Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Meet the requirements of environmental standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combustion system for changing methanol into hydrogen fuel used in industrial furnace and thermal power plant.

InactiveCN101038078AReduce dependenceAvoid pollutionBurnersHydrogenManufacturing cost reductionLiquid fuel

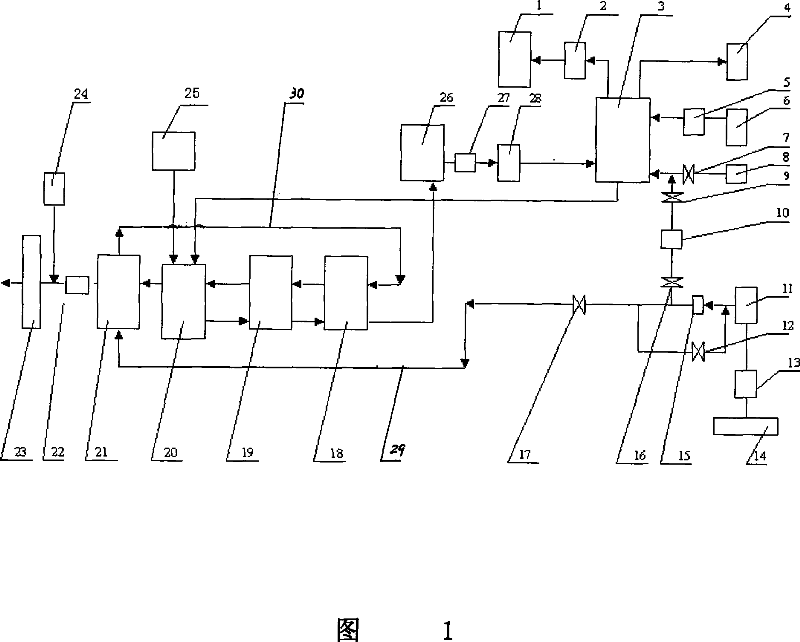

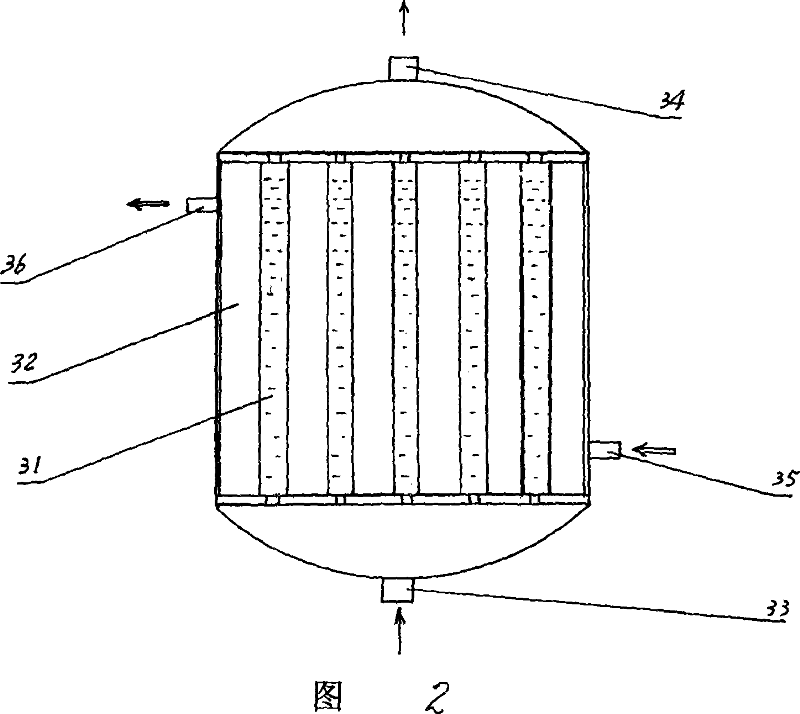

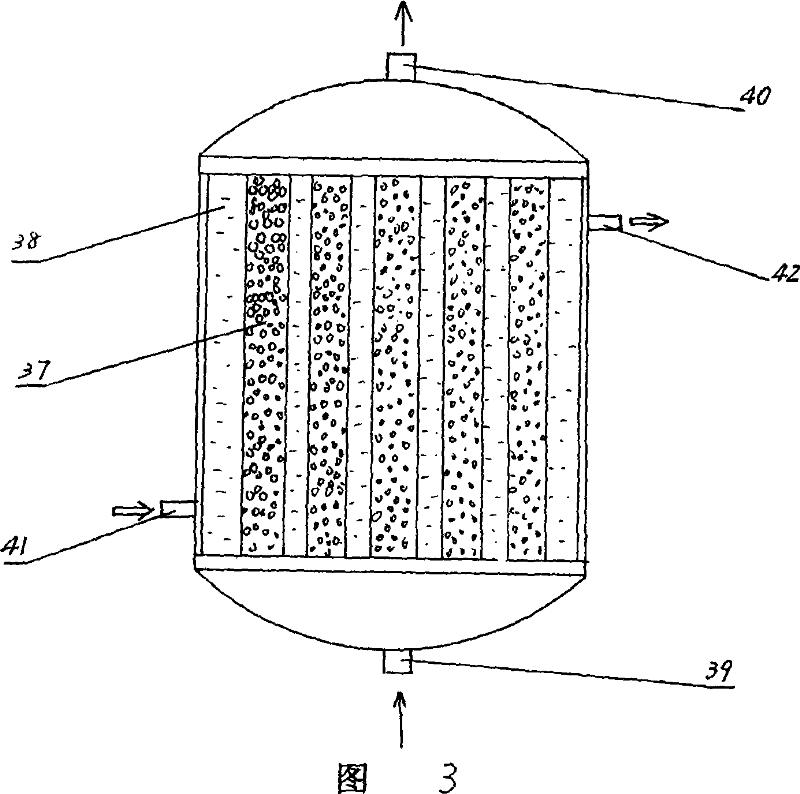

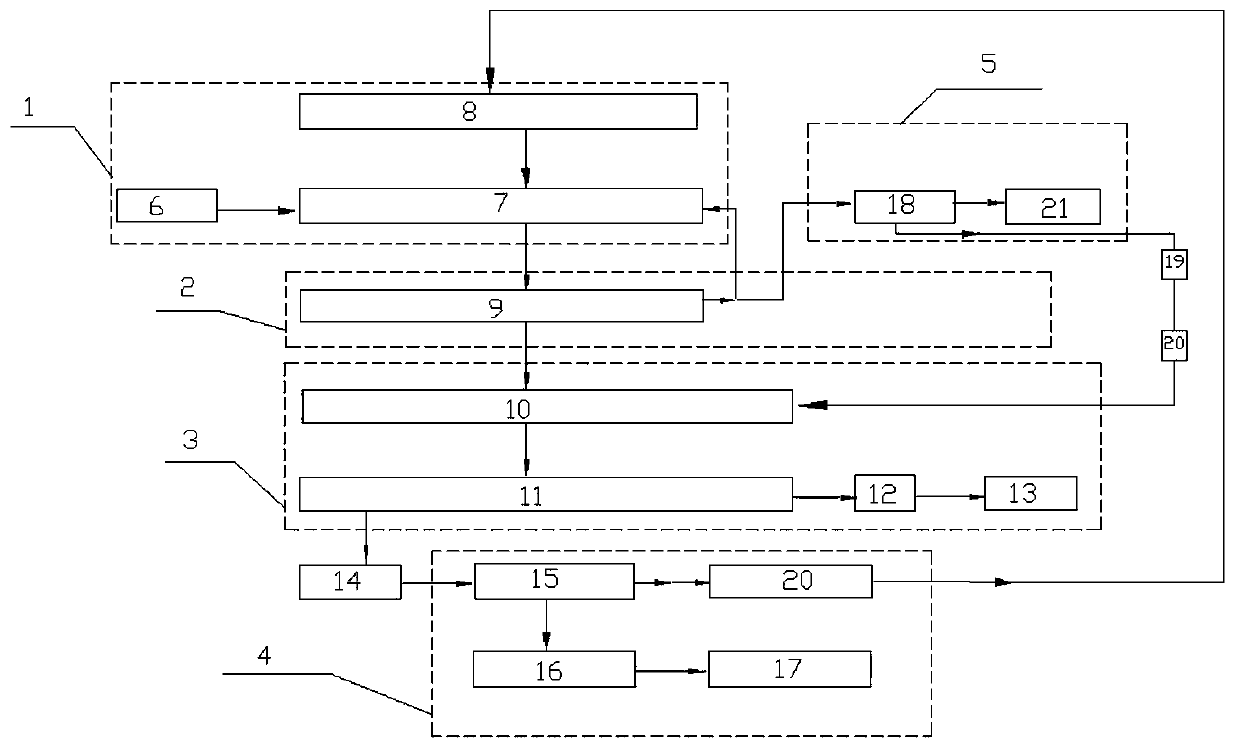

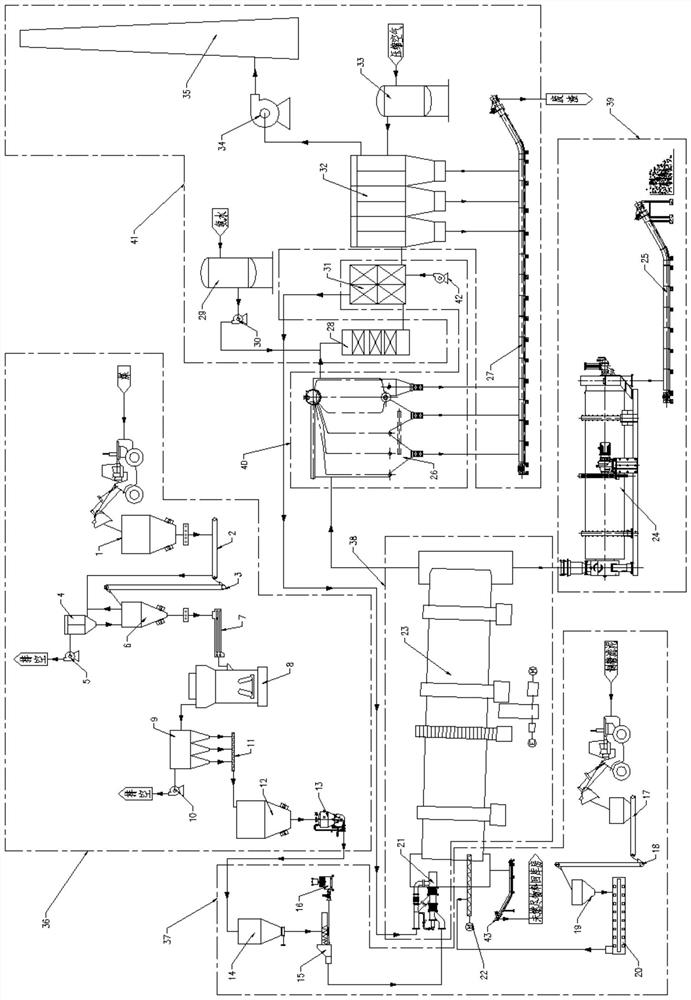

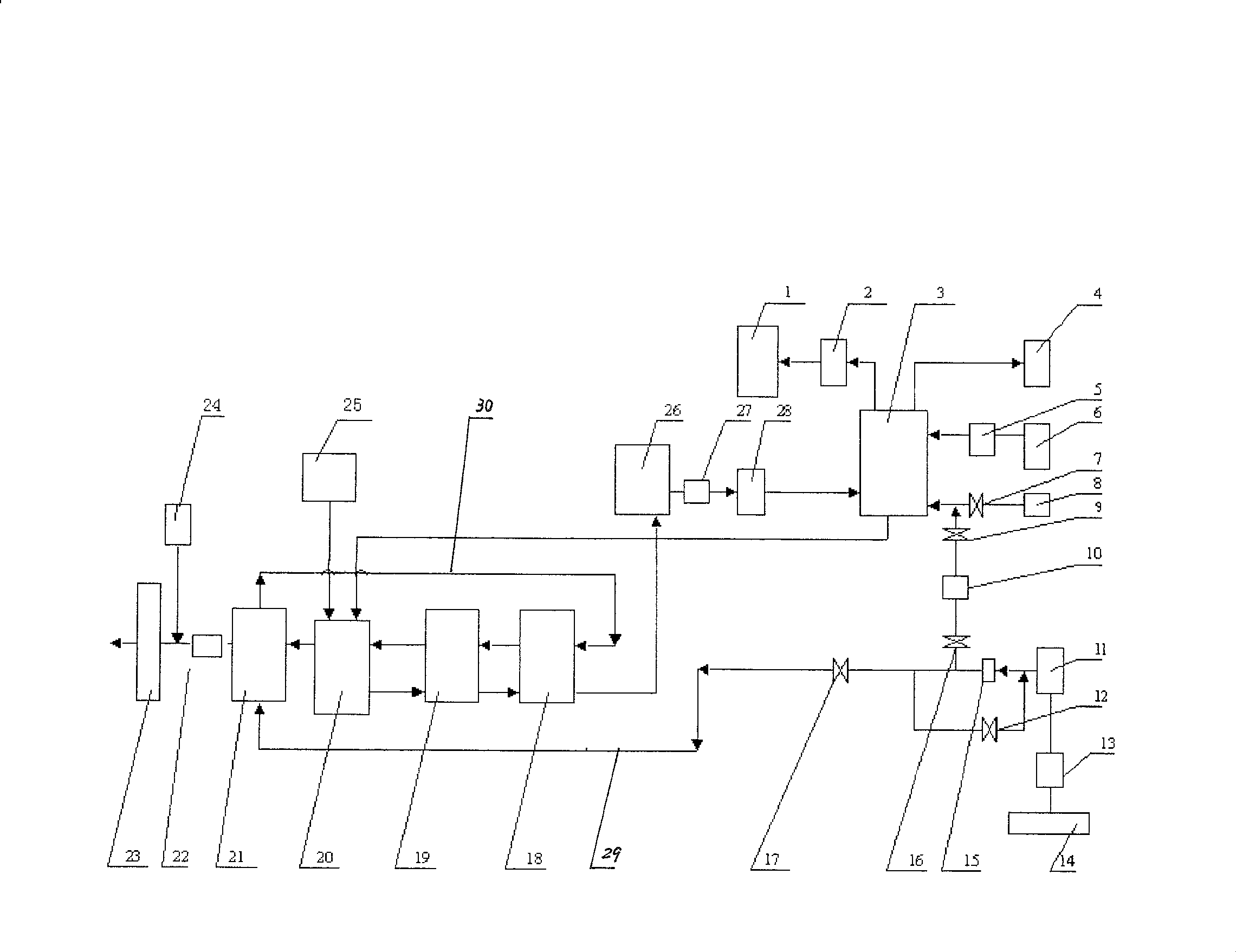

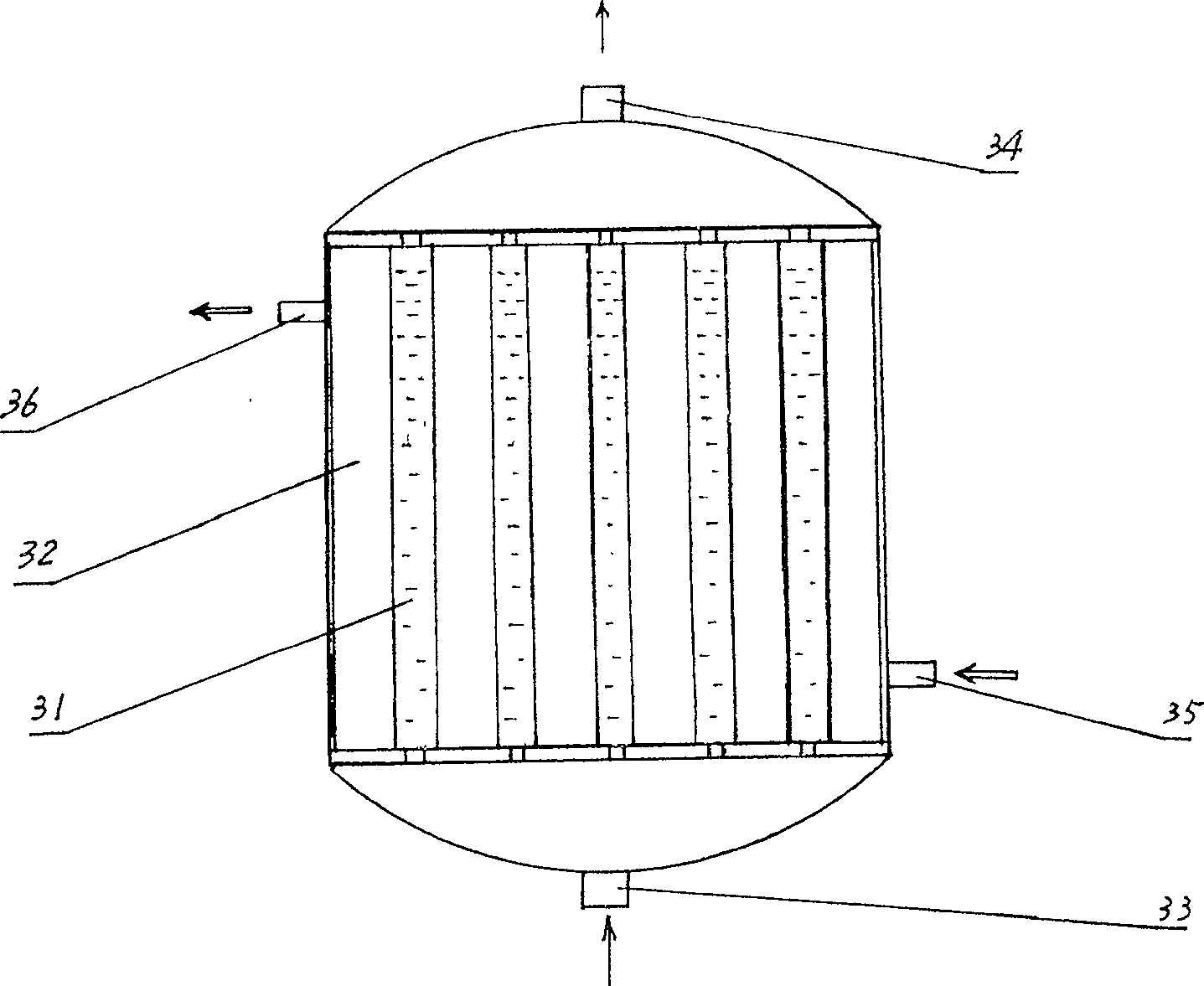

The present invention discloses a burning system using hydrogen fuel changed from methanol in industrial furnace and power station. The burning system is composed of a hydrogen making burning system, a heat transfer oil heating cycle system, a furnace remaining heat smoke heating system, an air preheating system, a start system and a bypass recycle system. The heat transfer oil is heated by furnace smoke remaining heat, and makes the methanol liquid fuel vaporize. The methanol is transferred to fuel with hydrogen as main component by the hydrogen making system, the fuel is then provided to furnace to burn. The burning process will not generate dust and sulfur dioxide harmful gas, and greatly reduces the discharge amount of the carbon dioxide gas. The fuel is satisfy with the national environmental protection standard requirement and can become new type substitute energy for the industrial furnace. The system has the advantages of safety, stable running, miniaturization of equipments and reduced manufacturing cost.

