Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Low shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

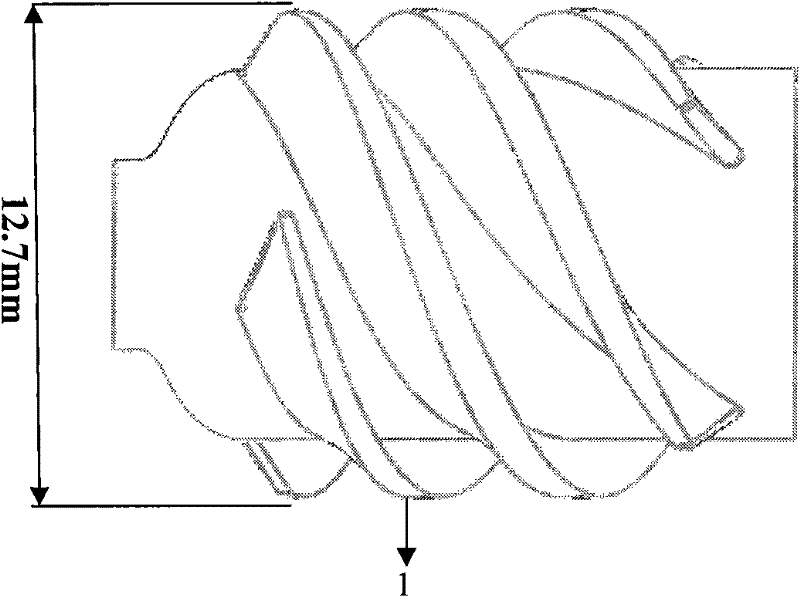

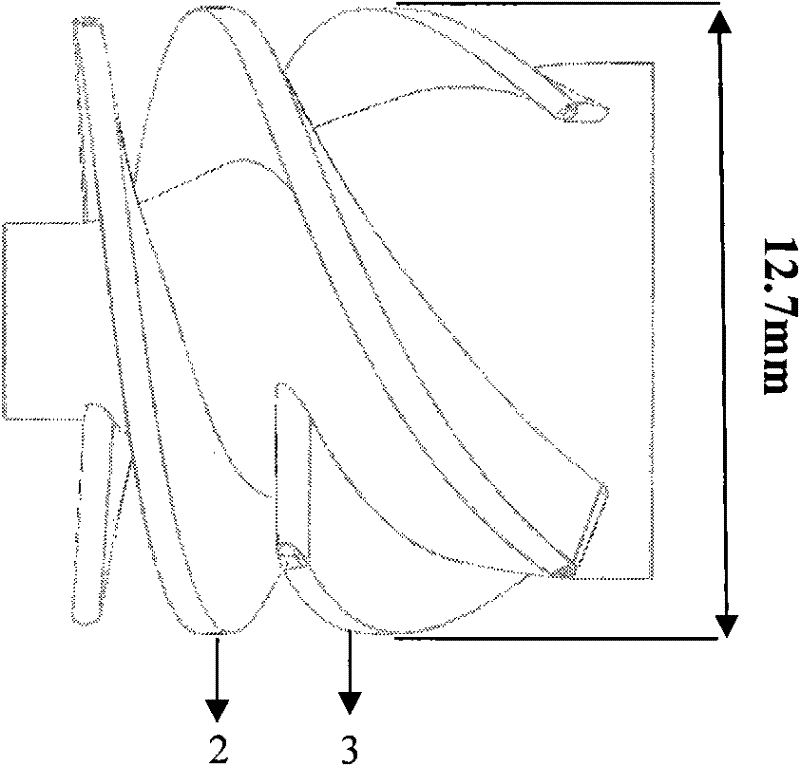

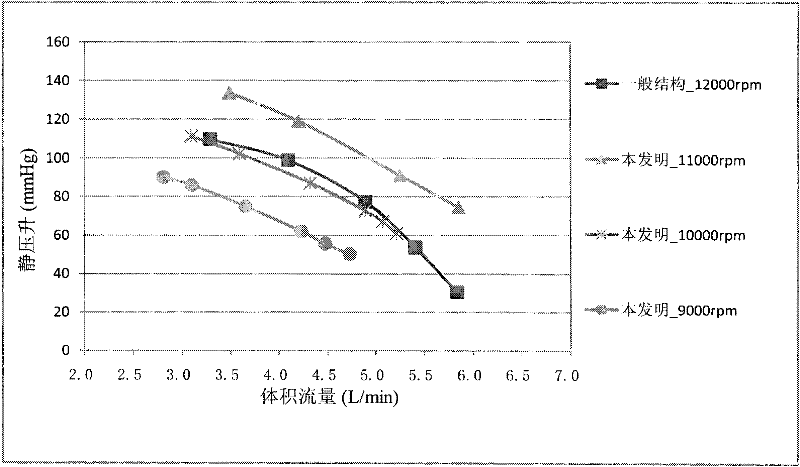

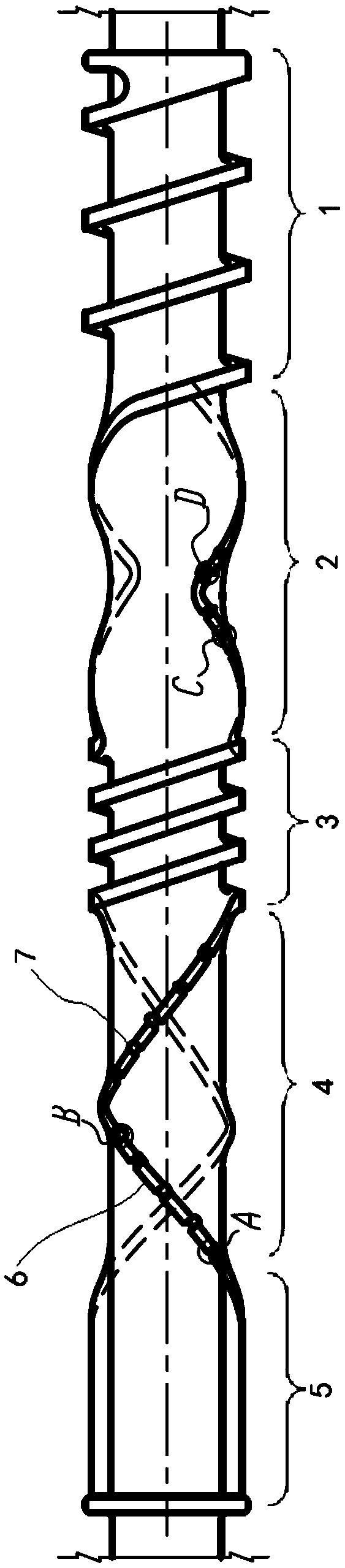

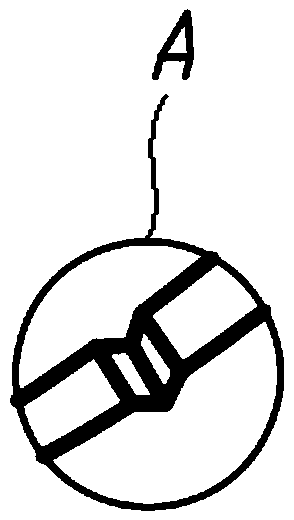

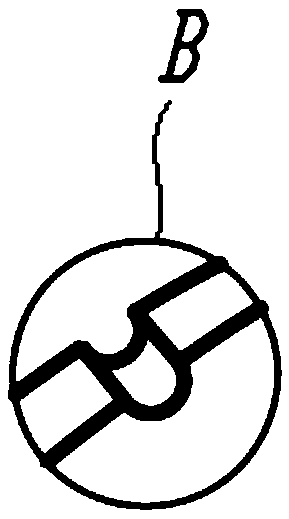

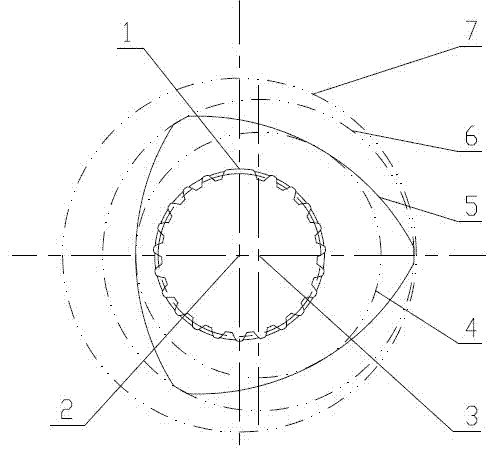

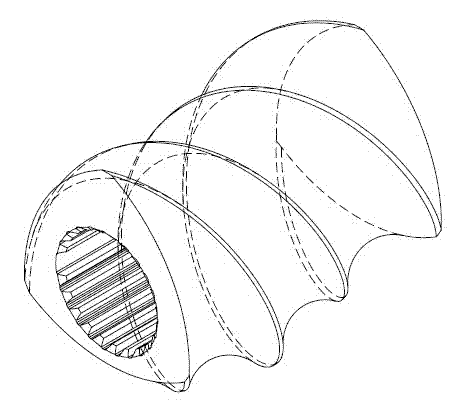

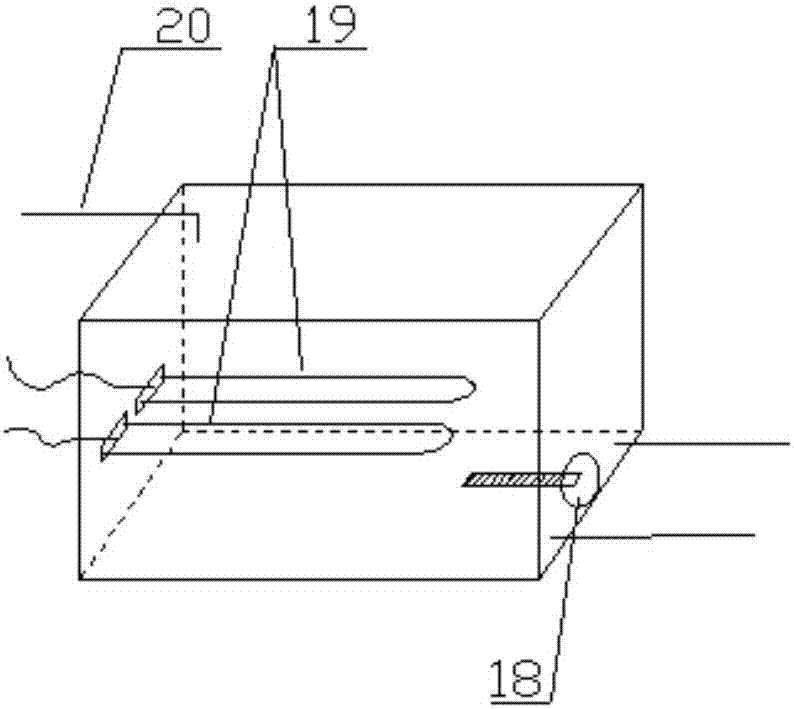

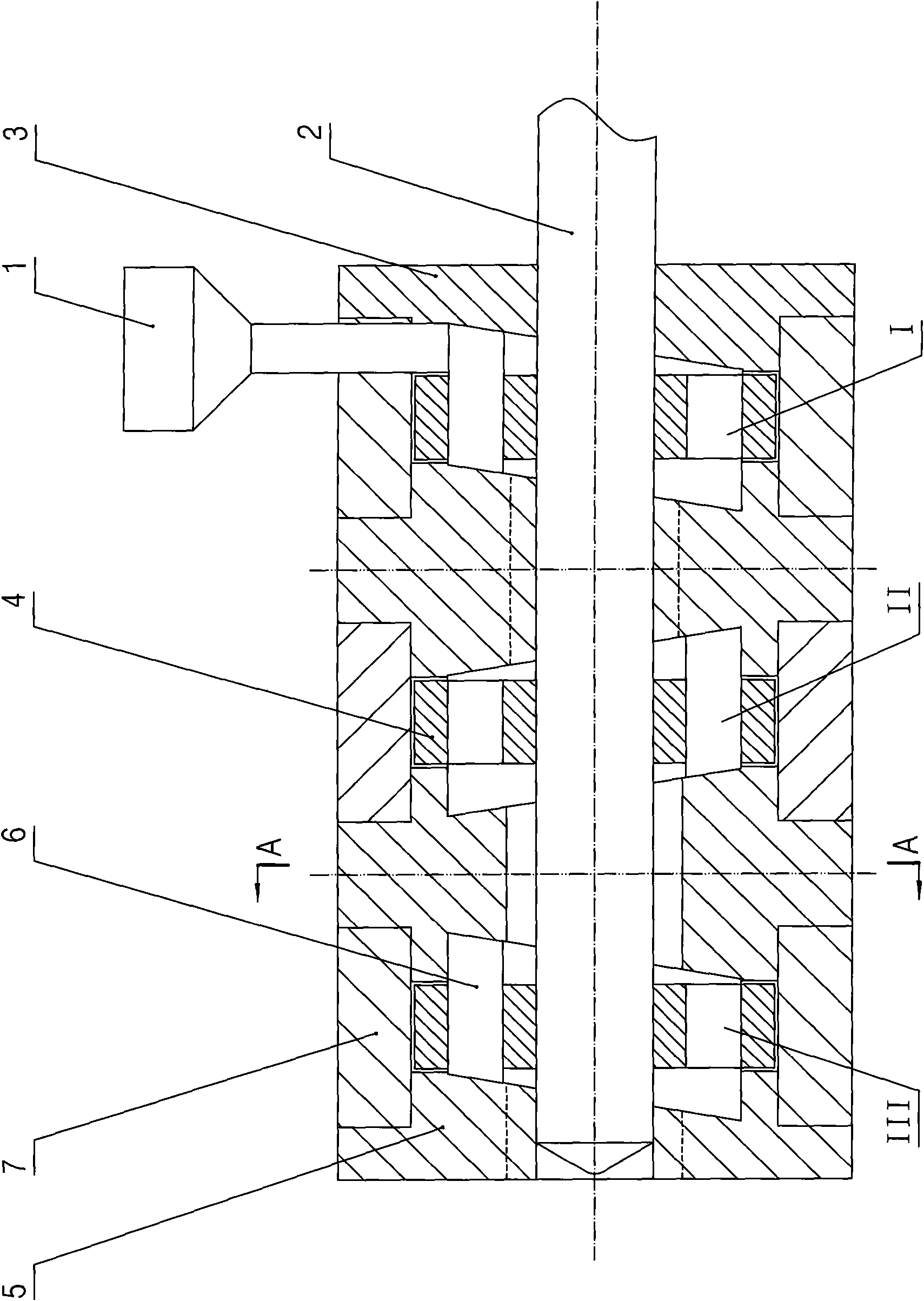

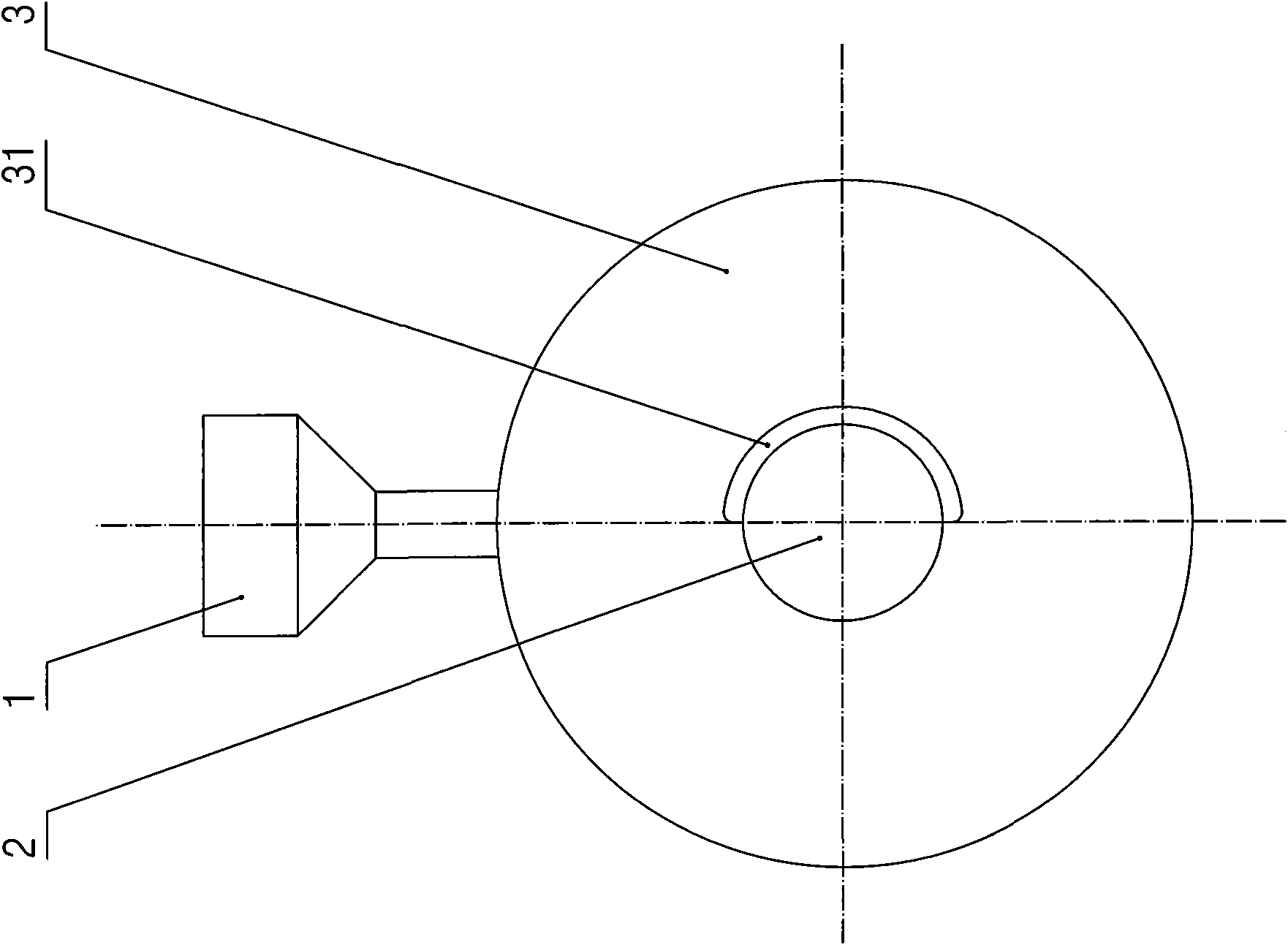

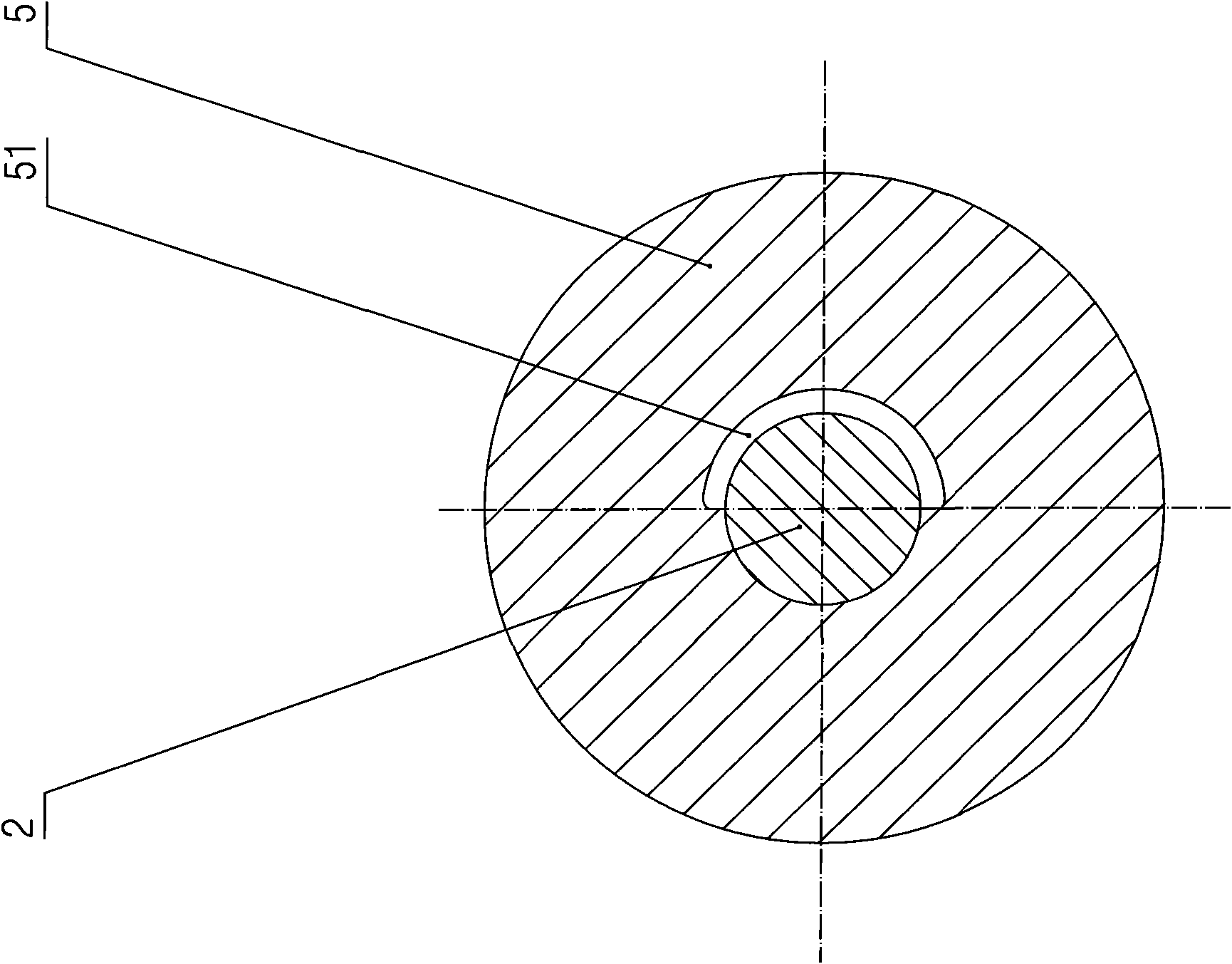

Front diversing flow rotor structure with tapping splitter blades for artificial heart blood pump

InactiveCN101822854ALow shearSatisfy blood pressure rise requirementsProsthesisPressure riseBlood pump

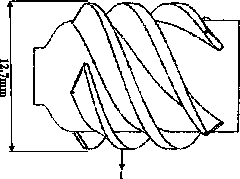

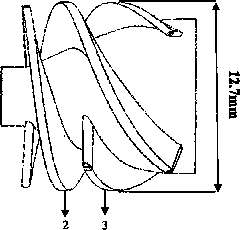

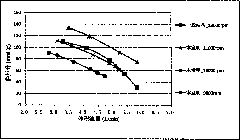

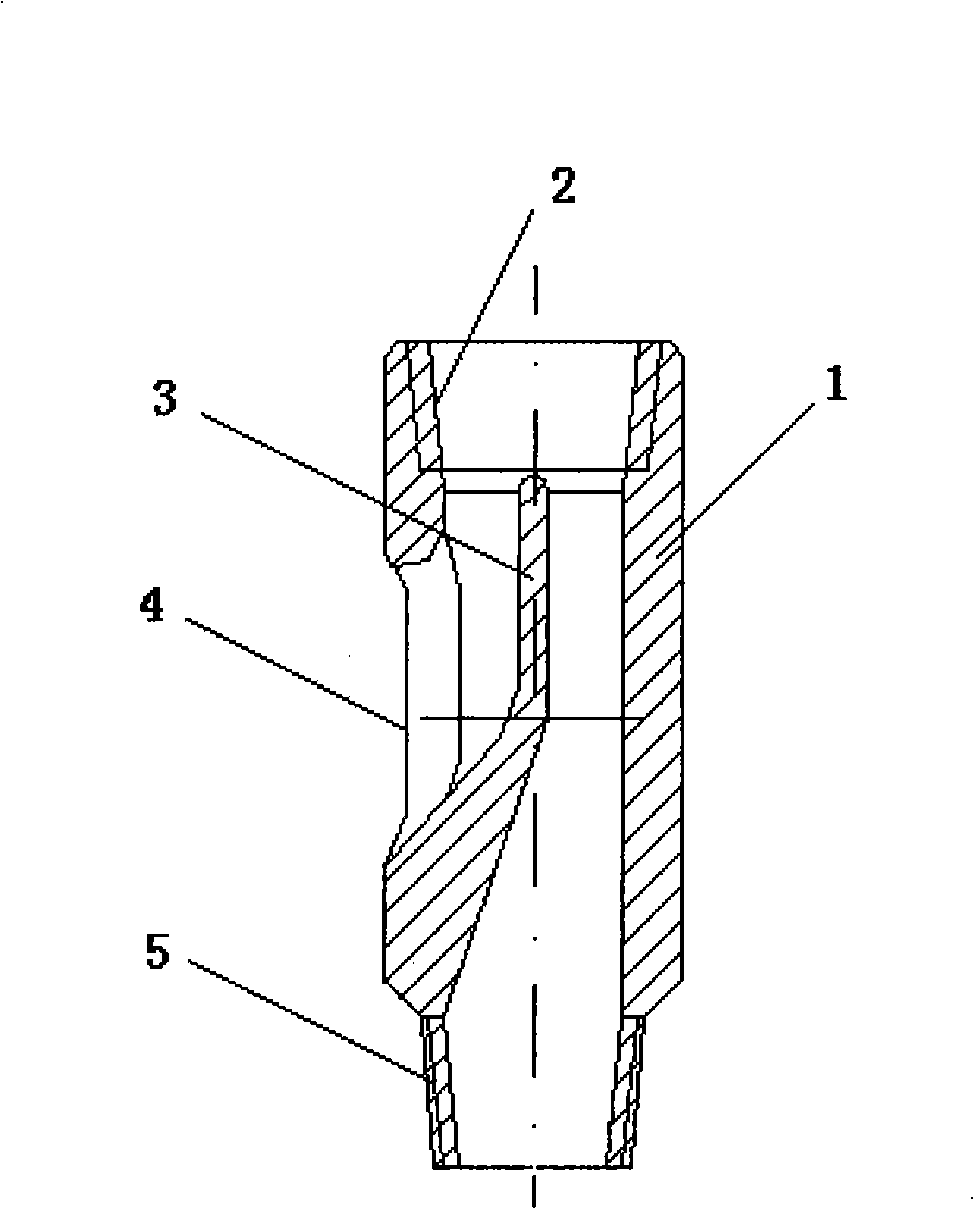

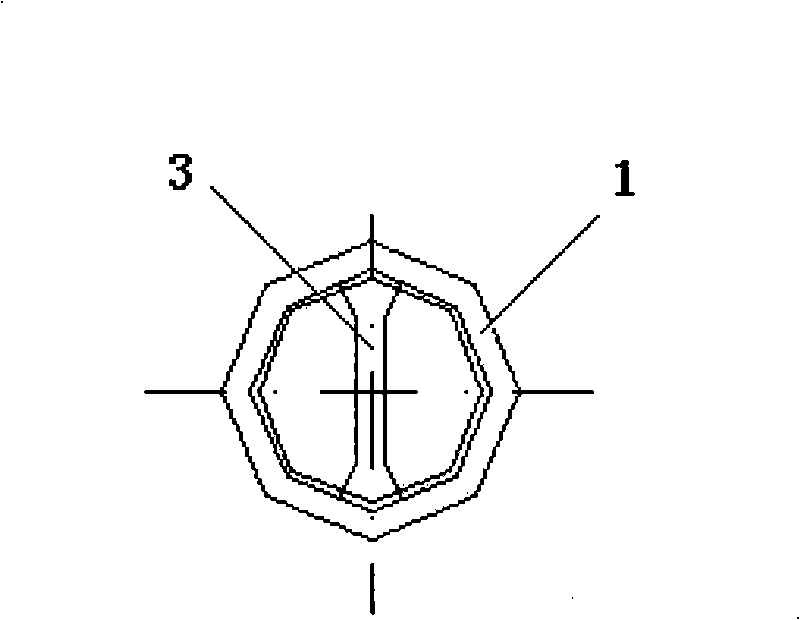

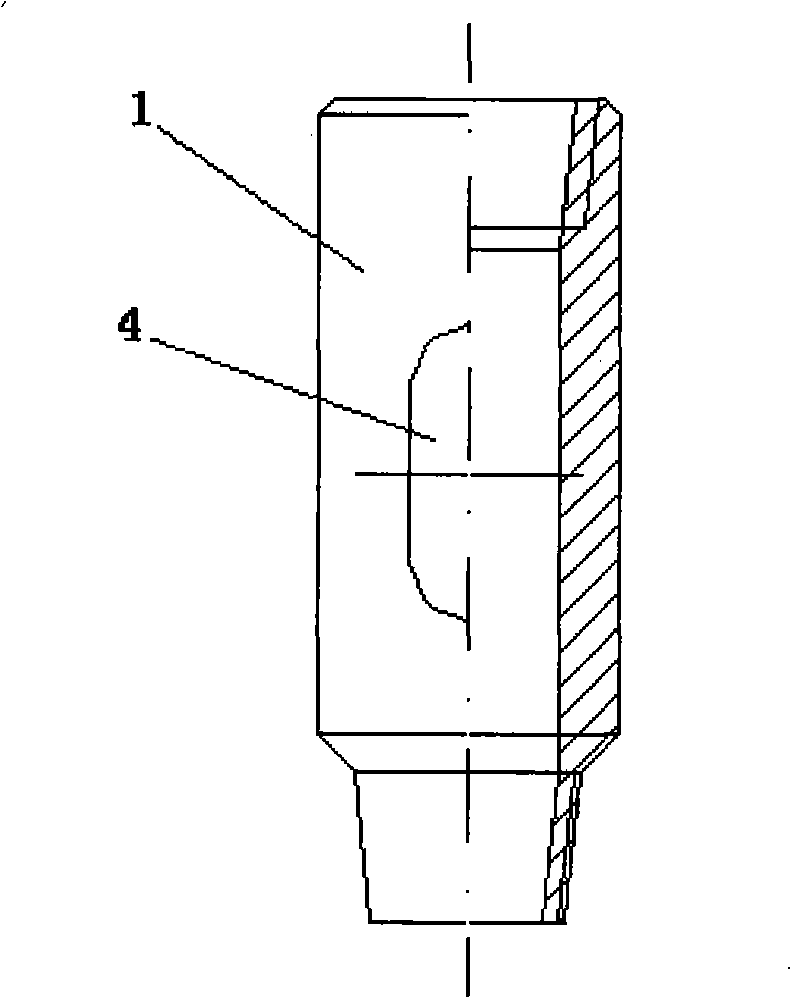

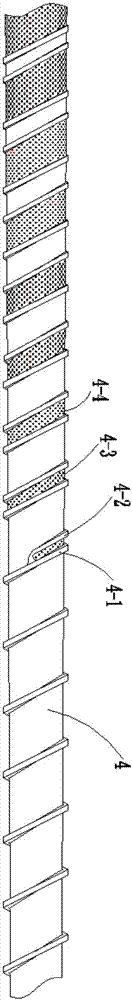

The invention relates to a front diversing flow rotor structure with tapping splitter blades for an artificial heart blood pump, comprising a rotor hub passageway and rotor blades, wherein the rotor hub passageway adopts a gradual contraction structure; a streamline cubic spline curve is used to define the hub passageway; and the rotor blades are composed of two overall large blades and two small splitter blades; and the overall large blades adopt a two-section blade-type structure design at a root part and a tip part respectively. The circumferential position structure of the rotor blades is as follows: the small splitter blades are located at 47% of a circumferential angle between the two overall large blades. After adopting the rotor structure, the blood-supply and pressure rising capability of the rotor is strengthened, the tangential velocity of a rotor blade tip and the shearing action of the rotor blades on blood are reduced, and the internal flow of the rotor is smooth without flow separation.

Owner:BEIHANG UNIV

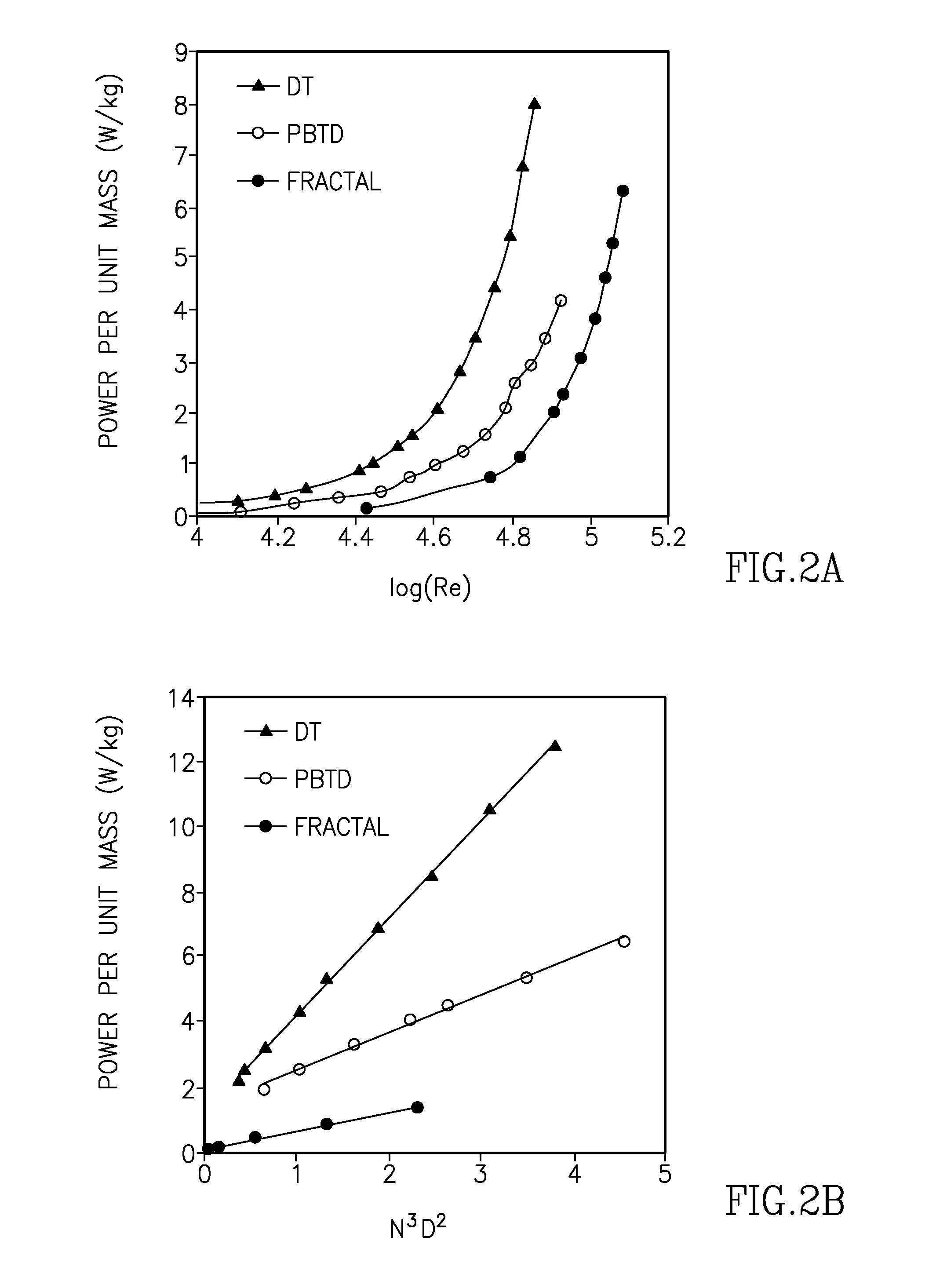

Fractal impeller for stirring

