Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Narrow diameter distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cerium oxide particles and production method therefor

InactiveUS7431758B2Increase temperatureIncrease productionPigmenting treatmentOther chemical processesProduction rateCerium

The production method for cerium oxide particles of the present invention is a method of producing a cerium oxide particle by heating a cerium compound from a normal temperature to a temperature range of 400° C. to 1200° C., and comprises at least a temperature raising stage of a temperature rise speed of 2° C. / hour to 60° C. / hour, or proceeds via a stage of heating while supplying a humidified gas in a temperature raising process. By the method of the present invention, a cerium oxide powder whose particle diameter distribution of primary particles is narrow can be obtained. An aqueous cerium oxide slurry produced from the powder enables an improvement in the productivity and a reduction in the cost of a polishing step, because if it is used as an abrasive a high-quality polished face is obtained without deteriorating the polishing speed. The aqueous cerium oxide slurry of the present invention is particularly useful as an abrasive for final finish of a substrate whose main component is silica.

Owner:NISSAN CHEM CORP

Cerium oxide particles and process for the production therefor

InactiveUS20060150526A1Reduce dehydrationDehydration fastPigmenting treatmentOther chemical processesProduction rateCerium

The production method for cerium oxide particles of the present invention is a method of producing a cerium oxide particle by heating a cerium compound from a normal temperature to a temperature range of 400° C. to 1200° C., and comprises at least a temperature raising stage of a temperature rise speed of 2° C. / hour to 60° C. / hour, or proceeds via a stage of heating while supplying a humidified gas in a temperature raising process. By the method of the present invention, a cerium oxide powder whose particle diameter distribution of primary particles is narrow can be obtained. An aqueous cerium oxide slurry produced from the powder enables an improvement in the productivity and a reduction in the cost of a polishing step, because if it is used as an abrasive a high-quality polished face is obtained without deteriorating the polishing speed. The aqueous cerium oxide slurry of the present invention is particularly useful as an abrasive for final finish of a substrate whose main component is silica.

Owner:NISSAN CHEM IND LTD

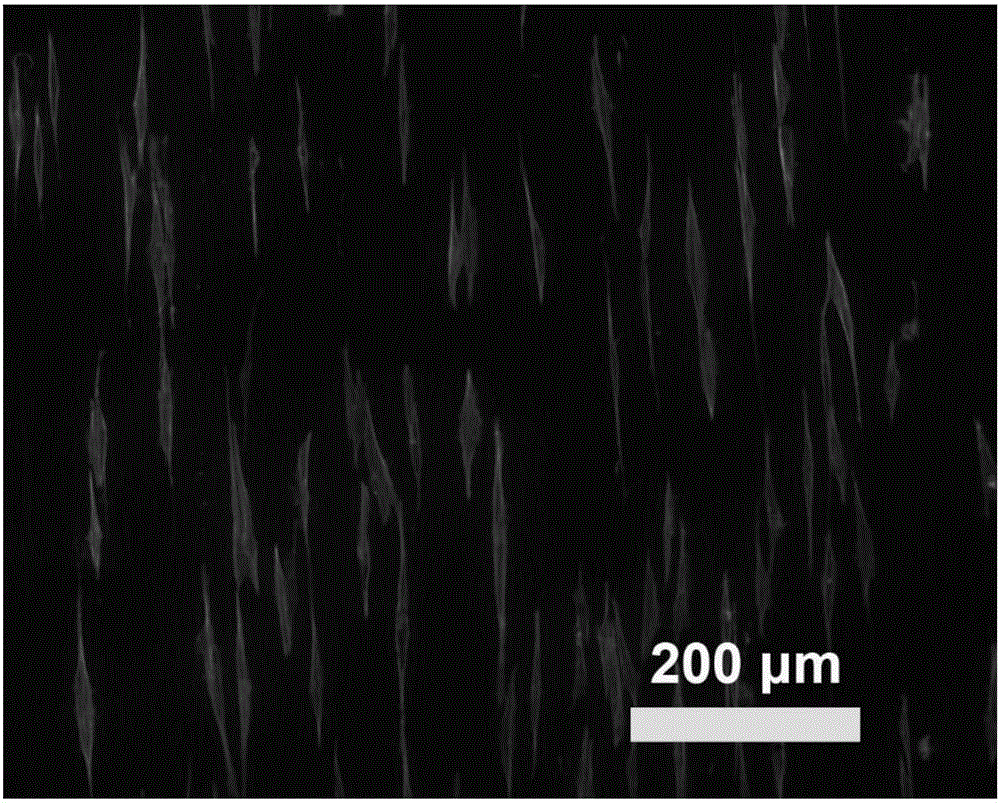

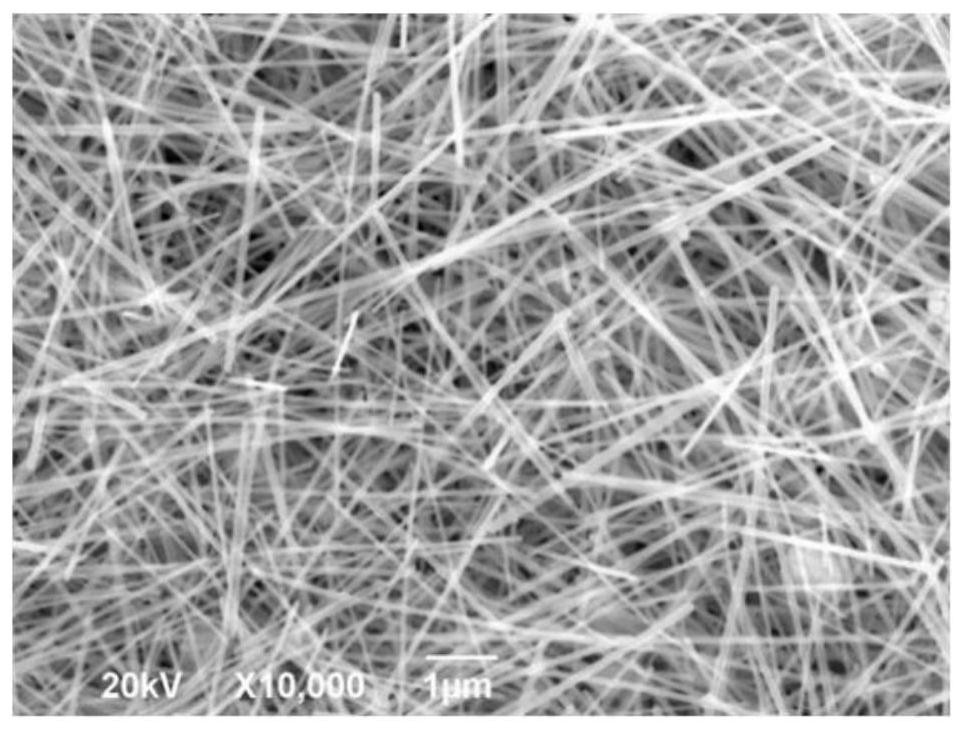

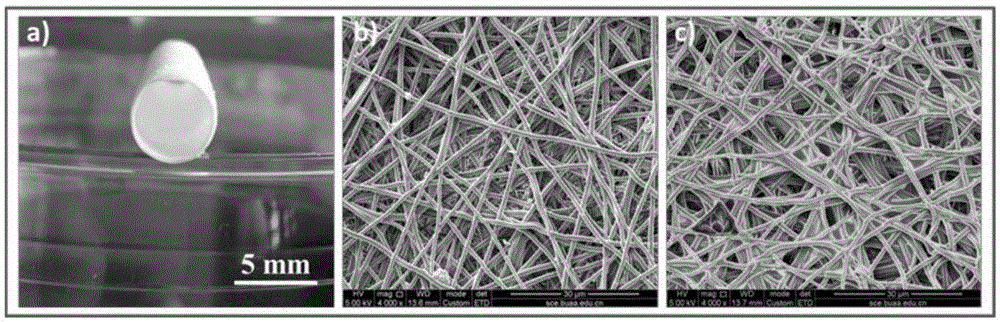

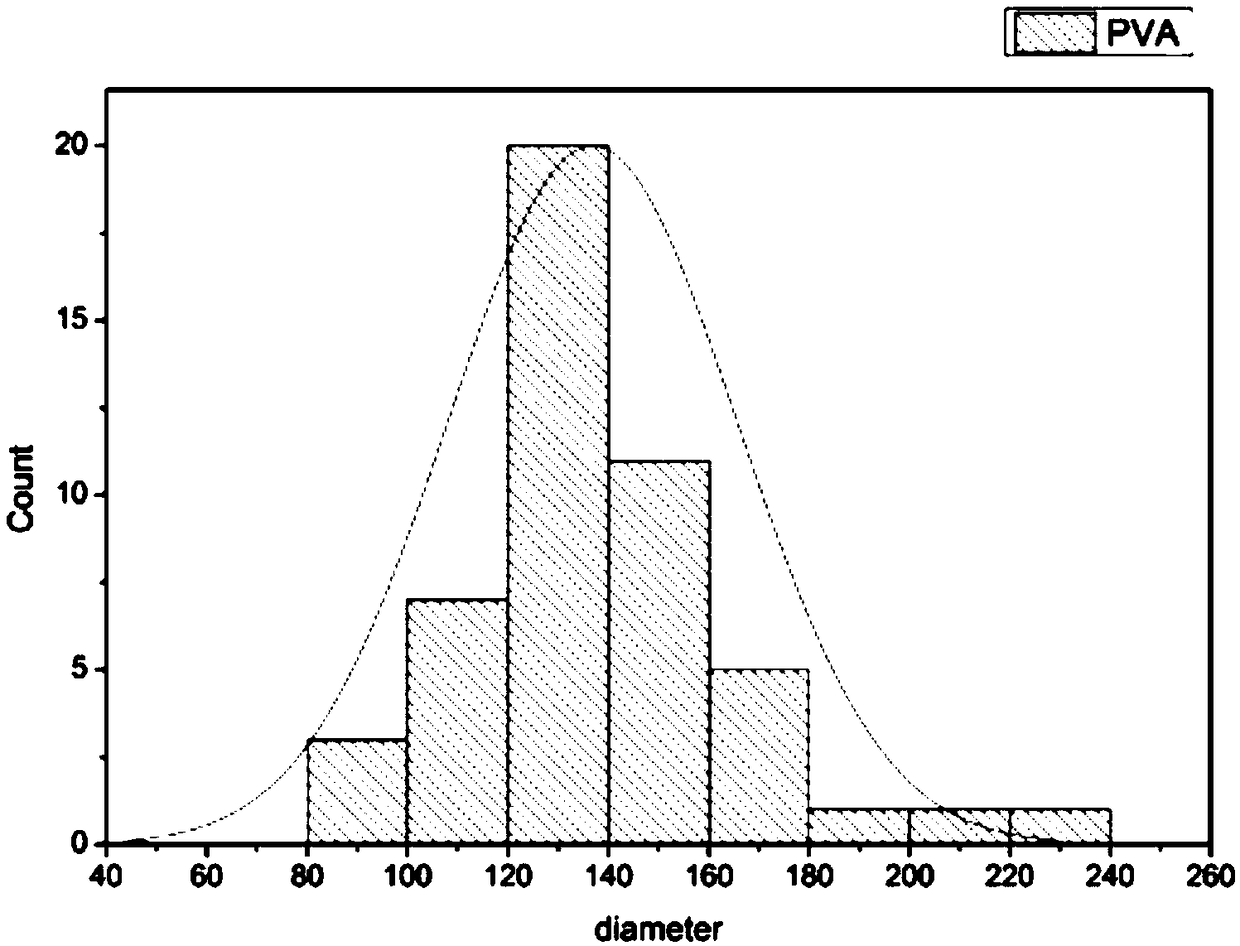

Artificial blood vessel stent with aligned fibers and manufacturing method of artificial blood vessel stent

InactiveCN106512087AGood cell compatibilityUniform shapeFilament/thread formingPharmaceutical delivery mechanismFiberSmooth muscle

The invention discloses an artificial blood vessel stent with aligned fibers and a manufacturing method of the artificial blood vessel stent, and belongs to the field of tissue engineering. According to the artificial blood vessel stent provided by the invention, a bio-compatible polymer material is taken as a spinning solution; firstly, the influence of different rotating speeds on fiber alignment is researched by virtue of an electrostatic spinning method, so that a rotating speed that the best alignment degree is achieved is determined; and then, the aligned fiber artificial blood vessel stent is manufactured on the basis of the rotating speed; the artificial blood vessel stent is relatively good in biocompatibility; and in addition, the alignment of smooth muscle cells on blood vessels can be guided. The artificial blood vessel stent provided by the invention is applicable to large-scale production and is expected to be applied to actual clinical diagnosis.

