Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

142results about How to "Low cost operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

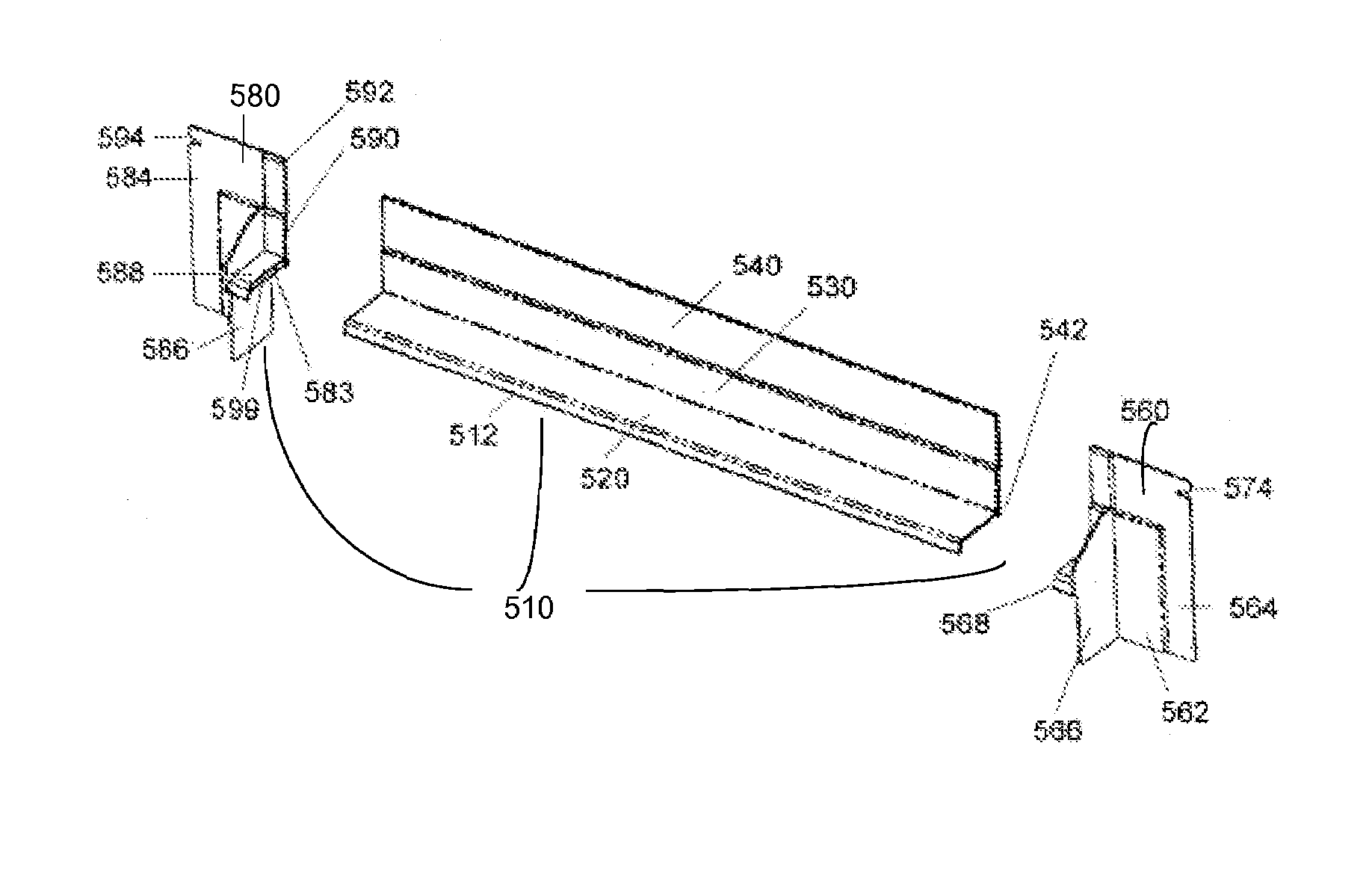

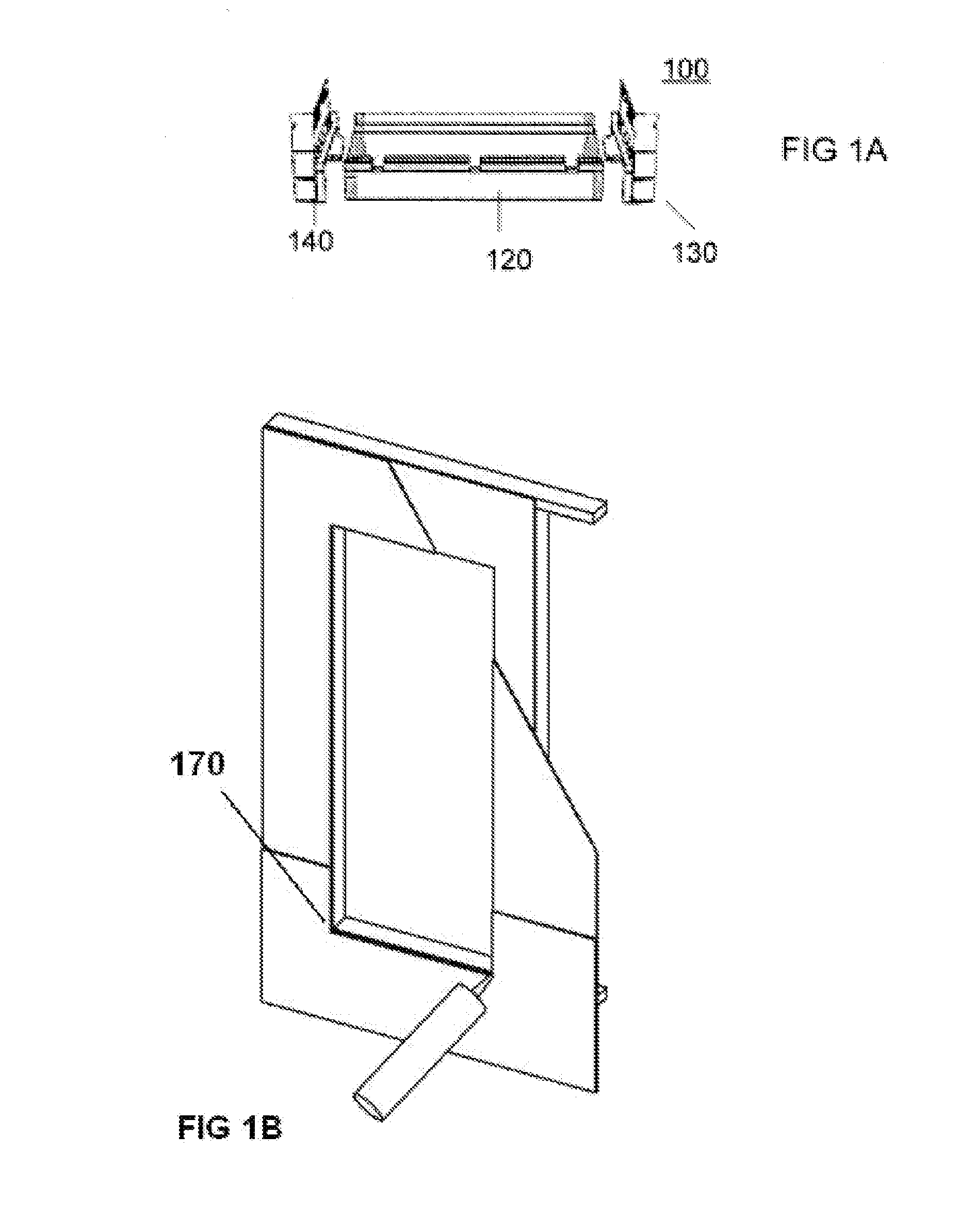

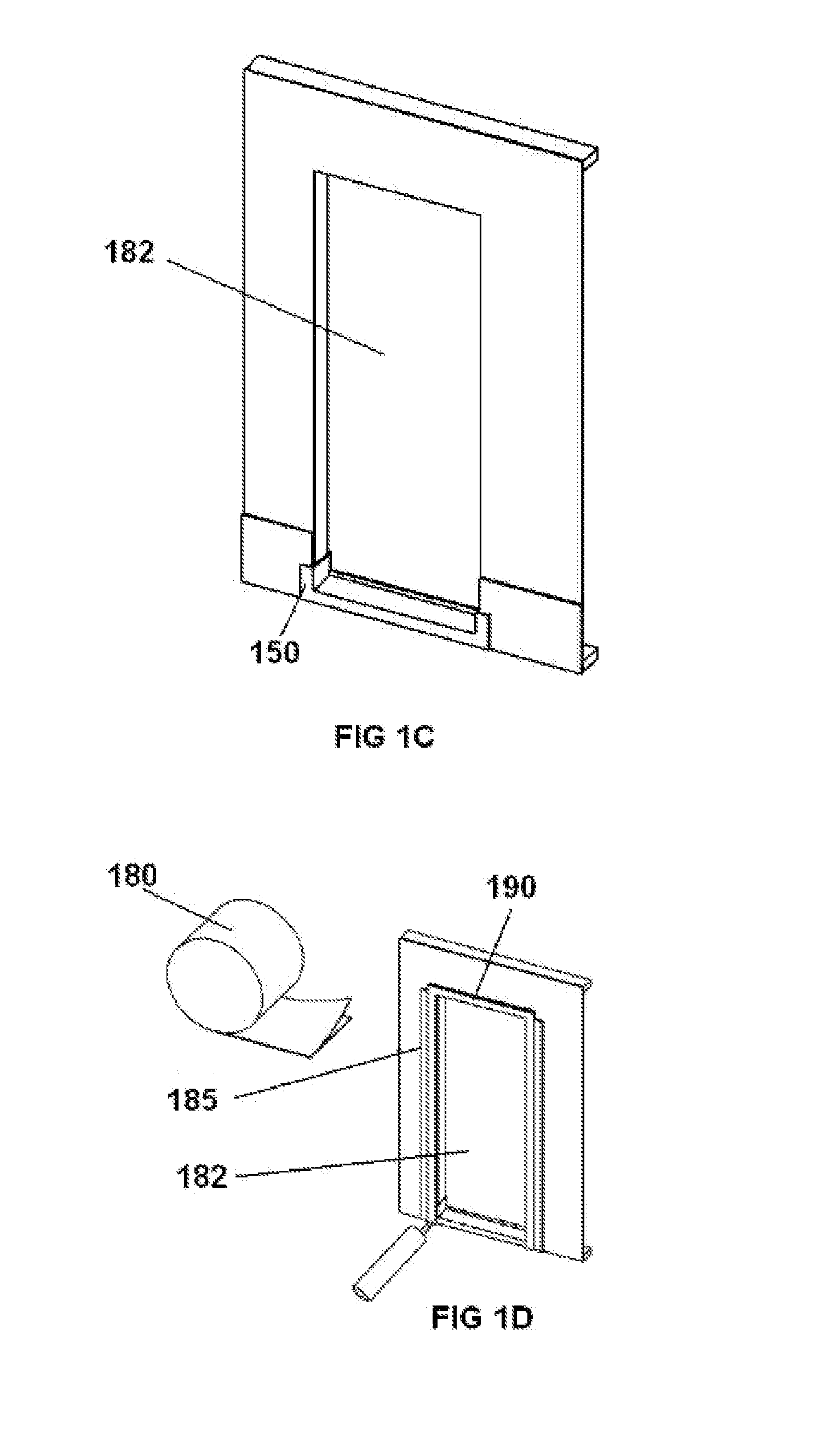

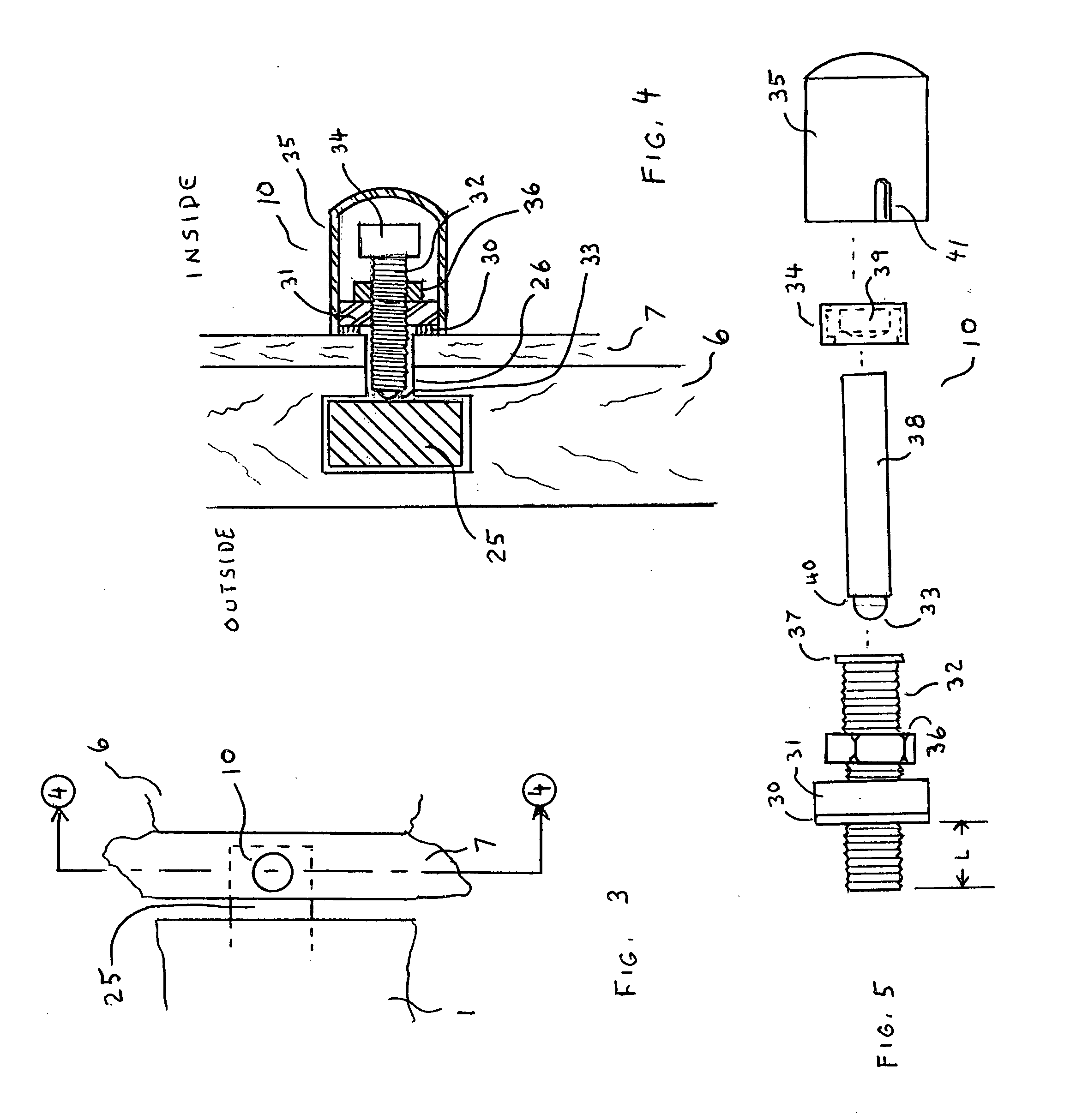

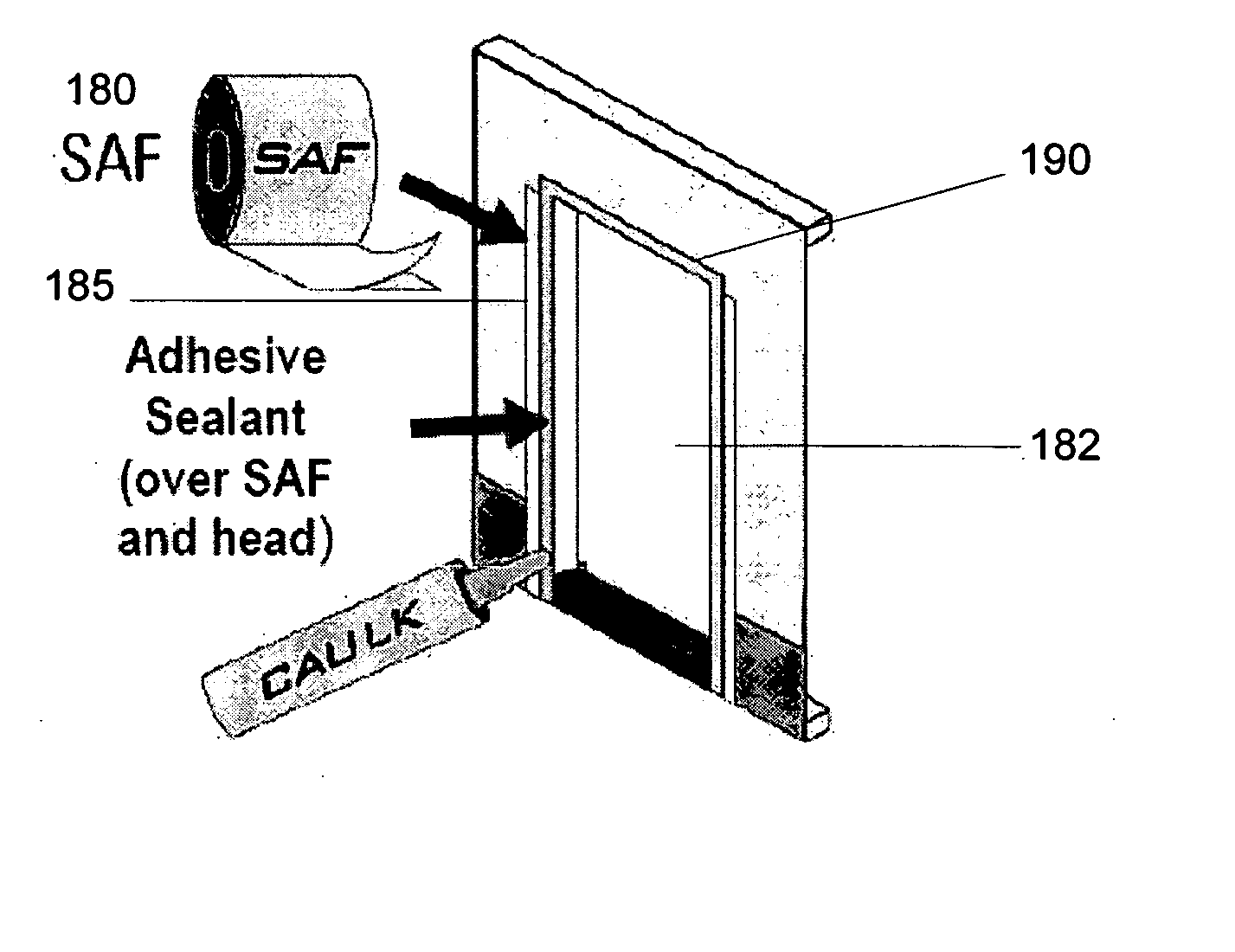

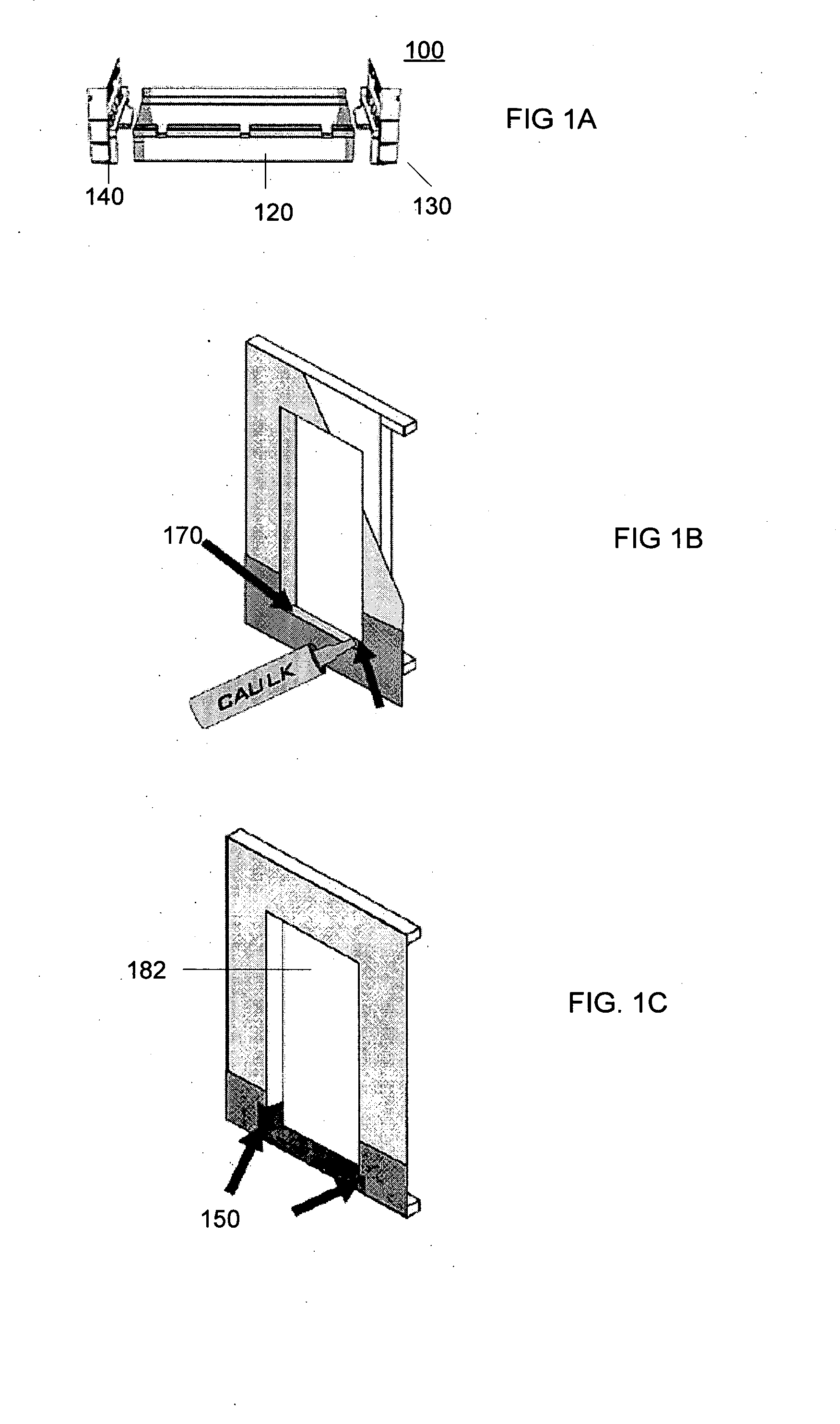

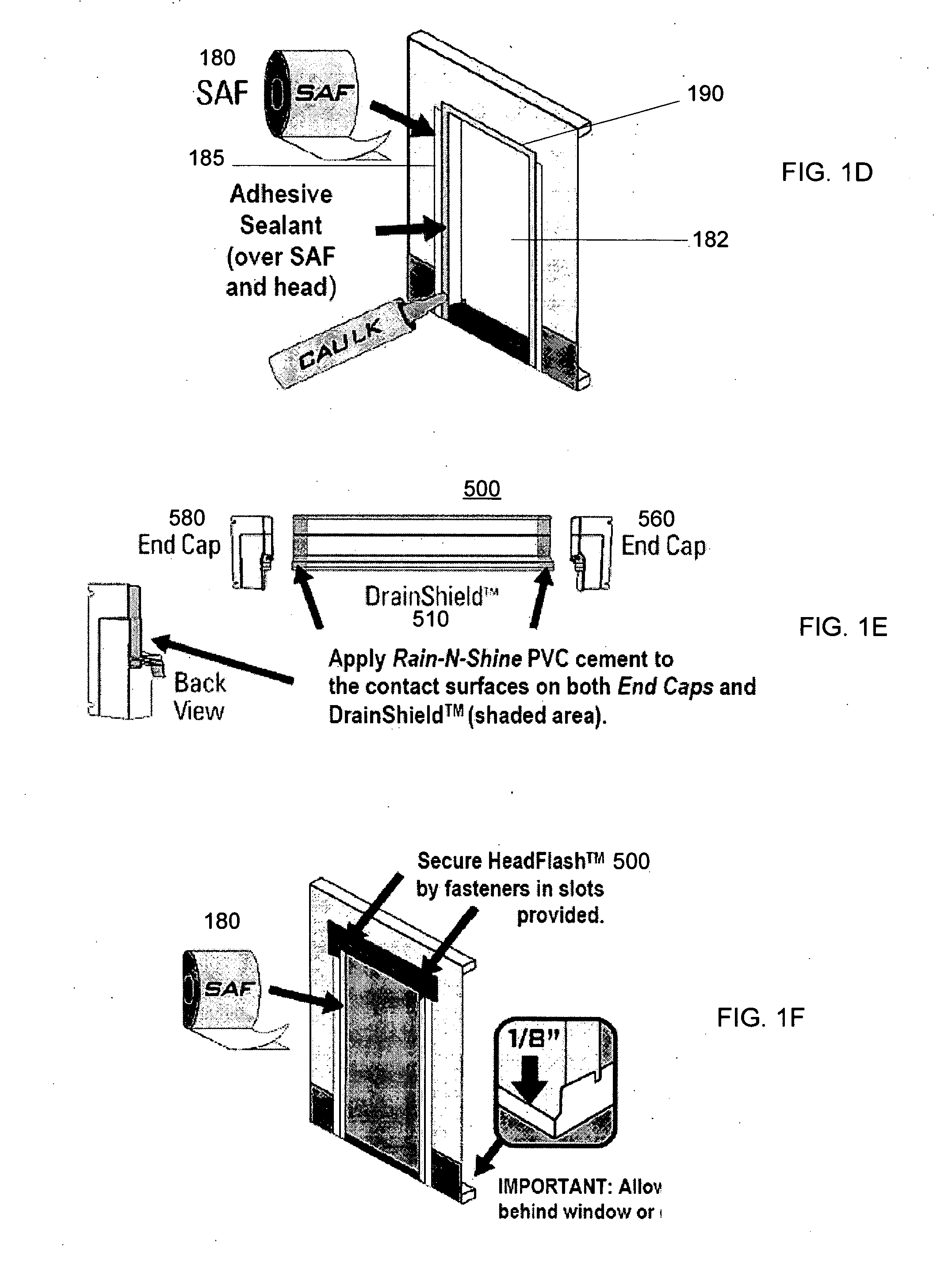

Apparatus and method for door and window head flashing

ActiveUS7676996B2BuildLow costRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringWindow Width

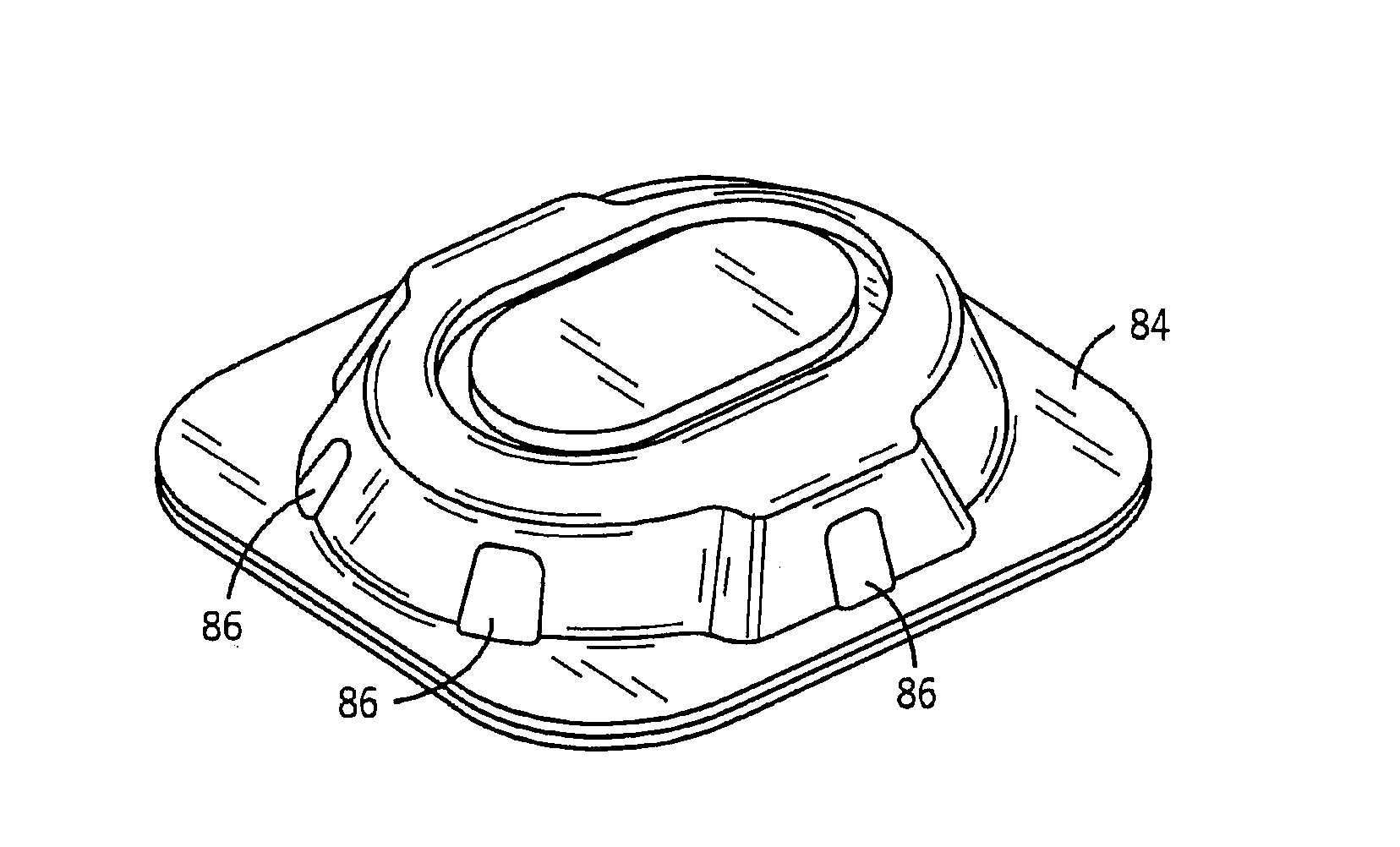

A window and door head flashing assembly is fabricated at a construction site to fit specific door or window widths. A center section which may be extruded with a sloped base, a rear flange, and a front lip. End caps may be provided to snap or glue on the center section. The end caps have a perpendicular fin which serves as an end dam to block the lateral movement of water. The assembly may be inverted for use as a sill pan. The center section may be cut to a desired length and installed over arched windows or doors by bending to shape as it is installed. For arched applications, a combination of rigid and flexible PVC may be coextruded to provide a desired cross sectional profile that is flexible enough to be bent around the arch, but stiff enough to retain its cross section for drainage.

Owner:TEODOROVICH MISHKO

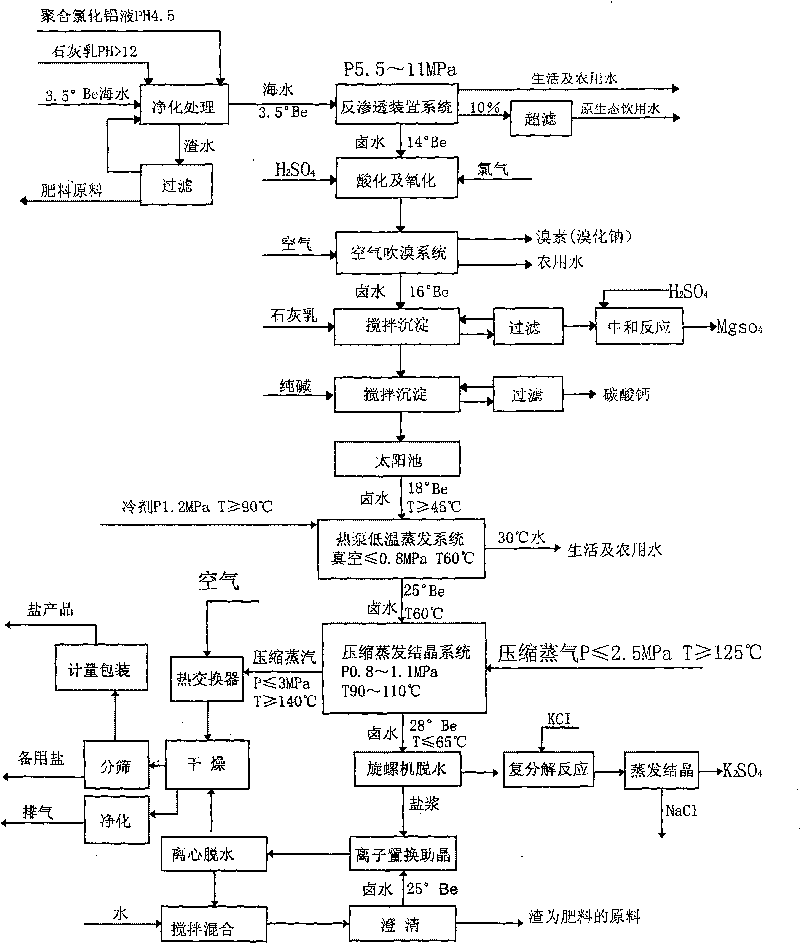

Technique for desalting sea water, making salt and comprehensively using by-products thereof by utilizing wind energy, solar energy and heat pump technologies

ActiveCN101704560AIncrease volumeAchieve balanceGeneral water supply conservationEnergy inputWater desalinationSolar pond

The invention relates to a technique for desalting sea water, making salt and comprehensively using by-products thereof by utilizing wind energy, solar energy and heat pump technologies, the main procedures comprise desalting sea water, air-blowing bromine, removing impurities for clarification, heating solar pond and storing halogen, evaporating for concentration, compressing and crystallizing for salt making, brine chemical engineering, etc. the invention desalts sea water, makes salt and comprehensively uses by-products thereof by utilizing wind energy, solar energy and heat pump technologies, organically combines sea water desalting, salt making and comprehensive use of dregs and waste liquor, takes wind energy, solar energy and other renewable energy resources as main energy sources, changes sea salt production from drying on beach in the open air manually to mechanized and automated operation, puts an end to the backward state of sea salt enterprises, can save energy consumption and reduce pollution, can save investment by about 50% and occupied area by 95%, not only lowers production cost, but also recovers 35m<2> of fresh water by producing one ton of salt, thus protecting fresh water resource.