InactiveUS20130208560A1Well mixedReduce shearRotary stirring mixersTransportation and packagingImpellerMain branch

A fractal impeller design for stirred tank reactors comprising plurality of main branches, each of which further having plurality of sub-branches with each sub branch having plurality of blades to distribute / dissipate energy in uniform manner and to achieve uniform temperature throughout the reactor while operating it at lower impeller speed to avoid high shear zones; wherein, the angular distances covered by the blades vary and yield variation in the local blade passage velocity for a given impeller rotation speed.

Owner:COUNCIL OF SCI & IND RES

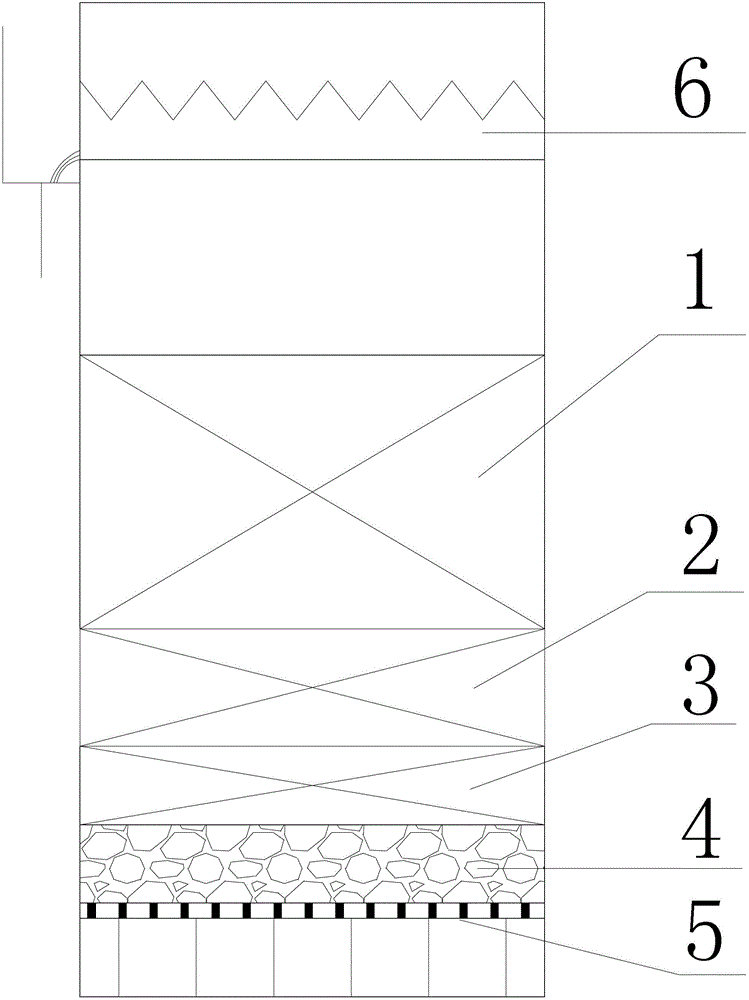

High efficiency fluidization upward flow multilayer composite filter material biological filter tank coupled with ozonation and water treatment method thereof

InactiveCN102745863AGuaranteed removal rateGuarantee the water qualityMultistage water/sewage treatmentBiomassFilter material

The invention provides a high efficiency fluidization upward flow multilayer composite filter material biological filter tank coupled with ozonation and a water treatment method thereof, relating to a biological filter tank and a water treatment method using the biological filter tank. The biological filter tank is composed of an upper filter material, a medium filter material, a lower filter material and a supporting layer, wherein the upper filter material is active carbon, anthracite or biological ceramsite, the medium filter material is modified zeolite, natural zeolite or synthetic zeolite and the lower filter material is a phosphorus functional material. The filter tank is characterized by fast start, a complex and stable biological phase, great biomass, high activity, strong impact resistance, a filter material expansion rate of 0% to 50%, small resistance at the head of the filter tank, high mass transfer efficiency of materials, oxygen and pollutants, a high utilization rate of filter layers and filter materials and small possibility of occurrence of hardening of the filtering materials. The filter tank is applicable to treatment of raw water in which the concentration of water source phosphorus, ammonia nitrogen and organic pollutants fluctuates and can stably operate at a low temperature.