Owner:王衍衡

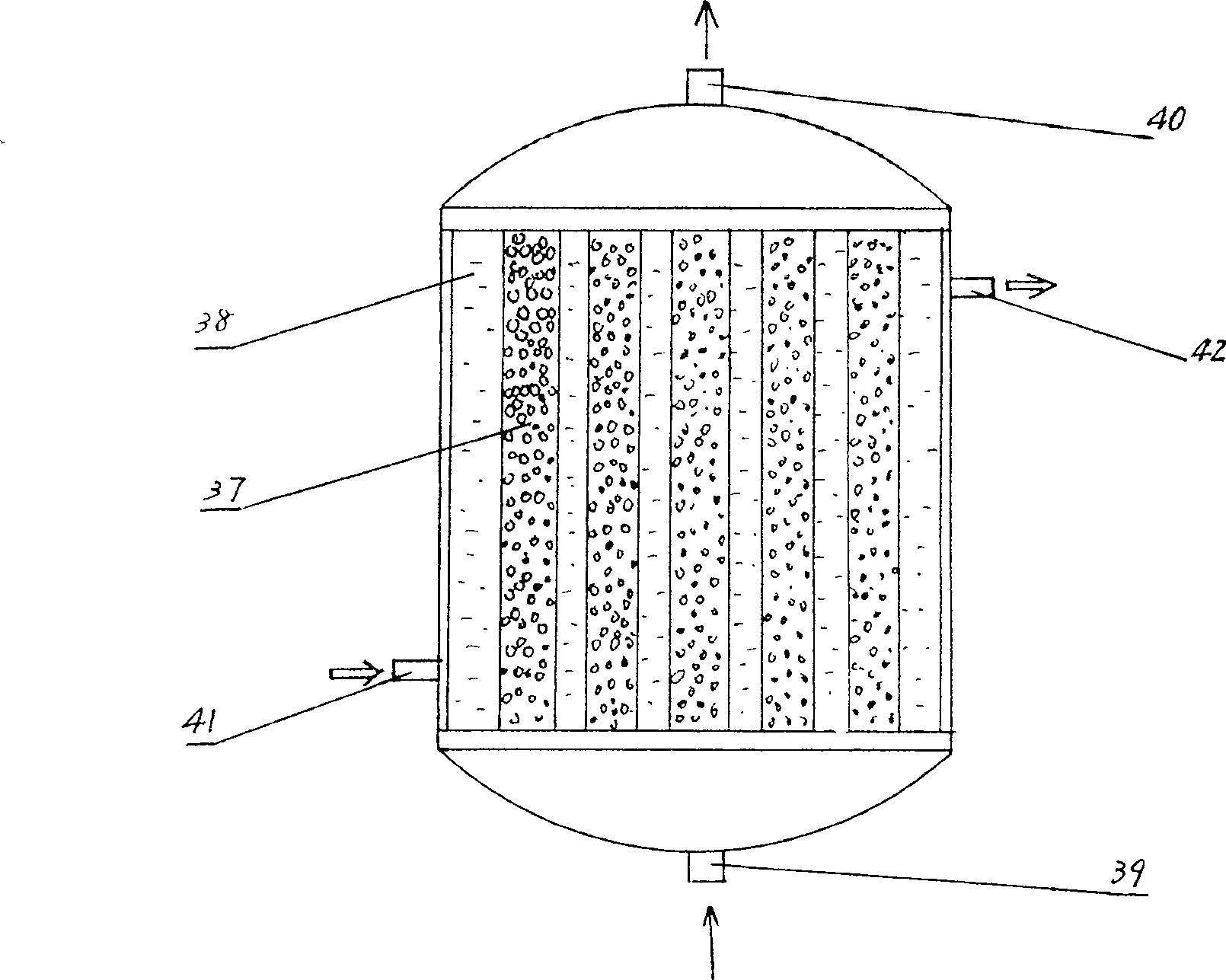

Heat exchange method for low-temperature heat accumulating type catalytic oxidation treatment device

ActiveCN105066149AHigh processing indexImprove securityIncinerator apparatusCatalytic oxidationEngineering

The invention relates to a heat exchange method for a low-temperature heat accumulating type catalytic oxidation treatment device. The problems that in the prior art, serious potential safety hazards exist, ignition temperature is high, and energy consumption is large are mainly solved. The heat exchange method for the low-temperature heat accumulating type catalytic oxidation treatment device is adopted, VOCs gas with the concentration lower than 25% of an explosion limit enters a cold stroke of a rotary type honeycomb ceramic heat accumulator, and then enters a heating chamber to be heated; heated gas enters a low-temperature catalytic oxidation bed to be in contact with nano-silver or nano-silver / manganese oxide / cerium oxide loaded honeycomb ceramic catalysts, and then gas enters a high-temperature catalytic oxidation bed to be in contact with a Pt or Pd loaded noble metal catalyst; and after heat is released, gas enters a hot stroke of the rotary type honeycomb ceramic heat accumulator to be subjected to further high-temperature combustion in the rotary type honeycomb ceramic heat accumulator, and the treatment efficiency of above 99% is achieved. According to the technical scheme, the problems are solved well, and the method can be used for the low-temperature heat accumulating type catalytic oxidation treatment device.

Owner:CHINA PETROLEUM & CHEM CORP +1

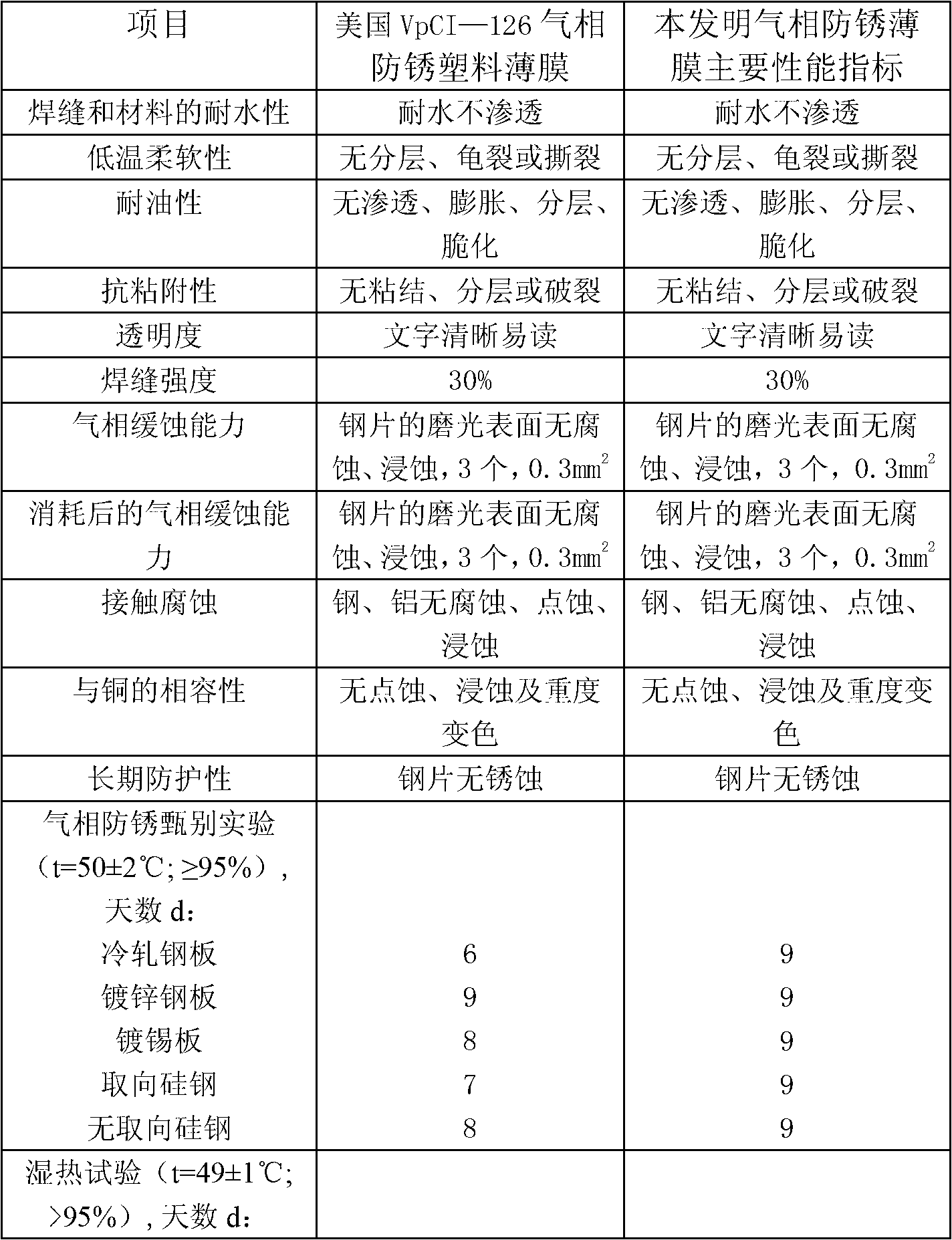

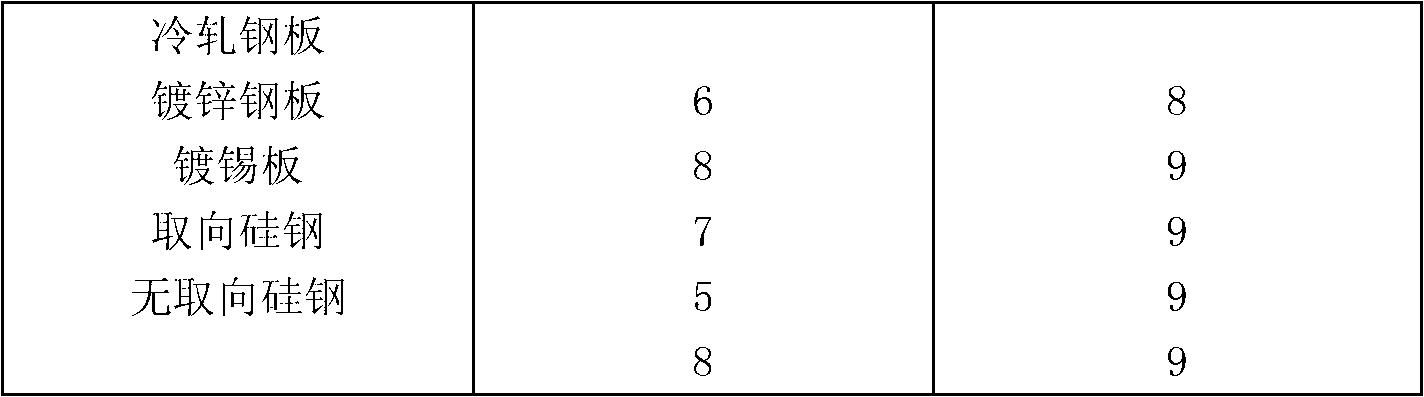

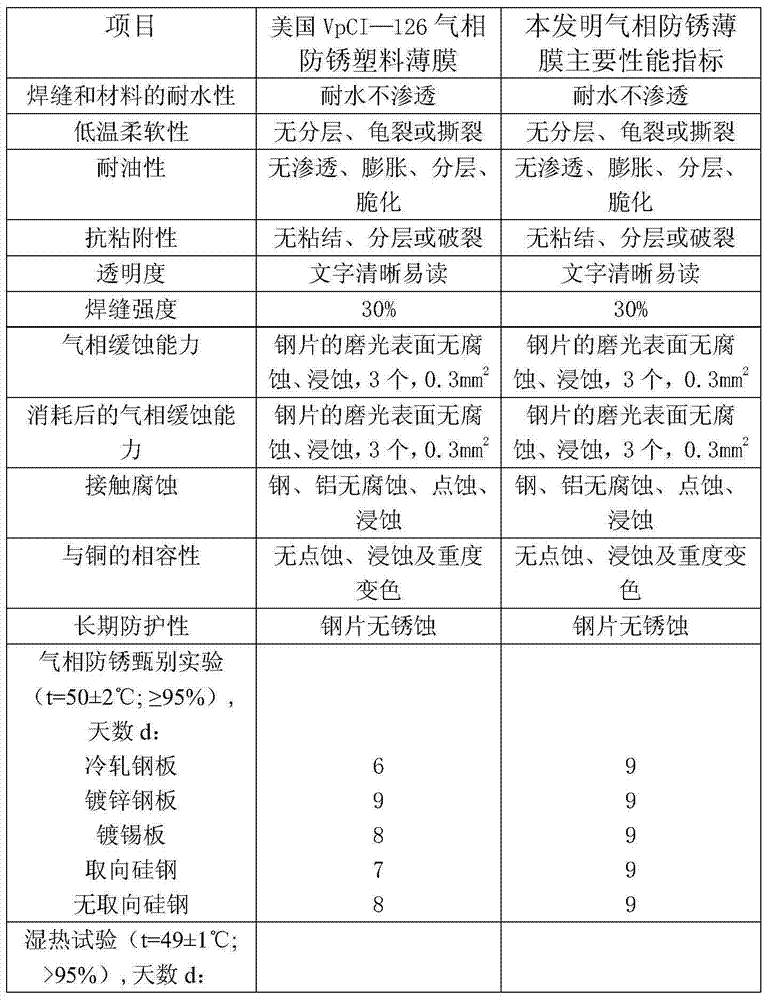

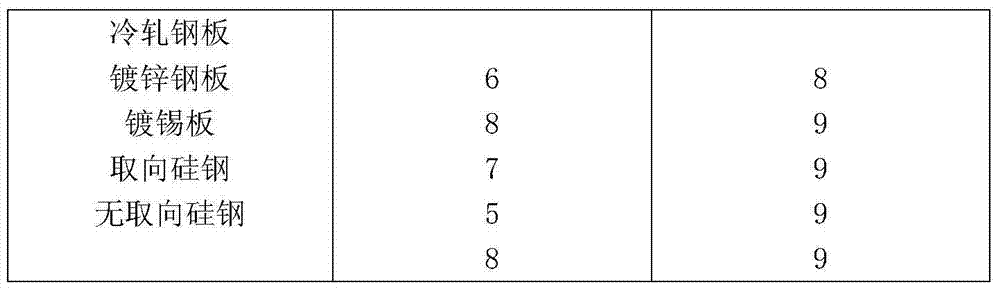

Environment-friendly vapor phase rust-proof film

The invention discloses an environment-friendly vapor phase rust-proof film which is formed by carrying out mixing, coextrusion and blow molding on 85-95% of matrix plastic and 15-5% of additive by weight. The additive comprises the following components by weight percent: 70-85% of vapor phase inhibitor, 2-5% of dispersed lubricant and 10-28% of carrier plastic. The vapor phase inhibitor is formed by combining sodium benzoate, tungstate and morpholine unit-containing diamine type, and the weight ratio of sodium benzoate to tungstate to diamine type containing morpholine unit is (1-3):(1-2.5):(1-3). The environment-friendly vapor phase rust-proof film has the characteristics of high strength, stable sealing performance, good rust-proof performance and single material, and is energy-saving and environment-friendly. Each component has synergistic effect, and inherent physical and chemical rust-proof performances of each component can be fully exerted.

Owner:上海福岛新材料科技有限公司

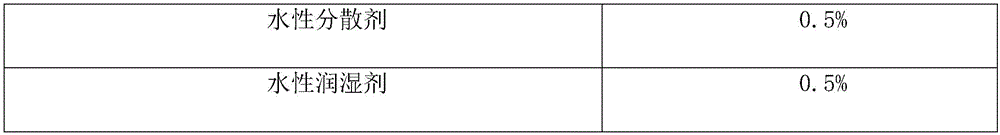

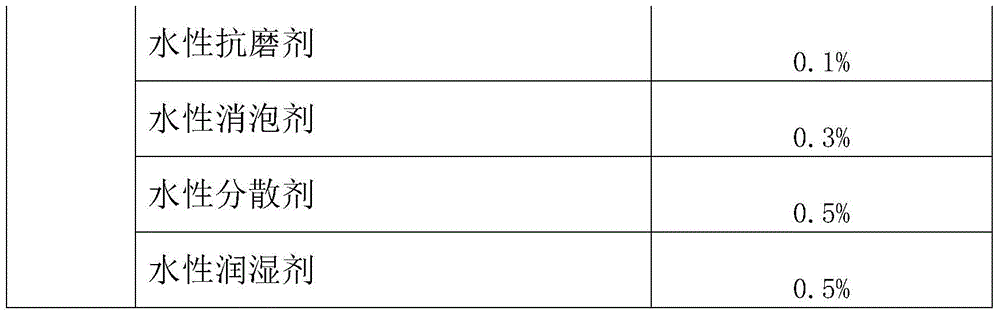

Novel water-based paint for environment-friendly glassine and preparation method of novel water-based paint

InactiveCN105887559AEmission reductionNon-toxicDefoamers additionCoatings with pigmentsWater basedEmulsion

The invention relates to novel water-based paint for environment-friendly glassine and a preparation method of the novel water-based paint, and provides the novel water-based paint and the preparation method which are mainly aimed at solving the problems that at present, water-based paint for glassine is not large enough in adhesion, too high in coating hardness, poor in coating folding endurance, not complete in coating transfer and not wide in printing adaptability. The novel water-based paint is prepared from, by weight, 60-80 parts of water-based acrylic acid opaque emulsion, 10-20 parts of self-crosslinking solidified acrylic acid emulsion, 3-8 parts of calcium carbonate, 5-10 parts of water, 1.0-3.0 parts of water-based coalescing agent, 0.3-0.8 part of water-based defoaming agent, 0.5-1 part of water-based dispersing agent and 0.5-1 part of water-based wetting agent. The novel water-based paint has the advantages of being environmentally friendly, good in film forming property, high in glossiness, wide in printing adaptability and the like.