Owner:ZHANJIANG NONGHAI TECHNOLOGY CO LTD

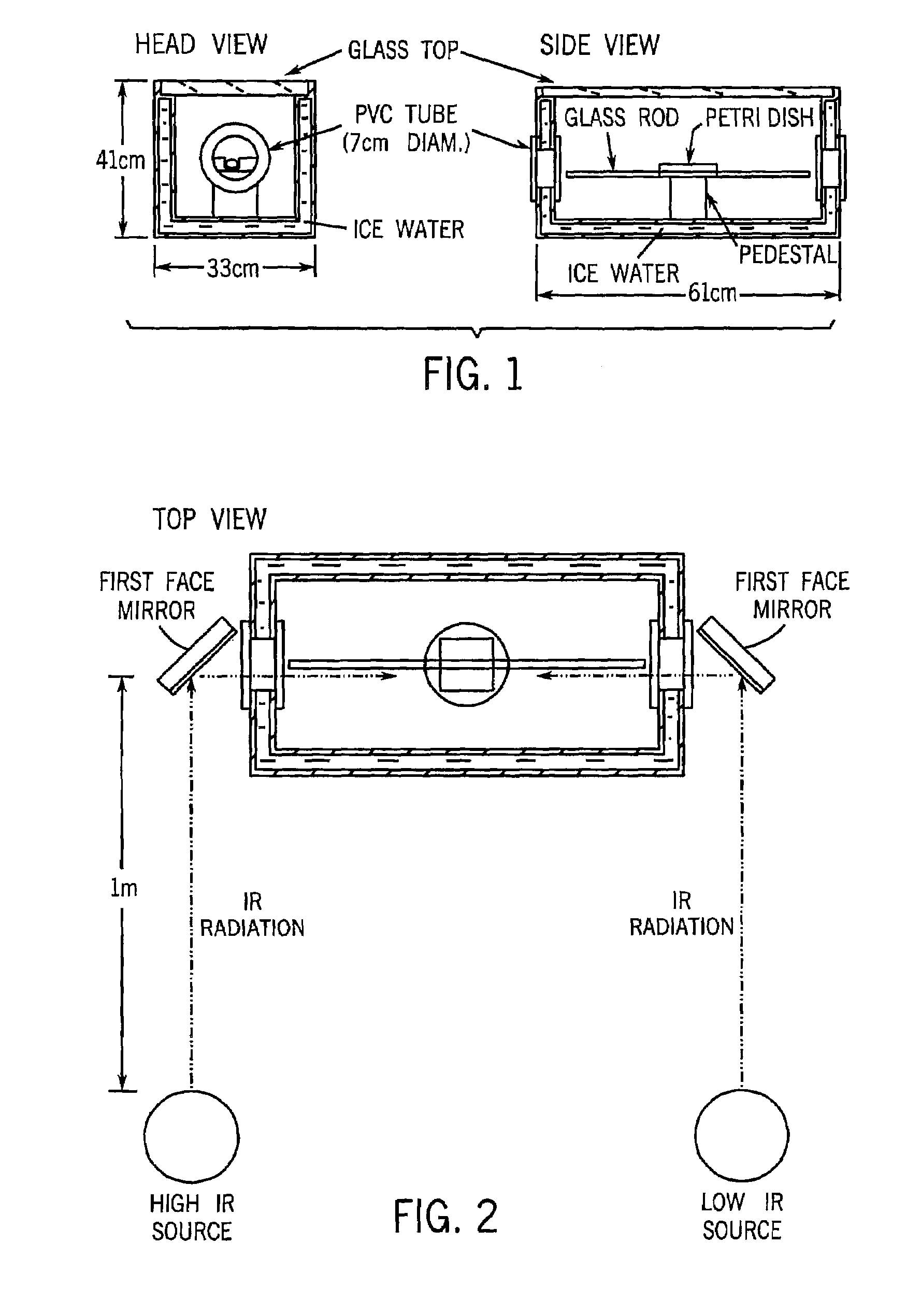

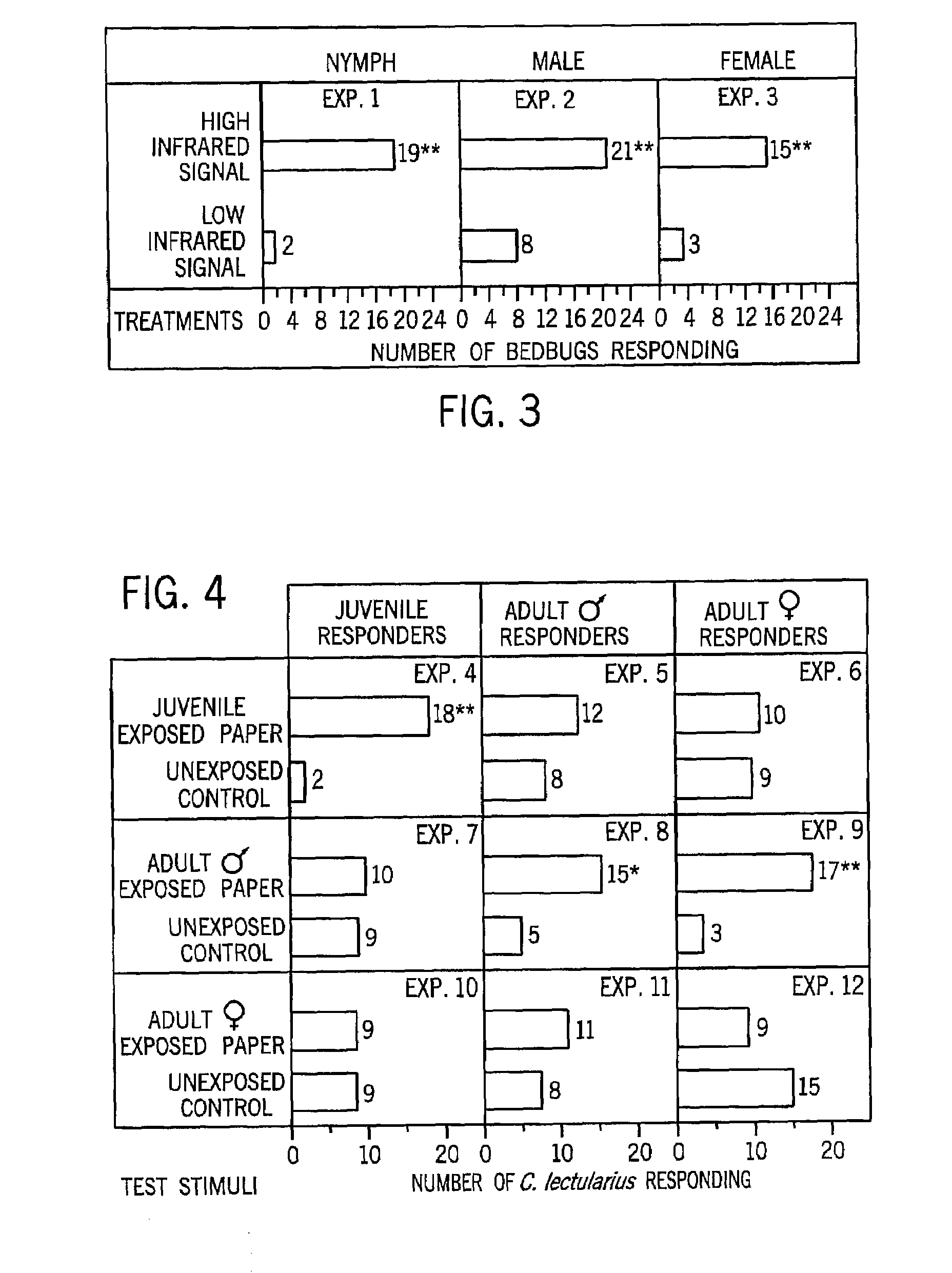

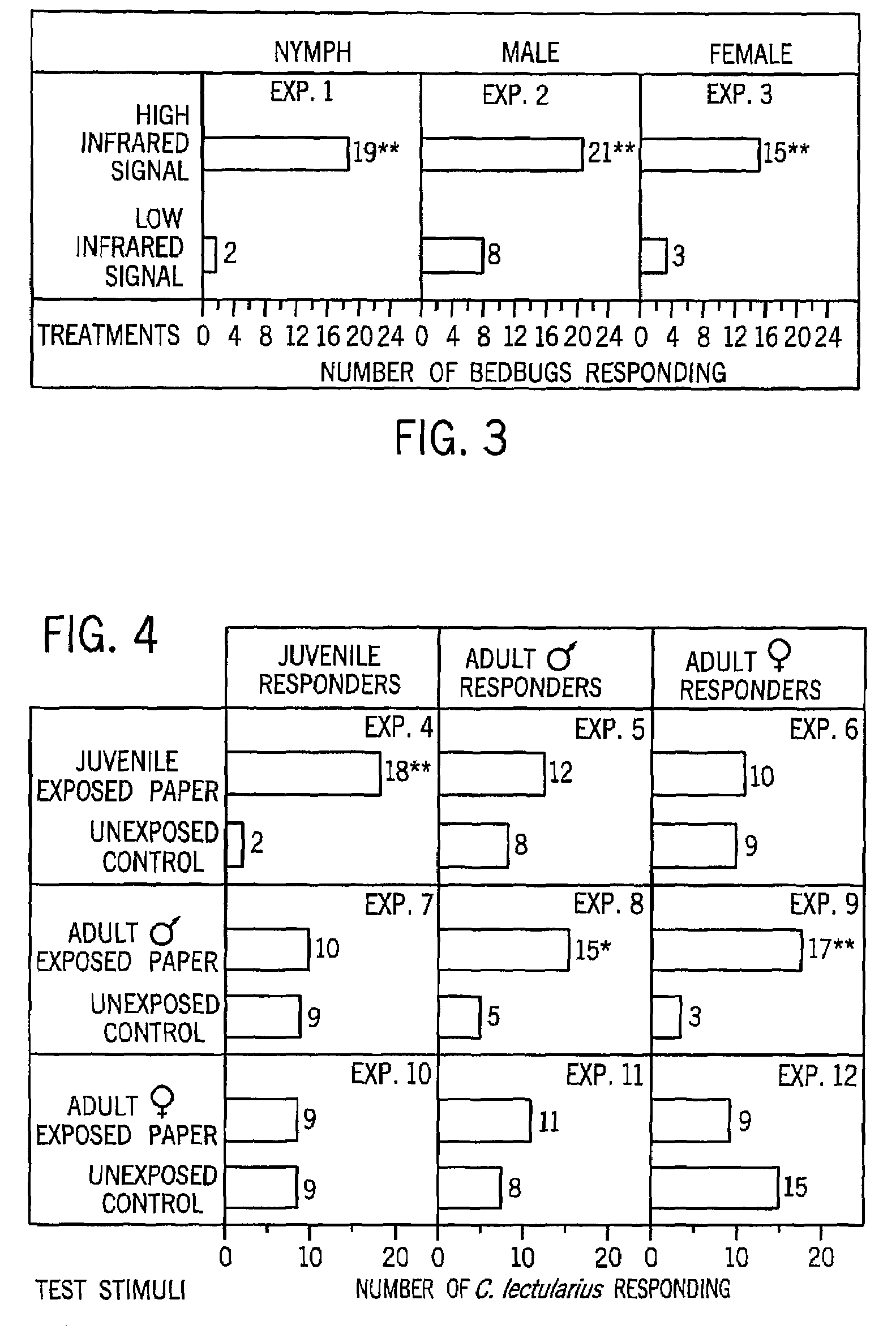

Controlling bedbugs with synthetic pheromones and/or infrared radiation

Disclosed are methods for attracting and thereby controlling bedbugs. One volatizes a synthetic pheromone and generates infrared radiation adjacent the location and exposes bedbugs thereto. The pheromone volatizer and / or radiation generator are preferably incorporated into traps, bait stations and monitoring stations.

Owner:SILJANDER ERIC D +3

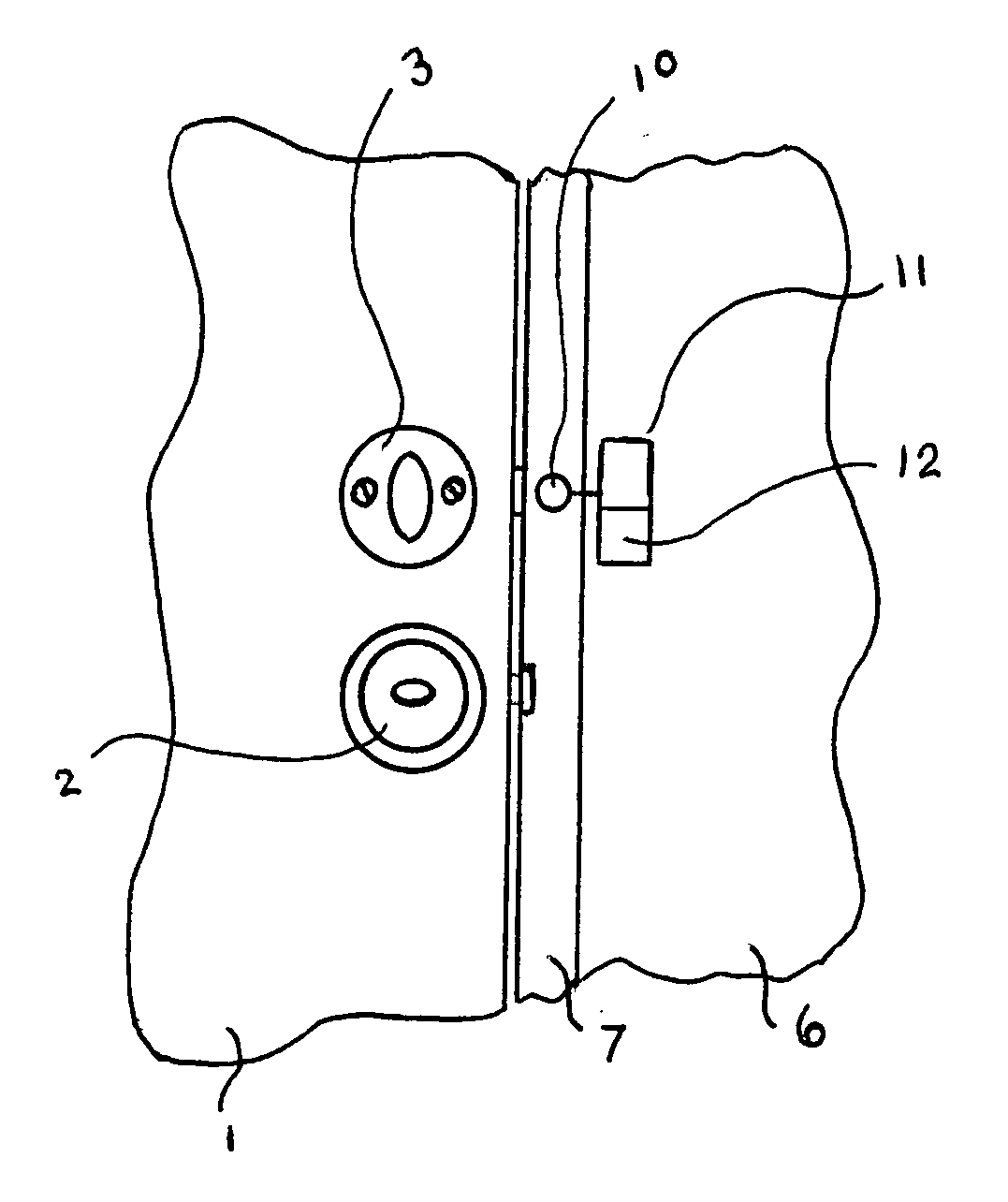

Low-cost switch sensor remote dead bolt status indicator

InactiveUS20100313612A1Prolong lifeEasy to replaceProgramme controlElectric signal transmission systemsHand heldTransmitter

A low-cost switch sensor remote dead bolt status indicator includes a switch sensor which starts a transmitter at a door lock location upon sensing of a dead bolt entering into a locked position. The transmitter is provided with a self shut-off feature operating after a fixed duration of minutes length has elapsed. The indicator also includes a receiver in a hand held unit, such as a key fob capable of receiving signals from the transmitter after the user presses an inquiry key on its surface. The hand held receiver having two indicators for alternately displaying the lock's dead bolt status as being locked or unlocked. In an alternate embodiment, the switch sensor is provided as an integral part bonded to the conventional manufactured metal strike plate dead bolt frame that is typically attached to the door jamb.

Owner:EICHENSTEIN JOSEPH

Apparatus and method for door and window head flashing

ActiveUS20050268569A1Avoid accumulationPrevent water intrusionRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringWindow Width

A window and door head flashing assembly is fabricated at a construction site to fit specific door or window widths. A center section which may be extruded with a sloped base, a rear flange, and a front lip. End caps may be provided to snap or glue on the center section. The end caps have a perpendicular fin which serves as an end dam to block the lateral movement of water. The assembly may be inverted for use as a sill pan. The center section may be cut to a desired length and installed over arched windows or doors by bending to shape as it is installed. For arched applications, a combination of rigid and flexible PVC may be coextruded to provide a desired cross sectional profile that is flexible enough to be bent around the arch, but stiff enough to retain its cross section for drainage.

Owner:TEODOROVICH MISHKO

Controlling bedbugs with synthetic pheromones and/or infrared radiation

Disclosed are methods for attracting and thereby controlling bedbugs. One volatizes a synthetic pheromone and generates infrared radiation adjacent the location and exposes bedbugs thereto. The pheromone volatizer and / or radiation generator are preferably incorporated into traps, bait stations and monitoring stations.