Owner:HARBIN INST OF TECH

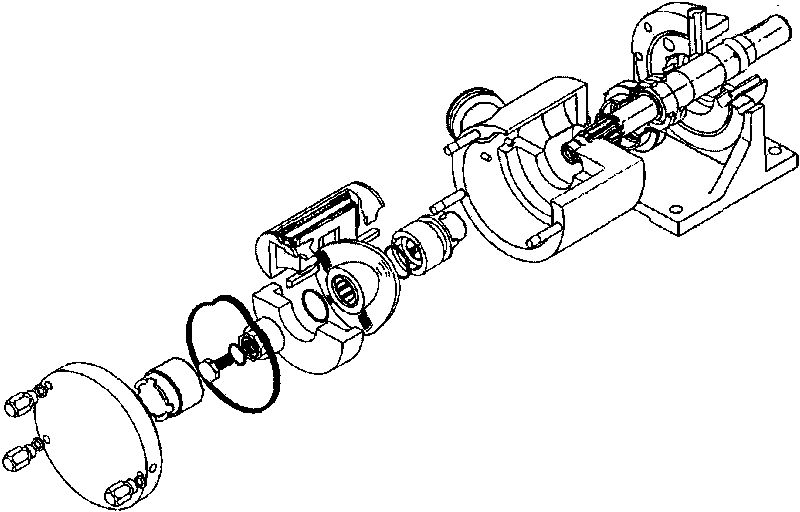

High-temperature high-pressure high-shear rate lubricating oil rheometer

The invention discloses a high-temperature high-pressure high-shear rate lubricating oil rheometer. The high-temperature high-pressure high-shear rate lubricating oil rheometer comprises a lock nut, a cylinder body, a static torque sensor, a temperature sensor, a splitter plate, a micro-gap measurer, a cylinder cover, a motor frame, a coupling, a rotating shaft sealing device, a rotating shaft, a threaded hole, an outer barrel, an inner barrel, a heater, an inner barrel hole, and the like. When the rheometer runs, the outer barrel rotates, and a lubricating oil sample is subjected to a shearing force, and then the shearing force of the lubricating oil sample acts on the inner barrel according to the principle of force balance; the micro-gap measurer is used for real-time measurement of the gap between the outer barrel and the inner barrel; the temperature sensor, the torque sensor, a pressure gage, a motor speed counter, and the like are connected with a computer, and data information is sent to the computer. Flow curves of the lubricating oil sample are drew by using a specific program in the computer, and constitutive equations of the lubricating oil sample is further determined, so that a relatively accurate lubricating oil rheological model is provided for theory and engineering practice.

Owner:SHANDONG UNIV OF TECH

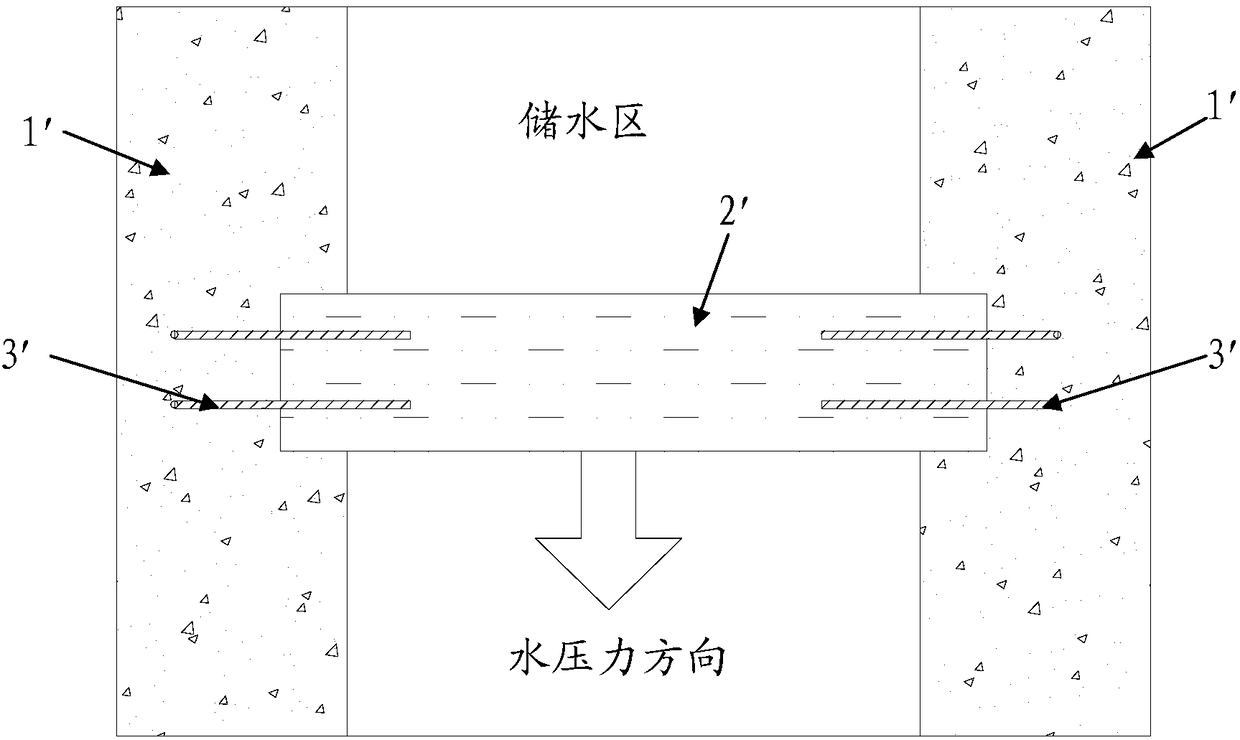

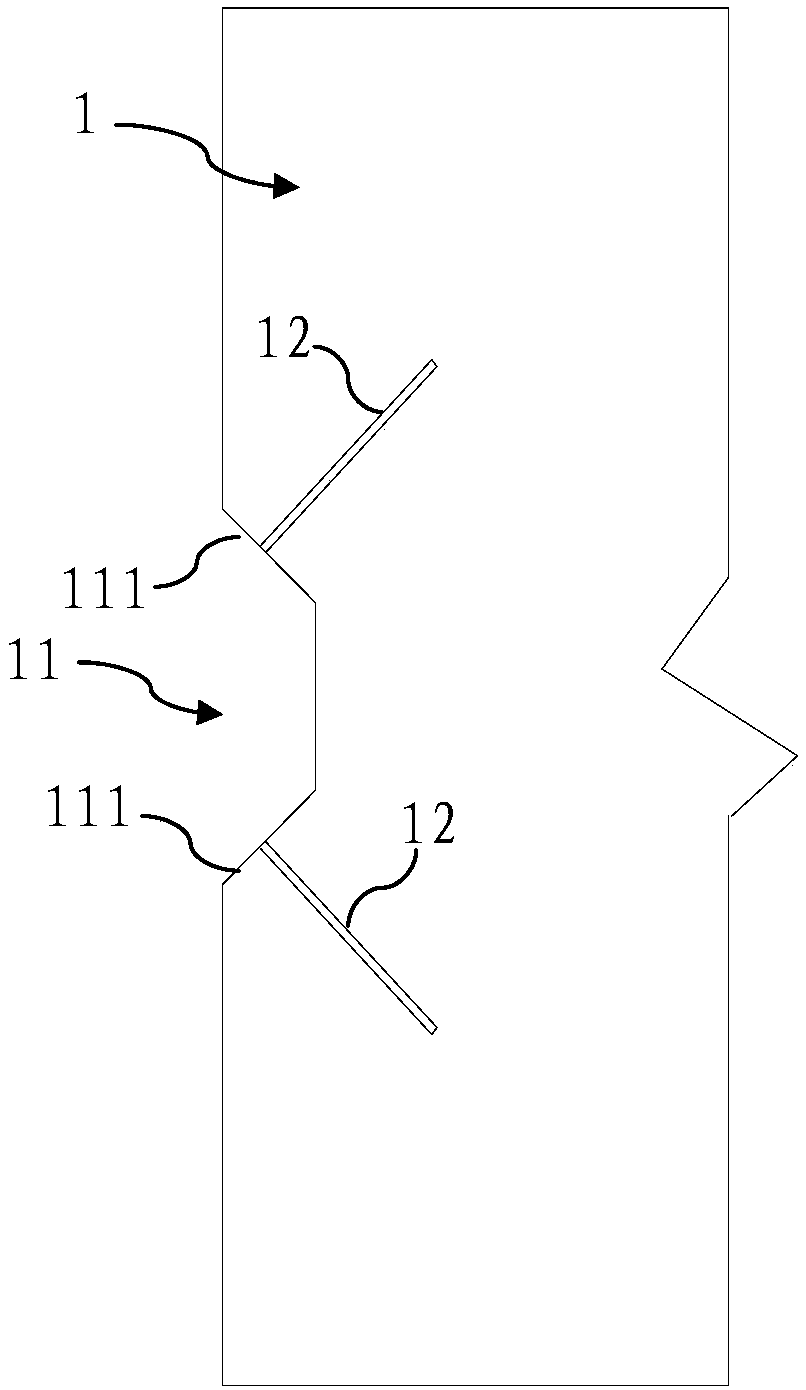

Underground reservoir artificial dam body and coal pillar dam body connecting structure and construction technology thereof

The invention discloses an underground reservoir artificial dam body and coal pillar dam body connecting structure and further discloses a construction technology of the underground reservoir artificial dam body and coal pillar dam body connecting structure. The underground reservoir artificial dam body and coal pillar dam body connecting structure comprises an artificial dam body and a coal pillar dam body. A dam body groove is formed in the coal pillar dam body and provided with a groove oblique surface, and an acute angle is formed between the extending directions of the groove oblique surface and the artificial dam body. Anchor rod drill holes are formed in the groove oblique surface, and the extending directions of the anchor rod drill holes are perpendicular to the extending direction of the groove oblique surface. An inverted-hook-type grouted anchor rod is fastened in each anchor rod drill hole, and a plurality of reinforcement framework beams are arranged in the artificial dambody. The two ends of each reinforcement framework beam are in fastening connection with the ends of the inverted-hook-type grouted anchor rods on the two sides of the reinforcement framework beam correspondingly. According to the underground reservoir artificial dam body and coal pillar dam body connecting structure and the construction technology thereof, the connecting strength and stability are improved, and the construction technology is further simplified.

Owner:CHINA SHENHUA ENERGY CO LTD +2

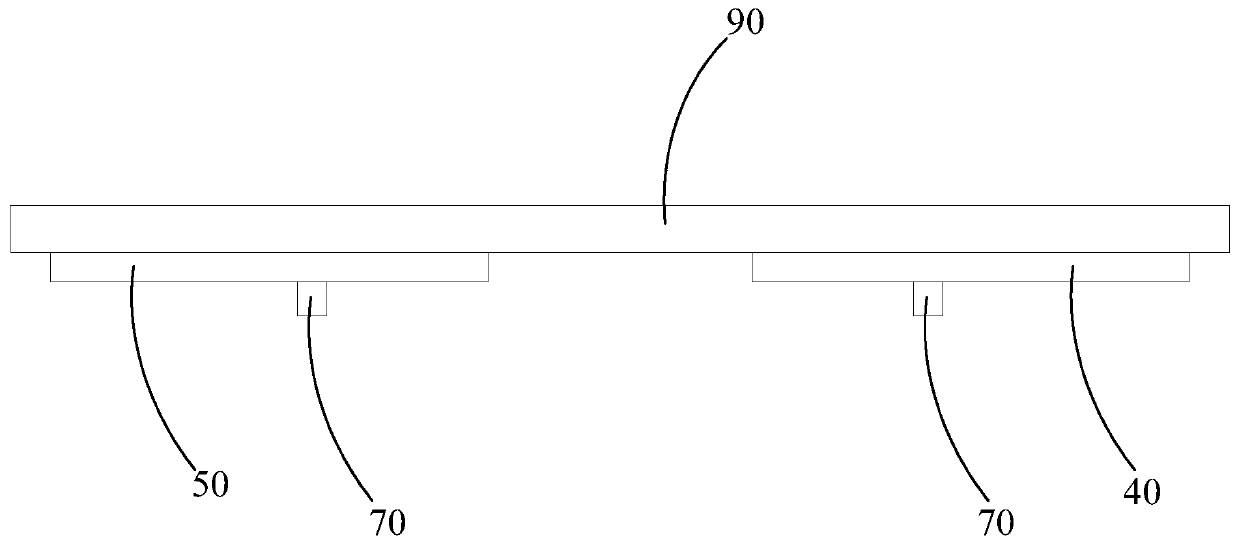

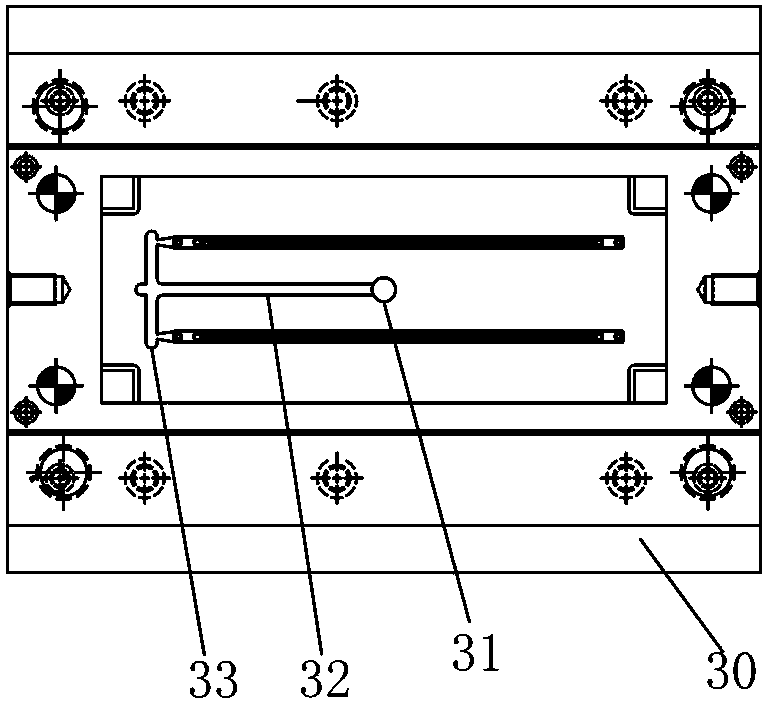

Shell assembly and foldable electronic device

ActiveCN110913628AAvoid stretching outwardsAvoid deformationCasings with display/control unitsCasings/cabinets/drawers detailsEngineeringMechanical engineering

The invention discloses a shell assembly and a foldable electronic device. The shell assembly includes: a first shell; a second shell, arranged side by side at an interval with the first shell; a bending part, arranged between the first shell and the second shell and being provided with a first side edge and a second side edge which are arranged back to back, the first side edge facing the first shell and being connected with the first shell, and the second side edge facing the second shell and being connected with the second shell; a first supporting sheet, the first shell being provided witha first mounting surface, and the first supporting sheet being opposite to the first mounting surface and being connected to the first shell in a sliding manner; a second shell, provided with a second mounting surface which is opposite to or opposite to the first mounting surface when the second shell is folded in the first shell, and the second supporting sheet being opposite to the second mounting surface and is connected to the second shell in a sliding manner. The first supporting piece and the second supporting piece slide towards the bent part at the same time or deviate from the bent part at the same time. The layering risk of the flexible screen can be reduced, and the service life of the flexible screen is prolonged.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

