Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Low friction coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low wear and low friction coatings for articles made of low softening point materials

InactiveUS20030186060A1Low friction coefficientSolve the high wear rateNon-fibrous pulp additionLiquid surface applicatorsGraphiteBoron nitride

The present invention relates to an anti-friction and anti-wear liquid coating composition for use with parts made of materials that have softening points below about 300° F. and articles so coated. The present invention also relates to a method of coating parts made from a low softening point materials with an anti-friction and anti-wear hard coating composition. The coating composition comprises a mixture of (i) solid lubricants comprising boron nitride, graphite and molybdenum disulfide, (ii) a thermoset resin system, (iii) catalyst for curing the resin system and (iv) a solvent system comprising highly volatile solvents. The coating composition is applied to the part and cured to form a coating on the part.

Owner:FORD MOTOR CO

Polyamideimide-Based Film Coating Composition

ActiveUS20120065296A1Increase molecular weightLow friction coefficientEpoxy resin coatingsETHYL PYRROLIDONEPolymer chemistry

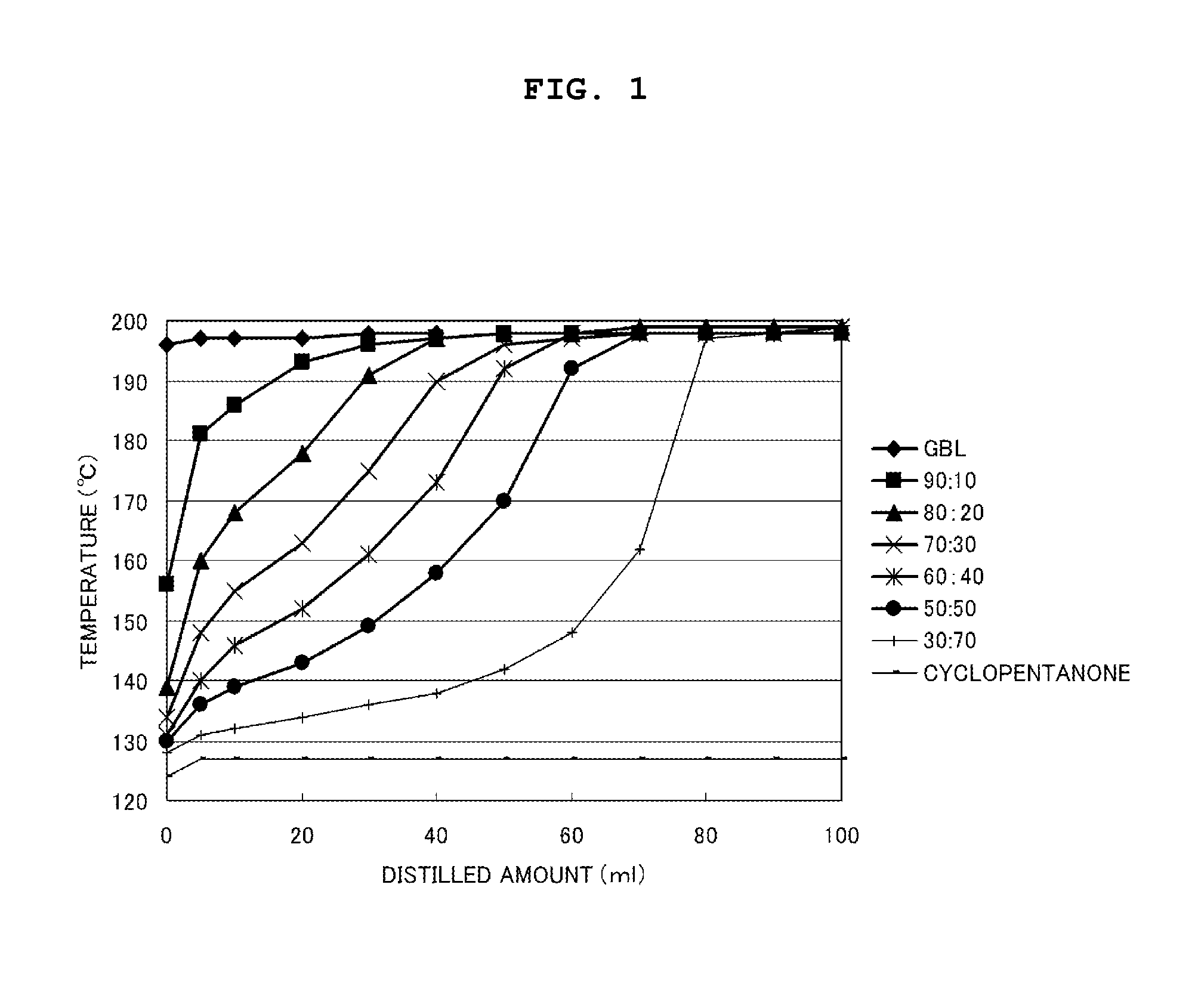

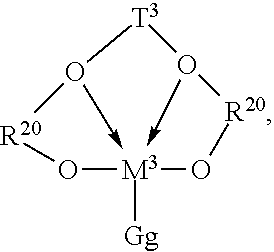

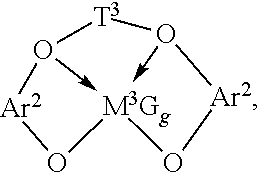

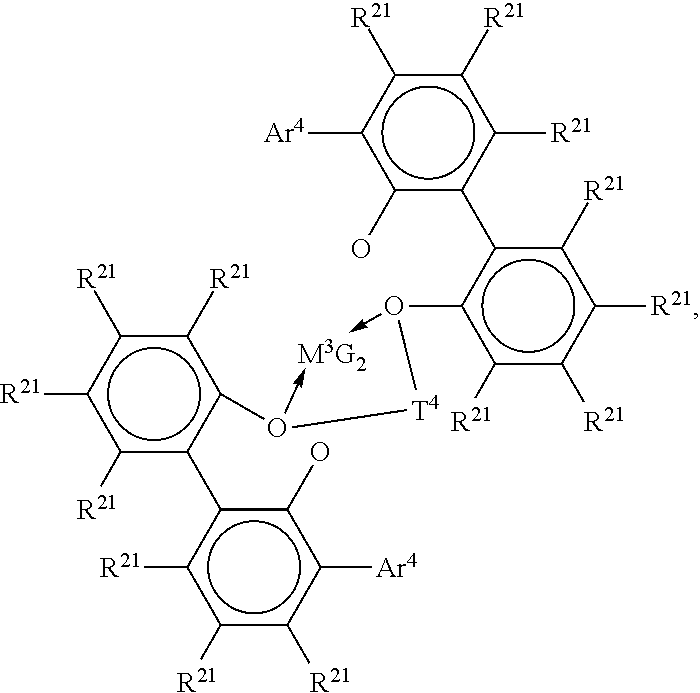

Disclosed is a polyamideimide-based film coating composition free from any restricted substance or a substance which might possibly be a restricted one such as N-methyl pyrrolidone and N-ethyl pyrrolidone and capable of replacing a conventional coating composition using a solvent such as N-methyl pyrrolidone. The polyamideimide-based film coating composition of the present invention is a polyamideimide-based film coating composition comprising a polyamideimide resin and a solvent, the polyamideimide resin being dissolved as a binder in the solvent, wherein the solvent contains γ-butyrolactone and cyclopentanone, and a volume of γ-butyrolactone is 50% by volume or more compared to a total volume of γ-butyrolactone and cyclopentanone.

Owner:VALEO JAPAN CO LTD

Retortable easy opening seals for film extrusion

A composition of matter particularly well suited for use as a peelable seal layer is described. The composition comprises from about 50 to about 85 percent by weight of a first polymer and from 15 to 50 percent of a second polymer. The first polymer is a propylene based polymer characterized by having a melting point of at least 125° C. together with a Comonomer Composition Distribution Breadth (“CCDB”) less than 2. The second polymer is characterized by having an interfacial adhesion with the first polymer of less than 1 lb / inch.

Owner:DOW GLOBAL TECH LLC

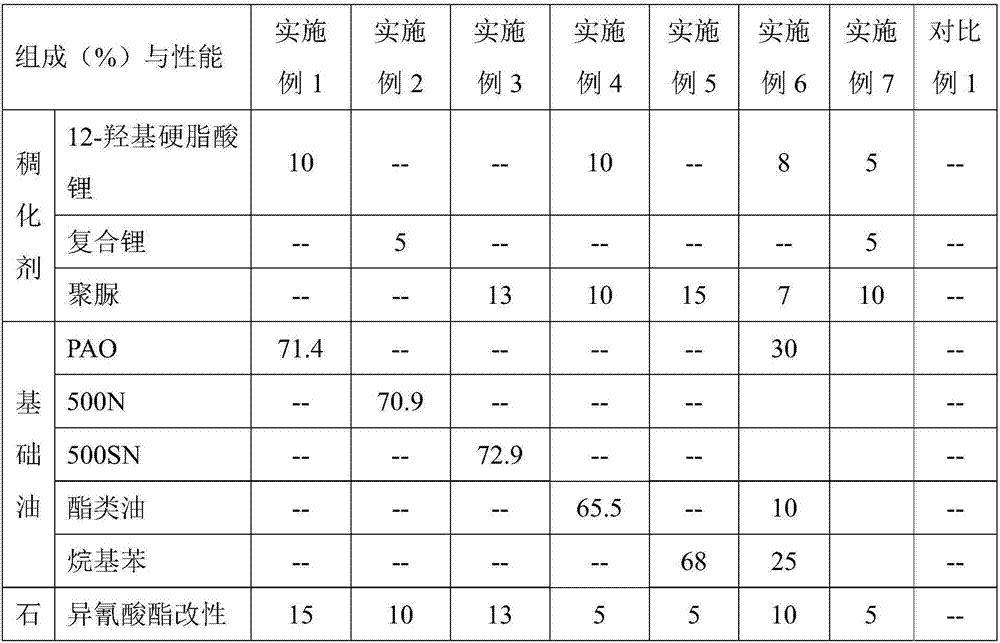

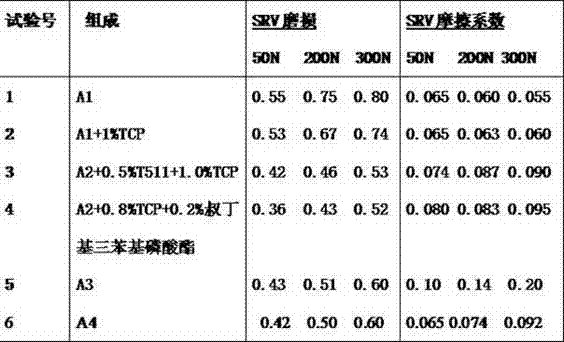

Antifriction heat-conducting lubricating grease for motor bearings of pure electric vehicles

InactiveCN108003997AIncrease mileageLow friction coefficientLubricant compositionFriction reductionHeat conducting

The invention relates to an antifriction heat-conducting lubricating grease for motor bearings of pure electric vehicles. The lubricating grease is prepared from, by weight, 65-85% of base oil, 5-20%of thickener, 0.1-5% of antioxidant, 0.1-5% of rust and corrosion inhibitor, and 5-20% of modified graphite. The lubricating grease has the advantages of friction reduction, energy conservation, excellent heat conductivity and the like. The product meets the lubricating requirements of high-rotating-speed, high-temperature, high-load and extremely-low-temperature motor bearings of pure electric vehicles, significantly reduces the friction coefficient of motor bearings and saves electric energy; meanwhile, the product has great heat conductivity, so that the running temperature of bearings is greatly reduced, and accordingly the service life of bearings is prolonged.

Owner:SHANDONG NORTH ZITE SPECIAL OIL

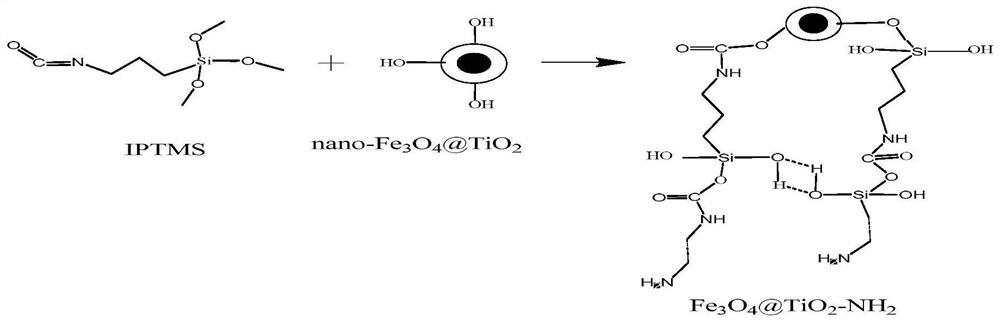

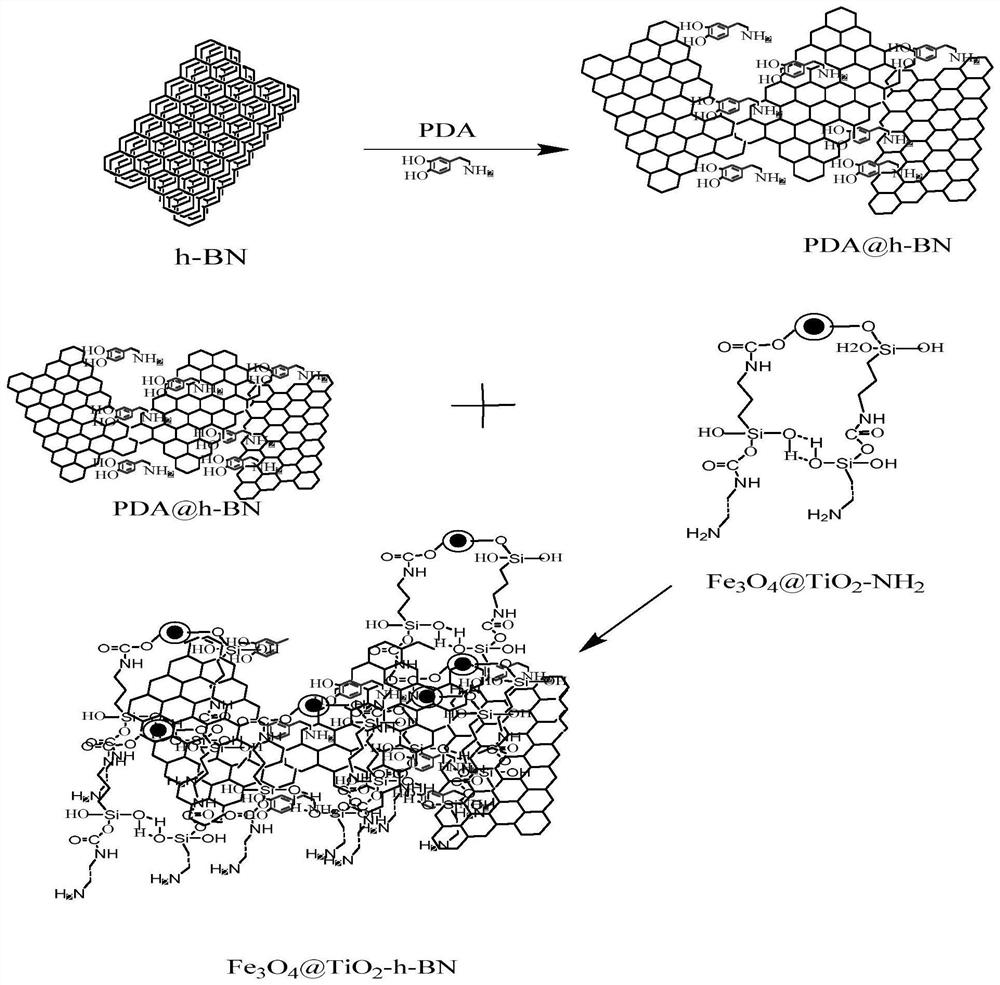

Nanometer composite ocean anticorrosion coating and preparation method thereof

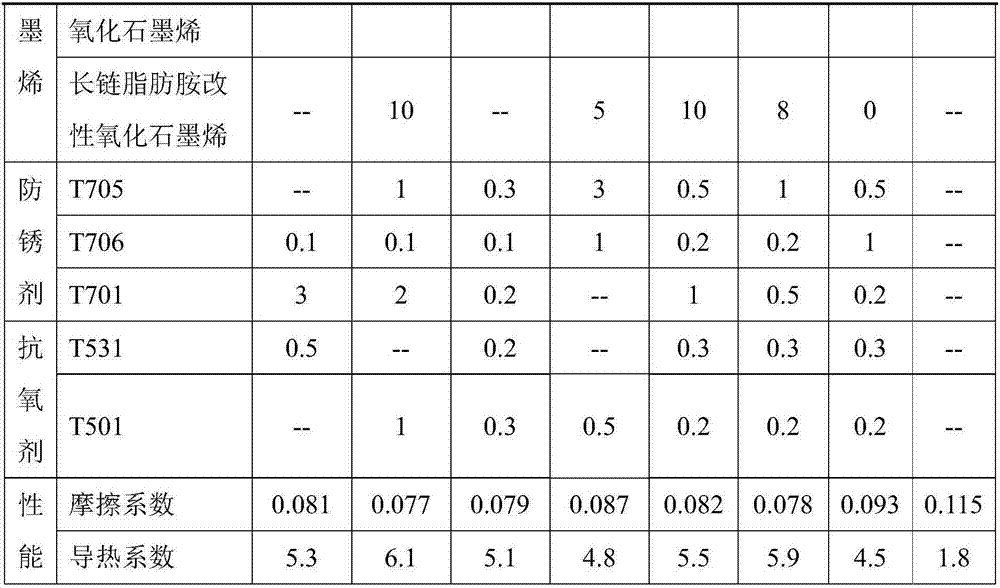

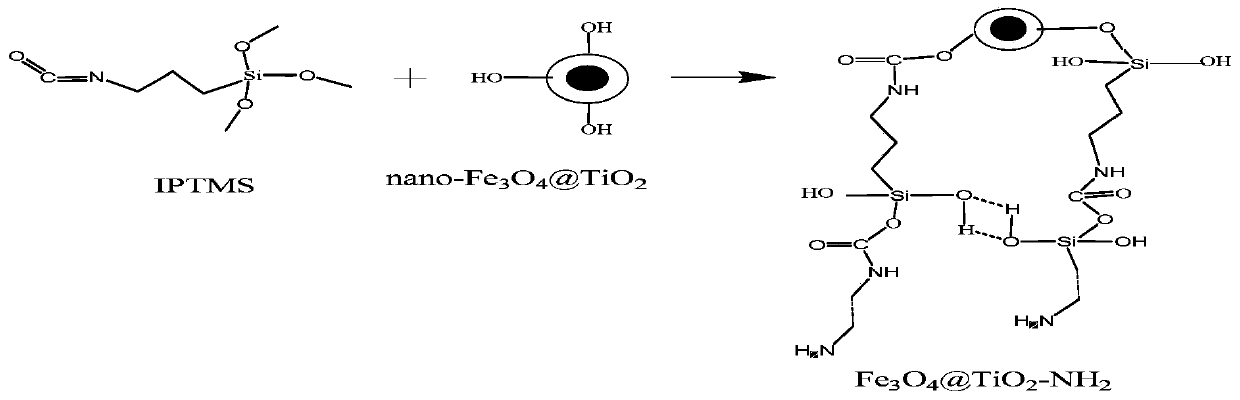

ActiveCN109943169AReduce biocorrosion hazardsLarge specific surface areaAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

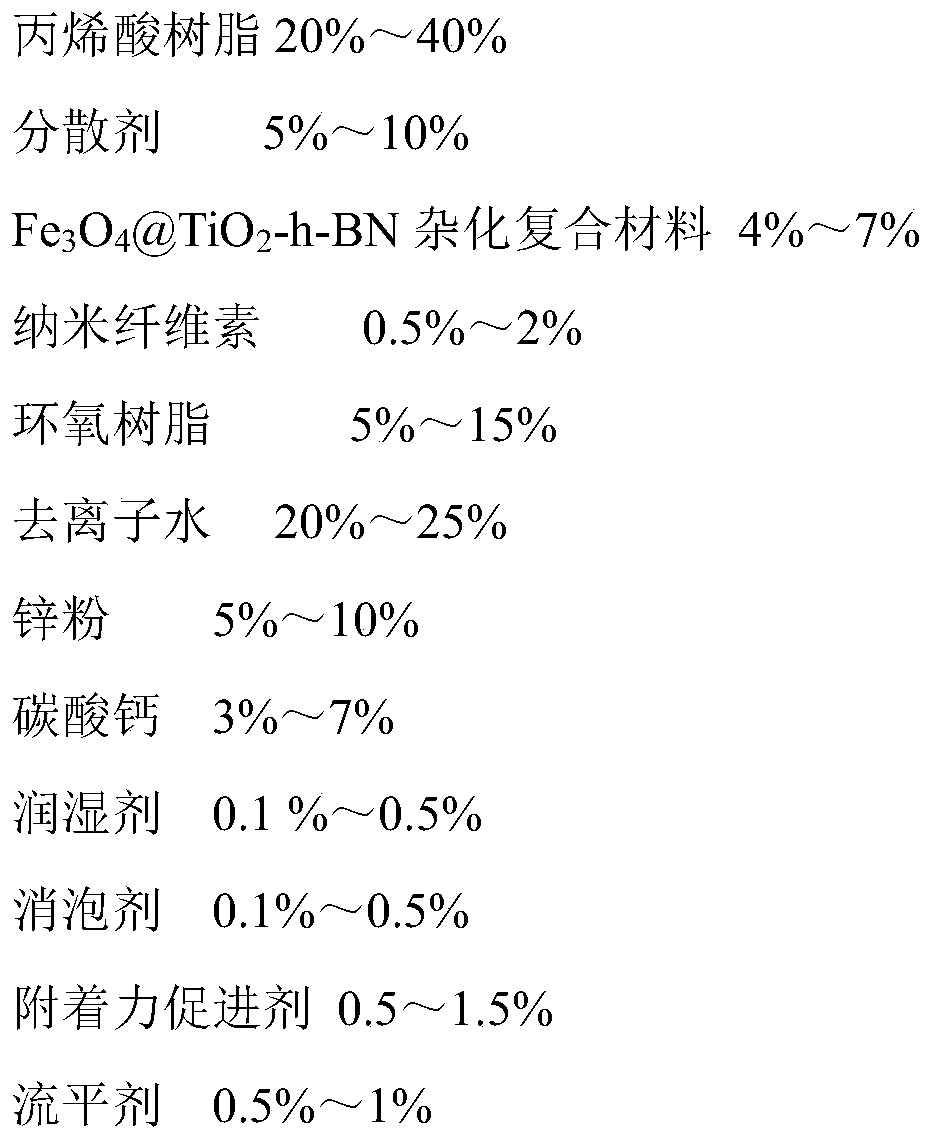

The invention discloses a nanometer composite ocean anticorrosion coating and a preparation method thereof, belonging to the field ofcorrosion prevention of coatings. The coating contains the following components in percentage by weight: a component A: 20%-40% of acrylic resin, 5%-10% of a hydroxyl epoxy phosphate dispersing agent, 4%-7% of a Fe3O4@TiO2-h-BN hybridized composite material, 0.5%-2%of nano-crystalline cellulose, 5%-15% of epoxy resin, 1.2%-3.5% of other aids, 20%-25% of deionized water, 5%-10% of zinc powder and 3%-7% of calcium carbonate; and a component B: a curing agent, namely 15%-25% of a water-based isocyanate curing agent. The coating prepared by virtue of the preparation method has good wear resistance, fouling resistance and corrosion resistance, is mainly applied to the fouling prevention and corrosion prevention of petroleum steel-frame structure platforms in an ocean atmospheric region environment and is also suitable for the fields of fouling prevention andcorrosion prevention of ships and underwater pipelines.