Owner:ZHONGSHAN BOHAI SPECIAL CHEM CO LTD

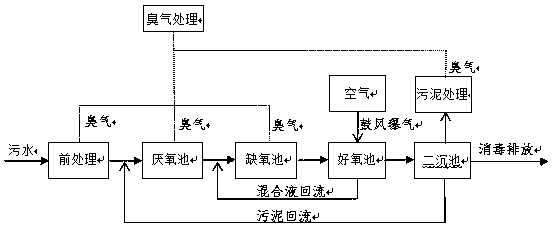

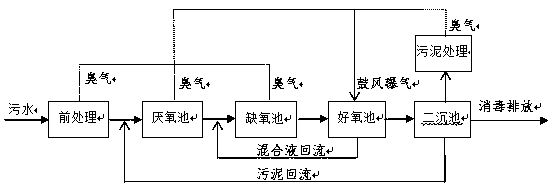

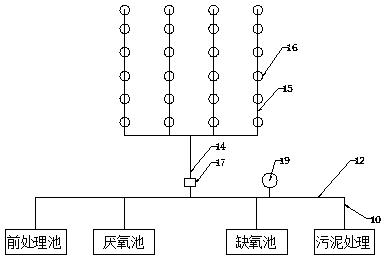

Synchronous aeration and deodorizing process of aerobic activated sludge for wastewater treatment plants

InactiveCN108325375ASmall footprintReduce pollutionWater treatment parameter controlGas treatmentActivated sludgeLand resources

The invention relates to a synchronous aeration and deodorizing process of aerobic activated sludge for wastewater treatment plants, comprising: collecting fouling odor from a wastewater plant; introducing the collected fouling odor into an aerating tank; allowing the fouling odor to replace air to supply oxygen to the activated sludge in the aerating tank, thereby removing the fouling odor and meeting the environmental protection standard. The process of the invention has no need for special deodorizing facilities, so that floor area is saved; land resources are saved, and in addition, deodorizing project investment is reduced for wastewater plants, operation and management are facilitated, and operation energy consumption is lowered.

Owner:CHONGQING WATER GROUP

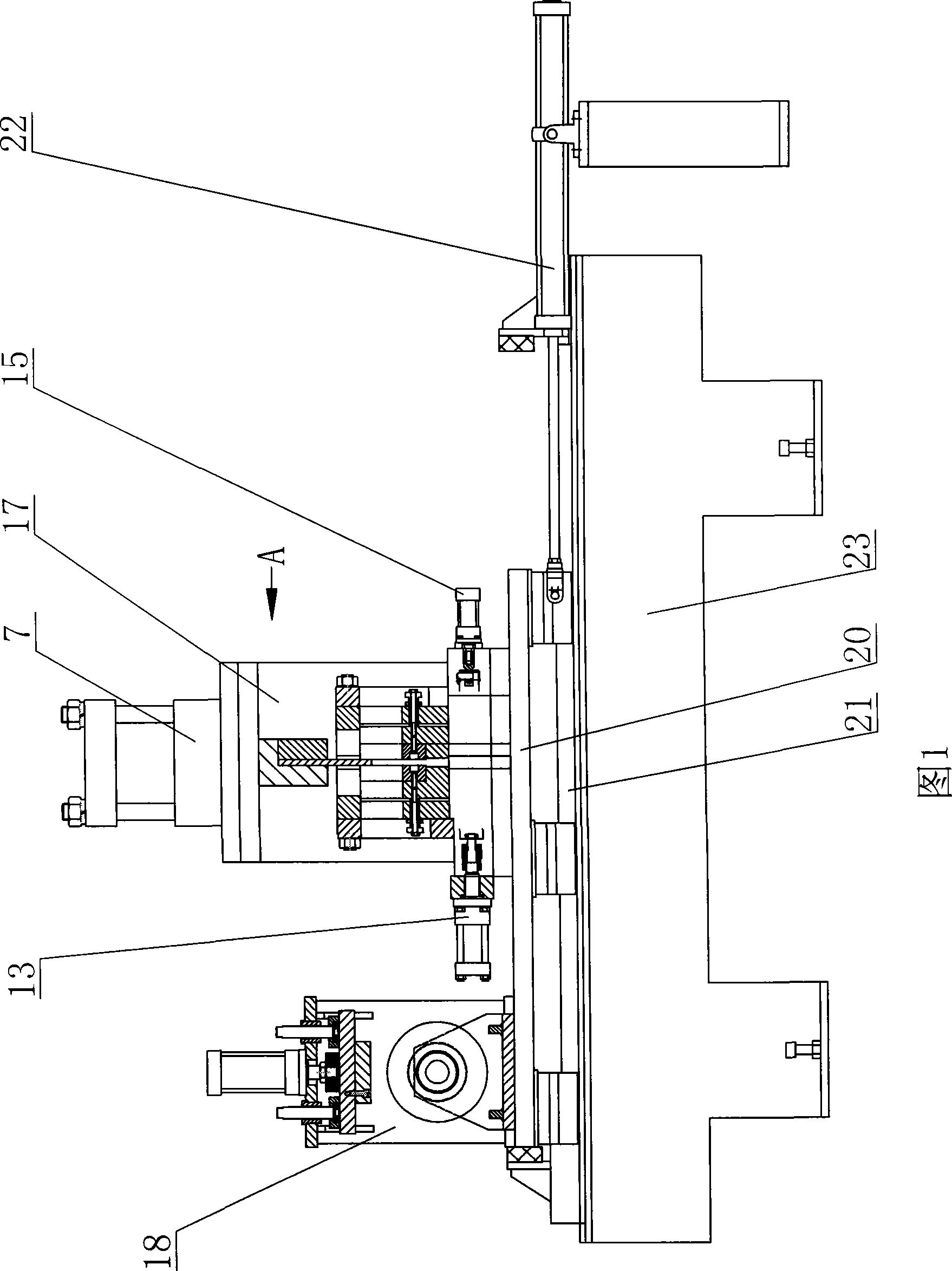

Blanket machine

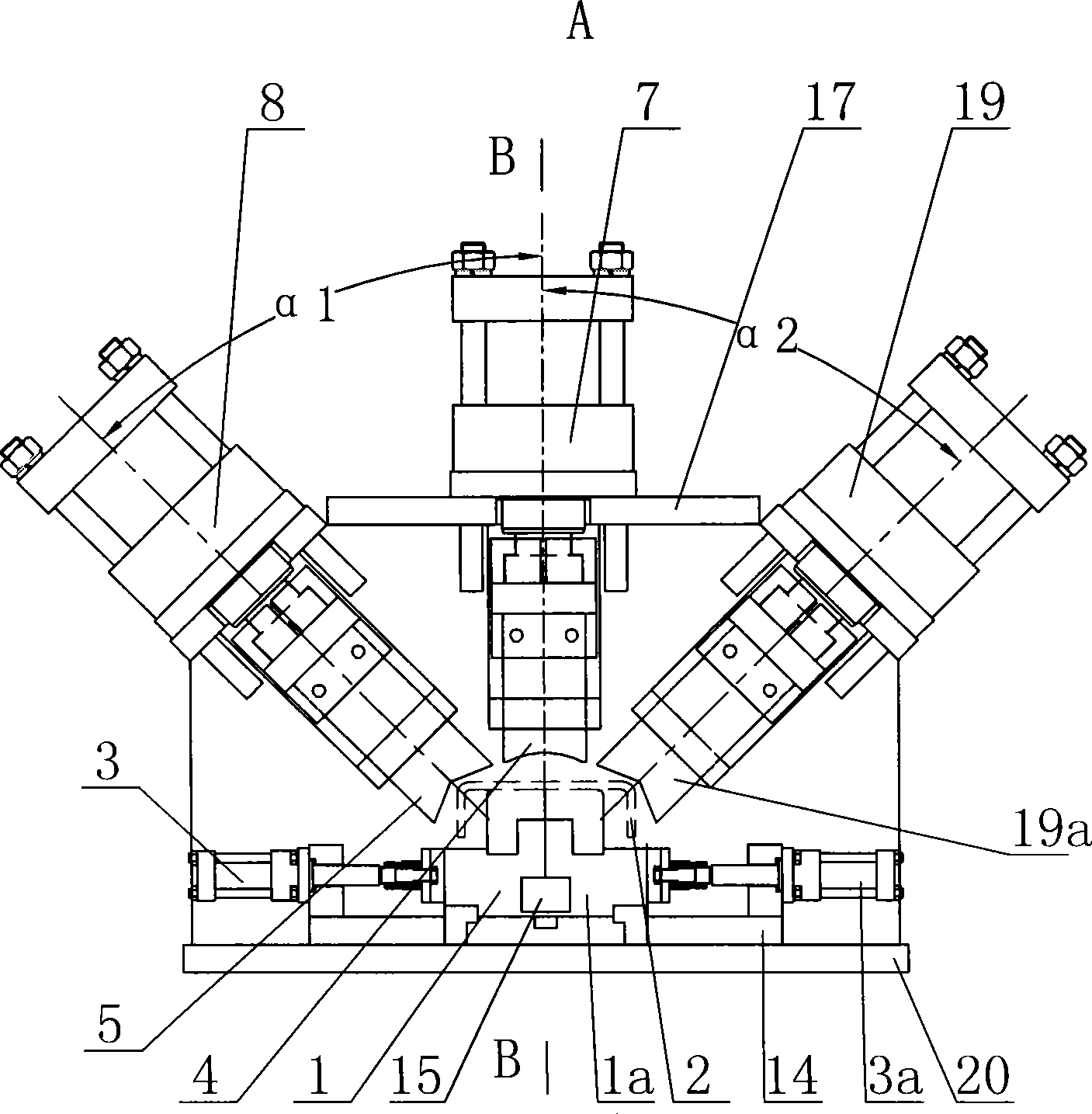

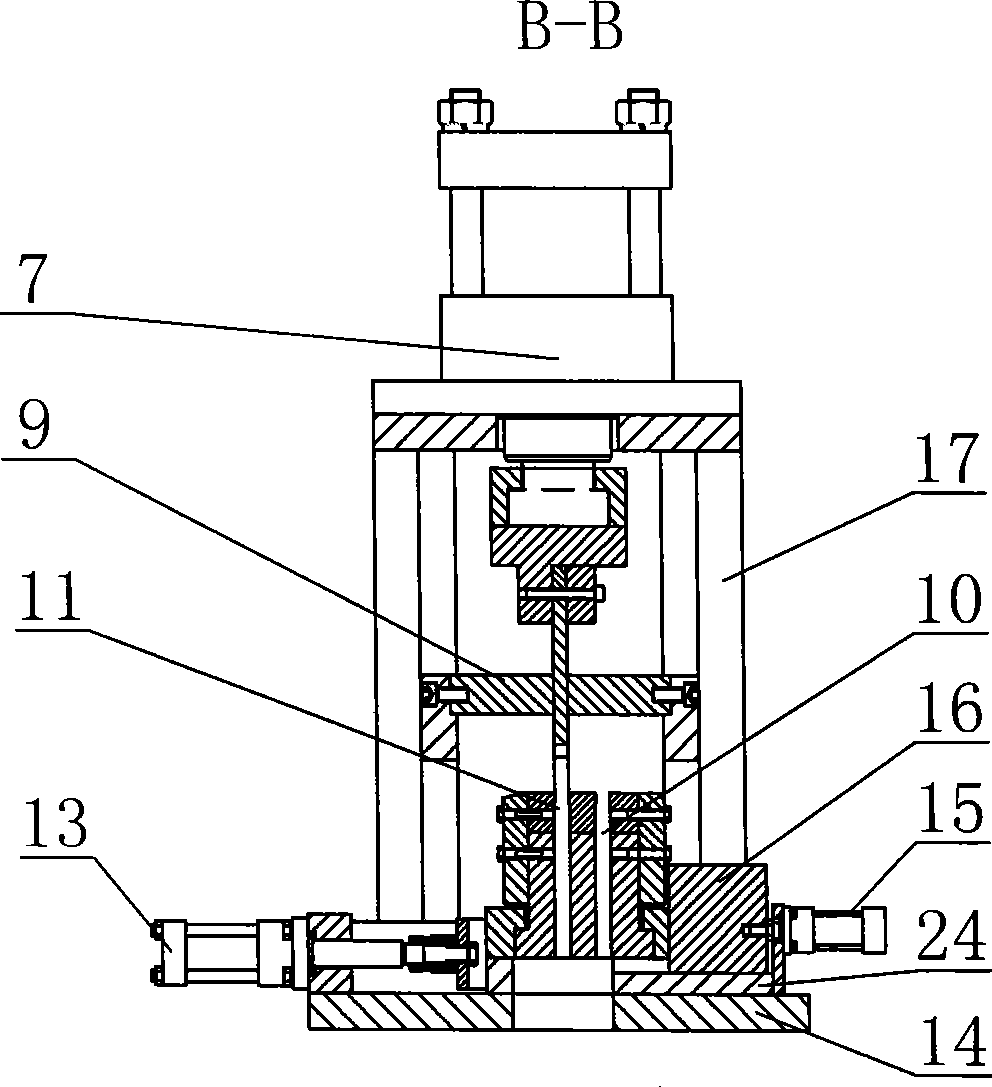

InactiveCN101433976AImprove shear section qualityImprove punching efficiencyStock shearing machinesNibbling shearing machinesContinuous operationManufacturing line

The invention discloses a piece cutter, which comprises a machine tool, wherein the machine tool is provided with a holding fixture, a tool apron and a stander; the stander is provided with a vertical cutting hydraulic cylinder; the lower end of the vertical cutting hydraulic cylinder is provided with a first punch knife; two sides of the vertical cutting hydraulic cylinder are provided with a first obliquely arranged cutting hydraulic cylinder and a second obliquely arranged cutting hydraulic cylinder respectively; lower end of the first obliquely arranged cutting hydraulic cylinder and the second obliquely arranged cutting hydraulic cylinder are provided with a second punch knife and a third punch knife respectively; and the tool apron is positioned on the lower side of the first punch knife and is provided with a tool groove. The piece cutter has the advantages that the piece cutter greatly improves quality of shearing area and punch efficiency; U-shaped beams after the punching need no straightening procedure and can be directly used in the next procedure; the movable tool apron is arranged, can be quickly adjusted according to models of the U-shaped beams, and can punch various models of U-shaped beams; and the piece cutter can perform following-up cutting to realize continuous operation of production lines, has good punching effect, reasonable structure and low noise, and meets the requirements of national environment protection.

Owner:JINAN CASTING FORGING MACHINERY INST

Antimony-free flame-retardant polyvinyl chloride wire and cable material and preparation method thereof

InactiveCN104403224AMeet the requirements of combustion classMeet the requirements of the combustion levelPlastic/resin/waxes insulatorsPolymer scienceAluminium hydroxide

The invention relates to the field of a polyvinyl chloride wire and cable material, especially to an antimony-free flame-retardant polyvinyl chloride wire and cable material. The formula of the wire and cable material contains the following ingredients, by weight, a. 100 parts of polyvinyl chloride (PVC); b. 45-55 parts of one or more substances selected from aliphatic dibasic acid ester, trimellitate, polyester and an epoxy plasticizer; c. 5-11 parts of one or more substances selected from a compound stabilizer and an epoxy compound; d. 10-50 parts of one or more substances selected from hydrous zinc borate, magnesium hydroxide, aluminium hydroxide, huntite and a compound flame retardant; e. 4-25 parts of one or more substances selected from kaolin, ceramic microbead and silica-alumina mineral powder; f. 0-6 parts of zero or more substances selected form ethylene chloride and acrylate; g. 0.5-0.8 part of one or more substances selected from stearic acid, polyethylene wax and a compound lubricant; and h. 1-2 parts of color masterbatch. By the technical scheme, latent personal safety threat existing due to antimony can be minimized, pollution is reduced, and the wire and cable material is more environmentally-friendly and has higher safety.

Owner:HUIZHOU LTK ELECTRONICS CABLE +3

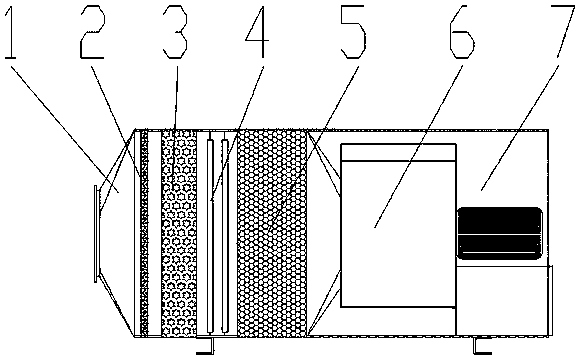

Fume removal device for asphalt road maintenance vehicle

PendingCN108310890ANo pollution in the processMeet the requirements of environmental standardsCombination devicesGas treatmentActivated carbonEnvironmental standard

The invention discloses a fume removal device for an asphalt road maintenance vehicle. The fume removal device for the asphalt road maintenance vehicle comprises a filter pipe, wherein a settlement plate, a Raschig ring demisting plate, a UV (ultraviolet) photolysis oxidation pipe and an activated carbon adsorption cavity are sequentially arranged in the filter pipe from an air inlet end to an airoutlet end. An asphalt fume is filtered through the Raschig ring demisting plate, photolyzed through VOCs (Volatile Organic Chemicals) and adsorbed through activated carbon, so that a heating processof the fume removal device configured for a heating wall of the asphalt road maintenance vehicle is free of pollution, and the treated fume can meet the requirement of a national environmental standard.