Owner:SILJANDER ERIC D +3

Apparatus and method for door and window head flashing

ActiveUS8561357B2BuildLow costRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringWindow Width

A universal flashing is provided for windows and doors. A head flashing assembly is fabricated at a construction site to fit specific door or window widths. A center section which may be extruded with a sloped base, a rear flange, and a front lip. End caps may be provided to snap or glue on the center section. The end caps have a perpendicular fin which serves as an end dam to block the lateral movement of water. The assembly may be inverted for use as a sill pan. The center section may be cut to a desired length and installed over arched windows or doors by bending to shape as it is installed. For arched applications, a combination of rigid and flexible PVC may be coextruded to provide a desired cross sectional profile that is flexible enough to be bent around the arch, but stiff enough to retain its cross section for drainage.

Owner:TEODOROVICH MISHKO

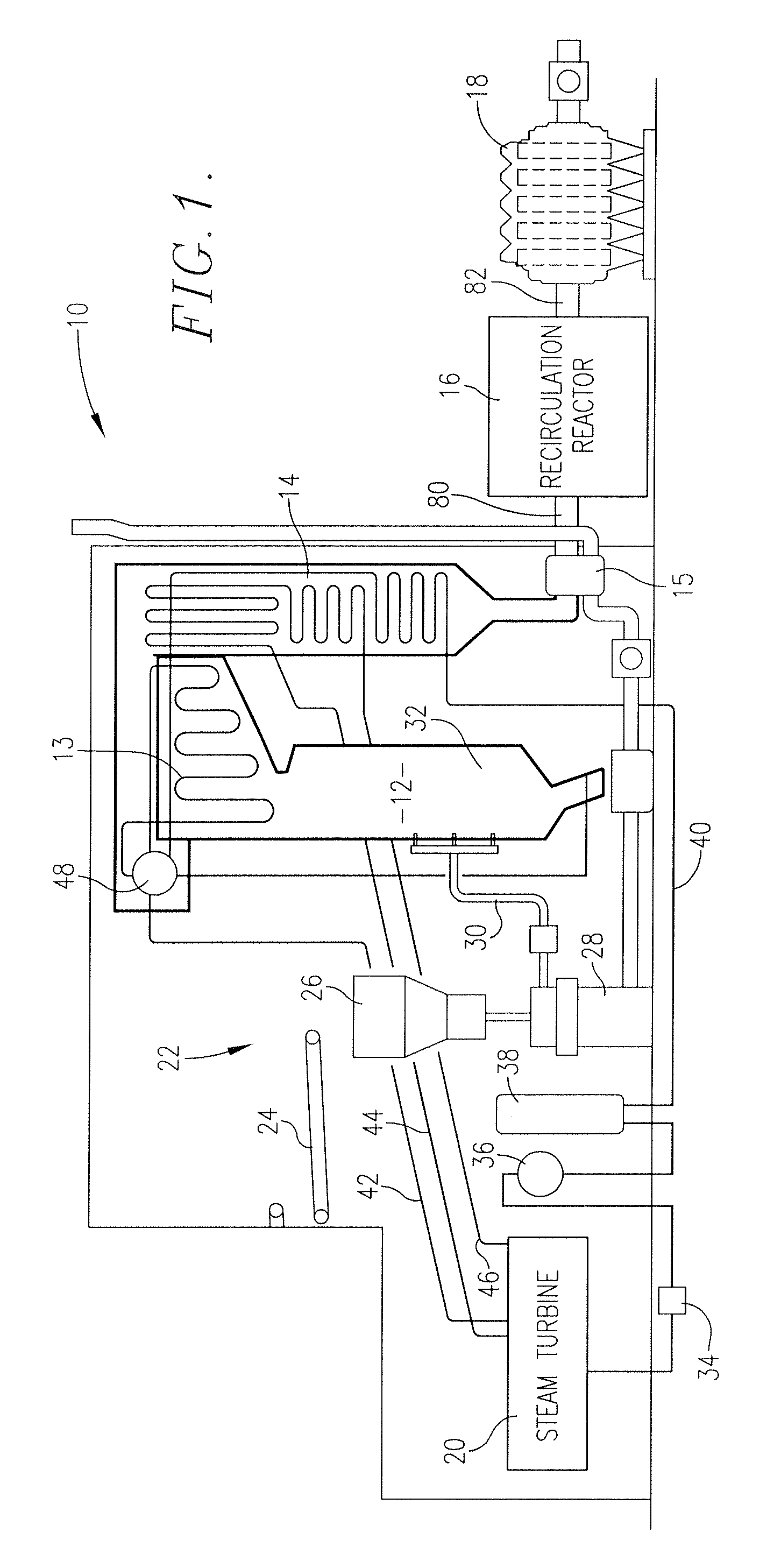

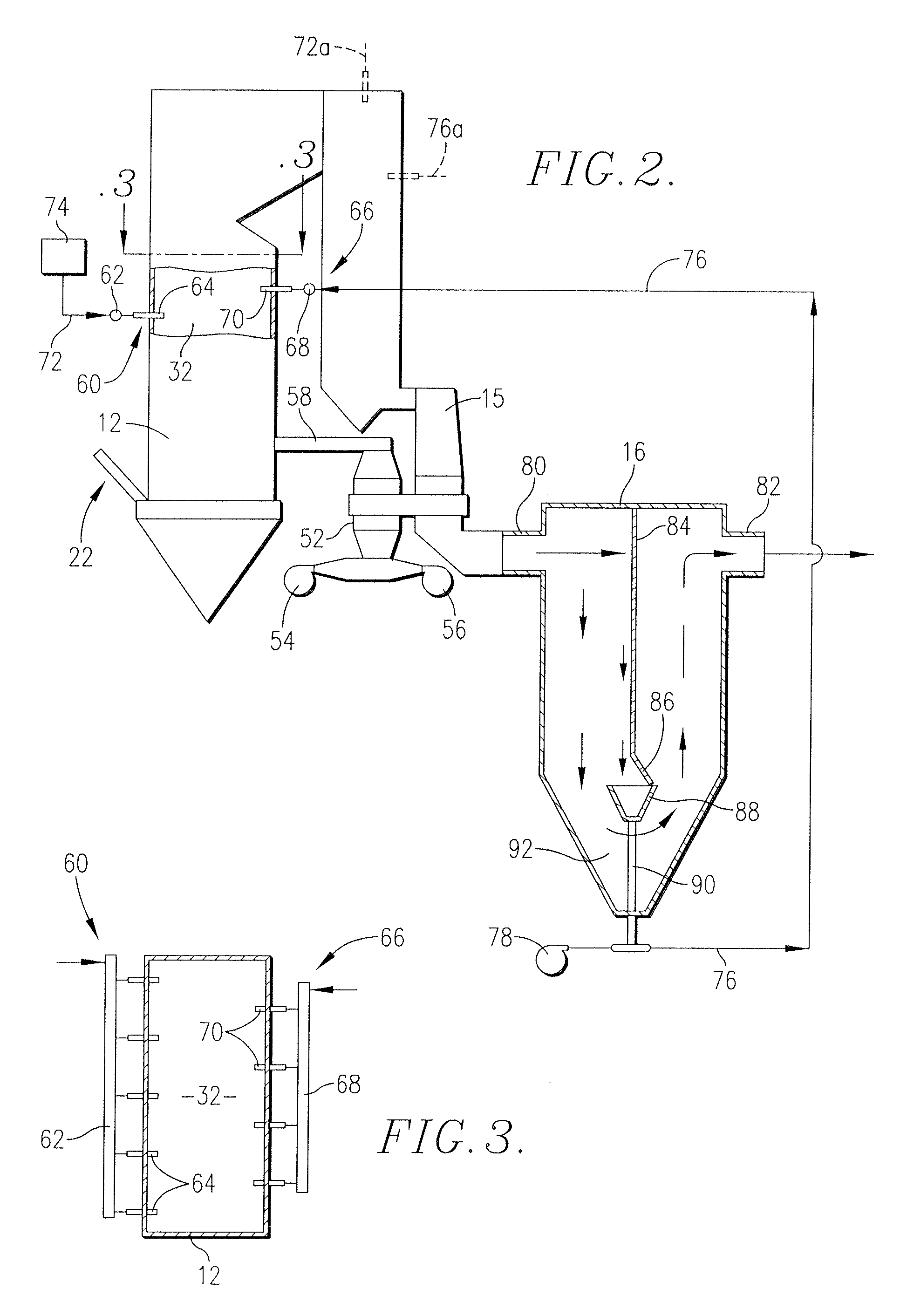

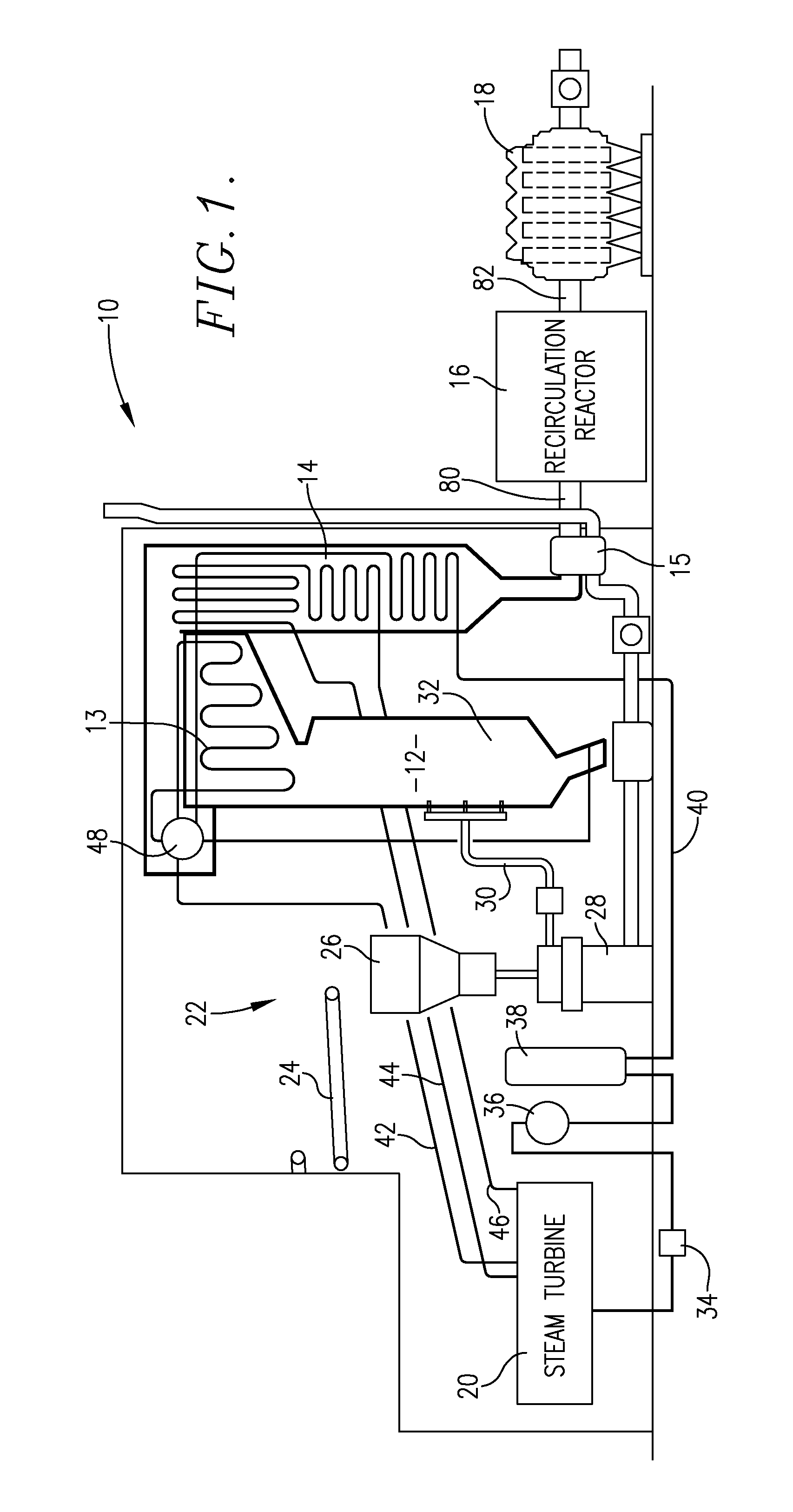

Pollution abatement process for fossil fuel-fired boilers

InactiveUS20100263577A1High degreeLow-cost operationGas treatmentSteam generation heating methodsParticulatesSodium bicarbonate

The present invention provides improved boiler assemblies (10) with enhanced pollution abatement properties through injection and recycling of particulate sorbent materials including sodium bicarbonate, trona, and mixtures thereof. The assemblies (10) include a boiler (12), economizer (14), air heater (15), and recirculation reactor (16). Fresh sorbent material is introduced via assembly (60) into the boiler assembly (10) at one or more injection locations, and serves to sorb NOx, SOx, and other pollutants in the flue gas. The flue gas and entrained sorbent material then pass through reactor (16) for separation of sorbent, which is then recycled for injection back into the assembly (10) upstream of reactor (16).The present invention can also be used in industrial applications where the same emissions are generated and are needed to be controlled. Examples of such applications are Cement and Lime Kilns.