Owner:CHANGZHOU UNIV

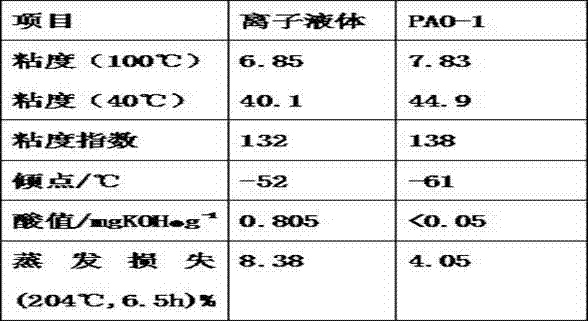

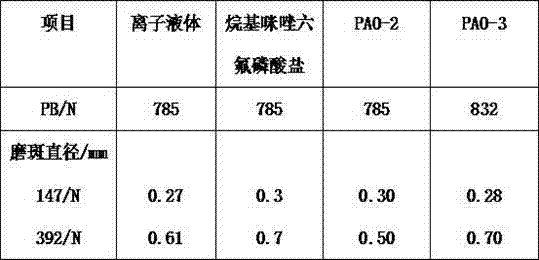

Cis-12 hydroxy octadecenoic acid-3-methyl-imidazole hexafluorophosphate ionic liquid and four-stroke engine lubricating oil composition containing same

ActiveCN102775352AReduce volatilityHigh viscosityOrganic chemistryAdditivesFour-stroke engineOil production

The invention discloses cis-12 hydroxy octadecenoic acid-3-methyl-imidazole hexafluorophosphate ionic liquid and a four-stroke engine lubricating oil composition containing the same, and belongs to the field of lubricating oil production. The lubricating oil composition is mainly mixed by the following raw materials according to the weight ratio: lubricating oil base oil, cis-12 hydroxy octadecenoic acid-3-methyl-imidazole hexafluorophosphate, a viscosity index improver, a dispersing agent, a clearing agent, an oxidation and corrosion inhibitor, a base number reserving agent and an antifoaming agent. Compared with the prior art, the cis-12 hydroxy octadecenoic acid-3-methyl-imidazole hexafluorophosphate ionic liquid solves the problem that various annexing agents are easy to separate out when lubricating oil is placed for a long time, has the characteristics of good usability, environmental protection, energy saving and the like, and has a good application and dissemination valve, and abrasion of an engine can be obviously reduced.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

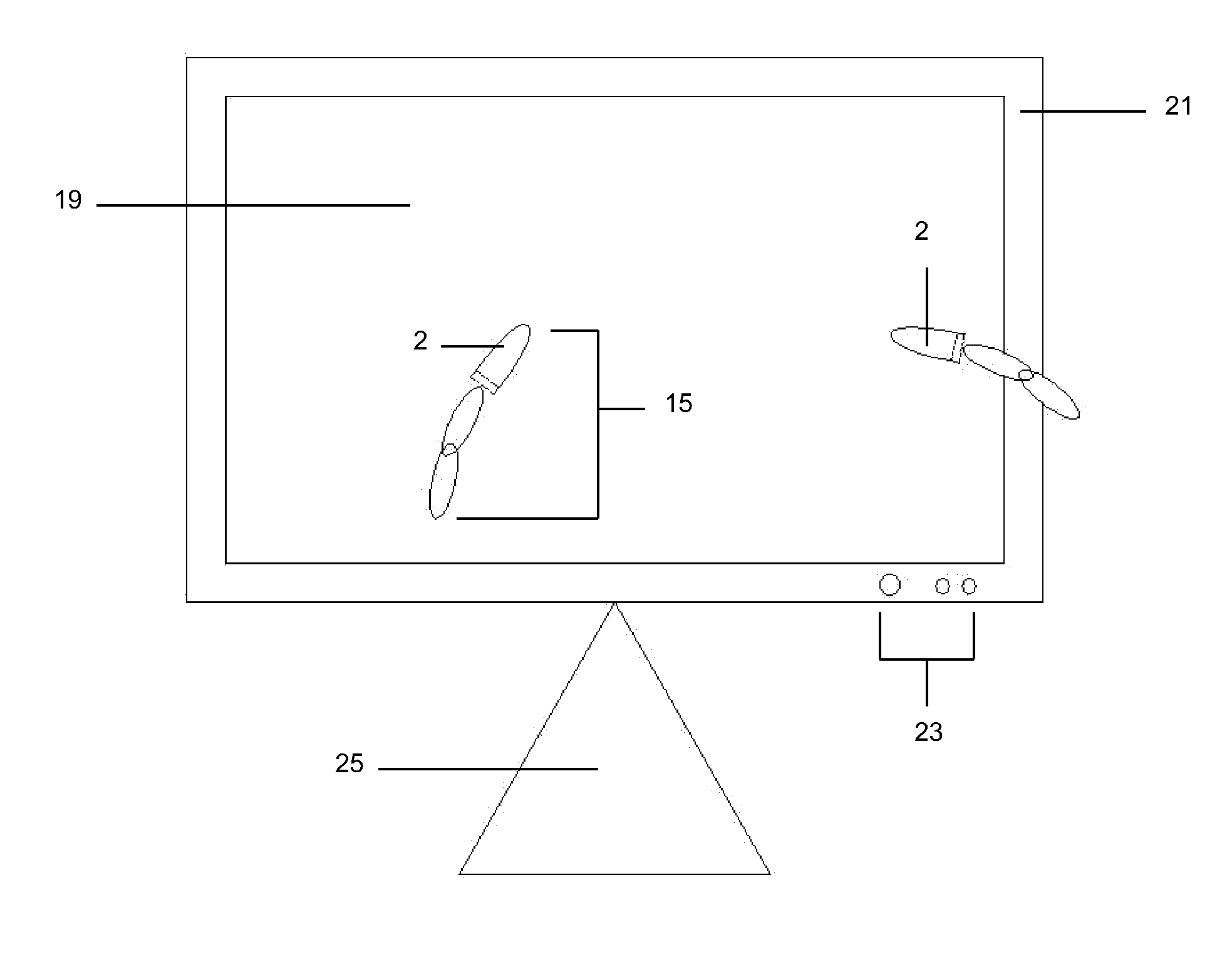

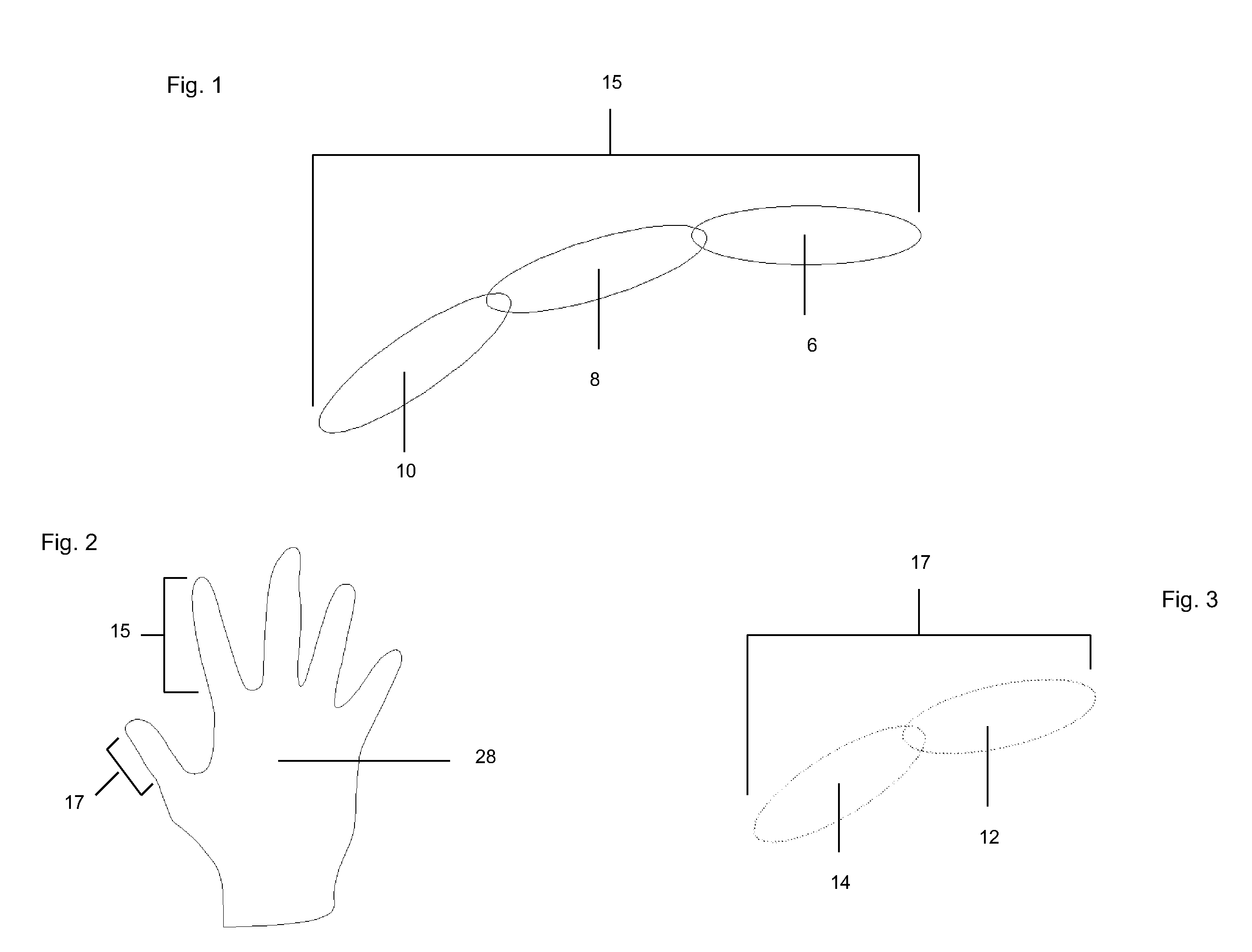

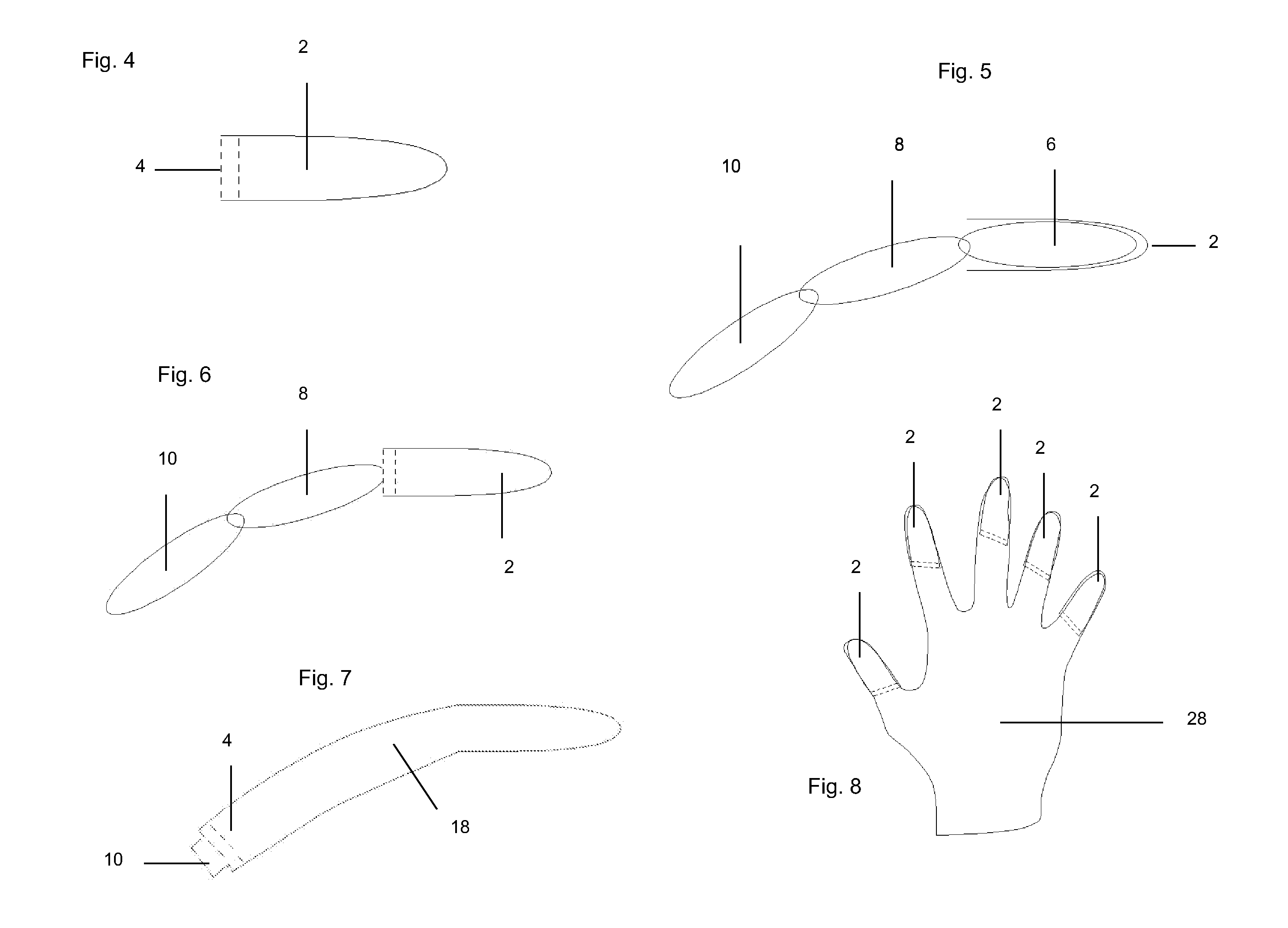

Touch Screen Friction Reducing Finger Caps

InactiveUS20120019464A1Low friction coefficientGlovesInput/output processes for data processingEngineeringLow friction

Owner:BRAIN BOX CONCEPTS

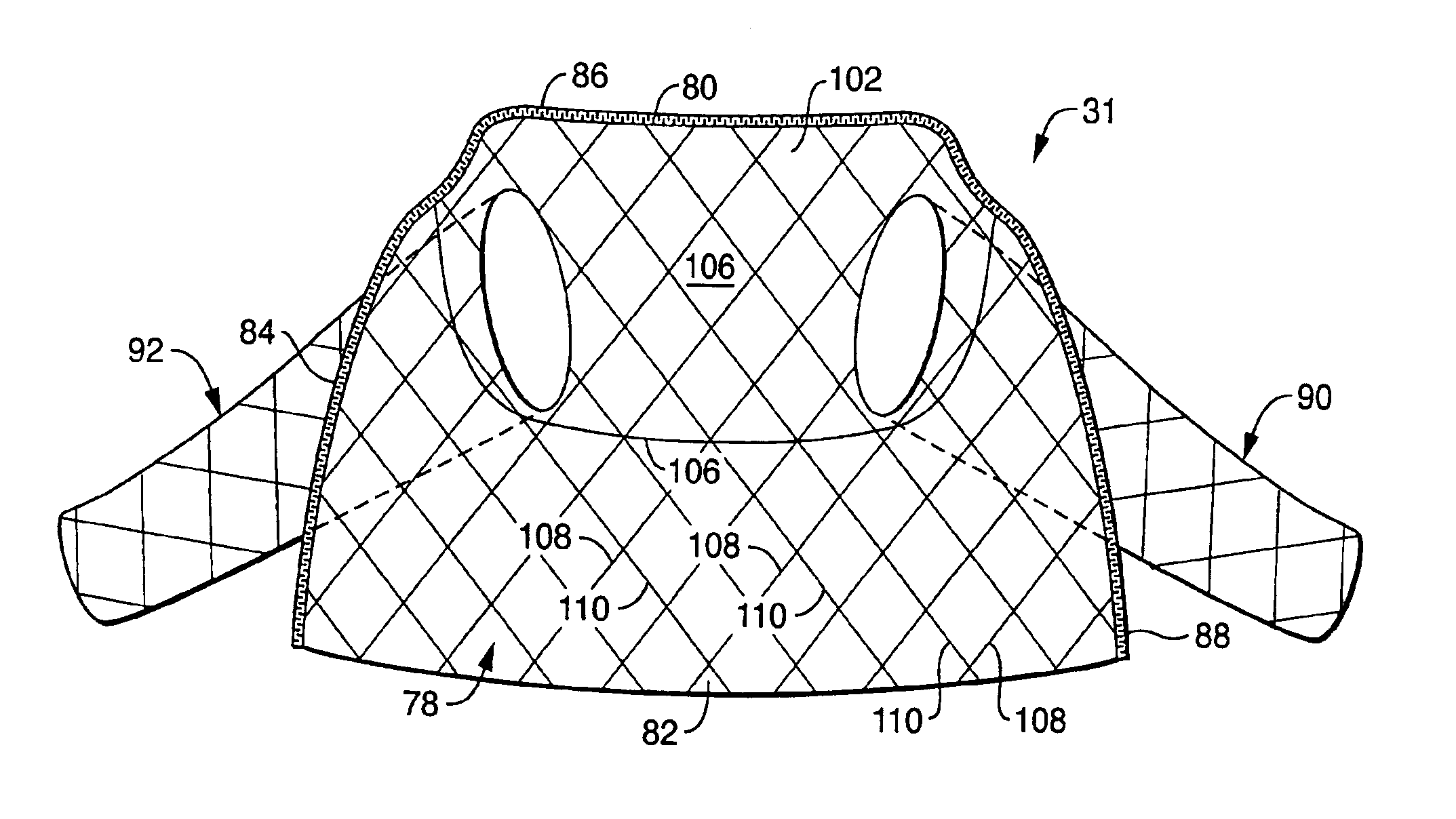

Crumple resistant lining and outerwear for use therewith

InactiveUS6898803B1Good dimensional stabilityReduce coefficient of frictionOvergarmentsProtective garmentEngineeringCoefficient of friction

A detachable lining for outerwear comprises a bodice, which includes an inner substantially full layer composed of a relatively rough fabric, an outer substantially full layer composed of a relatively smooth fabric, and an overlay partial layer composed of a relatively smooth fabric. The partial layer is superposed on the inner layer at an upper region of the bodice. The inner layer and outer layer are quilted together for enhancing dimensional stability and preventing bunching. The overlay partial layer has a relatively low coefficient of friction for encouraging sliding and preventing catching.