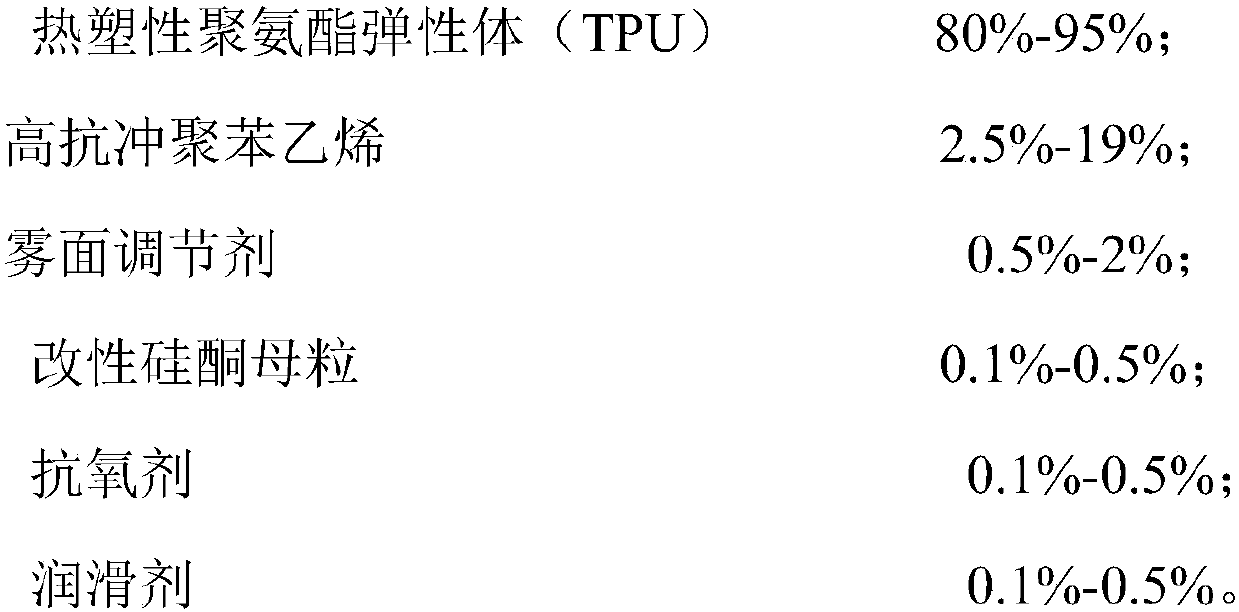

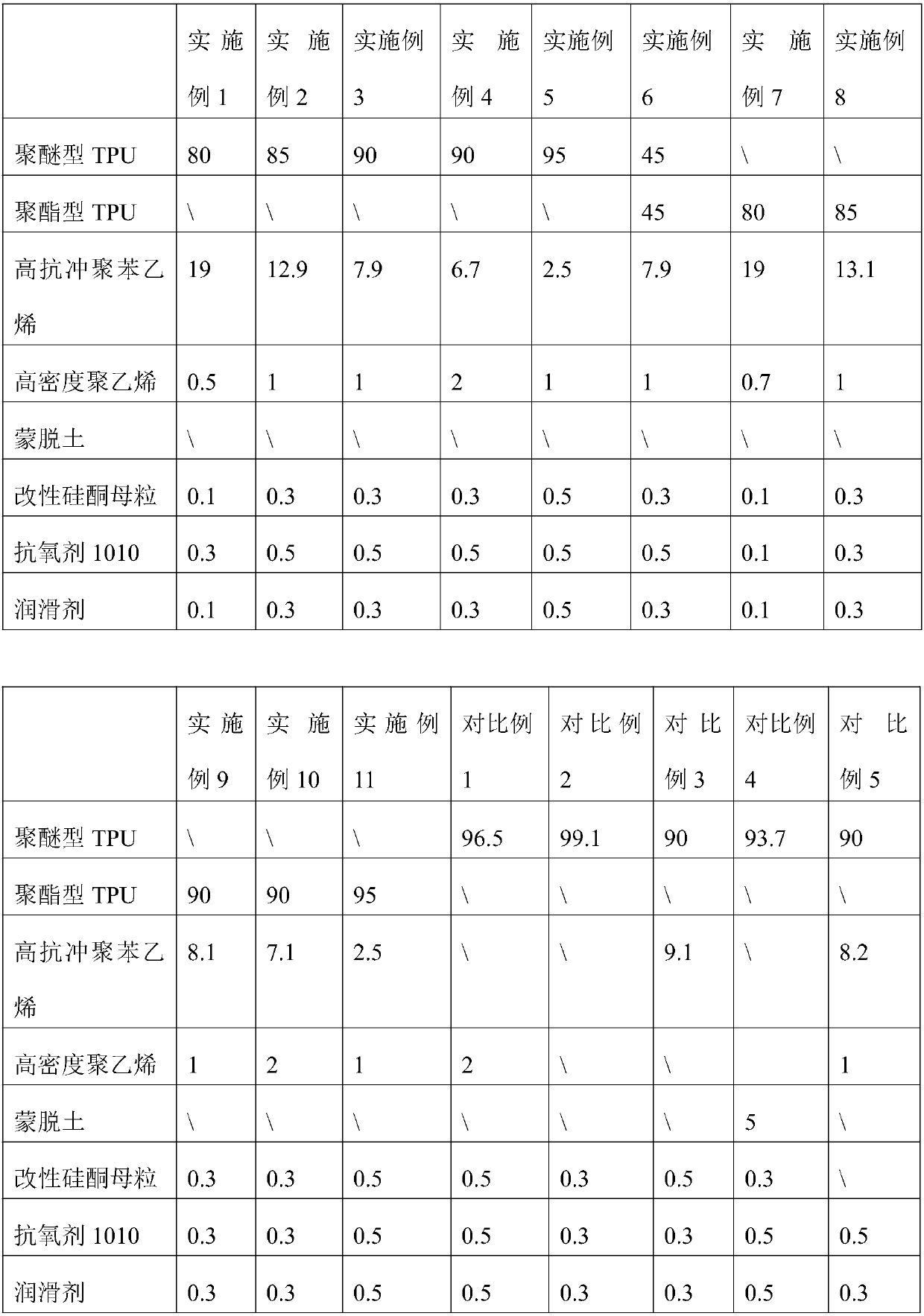

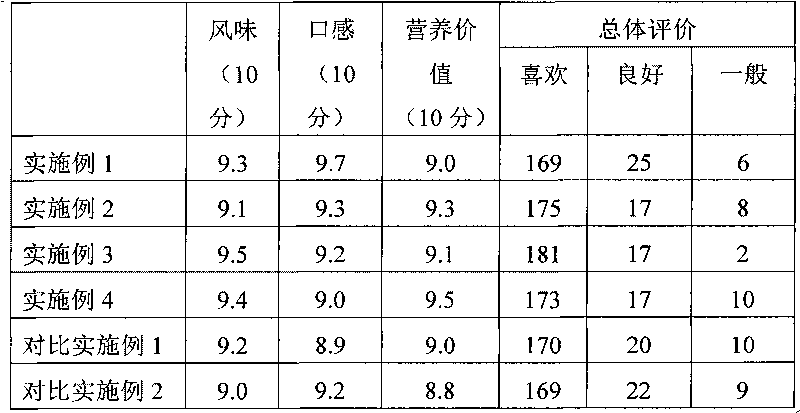

High-physical-property matte thermoplastic polyurethane elastomer and preparation method thereof

ActiveCN108102347AImprove the disadvantages of reduced physical properties and poor matte effectGood matte effectAntioxidantThermoplastic polyurethane

The invention discloses a high-physical-property matte thermoplastic polyurethane elastomer and a preparation method thereof. The high-physical-property matte thermoplastic polyurethane elastomer is prepared from the following ingredients in percentage by mass: 80 to 95 percent of thermoplastic polyurethane elastomer, 2.5 to 19 percent of high impact polystyrene, 0.5 to 2 percent of matte surfaceregulating agents, 0.1 to 0.5 percent of modified silicone master batch, 0.1 to 0.5 percent of antioxidant and 0.1 to 0.5 percent of lubricating agent. Compared with the prior art, the high-physical-property matte thermoplastic polyurethane elastomer has the advantages that the matte surface effect is good; the cost is lower; the defects of material physical property reduction due to the use of inorganic matte surface agent and poor matte surface effect are avoided; the defect of higher cost due to the use of other organic macromolecular material matte surface agents is avoided; in addition, the processing process can be regulated according to practical requirements to obtain the ideal matte effect.

Owner:ZHEJIANG HUAFENG THERMOPLASTIC POLYURETHANE

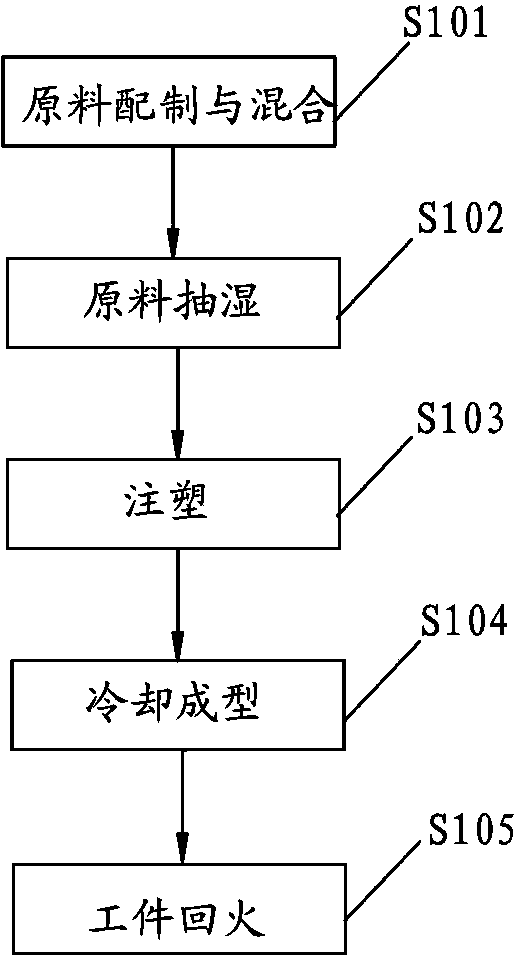

Injection moulding method of long glass fiber reinforced nylon 66 materials

An injection moulding method of long glass fiber reinforced nylon 66 materials comprises the steps of raw material preparing, mixing, raw material dehumidifying, injection moulding, cooling forming and workpiece tempering in sequence. In the step of injection moulding, mixed particle materials which are subjected to dehumidifying in the second step are placed to an injection moulding machine for melting, the portion between the tail end of the injection moulding machine to a jetting mouth is divided into five sections of temperature grades, temperature is controlled between 210-320 DEG C, so that the mixed particle materials are molten, then glue jetting is carried out slowly in a one-section or subsection mode through the injection moulding machine, the molten materials are added into a product mould in an injection-moulding mode, and the mould for injection moulding is kept under the constant temperature of 120 DEG C. According to the injection moulding method of the long glass fiber reinforced nylon 66 materials, under the situation that cost is not changed greatly, the fatigue resistance of a product is improved, and the service life of the product is prolonged. Meanwhile, according to the material formula used in the scheme, product tenacity can be effectively improved, and surface effect is good.