Owner:BEIHANG UNIV

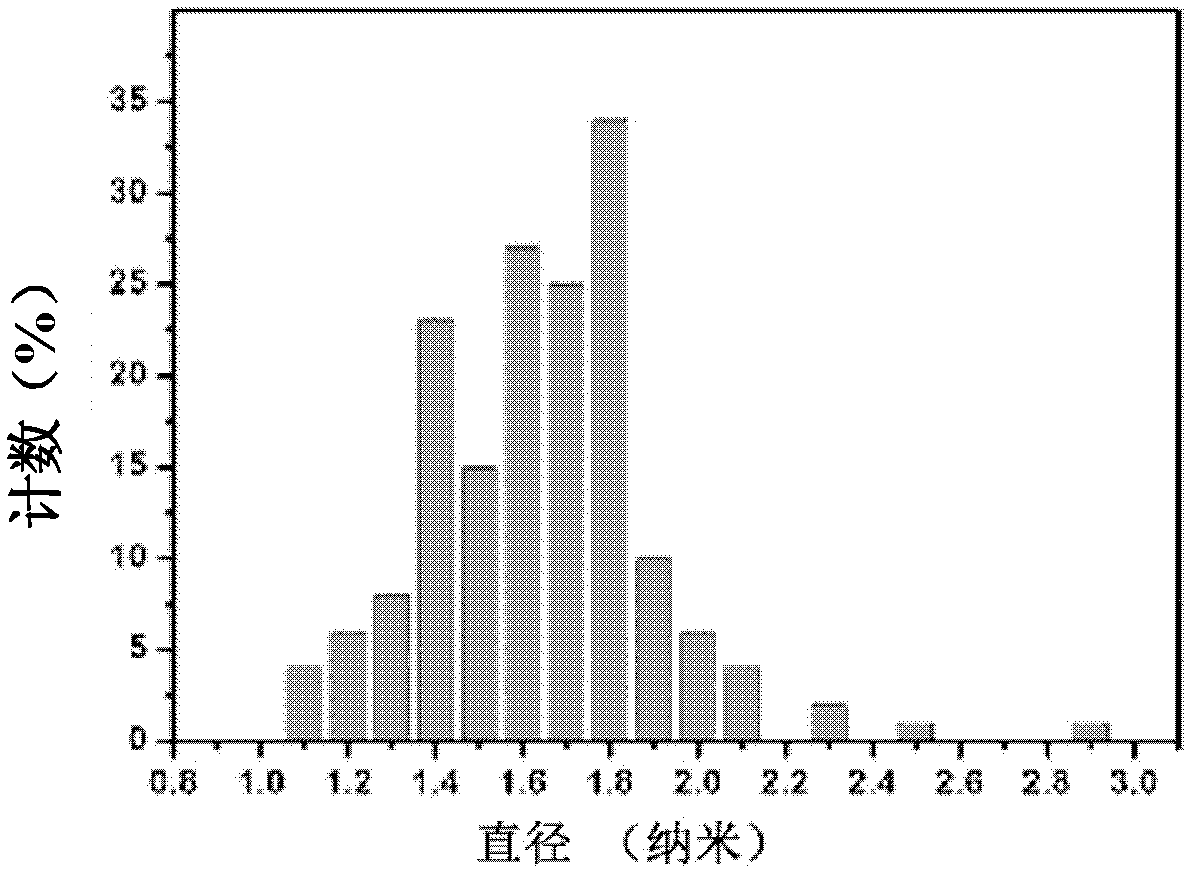

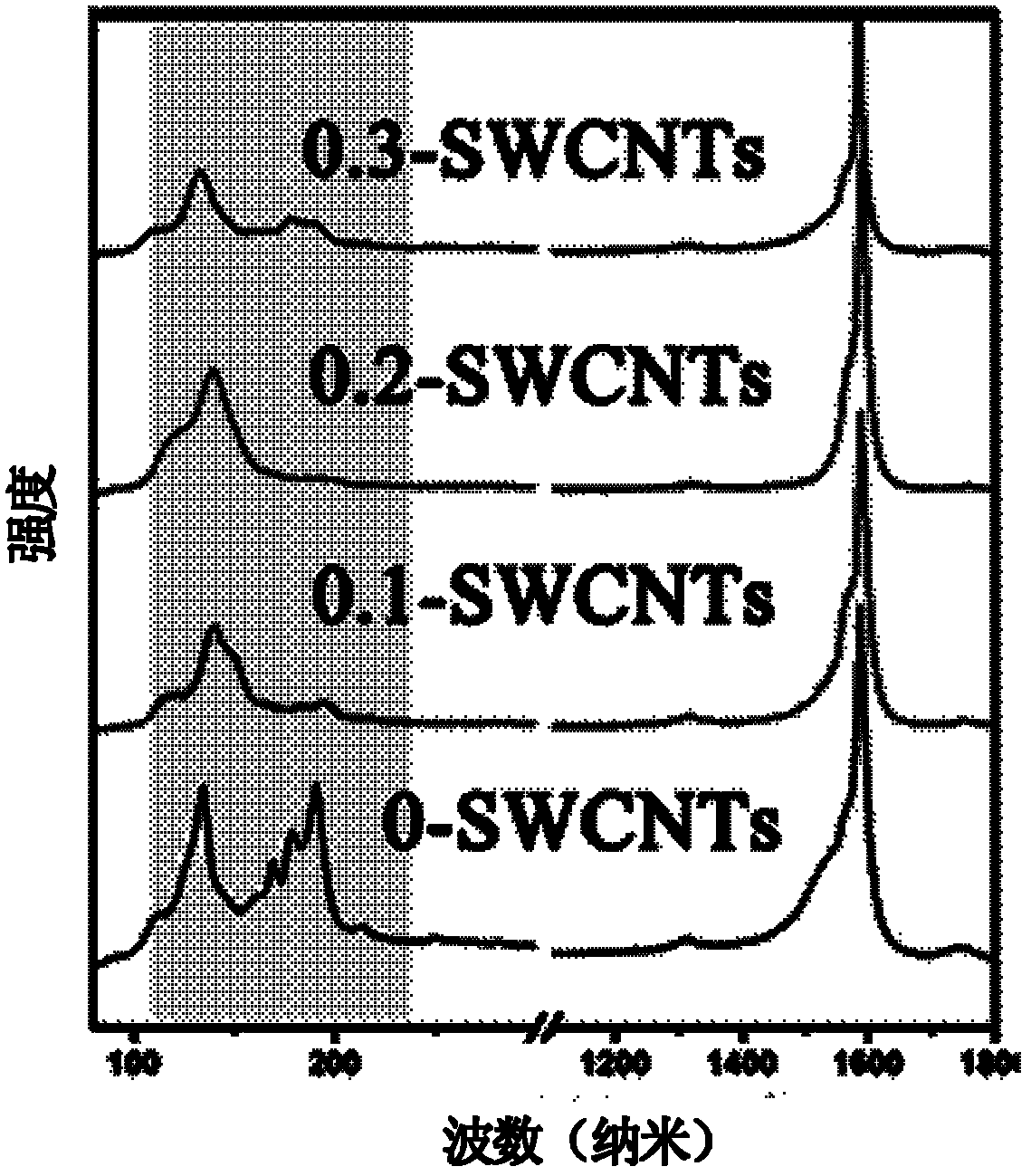

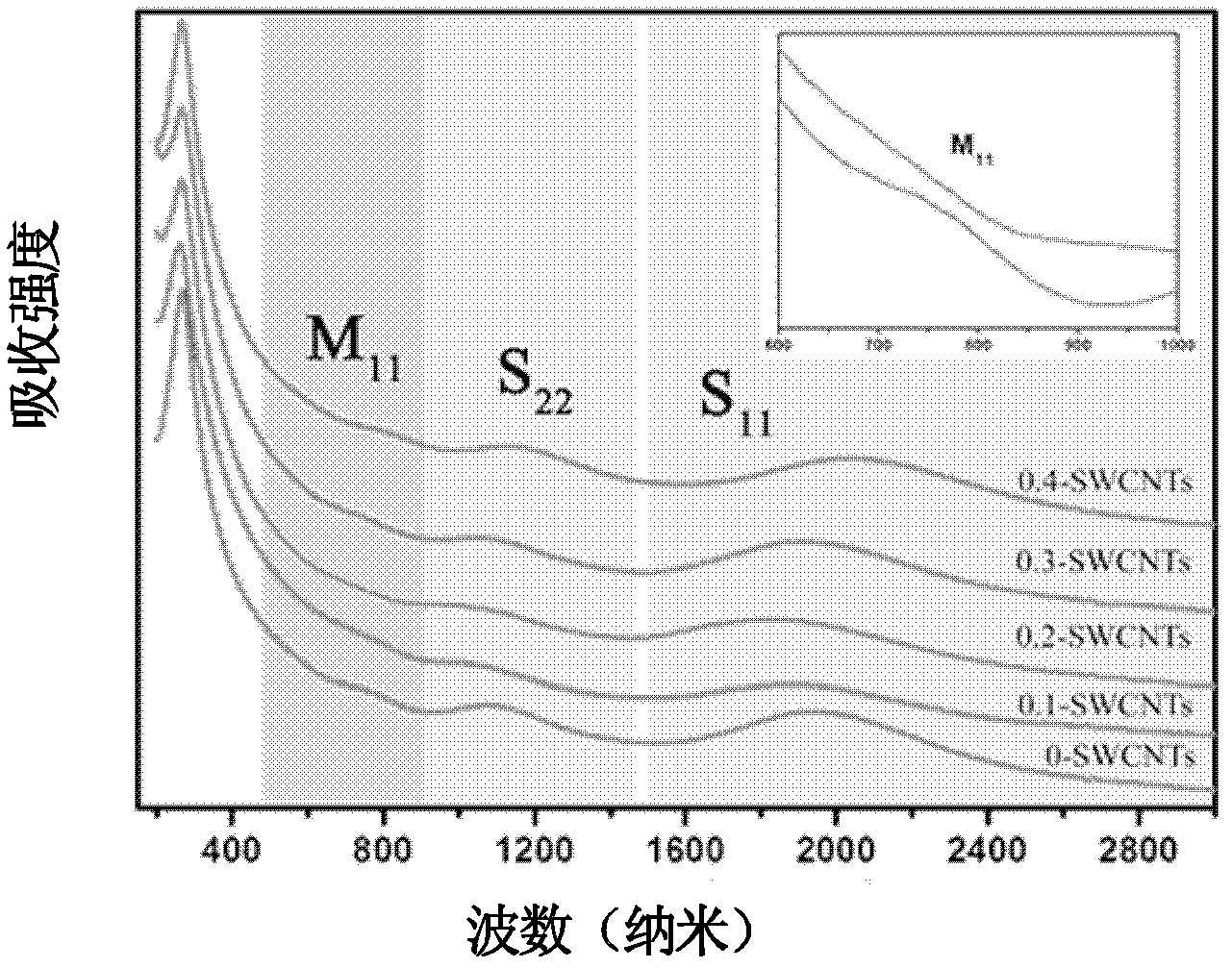

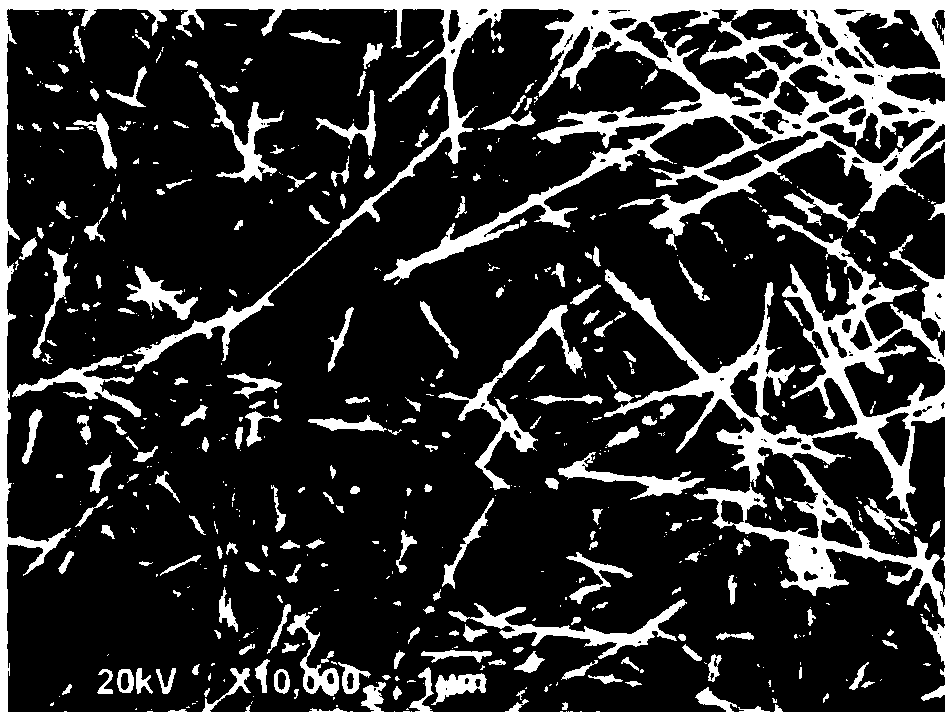

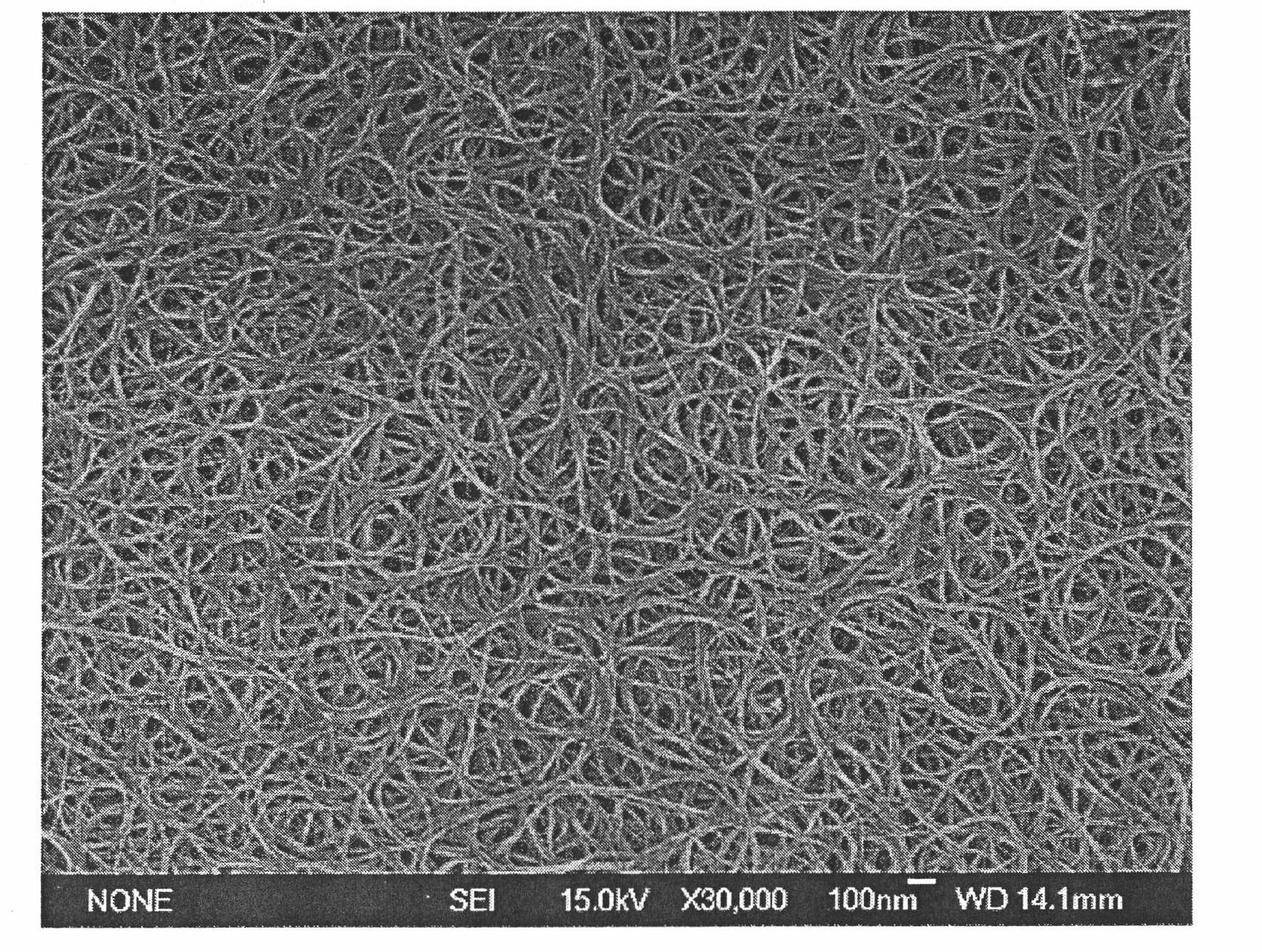

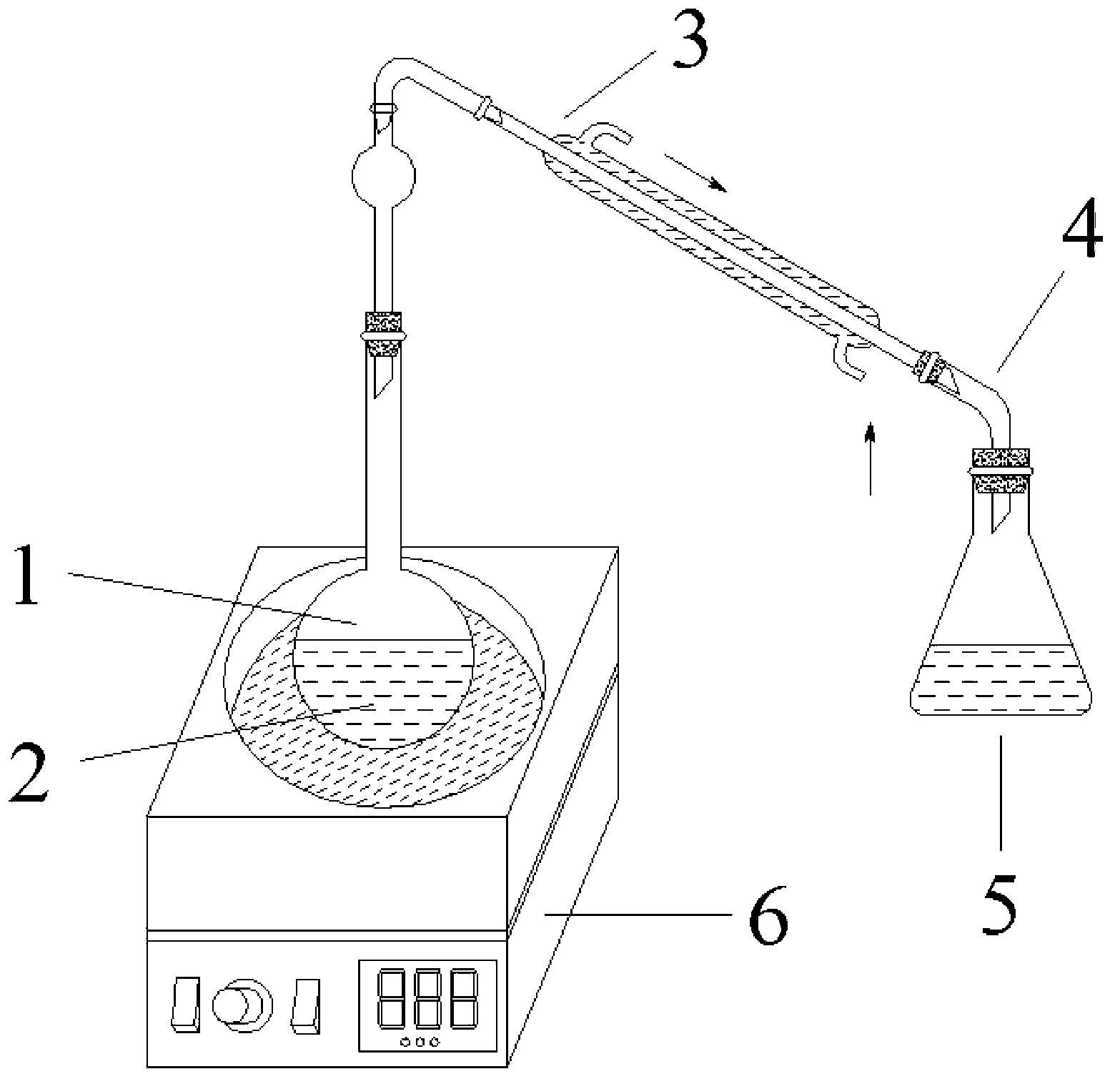

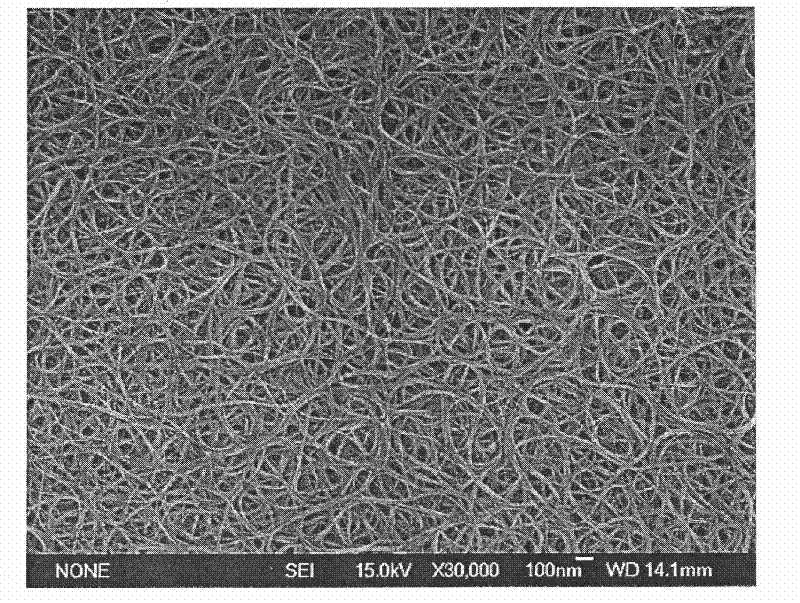

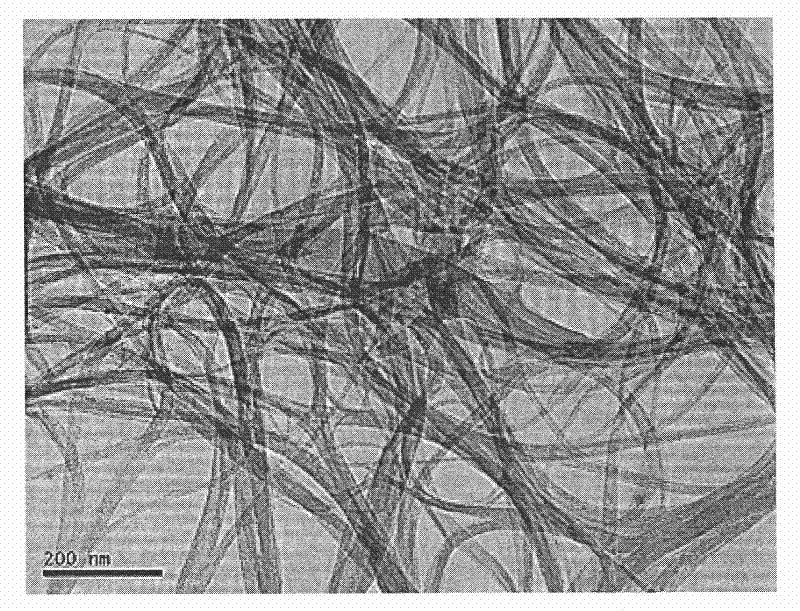

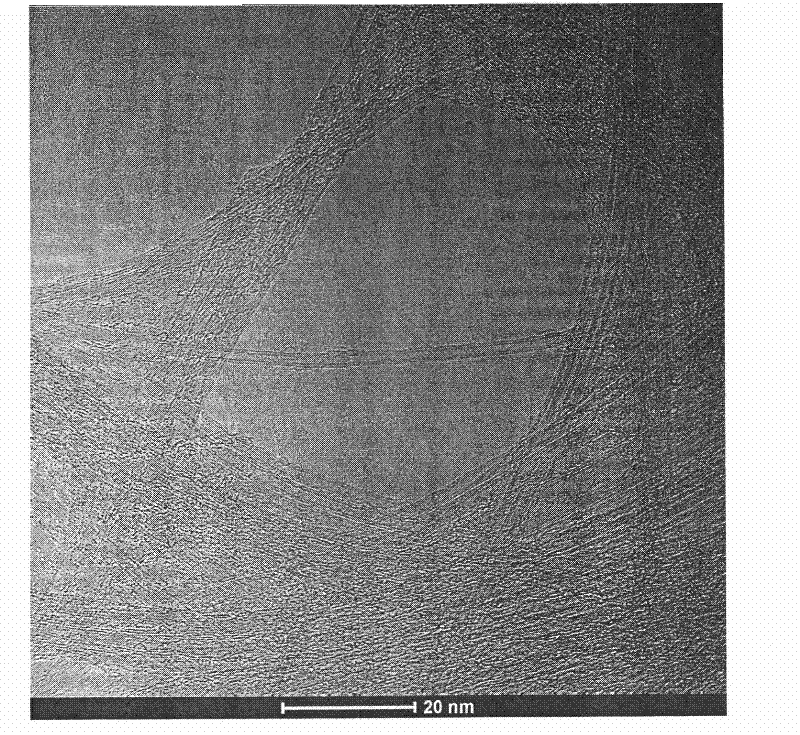

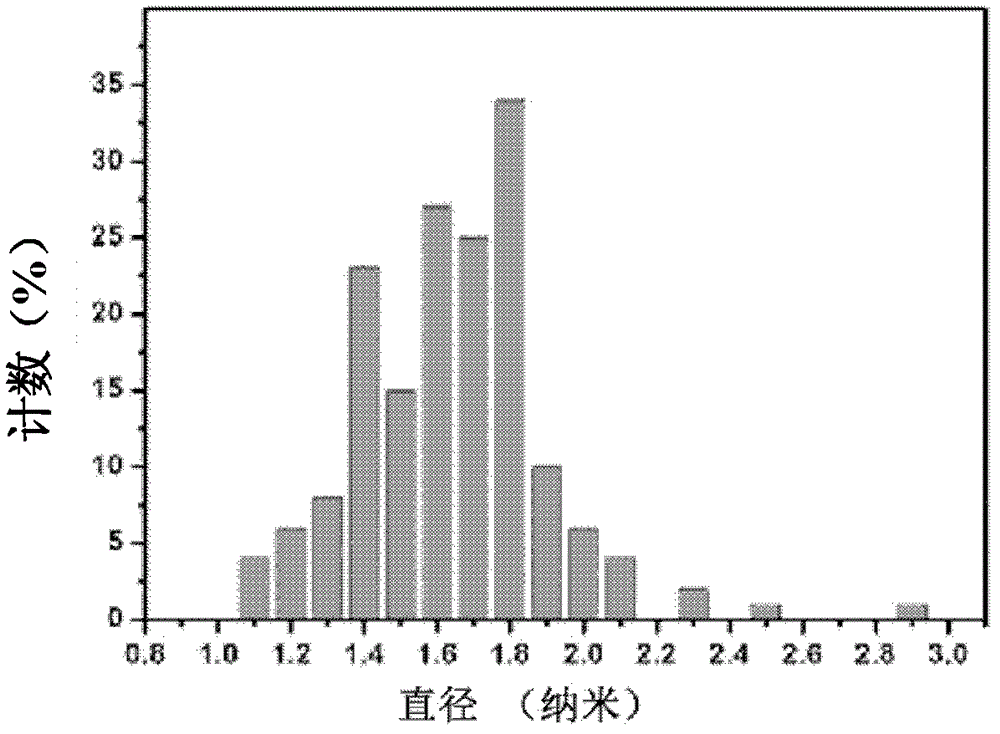

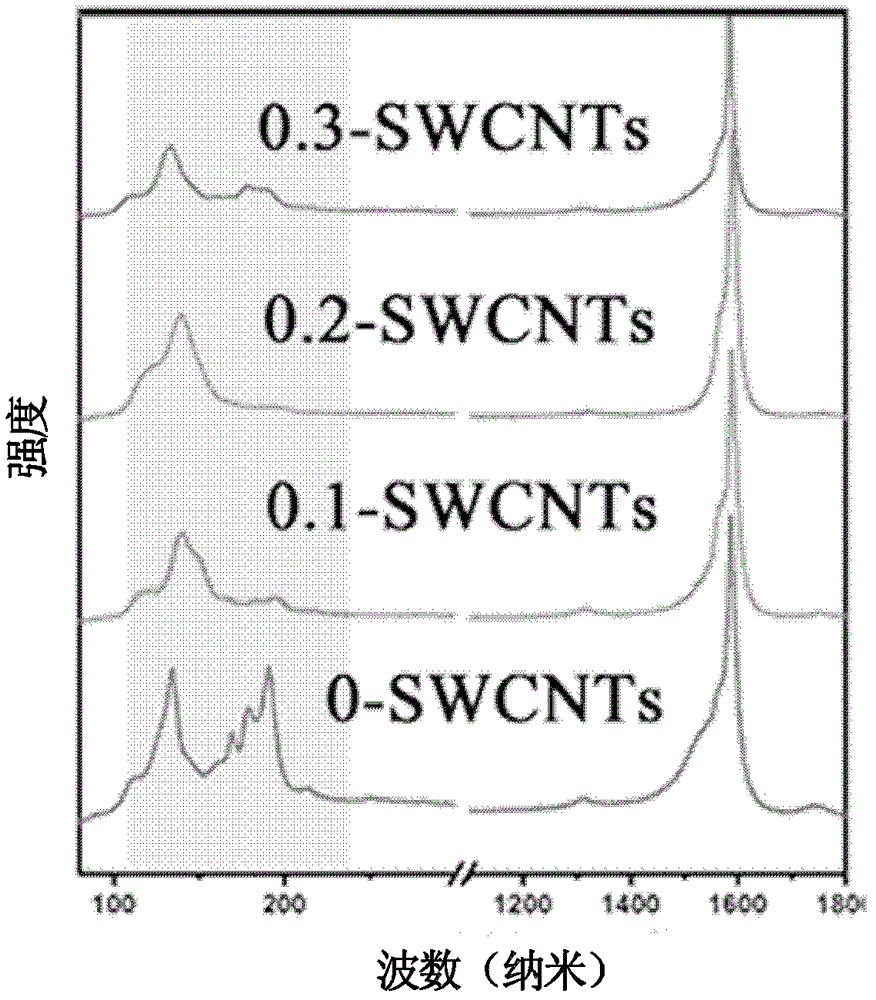

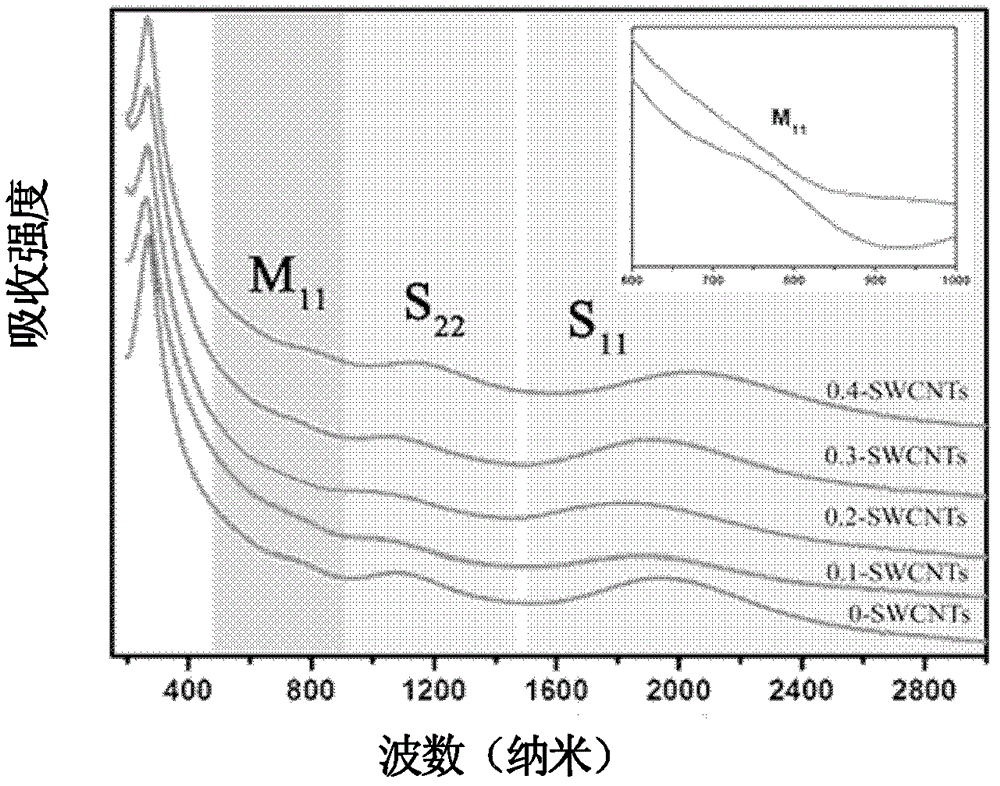

Method for directly growing semiconductor type single-walled carbon nanotube with floating catalyst and auxiliary oxygen

The invention relates to massive and controllable preparation field of semiconductor type single-walled carbon nanotubes, specifically to a method for directly growing the semiconductor type single-walled carbon nanotube with floating catalyst and auxiliary oxygen. The method comprises the following steps of: taking ferrocene as precursor of the catalyst, taking right amount of sulphur powder as growth promoter, and taking hydrogen as a carrier gas; simultaneously introducing a carbon source gas and small amount of oxygen to grow the single-walled carbon nanotube, and etching the small-diameter and metallic single-walled carbon nanotube in situ; and finally, obtaining a sample in which the semiconductor type single-walled carbon nanotube is dominant, wherein content of the semiconductor type single-walled carbon nanotube is 90 wt%, and diameter distribution of the semiconductor type single-walled carbon nanotube is 1.4-1.8 nm. With the method, massive and directly controlled growth ofthe semiconductor type single-walled carbon nanotube with narrower diameter distribution is realized; and the method solves the problems, such as that the separation process of the existing chemical and physical methods seriously damages the intrinsic structure of the single-walled carbon nanotube and the process is complex, and sample amount is less, diameter distribution is wider and the diameter is smaller in the direct preparation technology, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Horizontal disc rotating centrifugal spinning method

InactiveCN102373513ANarrow diameter distributionGreat practicabilityFilament/thread formingApparent SizeFiber

The invention provides a horizontal disc rotating centrifugal spinning method. The method is characterized in that spinning raw materials are spread on the surface of a rotary disc under the centrifugal action of the rotary disc in the molten state and then the melt films become thin gradually, thus causing film rupture, and the melt or solution is drawn into filaments through adhesive force and centrifugal action and the filaments are finally condensed to form fibers. The method is suitable to manufacture various inorganic fibers and polymer fibers, is suitable for wide range of spinning raw materials, has strong controllability and high production efficiency and can be used for manufacturing fibers with different physical properties or apparent sizes by only changing the working parameters of the reaction process, without changing the equipment.

Owner:EAST CHINA NORMAL UNIV

