Environment-friendly lead-free easily-cutting anti-heat-cracking brass alloy material and preparation method thereof

A brass alloy and free-cutting technology is applied in the field of environmentally friendly lead-free free-cutting hot-crack-resistant brass alloy materials and their preparation, which can solve the problem of difficulty in taking into account cutting performance and cold and hot processing performance, high price of rare earth elements, and the addition of rare earth elements. There are many types of elements, etc., to achieve the effects of excellent thermal crack resistance, simple production equipment and process, and excellent cutting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Melting

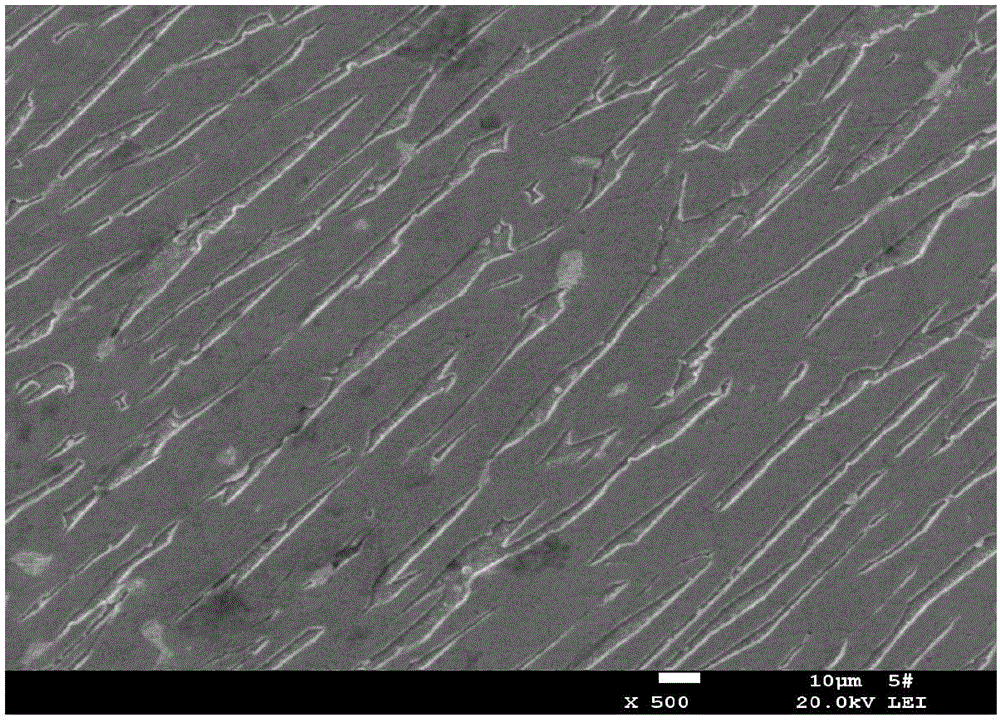

[0048] Add 58 parts of cathode copper into the smelting furnace, and heat up and melt under the cover of charcoal protective agent; after the cathode copper is completely melted, add 0.03 part of phosphor-bronze master alloy for deoxidation to avoid selenium dioxide poisoning during the process of adding selenium; adjust the furnace temperature to 1150°C, add 0.03 parts of high-purity selenium, add 0.3 parts of high-purity tin and 0.4 parts of high-purity bismuth successively, after completely melting, stir the molten pool, adjust the temperature of the molten pool to 1020 °C, add 43 parts of electrolytic zinc, and heat up the slag , adjust the molten pool temperature to 1000 ℃, slag casting or traction molding.

[0049] (2) extrusion

[0050] Casting or traction-molded ingots, after passing the composition and surface quality inspections, are placed in an induction furnace, heated to 70±5°C, and kept warm for 5 minutes to make the grains evenly refined, ...