Owner:JIANGSU JITRI ROAD ENG TECH & EQUIP RES INST CO LTD

Oily sludge innocent treatment system and treatment method thereof

PendingCN110845101ASimple preparation processLow costSludge treatmentLiquid hydrocarbon mixture productionProcess engineeringOil content

The invention relates to an oily sludge innocent treatment system and a treatment method thereof. The oily sludge innocent treatment system comprises a vacuum drying system, a feeding stirring system,a solid-liquid two-phase separation system, an oil-water separation system and an extractant recovery system, and the solid-liquid two-phase separation system is communicated with the vacuum drying system. And the vacuum drying system is communicated with the oil-water separation system. And the extractant recovery system is communicated with the feeding and stirring system. The extracting agentcomprises butyl acetate and water, the extracting agent is simple in preparation process, low in cost, small in dosage and high in safety, the extracting agent can be recycled, and after the extracting agent is used for treatment, the oil content in the oily sludge meets the national relevant standard requirement (the oil content is smaller than or equal to 0.3%). In the treatment process of the oily sludge, secondary pollution cannot be generated, and the purposes of reduction, harmlessness and recycling of the oily sludge are achieved; meanwhile, in the implementation process of the treatment method, process conditions are mild, and operation is safe.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

High-flexibility water varnish suitable for UV (Ultraviolet) curable offset printing and preparation method of water varnish

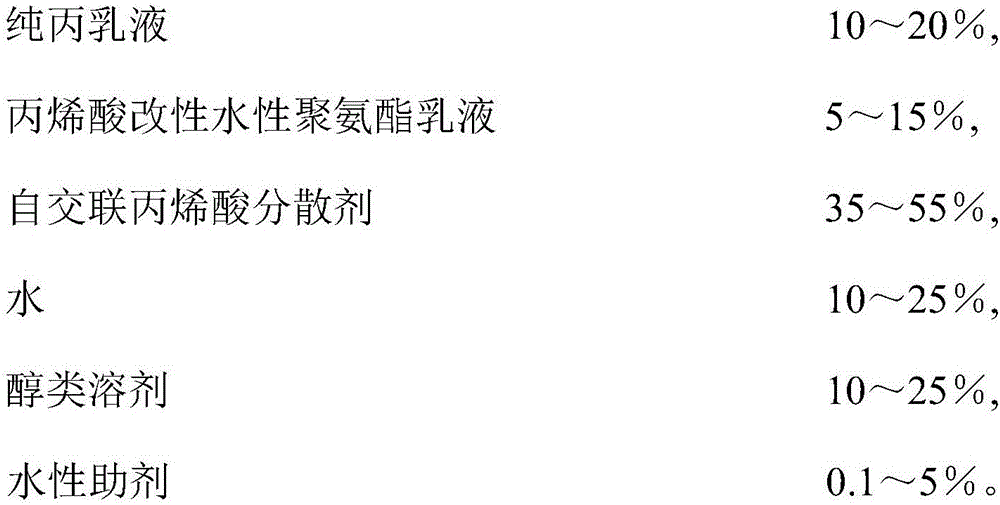

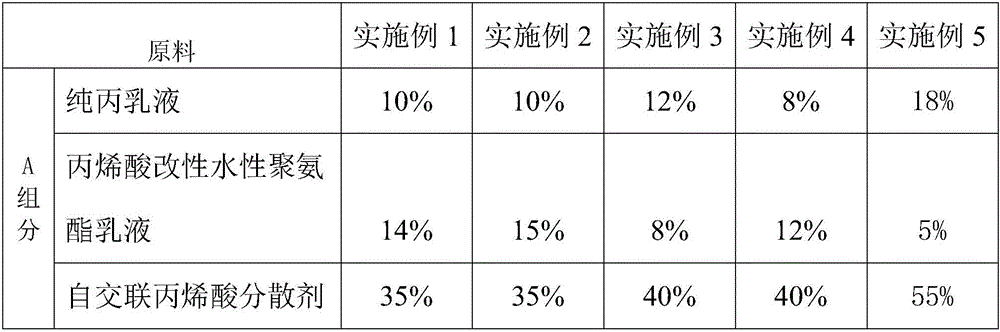

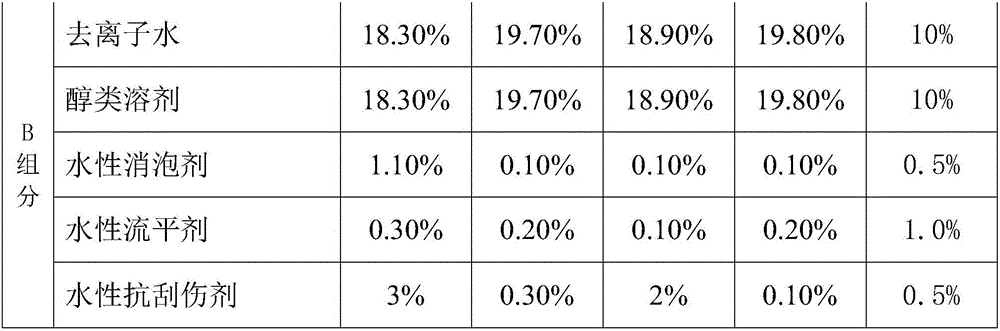

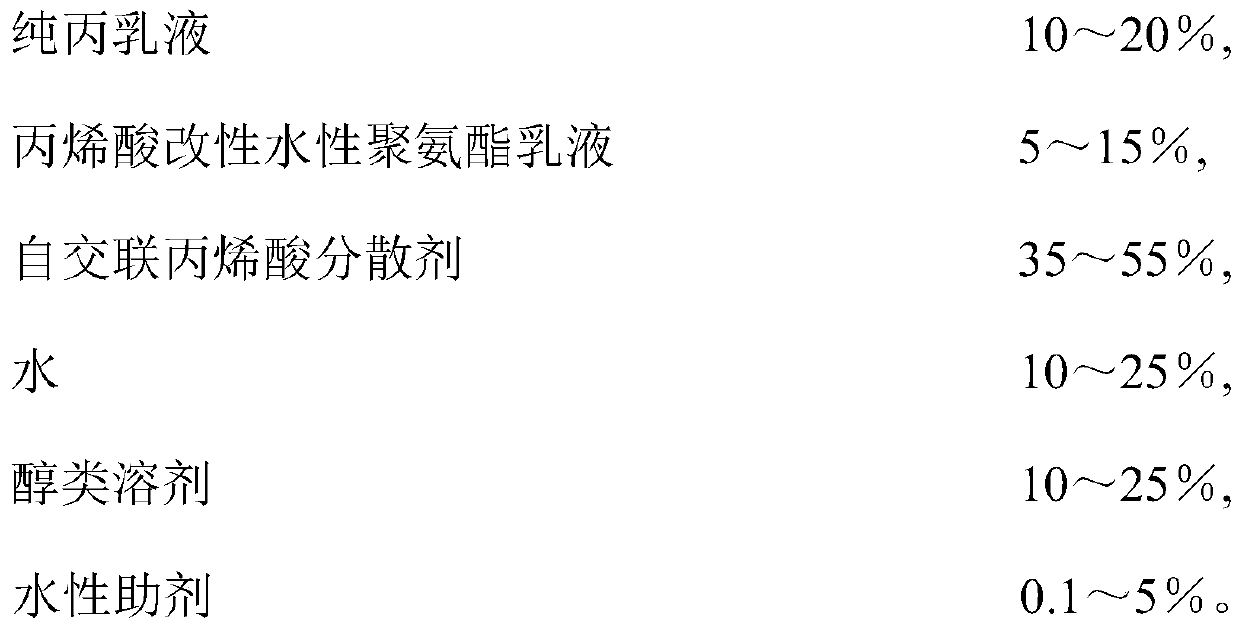

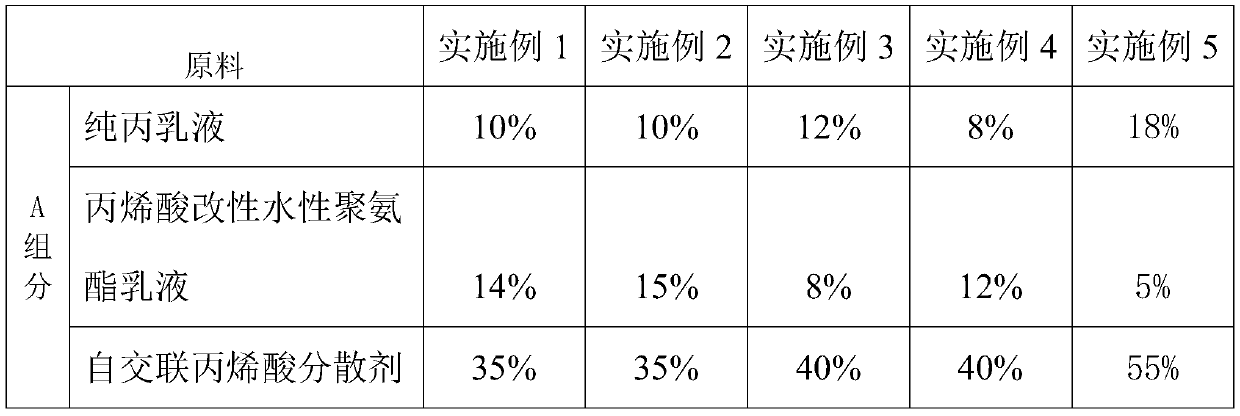

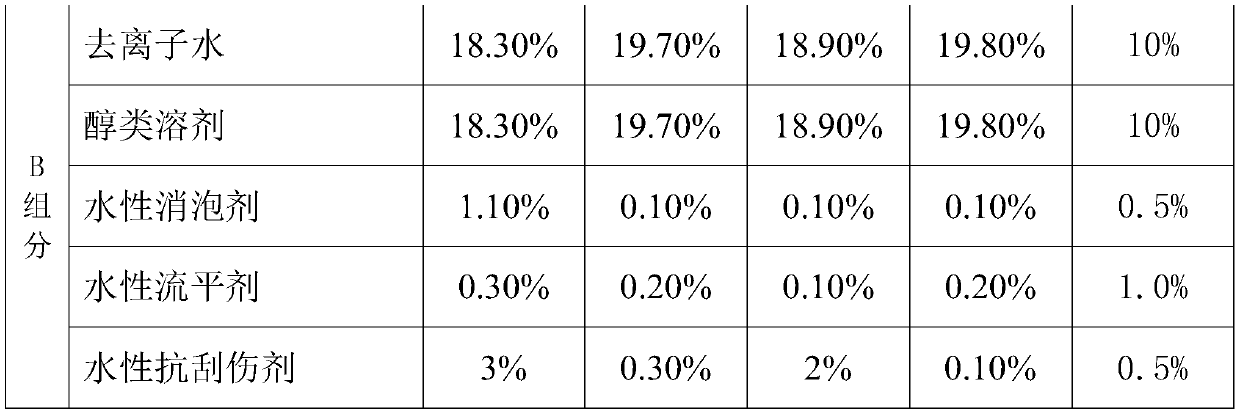

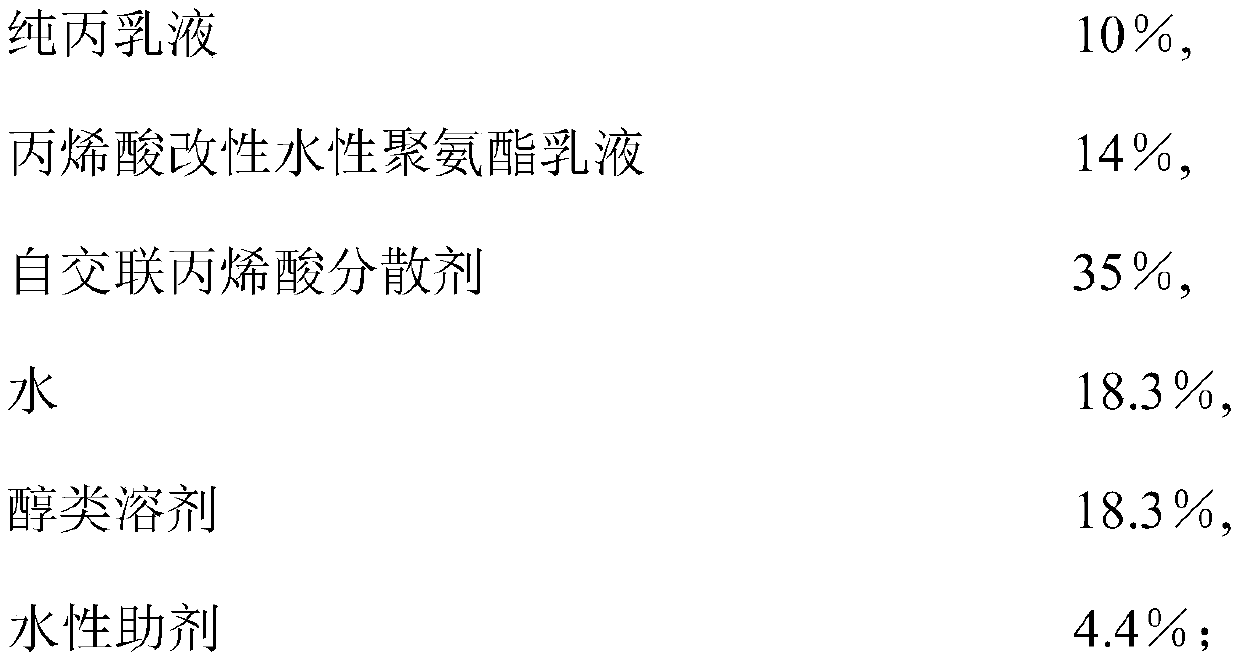

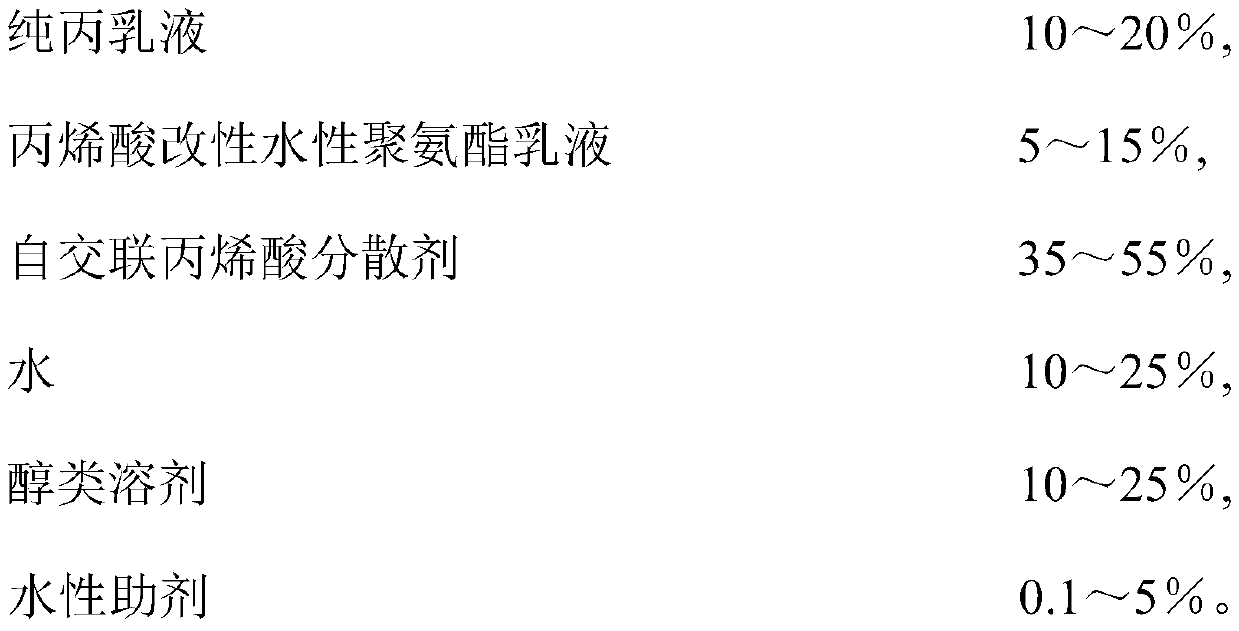

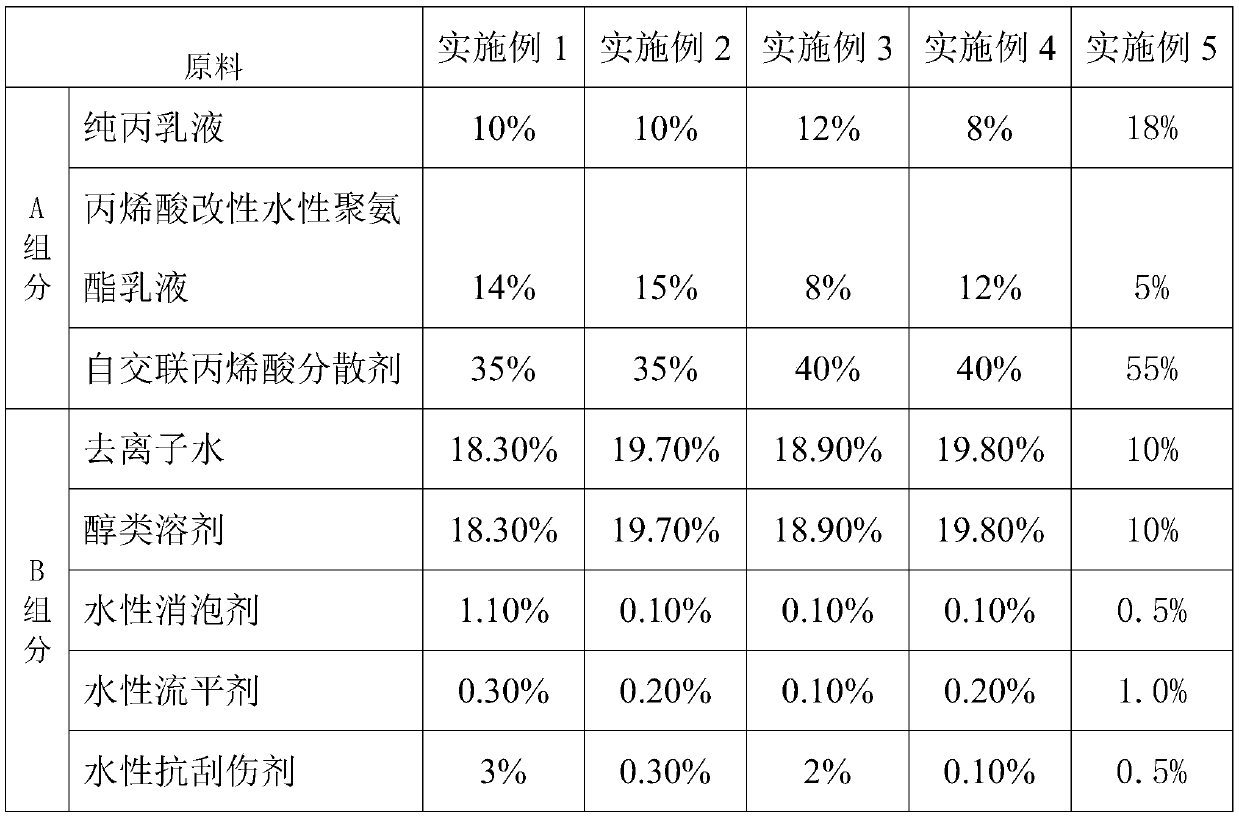

The invention discloses high-flexibility water varnish suitable for UV curable offset printing. According to key points of the technical scheme, the water varnish is composed of the following components by weight percent: 10-20% of pure acrylic emulsion, 5-15% of acrylic-modified aqueous polyurethane emulsion, 35-55% of a self-crosslinked acrylic dispersing agent, 10-25% of water, 10-25% of an alcohol solvent and 0.1-5% of waterborne additives. The invention provides the high-flexibility water varnish suitable for UV curable offset printing. The invention further provides a method for preparing the high-flexibility water varnish suitable for UV curable offset printing.