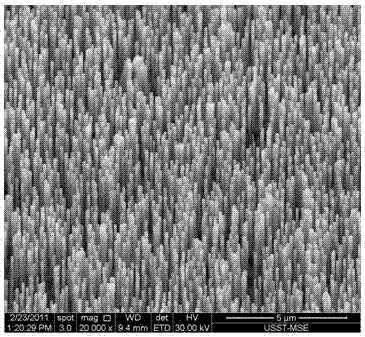

Preparation method of gallium nitride nanowires

InactiveCN104313548AUniform diameterImproved nanowire qualityMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsGalliumGallium nitride

The invention discloses a preparation method of gallium nitride nanowires. The method comprises the steps of loading Ga2O3 and GaN as a mixed gallium source into a small porcelain boat, placing a Si substrate material plated with a catalyst Ni layer or Au layer into a quartz tube, and placing the small porcelain boat into the quartz tube, wherein a distance from the center of the mixed gallium source to the center of the Si substrate material is 10-20cm; then placing the quartz tube into a tube furnace while enabling the small porcelain boat to be aligned with the center of the tube furnace, heating to 1100 DEG C at 30-35 DEG C / min, introducing Ar gas at 20sccm during heating and keeping for 31-37min, stopping introducing the Ar gas, introducing NH3 gas at 15-45sccm and keeping for 15-30min, stopping introducing the NH3 gas and introducing Ar gas again, and cooling naturally to room temperature, wherein faint yellow substances formed on the surface of the Si substrate material are gallium nitride nanowires. The gallium nitride nanowires prepared by the method have high crystal quality, and the preparation process has good controllability.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

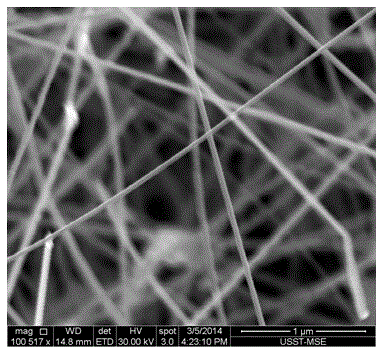

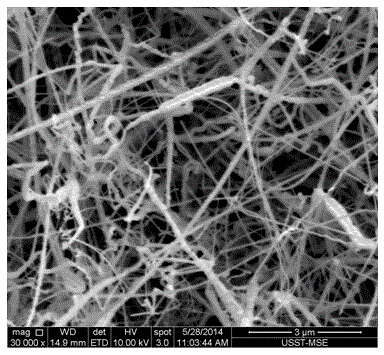

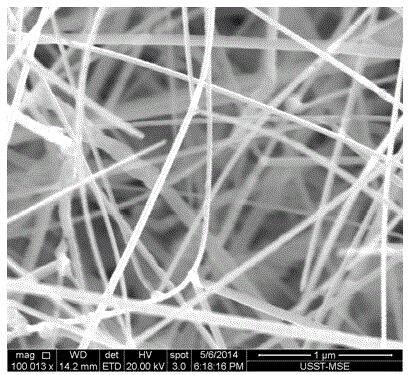

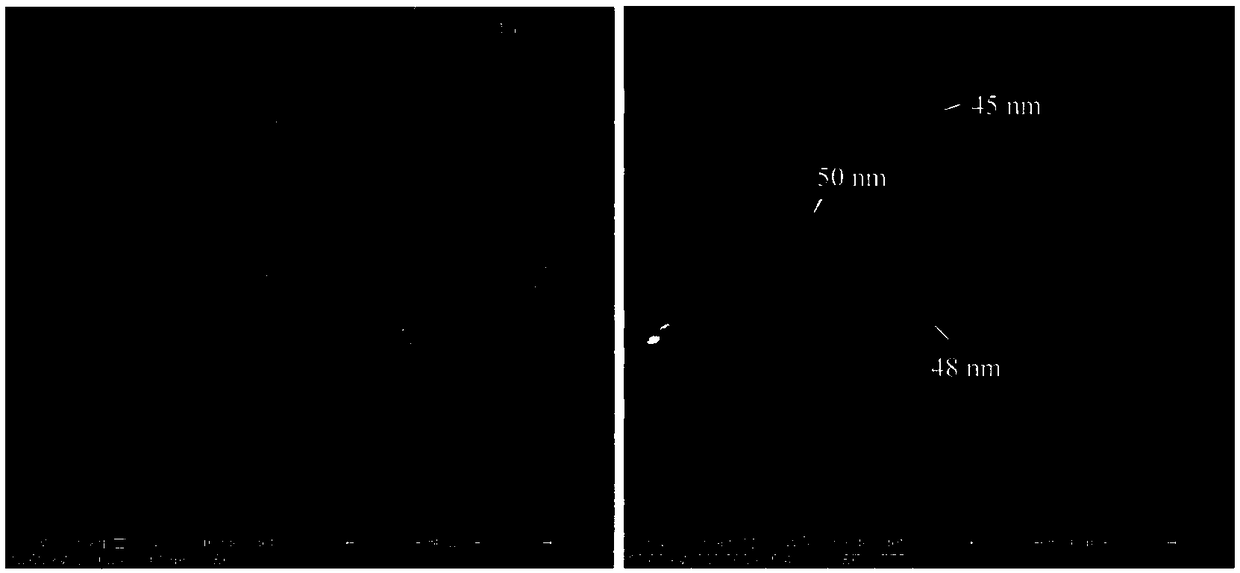

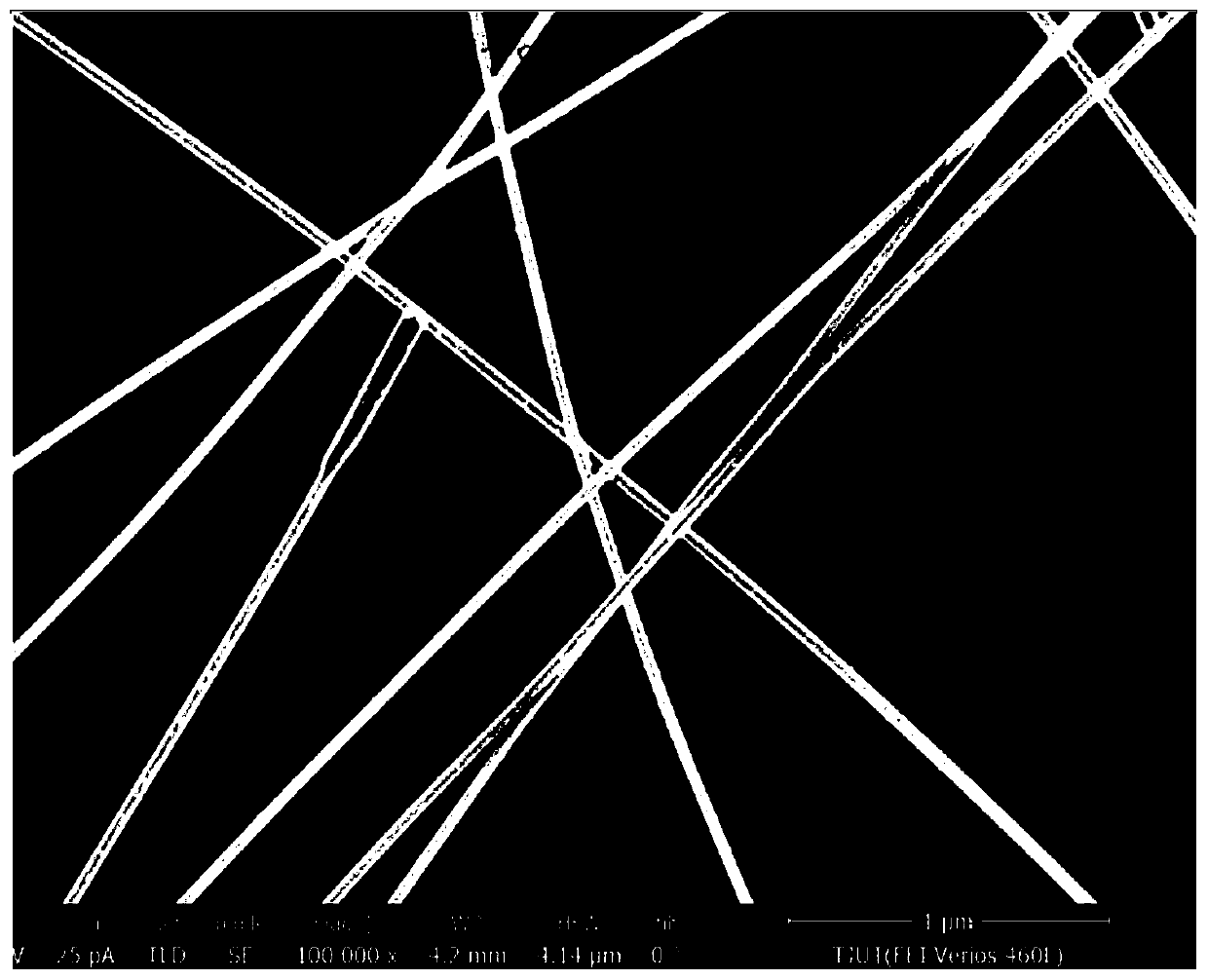

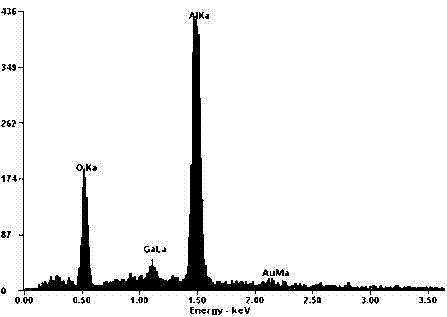

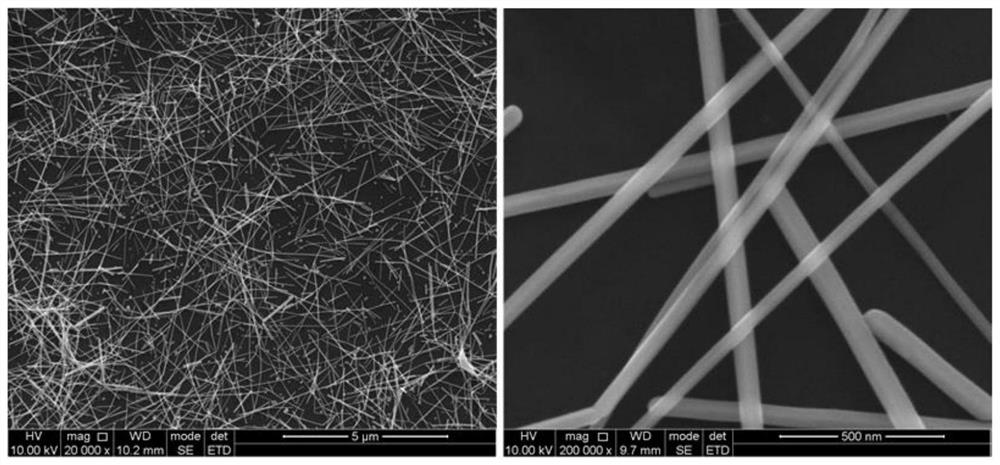

Controllable preparation method of uniformnanosilverwirewith small diameter and ultra-high aspect ratio

ActiveCN109175394ASmall diameterNarrow diameter distributionTransportation and packagingMetal-working apparatusIron saltsBromine

The invention discloses a controllable preparation method of a uniformnanosilverwire with a small diameter and ultra-high aspect ratio. The nano silver wire is prepared by using chlorine salt, brominesalt, and iron salt as co-control agents. The method comprises the following steps that a ethylene glycol solution of polyvinylpyrrolidone (PVP) is prepared first, inductive agents of the chlorine salt, bromine salt, and iron salt are added and uniformly mixed to obtain mixed liquor A; an ethylene glycol solution B of silver nitrate is prepared; the solution B is slowly added into the mixed liquor A and is uniformly mixed; the solution B and the mixed liquor A are positioned in a reaction kettle to reach the temperature of 155-165 DEG C, and the temperature is maintained for 1.5-2.5 hours; the reaction product is subjected to centrifuging and washing after cooling to the room temperature to obtain the nanosilverwire with the small diameter, uniform diameter distribution and ultra-high aspect ratio. Preparation of the nanosilverwireis short in time, operation is simple, and mass production can be achieved. Diameter of the prepared silverwireis 45-50nm, and the aspect ratio is 2000.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