Owner:BLAUER MFG

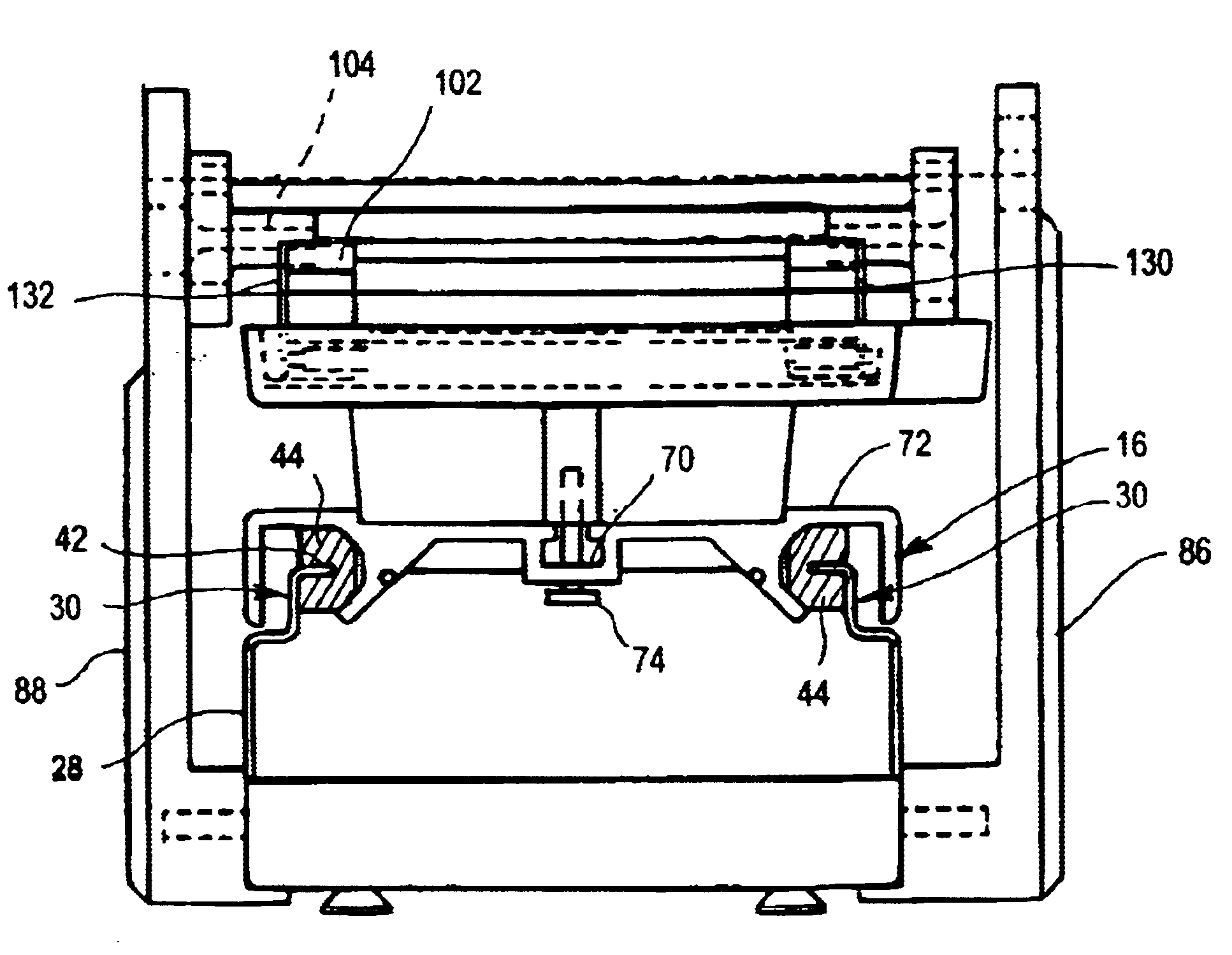

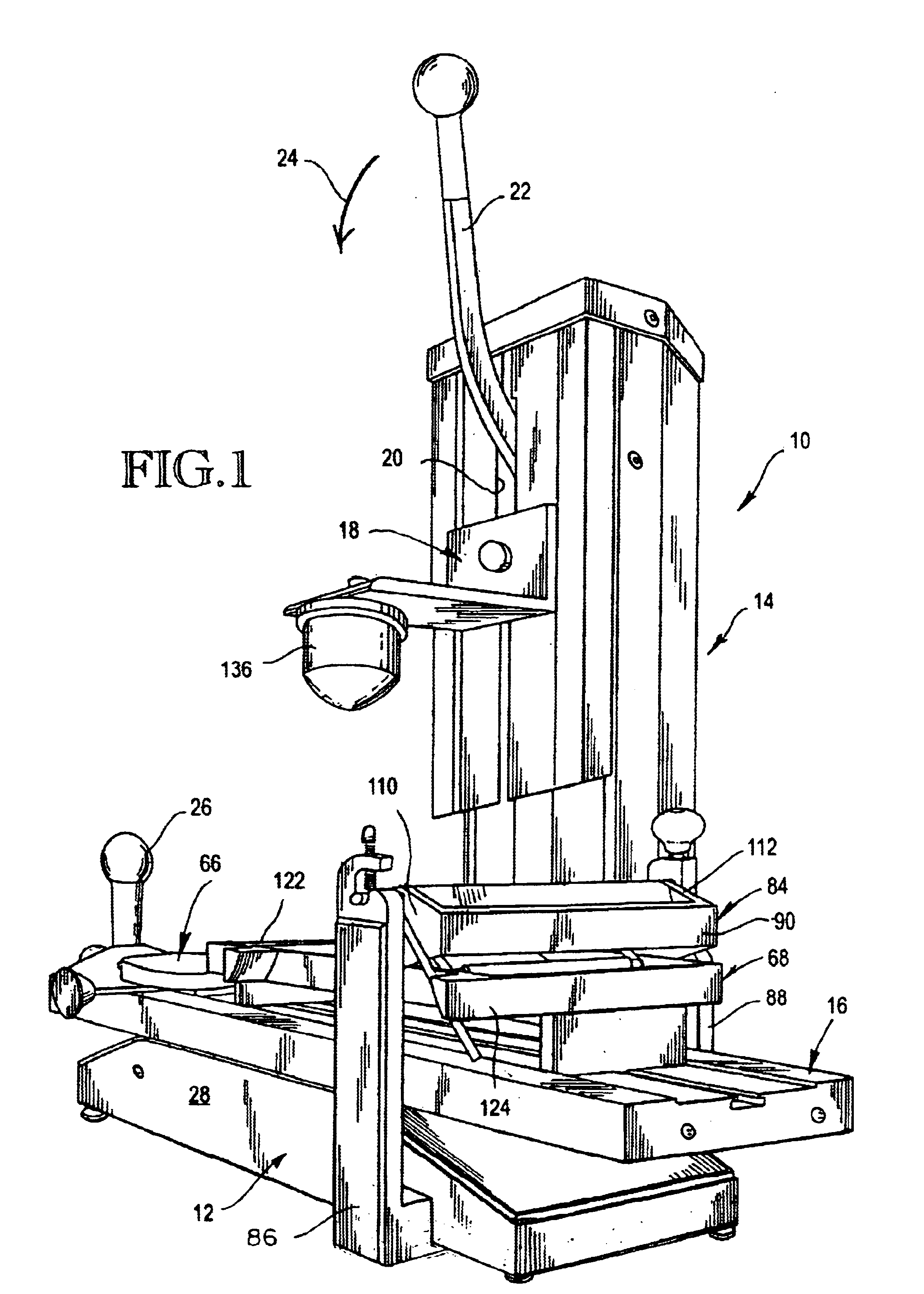

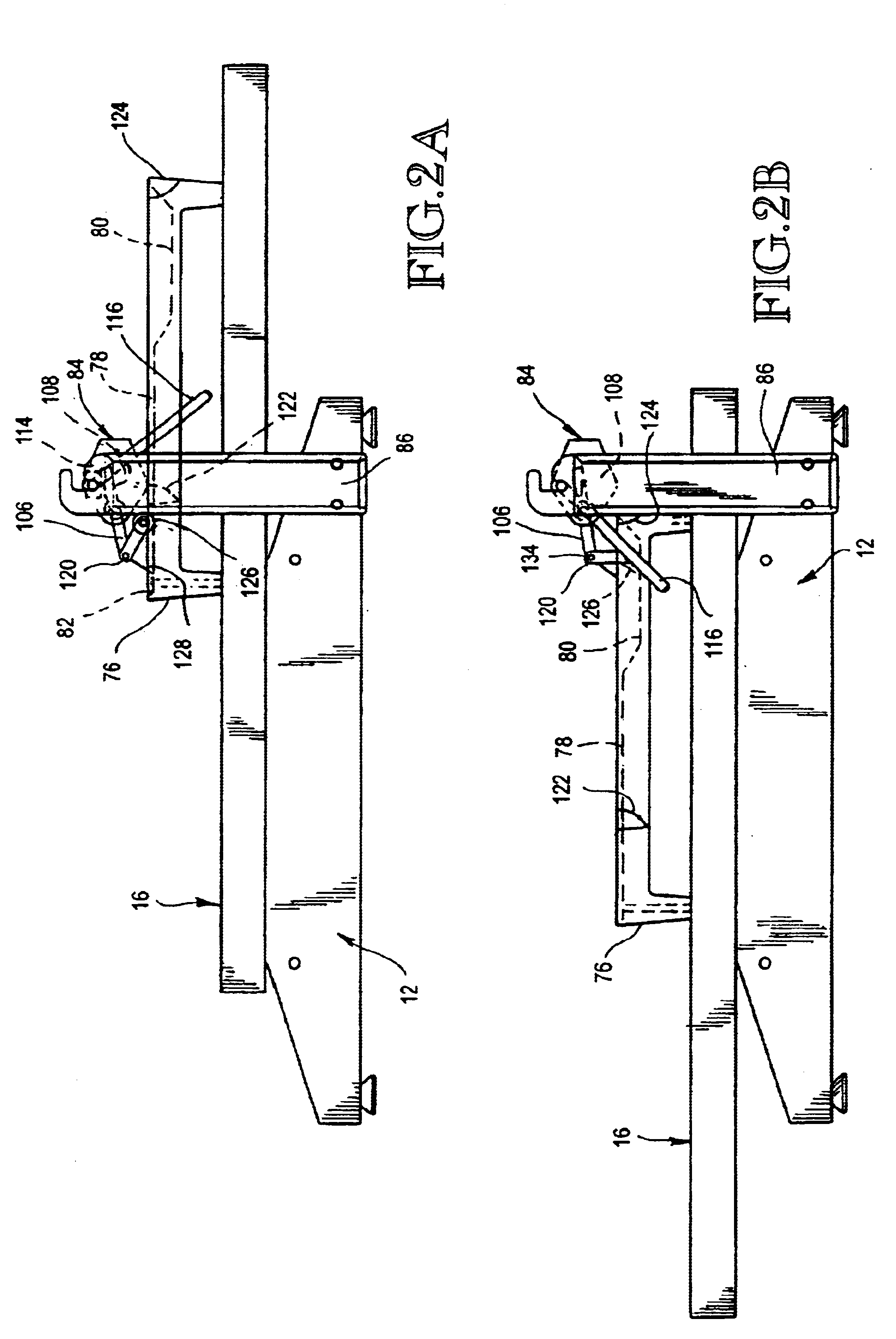

Pad printer cartridge and reciprocating table having bearing members

InactiveUS6857362B1Low friction coefficientImproved versionPlaten pressesRotary pressesEngineeringMechanical engineering

An improved table and ink wipe cartridge for a pad printer consists of a table mounted to a base by a pair of parallel, nylon bearings. The bearings enable the table to slide back and forth easily without requiring conventional ballbearings and guides. The cartridge automatically rolls and wipes ink on a print tray carried by the table.

Owner:PRINTA SYST

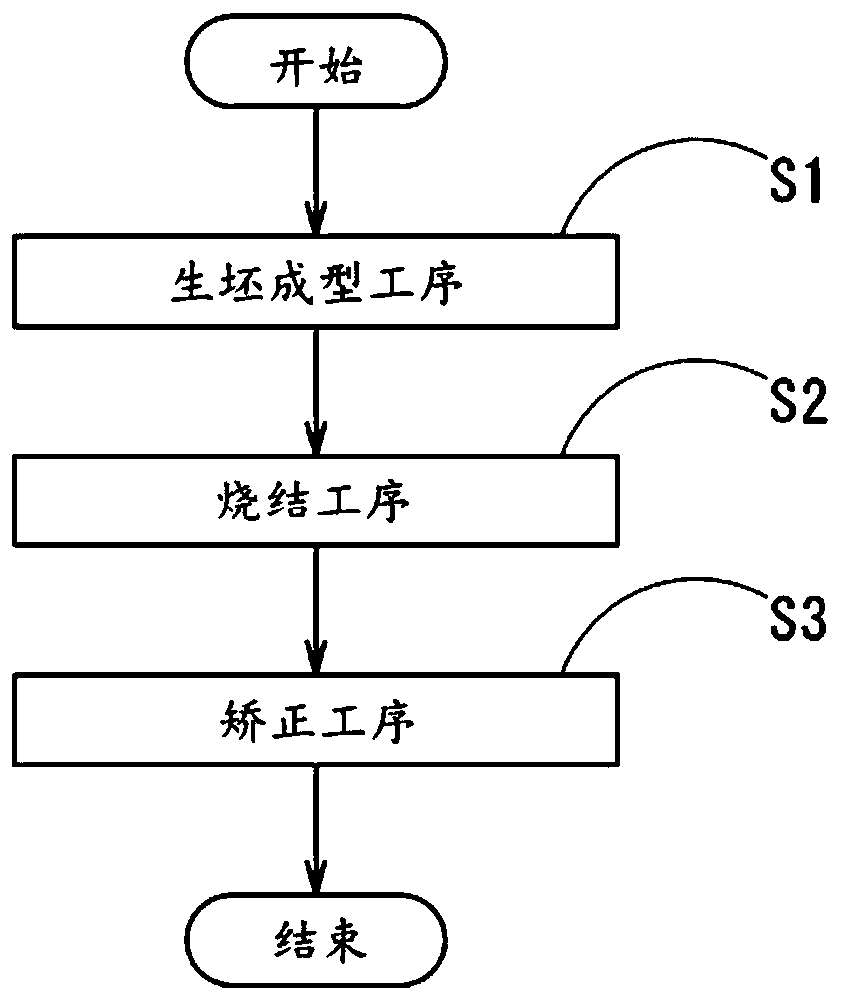

Method for preparing graphene composite material for pantograph

InactiveCN107755703ALow friction coefficientReduce wearMetal-working apparatusCoatingsIonCvd graphene

The invention discloses a method for preparing a graphene composite material for a pantograph. The method comprises the steps as follows: S1, graphene nano-platelets are placed into a furnace at 300-400 DEG C for heat treatment for 40-60 min, and the activity of the graphene nano-platelets is improved; S2, the graphene nano-platelets treated in S1 are placed in a CuSO4 plating solution for copperplating, are taken out after 3-6 min, are washed with deionized water for 3-6 times and then are placed into a vacuum drying oven for drying; S3, the graphene nano-platelets treated in S2 are evenly mixed with graphene powder, copper powder and an additive, then the mixture is placed into a mold to be subjected to cold-press molding under the pressure of 150-270 MPa, and a composite block is obtained; the graphene nano-platelets, the graphene powder, the copper powder and the additive are evenly mixed in parts by weight as follows: 10-30 parts of the graphene nano-platelets, 10-20 parts of thegraphene powder, 64-78 parts of the copper powder and 5 parts of the additive; S4, the composite block formed through cold-press molding in S3 is placed into a sintering furnace for sintering, a shielding gas is introduced to prevent the composite block from being oxidized, the sintering temperature ranges from 800 DEG C to 900 DEG C, and the duration ranges from 3 h to 5 h; S5, the composite block treated in S4 is machined into the pantograph adopting the structure designed in advance.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

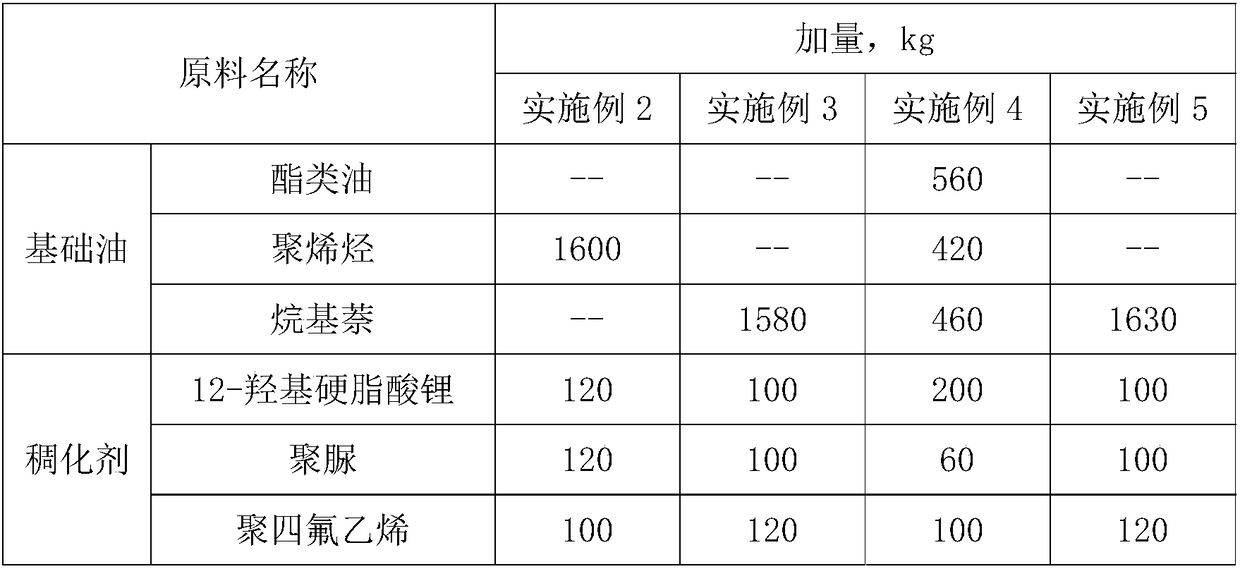

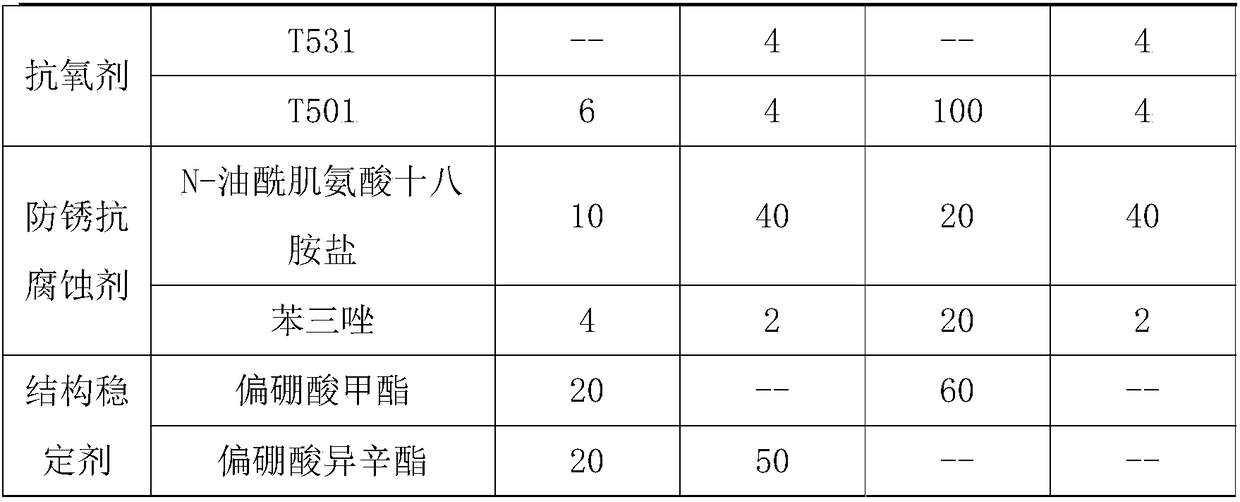

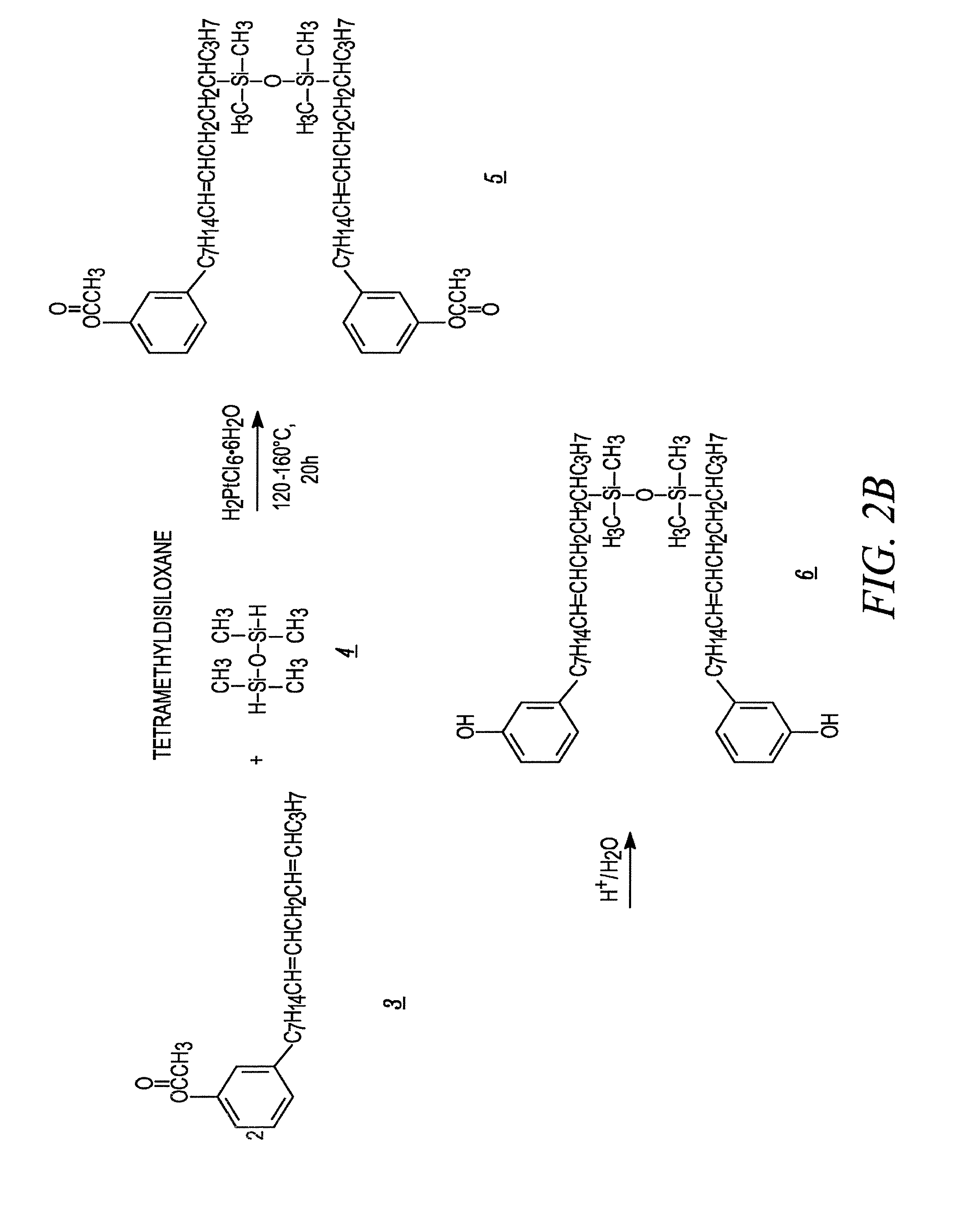

Long-life friction-reducing energy-saving lubricating grease for pure electric vehicle motor bearing and preparation method thereof

The invention relates to long-life friction-reducing energy-saving lubricating grease for a pure electric vehicle motor bearing and a preparation method thereof. The long-life friction-reducing energy-saving lubricating grease comprises, by mass, 70-93% of base oil, 5-20% of a ternary composite thickener, 0.1-5% of an antioxidant agent, 0.1-5% of a rust and corrosion inhibitor and 1-5% of a structural stabilizer. The long-life friction-reducing energy-saving lubricating grease has good low-temperature use performances, a long service life and a low friction factor and saves electric energy. Under the same reserve of electricity, the lubricating grease increases the travelled distance of the pure electric vehicle, prolongs the service life of the pure electric vehicle motor bearing, reducesthe use and maintenance costs of the pure electric vehicle, has good high and low temperature performances and colloidal stability, does not produce three wastes and is safe and environmentally friendly.