Owner:广东博海化工科技有限公司

Low-volatility environment-friendly building interior concrete interface treating agent and preparation method thereof

Owner:MEICHAO GROUP

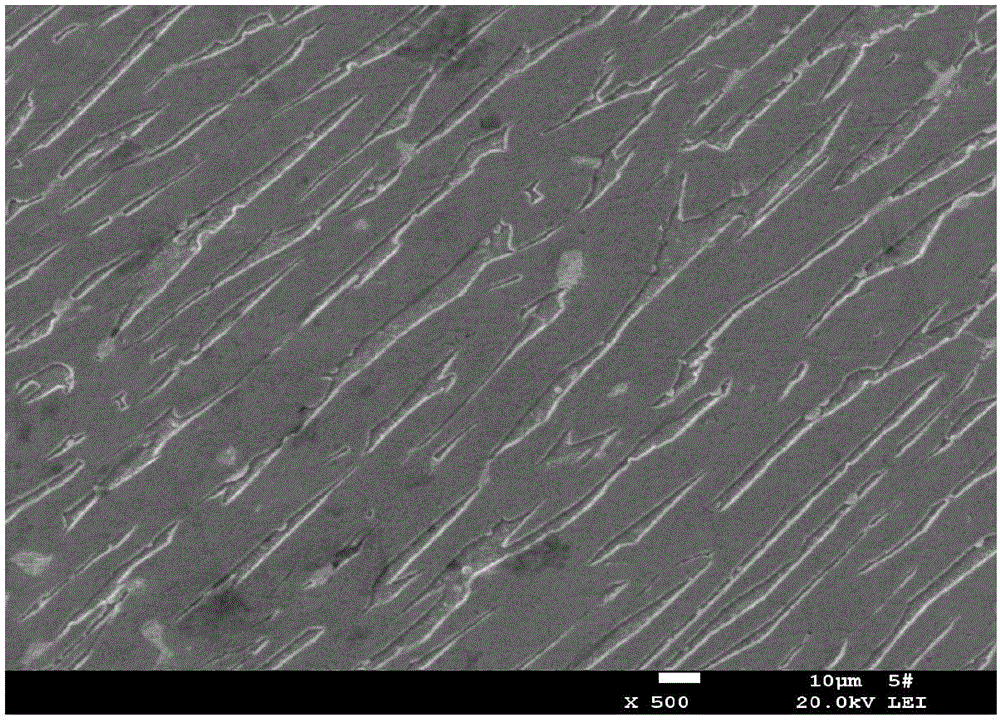

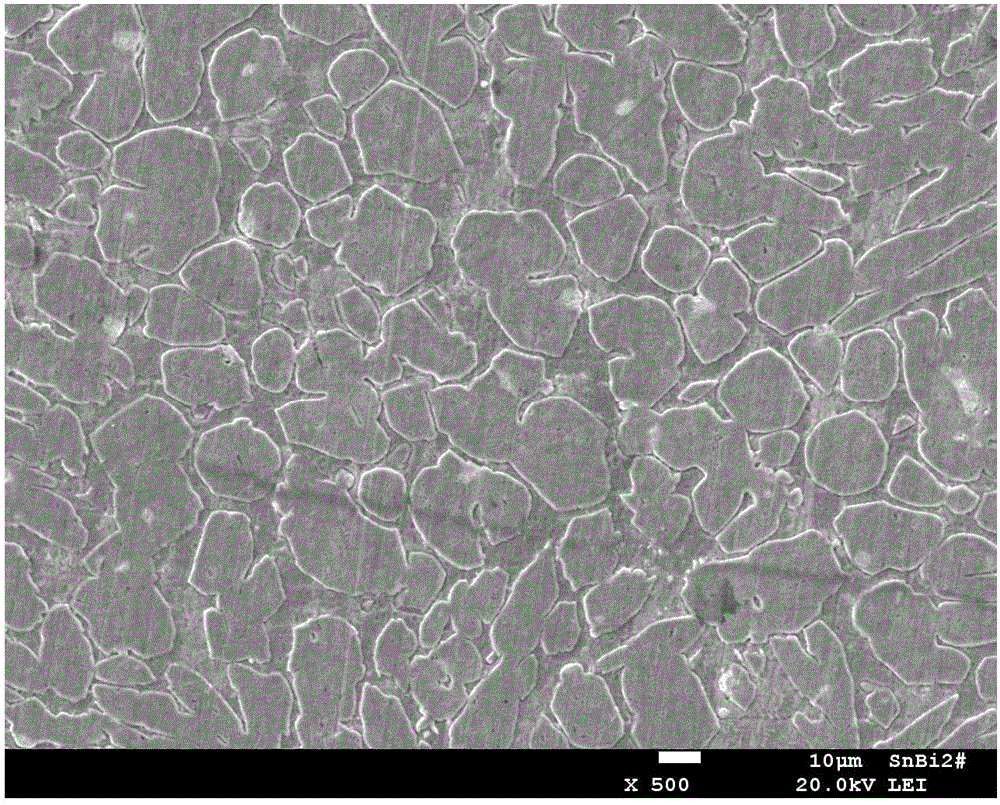

Environment-friendly lead-free easily-cutting anti-heat-cracking brass alloy material and preparation method thereof

InactiveCN105908012AMeet the requirements of environmental standardsSatisfy the use effectMaterials preparationChemical composition

The invention discloses an environment-friendly lead-free easily-cutting anti-heat-cracking brass alloy material and a preparation method thereof. The brass alloy material is characterized by comprising, by weight, 58-64 parts of Cu, 0.4-1.5 parts of Bi, 0.3-0.7 part of Sn, 0.03-0.2 part of Se, 34-41 parts of Zn, and less than 0.2 part of other impurities. The alloy material with the required specifications is prepared through the steps of conventional material preparation, batching, smelting and cold and hot machining. The tensile strength sigma b of the brass alloy material is 400-550 MPa, the hardness HRB of the brass alloy material is 65-80, and the elongation delta of the brass alloy material is greater than 10%. The contents of Pb, Fe and Cd of the brass alloy material meet the national standards, and the brass alloy material has excellent cutting performance and cold and hot machining performance and is applicable to various kinds of connecting parts, valves, valve rod bearings, plumbing bathroom accessories, electronic products and clock instruments.

Owner:SICHUAN XINJU MINERAL RESOURCE DEV CO LTD

Luminous printing colorant and preparation method thereof

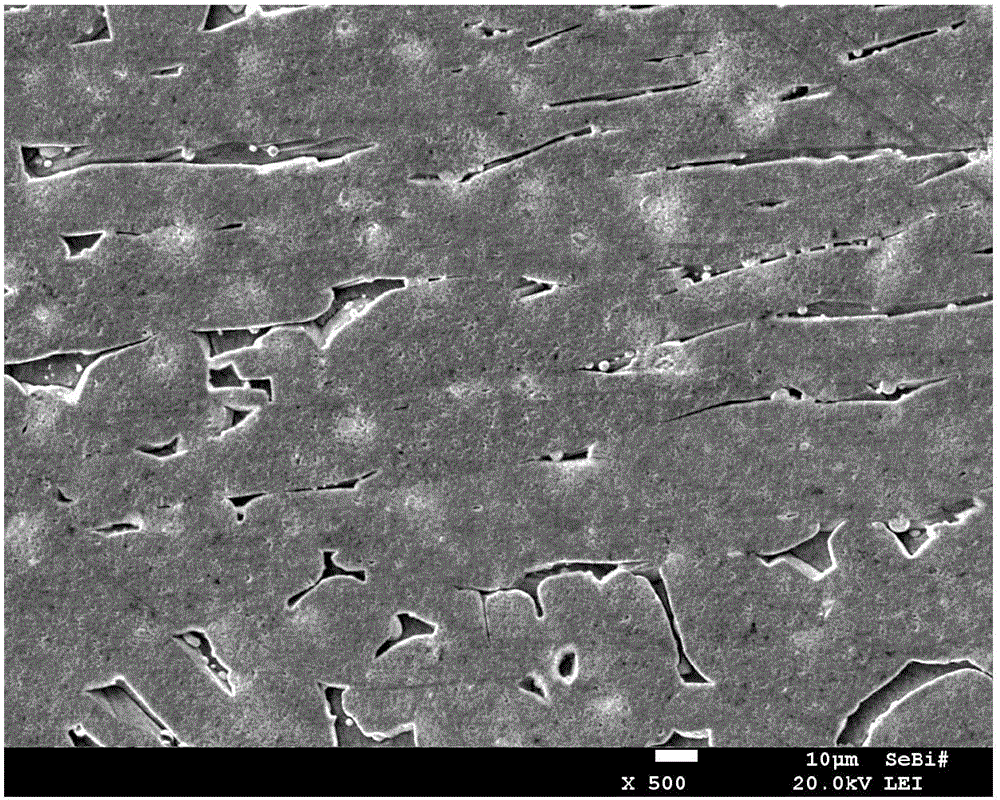

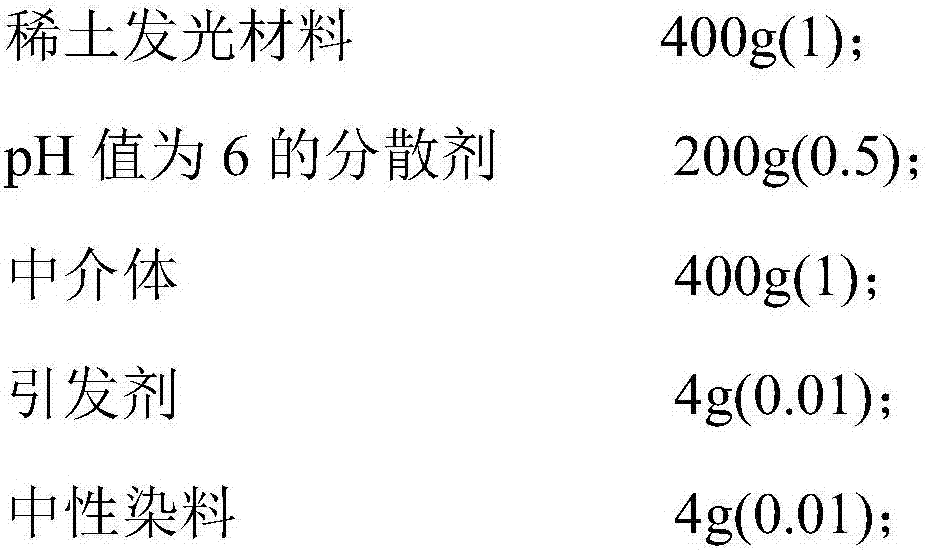

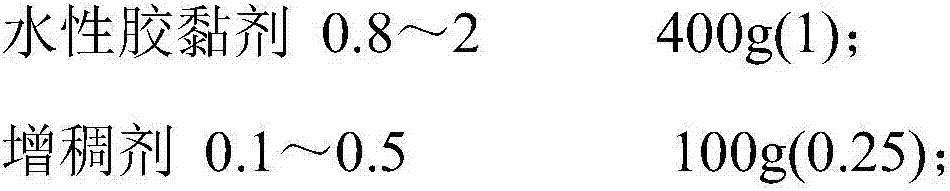

InactiveCN107956160AMaintain luminous propertiesImprove performanceDyeing processTextile printerPolymer science

The invention discloses luminous printing colorant. The luminous printing colorant comprises the following components by mass: 1 parts of a rare earth luminous material, 0.25-1 part of a dispersing agent, 0.8-3 parts of a mesosome, 0.1-0.3 part of an initiator, less than or equal to 0.05 part of dyestuff, 0.8-2 parts of a waterborne adhesive and 0.1-0.5 part of a thickening agent, wherein the rareearth luminous material comprises one or more of Sr(NO3)2, Al(NO3)3.9H2O, Eu2O3 and Dy2O3. On the basis of features of printing of textile, the prepared colorant is applied to a textile fabric, printing fabrics and coating textile fabrics which contain the rare earth luminous material are prepared, the products have appearances and various properties of conventional textile printing and coating fabrics, and furthermore, printing patterns or a whole fabric can be luminous in a dark environment after being illuminated.

Owner:JIANGSU NEW REBA TECH CO LTD

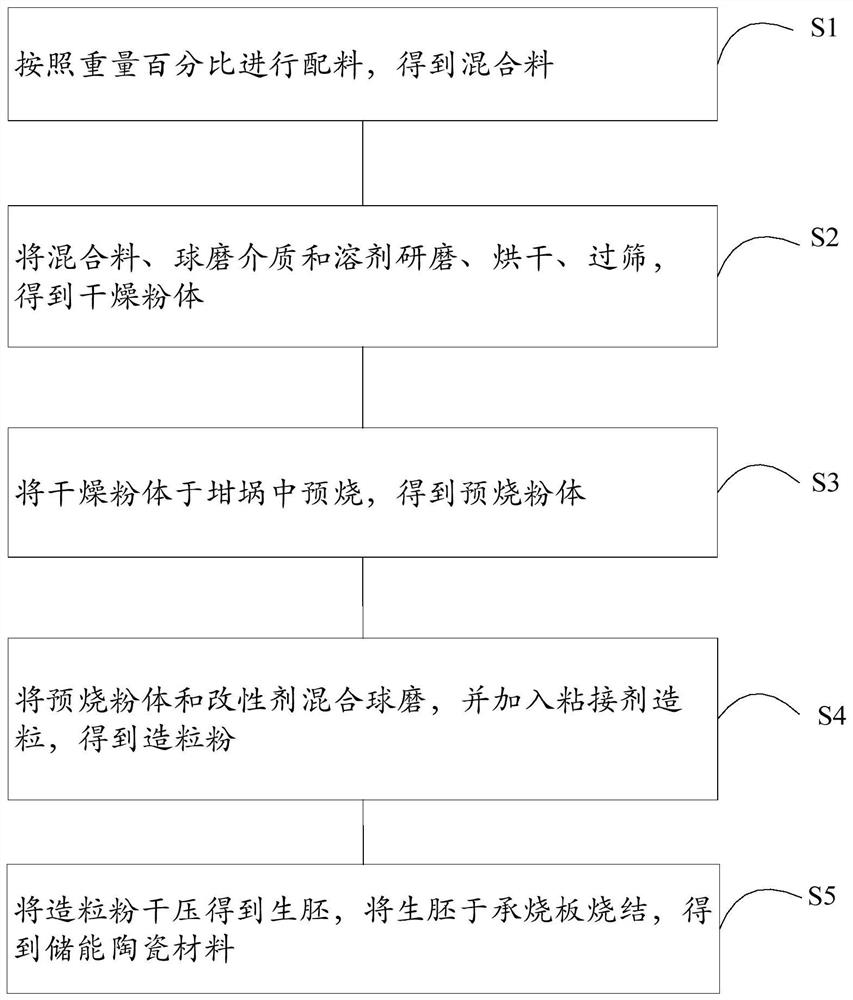

Wide-temperature stable energy storage ceramic material and preparation method thereof

PendingCN114349497AGood energy storage temperature stabilityExcellent dielectric propertiesHigh energyComposite material

The invention relates to the technical field of ceramic materials, in particular to a wide-temperature stable type energy storage ceramic material and a preparation method thereof.The wide-temperature stable type energy storage ceramic material comprises a principal crystalline phase and a modifier, the general chemical formula of the principal crystalline phase is (1-x) BaTiO3-x [ySr0. 7Bi0. 2TiO3-(1-y) Bi (Mg2 / 3Nb1 / 3) O3], x is larger than or equal to 0.1 and smaller than or equal to 0.4, y is larger than or equal to 0.5 and smaller than or equal to 0.95, the modifier is a simple oxide or carbonate, and the main crystalline phase and the modifier are mixed to form the wide-temperature stable type energy storage ceramic material. The main crystal phase is modified by adding the modifier, so that the energy storage performance is obviously improved, high energy density and high energy efficiency are realized, and the material has excellent frequency and temperature stability; according to the preparation method of the wide-temperature stable energy storage ceramic material provided by the invention, the energy storage ceramic material is prepared by ball-milling and mixing for the first time, pre-sintering, ball-milling and mixing for the second time, and sintering at 1100-1250 DEG C. The method is simple, the cost is low, the control is easy, and the preparation is easy.