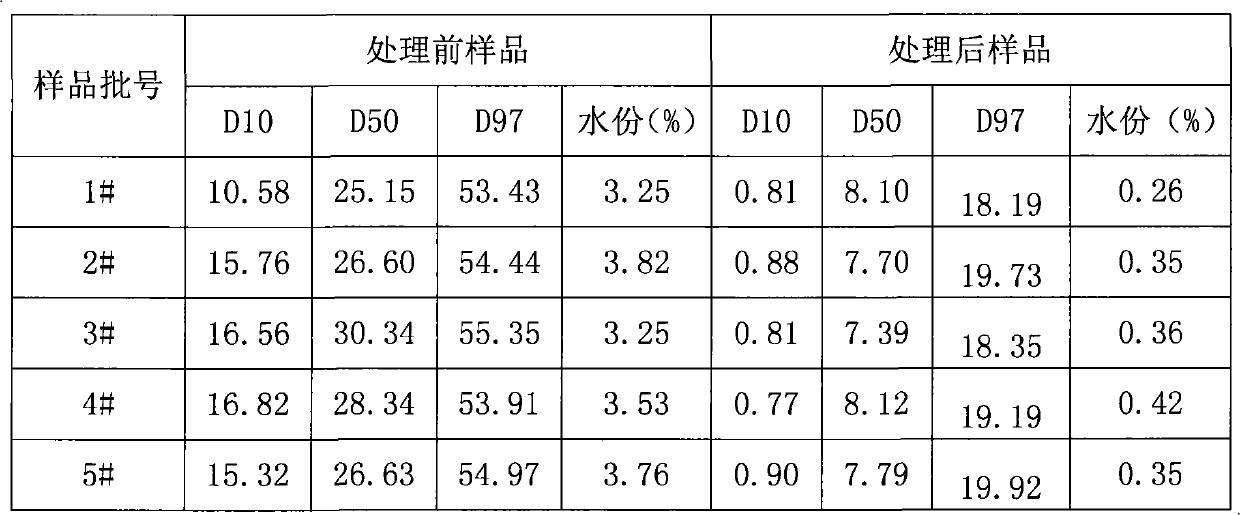

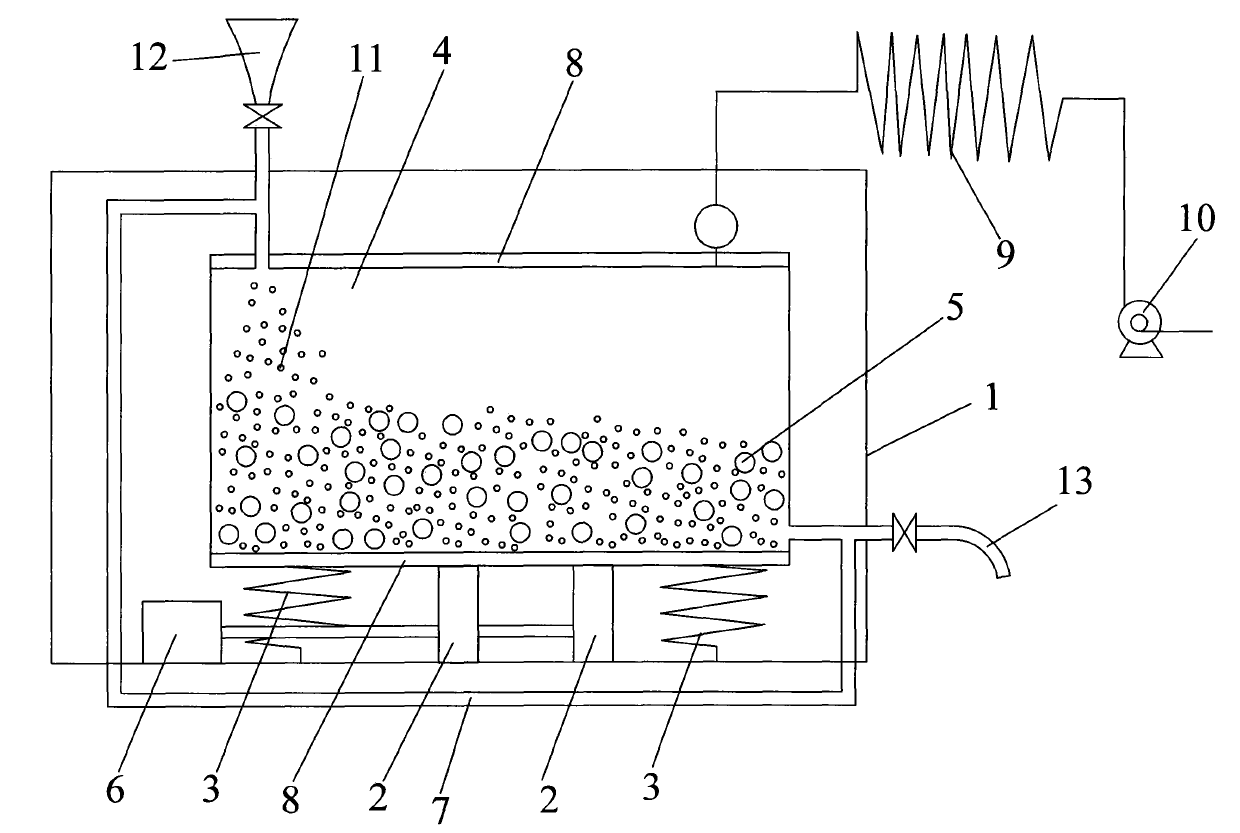

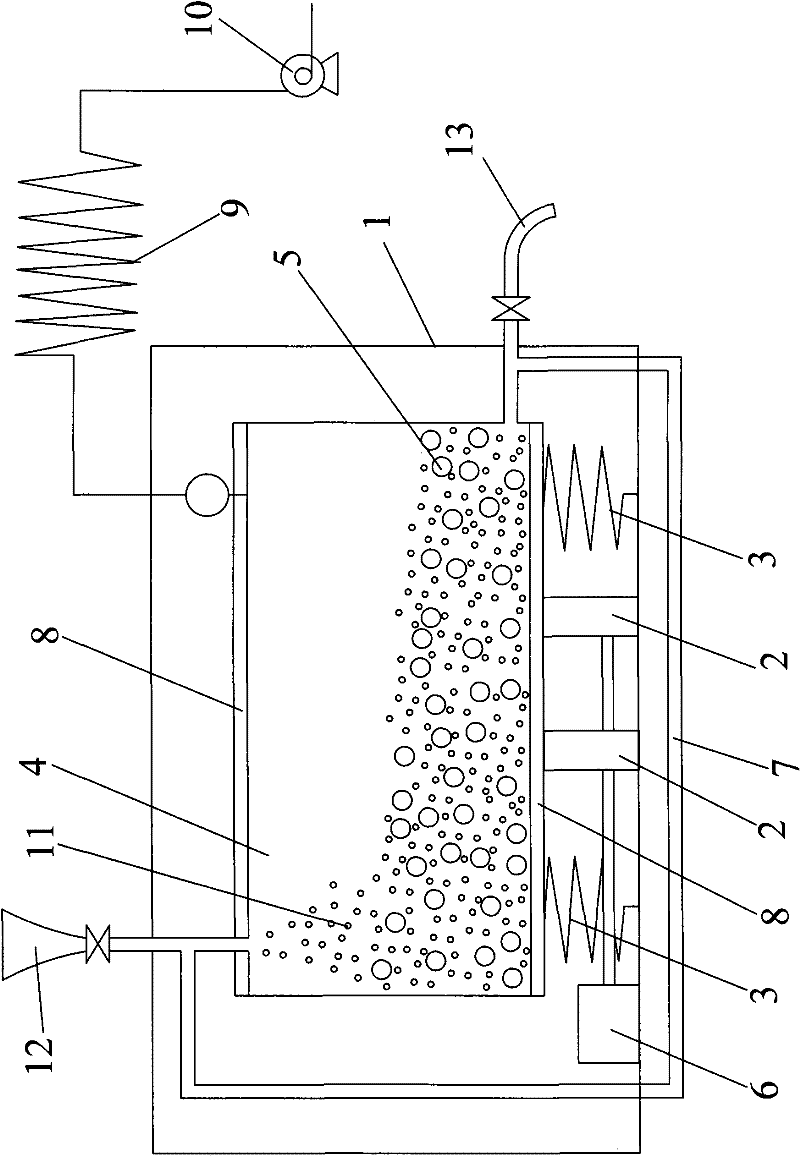

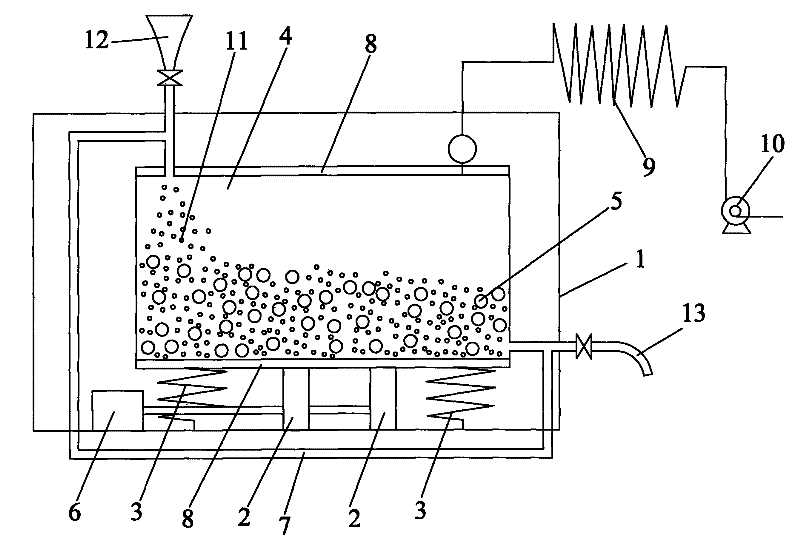

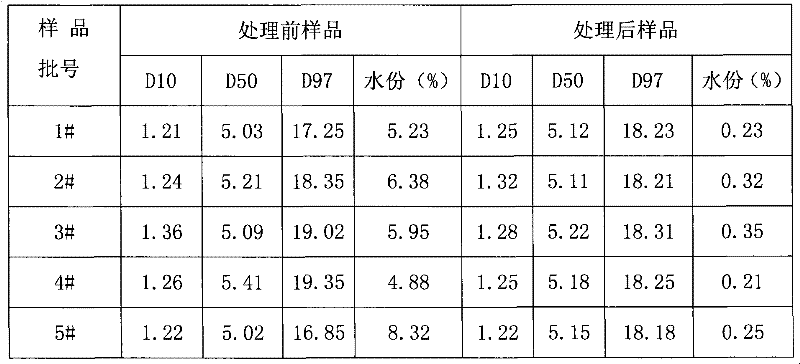

Dispersing, mixing and drying device

InactiveCN101816903AImprove the mixing effectFully dispersedShaking/oscillating/vibrating mixersGrain treatmentsEngineeringVibration exciter

The invention discloses a dispersing, mixing and drying device, comprising a stand, a vibration exciter mounted on a base of the stand, an electric motor driving the vibration exciter to operate, and a grinding barrel located inside the stand and mounted on the base of the stand via a vibration reduction spring. The grinding barrel is filled with grinding medium therein, the vibration exciter acts on the grinding barrel, the grinding barrel can be vacuumized or be used for heating and cooling the medium therein via a jacket arranged at the periphery of the grinding barrel. The materials at a discharging hole can be circularly fed into a feeding hole repeatedly via a material pipeline to be mixed and dispersed. The invention can enable the materials to be evenly dispersed and dried within a short time so that a desired crushing result is achieved.

Owner:赛福能源科技(徐州)有限公司

Method for obtaining large number of semi-conductive single-wall carbon nanometer tubes

InactiveCN102431989AEasy to scaleGood prospects for industrial applicationAir atmosphereCarbon nanotube

The invention relates to the field of single-wall carbon nanometer tubes, in particular to a method for obtaining a large number of semi-conductive single-wall carbon nanometer tubes through combining post treatment oxidation with chemical gas-phase deposition in-situ weak oxidation. Trace oxygen is introduced in the process of chemical gas-phase deposition growth of the singe-wall carbon nanometer tubes, and then, the prepared single-wall carbon nanometer tubes are oxidized in the air at the proper temperature. Ferrocene is used as a catalysis precursor, hydrogen is used as carrying gas, sulfur powder is used as growth promoters, carbon source gas and trace oxygen are simultaneously introduced at a certain temperature for carrying out the growth and in-situ weak oxidation of single-wall carbon nanometer tubes, the obtained single-wall carbon nanometer tube samples are oxidized for a long time in the air atmosphere at the low temperature, and the oxidized samples are soaked into hydrochloric acid solution to remove catalyst particles, are cleaned and dried. The method realizes the mass preparation of the single conductive (semi-conductive) single-wall carbon nanometer tubes and solves the problems that the damage to the intrinsic structure of the single-wall carbon nanometer tubes in the existing chemical and physical method separation process is serious, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

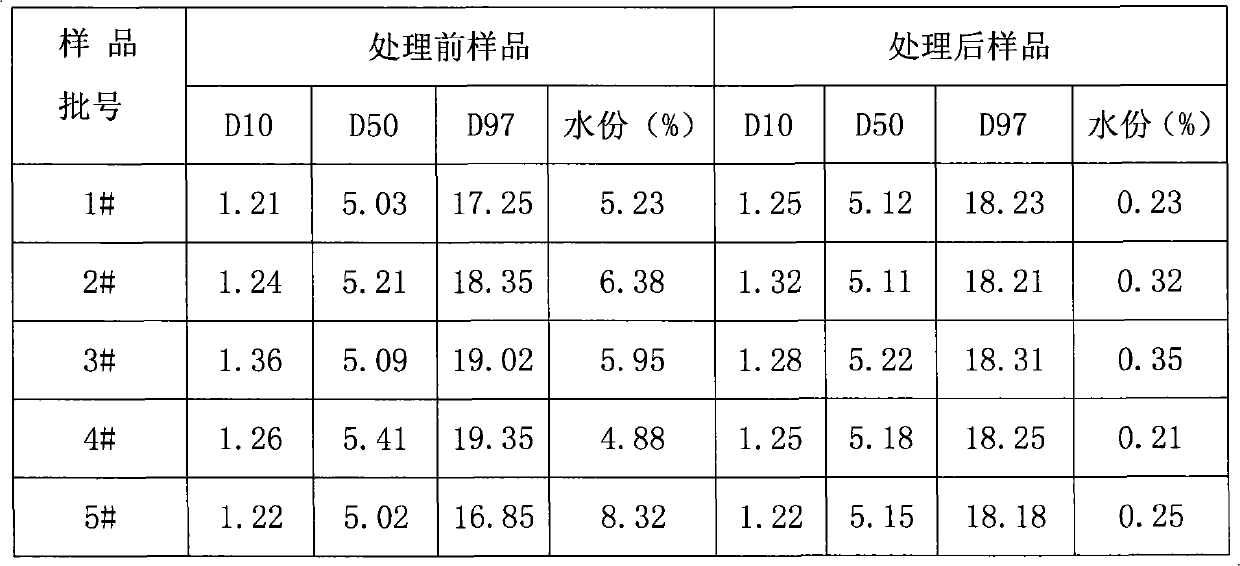

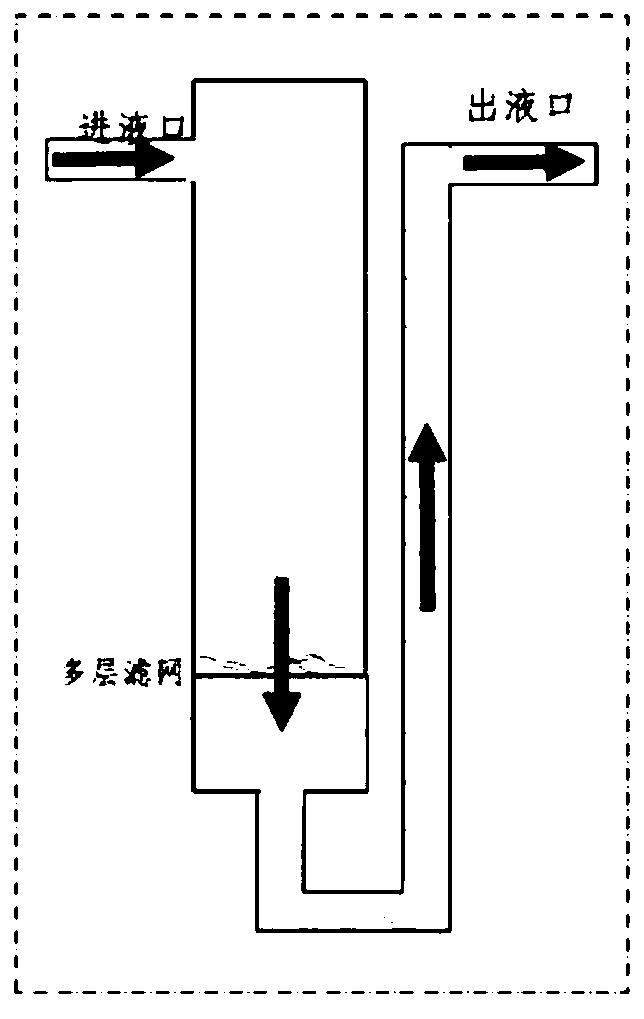

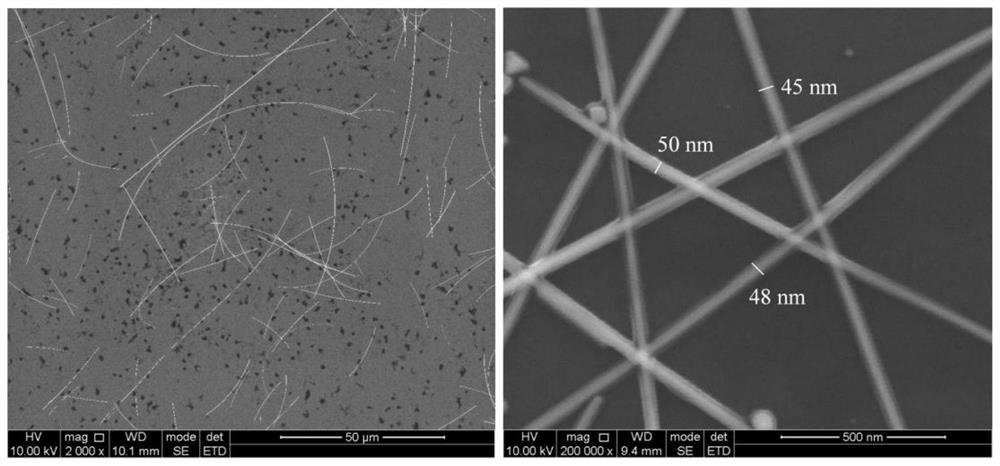

High-purity silver nanowire and preparation method thereof, and silver nanowire conductive film

PendingCN111014719AReduce pollutionEasy separationMaterial nanotechnologyTransportation and packagingThin membraneLight transmission

The invention discloses a preparation method of a high-purity silver nanowire. The method comprises steps of step 1, preparing silver nanowire synthetic liquid; 2, uniformly stirring the obtained silver nanowire synthetic liquid and solvent, and centrifuging to obtain silver nanowire precipitate; and 3, uniformly stirring the obtained silver nanowire precipitate and the dispersion solution, and separating and purifying through a multi-stage filtering device to obtain the silver nanowire. The method is advantaged in that high-speed centrifugation and step-by-step filtration are combined, the separation process is simple, efficient, safe and environmentally friendly, the silver nanowires obtained through separation are high in purity, narrow in diameter distribution range, good in dispersityand not prone to agglomeration, and a coated silver nanowire conductive film has advantages of high light transmittance, low haze, low sheet resistance and the like.