Owner:INDAL ACCESSORIES

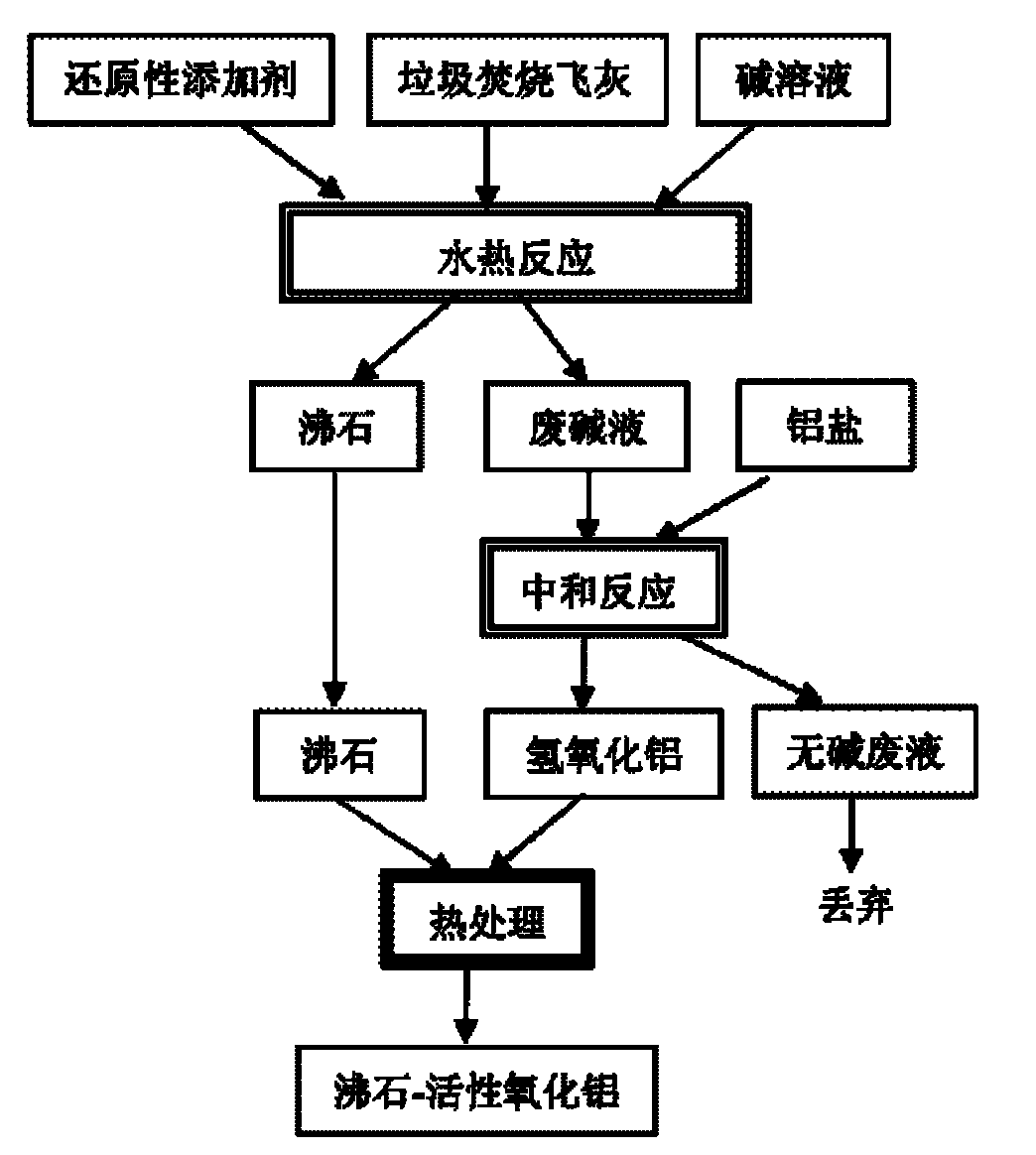

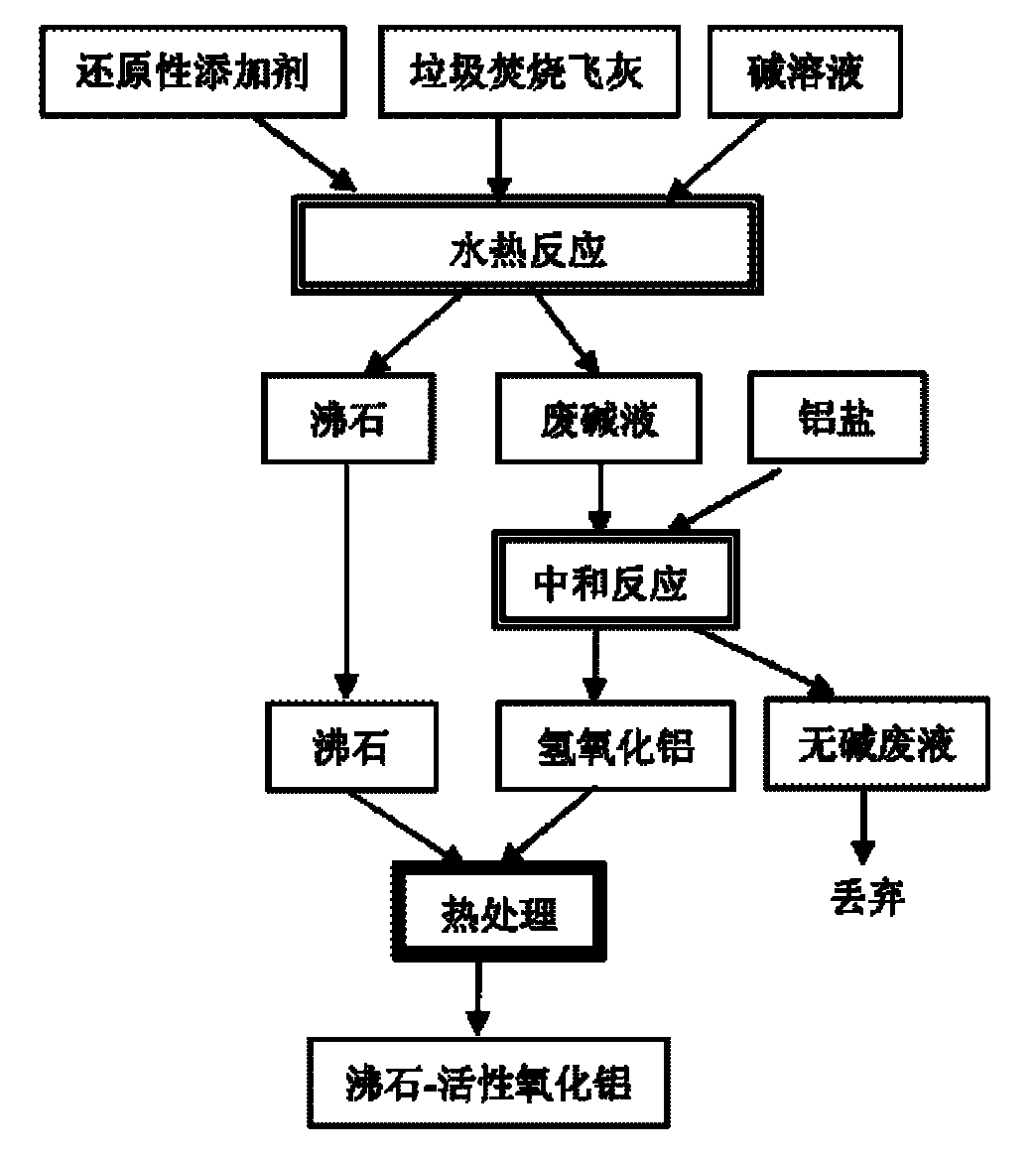

Heavy metal recycling method based on municipal solid waste incineration (MSWI) fly ash

InactiveCN102206757AWith resource recyclingAchieving harmlessnessOther chemical processesSolid waste disposalSorbentWater soluble

The invention relates to a heavy metal recycling method based on municipal solid waste incineration (MSWI) fly ash in the technical field of treatment for environmental protection. After an alkali solution and hydrazine substances are added to the MSWI fly ash and heated, and a water-soluble aluminum salt solution is further dripped; finally, after solid and liquid separation is conducted, heat treatment is carried out on an obtained solid phase to obtain a zeolite-active alumina compound absorbant; and the absorbant is put into sewage full of heavy metal to absorb and recycle the heavy metal. In the preparation process of the absorbant provided by the invention, dioxin in the MSWI fly ash is decomposed and removed; the MSWI fly ash is recycled as resources, and the heavy metal in the MSWI fly ash and the heavy metal in the sewage are recycled as the resources; and because the dioxin is decomposed and removed and the heavy metal is also extracted, the recycling method provided by the invention is safer and more reliable compared with the traditional treatment manner.

Owner:SHANGHAI JIAO TONG UNIV

Labelling Machine

InactiveUS20090160901A1Amount of ink can be minimizedQuantity minimizationTypewritersLabelling machinesLabelling machineInkjet printing

A labelling machine and a method of applying information onto containers and / or labels by means of an ink jet printer which has at least one print head with at least one nozzle and in the case of which a cover can selectively be moved to a position in front of the discharge opening of the nozzle so as to recirculate ink discharged from the nozzle into the ink circuit. The printer can also be operated during a printing pause whereby the ink is prevented from drying up in the print head.

Owner:KRONES AG

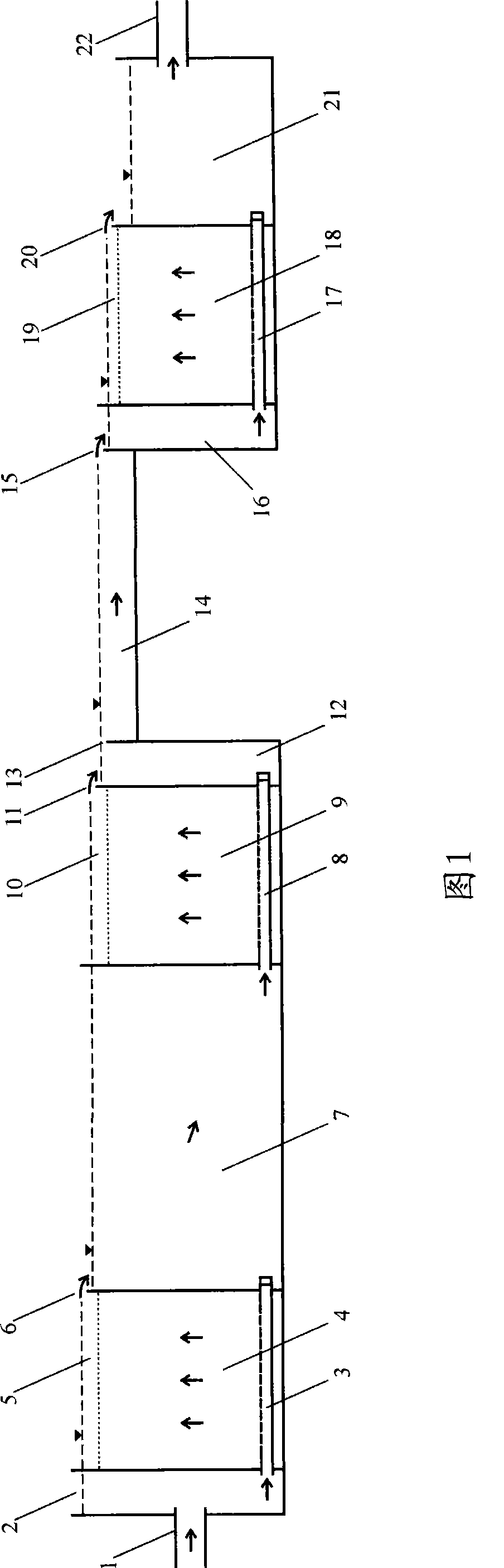

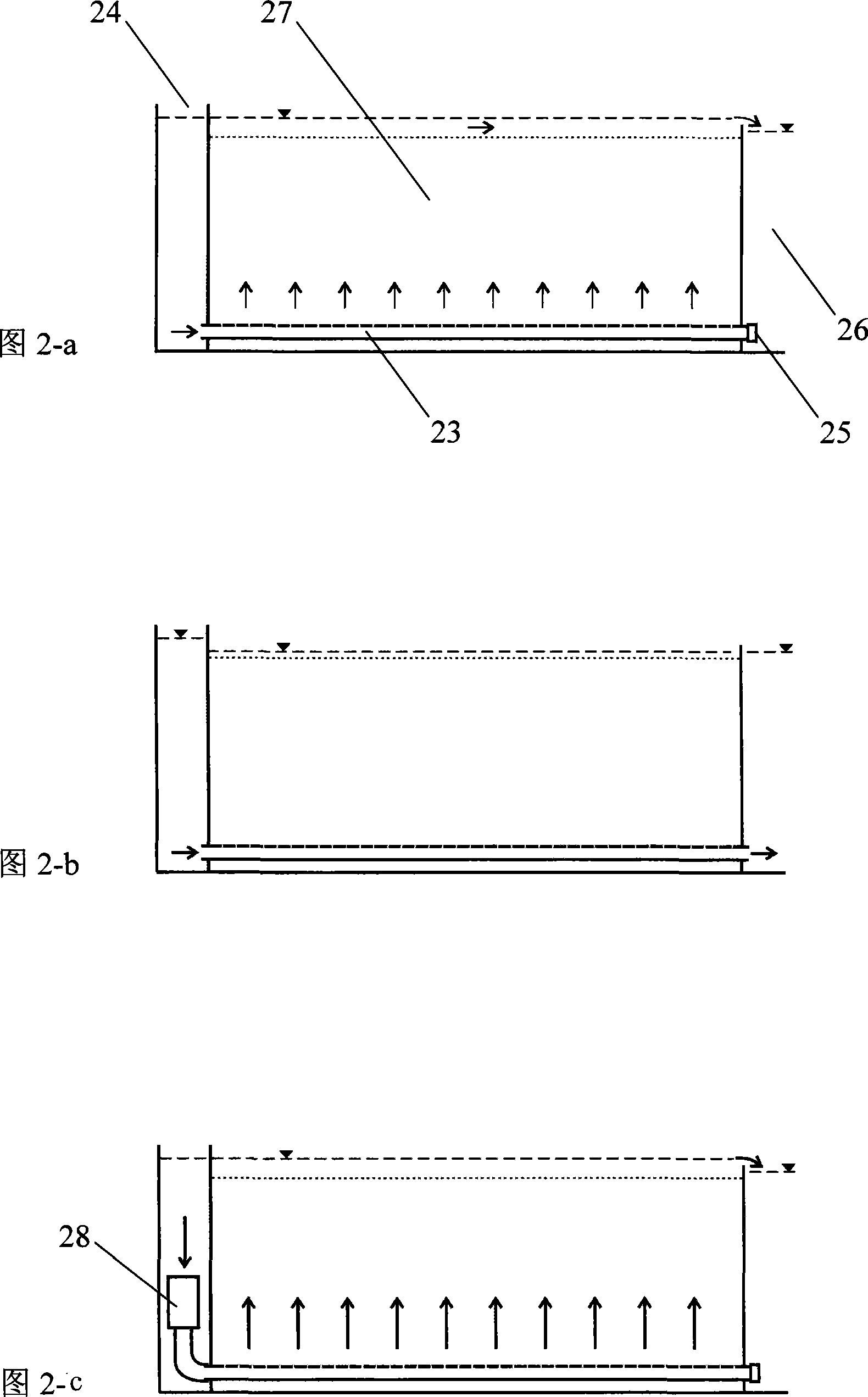

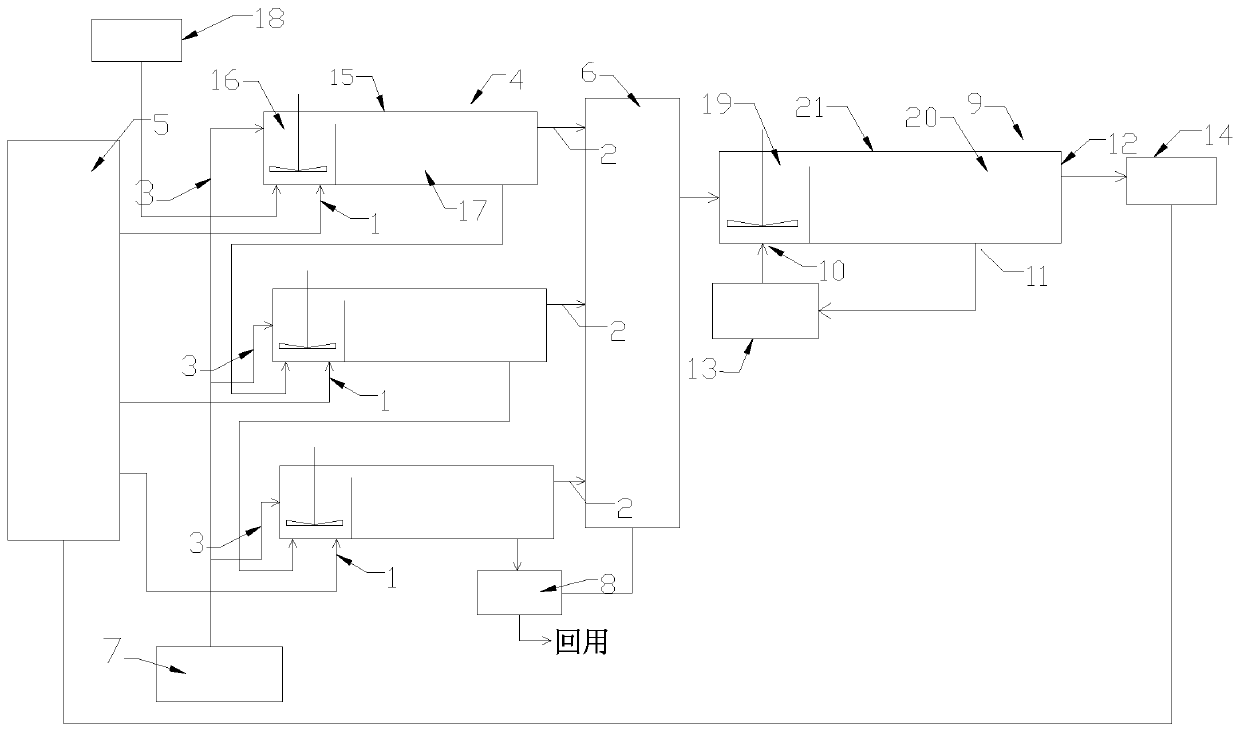

Wet land technique for deep purification of tail water of sewage plant

ActiveCN101412564ACreate living conditionsThe nitrification process went smoothlySustainable biological treatmentBiological water/sewage treatmentWater sourceHectare

The invention discloses a wetland process for deep purification of tail water of a sewage plant, which comprises the tail water of the sewage plant, a limestone filter pool, a submerged plant oxidation pond, a vertical-flow wetland, a surface-flow wetland, a composite substrate filter pool, an ecological reoxygenation pond and a receiving water body. The wetland process has the characteristics of efficient and ecological denitrification and dephosphorization, utilizes a water head with the height of about 0.5m to automatically flow, has the hydraulic load of 200mm / d, has no energy consumption and drug consumption, is anti-clogging, and can perpetually and steadily operate with low cost; the removal rate of nitrogen and phosphorus is higher than 95 percent, and the water quality of water output is superior to the GB3838-2002 ground surface class III water standard. The wetland process is suitable for the deep purification of the tail water of small sewage plants in cities and towns, and the treated output water can be recycled in water-deficient areas and can serve as a high-quality water source for the supply of water bodies of landscapes in the cities or residential areas. The process needs larger land area which can be merged into a whole with green areas and wetland parks of the cities. In the sewage plant of Eryuan county, Yunnan province, the process is utilized to build 2.2 hectares of wetland engineering for the deep purification of the tail water, the daily water treatment capacity is 4,000m<3>, the sewage plant has been steadily operated for 5 years, and the annual operation management cost is fifty thousand yuan.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Image forming apparatus, and control method and program for same

InactiveUS20070071477A1Improve performanceImprove system throughputElectrographic process apparatusImage formationProcess efficiency

An image forming apparatus, and a control method and program for same, whereby processing efficiency can be improved by permitting processing in respect of other print requests, even when paper has not been loaded in a manual paper supply unit after a manual print request has been made. When a print request relating to a prescribed paper is received, processing in respect of other print requests is permitted until it is detected that the prescribed paper has been loaded.

Owner:RICOH KK

Adaptive wind-air-light-heat energy optimization system and control method

ActiveCN105914863ASolve the unreasonable useSolve supply problemsSolar heating energyFluid heatersEngineeringOptimization system

The invention relates to an adaptive wind-air-light-heat energy optimization system and control method, and belongs to the field of building energy supply. The invention mainly aims at solving problems that the conventional energy-saving technology is not ideal and is not good in adaptability. The system comprises a wind power generator set, a photovoltaic power generator set, an electric heating water storage and energy storage device, a solar energy collector, an air source heat pump set, a control system, an energy acceptor system, and a building power supply system. The control method carries out the adjustment of indoor temperature, power generation and heat storage. The adjustment of indoor temperature is carried out through collecting the indoor and outdoor temperatures and judging the starting of a heat supply system or a cooling system; The adjustment of a power generation system is carried out through the following steps: collecting the weather condition of a geographic position where a building is located, judging the user type of the building, judging whether time is a peak moment or not, and carrying out power storage or power supply. The adjustment of a heat storage system is carried out through the following steps: collecting the pressure value and temperature value of the heat storage system, comparing the pressure value and the temperature value with set values, and controlling the starting of the heat storage system, the air source heat pump set, or the hot water system according to a comparison result.