Owner:SHANDONG NORTH ZITE SPECIAL OIL

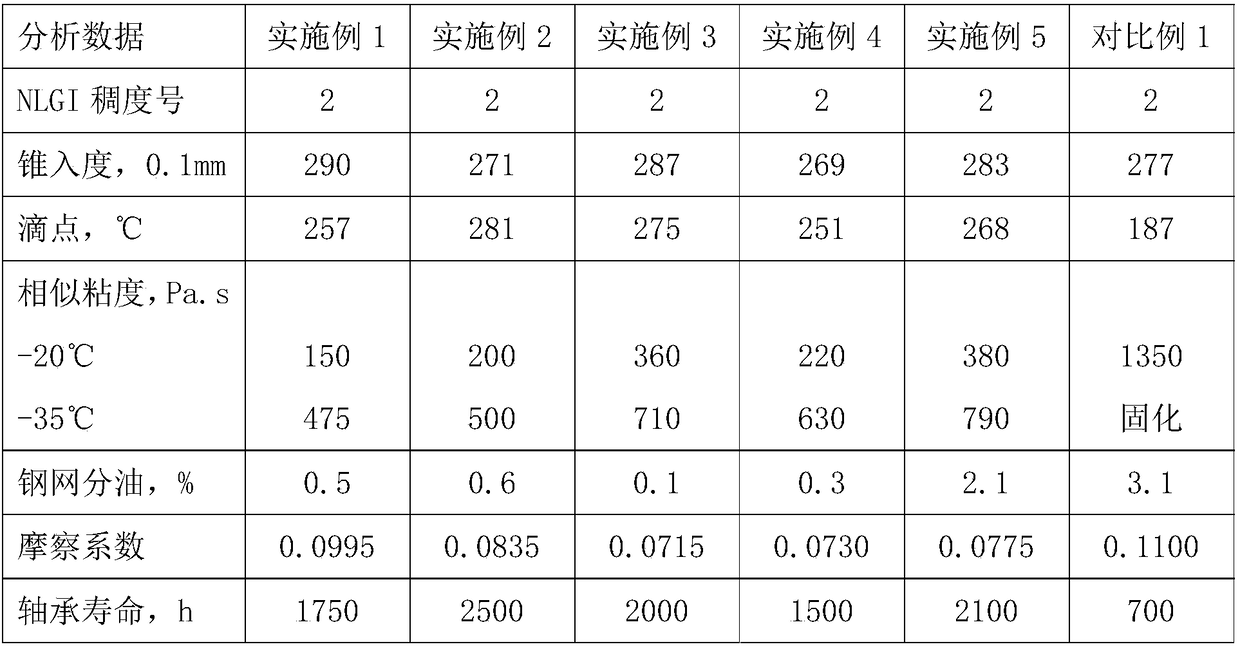

Cardanol based dimers and uses therefor

InactiveUS20080312399A1Reduce coefficient of frictionImprove adhesionSilicon organic compoundsCoatingsSilanesHydrosilylation

Cardanol based dimers are provided. The cardanol dimers are formed by hydrosilylation with silanes. Cardanol based dimers may be further reacted to form epoxy curing agents and epoxies which can be used as anti-fouling coatings on ship hulls and marine structures. The cardanol dimers may also be used to produce friction particles or phenolic resins. Methods of synthesizing the cardanol based dimers, the epoxy curing agents and the epoxies are also provided.

Owner:CARDOLITE CORP

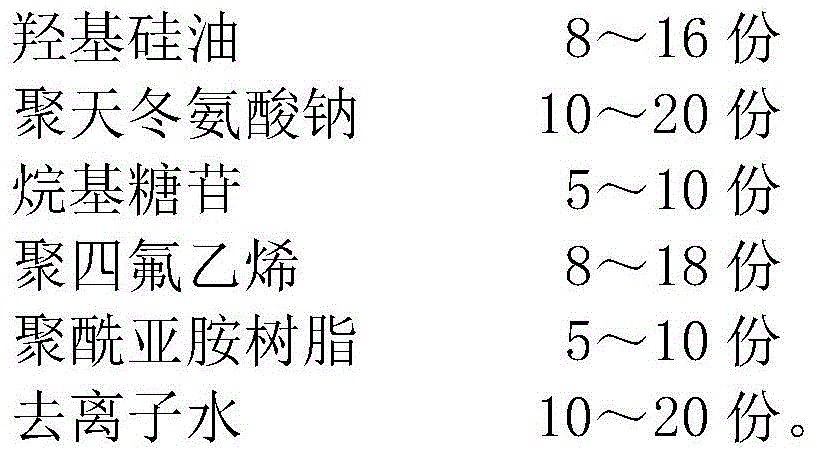

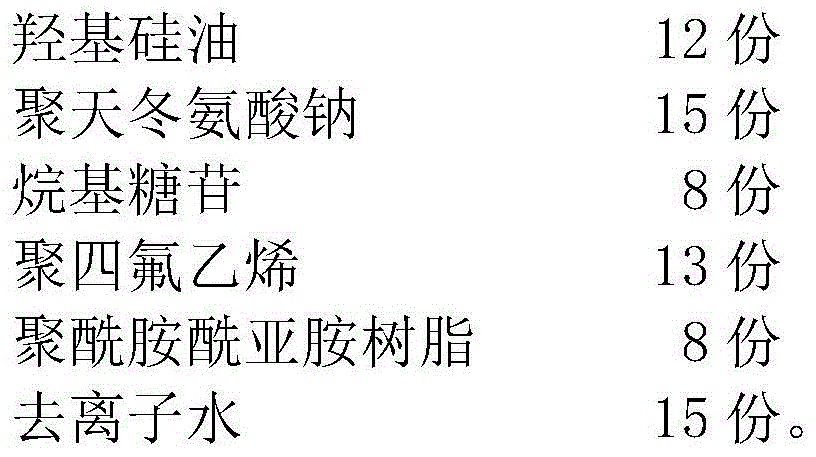

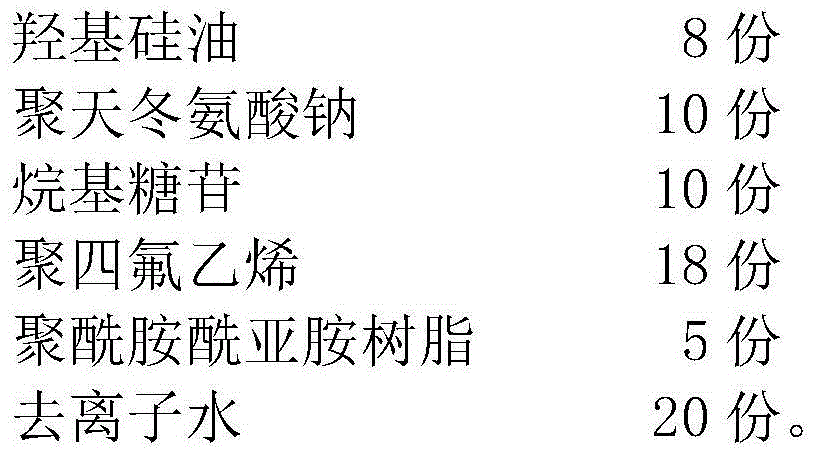

Metal surface treatment anti-sticking agent

The invention relates to the anti-sticking agent technical field, and particularly relates to a metal surface treatment anti-sticking agent prepared from the following raw materials in parts by weight: 8-16 parts of hydroxyl silicone oil, 10-20 parts of polyaspartic acid, 5-10 parts of alkyl glycoside, 8-18 parts of polytetrafluoroethylene, 5-10 parts of polyamideimide resin, and 10-20 parts of deionized water. The metal surface treatment anti-sticking agent is reasonable in composition, obvious in effect and stable in chemical properties, can effectively prevent adhesion between layers of a metal strip, and also has the function of corrosion resistance; the metal product surface quality is bright and clean; and the anti-sticking agent has good levelling property and thixotropy, meets processing at various temperatures, and can be used for a long time.

Owner:黄琳

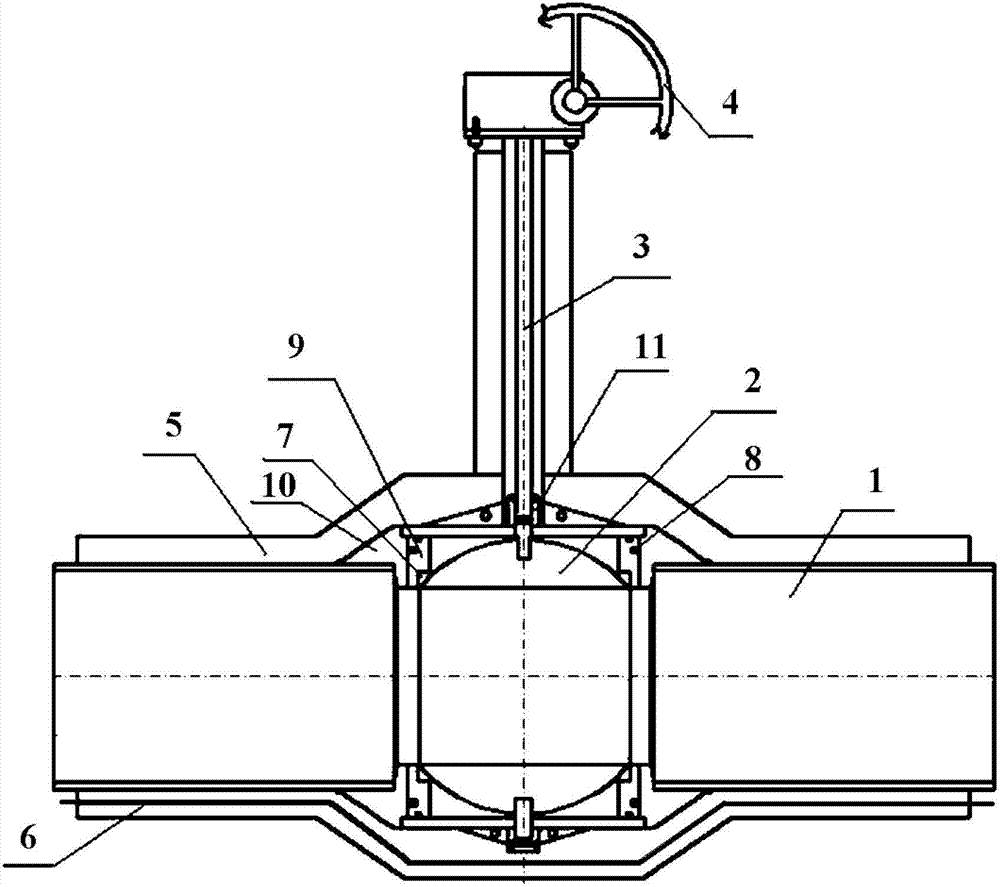

Direct buried type all-welded insulation ball valve

InactiveCN103032600AEmission reductionLow friction coefficientPlug valvesThermal insulationInsulation layerEngineering

The invention provides a direct buried type all-welded insulation ball valve. The direct buried type all-welded insulation ball valve comprises a valve body with a fluid passageway in internal part, a ball body placed at the center of the fluid passageway, a valve rod connected with the upper end of the ball body and a handle connected to the upper end of the valve rod. The direct buried type all-welded insulation ball valve is characterized in that the valve body sequentially comprises a seamless steel tube layer, an insulation layer and a plastic board layer from inner part to outer part, wherein the insulation layer is provided with at least one detection line to connect with a leakage alarming device; a valve base is arranged at the periphery of the ball body, and a valve base support and a spring supporting the valve support are arranged in the valve base; and the valve rod is an extension bar, and the distance of the valve rod extending the valve body is not less than the buried depth of the valve body. The direct buried type all-welded insulation ball valve has the advantages of being flexible to open and close, long in service life, and better in sealing effect under the action of pressure fluid; and the ball valve is provided with an extension valve rod, so that the opening and closing device is in earth surface, the valves can be conveniently opened and closed, the mounting period is shortened, the cost is reduced, and the maintenance is convenient.

Owner:精工伟业阀门集团有限公司

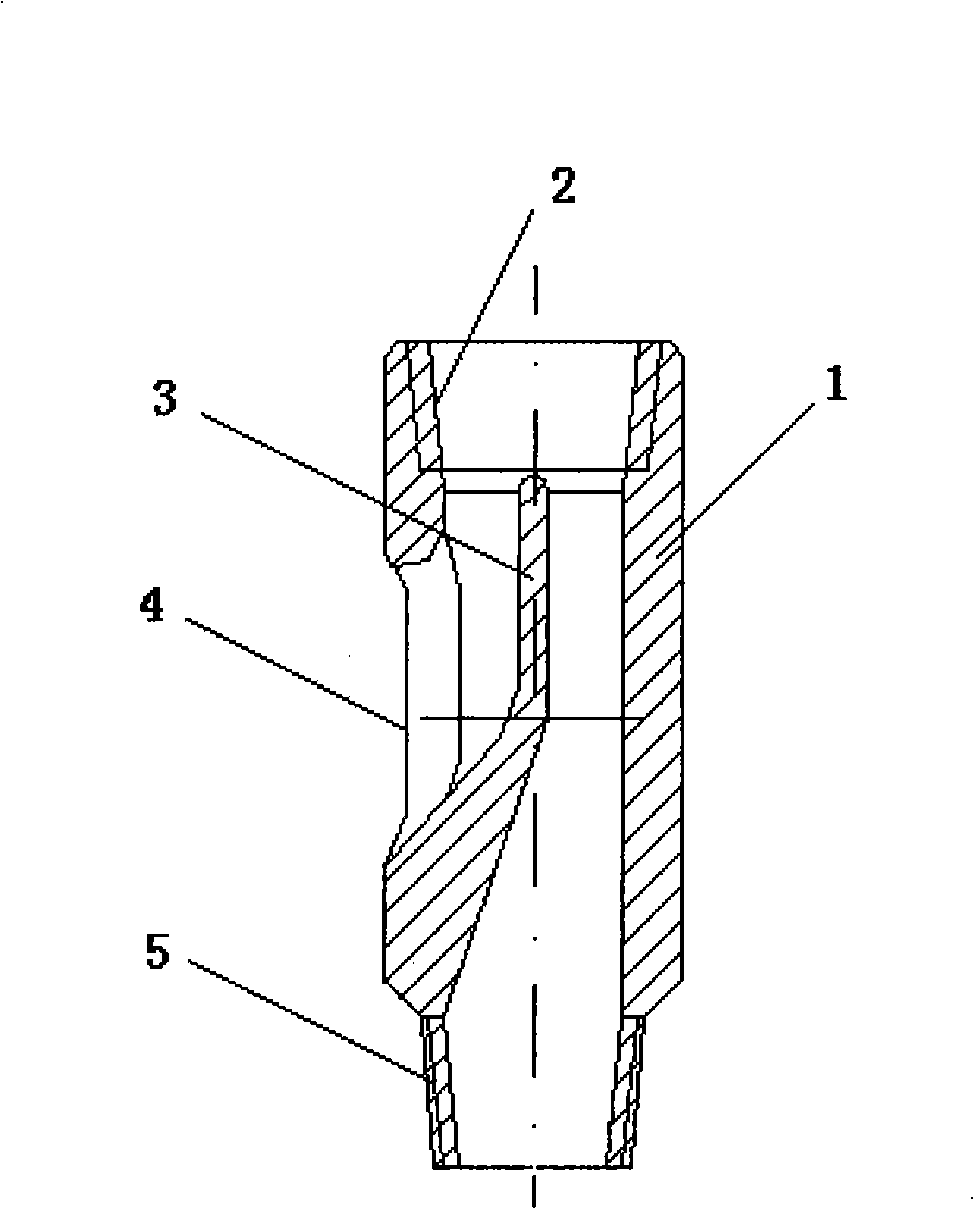

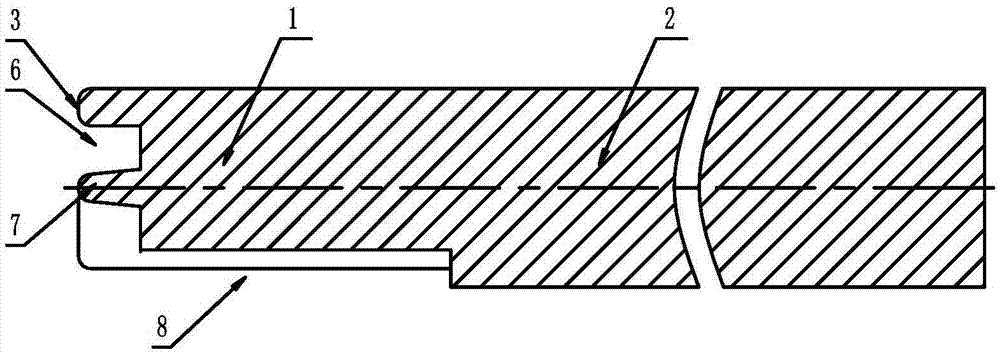

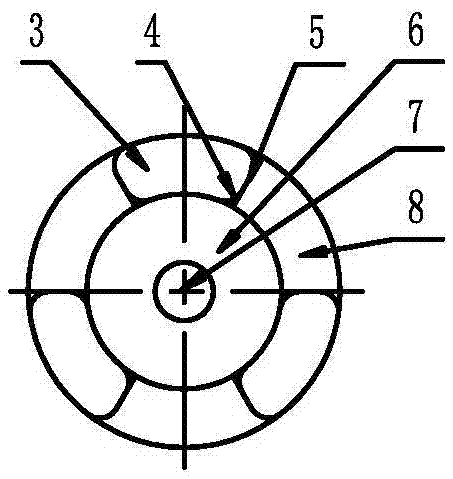

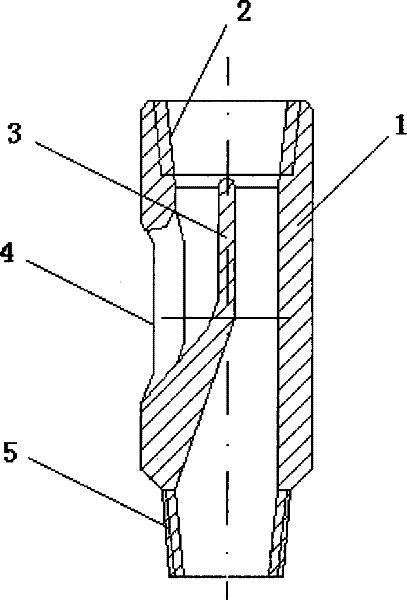

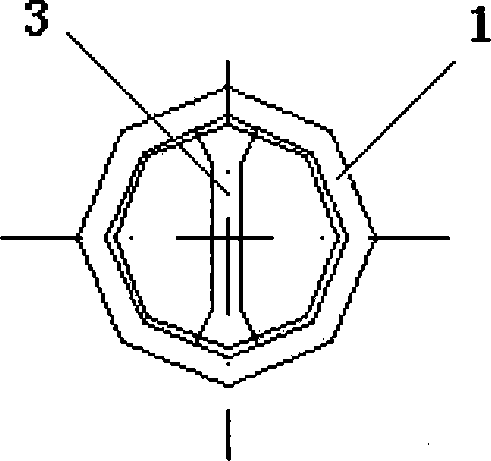

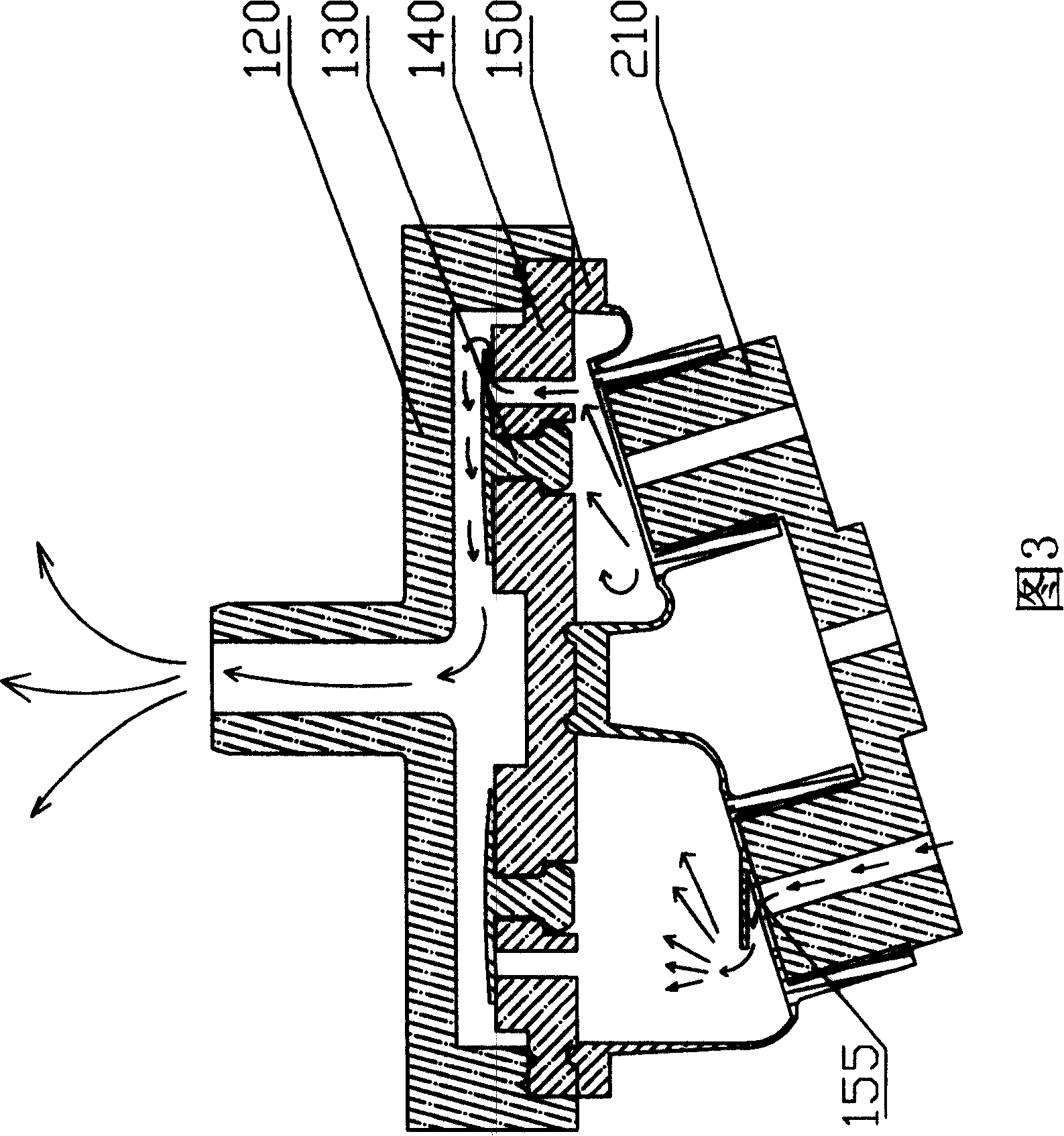

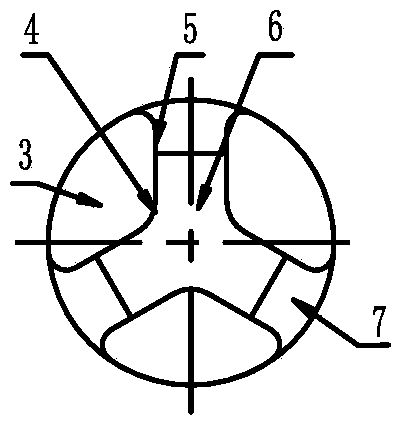

Shunting injection allocation method and shunting injection allocation machine

ActiveCN101270648ASmall local pressure drop lossLow friction coefficientFluid removalEngineeringPolymeric liquid

The invention relates to a split-flow injection allocation method and a split-flow distributor. The method of the invention is characterized in that every subsection of a polymer injection pipe is provided with at least one distributor, and a split-flow barrier is arranged in the distributor to divide polymeric liquid entering into the distributor into two parts, one part of which flows up to an upper oil reservoir and the other part of which continues to flow down to the lower oil reservoir. The polymer injection pipe is provided with the split-flow distributor and the surface of the split-flow distributor is sleekly connected with the outlet of the distributor. So liquid passing by the distributor has little partial drop pressure loss, low friction resistance and little shearing action, thus effectively reducing the loss of the viscosity of injected polymer. The split-flow injection allocation method and the split-flow distributor can be widely used for improving the recovery ratio of reservoir oil displacement in an offshore oilfield.