Owner:海泰纳鑫科技(成都)有限公司

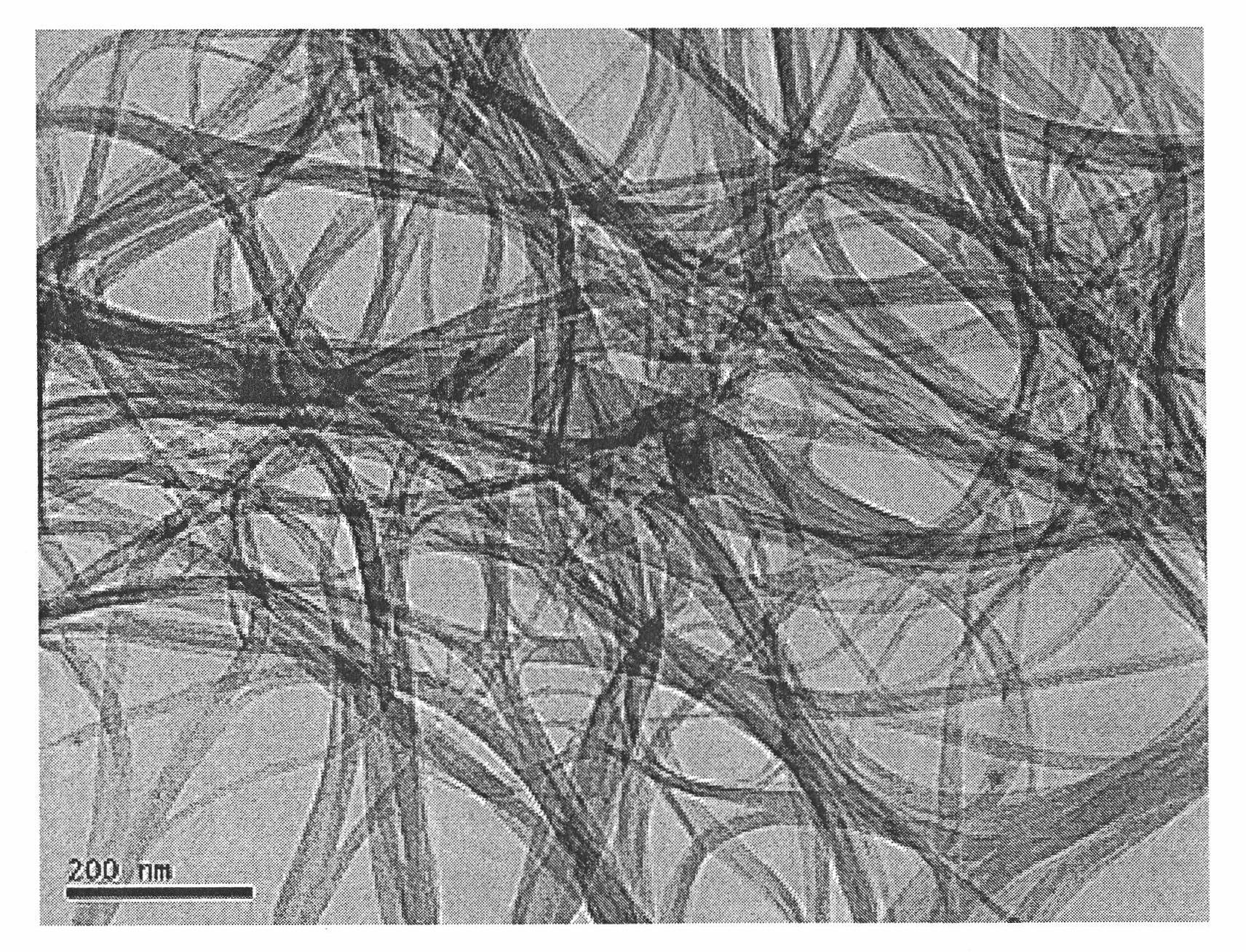

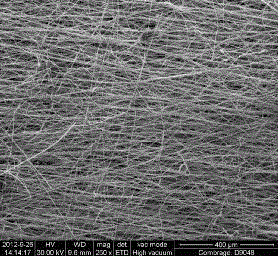

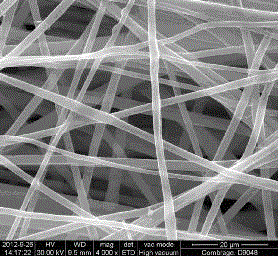

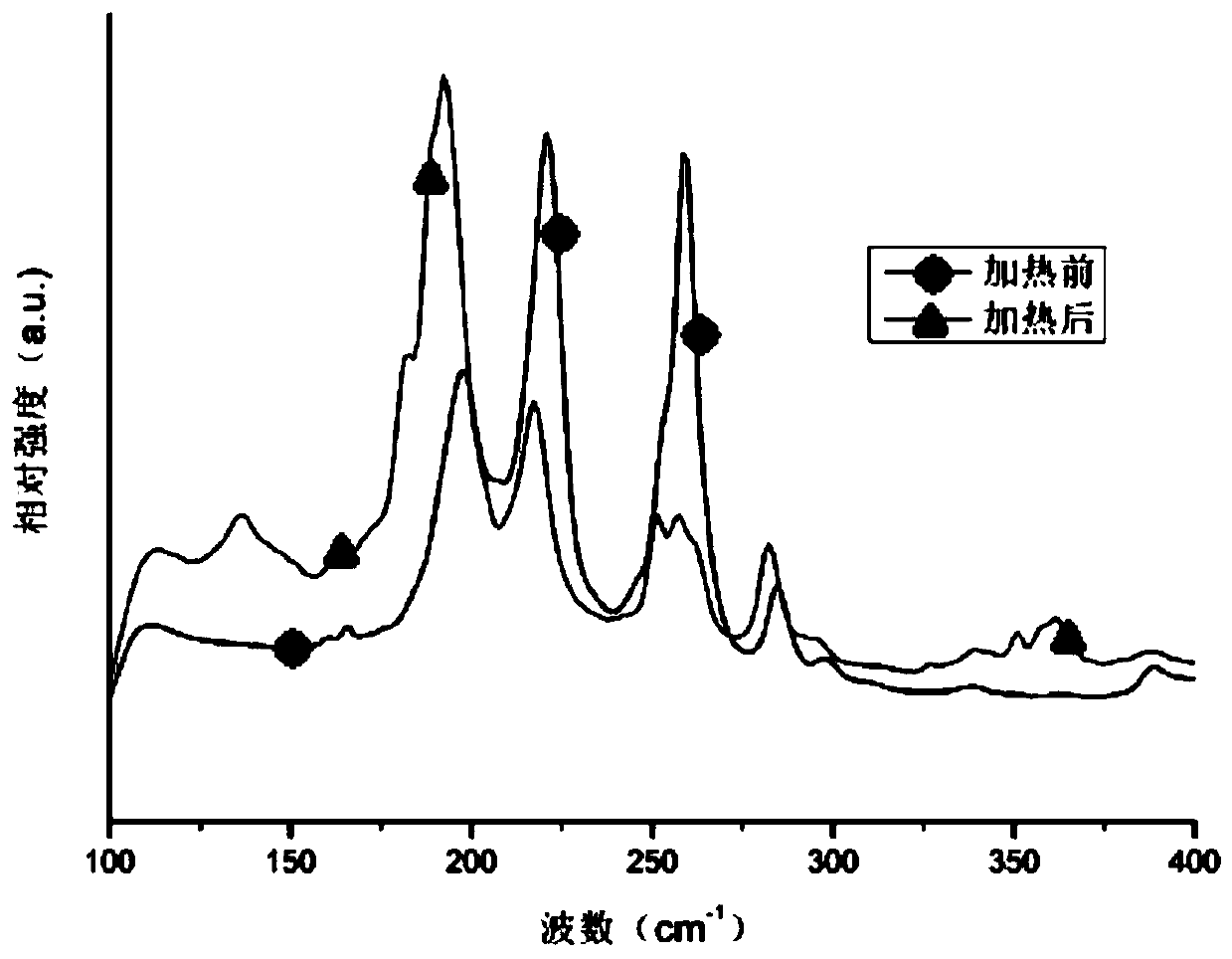

Preparation method of high-crystallinity double-walled carbon nano tube

The invention relates to a preparation method of a high-crystallinity double-walled carbon nano tube, belonging to the technical field of preparation processes of carbon nano tube materials. The preparation method is characterized in that the carbon nano tube is prepared by adopting an anodic carbon electrode bar containing an iron catalyst and realizing the arc discharge between a negative electrode and a positive electrode by using an arc discharging method under a discharging atmosphere of hydrogen or mixed gas of hydrogen and argon, and meanwhile, the double-walled carbon nano tube is purified under the high-temperature treatment of hydrogen and air so as to finally obtain the double-walled carbon nano tube with purity above 90 percent. The prepared double-walled carbon nano tube has the advantages of high crystallinity, narrow caliber distribution, small average diameter and high purity.

Owner:SHANGHAI UNIV

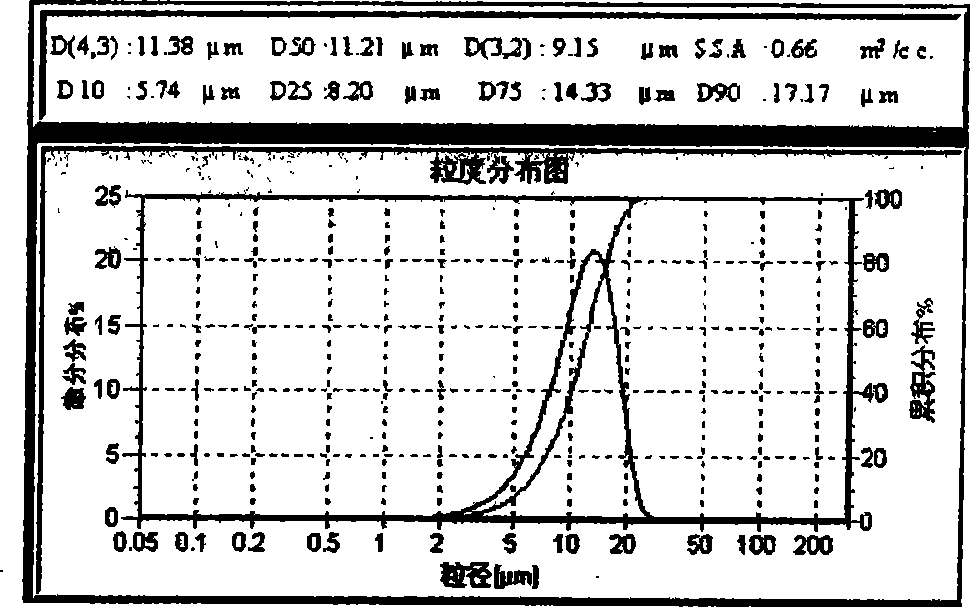

Preparation method of composite microspheres

InactiveCN102796219AIncreased rate of induced decompositionIncrease growth rateMicrospherePerylene derivatives

The invention relates to a preparation method of composite microspheres, in particular to the preparation method of the composite microspheres which are obtained by using acrylamide as well as acrylic acids and derivatives thereof as monomers and carrying on multivariate copolymerization on the monomers by a distillation precipitation method. The preparation method of the composite microspheres, provided by the invention, can be widely used for the biological medical, medical immunology and cosmetic manufacturing fields, in particular the tertiary oil recovery field, and can be used for profile control and oil flooding of low-permeability reservoirs. Polymer microspheres are prepared by using the distillation precipitation method, an improvement is made on the basis of the precipitation method and stirring is replaced with distillation; and the preparation method comprises the following steps of: in a distilled state, copolymerizing a mixture of one or more of the acrylamide as well as the acrylic acids and the derivatives thereof in a reaction container in the presence of an oil-soluble initiator; after all solvents are distilled, dispersing and washing obtained solid polymer microspheres by ethanol; and centrifuging, drying and grinding the solid polymer microspheres so as to obtain dry microspheres. The preparation method of the composite microspheres, provided by the invention, has the advantages of simple process and convenience in implementation.

