ammonia axial channel heat pipe bending and forming, can solve the problem of no in-depth research on ammonia axial channel heat pipe, no research, etc., to shorten the product production cycle and improve economic benefits , Improve the effect of stability and pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with embodiment.

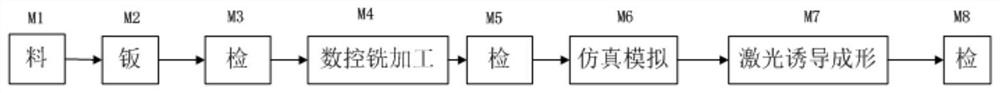

[0030] This paper presents a process scheme for forming ammonia axial channel heat pipes by laser-induced forming technology. Mainly study the process parameters of laser-induced bending forming under different bending radii and bending angles of different specifications of ammonia axial channel heat pipes currently applied to various models, and then expand the laser-induced bending forming process parameters of different angles under three-dimensional bending.

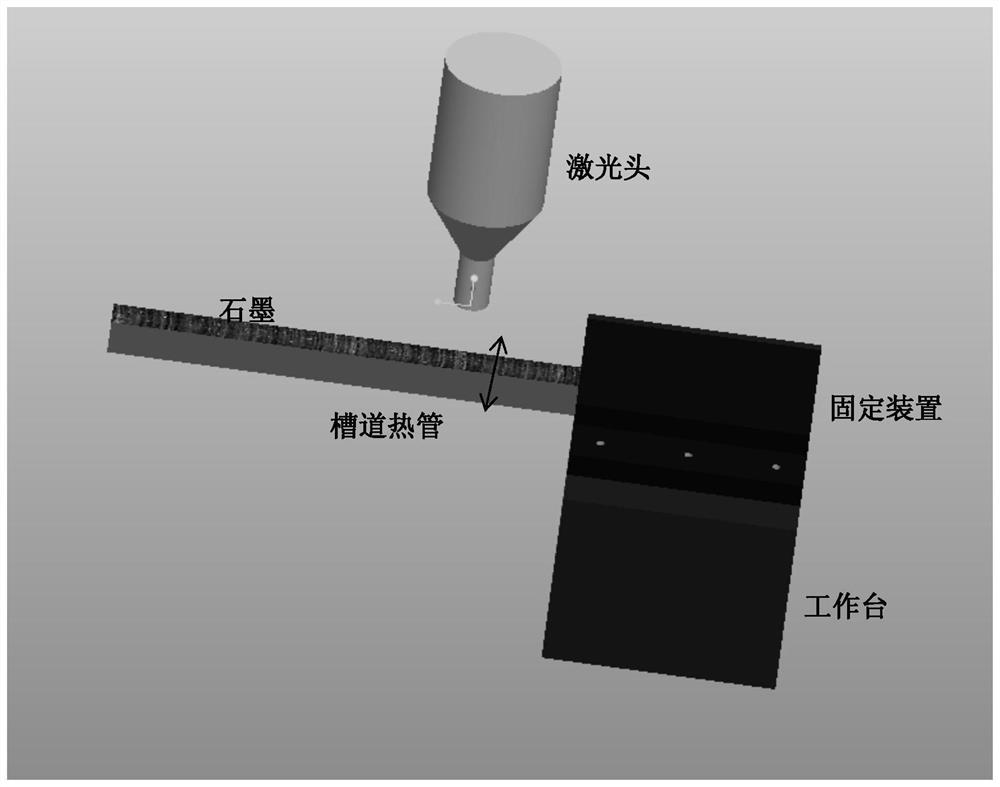

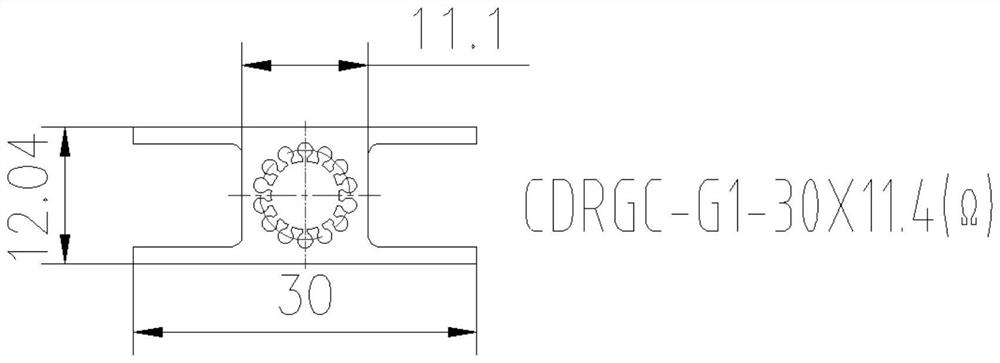

[0031] The laser-induced forming process device of ammonia axial channel heat pipe is mainly composed of laser device, fixing device, workbench and other parts. Before the test, remove the fins from the heat pipe machine (30×10 and 10×5 ammonia axial channel heat pipes have fins on the left and right sides of the section, such as image 3 and Figure 4 During the test, one end of the heat pipe is fixed on the fixture, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com