Owner:CHINA NAT OFFSHORE OIL CORP +1

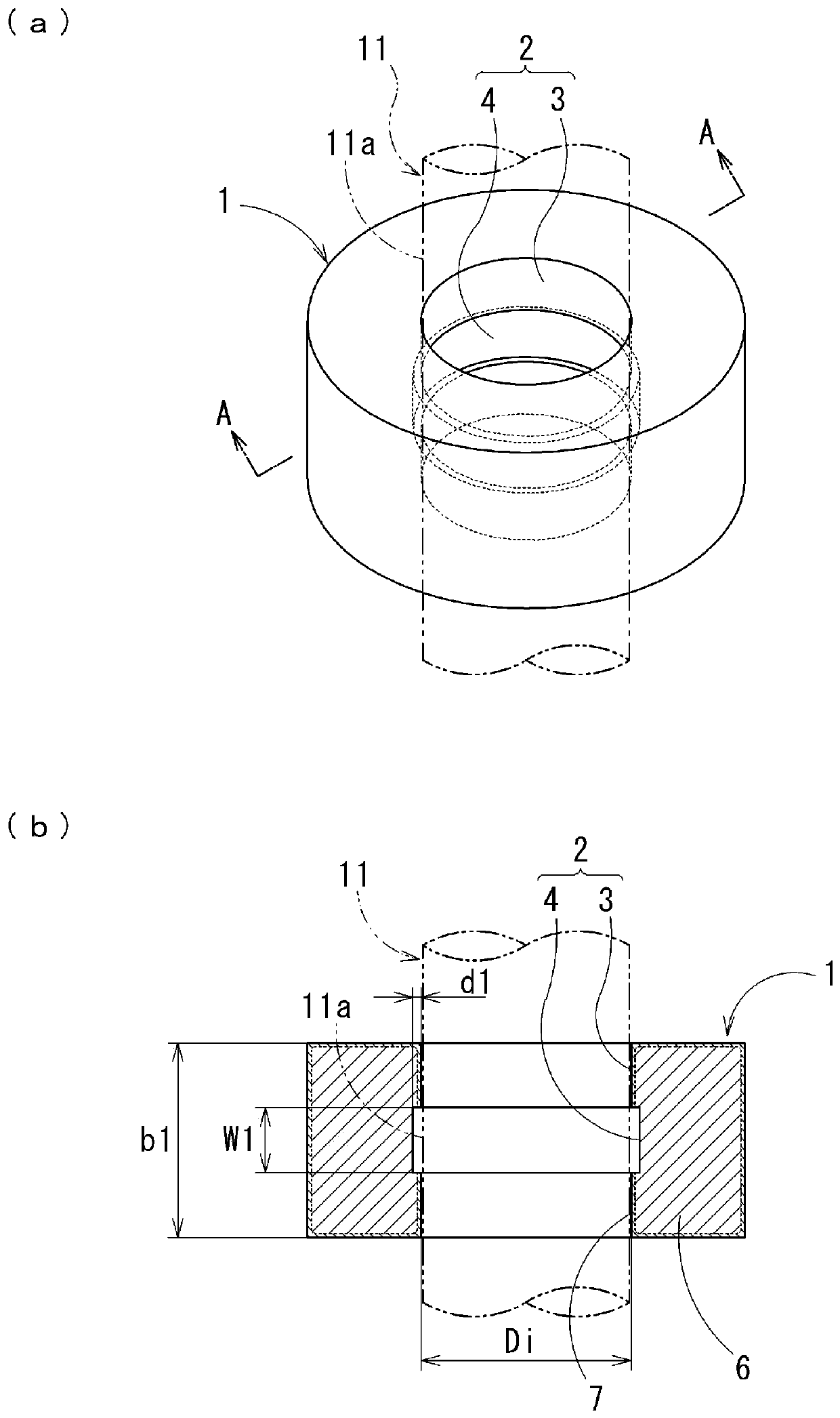

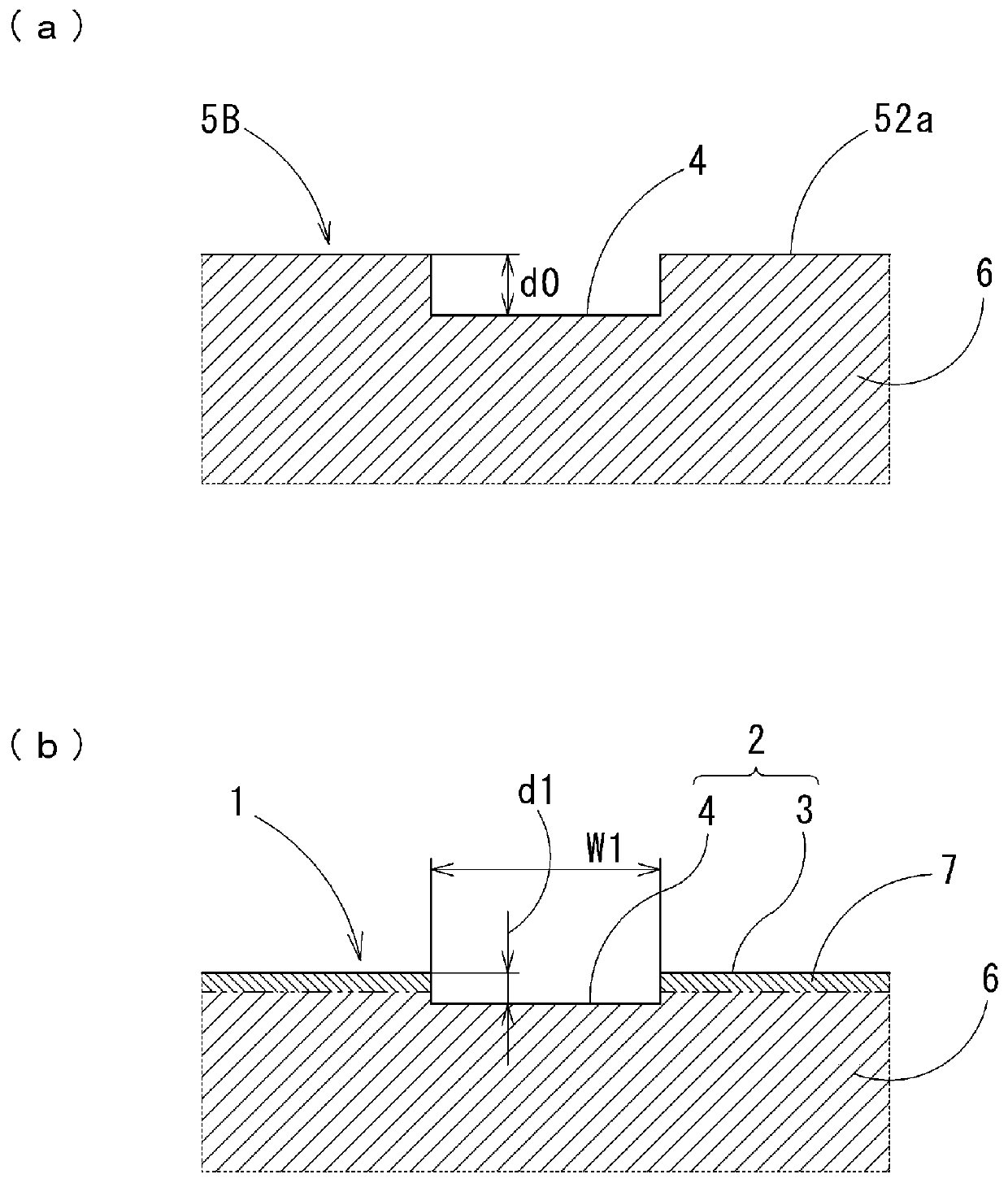

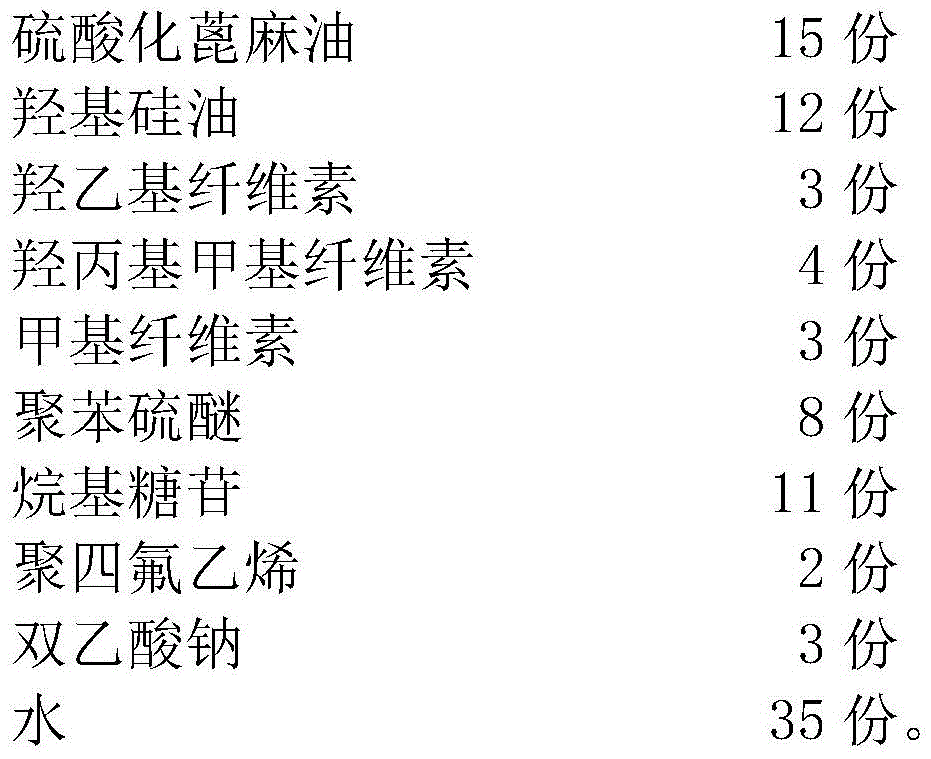

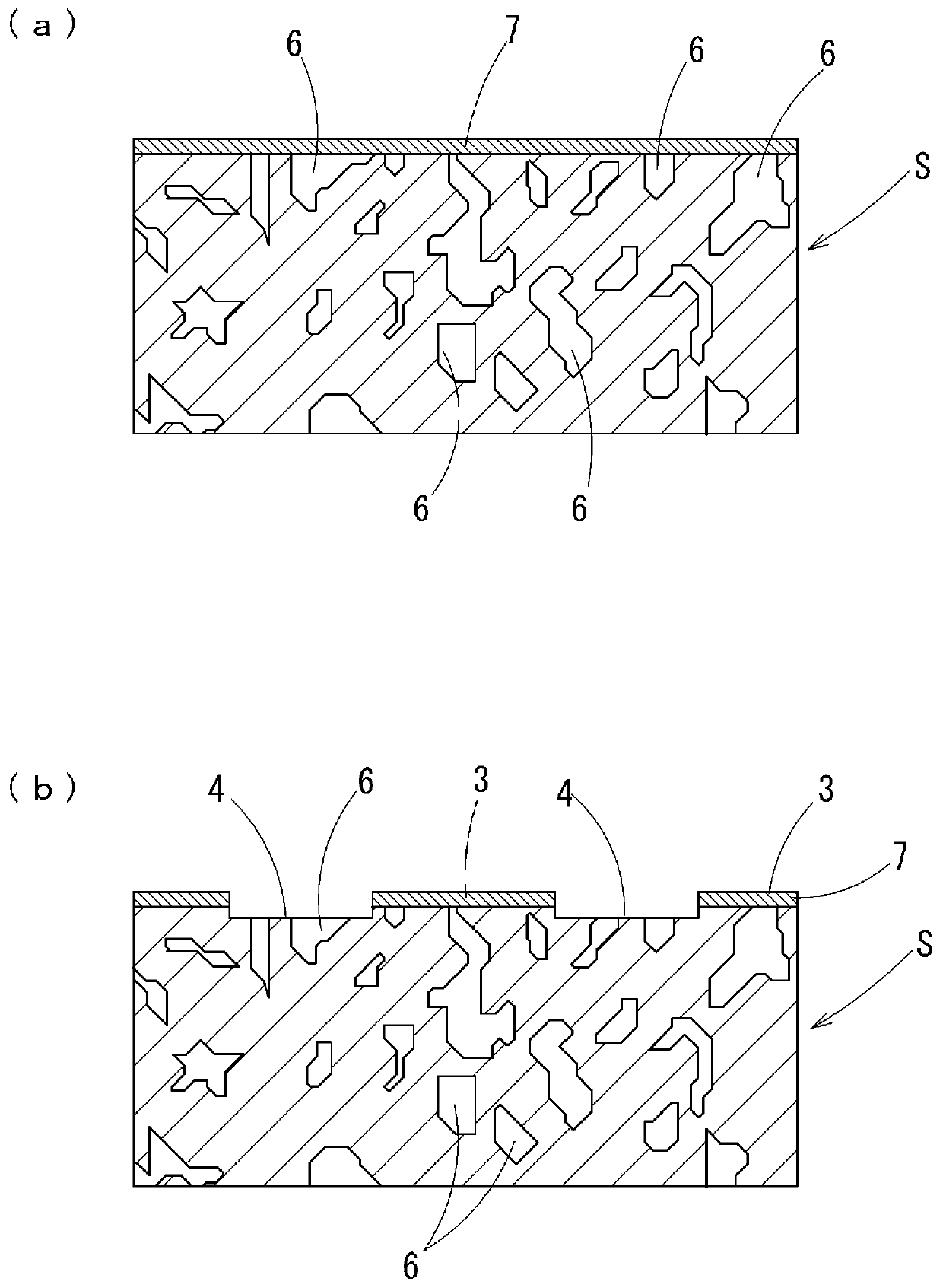

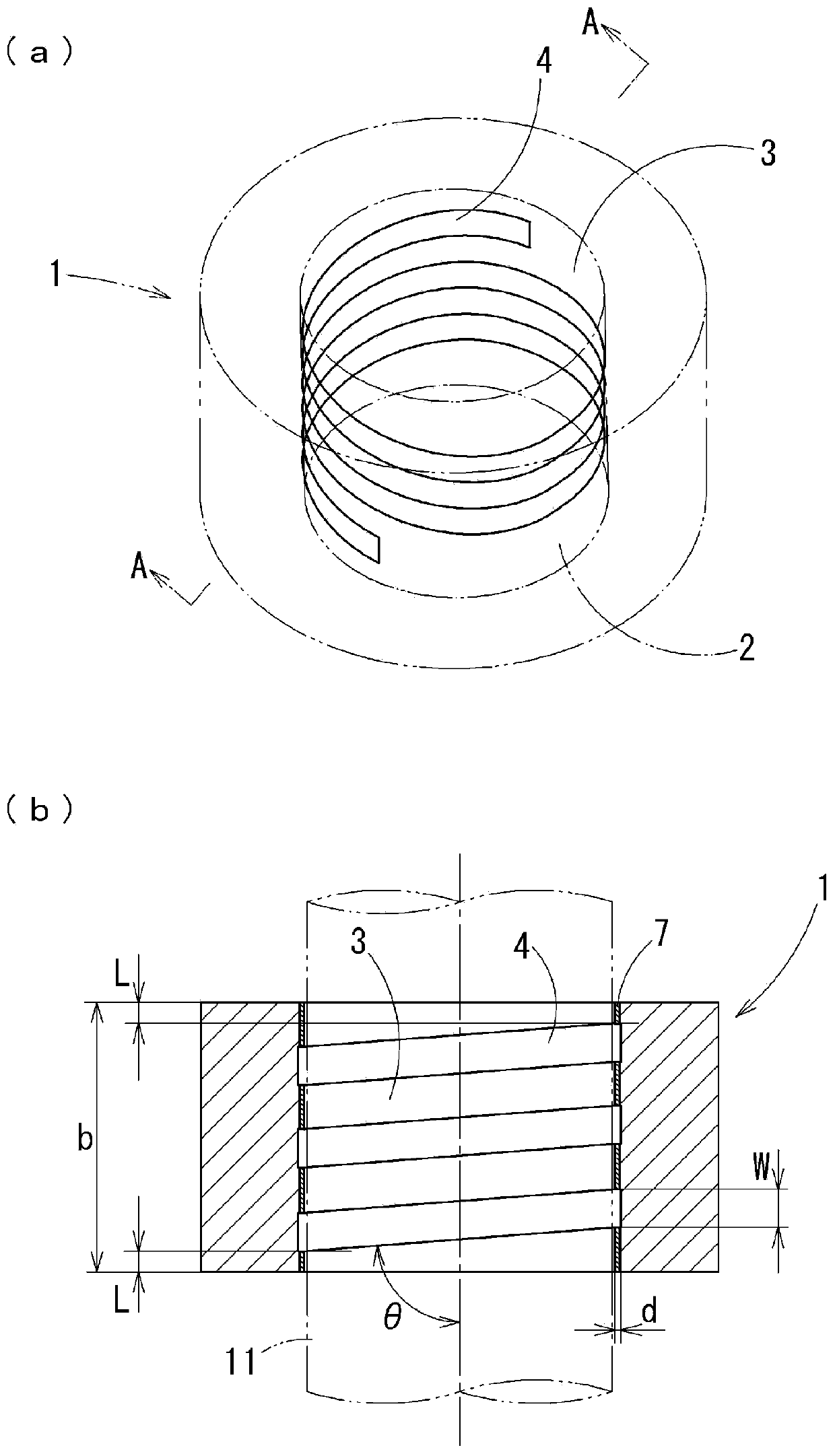

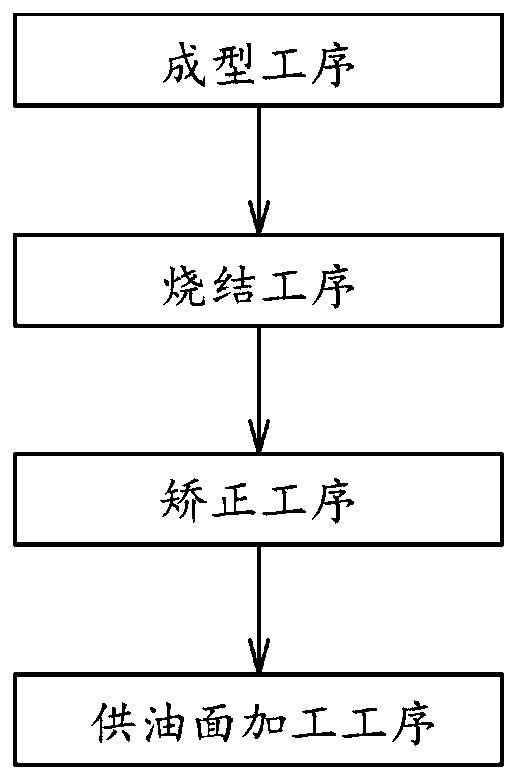

Oil-impregnated sintered bearing and method for manufacturing same

ActiveCN110168241APrevent movementGood sliding propertiesTransportation and packagingShaftsEngineeringLow friction

In order to provide an adequate amount of oil to a sliding surface and to prevent oil from moving from the sliding surface to the interior, thereby achieving lower friction and improving the bearing sliding characteristic, in this oil-impregnated sintered bearing (1) a sliding surface (3) supporting the outer circumferential surface of a shaft (11) and an oil supply surface (4) having a larger diameter than the sliding surface (3) are formed on the inner circumferential surface of a bearing hole (2) in which the shaft (11) is inserted, and are formed adjacent to each other in the axial direction of the bearing hole (2). The difference in height d1 between the sliding surface (3) and the oil supply surface (4) is 0.01% to 15% of the inner diameter of the sliding surface, the surface openingratio of the sliding surface (3) is 10% or less, the surface opening ratio of the oil supply surface (4) exceeds 10%, and the average equivalent-circle diameter of the openings of pores in the sliding surface is 20 mu m or less.

Owner:DIAMET CORP

High density, metal-based materials having low coefficients of friction and wear rates

InactiveUS6837915B2Reduce coefficient of frictionEasy to prepareTransportation and packagingMetal-working apparatusHigh densityHexagonal boron nitride

High theoretical density, metal-based materials containing graphite or hexagonal boron nitride have low coefficients of friction and wear rates are useful for bearings, bushings and other articles subject to bearing loads.