Owner:UNIV OF SCI & TECH BEIJING

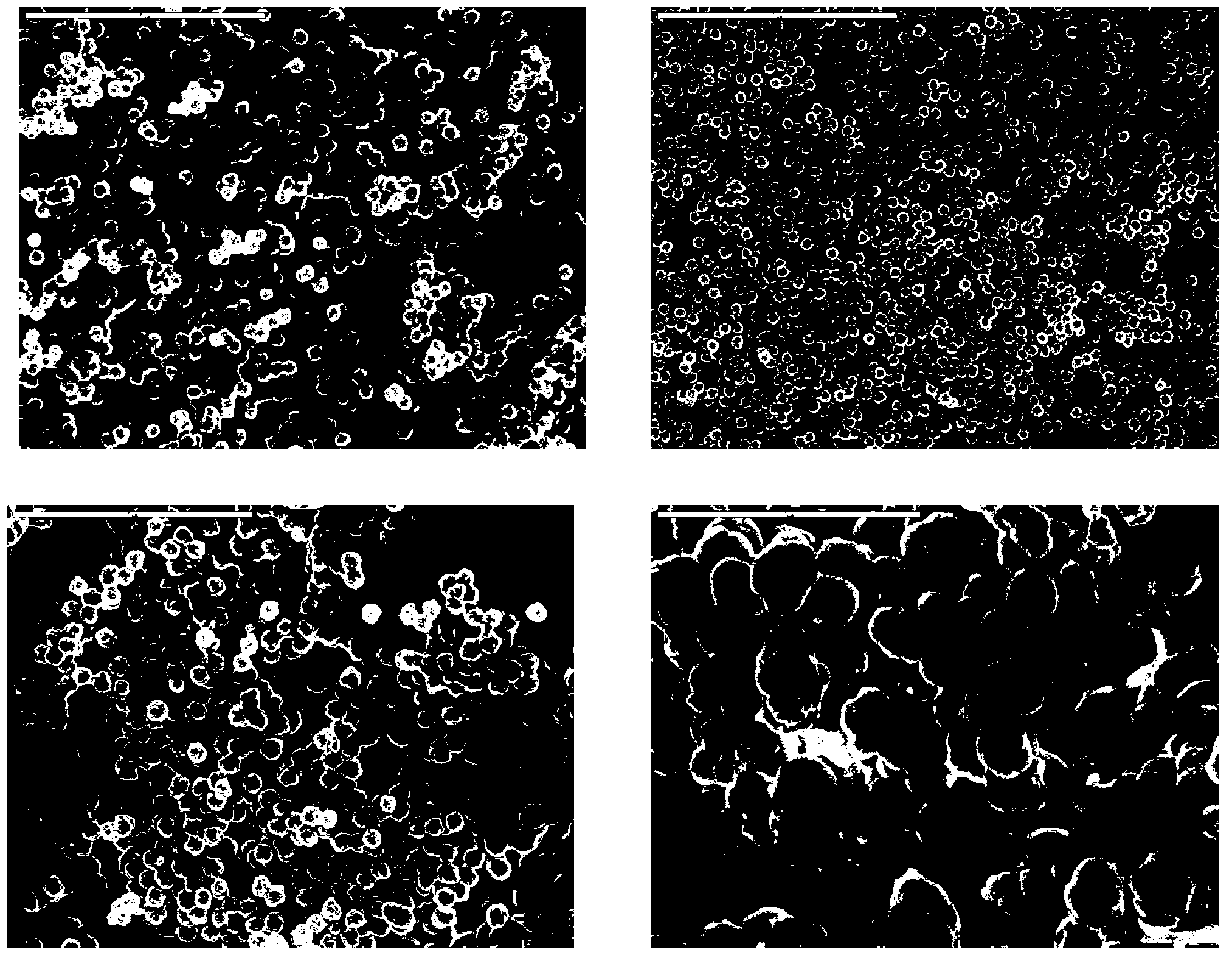

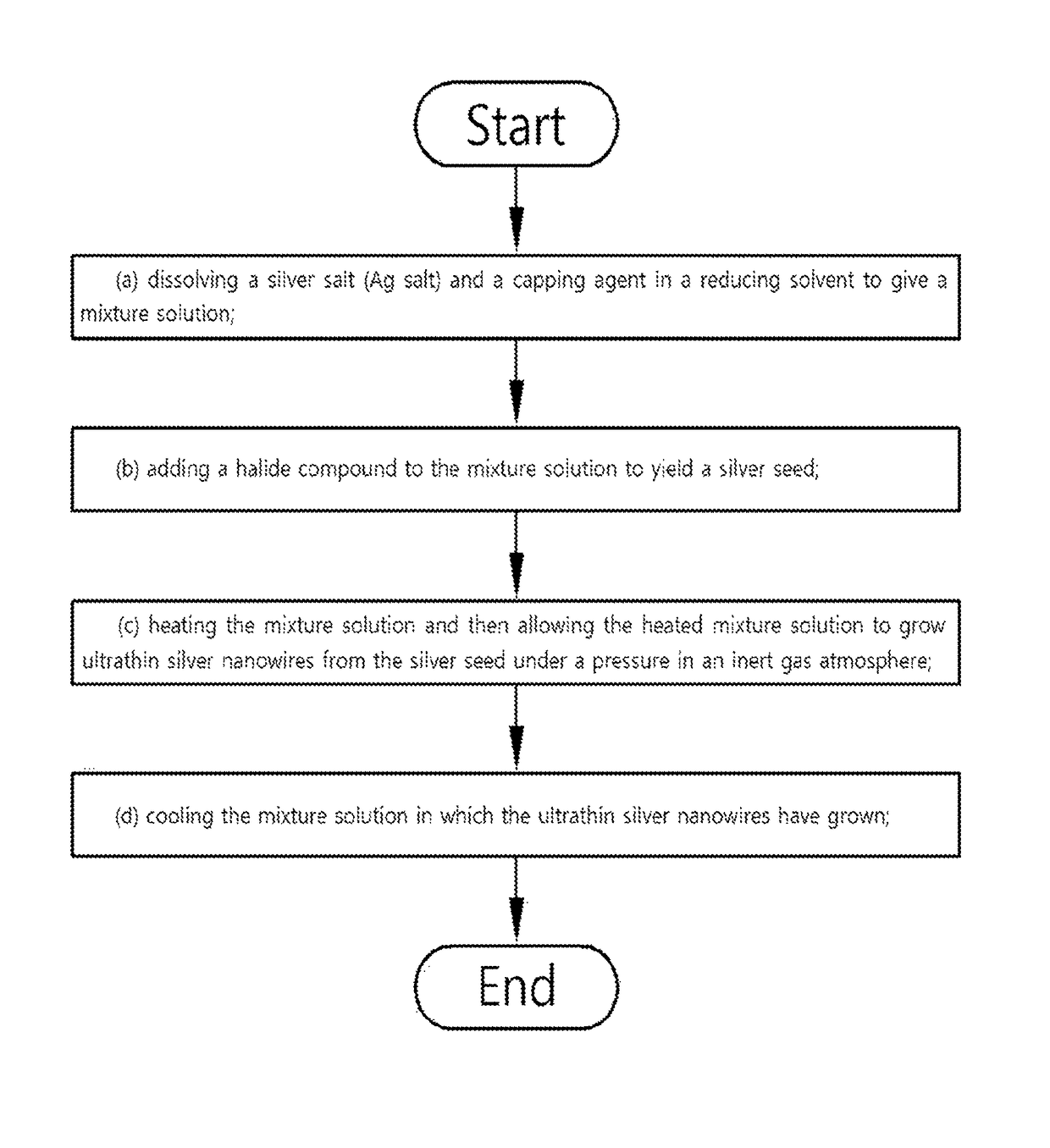

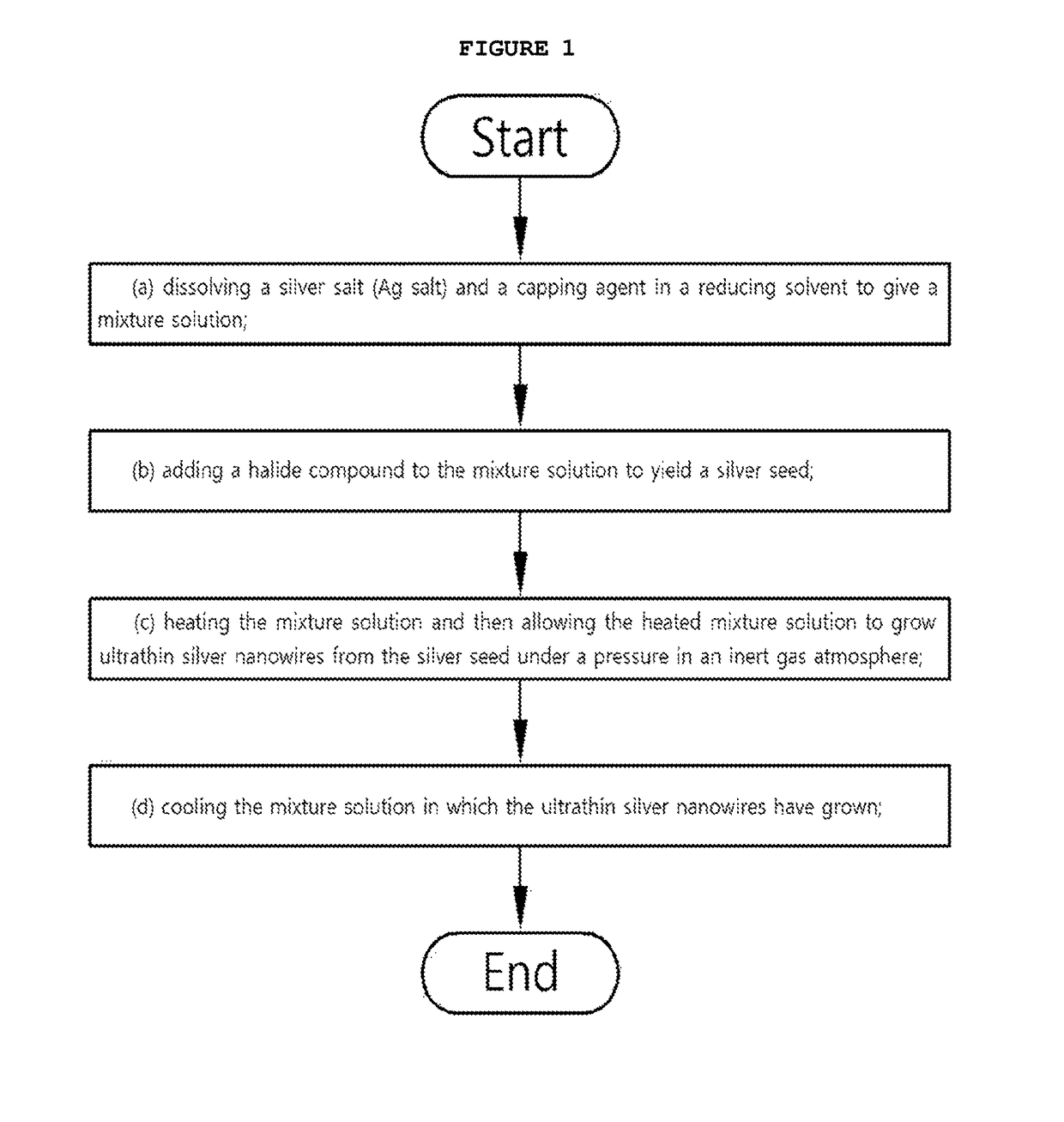

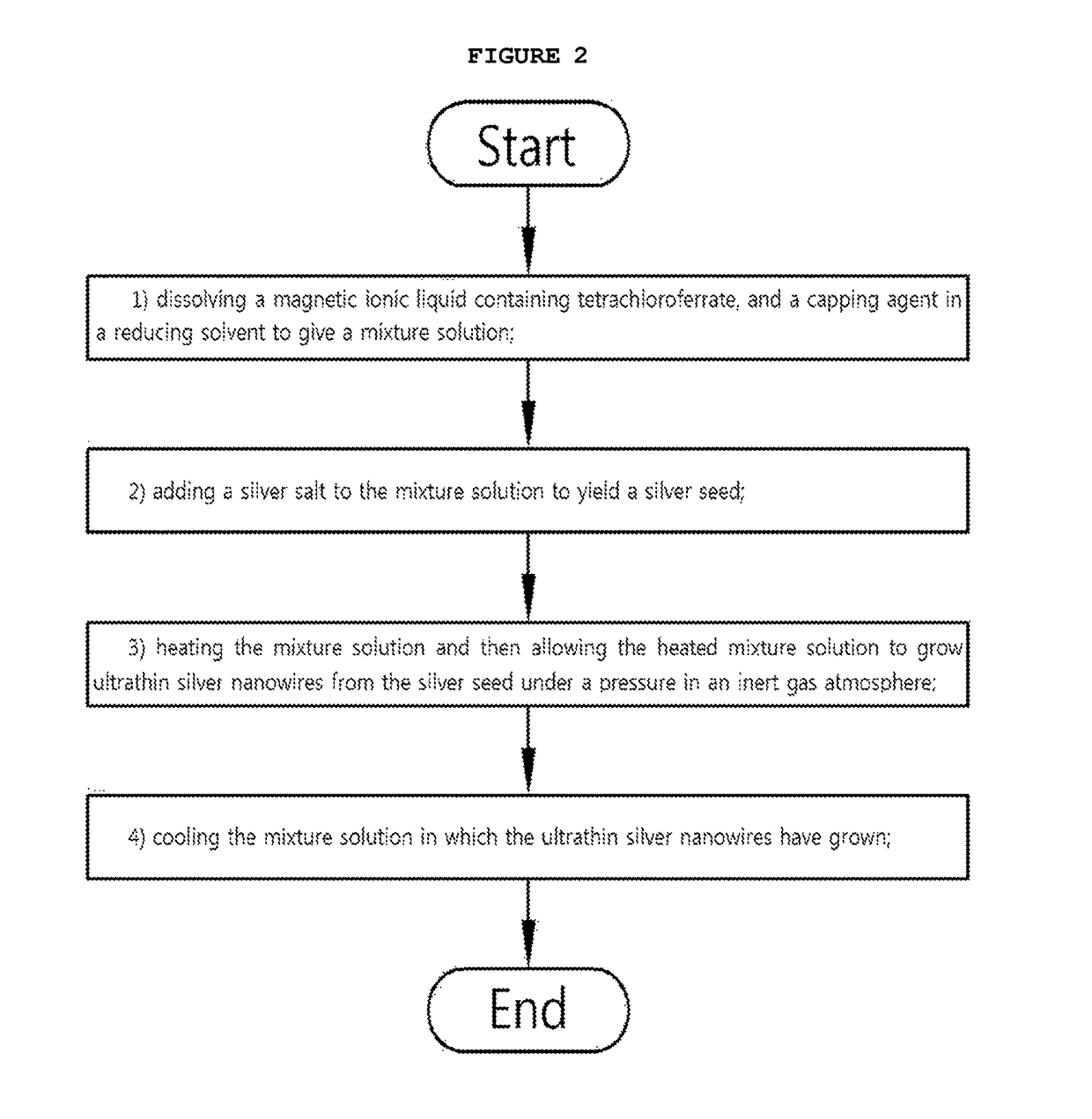

Method for preparing ultrathin silver nanowires, and transparent conductive electrode film product thereof

ActiveUS9908178B2High aspect ratioIncreasing the thicknessTransportation and packagingConductive materialSilver saltsSilver nanowires

Owner:NANOENICS

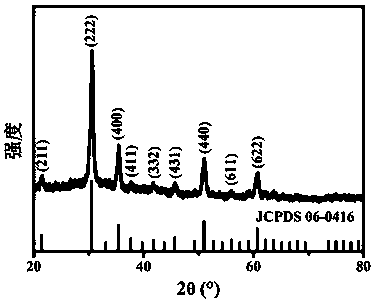

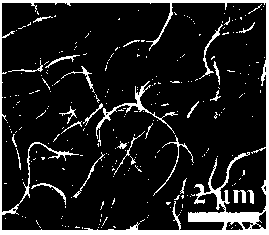

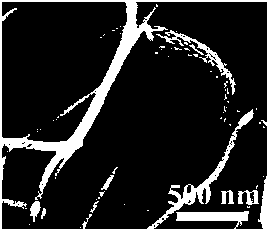

Preparation method of In2O3 particles/In2O3 fiber composite material as well as obtained product

InactiveCN108130628ALow priceEasy to synthesizeInorganic material artificial filamentsElectro-spinningFiberIndium

The invention discloses a preparation method of In2O3 particles / In2O3 fiber composite material as well as the obtained product. The preparation method comprises the following steps: mixing cane sugar,p-phenylenediamine and dimethylformamide, adding ethanol, soluble indium salt and polyvinylpyrrolidone into the obtained mixture, and stirring until transparency to obtain a precursor spinning solution; and performing an electrostatic spinning method on the precursor spinning solution to obtain precursor fiber and performing heat treatment to obtain the final product. A novel precursor spinning solution system is designed, and a cubic ferromanganese ore type In2O3 particle / In2O3 fiber composite material with adjustable size and special appearance is prepared by the electrostatic spinning method. The raw materials are low in price, the synthesis process is simple and convenient, the reaction system is stable, the product is high in appearance repeatability, high in yield and easy in large-scale production, and the obtained product has large application potential in the field of a gas-sensitive material.

Owner:UNIV OF JINAN

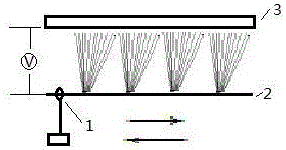

Electrostatic spinning device containing wire electrode and nano-fiber preparation method

InactiveCN106012049AAvoid cloggingImprove production efficiencyElectro-spinningNon-woven fabricsFiberElectricity

The invention provides an electrostatic spinning device containing a wire electrode and a nano-fiber preparation method. The electrostatic spinning device containing wire electrode comprises a feeding system (1), the wire electrode (2) and a receiving system (3), wherein the wire electrode and the receiving system are arranged on two planes which are parallel to each other; the feeding system does transverse reciprocating motion on the wire electrode to refresh an encapsulated polymer solution; the wire electrode, which is horizontally arranged, has high-voltage electrostatic electricity and an electric field is formed between the wire electrode and the receiving system; the receiving system is driven by a conveyor belt to do longitudinal movement; and the polymer solution on the wire electrode is cracked into nano-fibers under the action of the electric field and is deposited on the receiving system to form a nano-fiber membrane. In a traditional electrostatic spinning method, the polymer solution is covered with the electrode and the efficiency of preparing the nano-fibers is very low. In the invention, the electrode is covered with the polymer solution and the preparation efficiency is remarkably improved; and compared with a condition that a traditional needle head electrode is easy to block, the wire electrode avoids a solution blocking problem and the nano-fibers can be continuously machined and prepared.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

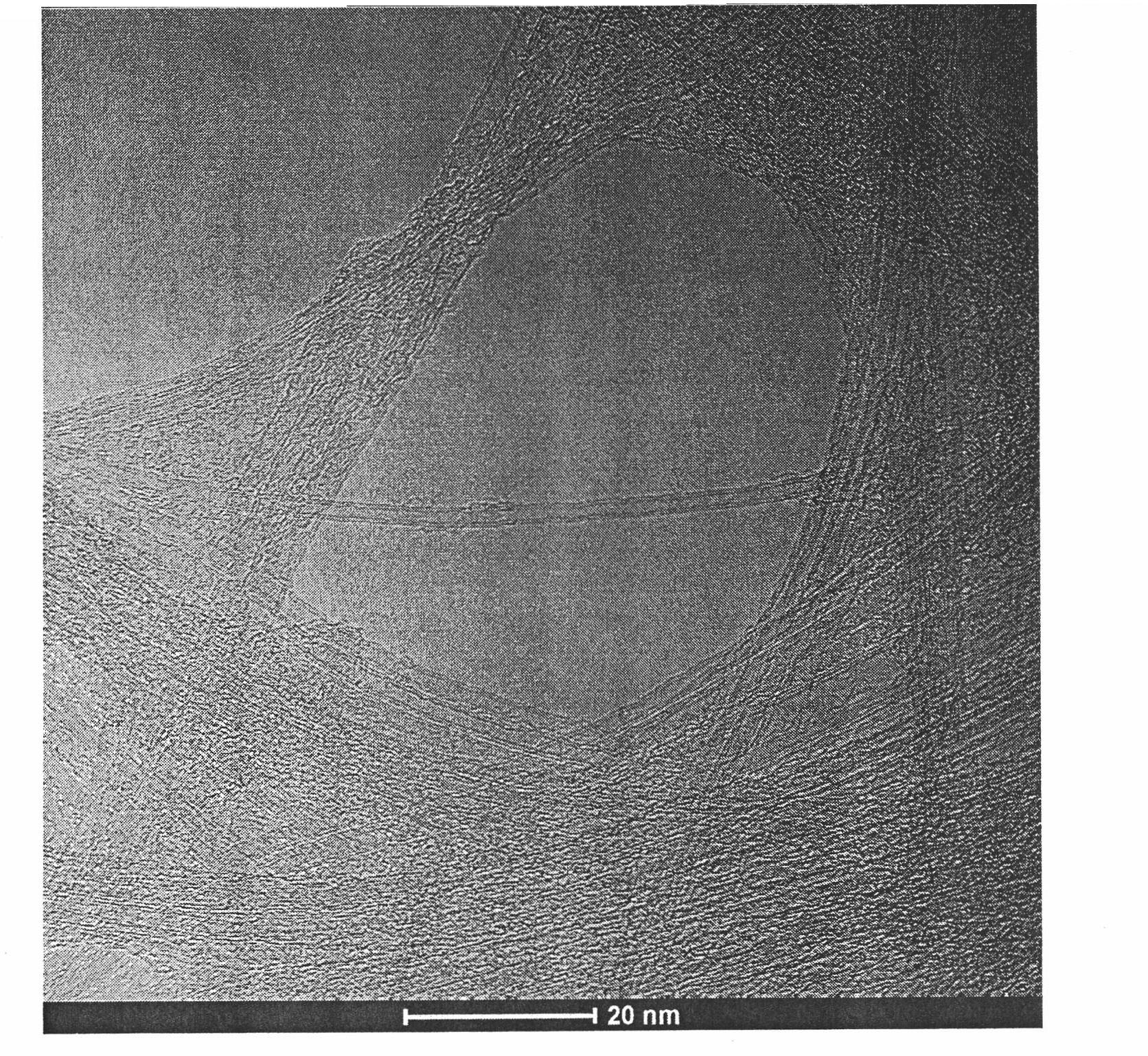

Conversion method for converting single-walled carbon nano tube into double-walled carbon nano tube

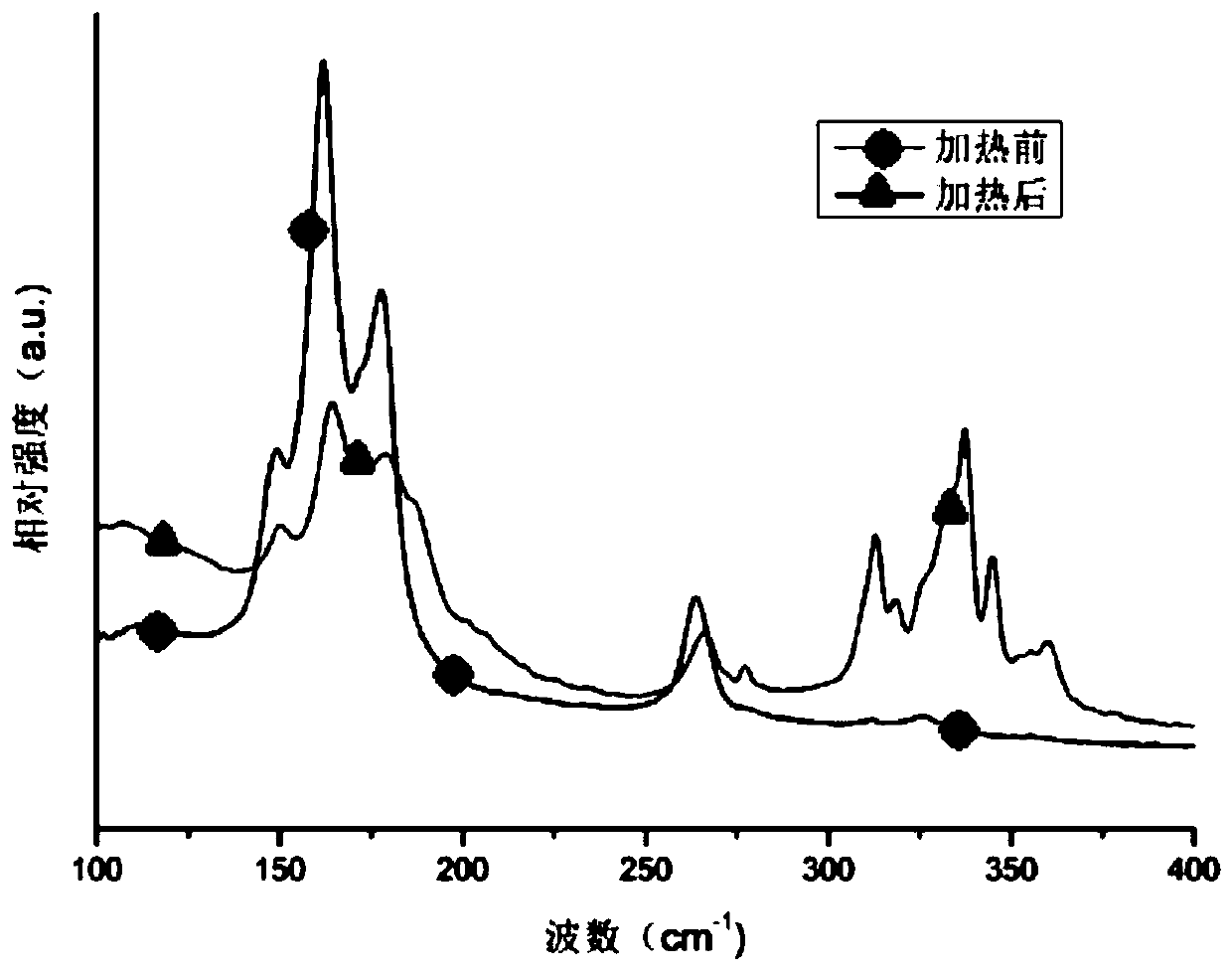

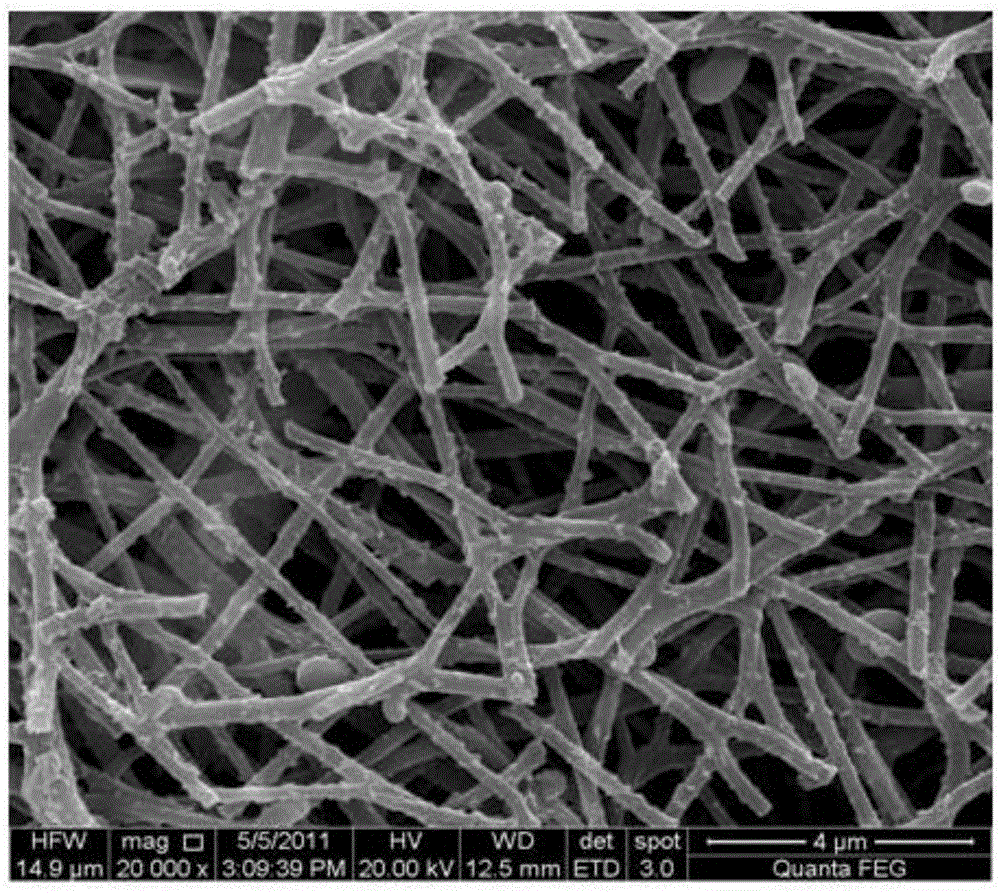

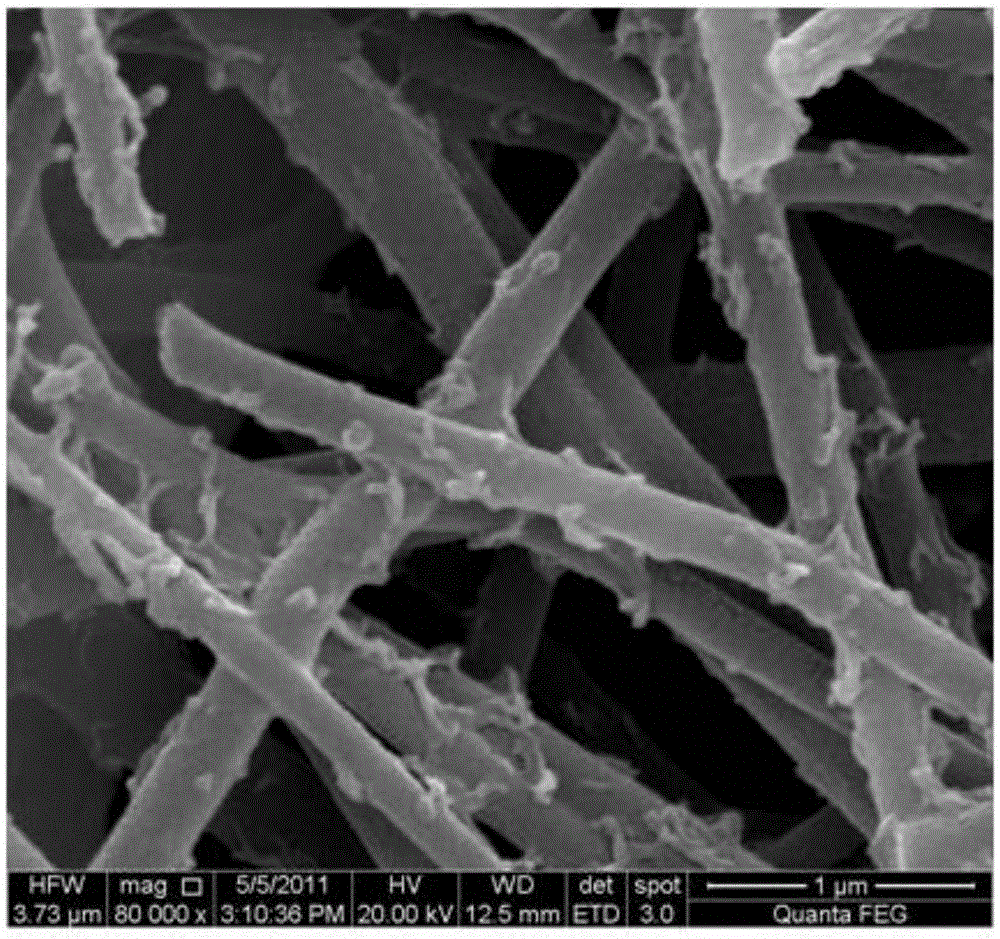

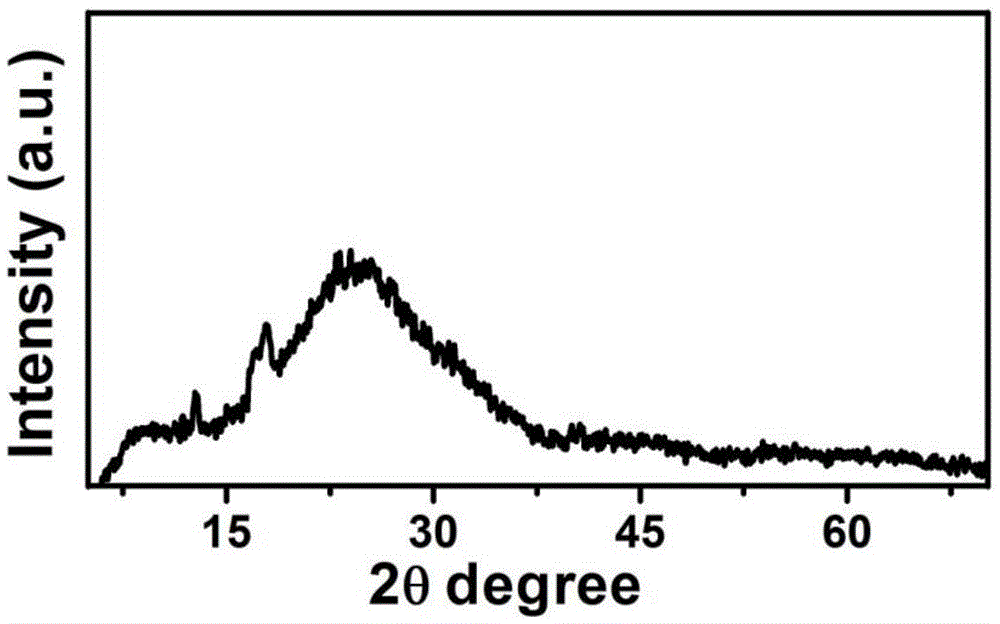

InactiveCN111470489ANarrow diameter distributionIncrease productionCarbon nanotubesNanotubeDouble walled