Owner:ZENGCHENG HUACHANG PLASTIC HARDWARE MOLD

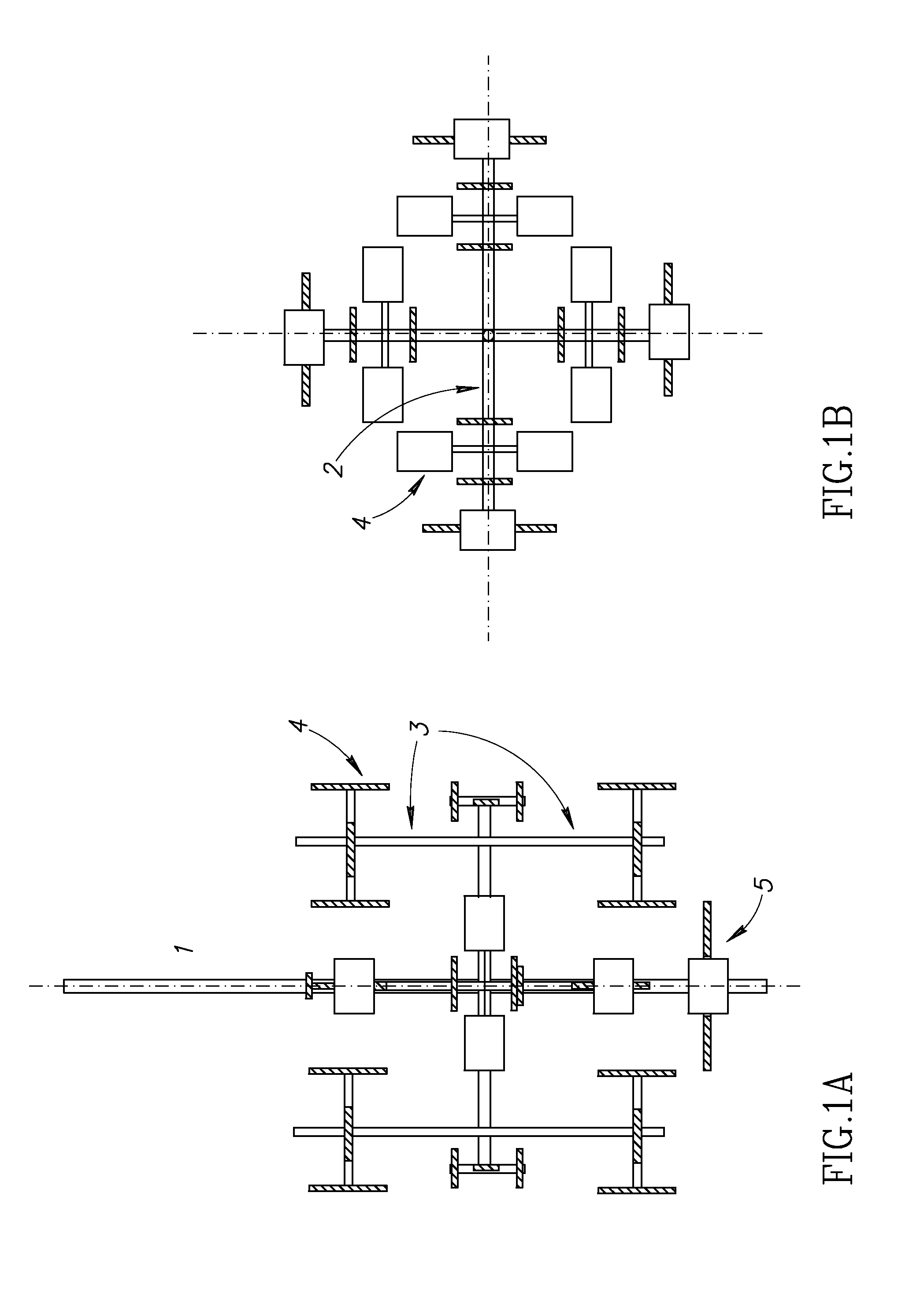

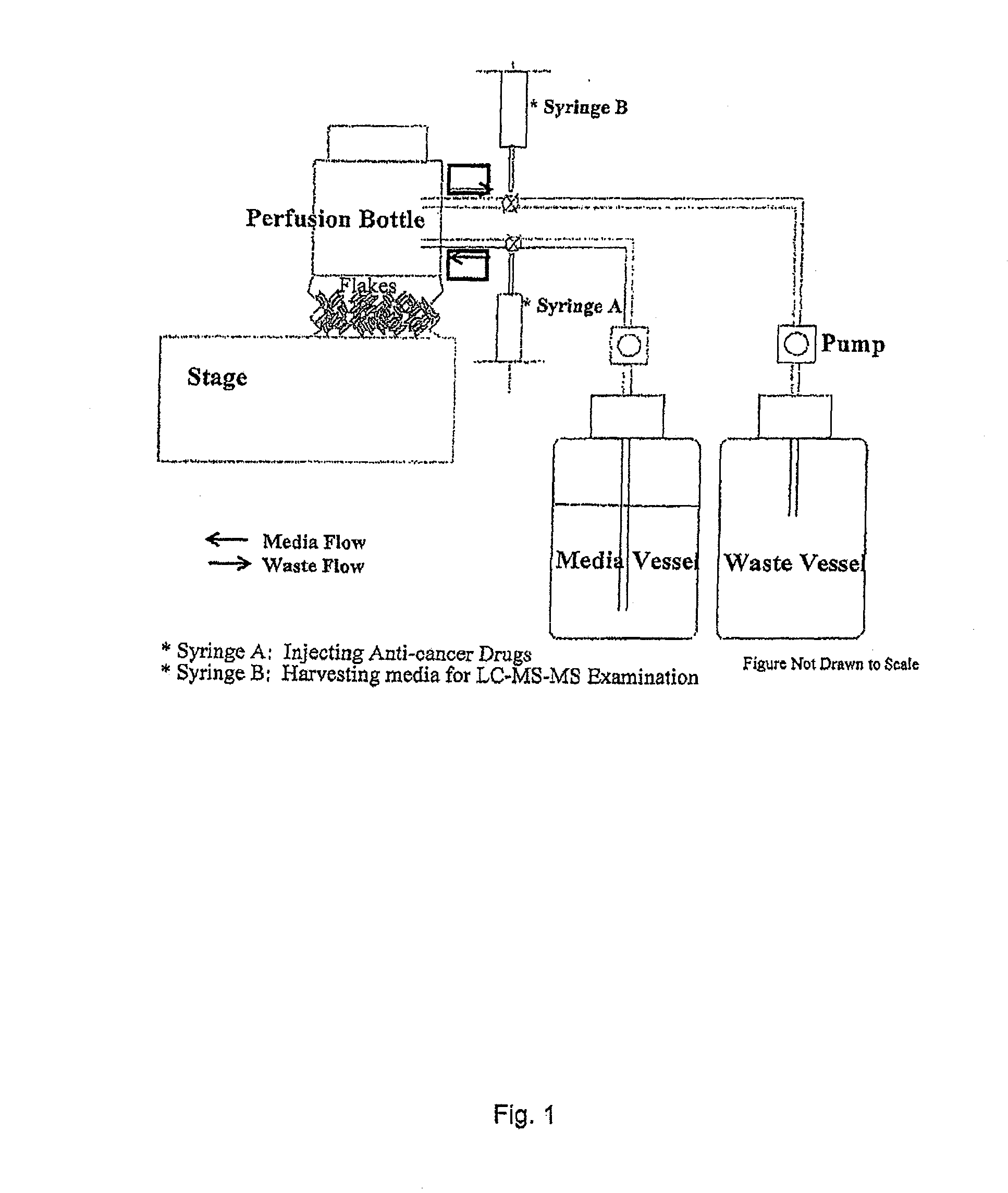

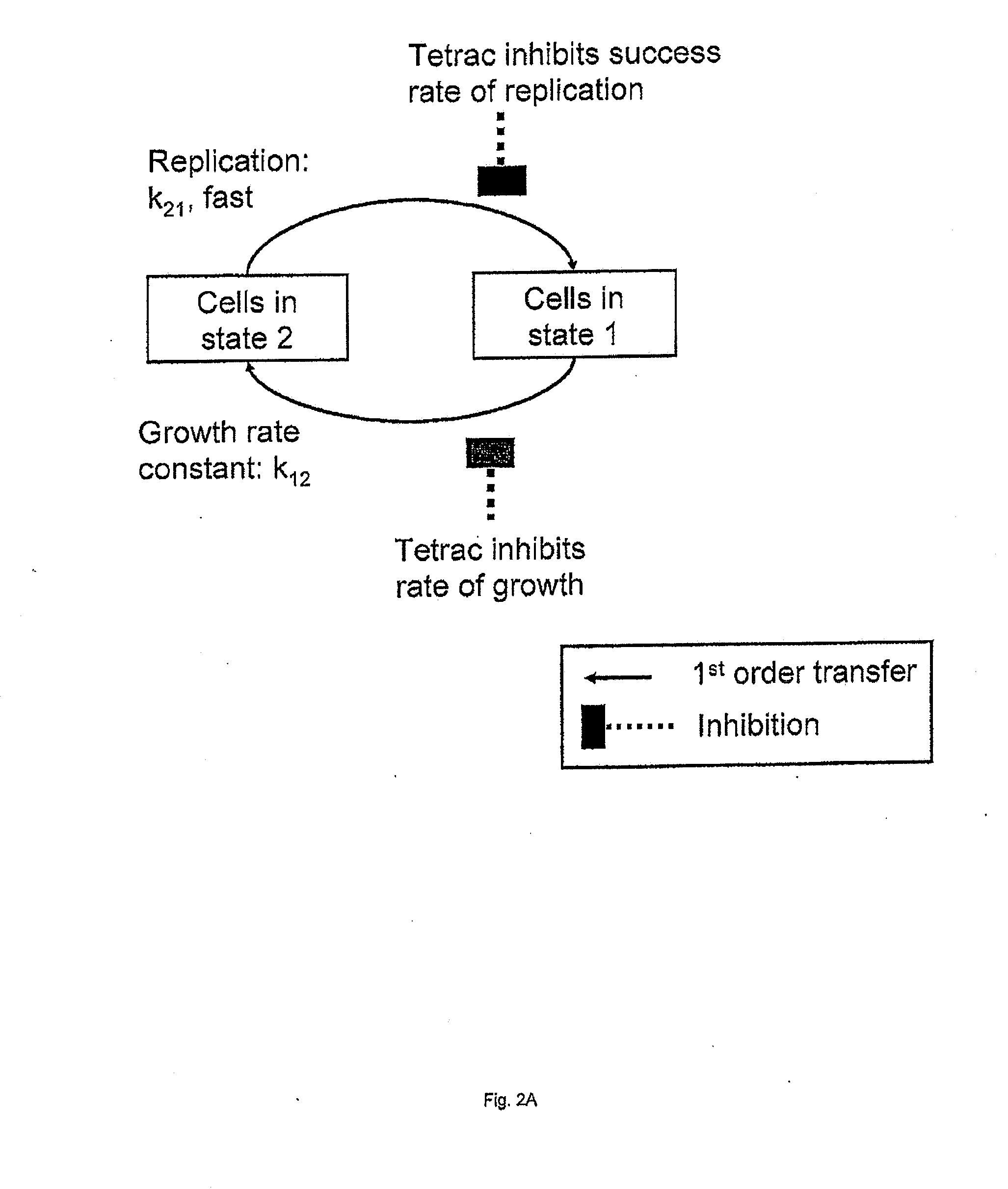

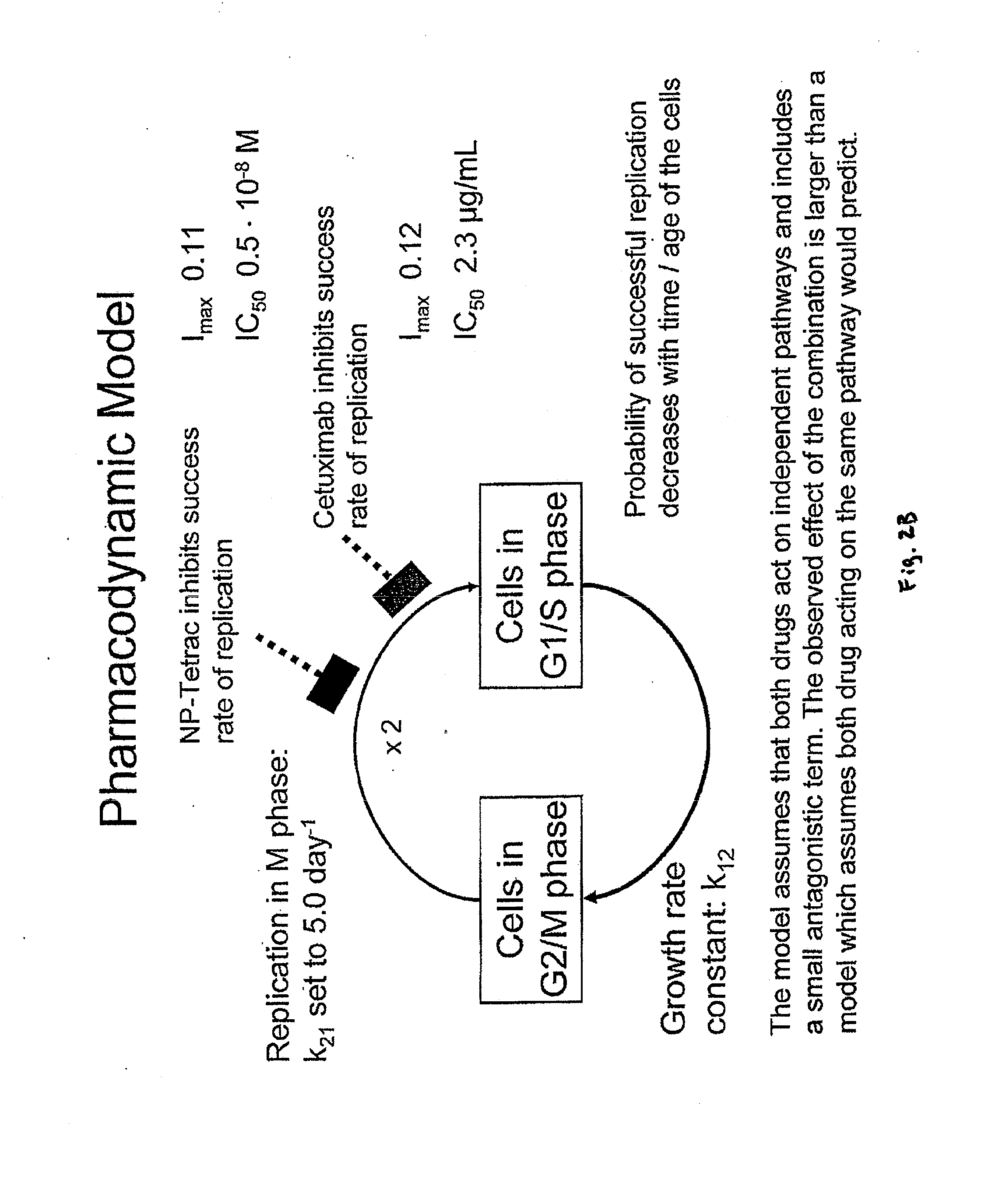

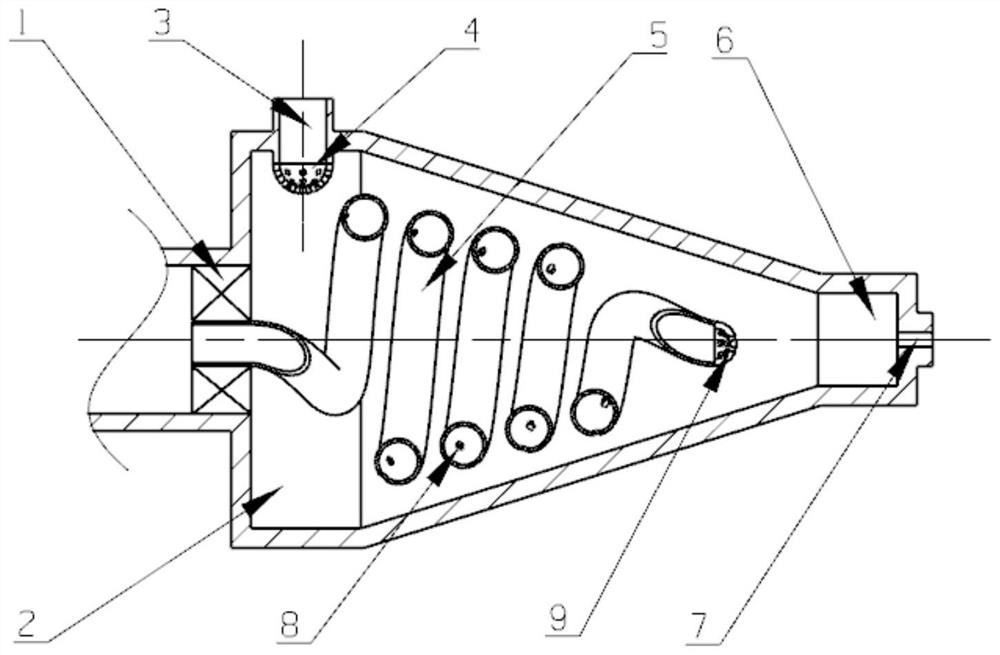

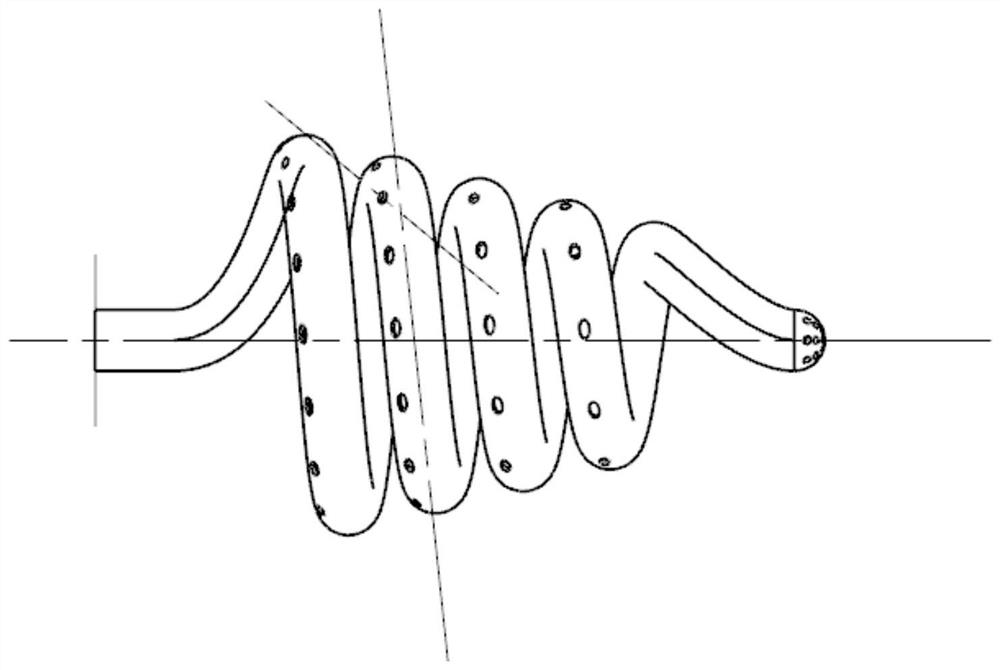

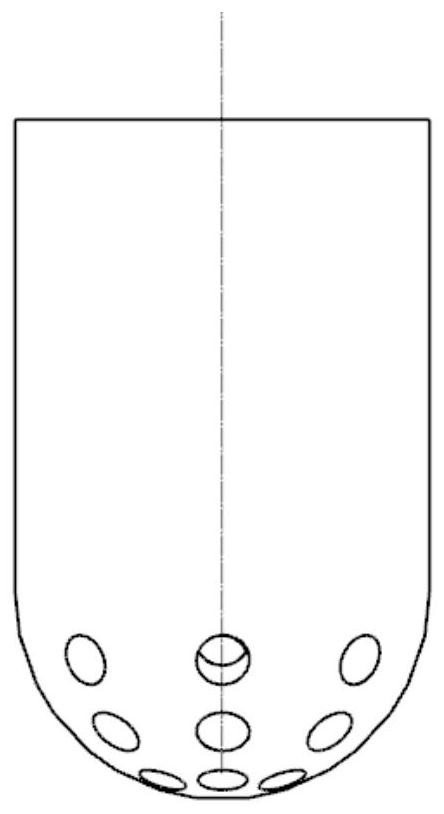

In Vitro Pharmacokinetics/Pharmacodynamics Bellows Perfusion System for Enhancing Effectiveness of Cancer Chemotherapy

InactiveUS20160348052A1Maximize oxygen transferLow shearBioreactor/fermenter combinationsOrganic active ingredientsDrugHuman cancer

Provided herein is a continuous cell perfusion model system that provides useful pharmacokinetic and pharmacodynamic information on the application of new drugs or combinations of various agents in vitro to human cancer cell lines. Also provided are methods of using this system to individualize cancer treatment.

Owner:LIN HUNG YUN +3

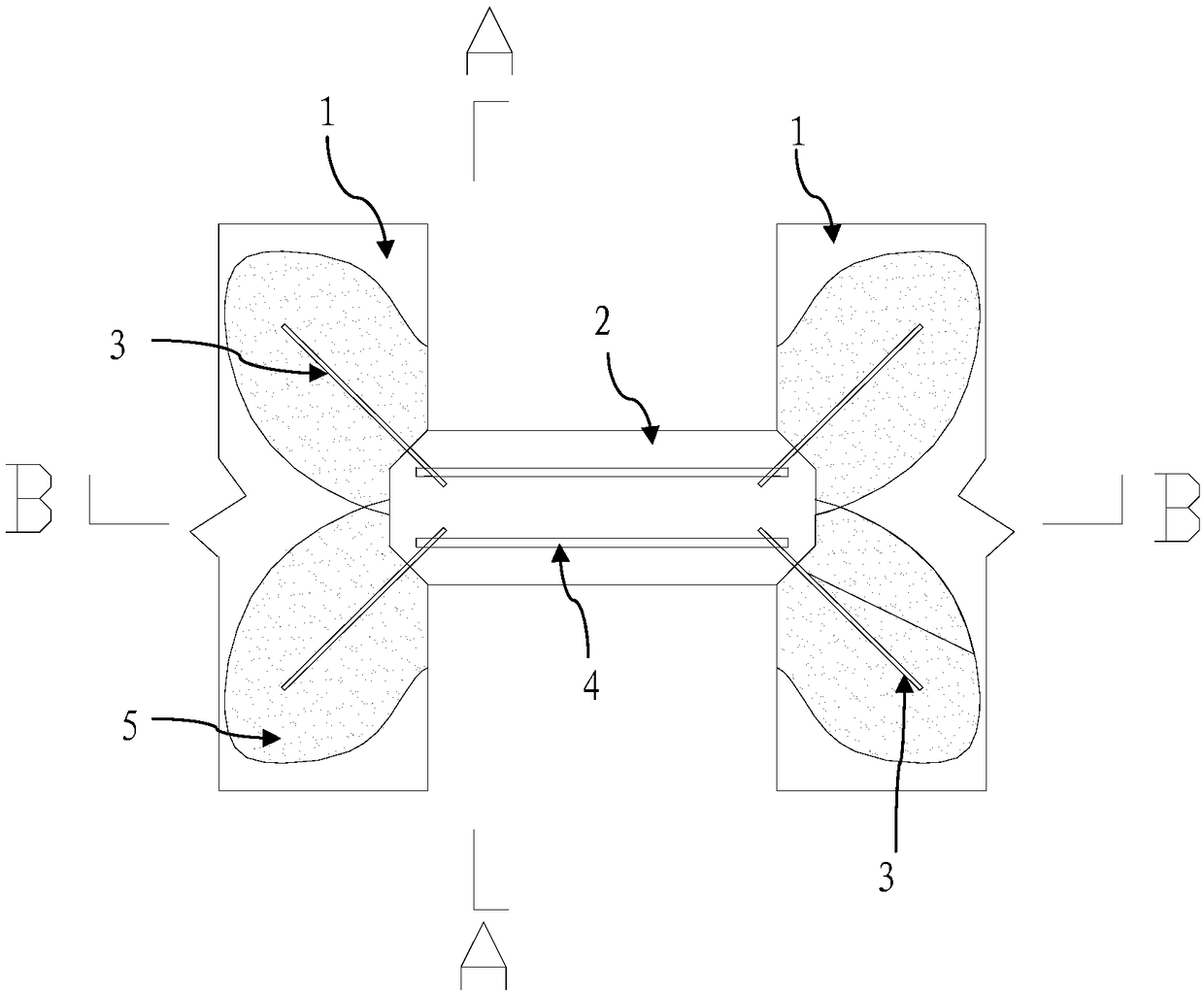

Front diversing flow rotor structure with tapping splitter blades for artificial heart blood pump

InactiveCN101822854BLow shearSatisfy blood pressure rise requirementsProsthesisPressure riseBlood pump

The invention relates to a front diversing flow rotor structure with tapping splitter blades for an artificial heart blood pump, comprising a rotor hub passageway and rotor blades, wherein the rotor hub passageway adopts a gradual contraction structure; a streamline cubic spline curve is used to define the hub passageway; and the rotor blades are composed of two overall large blades and two smallsplitter blades; and the overall large blades adopt a two-section blade-type structure design at a root part and a tip part respectively. The circumferential position structure of the rotor blades isas follows: the small splitter blades are located at 47% of a circumferential angle between the two overall large blades. After adopting the rotor structure, the blood-supply and pressure rising capability of the rotor is strengthened, the tangential velocity of a rotor blade tip and the shearing action of the rotor blades on blood are reduced, and the internal flow of the rotor is smooth withoutflow separation.

Owner:BEIHANG UNIV

Production of uniform polyphenylene terephthalamide fibre

ActiveCN101220530AStrong anti-aliasingImprove self-cleaning effectWet spinning methodsMonocomponent polyamides artificial filamentFiberPolymer science

The invention relates to a manufacturing method of homogeneous polyphenylene terephthalamide fibers. The polyphenylene terephthalamide fibers with high homogeneity can be produced by thoroughly mixing PPTA resin with 98 to 100 percent of concentrated sulfuric acid in an anisotropic twin-screw extruder, putting the mixture of the PPTA resin and 98 to 100 percent of the concentrated sulfuric acid into a homotropic twin-screw extruder to be dissolved, and leading the mixture through a filter equipment, a continuous film deaeration device and rectangular spinneret holes to carry out dry-jet and wet spinning. By adopting the anisotropic twin-screw extruder to mix materials, the manufacturing method has the advantages of easy feeding, strong mixing effect and weak shearing effect; the continuous film deaeration device can realize uniform and fast deaeration of high viscous PPTA / H2SO4 liquid crystal slurry; the spinneret holes which are arranged in a rectangle shape can ensure a larger contact area between injection tows and solidification liquid, and more even mass transfer and heat transfer between fibers and solidification liquid, thus facilitating the spinning of polyphenylene terephthalamide fibers with high homogeneity.

Owner:SINOCHEM HIGH PERFORMANCE FIBER MATERIALS CO LTD

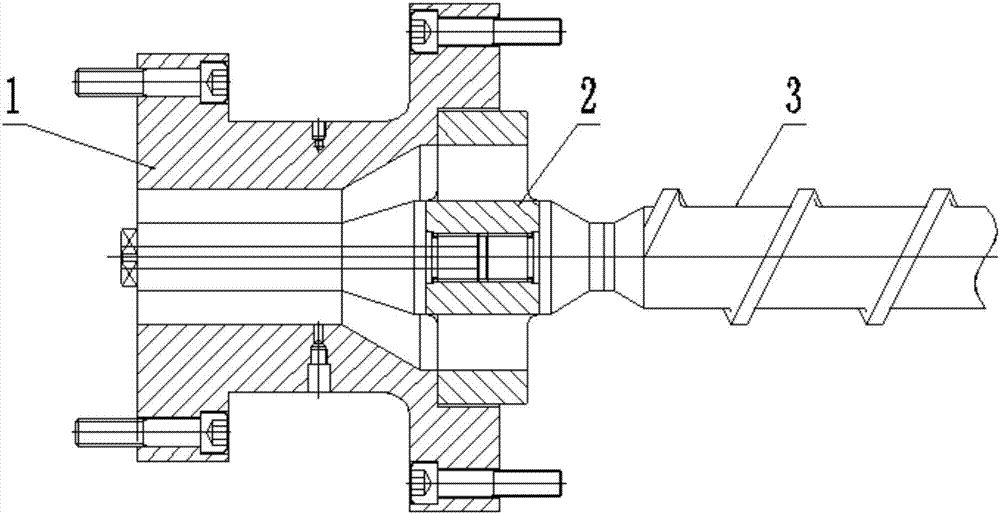

Rotor type mixing component

The invention relates to a rotor type mixing component. The rotor type mixing component comprises a feeding section, a first mixing section, a conveying section, a second mixing section and a discharging section which are sequentially arranged in the feeding direction. The first mixing section and the second mixing section are each provided with a plurality of pairs of screw flights. The top of each pair of screw flights is provided with a groove. Accordingly, the rotor type mixing component can relieve the shearing effect borne by the tops of the screw flights, backflow of some mixed materials is facilitated, original flowing of a rotor boosting face is disturbed, and homogenization of the material components is facilitated.