Owner:MOBILE ANTENNA TECH SHENZHEN +5

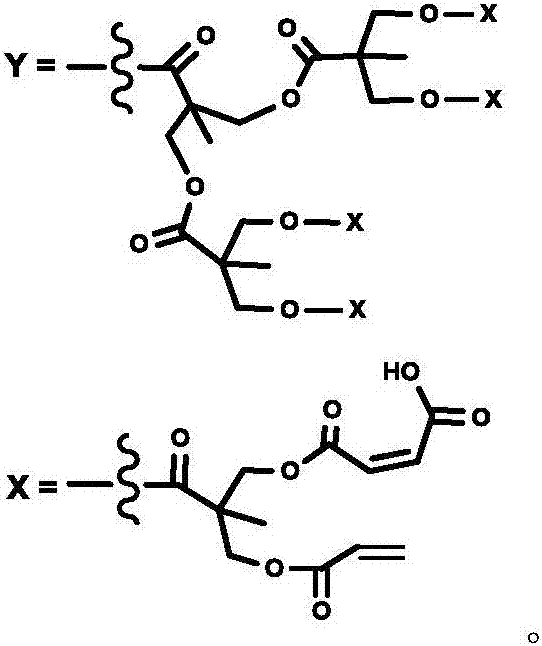

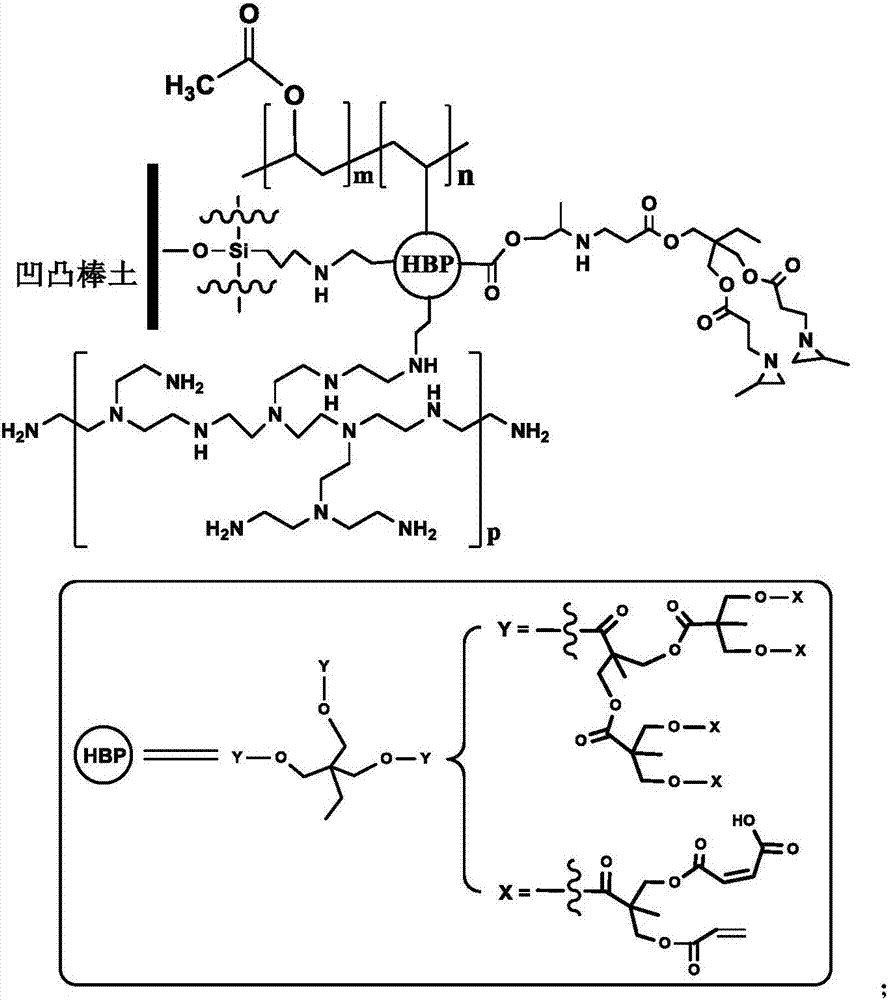

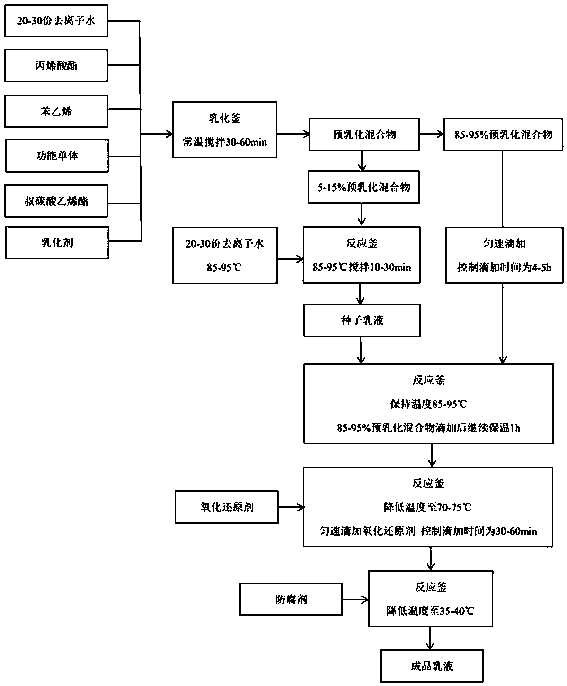

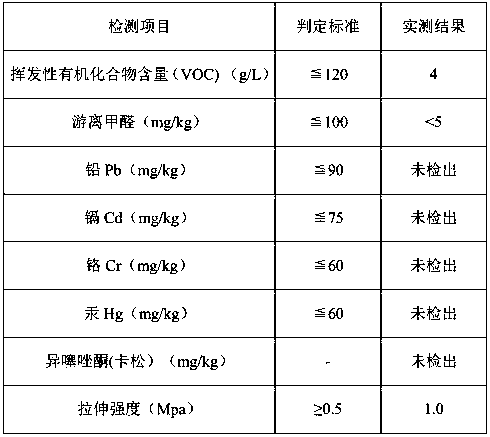

Environment-friendly tert-carbonic acid organic silicone-acrylic modified copolymer emulsion for ceramic tile back adhesive

InactiveCN111154026AHigh bonding strengthMeet the requirements of environmental standardsEster polymer adhesivesPolymer scienceFunctional monomer

The invention discloses an environment-friendly tert-carbonic acid organic silicone acrylic modified copolymer emulsion for a ceramic tile back adhesive. The copolymer emulsion is prepared from the following raw materials in parts by weight: 10 to 20 parts of styrene, 20 to 40 parts of acrylate, 5 to 20 parts of vinyl versatate, 2 to 10 parts of a functional monomer, 2 to 5 parts of an emulsifier,0.2 to 0.4 part of a water-based initiator, 0.1 to 0.3 part of a redox agent, 0.1 to 0.5 part of a preservative, and 40 to 60 parts of deionized water. According to the invention, the environment-friendly tert-carbonic acid organosilicone-acrylic modified copolymer emulsion for the ceramic tile back adhesive is prepared by polymerizing acrylate, tert-carbonic acid, styrene and organosilicon macromolecules; raw materials are environmentally friendly and meet the environmental protection standard requirements, and experimental research shows that the copolymer emulsion is high in bonding strength, not prone to hollowing and brick falling, convenient to construct and good in water resistance, freeze thawing resistance, aging resistance and the like.

Owner:中山保易达新材料有限公司

Complexing iron desulfurizing agent for Claus tail gas treatment

ActiveCN110876881AEmission reductionHigh activityGas treatmentDispersed particle separationIron saltsPhysical chemistry

The invention belongs to the technical field of gas purification, and particularly relates to a complexing iron desulfurizing agent for Claus tail gas treatment, wherein the complexing iron desulfurizing agent comprises the following components: a soluble iron salt, a soluble cerium salt, a chelating agent, an inorganic alkali, an organic additive and water, wherein the weight percentage of the iron ions is 0.5-5% wt, a molar ratio of Fe<3+> to Fe<2+> is 0.5-5.0, the weight percentage of the cerium ions is 0.1-0.5% wt, a molar ratio of the cations to the iron ions in the inorganic alkali is 0.5-1.0, a molar ratio of the chelating agent to the sum of the iron ions and the cerium ions is 1.0-3.5, and the weight percentage of the organic additive is 0.2-2 wt%. The desulfurizing agent can simultaneously remove hydrogen sulfide and carbonyl sulfide in Claus tail gas, wherein the content of the hydrogen sulfide in the purified tail gas after desulfurization is smaller than 10 mg / m<3>, and the content of the carbonyl sulfide in the purified tail gas after desulfurization is smaller than 20 mg / m<3>, so that the national environmental protection standard requirement is met, the cost is low,the desulfurizing agent activity is high, and the desulfurizing effect is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

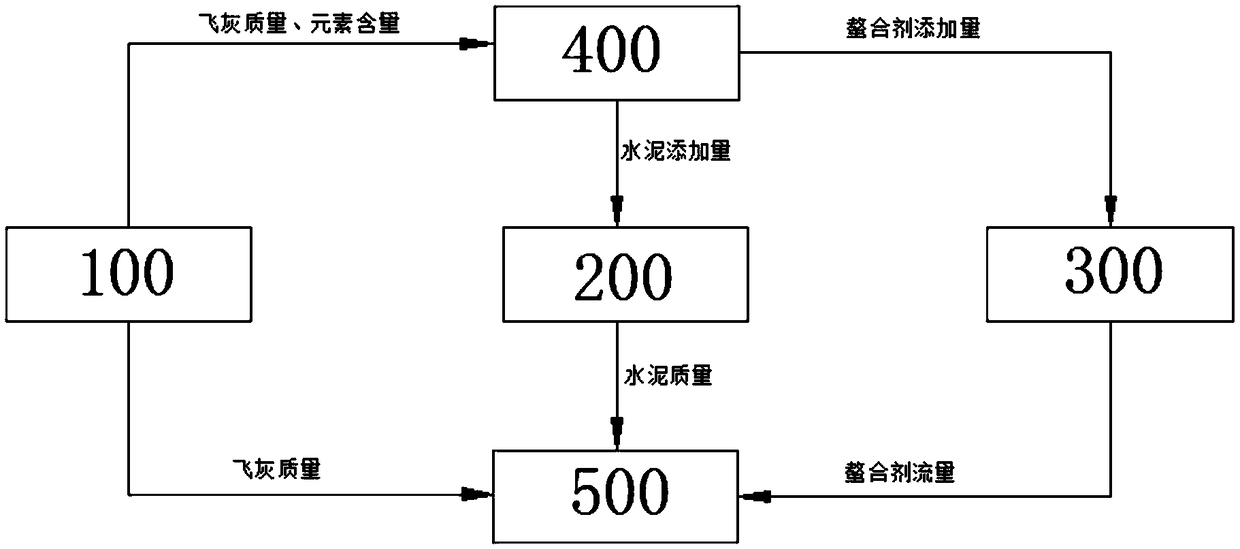

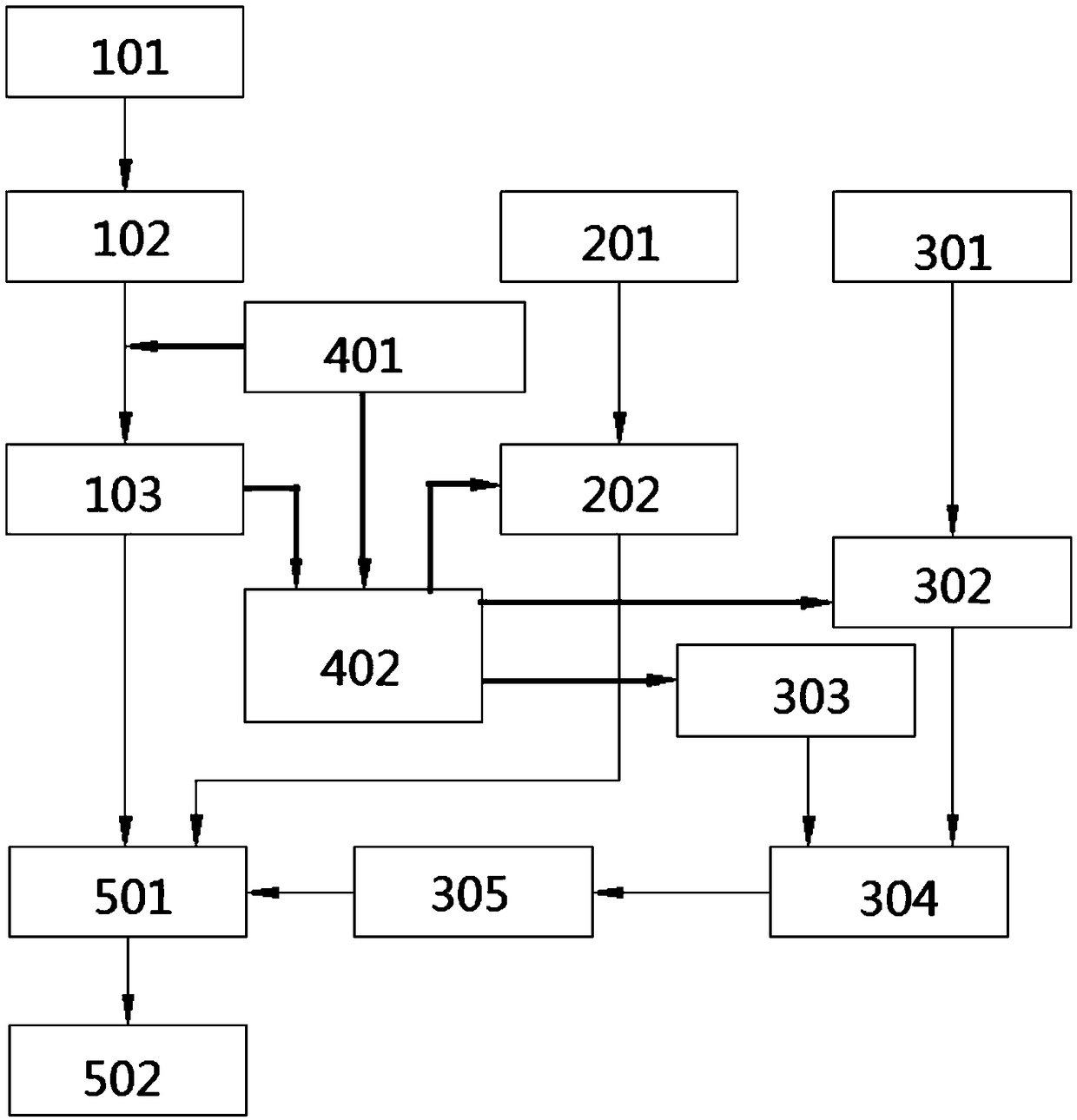

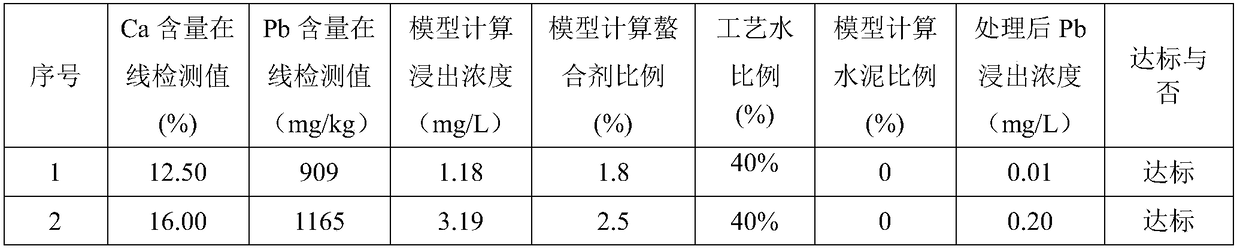

Stabilizing and curing processing system and processing system for fly ash by waste incineration

PendingCN109277402AReal-time detection of element contentMaster physical and chemical propertiesMaterial analysis using wave/particle radiationSolid waste disposalEnvironmental engineeringTherapeutic effect

The invention relates to a stabilizing and curing processing system and processing method for fly ash by waste incineration. The processing system comprises a fly ash metering unit, a cement meteringunit, a chelating agent metering unit, a detection and adding control unit and a stabilization unit, wherein the fly ash metering unit, the cement metering unit and the chelating agent metering unit communicate with the stabilization unit; and the detection and adding control unit comprises an on-line detection module and a control module. According to the system, the online detection module is adopted, so that the content of elements in each batch of fly ash can be detected in real time, the physical and chemical characteristics of each batch of fly ash are accurately mastered, and the stabilization and solidification treatment of the fly ash is facilitated; and in addition, the adding amount of cement and chelating agent is precisely adjusted and controlled according to the physical andchemical characteristics of each batch of fly ash, the treatment effect of the fly ash stabilization curing can be greatly improved, and the requirements of environmental protection standards can be met after the fly ash treatment is ensured.

Owner:YONKER ENVIRONMENTAL PROTECTION

Environment-friendly vapor phase rust-proof film

The invention discloses an environment-friendly vapor phase rust-proof film which is formed by carrying out mixing, coextrusion and blow molding on 85-95% of matrix plastic and 15-5% of additive by weight. The additive comprises the following components by weight percent: 70-85% of vapor phase inhibitor, 2-5% of dispersed lubricant and 10-28% of carrier plastic. The vapor phase inhibitor is formed by combining sodium benzoate, tungstate and morpholine unit-containing diamine type, and the weight ratio of sodium benzoate to tungstate to diamine type containing morpholine unit is (1-3):(1-2.5):(1-3). The environment-friendly vapor phase rust-proof film has the characteristics of high strength, stable sealing performance, good rust-proof performance and single material, and is energy-saving and environment-friendly. Each component has synergistic effect, and inherent physical and chemical rust-proof performances of each component can be fully exerted.

Owner:上海福岛新材料科技有限公司

System and method for calcining treatment and resource utilization of sugar-making filter mud

PendingCN112648621AReduce the workload of manual operationsEasy to operateEmission preventionIncinerator apparatusDust controlCalcination

The invention provides a system for calcining treatment and resource utilization of sugar-making filter mud. The system comprises a pulverized coal preparation system, a feeding system, a calcining system, a waste heat recovery system, a flue gas environment-friendly up-to-standard emission treatment system and a quick lime recovery system, Raw material coal is prepared into pulverized coal as auxiliary fuel, crude sugar filter mud is crushed, the pulverized coal and the crude sugar filter mud are simultaneously added into a calcining furnace, ash generated after calcining is discharged and cooled to serve as a quick lime material; flue gas generated after calcination enters a waste heat boiler to be subjected to heat recycling, saturated steam is generated, the flue gas obtained after heat exchange enters a denitration device to be subjected to denitration treatment, the flue gas obtained after denitration exchanges heat with air and then is subjected to dust removal, and clean flue gas is obtained; and air heated by the flue gas is introduced into the calcining furnace as combustion-supporting air, so that the temperature of the combustion-supporting air entering the calcining furnace is integrally increased. Reduction and harmless treatment of the sugar-making filter mud are achieved, meanwhile, quick lime generated in the high-temperature calcination process, namely the high-temperature decomposition reaction process, is recycled to achieve the purpose of resource utilization, high-temperature flue gas waste heat generated in calcination is recycled to generate saturated steam, and the purpose of energy conservation in the environment-friendly treatment process is achieved.

