Neat device for packaging printing paper after cutting

A packaging printing and cutting technology, which is applied in the field of trimming devices for packaging and printing paper after cutting, can solve the problems of wrong size, large number of pages, easy to overlap, misalignment, etc., to prevent wrinkling and avoid excessive number of pages More, reduce the effect of paper pile thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

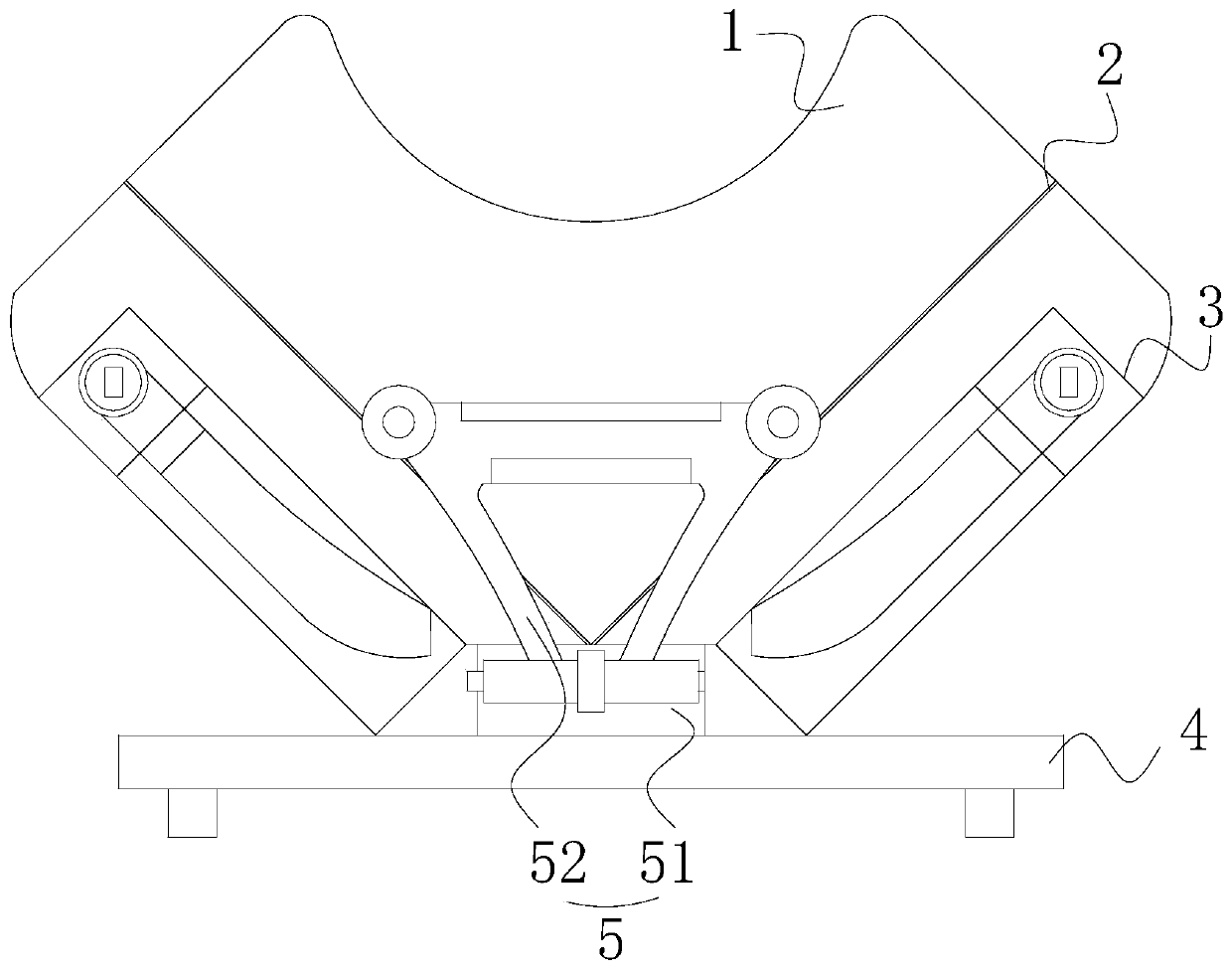

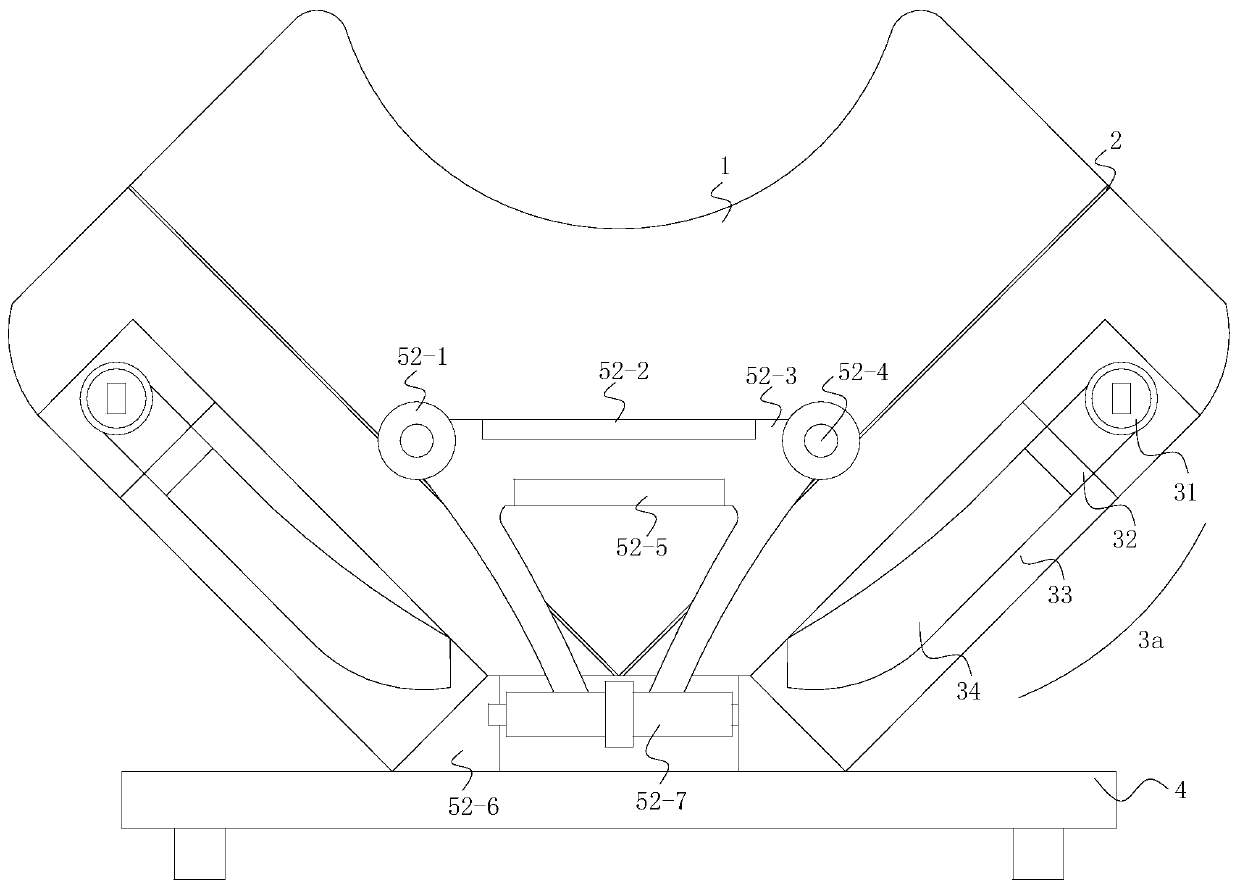