The invention belongs to the field of carbon nano tube preparation technologies, and particularly relates to a conversion method for converting a single-walled carbon nano tube into a double-walled carbon nano tube. The invention provides a conversion method for converting a single-walled carbon nano tube into a double-walled carbon nano tube. The conversion method comprises the following steps: carrying out a heat treatment: under vacuum or in a protective atmosphere, heating single-walled carbon nano tubes, and cooling the single-walled carbon nano tubes to the room temperature to obtain double-walled carbon nano tubes; wherein the average diameter of the single-walled carbon nano tubes is 1.1 to 1.7 nm. The detection result shows that the prepared double-walled carbon nano tube is narrow in diameter distribution; and meanwhile, the prepared double-walled carbon nano tube has higher yield, stability and purity. The technical defects of low yield and wide diameter distribution range of a conversion method for producing double-walled carbon nano tubes are overcome.

Owner:SUN YAT SEN UNIV

Transition metal oxide/silicon dioxide nano composite powder body catalyst, its synthesis method and carbon nano tube prepared by using said catalyst

InactiveCN1400049ALow costEasy to operateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSynthesis methodsCarbon nanotube

The present invention relates to a method for synthesizing transition metal oxide / silicon dioxide nano composite powder catalyst. Said invention adopts precursor hydrothermal method to make synthesis, and said catalyst can be used for preparing carbon nano tube, and said method includes the following steps: placing the catalyst into the catalytic bed quartz tube, heating to 500-600 deg.C under the condition of inert gas atmosphere, introducing hydrogen gas and reducing for 0.4-1.5 hr, when the temp. is reached to 630-780 deg.C, introducing acetylene and hydrogen gas whose volume ratio is 9:1-1:1 in the flowing rate of 40-200 ml / min to make it prduce cracking reaction to synthesize carbon nano tube, its reaction time is 0.5-1.0 hr.

Owner:GUANGDONG UNIV OF TECH

Preparing method for nanowire iron phthalocyanine/carbon nanofiber heterojunction composite material

InactiveCN105536872ANo breakNo crosslinkingOrganic-compounds/hydrides/coordination-complexes catalystsFiberHeterojunction

The invention relates to a preparing method for a nanowire iron phthalocyanine / carbon nanofiber heterojunction composite material, and belongs to the technical field of composite materials. The preparing method includes iron-carbon nanofiber preparation and composite material preparation, composite material preparation includes the following steps that iron-containing carbon nanofibers, 4-nitrophthalonitrile and ammonium molybdate are poured into a reaction kettle together, ethanediol is added into the reaction kettle, the reaction kettle is sealed, placed in a drying oven and heated to be treated for 7-9 h, the reaction kettle is taken out and naturally cooled to room temperature, and a reaction product at the bottom of the kettle is taken out, washed, placed in a vacuum drying box to be dried for 4-6 h to obtain the composite material. The preparing method is simple in process, efficient, easy to operate, low in price and environmentally friendly and achieves large-scale production easily.

Owner:HEBEI UNIV OF ENG

Sustained-release microsphere containing risperidone and preparation method thereof

InactiveCN101292960BHigh drug loadingHigh encapsulation efficiencyOrganic active ingredientsNervous disorderMicrosphereAntipsychotic Medications

The invention relates to a sustained-release microsphere of antipsychotic drug risperidone and the preparation method thereof.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

Catalyst for zinc oxide nanowire growth, and application of catalyst

InactiveCN102553588BIncrease growth rateIncrease growth densityZinc oxides/hydroxidesVacuum evaporation coatingPtru catalystZinc oxide nanowire

The invention discloses a catalyst for a zinc oxide nanowire and application of the catalyst in growth of the zinc oxide nanowire. The catalyst for the zinc oxide nanowire is an Au / M multilayer film or an Au-M alloy film formed by metal Au and metal M with a mass ratio of 0.2 to 5:1, wherein M is a metal, the eutectic point of which and Zn is below 500 DEG C, preferably, M is a metal, the eutectic point of which and Zn is below 300 DEG C. Compared with gold as a catalyst under similar conditions, the catalyst is used for the growth of the zinc oxide nanowire, and the higher growth rate of the zinc oxide nanowire can be obviously obtained, the density of arrays of the prepared zinc oxide nanowire is larger, the diameter and the length of the nanowire are more uniform, and the grown zinc oxide nanowire has higher crystalline quality.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A controllable preparation method of uniform silver nanowires with small diameter and ultrahigh aspect ratio

ActiveCN109175394BSmall diameterNarrow diameter distributionTransportation and packagingMetal-working apparatusPyrrolidinonesEngineering

The invention discloses a controllable preparation method for uniform nano-silver wires with small diameter and ultra-high aspect ratio. The method uses chloride salts, bromide salts and iron salts as synergistic control agents to prepare nano-silver wires. Specifically, the method comprises the following steps: firstly preparing an ethylene glycol solution of polyvinylpyrrolidone (PVP), adding inducers chloride salt, bromide salt and iron salt therein, and mixing uniformly to obtain a mixed solution A. Then prepare silver nitrate solution B in ethylene glycol. Slowly add solution B to mixed solution A, mix well, place in a reaction kettle and raise the temperature to 155-165°C, and keep warm for 1.5-2.5 hours. After the reaction product is cooled to room temperature, it is centrifuged and washed to obtain silver nanowires with small diameter, uniform diameter distribution and super high aspect ratio. The preparation of this silver nano wire takes a very short time, is simple to operate, and is convenient for large-scale production. The diameter of the prepared silver wire is 45-50nm, and the aspect ratio is as high as 2000.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

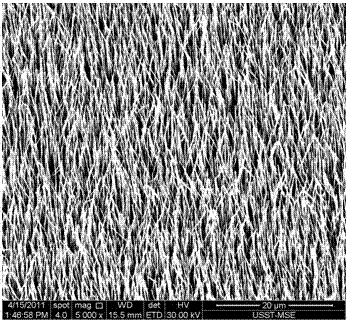

A kind of high-strength and high-elastic vascular stent and preparation method thereof

ActiveCN104383606BUniform shapeNarrow diameter distributionSurgeryFilament/thread formingHigh cellPorosity

The invention discloses a high-strength high-elasticity intravascular stent and a preparation method thereof and belongs to the field of chemical and ecological engineering. The high-strength high-elasticity intravascular stent has the advantages that a biocompatible polymer material is taken as a precursor; firstly, an electrostatic spinning method is adopted for preparing fibrous membranes with different mechanical properties; and on this basis, an electrospinning technology and a solution soaking and removing method are combined for preparing a high-strength, high-elasticity and high-porosity artificial intravascular stent, fibers used for forming the artificial intravascular stent are smooth in surface, uniform in morphology, narrow in fiber diameter distribution range, and excellent in vascular performance. The obtained artificial intravascular stent with high cell compatibility, strength, elasticity and porosity can be produced in a large scale and is expected to be applied to the actual clinical diagnosis.

Owner:BEIHANG UNIV

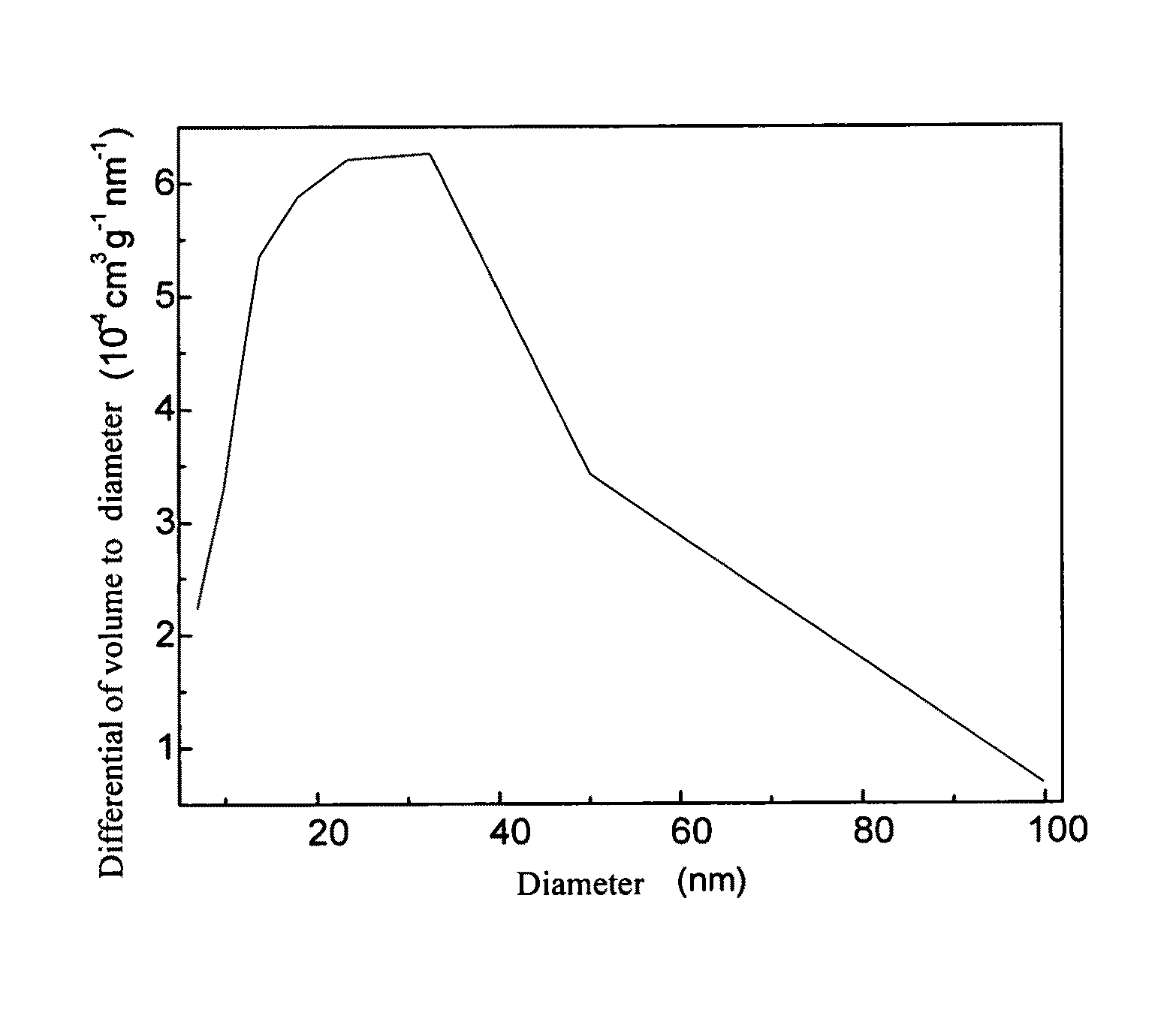

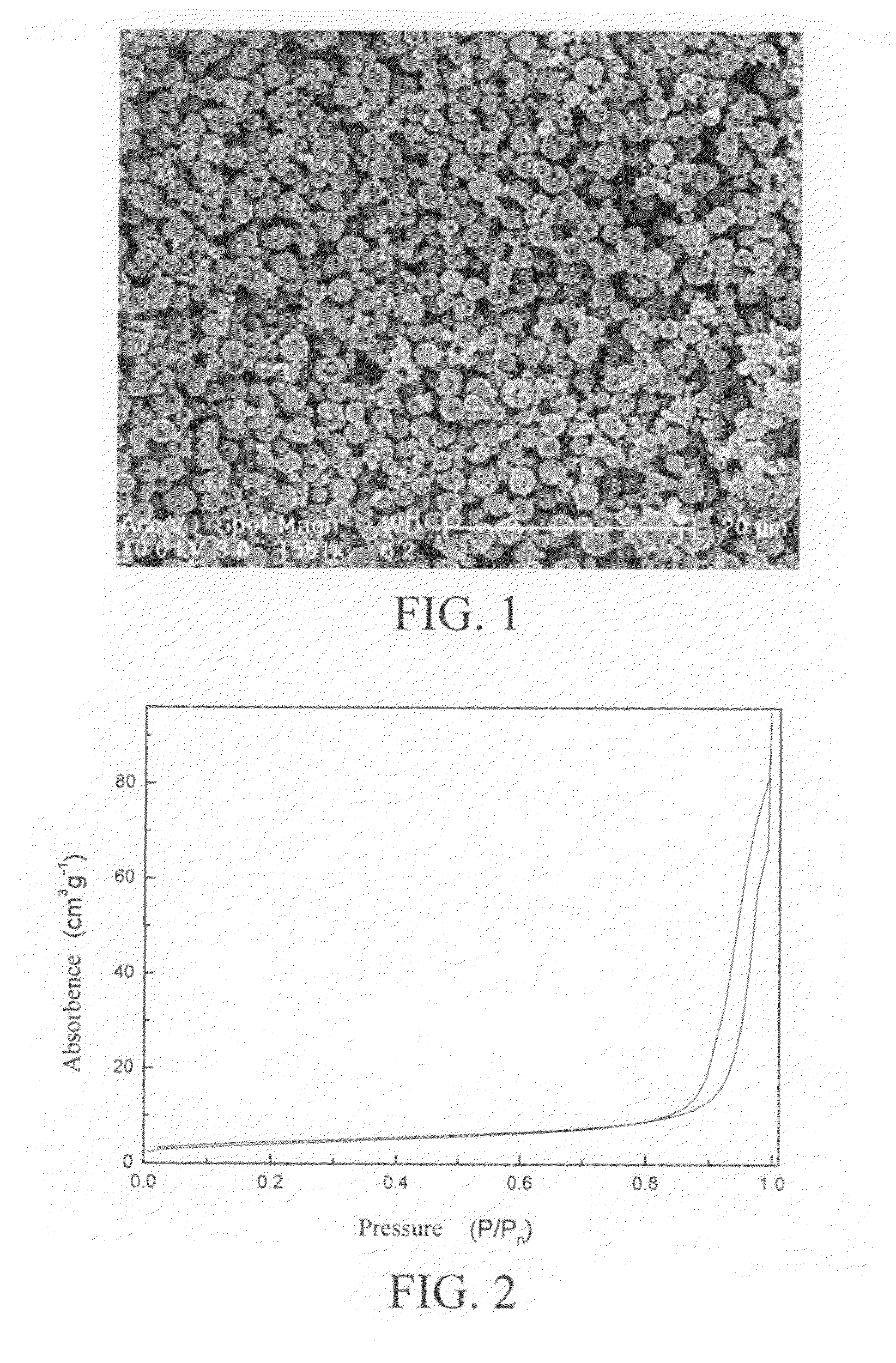

Method for making mesoporous material

ActiveUS8012450B2Low toxicLarge specific surface areaMaterial nanotechnologyManganese oxides/hydroxidesPorosityOrganic solvent