Owner:大连科林能源工程技术开发有限公司

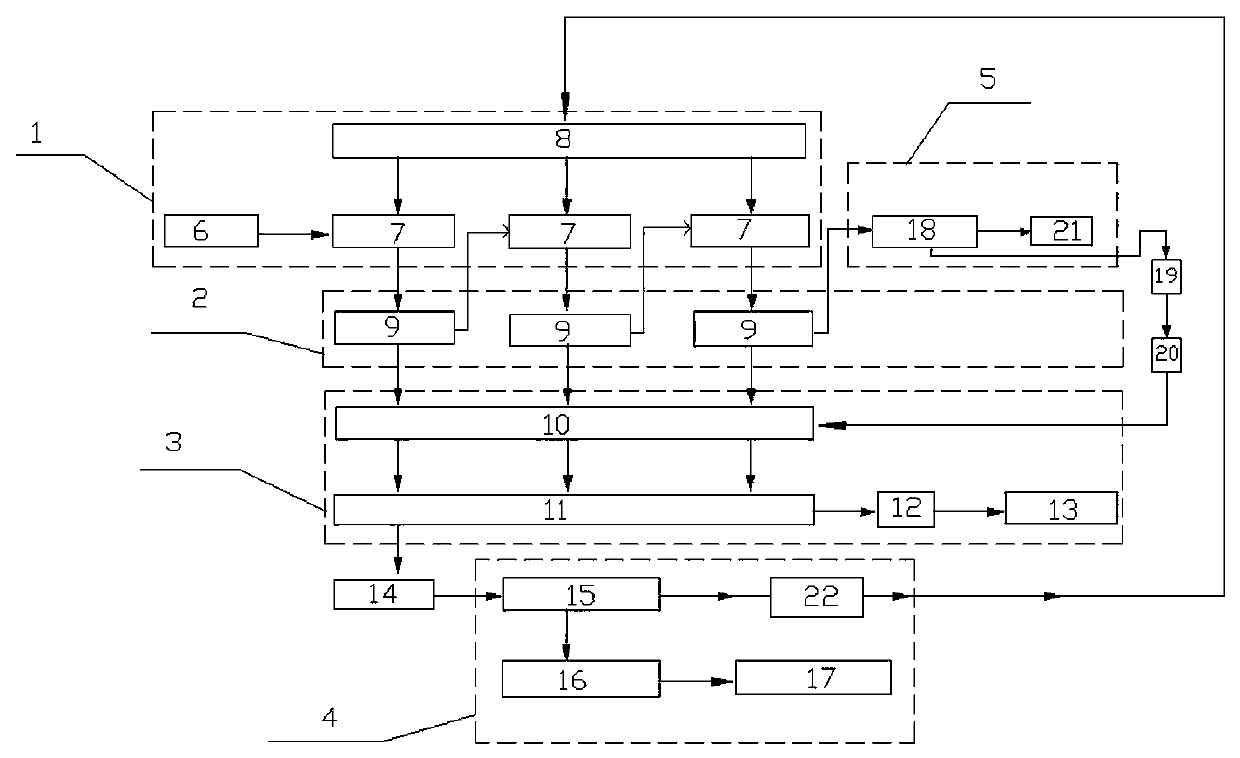

Combustion system for changing methanol into hydrogen fuel used in industrial furnace and thermal power plant.

InactiveCN100467946CReduce dependenceAvoid pollutionBurnersHydrogenManufacturing cost reductionLiquid fuel

The present invention discloses a burning system using hydrogen fuel changed from methanol in industrial furnace and power station. The burning system is composed of a hydrogen making burning system, a heat transfer oil heating cycle system, a furnace remaining heat smoke heating system, an air preheating system, a start system and a bypass recycle system. The heat transfer oil is heated by furnace smoke remaining heat, and makes the methanol liquid fuel vaporize. The methanol is transferred to fuel with hydrogen as main component by the hydrogen making system, the fuel is then provided to furnace to burn. The burning process will not generate dust and sulfur dioxide harmful gas, and greatly reduces the discharge amount of the carbon dioxide gas. The fuel is satisfy with the national environmental protection standard requirement and can become new type substitute energy for the industrial furnace. The system has the advantages of safety, stable running, miniaturization of equipments and reduced manufacturing cost.

Owner:王衍衡

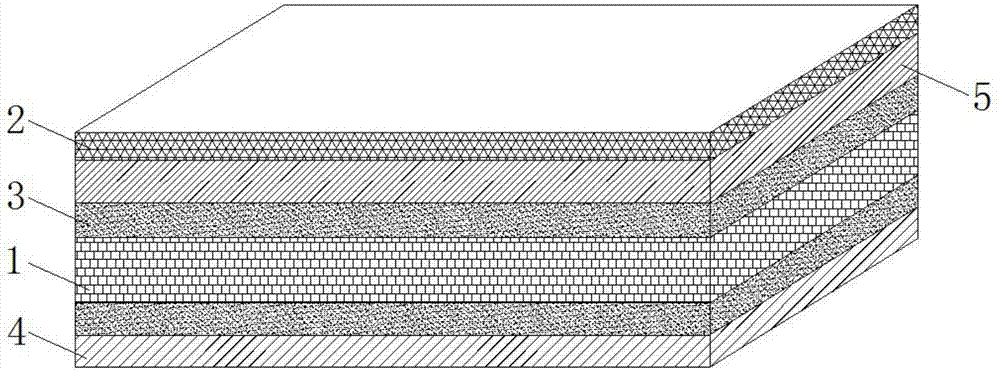

Antibacterial and anti-mite plywood structure and manufacturing method thereof

InactiveCN107139281AImproves anti-mite and antibacterial propertiesPracticalLamination ancillary operationsProtein adhesivesEngineeringMoisture

The invention discloses an antibacterial and anti-mite plywood structure and a manufacturing method thereof. The antibacterial and anti-mite plywood structure comprises a plywood body, a wearing plate, anti-mite plates, a moisture absorbing plate and a fireproof plate, wherein the anti-mite plates are glued at the top and the bottom of the plywood body, and the moisture absorbing plate is glued on the anti-mite plate close to the bottom of the plywood body; the fire-proof plate is glued on the anti-mite plate close to the top of the plywood body; and the wearing plate is glued on the side, far away from the anti-mite plate, of the fire-proof plate. According to the antibacterial and anti-mite plywood structure and the manufacturing method thereof, the plywood body is soaked in an anti-mite finishing agent, and an anti-mite finishing agent solution is added into glue, so that the plywood body is subjected to double-layer protection, accordingly, the anti-mite and antibacterial performance of the plywood body is effectively improved, and a safety guarantee is provided for the indoor life of users; and meanwhile, the anti-mite finishing agent is a DM-3031D anti-mosquito finishing agent, so that the mosquito repelling and disinfecting effects are achieved.

Owner:广东喜粤新材料科技有限公司

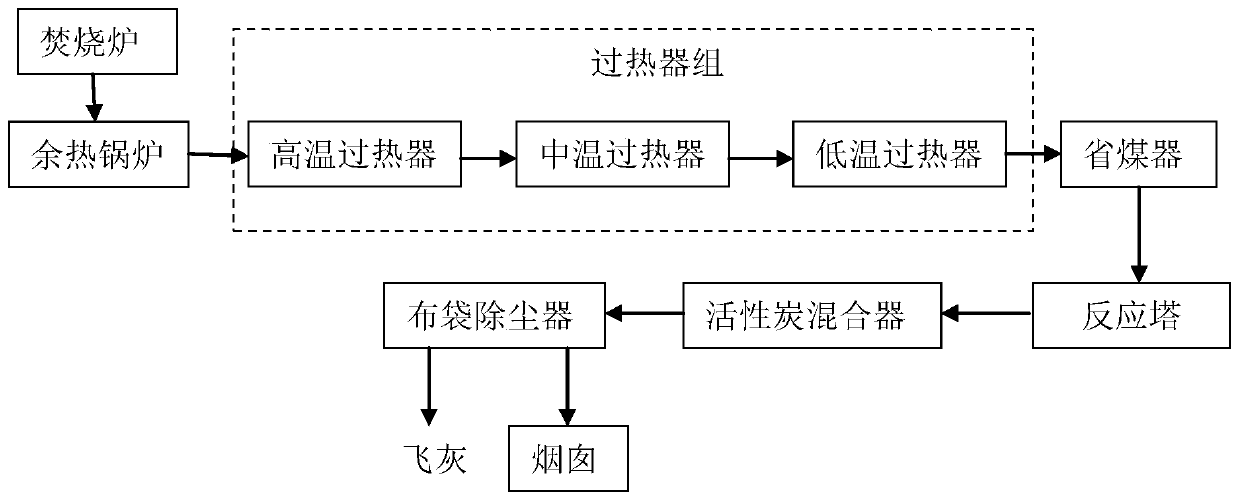

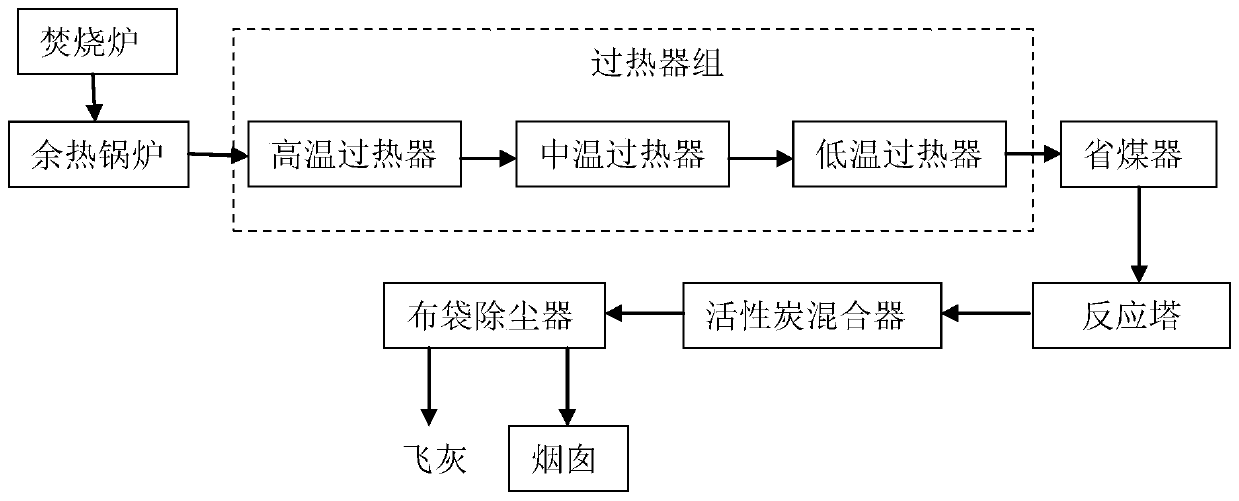

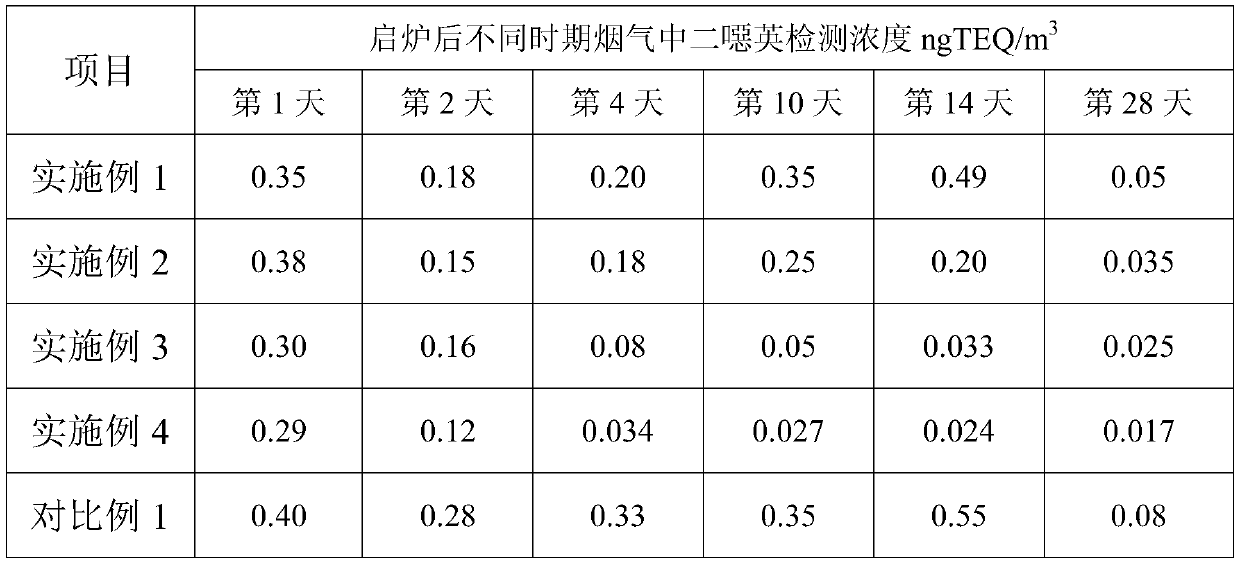

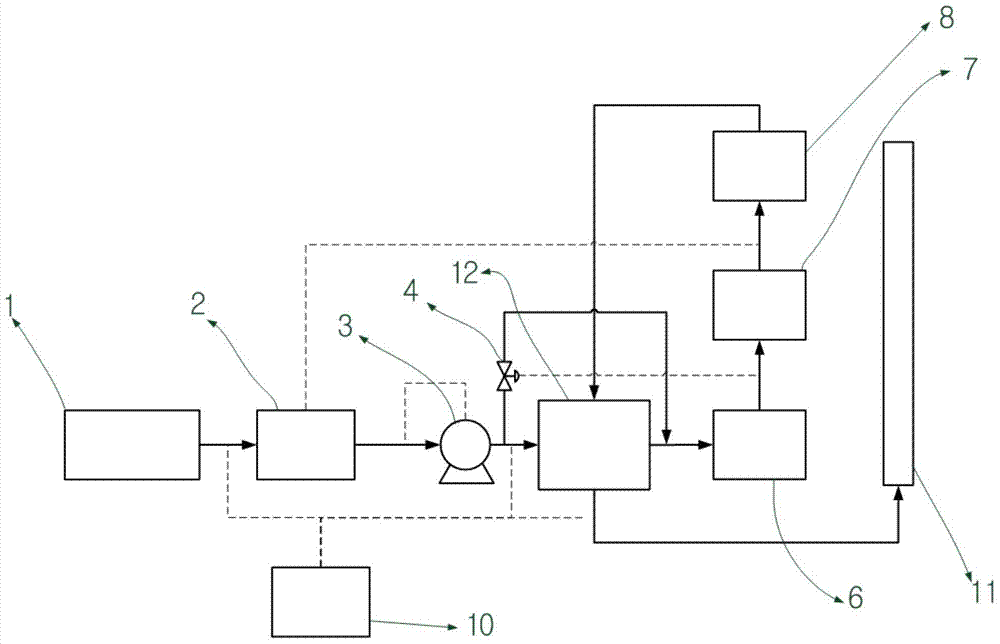

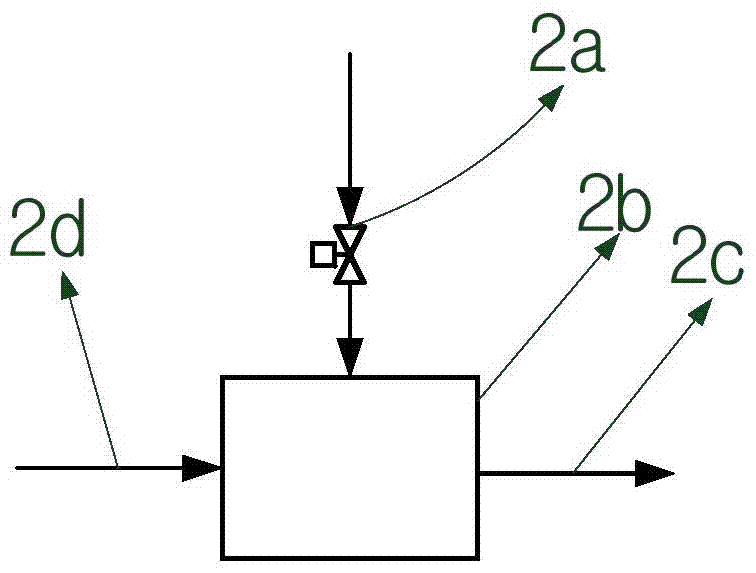

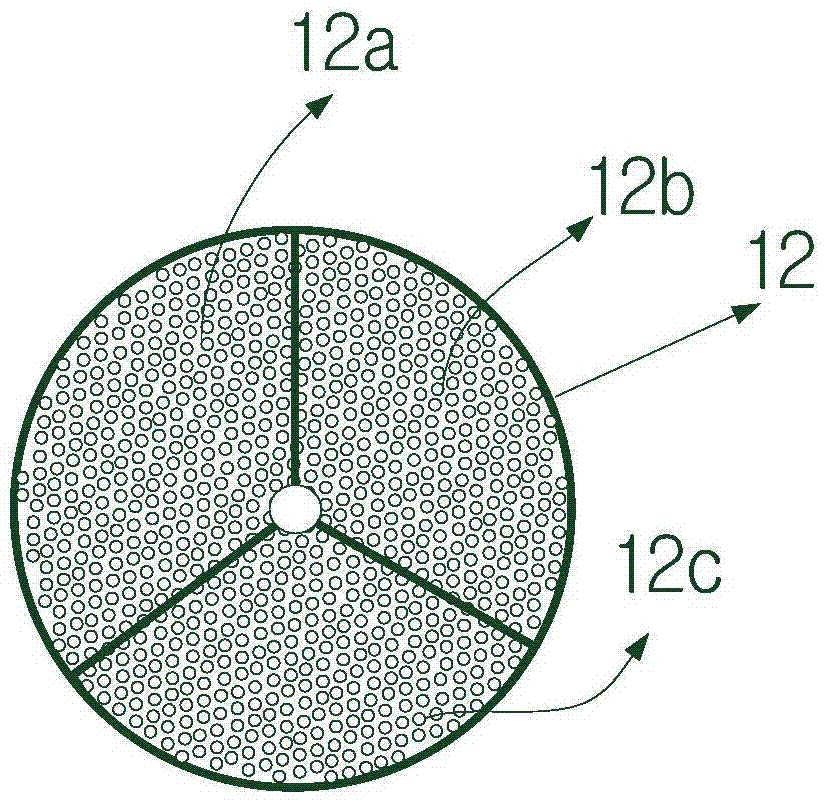

Waste incineration fume treatment method for controlling dioxin memory effect

InactiveCN111121063AGood effectExtended service lifeGas treatmentDispersed particle filtrationActivated carbonHeating efficiency

The invention discloses a waste incineration fume treatment method for controlling the dioxin memory effect. The waste incineration fume treatment method comprises the steps that fly ash and other sediments with the dioxin memory effect in a device and a pipeline are removed before an incinerator is started, activated carbon is pre-sprayed into a bag-type dust collector so that a lot of dioxin generated in the incinerator starting and incineration processes can be effectively adsorbed in time, and moreover, the severe dioxin memory effect caused when the bag-type dust collector adsorbs a massive amount of dioxin because of the device itself, aging and the like in the long-time using process can be controlled. By means of the method, it can be achieved that the discharging concentration ofthe dioxin can meet the discharging standards the next day when the furnace is started, and starts tending to be stable the fourth day after the furnace is started, and the environment-friendly standard requirements are met. The method can effectively control the dioxin memory effect, the heat efficiency is high, energy conservation and environment protection are achieved, the method is simple andfeasible, and the operation is convenient.