Embodiment 2

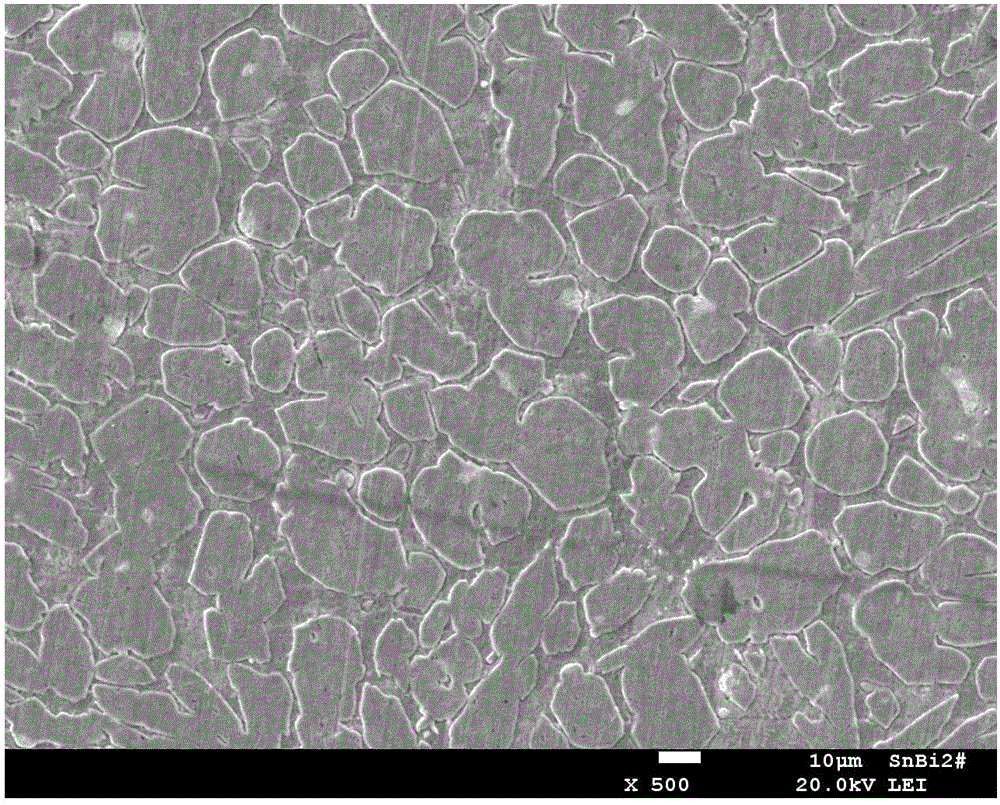

[0057] (1) Melting

[0058] Put 64 parts of cathode copper into the smelting furnace, and under the cover of charcoal protective agent, heat up and melt; after the cathode copper is completely melted, add 0.05 part of phosphor-bronze master alloy for deoxidation to avoid selenium dioxide poisoning during the process of adding selenium; adjust the furnace temperature to 1250°C, add 0.2 parts of high-purity selenium, add 0.7 parts of high-purity tin and 1.5 parts of high-purity bismuth successively, after completely melting, stir the molten pool, adjust the temperature of the molten pool to 1020-1050 °C, add 36 parts of electrolytic zinc, and heat up To melt slag, adjust the temperature of the molten pool to 1000-1050°C, and then slag-removed for casting or traction molding.

[0059] (2) extrusion

[0060] Casting or traction-molded ingots, after passing the composition and surface quality inspections, are placed in an induction furnace, heated to 650±5°C, and kept for 10 minutes...

Embodiment 3

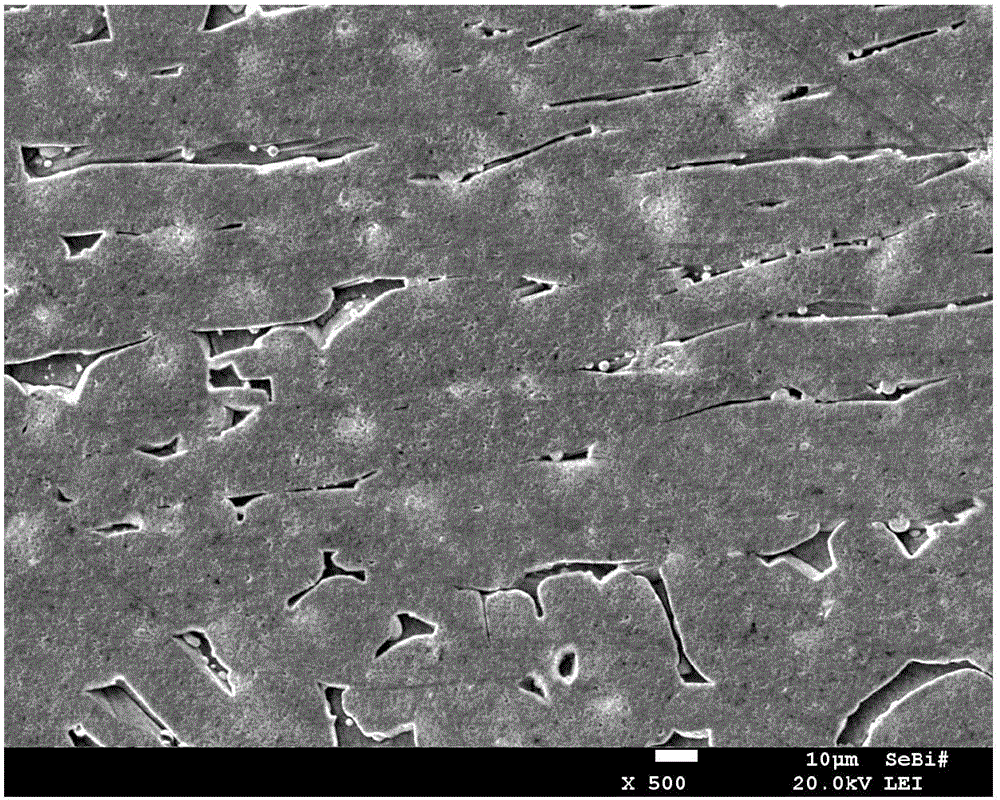

[0066] (1) Melting

[0067] Put 60 parts of cathode copper into the smelting furnace, and under the cover of charcoal protective agent, heat up and melt; after the cathode copper is completely melted, add 0.04 part of phosphor-bronze master alloy for deoxidation to avoid selenium dioxide poisoning during the process of adding selenium; adjust the furnace temperature to 1200℃, add 0.1 parts of high-purity selenium, add 0.7 parts of high-purity tin and 0.8 parts of high-purity bismuth successively, after completely melting, stir the molten pool, adjust the temperature of the molten pool to 1020-1050 °C, add 40 parts of electrolytic zinc, and heat up To melt slag, adjust the temperature of the molten pool to 1000-1050°C, and then slag-removed for casting or traction molding.

[0068] (2) extrusion

[0069] Casting or traction-molded ingots, after passing the composition and surface quality inspections, are placed in an induction furnace, heated to 640±5°C, and kept for 8 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com