Fume removal device for asphalt road maintenance vehicle

A technology for maintaining vehicles and roads. It is applied in the fields of combined devices, gas treatment, membrane technology, etc., and can solve the problems of asphalt organic matter that cannot be filtered and treated cleanly, and that there is no good treatment method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further.

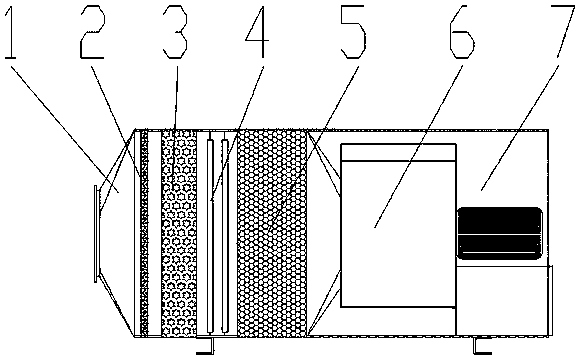

[0018] like figure 1 As shown, the function of the smoke removal equipment is mainly used to remove the asphalt fume VOCs organic pollutants generated by the asphalt road maintenance vehicle when heating the ground. The smoke removal equipment includes a filter tube 1, a settling plate 2, a Raschig ring defogging plate 3, a UV photolytic oxidation tube 4, and an activated carbon adsorption chamber 5 arranged sequentially inside the filter tube 1 along the inlet end to the gas outlet end. The air outlet is connected with the induced draft fan 6. The inlet end of the filter pipe 1 faces the position where the smoke is emitted or is connected to the structure that emits the smoke. The settling plate 2 is mainly used to settle large particles of dust and large particles of asphalt oil clusters. The Raschig ring defogging plate 3 is mainly used to remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com