Owner:SCM METAL PRODUCTS INC

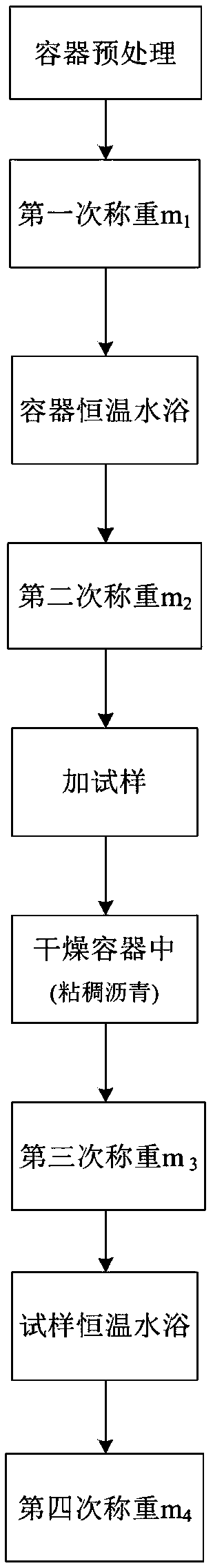

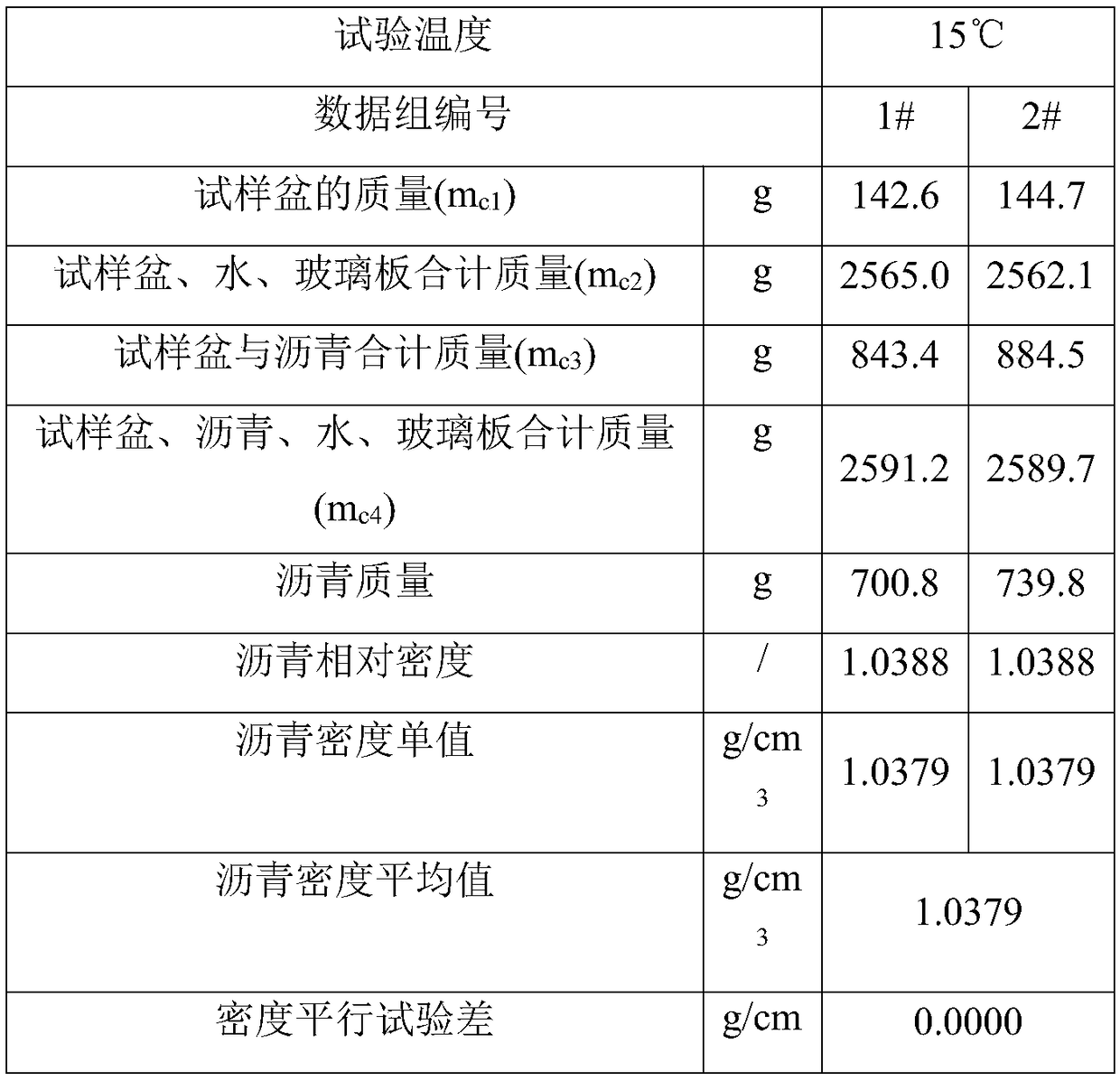

Asphalt density and relative density measuring method based on weighing method

ActiveCN109357965ALow friction coefficientImprove wear resistanceSpecific gravity measurementWide mouthEngineering

The invention provides an asphalt density and relative density measuring method based on a weighing method, comprising the following steps of: 1) performing a first weighing to obtain m1 after pretreating a wide-mouth container with a cover with an anti-sticking agent, injecting water at temperature t1 into the wide-mouth container after thermostatic water-bathing the wide-mouth container at the temperature t1, and performing a second weighing to obtain m2; 2) preparing the to-be-measured asphalt, so as to obtain the prepared asphalt, and performing a third weighing to obtain m3 after puttingthe prepared asphalt into the wide-mouth container; and 3) fully injecting water at temperature t1 into the wide-mouth container filled with the asphalt after thermostatic water-bathing the prepared asphalt and the wide-mouth container at the temperature t1, and performing a fourth weighing to obtain m4. According to the method, the complex specific gravity bottle method is replaced by a simple and practicable weighing method, the effect of air, sample number and the complex operations on measurement results is reduced, the method is simple in operation, and the accuracy of the measured valueis improved; and the test is simple in process, easy to operate, and the test result is small in error.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

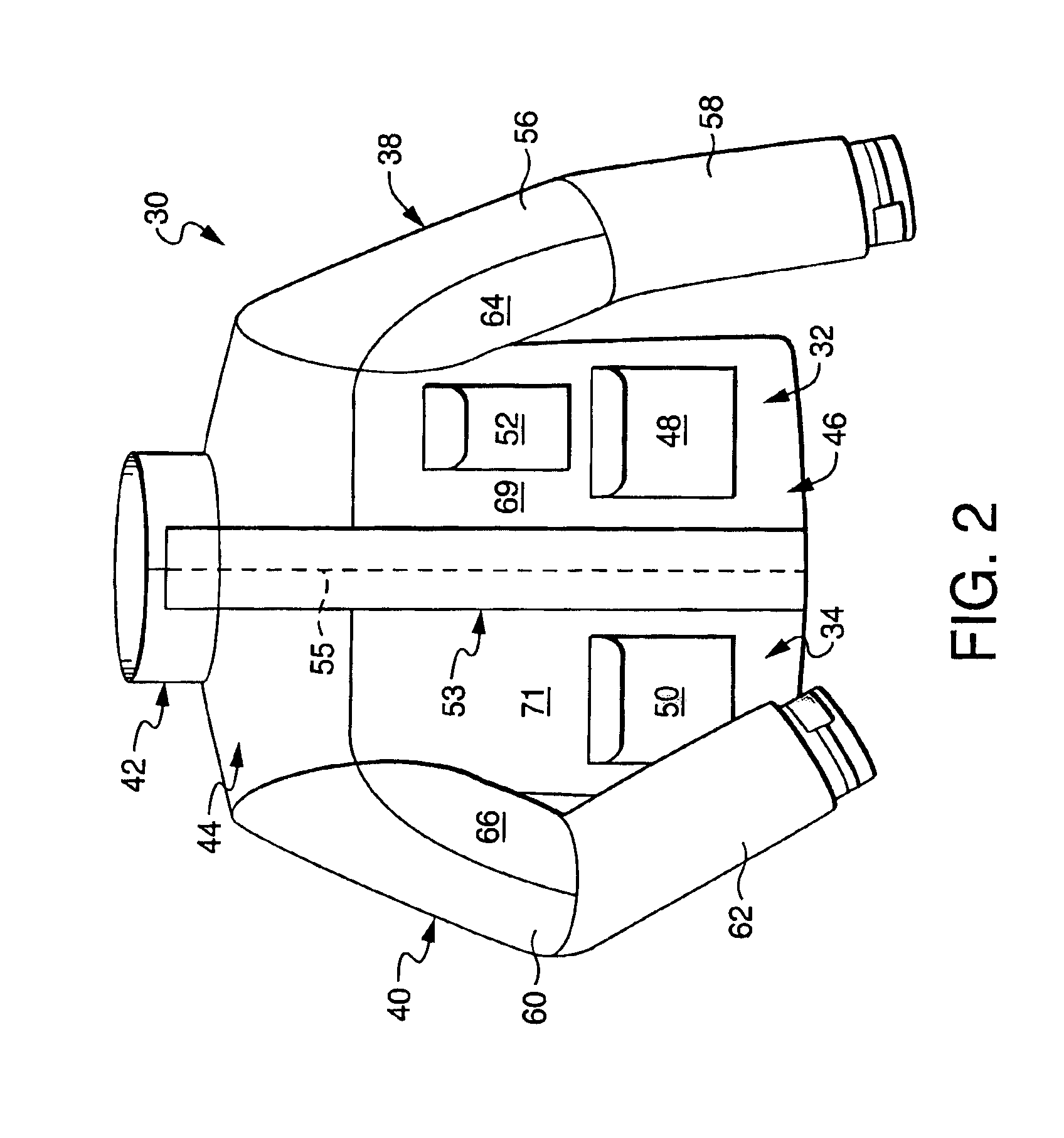

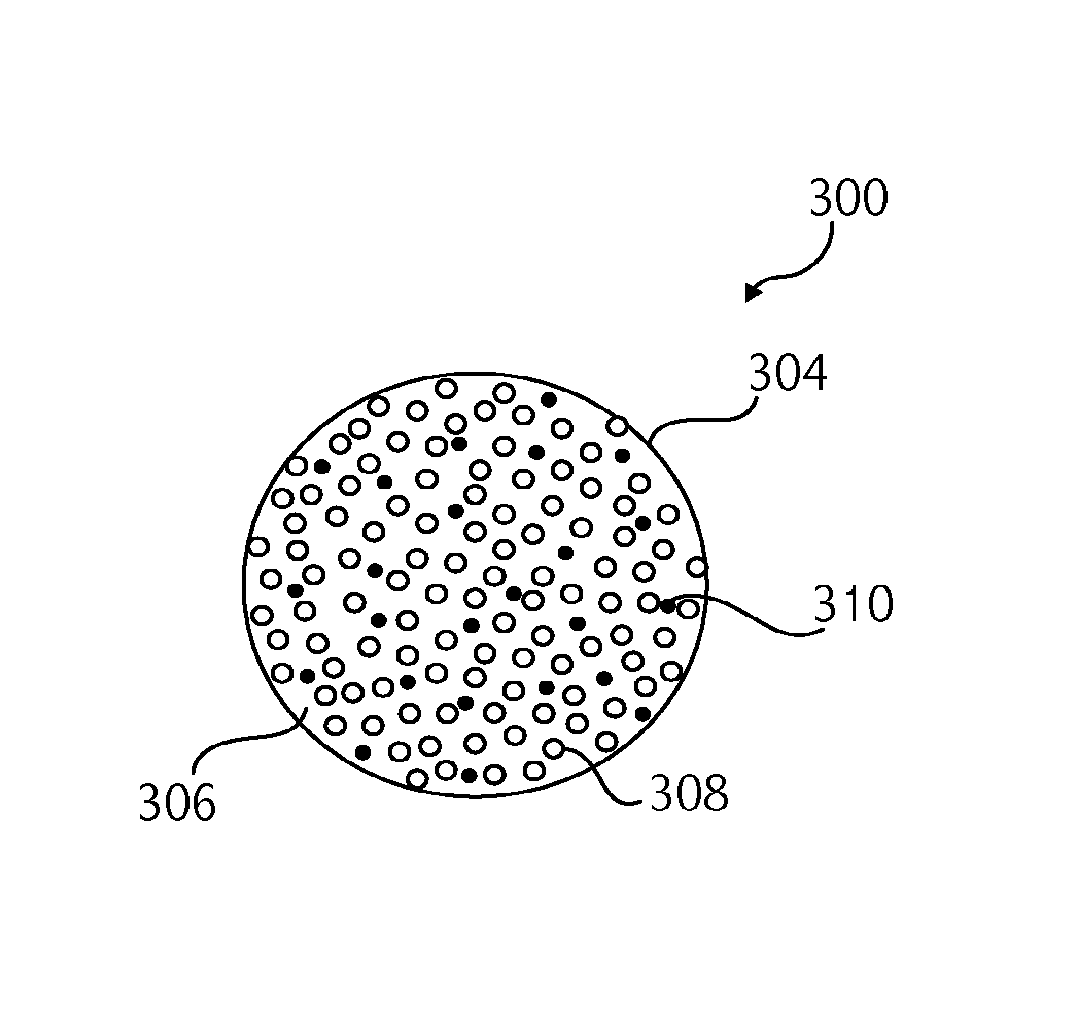

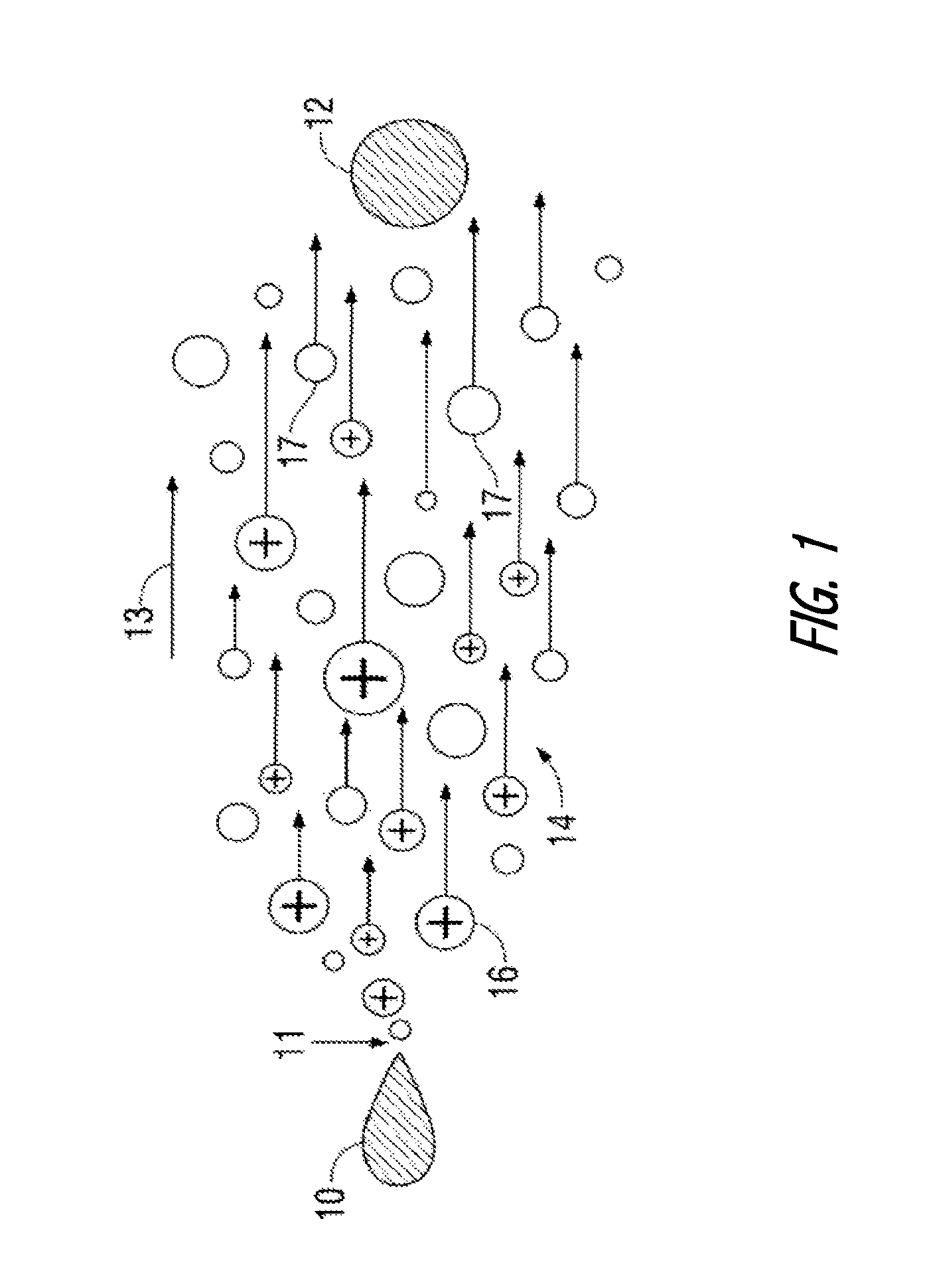

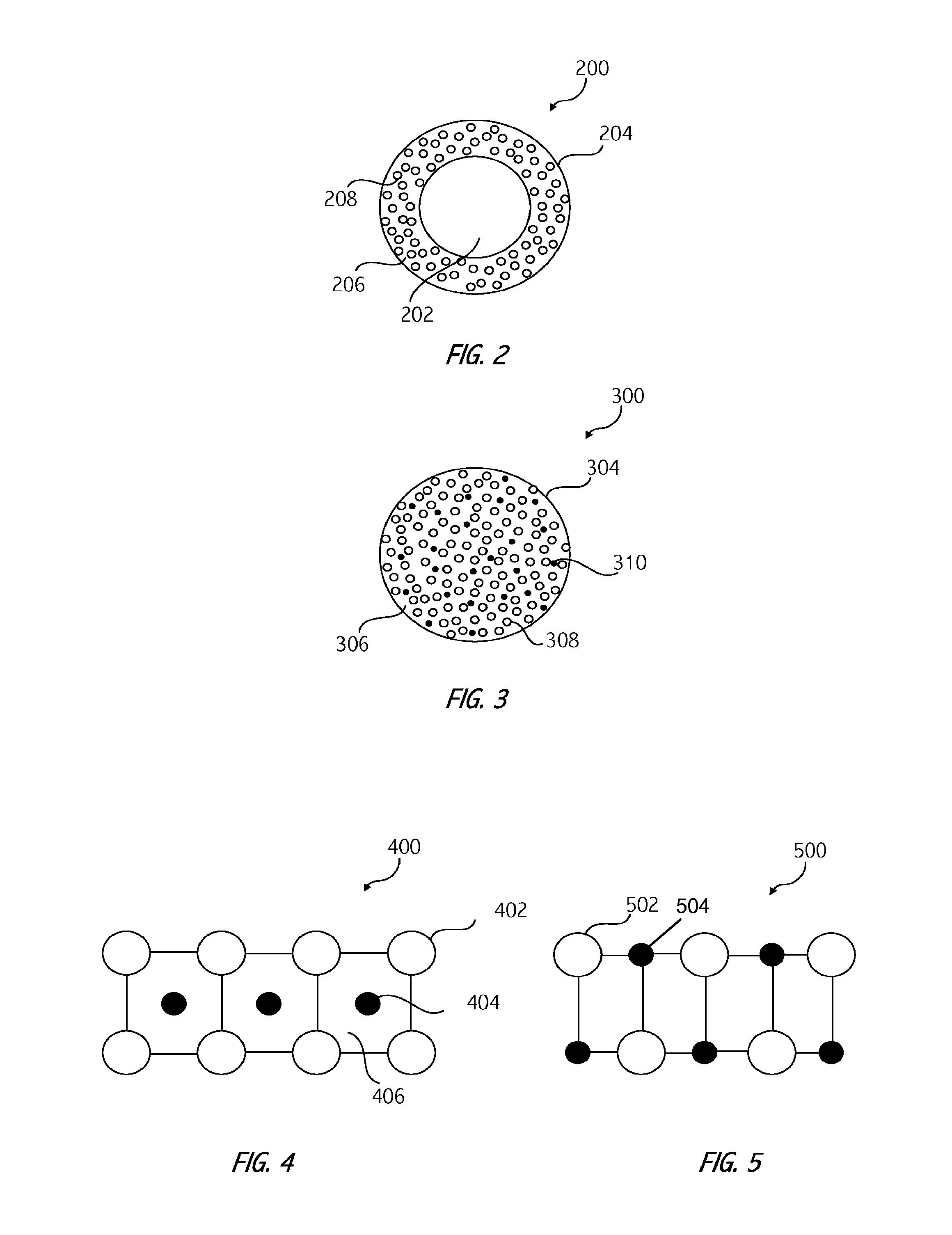

Electrohydrodynamic device components employing solid solutions

InactiveUS8545599B2Excellent catalyst for ozoneImprove conductivityCombination devicesNon-insulated conductorsSolid solutionSolvent

A thermal management apparatus includes an electrohydrodynamic fluid accelerator in which an emitter electrode and another electrode are energizable to motivate fluid flow. One of the electrodes includes a solid solution formed of a solvent metal having a first performance characteristic and a solute material having a second performance characteristic. The first and second performance characteristics are exhibited substantially independently in the electrode as the solvent metal and solute material remain substantially pure within the solid solution. A method of making an EHD product includes providing an electrode with such a solid solution and positioning the electrode relative to another electrode to motivate fluid flow when energized.

Owner:TESSERA INC

High pressure-resistant and high temperature-resistant material and preparation process thereof

InactiveCN106883538AStrong ability to withstand pressureLow friction coefficientTitanium tetrachloridePolytetrafluoroethylene

The invention relates to a high pressure-resistant and high temperature-resistant material and a preparation process thereof. The high pressure-resistant and high temperature-resistant material comprises the following raw materials in parts by weight: 30-40 parts of polytetrafluoroethylene, 15-20 parts of sodium laurylsulfate, 25-30 parts of chlorinated polyethylene, 15-25 parts of polyurethane, 5-10 parts of titanium dioxide, 5-10 parts of titanium tetrachloride, 8-12 parts of stearic acid, 35-40 parts of acetylacetone peroxide, 15-25 parts of alkane and 30-50 parts of absolute ethyl alcohol. The high pressure-resistant and high temperature-resistant material is high in resistance to the pressure of -0.2MPa to 6.6MPa, resistant to high temperature and low temperature in the temperature range of -200 DEG C to 360 DEG C, small in friction coefficient, high in wear resistance, high in adaptability and excellent in corrosion resistance, oxidation resistance and flame retardance.