Owner:HANLANLVDIAN SOLID WASTE TREATMENT (FOSHAN) CO LTD 2ND

Low-temperature regenerative catalytic oxidation method for treating vocs gas

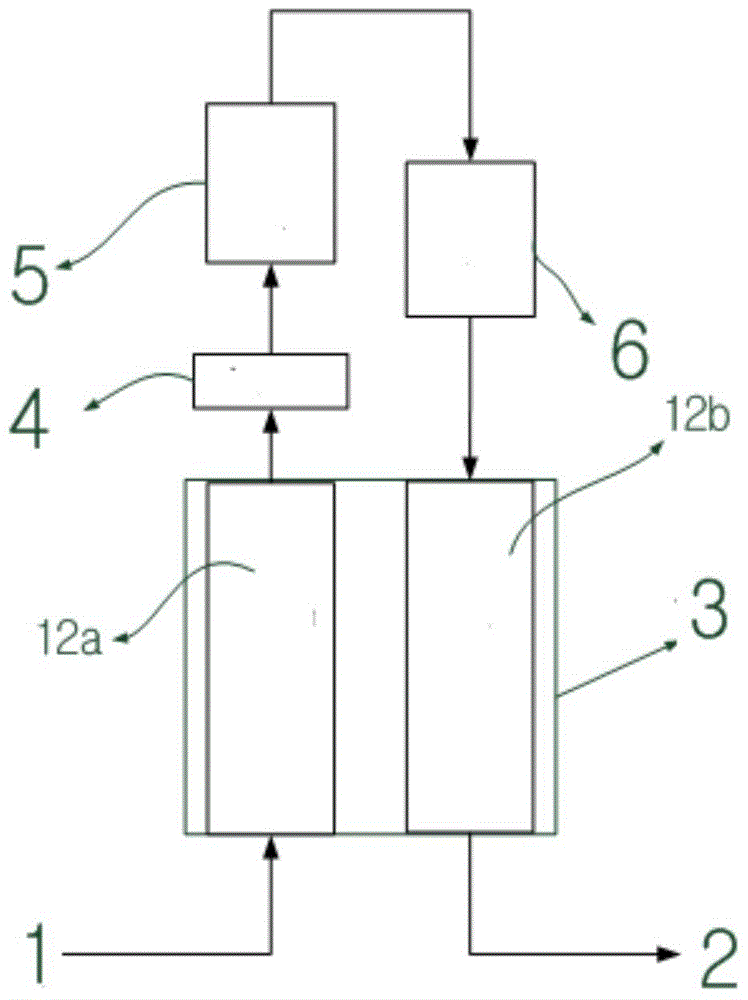

ActiveCN105066148BGuaranteed concentrationSatisfy the processing indexIncinerator apparatusHigh concentrationCatalytic oxidation

The invention relates to a low-temperature heat accumulating type method for treating VOCs gas in a catalytic oxidation manner. The problems that in the prior art, serious potential safety hazards exist, ignition temperature is high, and energy consumption is large are mainly solved. The low-temperature heat accumulating type method for treating VOCs gas in the catalytic oxidation manner is adopted, VOCs gas passes through a VOCs high-concentration recovery device and then enters a pre-treatment system, and pretreated gas enters a heat exchanger cold stroke through a fan; gas at an outlet of the heat exchanger cold stroke enters a heating chamber, and gas heated by the heating chamber enters a low-temperature catalytic oxidation bed, a high-temperature catalytic oxidation bed and a honeycomb ceramic heat accumulator; and gas at an outlet of the honeycomb ceramic heat accumulator enters a heat exchanger heat stroke, and gas at an outlet of the heat exchanger heat stroke enters a chimney. According to the technical scheme, an online concentration analysis system is connected with an inlet pipeline of the pre-treatment system, a fan outlet pipeline and an outlet pipeline of the heat exchanger hot stroke, so that the problems are solved well, and the method can be used for treating VOCs gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of highly flexible water-based varnish suitable for uv offset printing and preparation method thereof

The invention discloses high-flexibility water varnish suitable for UV curable offset printing. According to key points of the technical scheme, the water varnish is composed of the following components by weight percent: 10-20% of pure acrylic emulsion, 5-15% of acrylic-modified aqueous polyurethane emulsion, 35-55% of a self-crosslinked acrylic dispersing agent, 10-25% of water, 10-25% of an alcohol solvent and 0.1-5% of waterborne additives. The invention provides the high-flexibility water varnish suitable for UV curable offset printing. The invention further provides a method for preparing the high-flexibility water varnish suitable for UV curable offset printing.

Owner:广东博海化工科技有限公司

High-flexibility water-based varnish with good heat resistance and suitable for UV offset printing

InactiveCN110656534AImprove adhesionGood recoatabilityNon-macromolecular organic additionPaper coatingEmulsionEngineering

The invention is a divisional application with an application number of 2017100265557. The invention discloses a high-flexibility water-based varnish with good heat resistance and suitable for UV offset printing. The high-flexibility water-based varnish is composed of the following substances by weight: 10-20% of a pure acrylic emulsion, 5-15% of an acrylic acid modified water-based polyurethane emulsion, 35-55% of a self-crosslinking acrylic acid dispersing agent, 10-25% of water, 10-25% of an alcohol solvent and 0.1-5% of a water-based assistant. The invention provides the high-flexibility water-based varnish with good heat resistance and suitable for UV offset printing.

Owner:广东博海化工科技有限公司

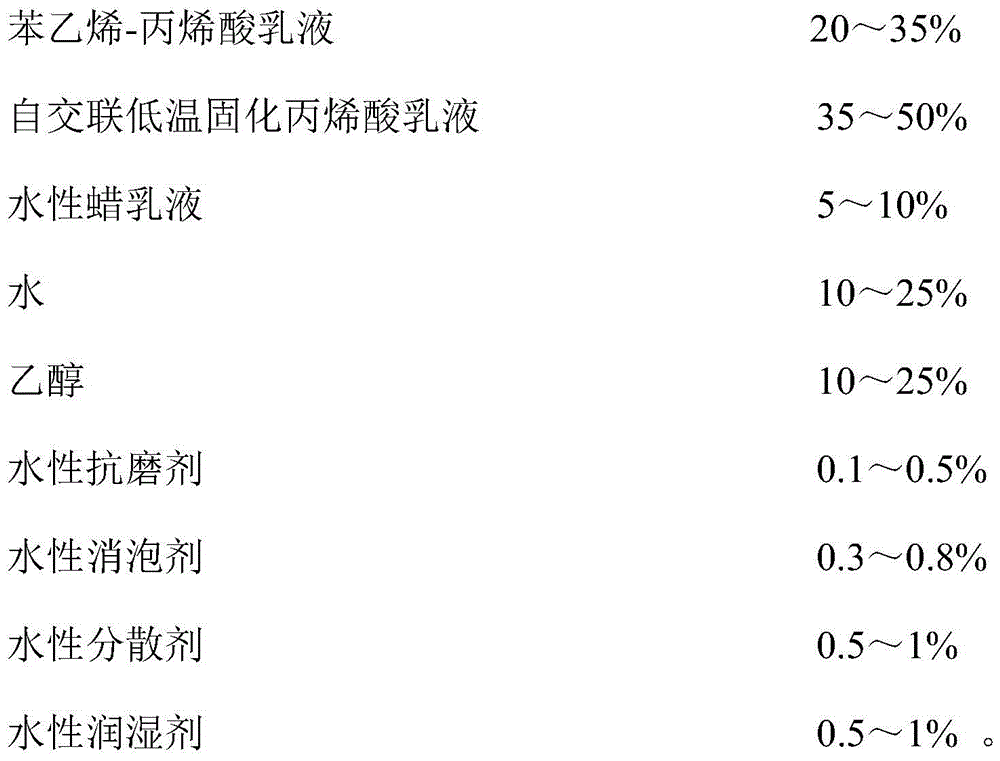

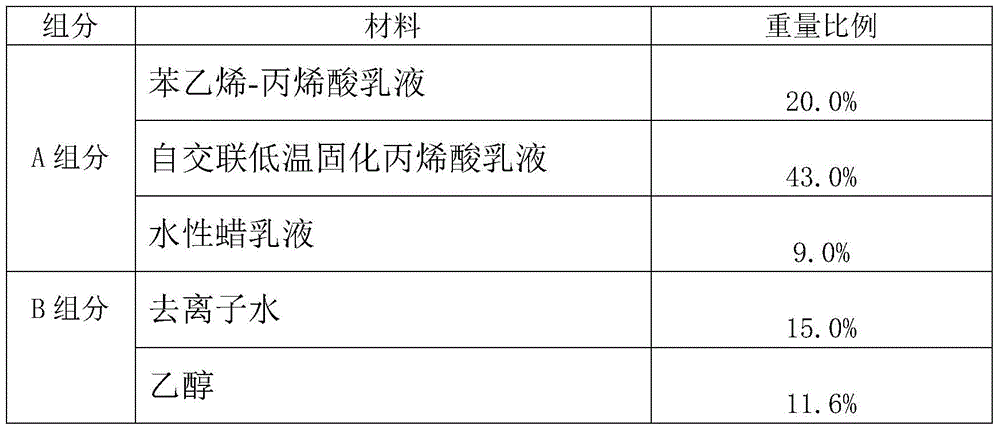

A kind of environment-friendly water-based varnish for composite gold cardboard and preparation method thereof

The invention relates to an environment-friendly waterborne varnish for compound gold card paper. According to the keys of the technical scheme, the waterborne varnish comprises the following substances in percentage by weight: 20-35% of a styrene-acrylic emulsion, 35-50% of a self-crosslinking low-temperature curing acrylic emulsion, 5-10% of a waterborne wax emulsion, 10-25% of water, 10-25% of ethanol, 0.1-0.5% of a waterborne wear-resistant agent, 0.3-0.8% of a waterborne defoaming agent, 0.5-1% of a waterborne dispersant and 0.5-1% of a waterborne wetting agent. The invention provides the environment-friendly waterborne varnish for the compound gold card paper, which has the advantages that the phenomena of flocculation and sedimentation are avoided, good compatibility with the dye and good color development are achieved and the production efficiency is improved.

Owner:广东博海化工科技有限公司

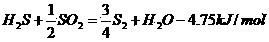

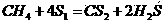

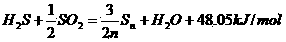

Integrated sour gas treating process

ActiveCN102838088BEasy to recycleHigh recovery rateHydrogen sulfidesSulfur preparation/purificationProcess engineeringEnvironmental engineering

The invention discloses an integrated sour gas treating process, and aims at the sour gas which contains light concentration H2S and is generated in a desulfuration decarburization device. The integrated sour gas treating process comprises the following steps of: adding a sour gas concentrating segment before a two-level Claus sulfur recovery segment, concentrating the H2S concentration in sour gas to more than 50%, and enabling the sour gas after concentrating to enter the two-level Claus sulfur recovery segment to carry out reaction, wherein the sulphur recovery rate of a sour gas concentrating + sulfur recovery segment is improved by 1%-2% compared with the general two-level Claus sulfur recovery segment, thereby being beneficial for sulfur recovery to obtain high sulfur recovery ratio. The integration sour gas treating process provided by the invention has the advantages that the technological operation is flexible and reliable, the investment is saved, the energy consumption is low, the total sulfur recovery ratio can achieve more than 99.8%, and the strict environmental standard requirements are met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of domestic waste incineration fly ash solidification processing method

ActiveCN111069227BReduce difficultyIndex value fluctuations are reducedSolid waste disposalTransportation and packagingFlue gasEnvironmental engineering

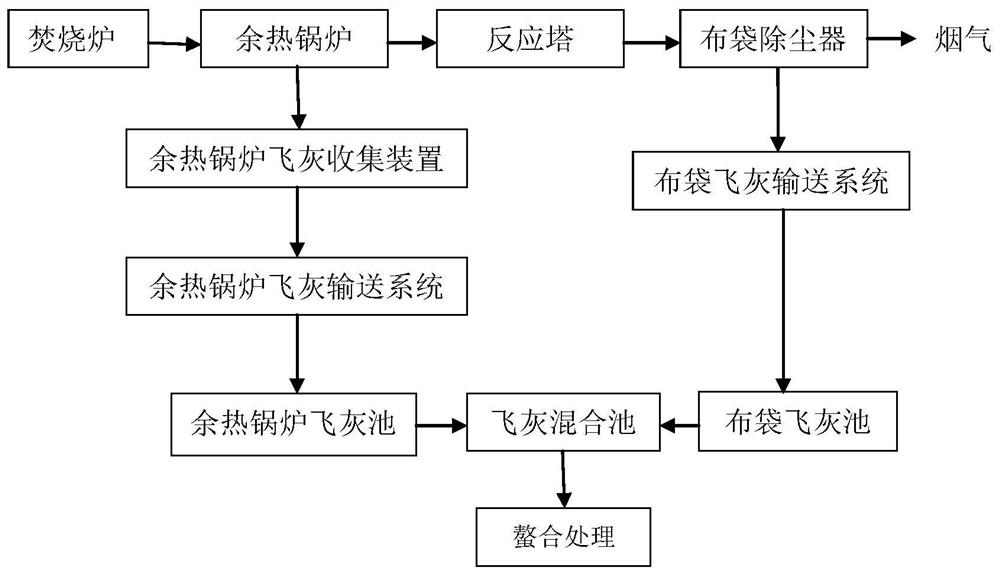

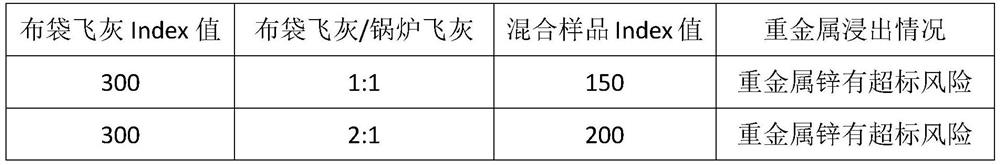

The invention discloses a solidification treatment method for domestic waste incineration fly ash. The incineration flue gas is processed through a waste heat boiler and a reaction tower. Real-time mixing is carried out in the ash tank, and the fly ash in the bag filter connected behind the reaction tower is continuously transported to the bag fly ash tank for real-time mixing. Finally, the bag fly ash and waste heat boiler fly ash are mixed according to the weight ratio of 3:( 1‑2) Transport to the fly ash mixing tank for mixing and chelation treatment. The invention improves the waste incineration fly ash treatment process, controls the index value of the fly ash by controlling the outlet temperature of the reaction tower, combined with the novel fly ash mixing process, can control the index value of the fly ash within the optimal range, and the fluctuation range is small, It minimizes the processing difficulty of fly ash, and ensures that the leaching toxicity of heavy metals after fly ash solidifies meets the requirements of environmental protection standards.

Owner:HANLANLVDIAN SOLID WASTE TREATMENT (FOSHAN) CO LTD 2ND

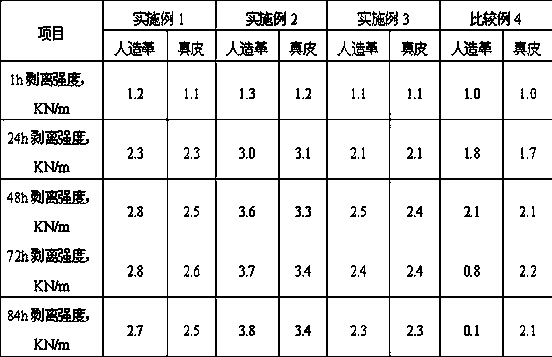

A kind of solvent-based rubber adhesive and preparation method thereof

ActiveCN105176443BReduces volatile odorsMeet the requirements of environmental standardsMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesVulcanizationPolymer science

Owner:GUANGDONG SANVO CHEM IND TECH

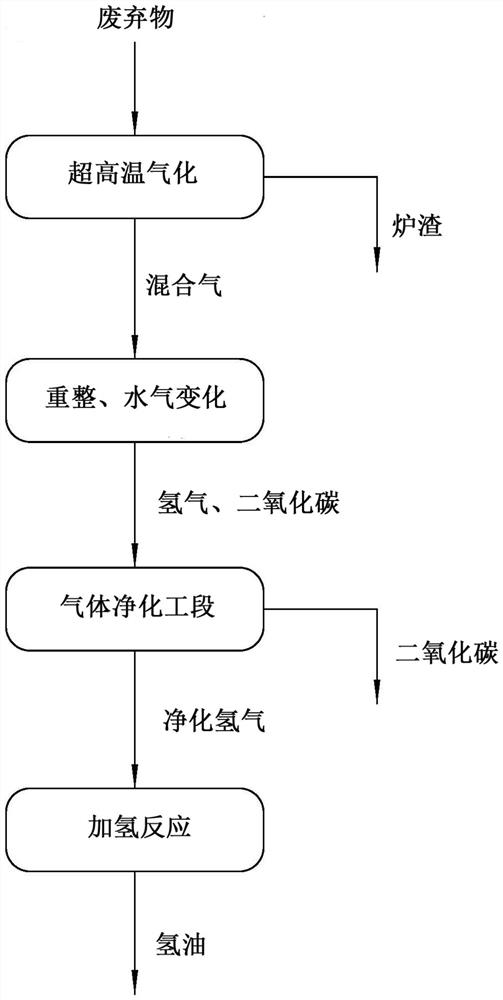

Method and system for converting ultrahigh-temperature waste into hydrogen oil

PendingCN114517112AImprove use valueSafe and Efficient TransportationGasification processes detailsBulk chemical productionPtru catalystHydrogenation reaction

The invention discloses a method and system for producing hydrogen oil by converting ultrahigh-temperature waste, and the system provided by the invention is used for gasifying waste at ultrahigh temperature to generate mixed gas, and the mixed gas is subjected to reforming and water-gas shift under the action of a high-selectivity reaction catalyst to generate hydrogen and carbon dioxide. Hydrogen passes through a gas purification section to prepare purified hydrogen, and the purified hydrogen and the liquid organic hydrogen storage carrier are subjected to hydrogenation reaction to obtain hydrogen oil which can be stored at normal temperature and normal pressure. According to the system for converting the ultrahigh-temperature waste into the hydrogen oil, various pollution sources generated in the waste treatment process can be fundamentally eradicated, the requirements of all environmental protection standards in the world at present are met, the waste can be converted into hydrogen energy and various useful substances, and good environmental protection and economic values are achieved.

Owner:武汉恒创能源技术有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com