Owner:JILIN DESIGNING INST OF CNPC NORTHEAST REFINING & CHEM ENG

Spiral pipe type air atomizing nozzle

ActiveCN112264209AImprove atomization effectImprove uniformityLiquid spraying apparatusPollutant emissionsEngineering

The invention provides a spiral pipe type air atomizing nozzle. The nozzle adopts a three-time atomization scheme so as to solve the problem of insufficient fuel oil atomization at present. A nozzle body is generally in a contracted cone shape, and the joint of an inner cavity of the nozzle body and a mixing cavity is an internal flow channel throat. A spiral pipe is fixed in the inner cavity, inclined holes are distributed in the pipe wall, and small holes are formed in the tail portion. A fuel pipe is fixed to the upstream of a flow channel, and oil holes in an outlet oil cover of the fuel pipe conduct primary atomization on fuel. Gas enters from the head of the nozzle, part of the gas forms outer ring gas through an axial cyclone, and part of the gas enters the spiral pipe to form innerring gas. According to the spiral pipe type air atomizing nozzle, primary atomization is conducted on fuel through the oil cover, then outer ring rotational flow gas and inner ring gas sprayed out ofthe inclined holes of the spiral pipe are mutually sheared and impacted to conduct secondary atomization, third-time atomization is conducted under the strong shearing effect of outer ring mixed gasand the inner ring gas sprayed out of the small holes of the spiral pipe on the throat, the air atomization effect is effectively enhanced, and pollutant emission is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

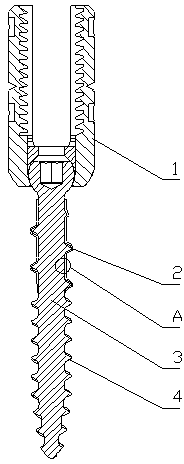

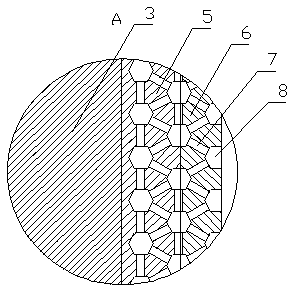

Pedicle screw

InactiveCN104398297ANot easy to come outLow shearInternal osteosythesisFastenersTreatment effectEngineering

The invention relates to a fixing device for operation on the pedicle, and particularly relates to a pedicle screw. The pedicle screw comprises a screw body and a U-shaped screw base, wherein the upper end of the screw body is connected with the U-shaped screw base; the upper 1 / 3-1 / 2 part of the screw body is an unthreaded rod; the unthreaded rod is externally provided with a porous healing layer; and the lower part of the screw body is provided with threads. The pedicle screw provided by the invention has the advantages that the pedicle screw can be easily turned into the pedicle by consuming the least time and labor, causes little shearing action and damage on the pedicle, can be merged into the bone tightly without separation, can ensure that a patient recovers rapidly after operation, has a good treatment effect and is suitable for non-merged operation on the pedicle.

Owner:SHANDONG WEIGAO ORTHOPEDIC DEVICE COMPANY

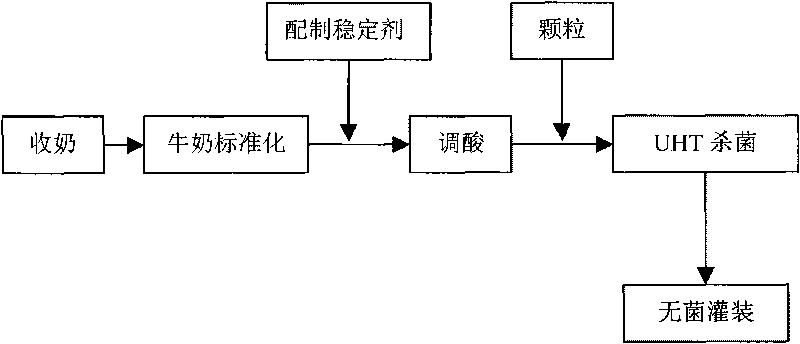

Method for producing fruit granule-containing dairy products

The invention relates to the field of dairy products, in particular to a method for producing fruit granule-containing dairy products. The method is suitable for the dairy products of which the viscosity is less than 40cp, and comprises the following steps: 1) checking and accepting; 2) preparing fruit granules; 3) adding mixed solution of the fruit granules into milk with a sinepump on line, and conveying the mixed feed liquid added with the fruit granules with a multi-cylinder plunger pump, wherein the upper limit of the rotation speed of the sinepump is 150r / min, and the aperture of the inlet and the outlet of the multi-cylinder plunger pump is 30 to 50mm; and 4) homogenizing, sterilizing and filling. Because the multi-cylinder plunger pump is adopted to convey the mixed feed liquid of the milk and the fruit granules, and the inlet and the outlet of the plunger pump are designed to have heavy caliber, the shearing action caused by equipment in a feed liquid conveying process is greatly decreased, the degree of damage to the fruit granules is reduced, the integrity of the granules is guaranteed and the product conveying continuity is also guaranteed by the multi-cylinder plunger pump.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

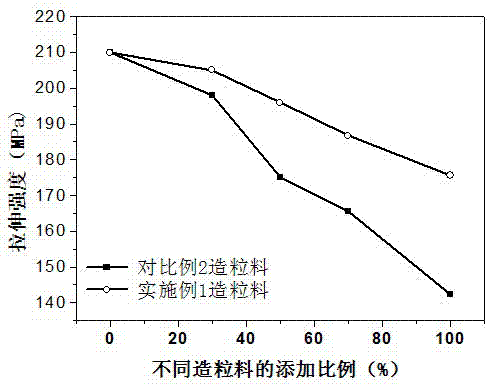

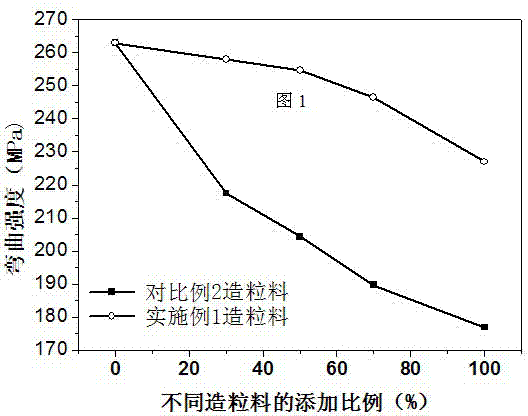

Recovering and granulating method of high-performance glass fiber reinforced flame-retardant secondary PA46 (Polytetramethylene Adipamide 46) material

The invention discloses a recovering and granulating method for a high-performance glass fiber reinforced flame-retardant secondary PA46 (Polytetramethylene Adipamide 46) material. The recovering and granulating method comprises the steps of crushing a secondary material or unqualified part generated in an injection molding process of a glass fiber reinforced flame-retardant PA46 material; sieving and removing metal chips; carrying out extrusion molding by using a single screw extruder, wherein the processing temperature ranges from 295 DEG C to 330 DEG C; carrying out stay conveyance by using a metal chain; when the material is cooled, granulating to obtain a recovered granulated material. According to the method, the shearing action of the single screw extruder is relatively weak, and the secondary material to be recovered is only subjected to weak shearing action in a plasticizing process, so that the length of glass fiber can be kept at a relatively large value, and the damage to a macromolecular chain segment of the PA46 is reduced; compared with a method for extruding and granulating by using a double screw extruder, the method disclosed by the invention has the advantages that the mechanical performance and the heat resistance are both kept at better values: the maximum reduction amplitude of the mechanical performance is not higher than 10%, the reduction amplitude of the thermal deformation temperature is not higher than 2.6 DEG C, and the granulation loss rate is not higher than 1.2%, so that the utilization ratio of the glass fiber reinforced flame-retardant secondary PA46 material can be increased.

Owner:深圳市磐汩新材料有限公司

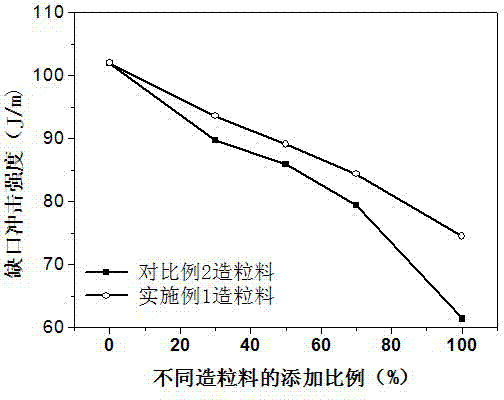

Systems and methods for separating proteins from connective tissue

InactiveUS8021709B2Avoid tearingEasy to separateImmunoglobulinsLiquid solutions solvent extractionMuscle tissueMyofibril

Methods and systems for separating muscle tissue from connective tissue are provided, in which animal tissue containing both muscle tissue and connective tissue is subjected to stress, and muscle proteins are separated from the connective tissue. Slurries of separated myofibrillar protein are also provided.

Owner:M P F

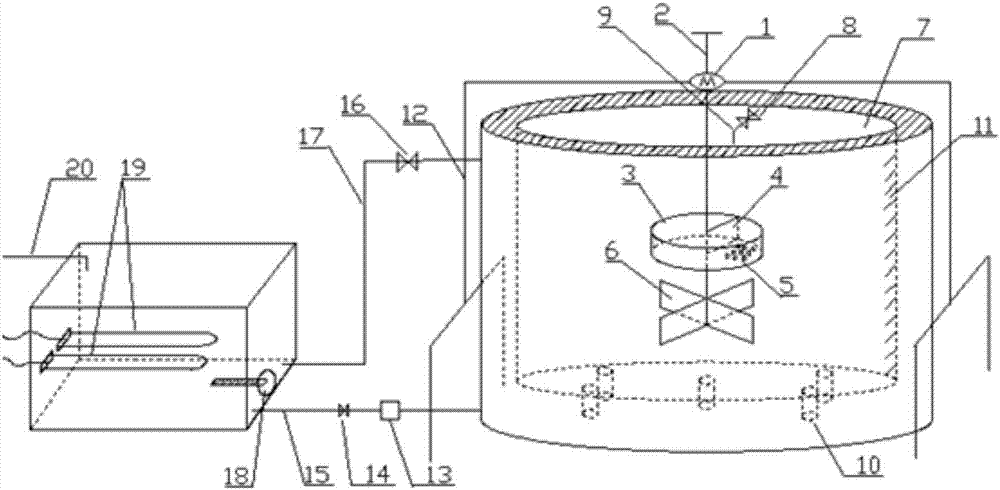

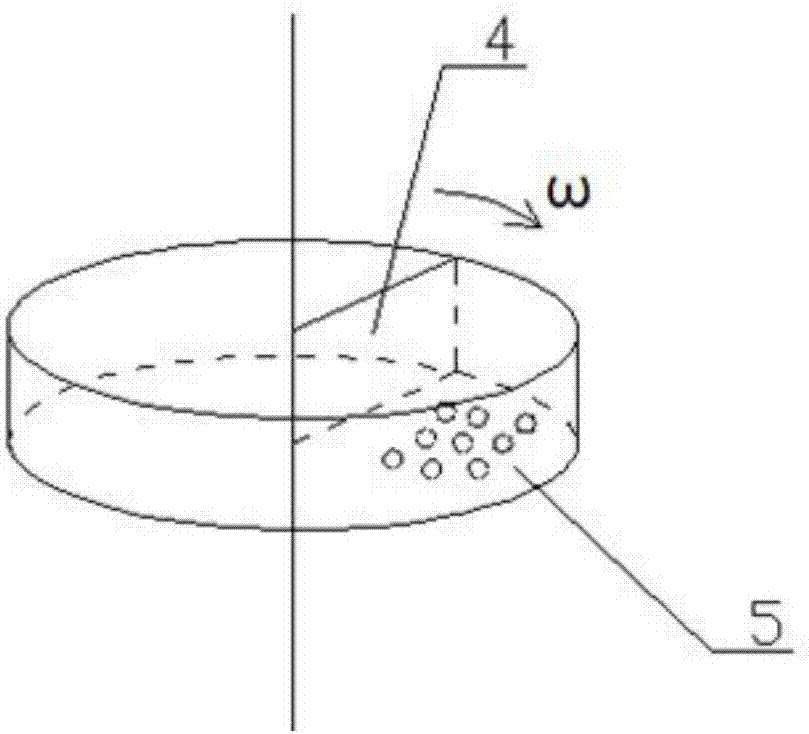

Film forming method for biological carrier in internal circulation bioreactor

ActiveCN102050518AReduce frictionImprove adsorption capacitySustainable biological treatmentBiological water/sewage treatmentLoad resistanceSludge

The invention relates to a film forming method for a biological carrier in an internal circulation bioreactor. The film forming method comprises the following steps of: adding the needed biological carrier into the internal circulation bioreactor by 2 to 5 times; every time after a biological filler is added, introducing air to make the biological carrier in a fluidized state; adding domesticated inoculation active sludge into the bioreactor in a spraying way; after spraying, ventilating for 6 to 72 hours; discharging the sludge; and culturing in a continuous water feeding way. In the method, needed starting power is low, film forming time is short and a formed biological film has high impact load resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

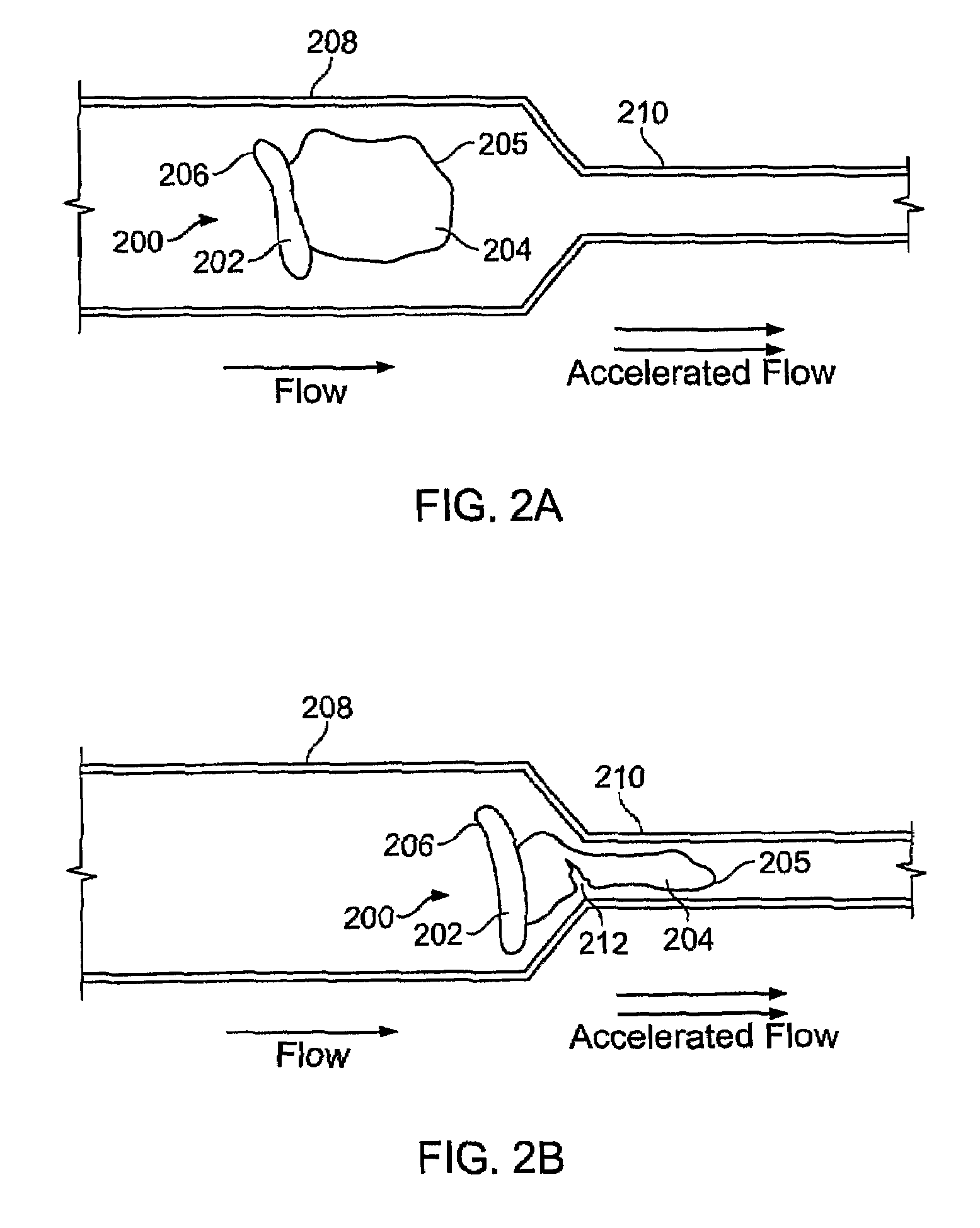

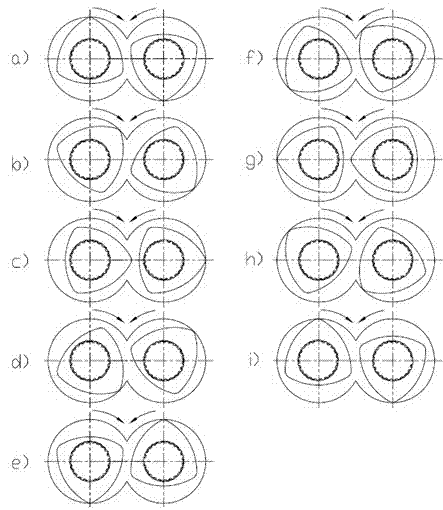

Three-stage alcohol fermentation bioreactor with fluidized-bed for fixed yeast

InactiveCN1840645AVigorous fermentation reactionLow shearBioreactor/fermenter combinationsBiological substance pretreatmentsYeastAlcohol

The three-stage fluid bed fixing barm alcohol fermentation bio-reactor comprises: a gas holder, a three-stage fusiformate fermentation body, and a storage chamber for fermented glutinour rice; all vertically connected in turn by flange. This invention is simple, needs low consumption and land area, and improves material utility.