Owner:马鞍山纽盟知识产权管理服务有限公司

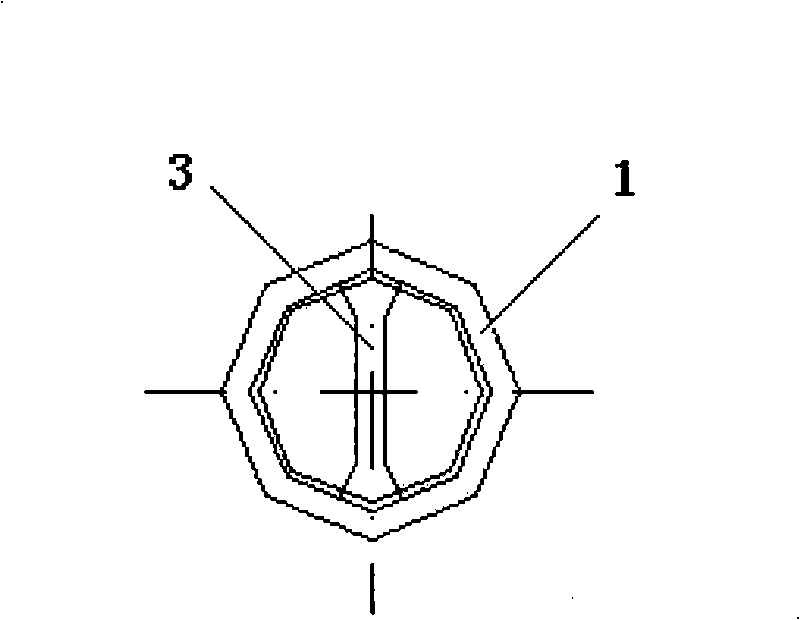

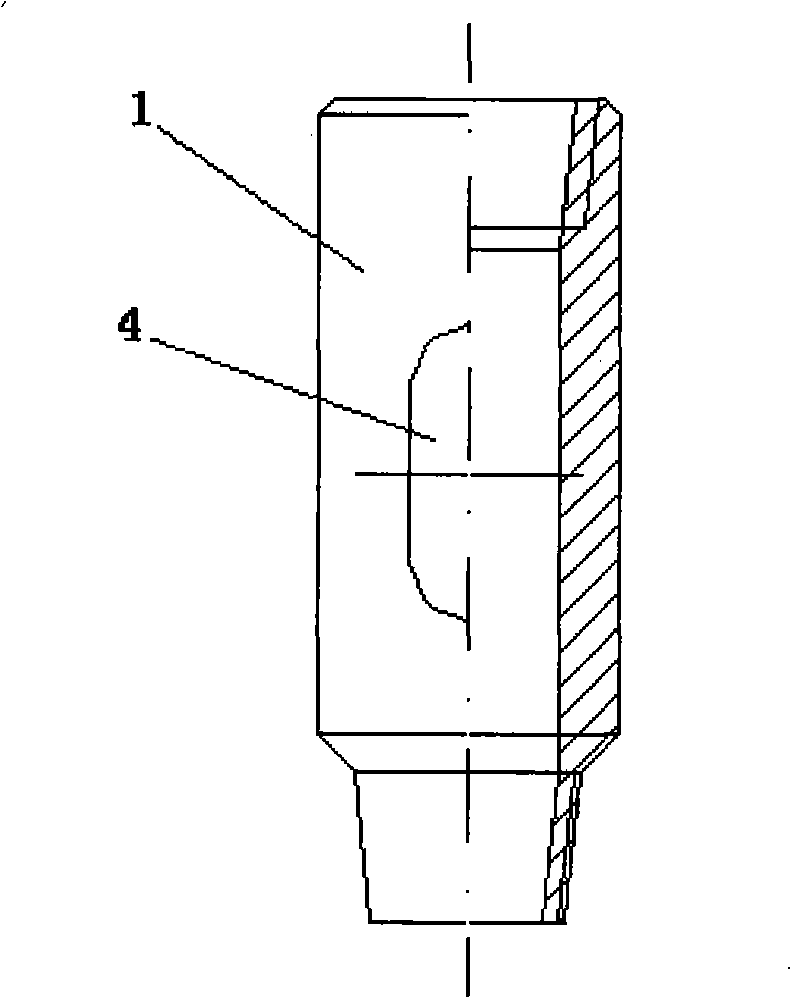

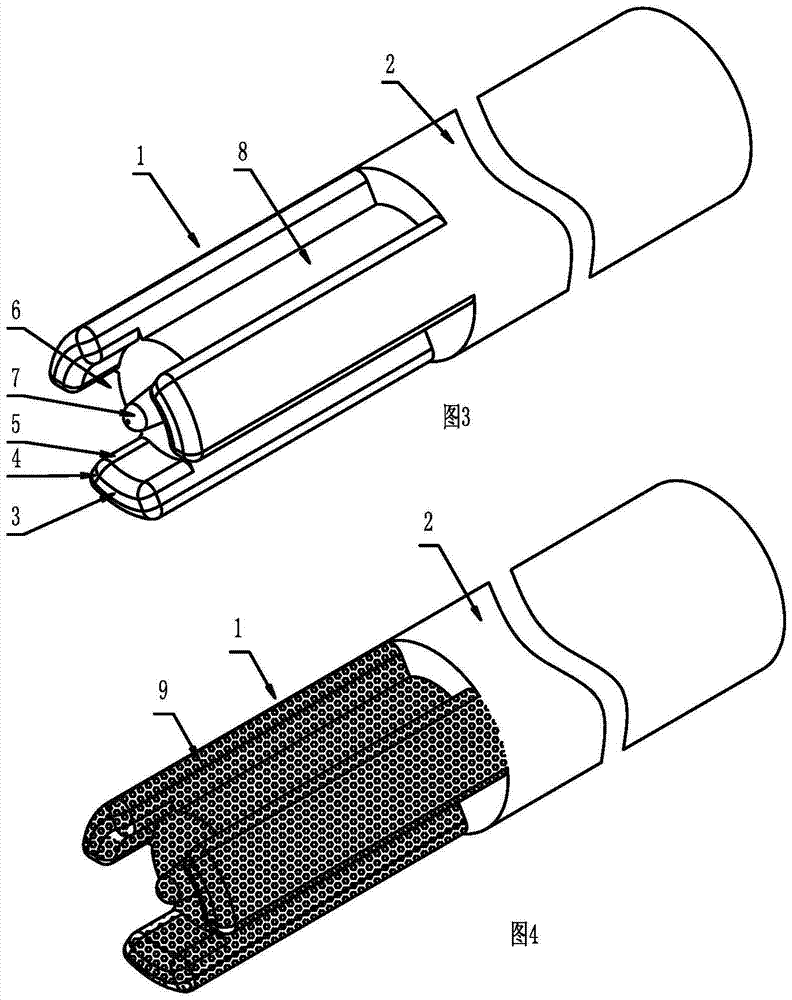

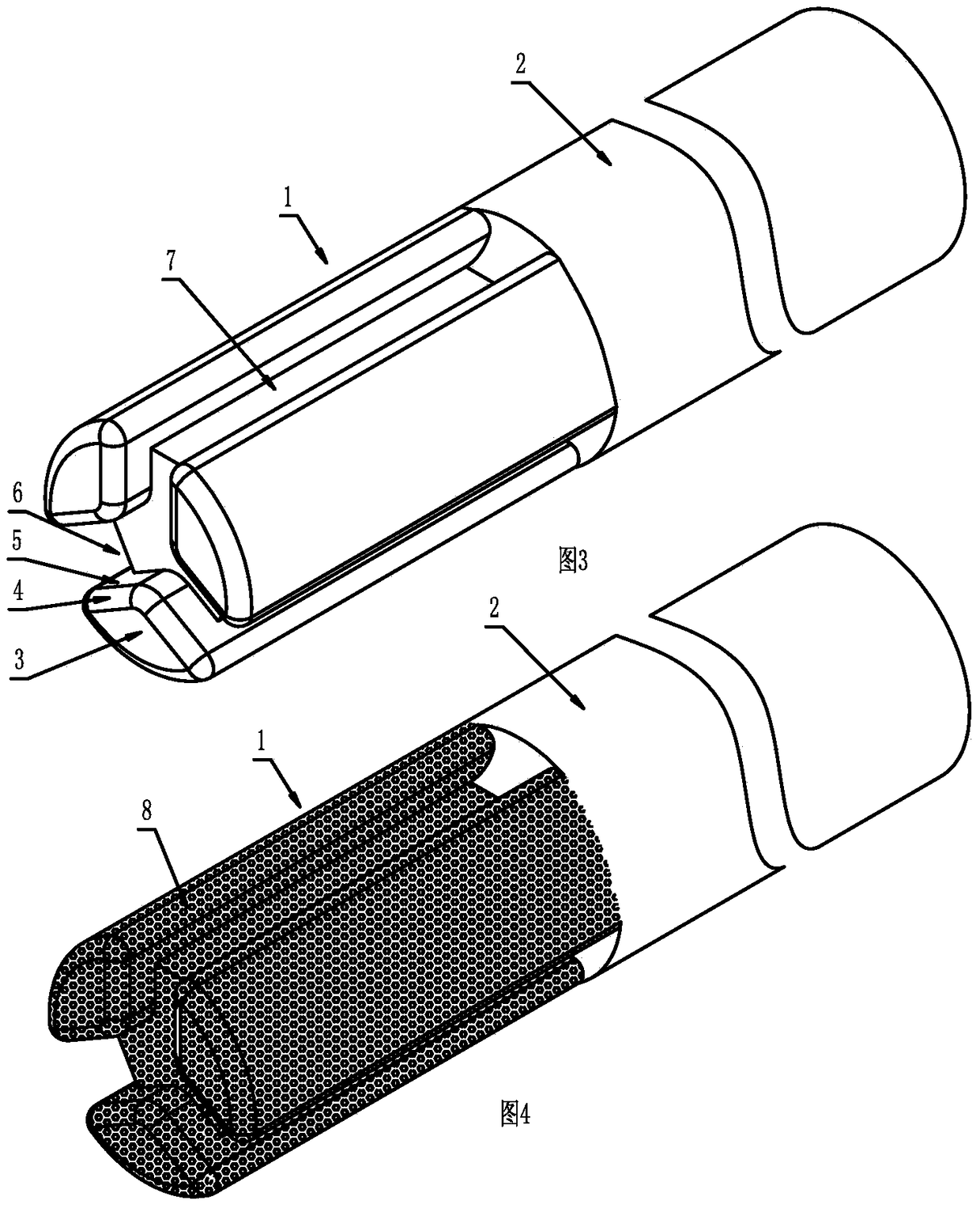

Fiber reinforced composite material perforation cutter based on electroplated diamond

InactiveCN105436577AImprove drilling efficiencyAvoid accumulationTransportation and packagingWorkpiecesFiber-reinforced compositeEngineering

The invention discloses a fiber reinforced composite material perforation cutter based on electroplated diamond. The cutter comprises a cutter bit arranged at the front end of a cutter bar and electroplated with diamond particles on the surface; the cutter bit includes multiple arc cutting parts and multiple chip removing grooves uniformly distributed in the radial direction; the arc cutting parts and the chip removing parts are staggered in the peripheral direction; the outer surfaces of all the arc cutting parts are one part of the same cylindrical surface; a center drill is arranged in a cylindrical space formed by the inner sides of the multiple arc cutting parts; each arc cutting part includes a back cutter surface and a front cutter surface; the back cutter surfaces are overlapped with the end faces, where the back cutter surfaces are positioned, of the corresponding arc cutting parts; the front cutter surfaces and one side surfaces of the chip removing grooves share one surfaces; the normal direction of the front cutter surfaces is consistent with the rotating linear speed of the cutter bit; arc main cutting edges are arranged in the cross places of the front cutter surface and the back cutter surface; and chip pre-storing grooves communicated with the multiple chip removing grooves are formed between the arc cutting parts and the center drill. The cutter can eliminate such phenomenon as easy generation of layering, tearing and burrs during drilling of fiber reinforced composite materials.

Owner:CIVIL AVIATION UNIV OF CHINA

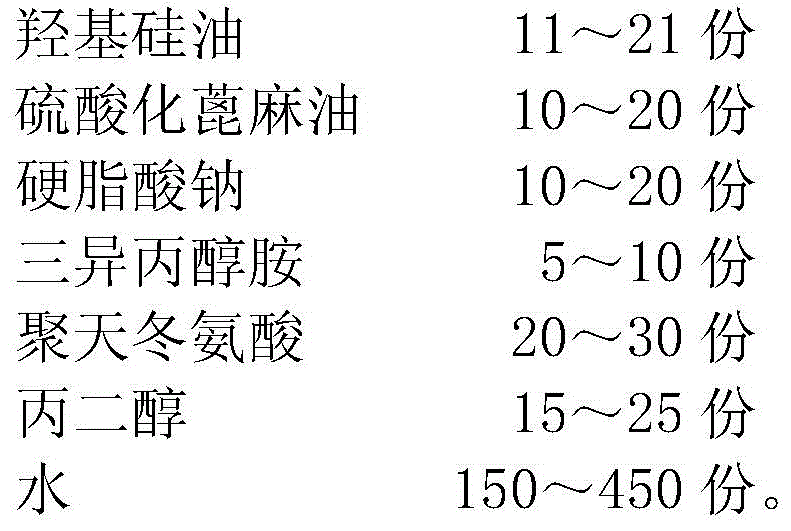

A kind of water-based lubricant for papermaking and preparation method thereof

ActiveCN104846693BHigh glossImprove the lubrication effectCoatingsPaper forming aids additionWater basedSodium stearate

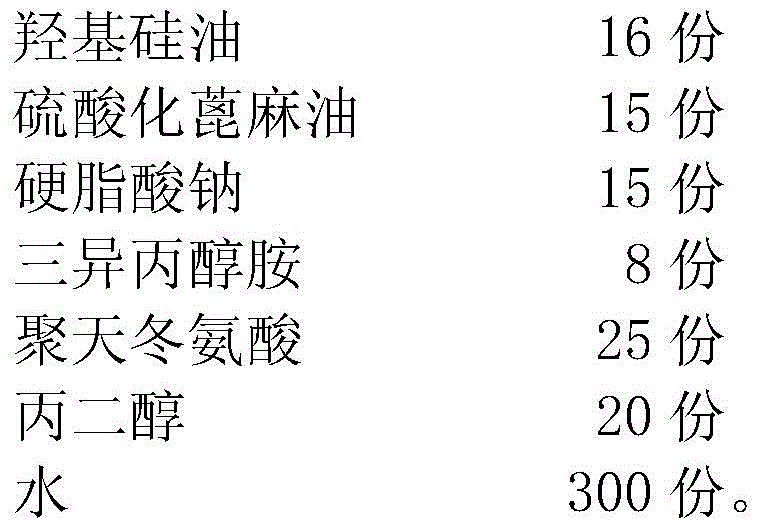

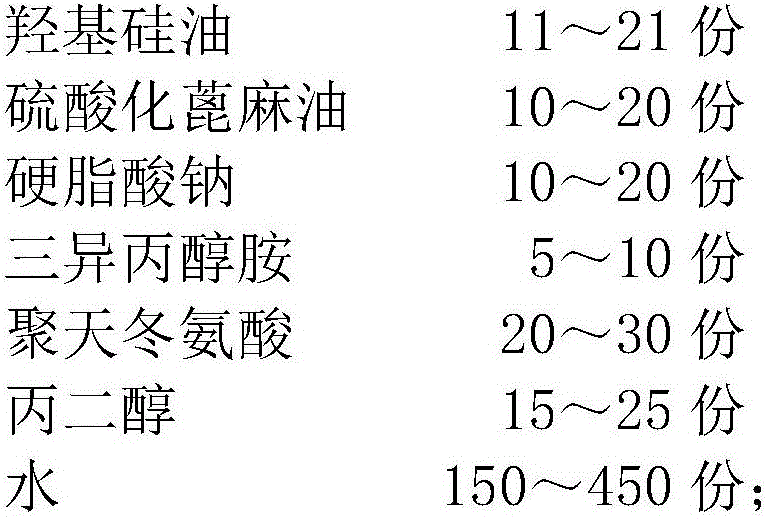

The invention relates to the technical field of lubricating agents, in particular to a papermaking water-based lubricating agent which is made of raw materials including, by weight, 11-21 parts of hydroxy silicone oil, 10-20 parts of sulfated castor oil, 10-20 parts of sodium stearate, 5-10 parts of triisopropanolamine, 20-30 parts of polyaspartic acid, 15-25 parts of propylene glycol and 150-450 parts of water. The invention further provides a preparation method of the papermaking water-based lubricating agent. Flowability of a coating is effectively improved by the papermaking water-based lubricating agent, the friction coefficient of coated paper is reduced, coating adaptability and paper smoothness and glossiness are improved, sticking of a coating roll is prevented, the lubricating agent is mainly applied to the papermaking coating of the coated paper, the preparation method is simple, and the water-based lubricating agent prepared by the method achieves the best effect.

Owner:淄博语嫣丹青纸业有限公司

Shunting injection allocation method and shunting injection allocation machine

ActiveCN101270648BSmall local pressure drop lossLow friction coefficientFluid removalPolymeric liquidEngineering

Owner:CHINA NAT OFFSHORE OIL CORP +1

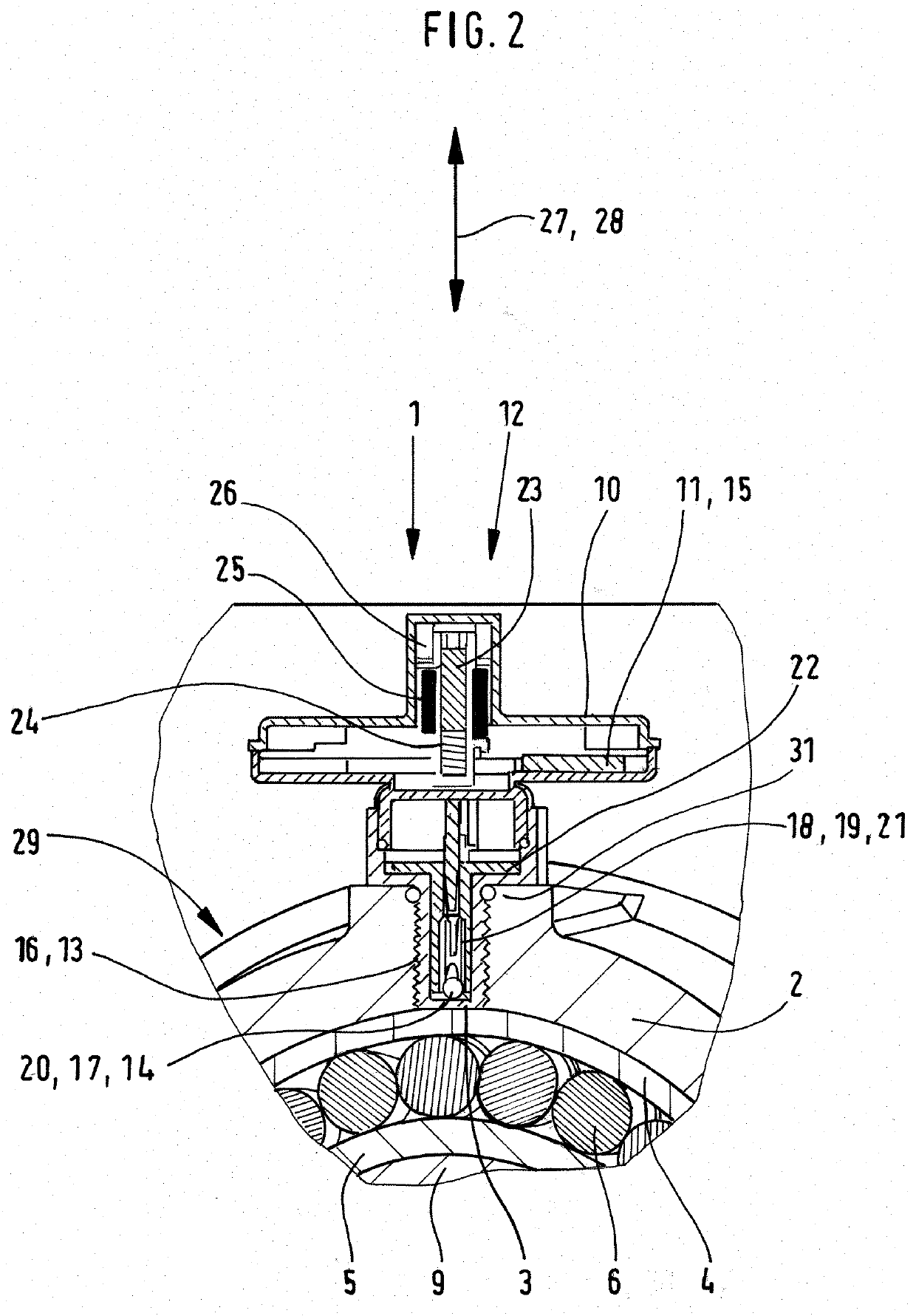

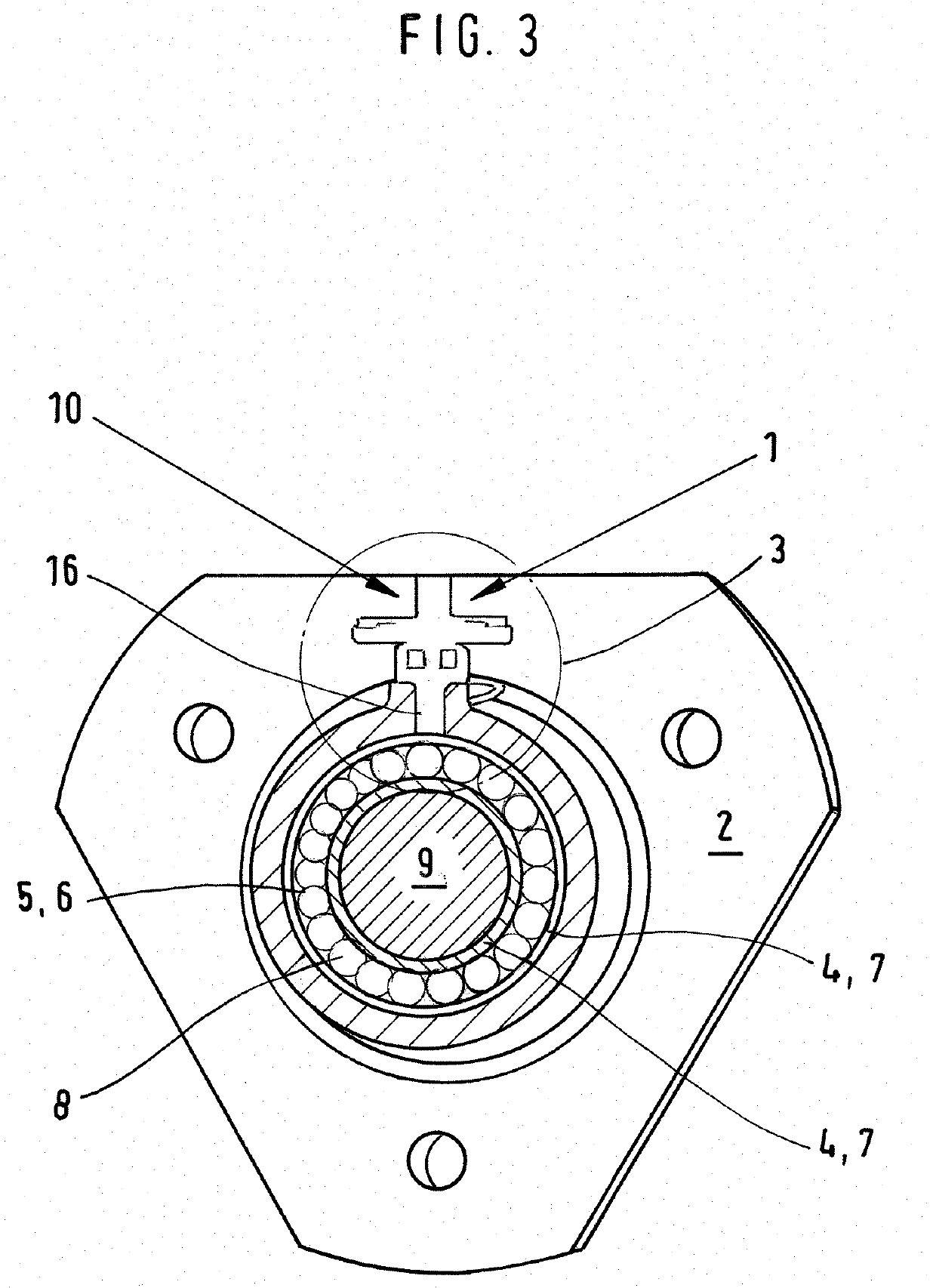

Device for Monitoring a Set of Bearings

PendingUS20210301868A1Low friction coefficientIncrease operating temperatureThermometer detailsRolling contact bearingsOperating temperatureElectrical connection

A device monitors the operating temperature of at least one set of bearings in a plurality of sets of bearings. The at least one set of bearings is arranged between a shaft and a carrier. The carrier has at least one temperature sensor that senses the temperature of the at least one set of bearings and generates a signal representative of an operating temperature of the at least one set of bearings. The at least one temperature sensor is operatively electrically connected to at least one controller. The controller processes the signal from the temperature sensor, including determining the operating temperature of the respective at least one set of bearings and whether the operating temperature of the respective at least one set of bearings exceeds at least one threshold temperature. The controller memory holds a unique identifier associated with the at least one bearing set.