Owner:NORTHEASTERN UNIV

Method for releasing biological toxicity of mixed acid nitrified wastewater

ActiveCN101531430AImprove stabilityReduce the concentration of toxic and harmful substancesMultistage water/sewage treatmentNature of treatment waterHigh concentrationNitrobenzene

The invention discloses a method for releasing biological toxicity of mixed acid nitrified wastewater, and belongs to the technical field of organic chemical wastewater treatment. The method comprises the following three steps: (1) zero-valent iron reaction, namely introducing high-concentration mixed acid nitrified wastewater into a reactor to carry out reduction reaction with zero-valent iron in the reactor; (2) advanced oxidation, namely adding oxidant into the wastewater subjected to the zero-valent iron reaction to carry out oxidation reaction under the condition of full mixing; and (3) coagulating sedimentation, namely adjusting the pH value of the oxidized wastewater to be weakly alkaline, adding coagulating agent into the wastewater to carry out full reaction and sedimentation, wherein the discharged water can flow into a biochemical system. The method can effectively reduce the biological toxicity of the wastewater to meet the requirement of subsequent biochemistry. By adopting the method, the removal rate of nitrobenzene and phenyl amine substances is more than 95 percent, the removal rate of COD is more than 50 percent, the BOD is improved by more than 80 percent, the ratio of B to D is improved to more than 0.4, and the biological toxicity is reduced greatly.

Owner:NANJING UNIV +1

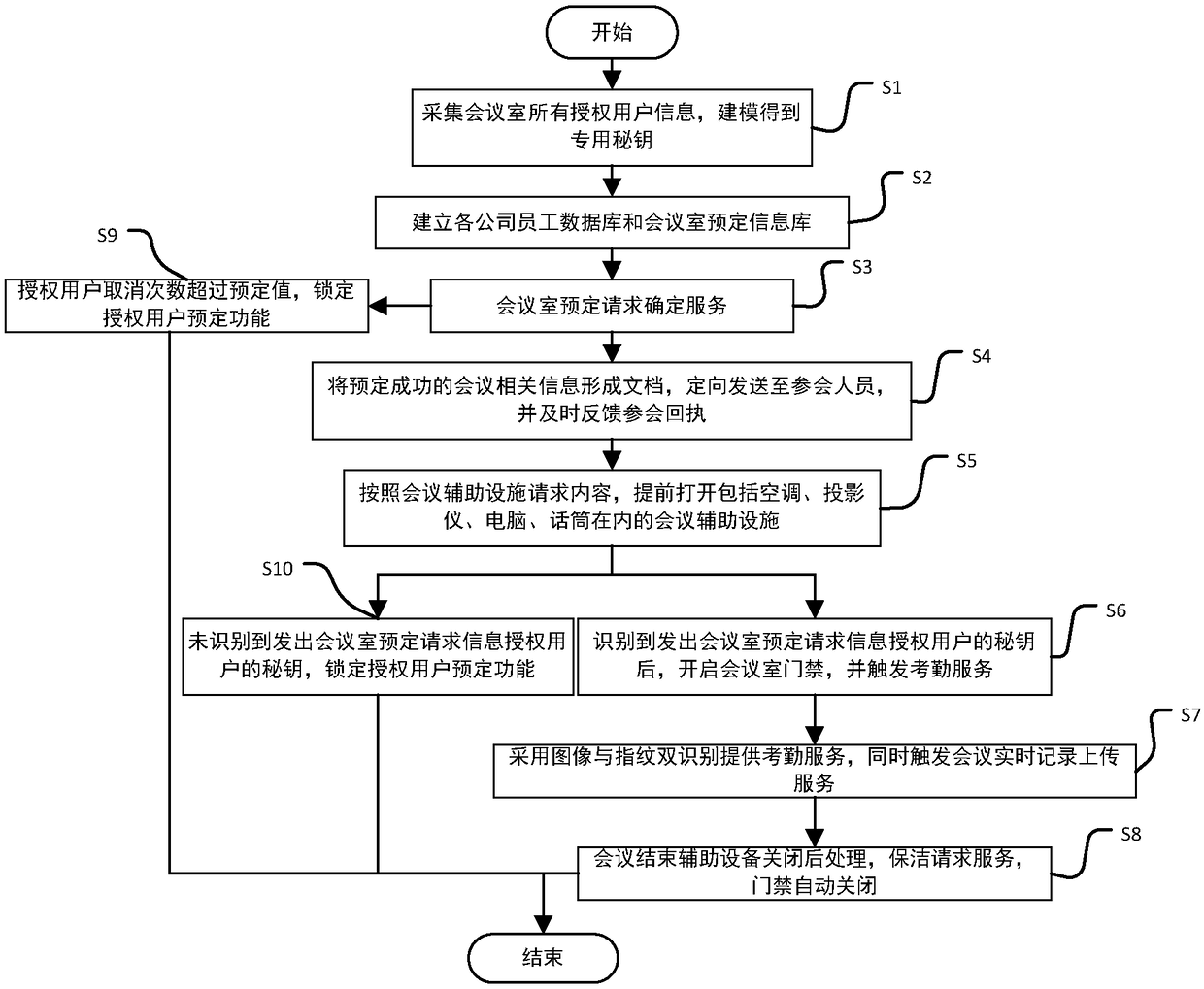

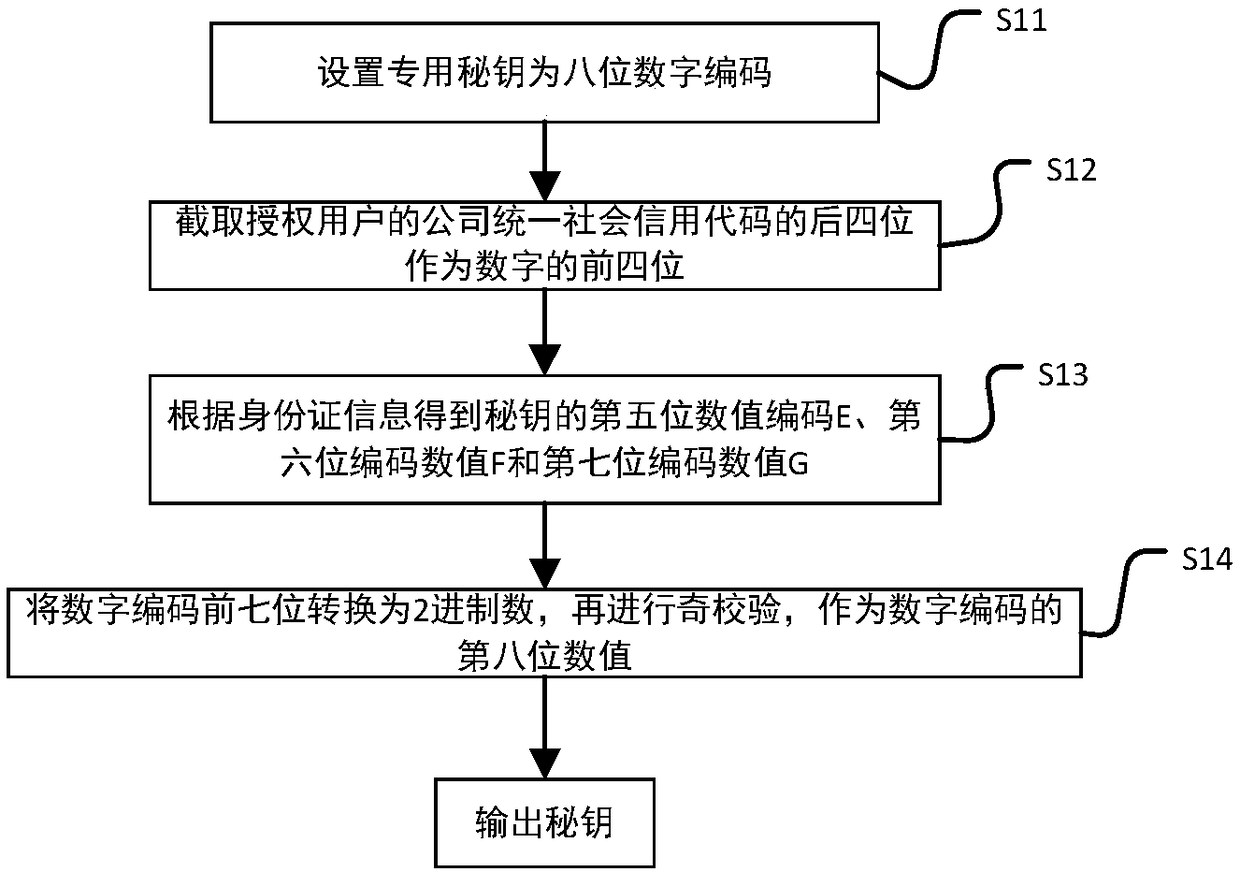

Intelligent conference control method and system

InactiveCN108846647AConvenient and fast bookingThe process is convenient and fastOffice automationData acquisitionComputer module

The invention discloses an intelligent conference control method and system. The method comprises acquisition of authorized user information, key generation, database establishment, conference room reservation request determination service, directional transmission of participant information, turn-on of conference auxiliary equipment, attendance service and conference end processing. The system comprises an authorized user data acquisition module, a key generation module, an employee data acquisition module, a conference room information acquisition module, a storage module, a conference roomreservation request determination service module, a conference determination information generation and transmission module, a conference room internal control module, a conference room access identification module, an attendance service module and a communication module. The method and the system can arrange conference proceedings accurately and efficiently, maximize the use of a conference room,reduce the labor intensity of manual registration schedules, conveniently and quickly handle the reservation and proceeding of various conferences, achieve automation and intelligence, realize the goal of unmanned management of the conference room, and have high practical value.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Ignition system and method for operating an ignition system

InactiveUS20160281673A1Cost-effectiveSimple mathematical operationInternal combustion piston enginesOther installationsVoltage generatorInternal combustion engine

A method is described for operating an ignition system for an internal combustion engine, including a primary voltage generator and a boost converter for maintaining a spark generated with the aid of the primary voltage generator. An ascertainment of a modified energy requirement for an ignition spark to be maintained with the aid of the boost converter is followed by a modification of a switch-on time of the boost converter relative to a switch-off time of the primary voltage generator.

Owner:ROBERT BOSCH GMBH

Pollution abatement process for fossil fuel-fired boilers

ActiveUS20110303133A1Requisite amount can be minimizedHigh degreeGas treatmentEmission preventionSodium bicarbonateParticulates

The present invention provides improved boiler assemblies (10) with enhanced pollution abatement properties through injection and recycling of particulate sorbent materials including sodium bicarbonate, trona, and mixtures thereof. The assemblies (10) include a boiler (12), economizer (14), air heater (15), and recirculation reactor (16).Fresh sorbent material is introduced via assembly (60) into the boiler assembly (10) at one or more injection locations, and serves to sorb NOX, SOX, and other pollutants in the flue gas. The flue gas and entrained sorbent material then pass through reactor (16) for separation of sorbent, which is then recycled for injection back into the assembly (10) upstream of reactor (16). In another aspect, the invention provides pollution abatement apparatus (110) and methods employing an upstream recirculation reactor (114), a supply of fresh sorbent (118), and a downstream collector (116). In the reactor (114), fresh sorbent reacts with incoming hot flue gas (112) to generate a reduced pollutant flue gas (128) and a solids fraction including reacted sorbent and pollutants, and unreacted sorbent. Recirculation apparatus (120) provided between the reactor outlet (126) and reactor (114) serves to generate a substantially constant mass or volume flow rate of the reactor solids fraction, which minimizes the use of fresh sorbent and maximizes the pollution abatement efficiency of the apparatus (110).