Owner:SHANGHAI JIAO TONG UNIV

Opthalmological compositions and methods of use thereof

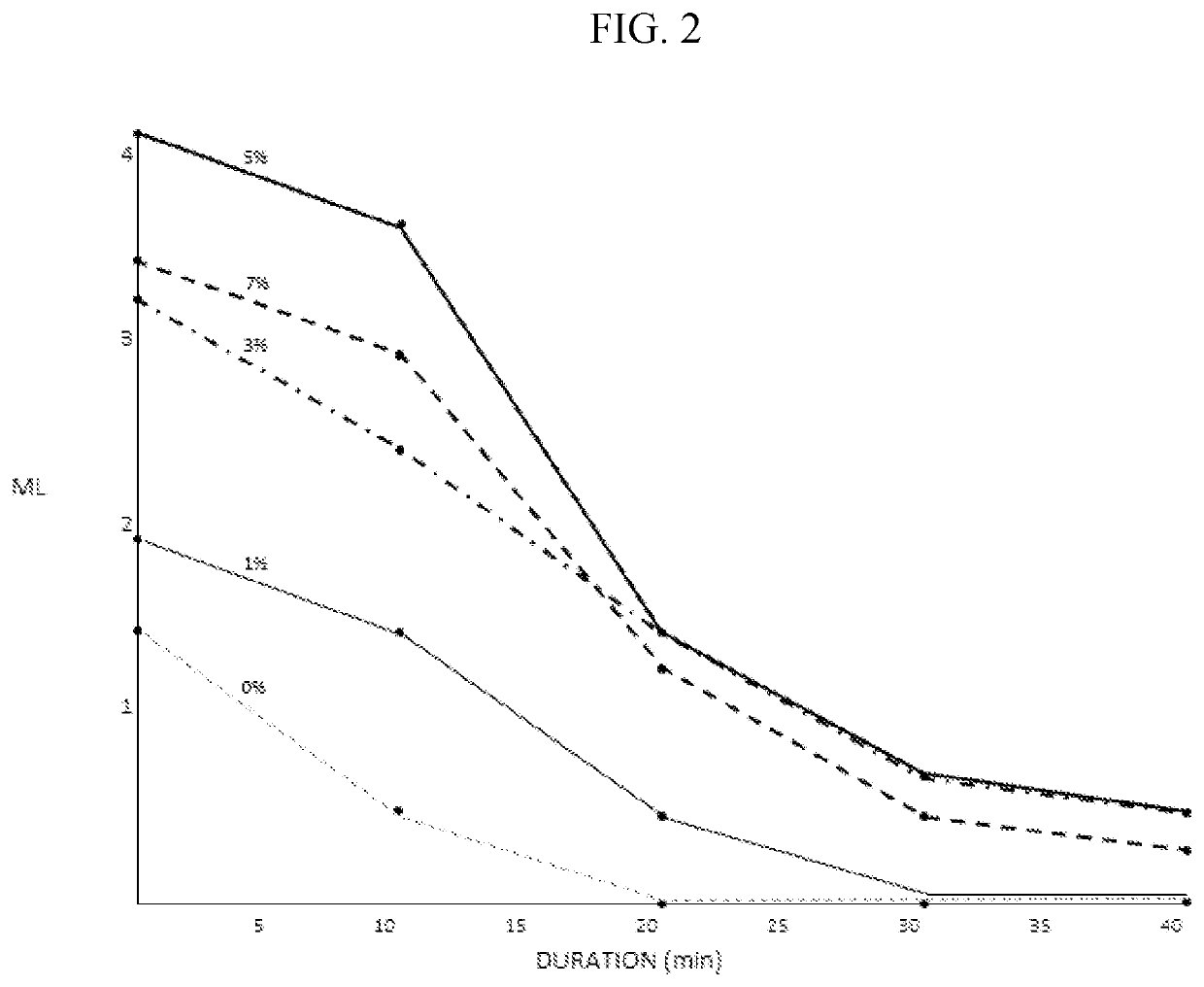

PendingUS20220080048A1High viscosityLow shear viscosityOrganic active ingredientsSenses disorderPolyoxyethylene castor oilCellulose

The invention is directed to compositions comprising polysorbate 80, poloxamer 407, poloxamer 188, polyoxyl 35 castor oil, hydroxypropyl gamma cyclodextrin, hydroxypropylmethylcellulose, polyethylene glycol 400, mannitol, magnesium chloride, sodium chloride and potassium sorbate. The invention is further directed to a method of treating dry eye comprising topically applying compositions of the present invention to the eye of a subject in need thereof.

Owner:PS THERAPY INC

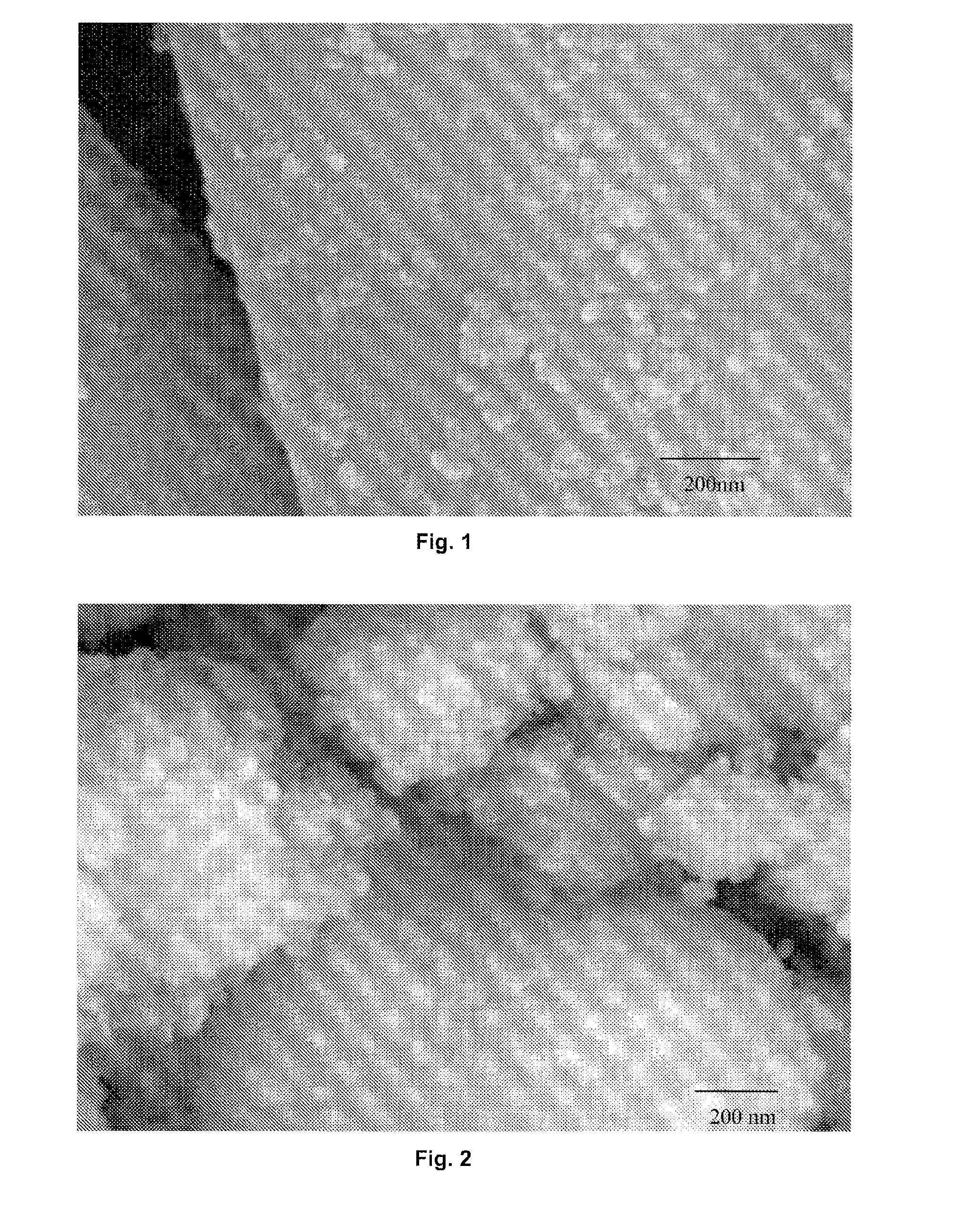

Method for the dry dispersion of nanoparticles and the production of hierarchical structures and coatings

The invention relates to a method for the dispersion of synthetic or natural nanoparticles and nanocomposite materials and to the use thereof in different sectors including those of ceramics, coatings, polymers, construction, paints, catalysis, pharmaceuticals and powdered materials in general.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC)

Shunting injection allocation method and shunting injection allocation machine

ActiveCN101270648ASmall local pressure drop lossLow friction coefficientFluid removalEngineeringPolymeric liquid

The invention relates to a split-flow injection allocation method and a split-flow distributor. The method of the invention is characterized in that every subsection of a polymer injection pipe is provided with at least one distributor, and a split-flow barrier is arranged in the distributor to divide polymeric liquid entering into the distributor into two parts, one part of which flows up to an upper oil reservoir and the other part of which continues to flow down to the lower oil reservoir. The polymer injection pipe is provided with the split-flow distributor and the surface of the split-flow distributor is sleekly connected with the outlet of the distributor. So liquid passing by the distributor has little partial drop pressure loss, low friction resistance and little shearing action, thus effectively reducing the loss of the viscosity of injected polymer. The split-flow injection allocation method and the split-flow distributor can be widely used for improving the recovery ratio of reservoir oil displacement in an offshore oilfield.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Coaxial extruder and extrusion method thereof

PendingCN107471595AMachining accuracy is easy to guaranteeGuaranteed machining accuracyDiameter ratioEngineering

The invention relates to a coaxial extruder and an extrusion method thereof. The coaxial extruder comprises a die, a rectifying disc, an extrusion device, a heater, a charging base and a power device, and is characterized in that the extrusion device comprises a main screw barrel, an outer screw and an inner screw; the two ends of the main screw barrel are connected with the charging base and the die correspondingly, and the outer screw is arranged in the main screw barrel and rotates; the inner screw is arranged in the outer screw and is in threaded connection with the rectifying disc; the inner screw and the outer screw are reverse in thread screwing direction, an additional thread is additionally arranged between main threads of the outer screw, the thread pitch of the additional thread is larger than that of the main threads, and an additional thread groove is formed by the additional thread and the main threads; and the bottom, at the position of the additional thread groove, of the outer screw is provided with a melt channel. The length-diameter ratio is greatly reduced, the strength of the outer screw is greatly improved, the number of heaters is reduced due to the shortened main screw barrel, and part of originally-emptied waste heat is sufficiently utilized; the material cost and the occupied area are saved, and the fusion raw material process time is shortened; the probability of decomposing of fusion materials due to overheating is reduced; and power consumption is reduced.

Owner:青岛威尔塑料机械有限公司

Durable lubricating and friction-reducing slide plate for bridge support

PendingCN110835887ALong-lasting slow-release lubrication effectPlay the role of lubrication and friction reductionBridge structural detailsBridge materialsPolymer scienceSlide plate

The invention relates to a durable lubricating and friction-reducing slide plate for a bridge support. The composite slide plate is formed by compounding a wear-resistant material and a slow-release friction-reducing material, the wear-resistant material is a non-metal wear-resistant sliding plate formed by a polymer-based polymer material, a pit or a groove is formed in the surface of the non-metal wear-resistant sliding plate, and the slow-release friction-reducing material is formed in the pit or the groove in the surface of the non-metal wear-resistant sliding plate; the slow-release friction-reducing material is compose of a carrier material, an adsorption material, a lubricating material and a stabilizer; the slow-release friction-reducing material comprises the following componentsin percentage by weight of 30%-60% of the carrier material, 5%-20% of the adsorption material, 10%-40% of the lubricating material and 10%-20% of the stabilizer. The composite sliding plate has the characteristics of strong bearing capacity, small friction coefficient, excellent wear resistance and long effective lubrication time.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

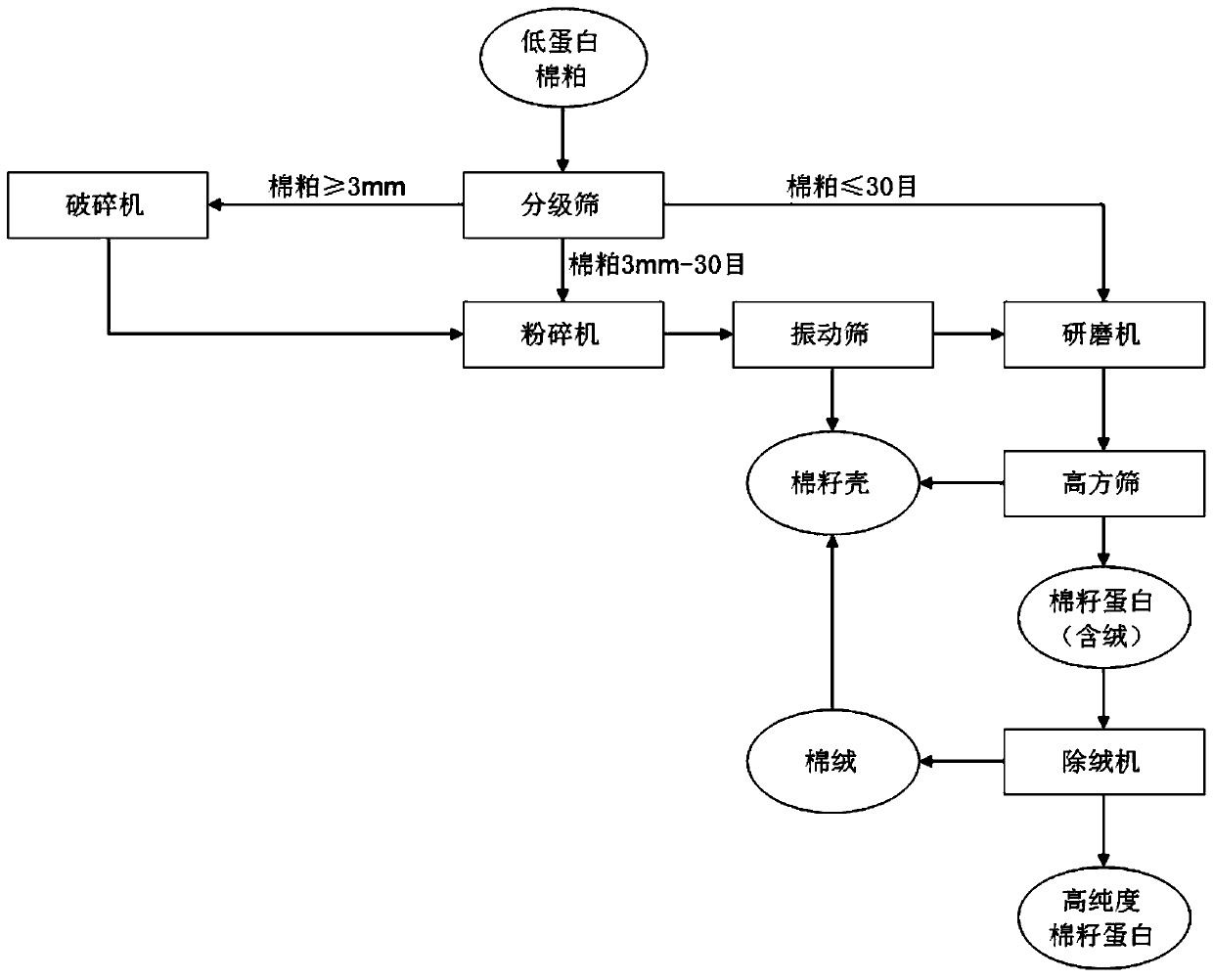

Process for producing high-purity cottonseed proteins through low-protein cottonseed meal

ActiveCN110813485AHigh precision requirementsDoes not affect activityGrain treatmentsNutritionOrganic matter

The invention specifically relates to a preparation process of cottonseed proteins, in particular to a process for producing high-purity cottonseed proteins through low-protein cottonseed meal. Cottonseed hulls and cotton velvet in conventional cottonseed meal can be completely separated, the removal rate of the cottonseed hulls reaches 98%, the removal rate of the cotton velvet reaches 96%, the ordinary cottonseed meal is converted into the cottonseed proteins, the content of the cottonseed proteins can reach 60% or above, and the cottonseed proteins can be applied to aquatic feed to replacefish meal. Part of the cottonseed proteins are taken away from generated products, namely the cottonseed hulls, in the screening process of a grading screen, thus the cottonseed hulls contain 10-14% of the cottonseed proteins, and the cottonseed hulls are rich in organic matter and nutrition, have quite high application value, are applied to the field of mushroom cultivation, and can also serve ashigh-protein feed for cattle and sheep. The preparation process can be suitable for industrial large-scale continuous production, the whole product production process is at the normal temperature, chemical extraction is not involved, the activity of original cottonseed proteins is not damaged, and the content of proteins in the conventional cottonseed meal (the content of the cottonseed proteinsis 40%-45%) is increased to 60% or above.

Owner:新疆德安环保科技股份有限公司

Three-head screw element and twin-screw extruder using the element

The invention discloses a three-head thread element and a twin-screw extruder using the element, wherein the center lines of the major diameter and the minor diameter of the thread element coincide, but the center lines of the two have an eccentric distance from the center of rotation. Due to the eccentricity between the center line of the major diameter and the minor diameter and the center of rotation, when the threaded element rotates in the barrel, there is always only one screw flight with a small gap with the inner wall of the barrel, and the other two screw flights are in contact with the inner wall of the barrel. The inner wall of the barrel maintains a large gap, so that the shearing effect on the material is much smaller than that of the ordinary three-threaded element, and the material generates less heat, which is especially suitable for some heat-sensitive materials; in addition, due to the large diameter and small diameter It is not concentric with the center of rotation, so the ratio of the major diameter to the minor diameter of the threaded element is low. Under the same process conditions, the filling degree of the material is higher than that of the ordinary three-start threaded element, so that high output can be obtained at low speed. , to reduce energy consumption.

Owner:SICHUAN SINOEXTRUDER TECH

Preparation device for viscoelasticity high-molecular polymer aqueous solution

The invention relates to a preparation device for a viscoelasticity high-molecular polymer aqueous solution. An outer shell of a cavity is placed in a support. A blade and a disperser are placed in the cavity. The blade penetrates through a rotary shaft of the disperser to be connected with a speed adjusting motor. A scraping piece of the disperser rotates along with the rotary shaft. An interlayer space is arranged between the cavity and the outer shell. A temperature control device is connected with the interlayer space to form a loop, and water temperature in the cavity reaches dynamic equilibrium through the temperature control device. In the preparation device, high-molecular polymer solute enters water periodically and can dissolve in water evenly through high-degree-of-freedom stirring action of a stirrer. The stirred speed of the solution in the cavity can be controlled by the speed adjusting motor on the stirrer, the shearing action on fluid can be reduced, damage to a high-molecular polymer molecular chain is reduced, hydrophobic coatings are applied on the surfaces of blades of the stirrer, adhesion of polymer molecules can be reduced, after preparation, hot water in the temperature control device can be led out to wash the blades and the inner wall of the cavity, and solute residues are prevented.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

High polymer material plasticizing transportation device based on tension rheology and shear rheology

The invention discloses a high polymer material plasticizing transportation device based on tension rheology and shear rheology for stretching and shearing materials synchronously in the high polymer material plasticizing transportation process, comprising at least one plasticizing transportation unit arranged on a same transmission shaft. All plasticizing transportation units are connected together in series and each plasticizing transportation unit comprises a feeding disc, an exhaust disc, an extrusion disc arranged between the feeding disc and the exhaust disc, and a plurality of tooth-shaped push rods arranged in a rectangular through hole of the extrusion disc and evenly distributed along a circumference direction. Full compound dynamic plasticizing transportation extruder can be combined by overlapping the plurality of plasticizing transportation units; plasticizing transportation unit, various screw extrusion units or plunger injection units can be combined into a compound dynamic plasticizing injector of various extruders or injectors.