Owner:METHODE ELECTRONICS MALTA

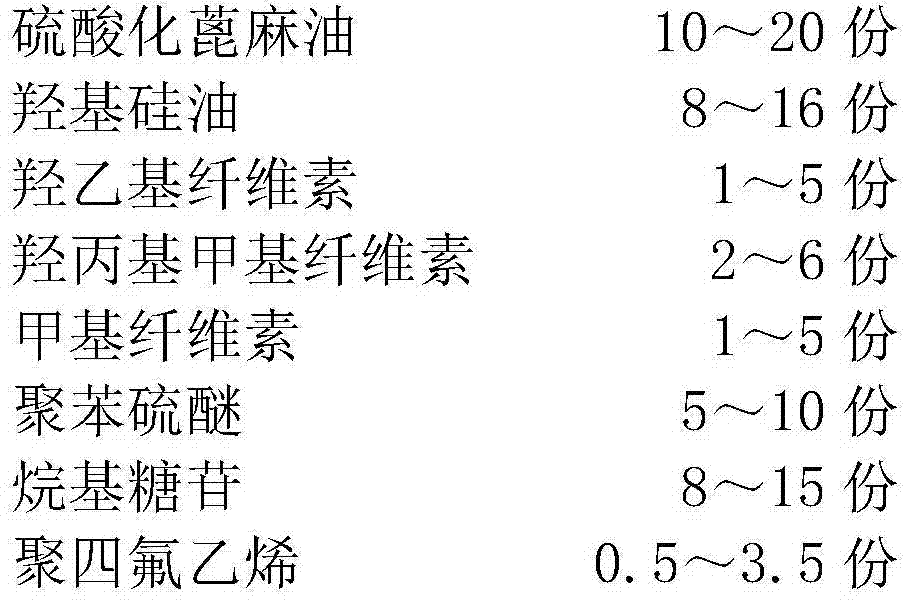

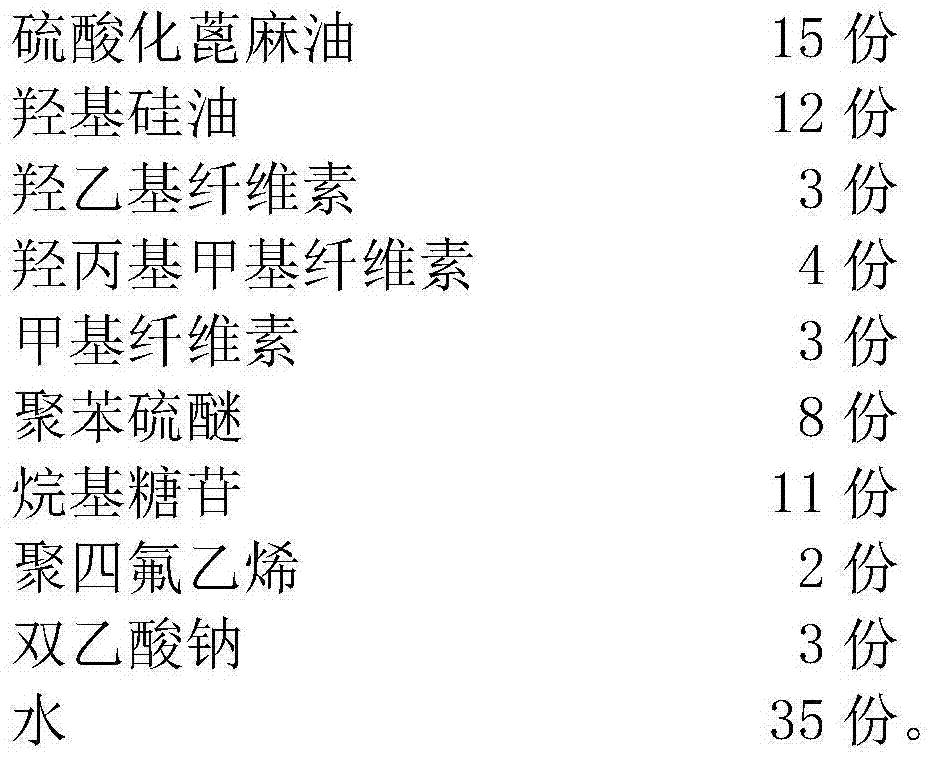

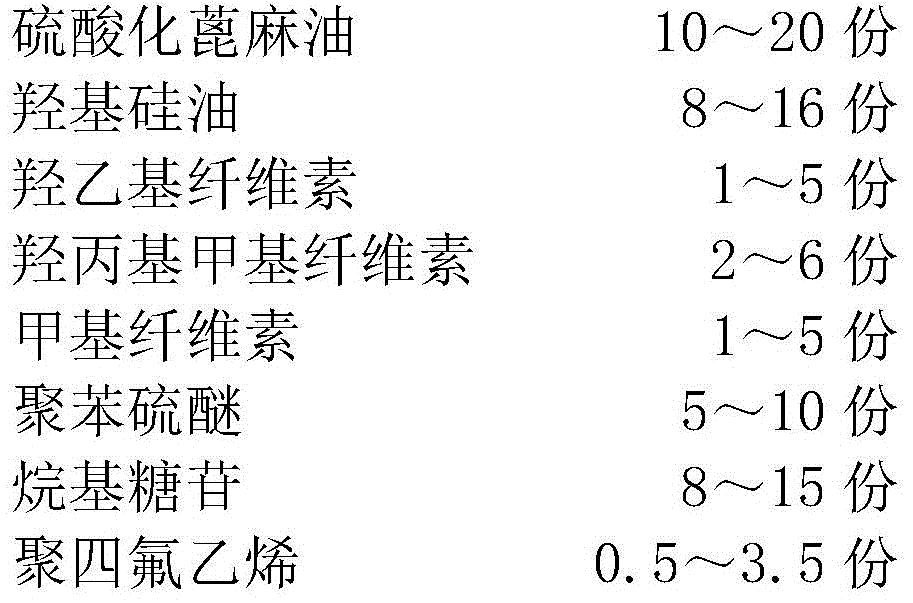

Water-based lubricant for paper making

ActiveCN104762848AGood anti-sticking effectAvoid Roll StickingNon-fibrous pulp additionWater basedSodium diacetate

The invention relates to the technical field of lubricant, in particular to water-based lubricant for paper making. The water-based lubricant for paper making is prepared, by weight, by the following raw materials of 10-20 parts of sulfated castor oil, 8-16 parts of hydroxyl silicone oil, 1-5 parts of hydroxyethyl cellulose, 2-6 parts of hydroxy propyl methyl cellulose, 1-5 parts of methyl cellulose, 5-10 parts of polyphenylene sulfide, 8-15 parts of alkyl glycoside, 0.5-3.5 parts of polytetrafluoroethylene, 1-5 parts of sodium diacetate and 30-40 parts of water. According to the water-based lubricant for paper making, the good lubricating effect is achieved, the friction coefficients of coating paper are greatly reduced, the coating adaptability and the smoothness, glossiness and surface strength of finished paper are improved, no carcinogenic ingredient is contained in the raw materials, and environmental protection is achieved; the water-based lubricant for paper making is mainly applied in paper making coatings of the coating paper.

Owner:JIANGSU SHUANGNENG SOLAR ENERGY

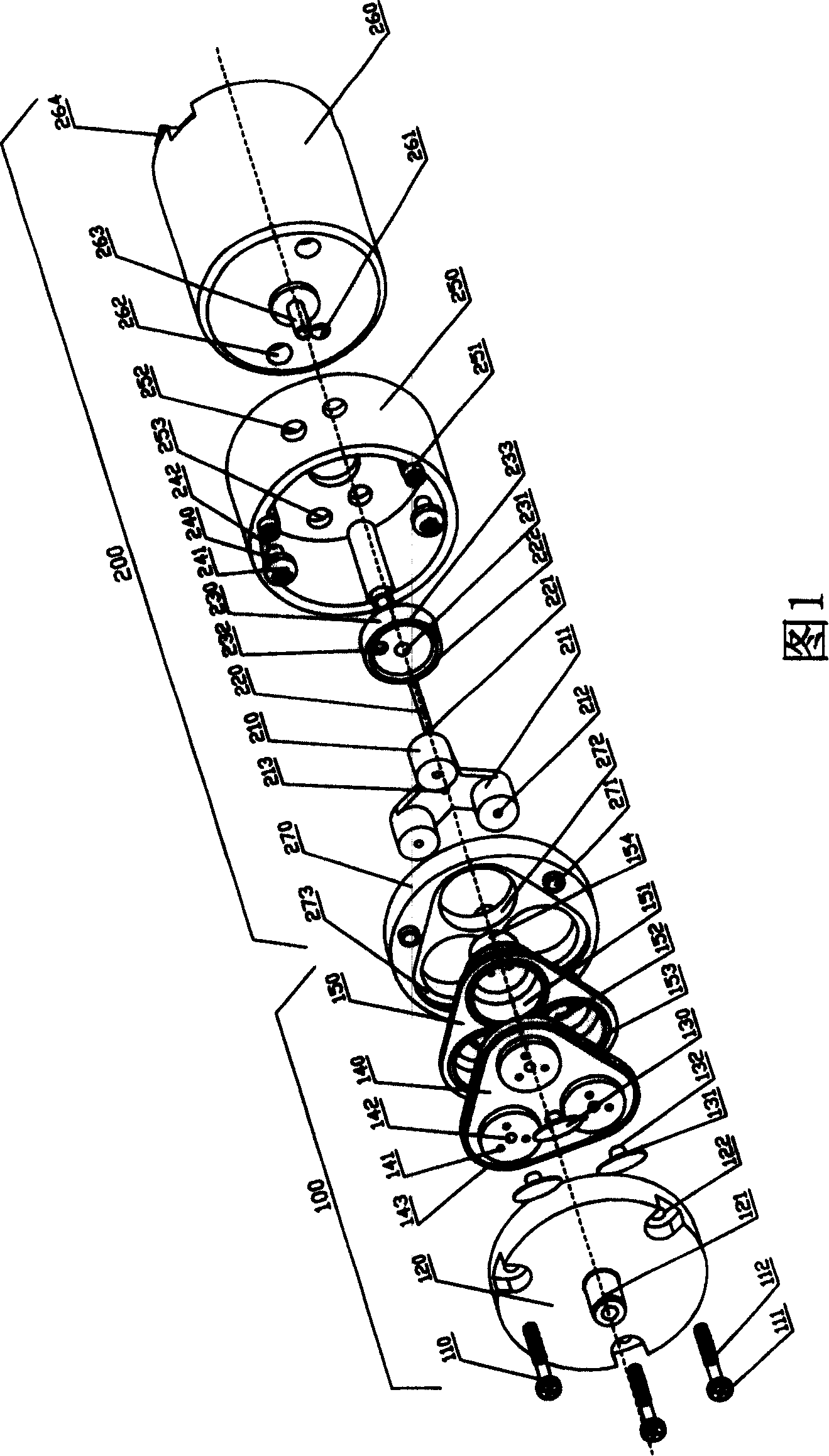

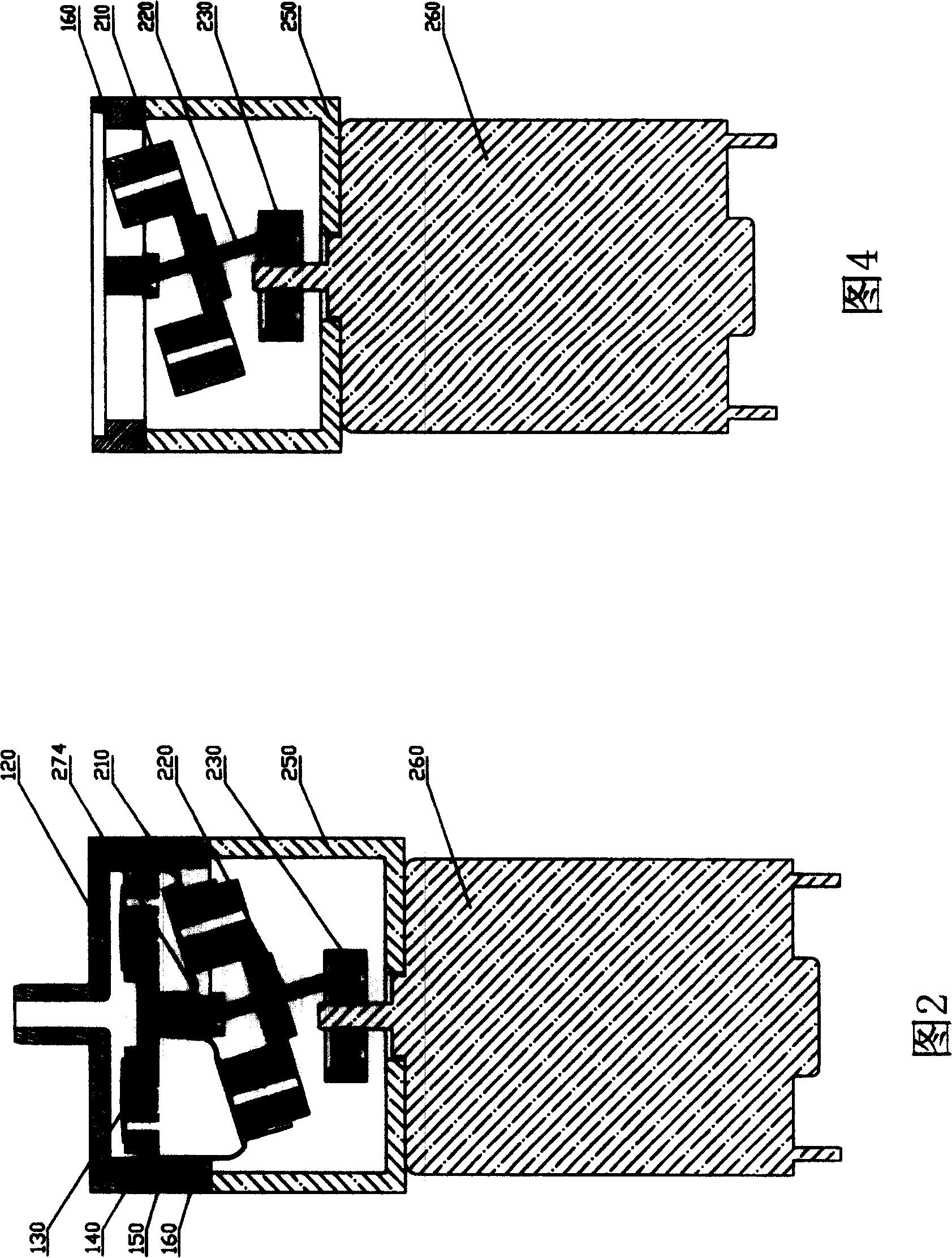

Minisize air lift pump with low power consumption air guide structure

InactiveCN100387838CReduce manufacturing costSimplify the assembly processPositive displacement pump componentsMulti-stage pumpsDrive shaftEngineering

The invention discloses a micro pneumatic pump of low power consumption air guiding structure, wherein the gas guiding component contains air cock, briquette and piston body with multiple small piston cavities; the air hole is opened on the briquette in connection with the air cock; the one-way air vent valve is fixed on the air hole; the air vent hole connects each piston cavity to form one-way air vent passage; the driving component contains motor, eccentric wheel, compression piece, driving shaft and piston rack; the elastic fixation case and air orifice are set under each piston cavity with one-way valve on the air orifice; the corresponding piston installment position and air orifice are set on the compression piece, which encase the elastic fixation case tightly; the one-way air-in passage is composed of air orifice under each piston cavity, one-way air orifice valve and air orifice on the compression piece; the motor compresses the piston cavity on the piston rack through the eccentric wheel and driving compression piece of driving shaft.

Owner:SHENZHEN KINGYIELD TECH

Water-based Lubricant for Papermaking

ActiveCN104762848BImprove the lubrication effectHigh glossNon-fibrous pulp additionWater basedSodium diacetate

The invention relates to the technical field of lubricant, in particular to water-based lubricant for paper making. The water-based lubricant for paper making is prepared, by weight, by the following raw materials of 10-20 parts of sulfated castor oil, 8-16 parts of hydroxyl silicone oil, 1-5 parts of hydroxyethyl cellulose, 2-6 parts of hydroxy propyl methyl cellulose, 1-5 parts of methyl cellulose, 5-10 parts of polyphenylene sulfide, 8-15 parts of alkyl glycoside, 0.5-3.5 parts of polytetrafluoroethylene, 1-5 parts of sodium diacetate and 30-40 parts of water. According to the water-based lubricant for paper making, the good lubricating effect is achieved, the friction coefficients of coating paper are greatly reduced, the coating adaptability and the smoothness, glossiness and surface strength of finished paper are improved, no carcinogenic ingredient is contained in the raw materials, and environmental protection is achieved; the water-based lubricant for paper making is mainly applied in paper making coatings of the coating paper.

Owner:JIANGSU SHUANGNENG SOLAR ENERGY

An Electroplated Diamond Tool for Drilling Fiber Reinforced Composite Materials

InactiveCN105458353BImprove drilling efficiencyExtended service lifeTransportation and packagingWorkpiecesTool bitEngineering

The invention discloses a diamond-electroplated tool for drilling of a fiber reinforced composite material. The diamond-electroplated tool comprises a cylindrical tool rod. A tool bit with the surface electroplated with diamond particles is arranged at the front end of the tool rod. The tool bit comprises a plurality of cutting parts and a plurality of chip discharge grooves. The cutting parts and the chip discharge grooves are evenly distributed in the radial direction and arranged in a staggered manner in the circumferential direction. The outer surfaces of all the cutting parts are part of the same cylindrical face. The cutting parts are located at the front end of the tool bit, and the length of the chip discharge grooves is equal to that of the tool bit. Each cutting part comprises a rear tool face and a front tool face. The rear tool faces coincide with the end face where all the cutting parts are located. The front tool faces and one side faces of the chip discharge grooves are coplanar. The normal direction of the front tool faces is consistent with the rotating linear speed direction of the tool bit. Arc main cutting edges are arranged at the cross positions of the front tool faces and the rear tool faces. A plurality of chip pre-storage grooves communicated with the chip discharge grooves are formed in the center of the end of the tool bit. According to the tool, the phenomenon that in the prior art, during drilling machining of a fiber reinforced composite material, layering, tearing, burrs and the like are likely to occur can be eliminated.

Owner:CIVIL AVIATION UNIV OF CHINA

Sintered oil-impregnated bearing and manufacturing method thereof

ActiveCN108431436BPrevent movementGood sliding propertiesShaftsBearing componentsMaterials scienceOil supply

The invention relates to a sintered oil-impregnated bearing, on the inner peripheral surface of a bearing hole (2) into which a shaft (11) is inserted, a sliding surface (3) supporting the outer peripheral surface of the shaft (11) and a bearing The shaft center of the hole (2) is a spiral oil supply surface (4), and the surface opening ratio on the sliding surface (3) is 10% or less, and the surface opening ratio of the oil supply surface (4) exceeds 10%. Thus, the present invention supplies a sufficient amount of oil to the sliding surface (3) and suppresses the supplied oil from moving inside from the sliding surface (3), thereby achieving a low coefficient of friction and improving the sliding characteristics of the bearing.

Owner:DIAMET CORP

A kind of nanocomposite marine anticorrosion coating and preparation method thereof

ActiveCN109943169BReduce biocorrosion hazardsLarge specific surface areaAntifouling/underwater paintsPaints with biocidesCelluloseAcrylic resin

The invention discloses a nanometer composite ocean anticorrosion coating and a preparation method thereof, belonging to the field ofcorrosion prevention of coatings. The coating contains the following components in percentage by weight: a component A: 20%-40% of acrylic resin, 5%-10% of a hydroxyl epoxy phosphate dispersing agent, 4%-7% of a Fe3O4@TiO2-h-BN hybridized composite material, 0.5%-2%of nano-crystalline cellulose, 5%-15% of epoxy resin, 1.2%-3.5% of other aids, 20%-25% of deionized water, 5%-10% of zinc powder and 3%-7% of calcium carbonate; and a component B: a curing agent, namely 15%-25% of a water-based isocyanate curing agent. The coating prepared by virtue of the preparation method has good wear resistance, fouling resistance and corrosion resistance, is mainly applied to the fouling prevention and corrosion prevention of petroleum steel-frame structure platforms in an ocean atmospheric region environment and is also suitable for the fields of fouling prevention andcorrosion prevention of ships and underwater pipelines.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com