Owner:INDAL ACCESSORIES

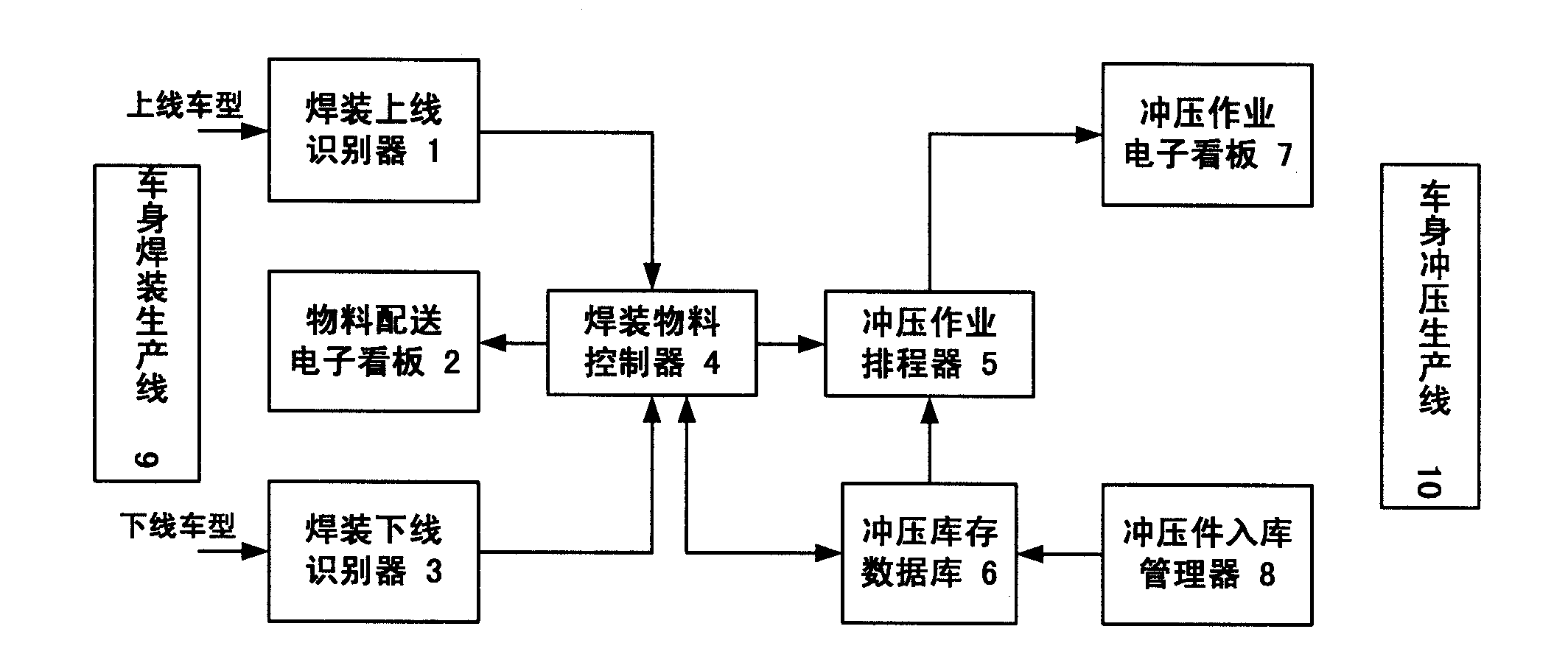

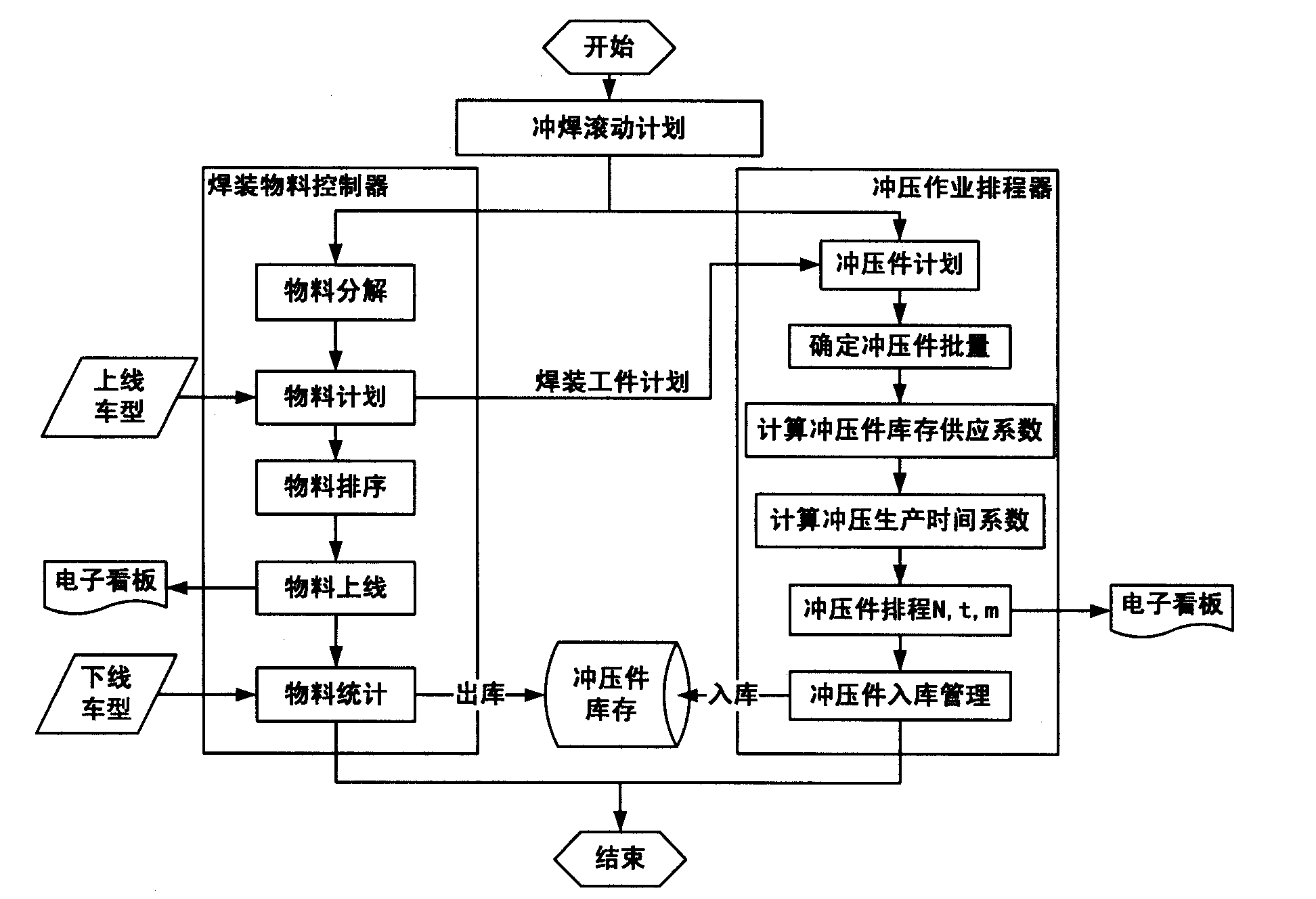

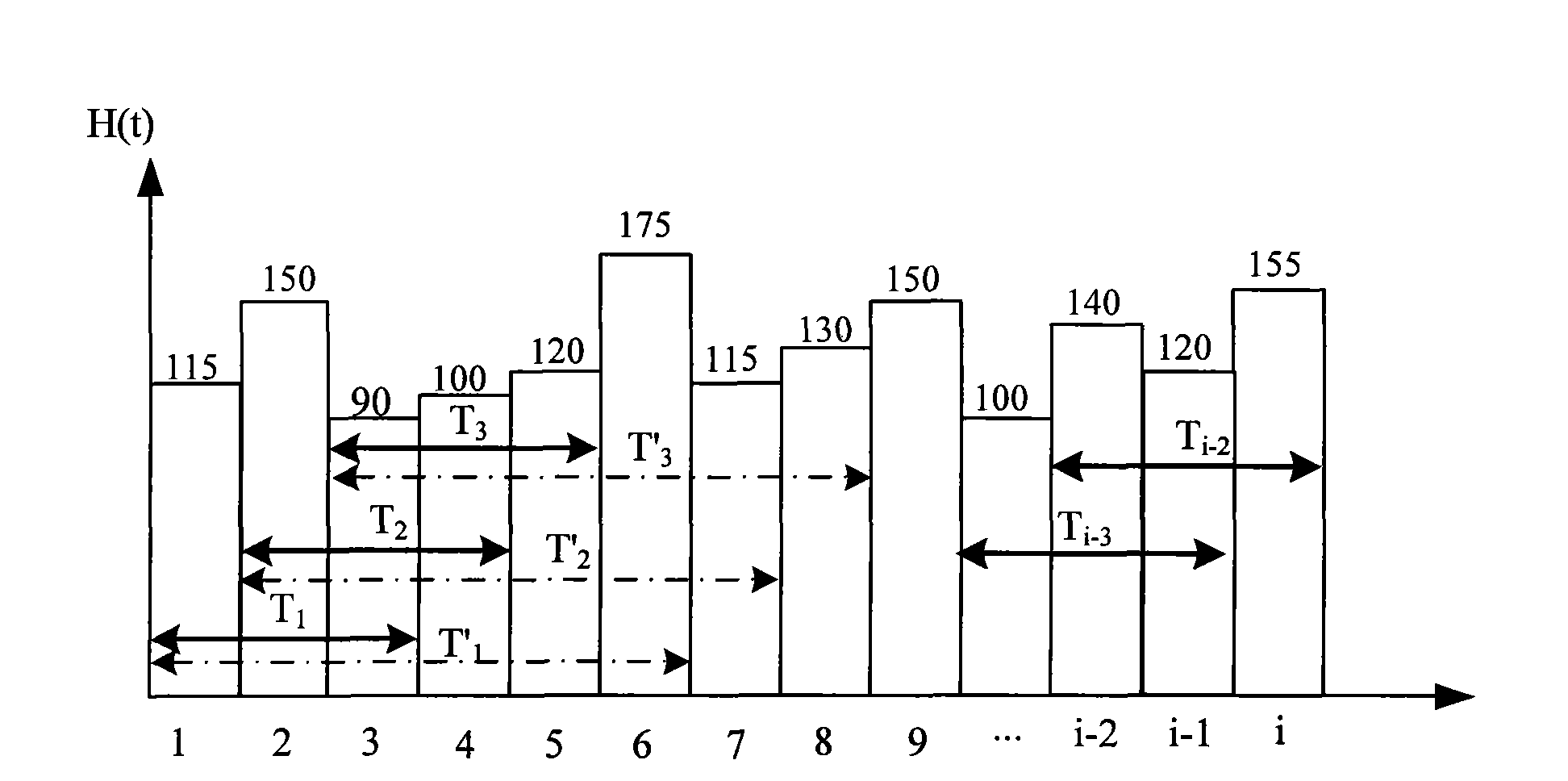

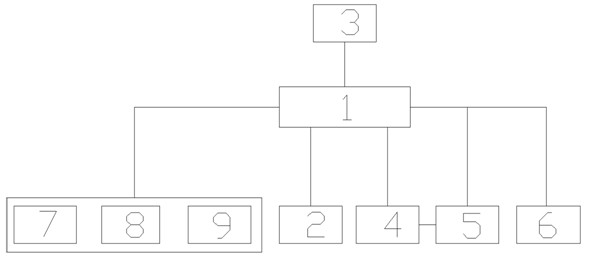

Vehicle body soldering, and drop forging shop work integration control system

InactiveCN101493693ADecrease stockGuaranteed timely supplyTotal factory controlProgramme total factory controlProduction lineRelevant information

The invention discloses an integrated control system of welding of car body and punching workshop operation; a welding material controller is connected with a welding upper and lower line recognizer so that the upper and lower line car body information of the welding production line is received; subsequently, the material decomposition is carried out according to the process material list corresponding to the car body; the material information required by welding production is generated; relevant information is sent to a material delivery electronic kanban; the welding material controller also sends the welding workpiece require plan to a punching operation scheduler; the data of the punching storage database is updated; the punching operation scheduler obtains the welding workpiece require plan from the welding material controller, obtains the punching part storage quantity from the punching storage database, carries out the scheduling control to the punching operation according to the welding rolling production plan, the welding workpiece require plan and the punching part storage, and updates the data of the punching storage database. The integrated control system of welding of car body and punching workshop operation realizes the running of the car body punching and welding production at high efficiency and low cost, reduces the storage and ensures smooth production with meeting the welding requirements.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and device of automatic control for sequencing batch type treatment process at non-DO state

InactiveCN102491507AEasy to expandPowerful Topology CapabilitiesSustainable biological treatmentBiological water/sewage treatmentAutomatic controlControl manner

The invention discloses a method and a device of automatic control for sequencing batch type treatment process at a non-DO state. Automatic control of the sequencing batch type treatment process independent of DO value is realized by steps: acquiring flow-in water quality parameter and water inlet quantity parameter in real time, transmitting the flow-in water quality parameter and water inlet quantity parameter and flow-out water quality parameter in the last period to an automatic aeration control device, and obtaining each parameter of the flow-in water treatment process after automatic computation of preset procedures of the automatic aeration control device. The acquired flow-in water quality parameter and the water inlet quantity parameter are combined with the flow-out water quality parameter in the last period to be used as main treatment parameters of the automatic control device to obtain ideal operating parameters, the DO value can be the designed value stably, and thereby the requirements of sewage treatment can be met while operating state of a fan can be more reasonable, energy consumption is reduced, the automatic control way can be independent of the DO state, and the problems of traditional control methods are avoided. Further, the automatic control method and a device for sequencing batch type treatment process at the non-DO state is evidently reduced in energy consumption and reduces more than 15%-35% of energy consumption as compared with the existing automatic control method.

Owner:西部水务集团(贵州)有限公司

Pollution abatement process for fossil fuel-fired boilers

ActiveUS8695516B2High degreeLow-cost operationGas treatmentEmission preventionParticulatesSodium bicarbonate

The present invention provides improved boiler assemblies (10) with enhanced pollution abatement properties through injection and recycling of particulate sorbent materials including sodium bicarbonate, trona, and mixtures thereof. The assemblies (10) include a boiler (12), economizer (14), air heater (15), and recirculation reactor (16). Fresh sorbent material is introduced via assembly (60) into the boiler assembly (10) at one or more injection locations, and serves to sorb NOx, SOx, and other pollutants in the flue gas. The flue gas and entrained sorbent material then pass through reactor (16) for separation of sorbent, which is then recycled for injection back into the assembly (10) upstream of reactor (16). In another aspect, the invention provides pollution abatement apparatus (110) and methods employing an upstream recirculation reactor (114), a supply of fresh sorbent (118), and a downstream collector (116). In the reactor (114), fresh sorbent reacts with incoming hot flue gas (112) to generate a reduced pollutant flue gas (128) and a solids fraction including reacted sorbent and pollutants, and unreacted sorbent. Recirculation apparatus (120) provided between the reactor outlet (126) and reactor (114) serves to generate a substantially constant mass or volume flow rate of the reactor solids fraction, which minimizes the use of fresh sorbent and maximizes the pollution abatement efficiency of the apparatus (110).

Owner:INDAL ACCESSORIES

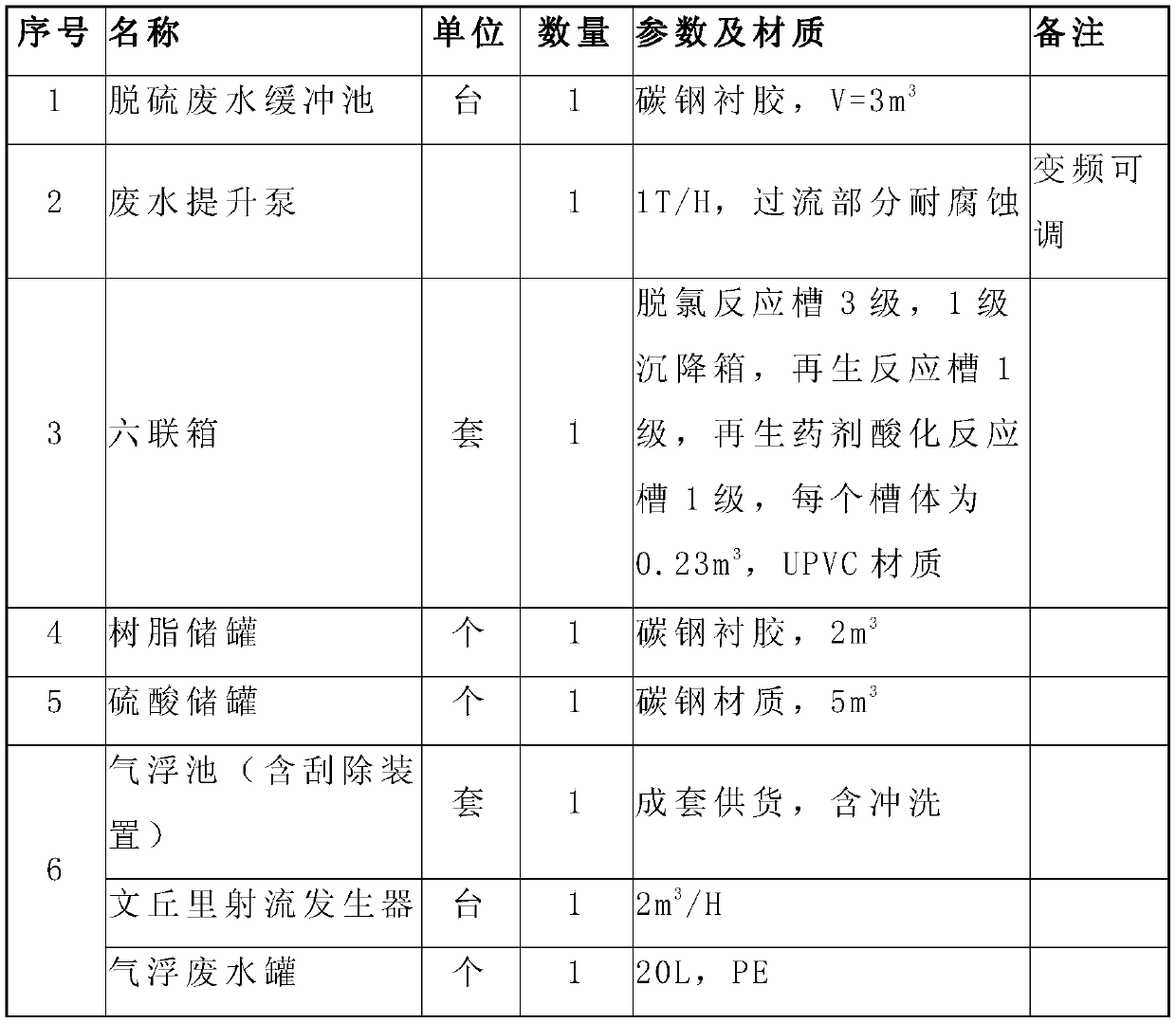

Desulfurization wastewater dechlorination treatment method and desulfurization wastewater treatment equipment

PendingCN110894113ASimple processFirmly connectedWater treatment parameter controlSpecific water treatment objectivesWater useProcess engineering

The invention discloses a desulfurization wastewater dechlorination treatment method and desulfurization wastewater treatment equipment. The method comprises the following steps: A, firstly, adding anacid into the desulfurization wastewater to adjust the pH value to 0.5-4, and then stirring and mixing with a liquid resin; B, separating an obtained mixture in a separation chamber; C, enabling theseparated liquid resin to enter a liquid resin buffer tank, and enabling separated desulfurization wastewater to enter a next-stage reactor for further treatment; and D, repeating the steps A, B and Cin the treatment process, removing the liquid resin dissolved in the water in an air floatation oil removal device, taking the desulfurization wastewater treated through air floatation treatment andpH adjustment as reuse water, and conveying the liquid resin brought out by bubble floatation into the liquid resin buffer tank. The method has the advantages that the equipment investment is small, the operation cost is low, the produced water after chloride ion removal can meet the industrial water recycling requirement, no waste is generated in the treatment process, real-time adsorption and real-time regeneration are achieved in the reaction process, 100% removal of chloride ions can be achieved, the whole process is continuously operated, waiting and time delay are not needed, and the production efficiency is high.

Owner:镇江泽润环境科技有限公司 +1

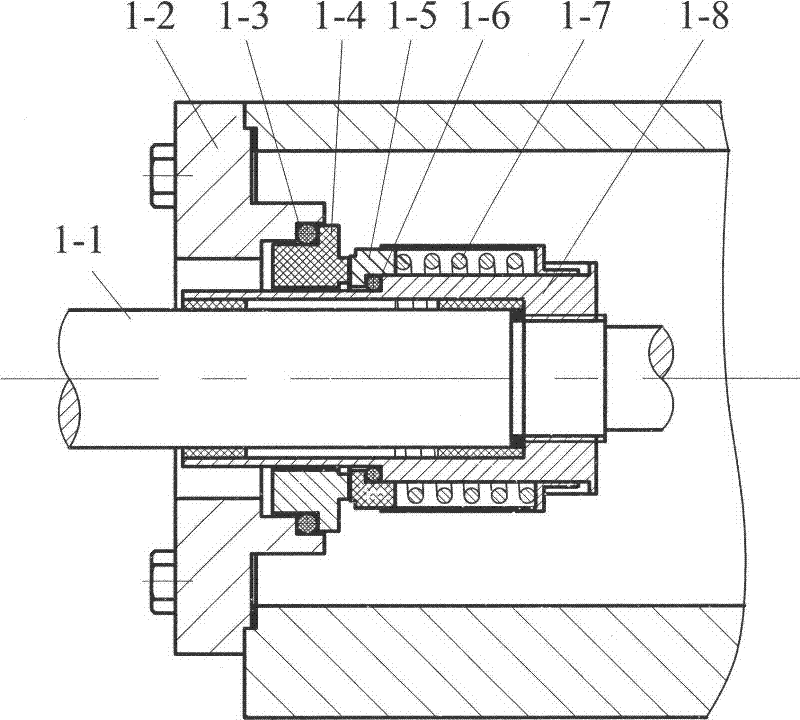

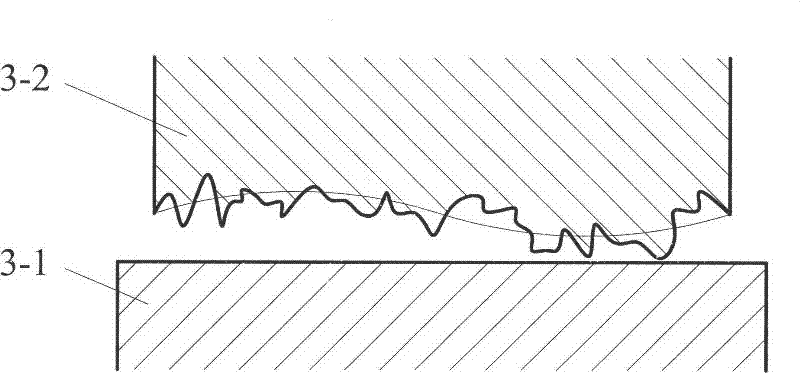

Prediction method of leakage rate of contact mechanical seal

ActiveCN102411669AGuarantee safety and reliabilityLow cost operationSpecial data processing applicationsEngineeringStress relaxation

The invention relates to a prediction technology of a leakage rate of an existing contact mechanical seal. By utilizing a seal interface topography evolvement rule in the wear process of a movable ring and a stationary ring, and a contact compression stress variation rule of primary and secondary seal interfaces due to the wear-down of the movable ring and the stationary ring and the stress relaxation of an O-shaped ring, the topography parameters of the seal interfaces and loads on the movable ring and the stationary ring seal interfaces, the O-shaped ring and the internal diameter and external diameter contact interfaces of the O-shaped ring are determined after the mechanical seal runs for a certain time, and the characteristic sizes of percolation channels between the movable ring and the stationary ring seal interfaces and the O-shaped ring and the internal diameter and external diameter contact interfaces of the O-shaped ring are obtained by a percolation theory, a contact mechanics theory and a fractal theory at the moment, the effect of surface tension and centrifugal force of the sealed medium is considered, and then the leakage state of the existing contact mechanical seal is predicated by a Navier-Stokes equation. The method is simple and practical, the accident problems caused by frequent replacement or expiration of the mechanical seal can be effectively solved, and the safety and reliability of equipment are improved.