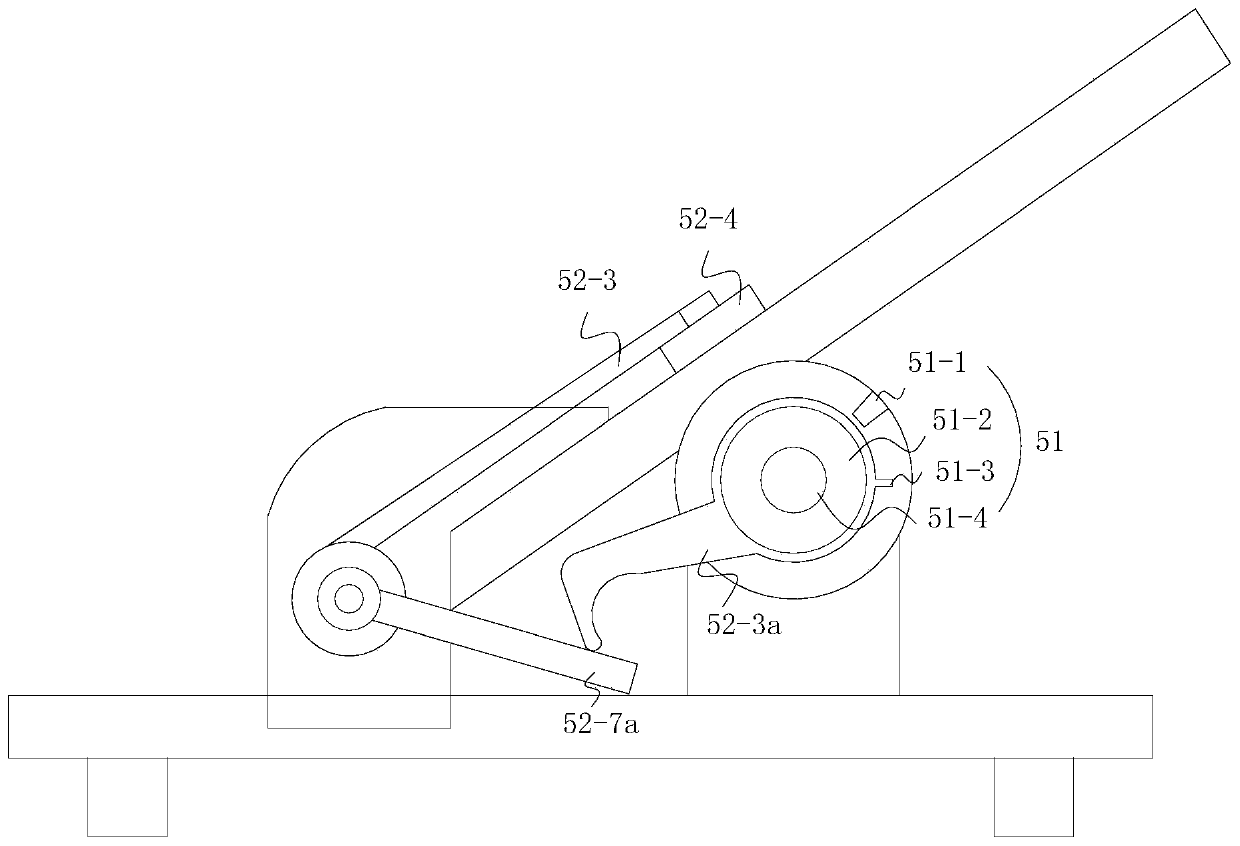

[0024] see Figure 1-Figure 4 , the present invention provides a trimming device for packaging and printing paper after cutting, its structure includes a triangular placement frame 1, a partition 2, a box body 3, a bottom plate 4, and a neat movable structure 5, and a movable column is installed in the middle of the bottom plate 4 Triangular placement frame 1, described triangular placement frame 1 is respectively equipped with a box body 3 near the both sides of bottom plate 4, is provided with orderly movable structure 5 between two box bodies 3, and described triangular placement frame 1 upper surface uses two The partition board 2 separates a triangular placement area, and a piercing hole is drilled on the partition board 2 .

[0025] The neat movable structure 5 includes a linkage structure 51 and a pressing structure 52. The pressing structure 52 is located between the two boxes 3 and is movably attached to the triangular placement area. The linkage structure 51 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com