Owner:JIANGSU VICTORY MACHINERY

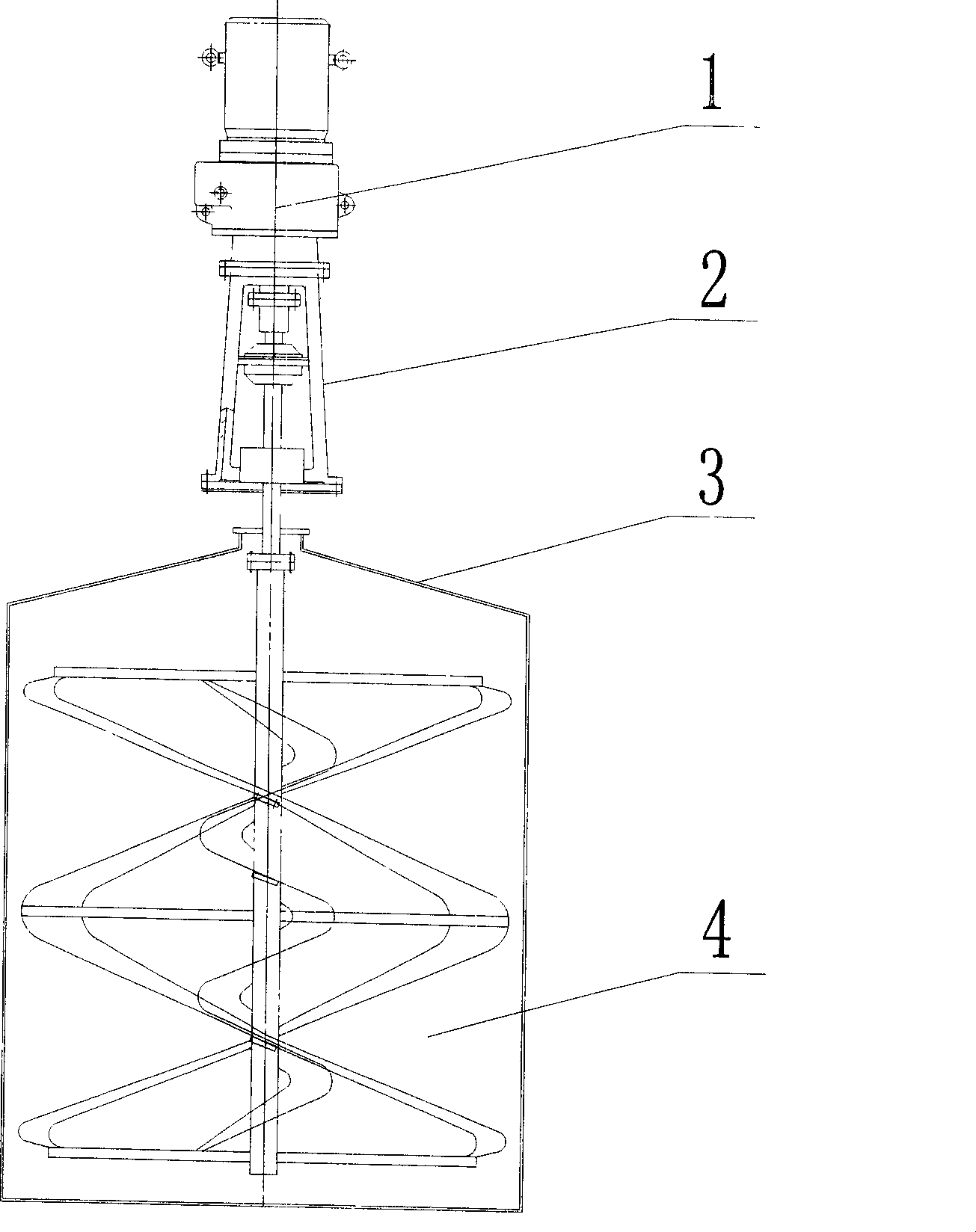

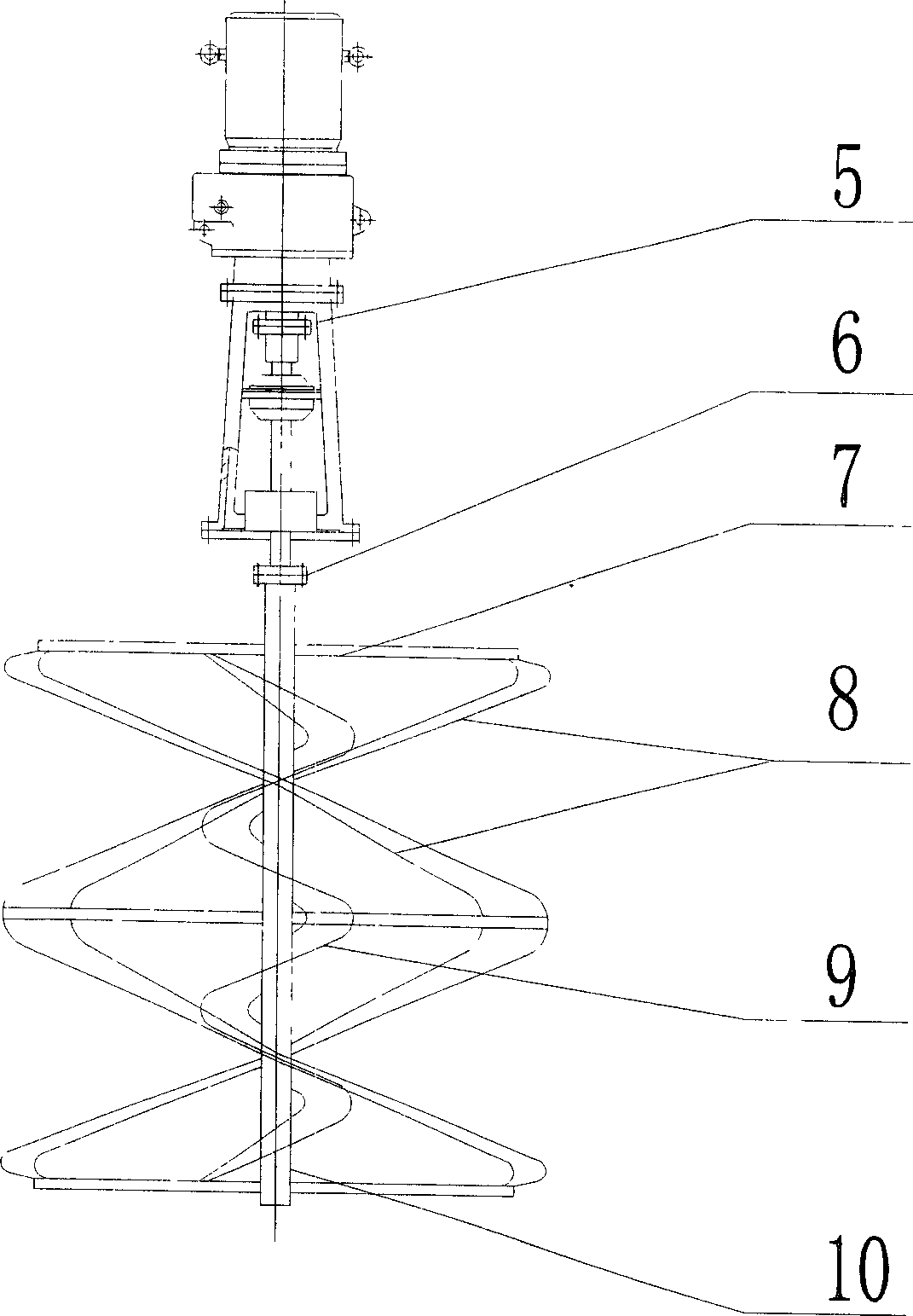

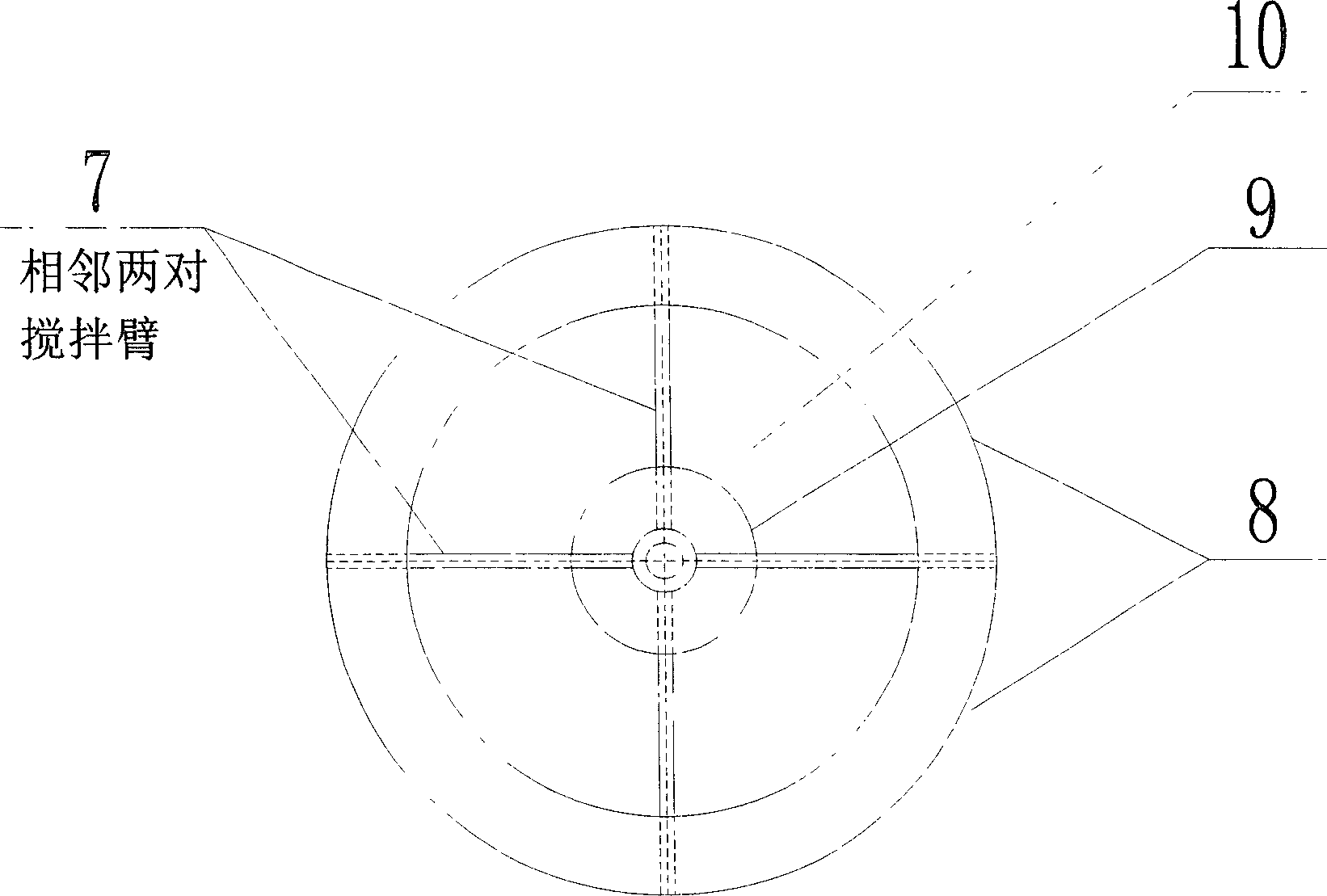

Polymer with ultrahigh molecular weight hydrolytic agitator

InactiveCN1817428ALow shearHigh apparent viscosityRotary stirring mixersEmulsificationApparent viscosityCoupling

Owner:TIANJIN UNIV

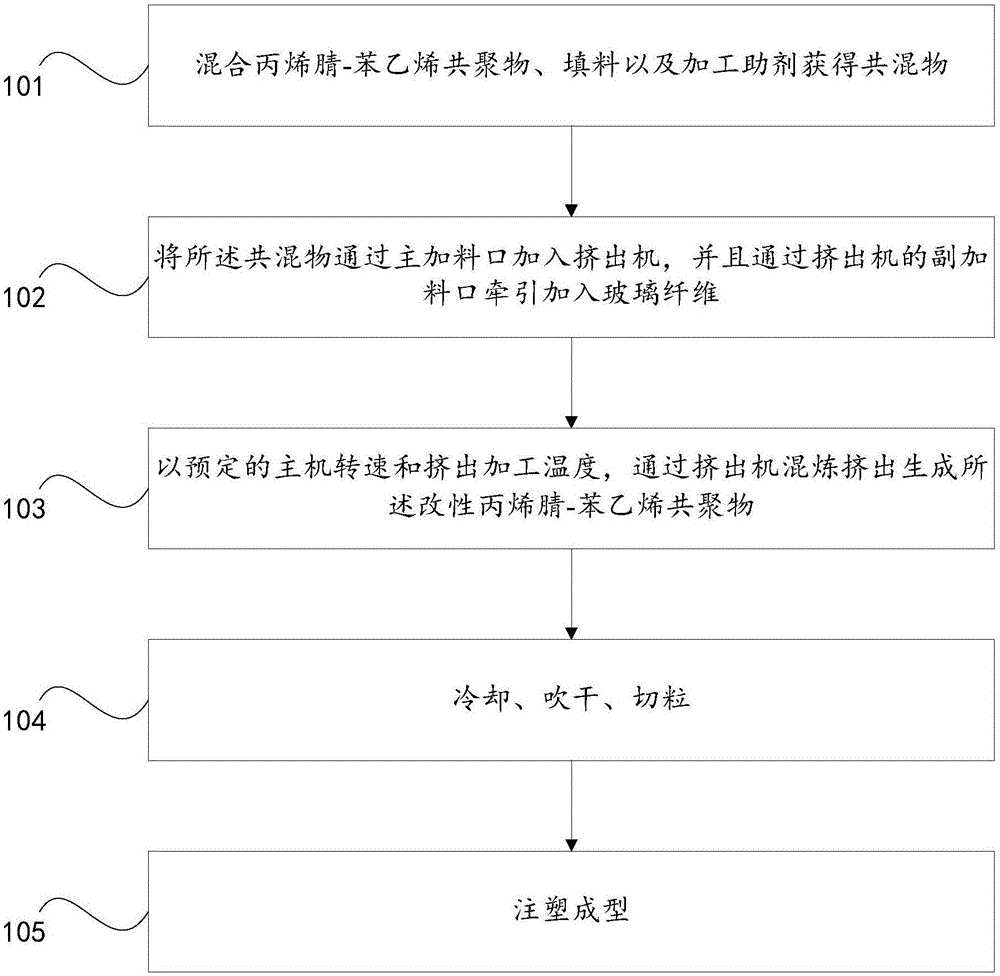

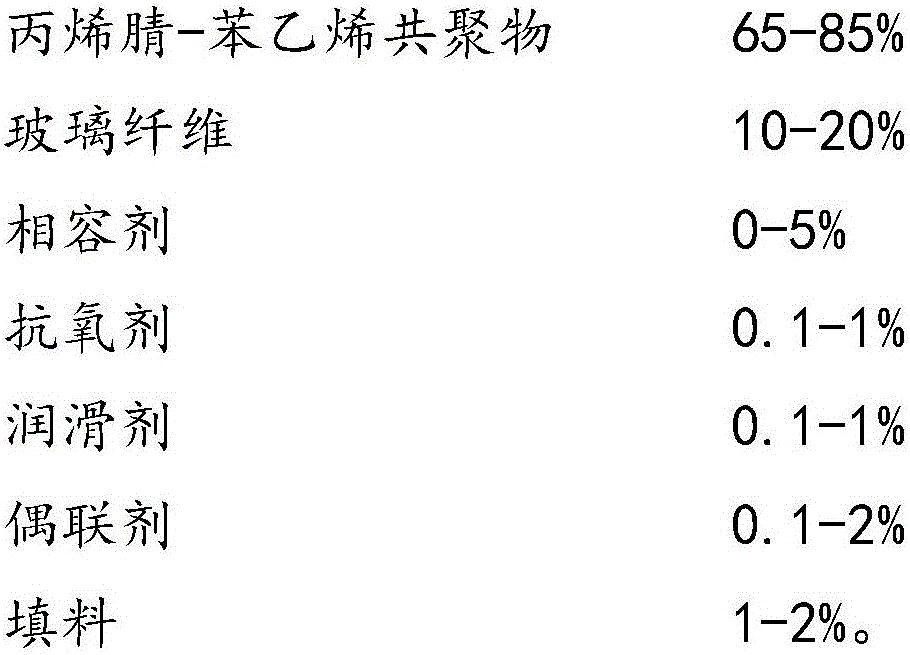

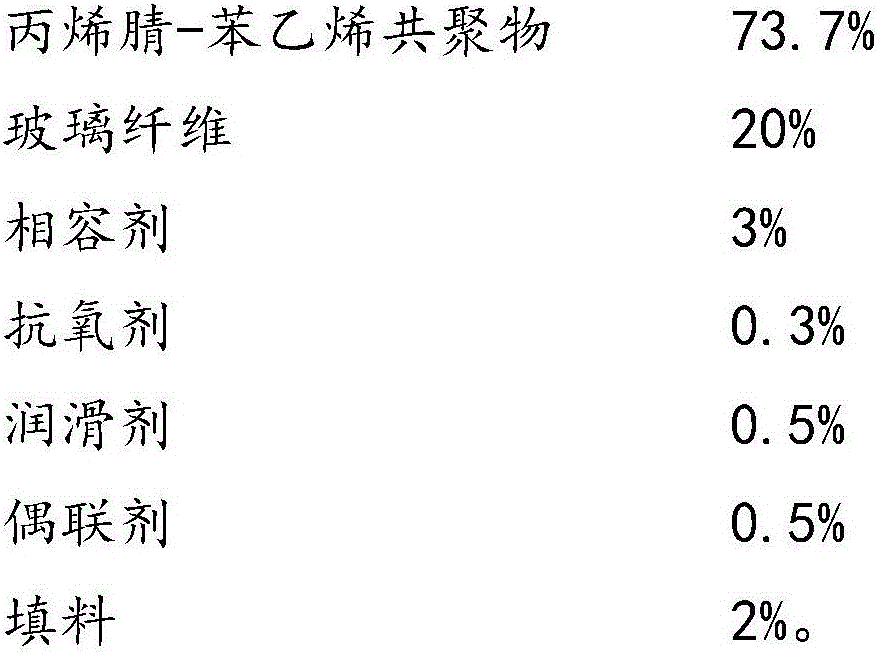

Modified acrylonitrile-styrene copolymer and preparation method thereof

The invention discloses a modified acrylonitrile-styrene copolymer and a preparation method thereof. The preparation method comprises steps as follows: a blend is obtained by mixing an acrylonitrile-styrene copolymer, filler and a processing aid; the blend is added to an extruder via a main charging port, and glass fiber is added under traction of an auxiliary charging port of the extruder; the modified acrylonitrile-styrene copolymer is generated through mixing extrusion of the extruder at a preset main machine rotating speed and extruding processing temperature. A technology used in the whole preparation process is simple, and the prepared modified acrylonitrile-styrene copolymer has excellent use performance, tensile strength, impact resistance, bending strength and size stability and can meet the severe application environment requirements.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com