A spherical rotating brush type batch electrospinning device and its use method

An electrospinning and mass production technology, which is applied in the field of spherical rotating brush type mass electrospinning devices, can solve the problems of non-orientation of final nanofiber product structure, volatile solvent, and limited spinning direction, etc. The fiber structure is uncontrollable, the solvent is easy to volatilize, and the solution concentration is well controlled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

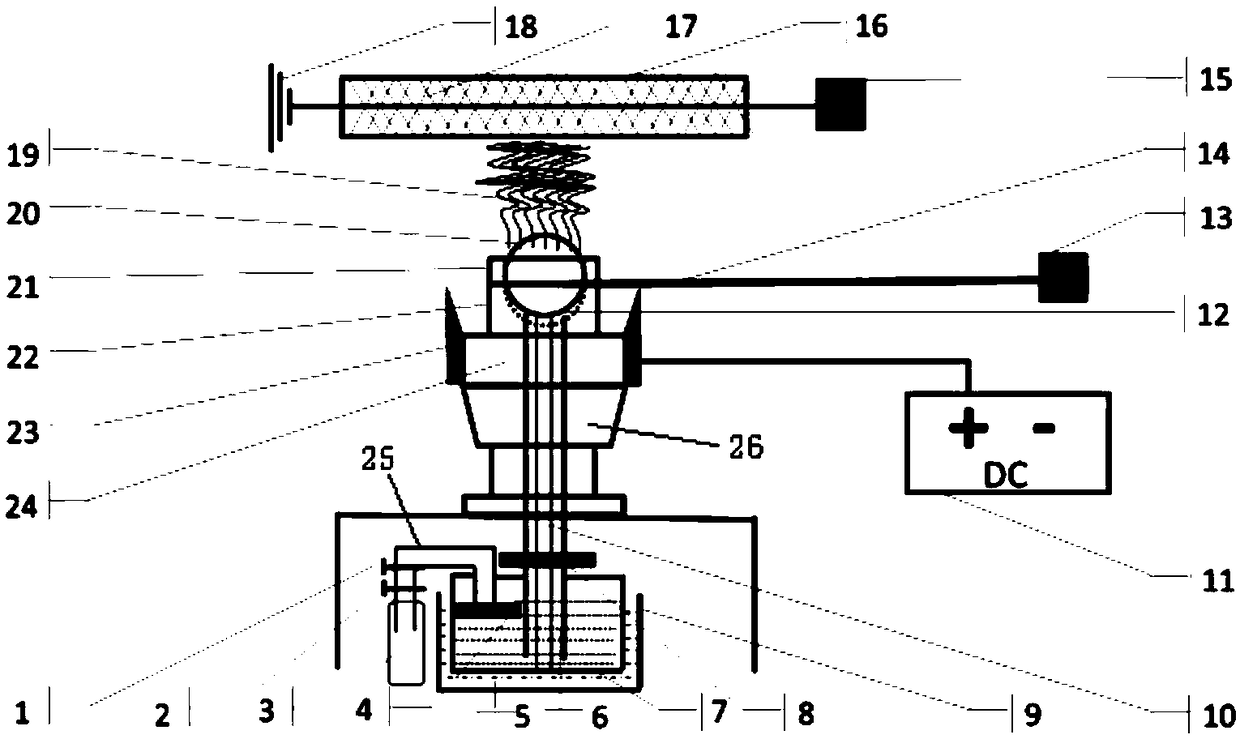

[0036]like figure 1 As shown, a spherical rotating brush-type batch electrospinning device includes a liquid supply system, a separation electric field control system, a spherical rotary spinning system and a nanofiber collection system, wherein the liquid supply system includes a gas cylinder 3, a spinning Liquid storage bottle 7, oil bath 9 and catheter 10, the spinning solution storage bottle 7 is arranged in the oil bath 9, the spinning solution storage bottle 7 and the catheter 10 to the brush liquid tank 12 forms a connector structure, the spinning liquid storage bottle 7 is connected to the gas cylinder 3 through the air pipe 25, and the air pipe 25 is provided with a main valve 2 and a pressure reducing valve 1 in sequence near the gas cylinder 3, and the separation The electric field control system comprises a high voltage generator 11, a metal ring 23, a cylindrical seat 24 and a support 26, the support 26 is arranged on the upper end of the spinning solution storage...

Embodiment 2

[0057] Next, nanofibers are prepared by using a polymer solution prepared from polyacrylonitrile (PAN) and N-N dimethylformamide (DMF). The mass fraction of the prepared PAN polymer solution is 10%. The configured PAN / DMF polymer solution is injected into the spinning solution storage bottle 7, and the spinning solution storage bottle 7 and the brush solution tank 12 are connected with the catheter 10. Adjust the height of the metal ring 23 so that the distance between its top and the top of the spherical shower head 20 is 70mm. Open the middle switch 8 of the catheter tube 10, open the main valve 2 of the gas cylinder 3, adjust the pressure reducing valve 1 to push the piston 4 so that the polymer solution 6 slowly flows into the brush liquid tank 12 through the catheter tube 10, so that the polymer solution 6 exists in the brush liquid tank 12 in a certain amount. Add silicone oil 5 into the oil bath 9, and heat it to the set temperature of 30° C. with a hot stage. Connec...

Embodiment 3

[0059] Next, nanofibers are prepared by using a polymer solution prepared from polyacrylonitrile (PAN) and N-N dimethylformamide (DMF). The mass fraction of the prepared PAN polymer solution is 12%. The configured PAN / DMF polymer solution is injected into the spinning solution storage bottle 7, and the spinning solution storage bottle 7 and the brush solution tank 12 are connected with the catheter 10. Adjust the height of the metal ring 23 so that the distance between its top and the top of the spherical shower head 20 is 90mm. Open the middle switch 8 of the catheter tube 10, open the main valve 2 of the gas cylinder 3, adjust the pressure reducing valve 1 to push the piston 4 so that the polymer solution 6 slowly flows into the brush liquid tank 12 through the catheter tube 10, so that the polymer solution 6 exists in the brush liquid tank 12 in a certain amount. Add silicone oil 5 into the oil bath 9, and heat it to the set temperature of 40° C. with a hot stage. Connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com