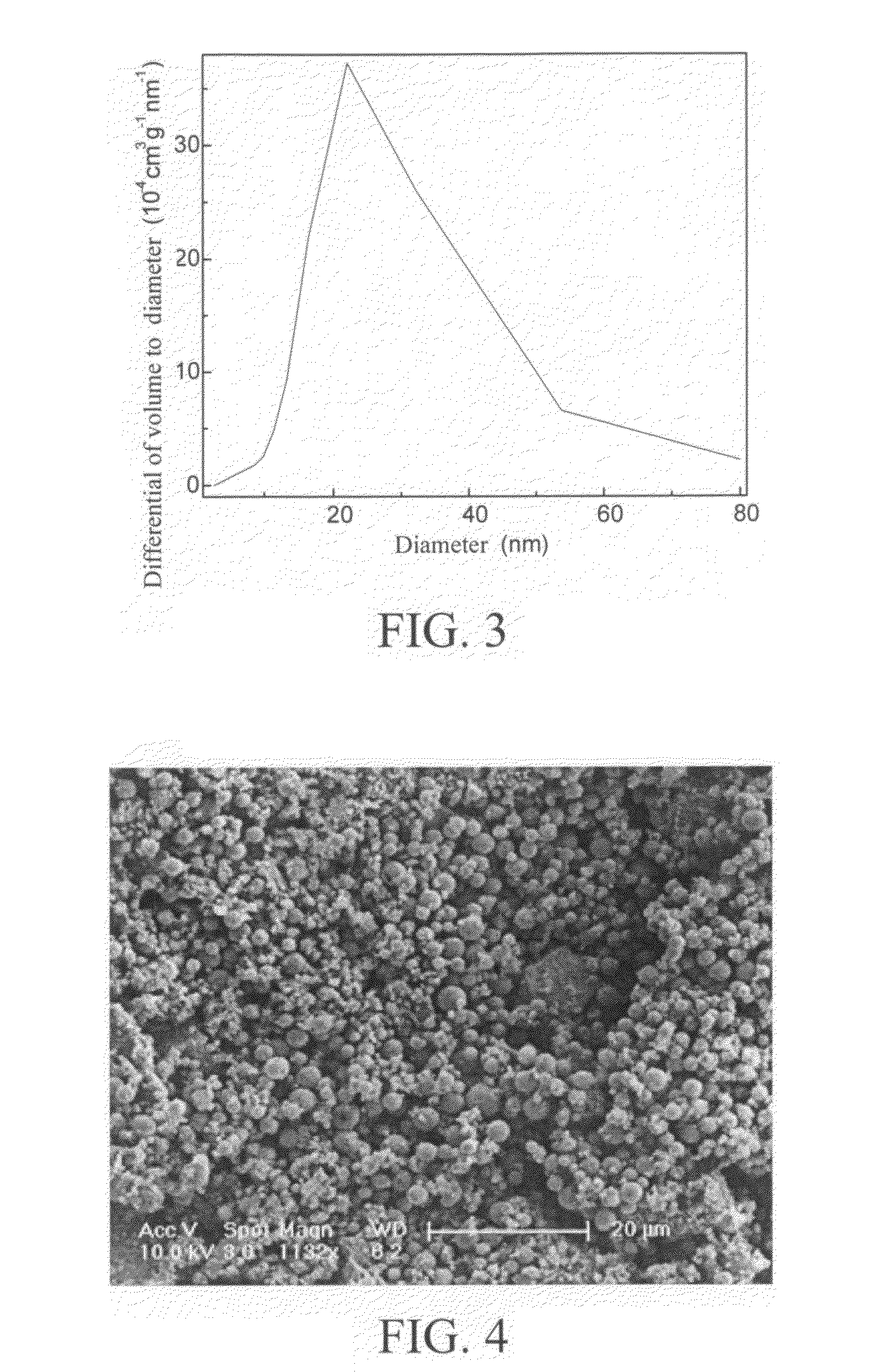

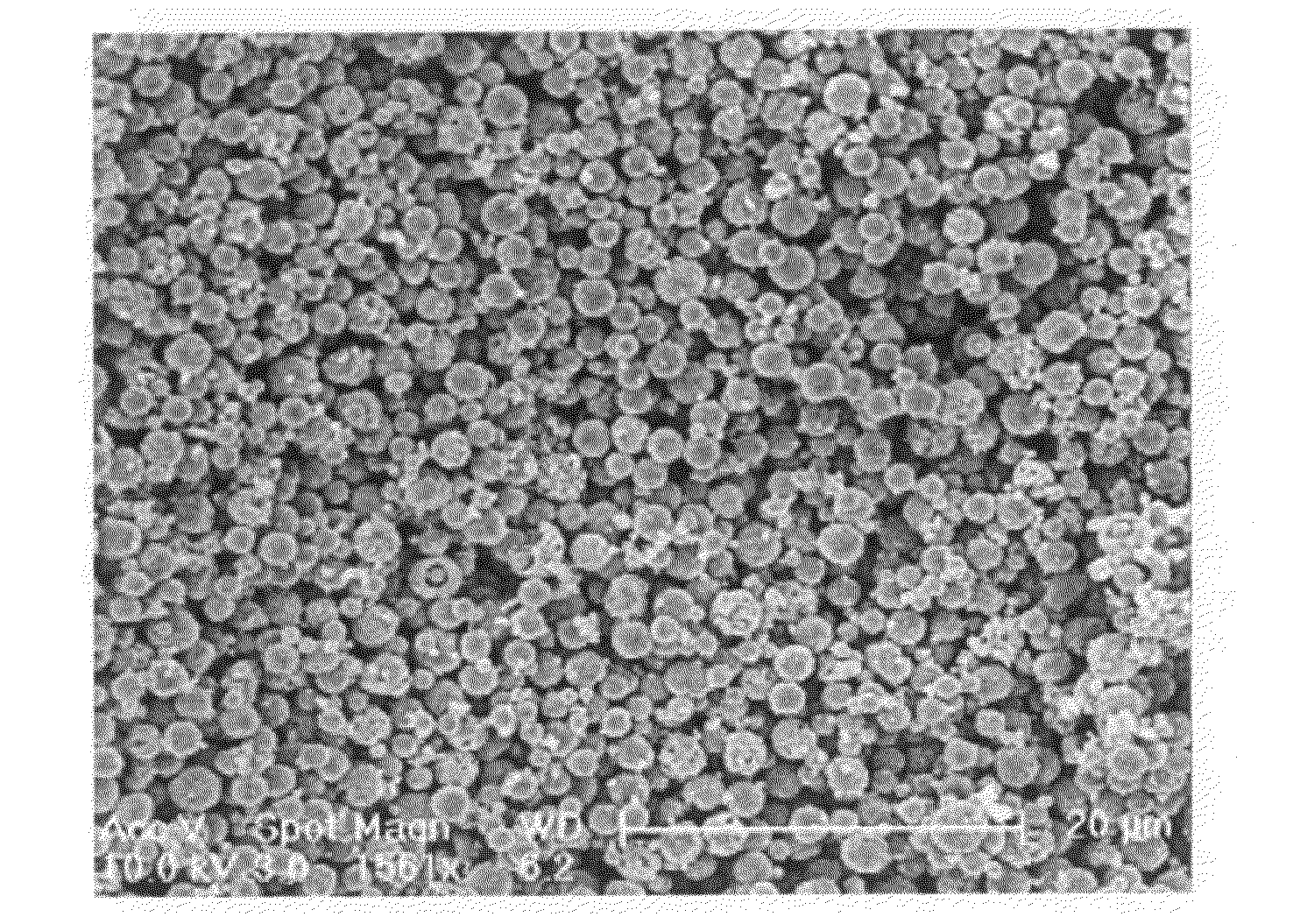

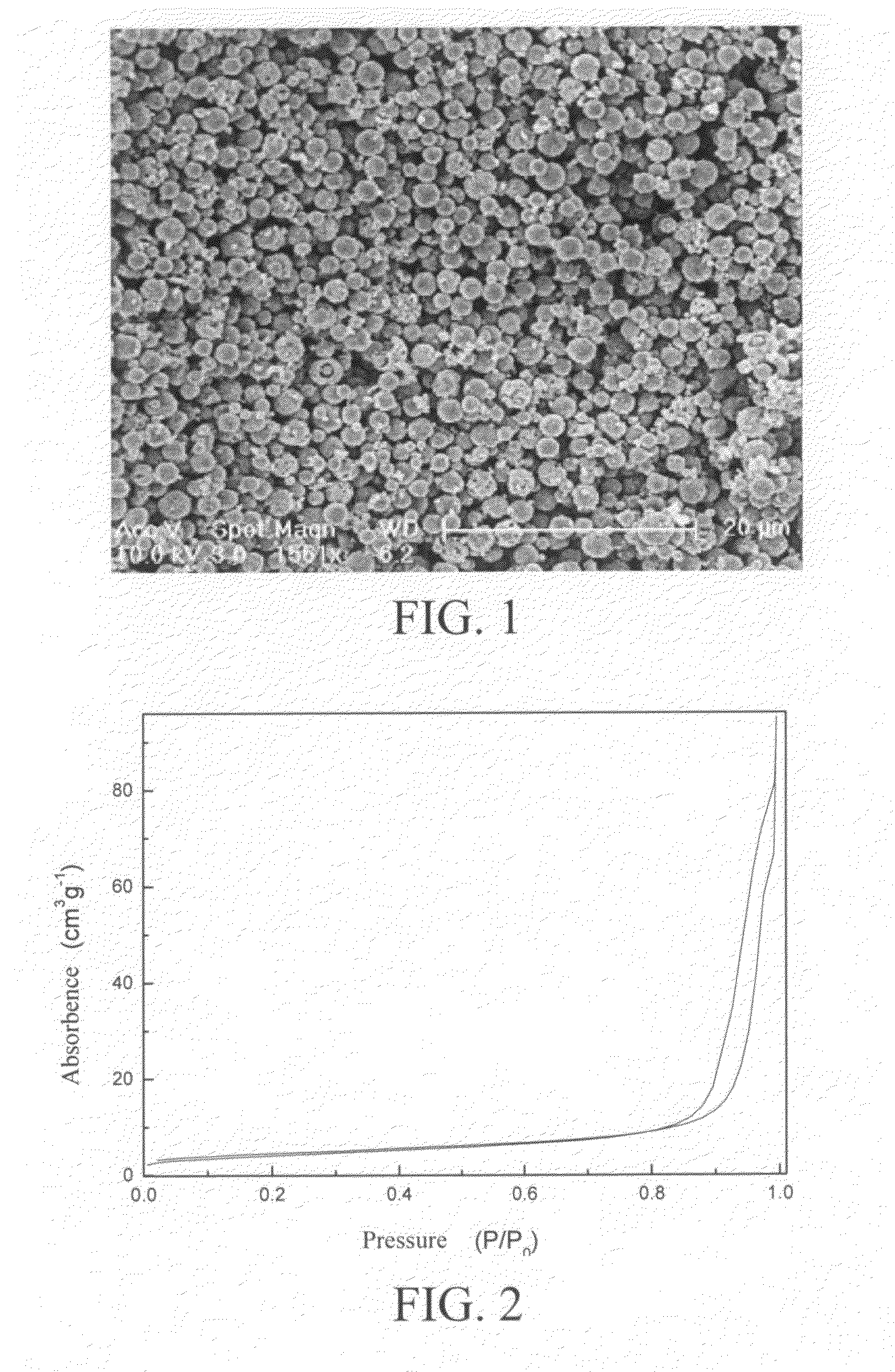

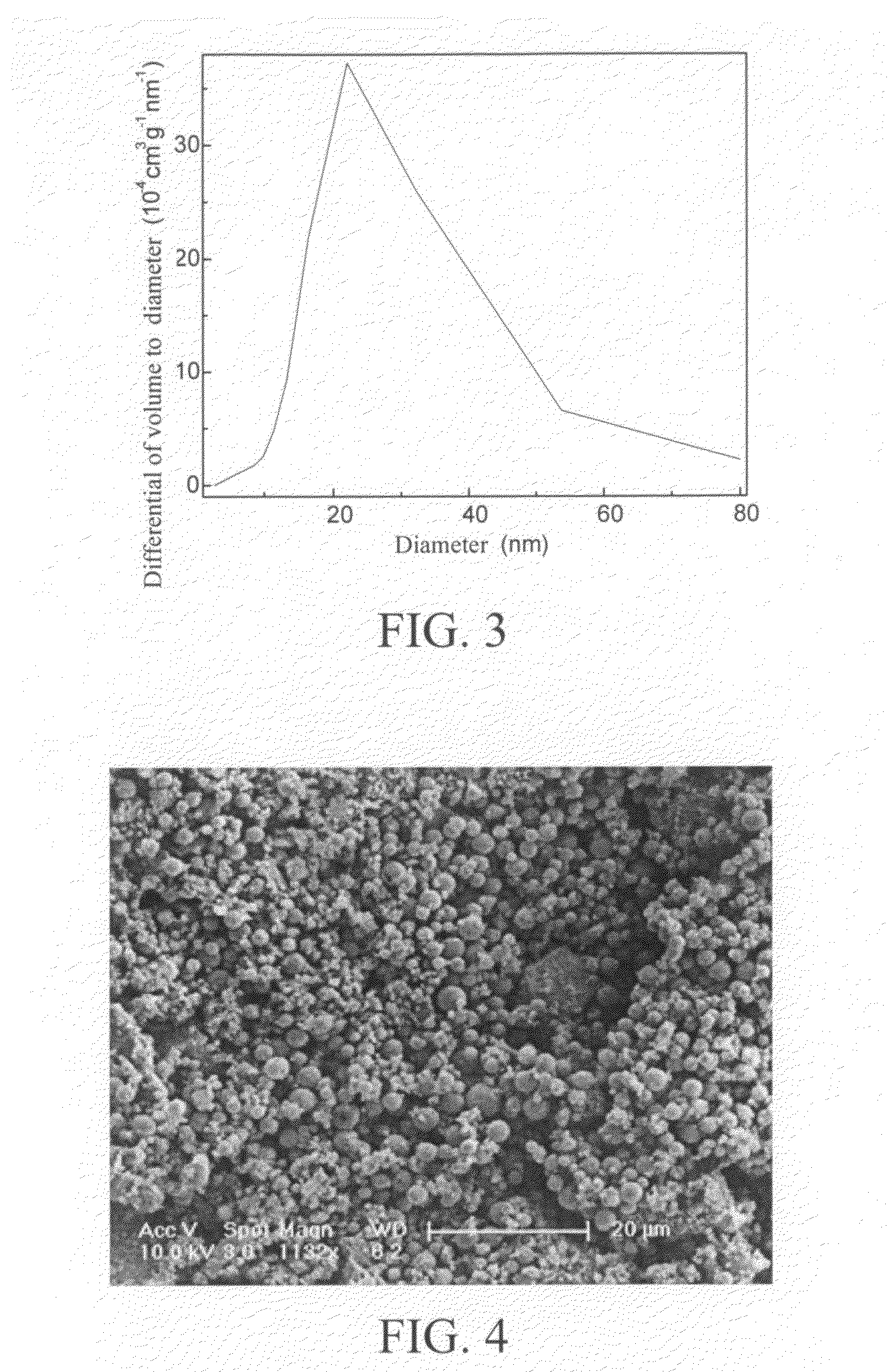

A method for making the mesoporous material includes the following steps: dissolving a nanocrystal powder in an organic solvent, and achieving a solution A with concentration of 1-30 mg / ml; dissolving a surfactant in water, and achieving a solution B with an approximate concentration of 0.002-0.05 mol / ml; mixing the solution A and the solution B in a volume ratio of 1:(5-30), and achieving a mixture; stirring and emulsifying the mixture, until an emulsion C is achieved; removing the organic solvent from the emulsion C, and achieving a deposit; washing the deposit with deionized water, and achieving a colloid; and drying and calcining the colloid, and eventually achieving a mesoporous material. The mesoporous material has a large specific surface area, a high porosity, and a narrow diameter distribution.

Owner:TSINGHUA UNIV +1

Method for making mesoporous material

ActiveUS20100278721A1Low toxicLarge specific surface areaMaterial nanotechnologyManganese oxides/hydroxidesPorosityOrganic solvent

A method for making the mesoporous material includes the following steps: dissolving a nanocrystal powder in an organic solvent, and achieving a solution A with concentration of 1-30 mg / ml; dissolving a surfactant in water, and achieving a solution B with an approximate concentration of 0.002-0.05 mol / ml; mixing the solution A and the solution B in a volume ratio of 1: (5-30), and achieving a mixture; stirring and emulsifying the mixture, until an emulsion C is achieved; removing the organic solvent from the emulsion C, and achieving a deposit; washing the deposit with deionized water, and achieving a colloid; and drying and calcining the colloid, and eventually achieving a mesoporous material. The mesoporous material has a large specific surface area, a high porosity, and a narrow diameter distribution.

Owner:TSINGHUA UNIV +1

Transition metal oxide/silicon dioxide nano composite powder body catalyst, its synthesis method and carbon nano tube prepared by using said catalyst

InactiveCN1150985CSmall particlesGood dispersionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The present invention relates to a method for synthesizing transition metal oxide / silicon dioxide nano composite powder catalyst. Said invention adopts precursor hydrothermal method to make synthesis, and said catalyst can be used for preparing carbon nano tube, and said method includes the following steps: placing the catalyst into the catalytic bed quartz tube, heating to 500-600 deg.C under the condition of inert gas atmosphere, introducing hydrogen gas and reducing for 0.4-1.5 hr, when the temp. is reached to 630-780 deg.C, introducing acetylene and hydrogen gas whose volume ratio is 9:1-1:1 in the flowing rate of 40-200 ml / min to make it prduce cracking reaction to synthesize carbon nano tube, its reaction time is 0.5-1.0 hr.

Owner:GUANGDONG UNIV OF TECH

Dispersing, mixing and drying device

InactiveCN101816903BImprove the mixing effectFully dispersedShaking/oscillating/vibrating mixersGrain treatmentsEngineeringVibration exciter

Owner:赛福能源科技(徐州)有限公司

Preparation method of high-crystallinity double-walled carbon nano tube

Owner:SHANGHAI UNIV

Method for directly growing semiconductor type single-walled carbon nanotube with floating catalyst and auxiliary oxygen

The invention relates to massive and controllable preparation field of semiconductor type single-walled carbon nanotubes, specifically to a method for directly growing the semiconductor type single-walled carbon nanotube with floating catalyst and auxiliary oxygen. The method comprises the following steps of: taking ferrocene as precursor of the catalyst, taking right amount of sulphur powder as growth promoter, and taking hydrogen as a carrier gas; simultaneously introducing a carbon source gas and small amount of oxygen to grow the single-walled carbon nanotube, and etching the small-diameter and metallic single-walled carbon nanotube in situ; and finally, obtaining a sample in which the semiconductor type single-walled carbon nanotube is dominant, wherein content of the semiconductor type single-walled carbon nanotube is 90 wt%, and diameter distribution of the semiconductor type single-walled carbon nanotube is 1.4-1.8 nm. With the method, massive and directly controlled growth of the semiconductor type single-walled carbon nanotube with narrower diameter distribution is realized; and the method solves the problems, such as that the separation process of the existing chemical and physical methods seriously damages the intrinsic structure of the single-walled carbon nanotube and the process is complex, and sample amount is less, diameter distribution is wider and the diameter is smaller in the direct preparation technology, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Process for preparing vapor-grown carbon fibers

A process for preparing vapor-grown carbon fibers comprises adding 10-35% iron or cobalt oxide and 65-90% zirconia carrier composed of ferric nitrate or cobalt nitrate solution according to weight percent of a catalyzer into the zirconia carrier, and dipping, airing, calcination to obtain the catalyzer. The catalyzer is reduced in a hydric ambience, thereafter the catalyzer's temperature is lifted to a rature 1000-1160 DEG C and a carbon source is entered, an adding amount of the carbon source of a unit quality catalyzer is 0.005-0.040 ml / min, the vapor-grown carbon fibers are obtained by 20-60 minutes reaction. The invention has advantages that the preparing process is simple and easy to operate, the obtained vapor-grown carbon fibers are even, and having a narrow diameter distribution range.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

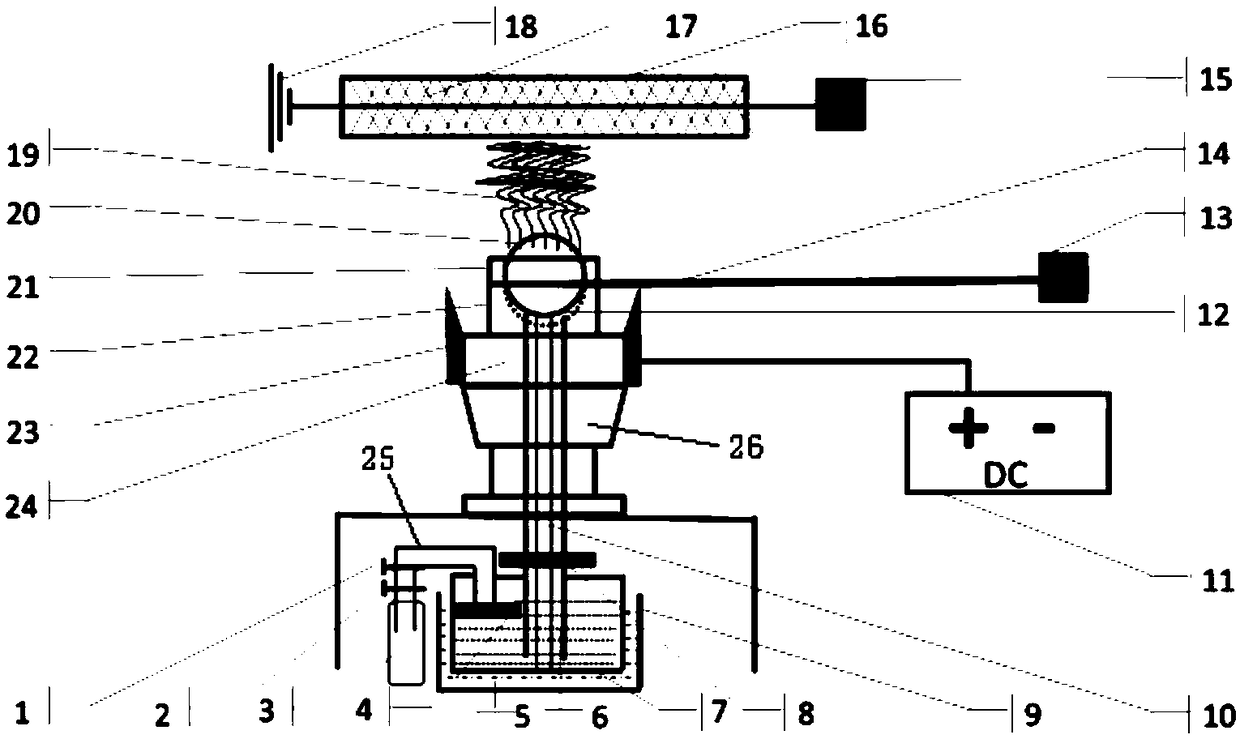

A spherical rotating brush type batch electrospinning device and its use method

ActiveCN106811811BRealize automatic supplyEasy to controlSpinning head liquid feederFilament/thread formingGas cylinderControl system

The invention relates to a spherical revolving brush type batched electrostatic spinning device and a usage method thereof. The spherical revolving brush type batched electrostatic spinning device comprises a liquid supply system, a separating electric field control system, a spherical rotary spinning system and a nanofiber collecting system, wherein the liquid supply system comprises an air cylinder, a spinning solution storage bottle, an oil batch tank and a solution guiding tube, the spinning solution storage bottle is arranged in the oil batch tank, the spinning solution storage bottle and the solution guiding tube form a communicator structure through a solution brushing tank, the spinning solution storage bottle is connected with the air cylinder through an air tube, and a main valve and a pressure reducing valve are sequentially arranged at the position, close to the air cylinder, on the air tube. The separating electric field control system comprises a high-pressure generator, a metal round ring, a cylindrical seat and a support, wherein the support is arranged at the upper end of the spinning solution storage bottle, the cylindrical seat is arranged on the support, and the metal round ring is installed on the cylindrical seat in a sleeving mode to be connected with the high-pressure generator. Automatic supply of a high polymer solution and stable batched nanofiber preparation can be completed.

Owner:安徽弋尚纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com