Owner:NANJING FORESTRY UNIV

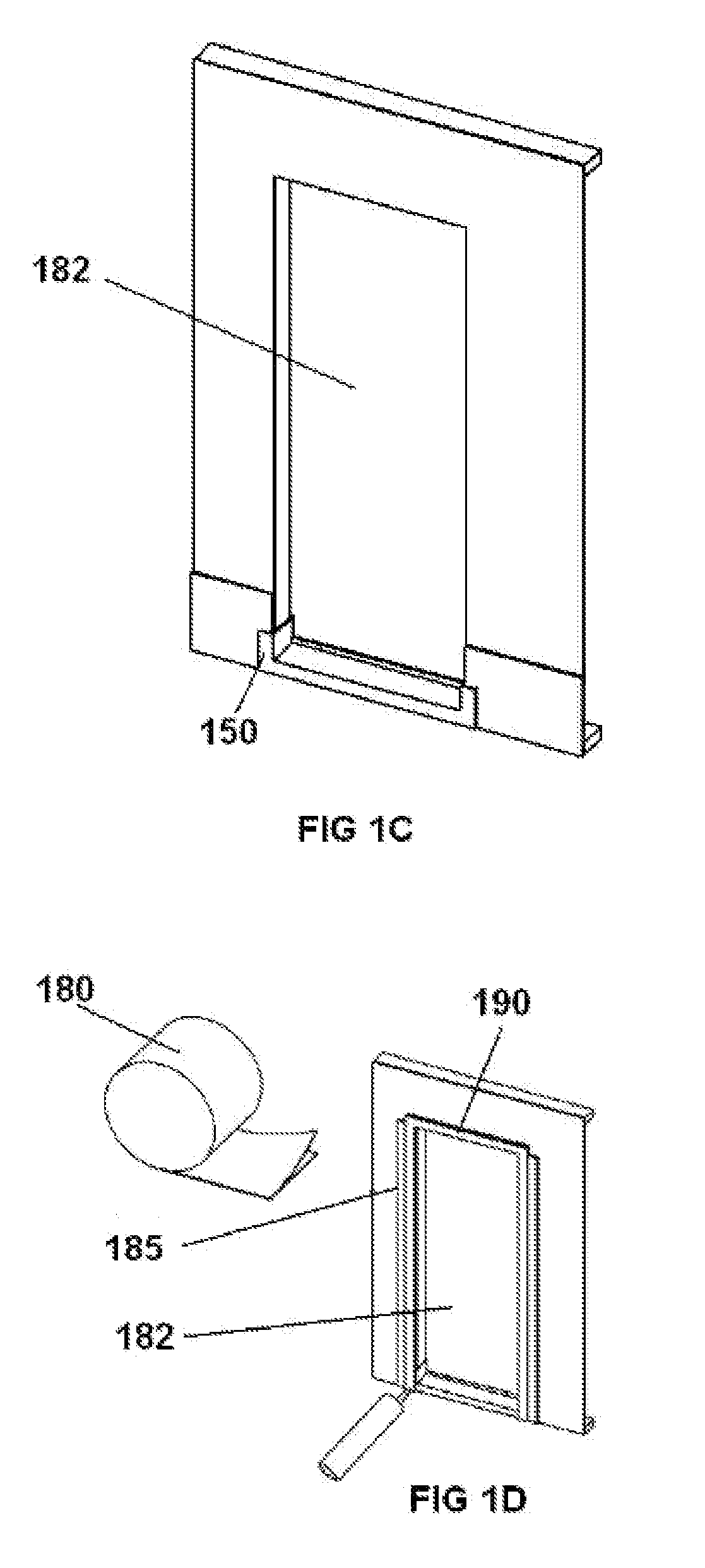

Apparatus and method for door and window head flashing

ActiveUS20100162634A1Avoid accumulationPrevent water intrusionRoof covering using slabs/sheetsConstruction materialEngineeringWindow Width

A universal flashing is provided for windows and doors. A head flashing assembly is fabricated at a construction site to fit specific door or window widths. A center section which may be extruded with a sloped base, a rear flange, and a front lip. End caps may be provided to snap or glue on the center section. The end caps have a perpendicular fin which serves as an end dam to block the lateral movement of water. The assembly may be inverted for use as a sill pan. The center section may be cut to a desired length and installed over arched windows or doors by bending to shape as it is installed. For arched applications, a combination of rigid and flexible PVC may be coextruded to provide a desired cross sectional profile that is flexible enough to be bent around the arch, but stiff enough to retain its cross section for drainage.

Owner:TEODOROVICH MISHKO

Monoterpene component-rich essential oil, method for producing same and method for remediating environmental pollutants using the essential oil

ActiveUS20120012002A1Efficient removalSmall sizeUsing liquid separation agentHydrocarbon purification/separationSteam distillationThinning

To develop a means for effectively utilize terpene compounds contained in tree leaves, whereby branches and leaves cut in tree thinning and pruning can be effectively utilized as a resource. For this purpose, provided are a monoterpene component-rich essential oil containing 90% or more of monoterpene components; a method for producing the monoterpene component-rich essential oil which includes subjecting coniferous leaves to microwave steam distillation and collecting a distillate thus obtained; and a method for removing environmental pollutants which includes bringing the monoterpene component-rich essential oil into contact with atmosphere containing the environmental pollutants.

Owner:S T CORP

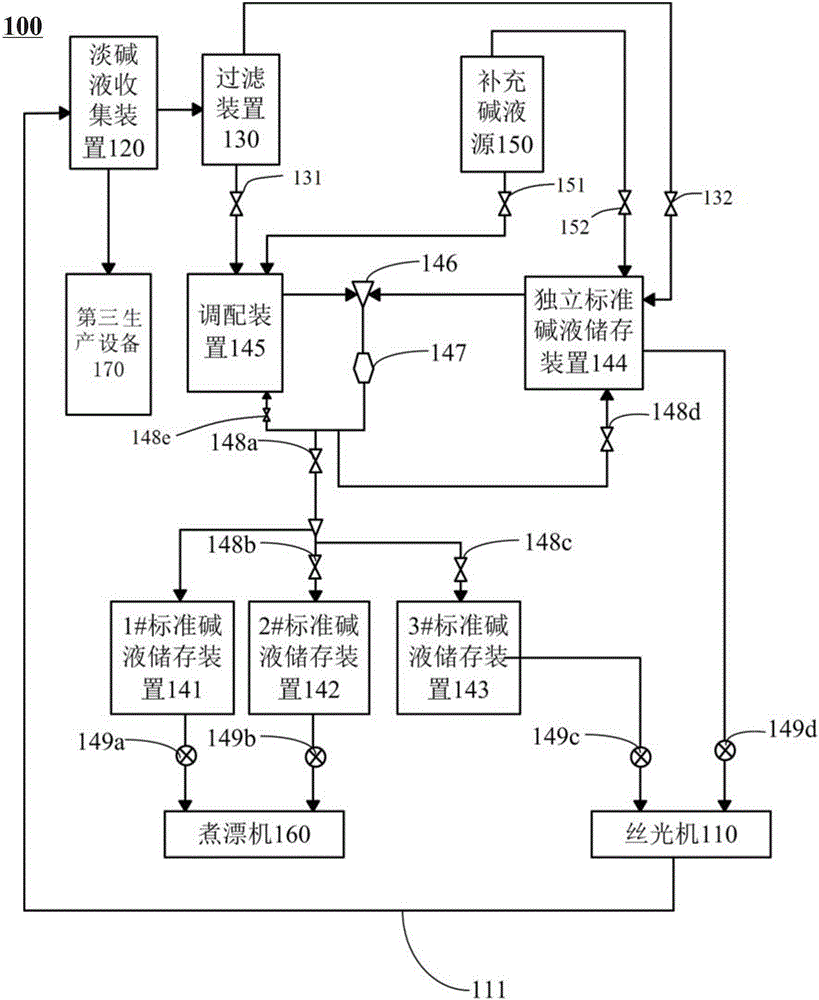

An alkali liquor control system

ActiveCN106120221ARealize cost operationLow cost operationTextile treatment machine arrangementsChemistryWhole systems

Owner:江苏欧化纺织有限公司

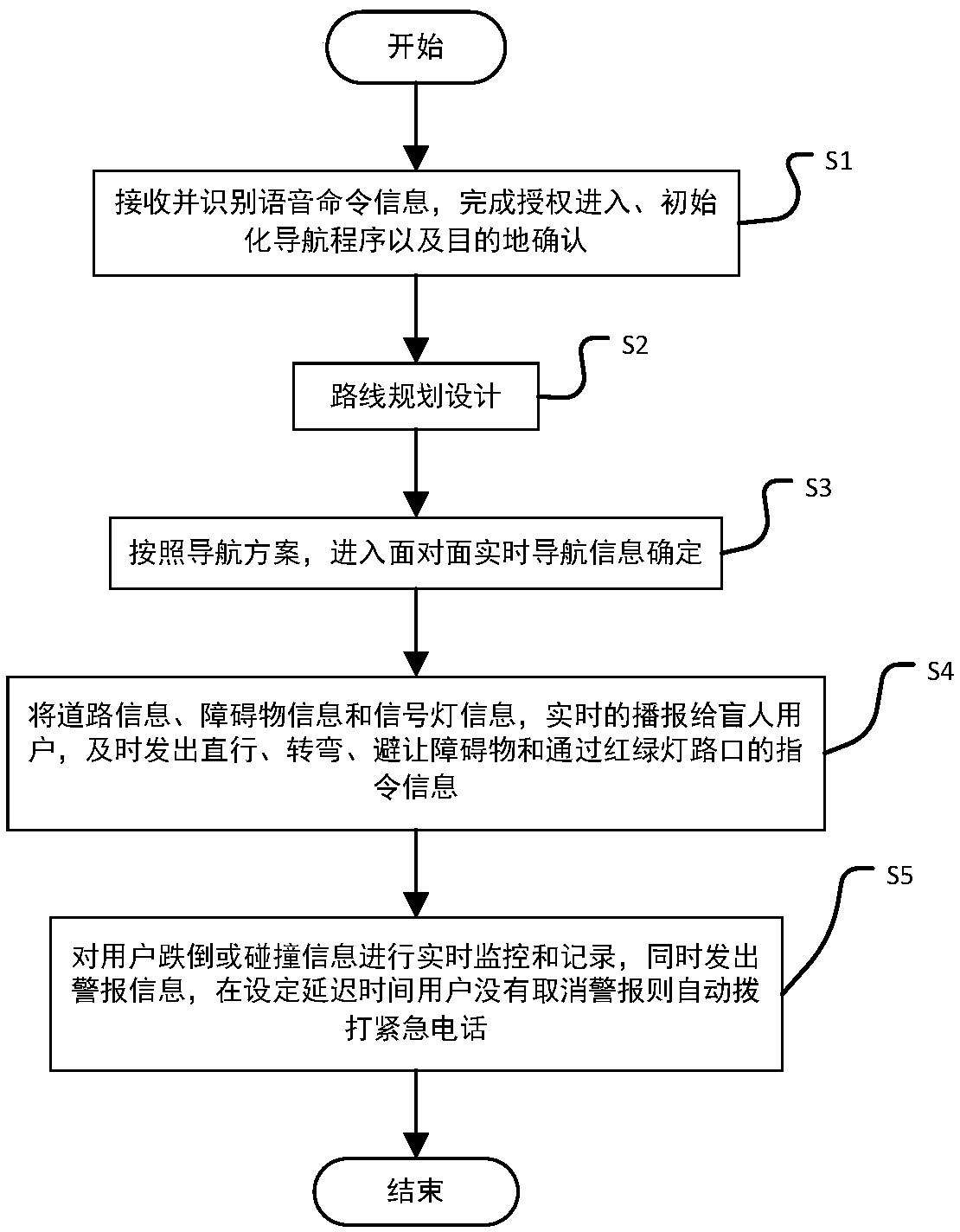

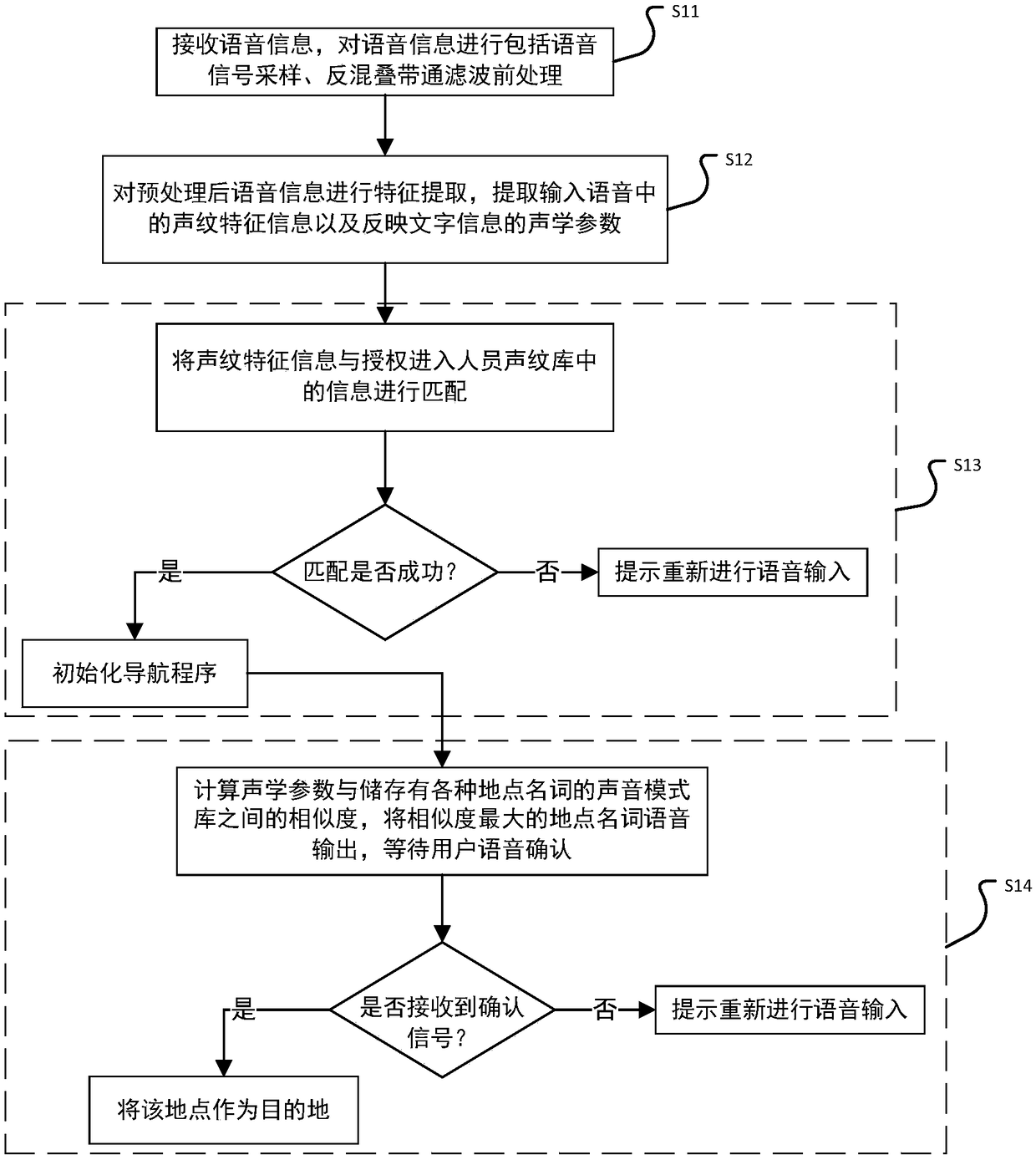

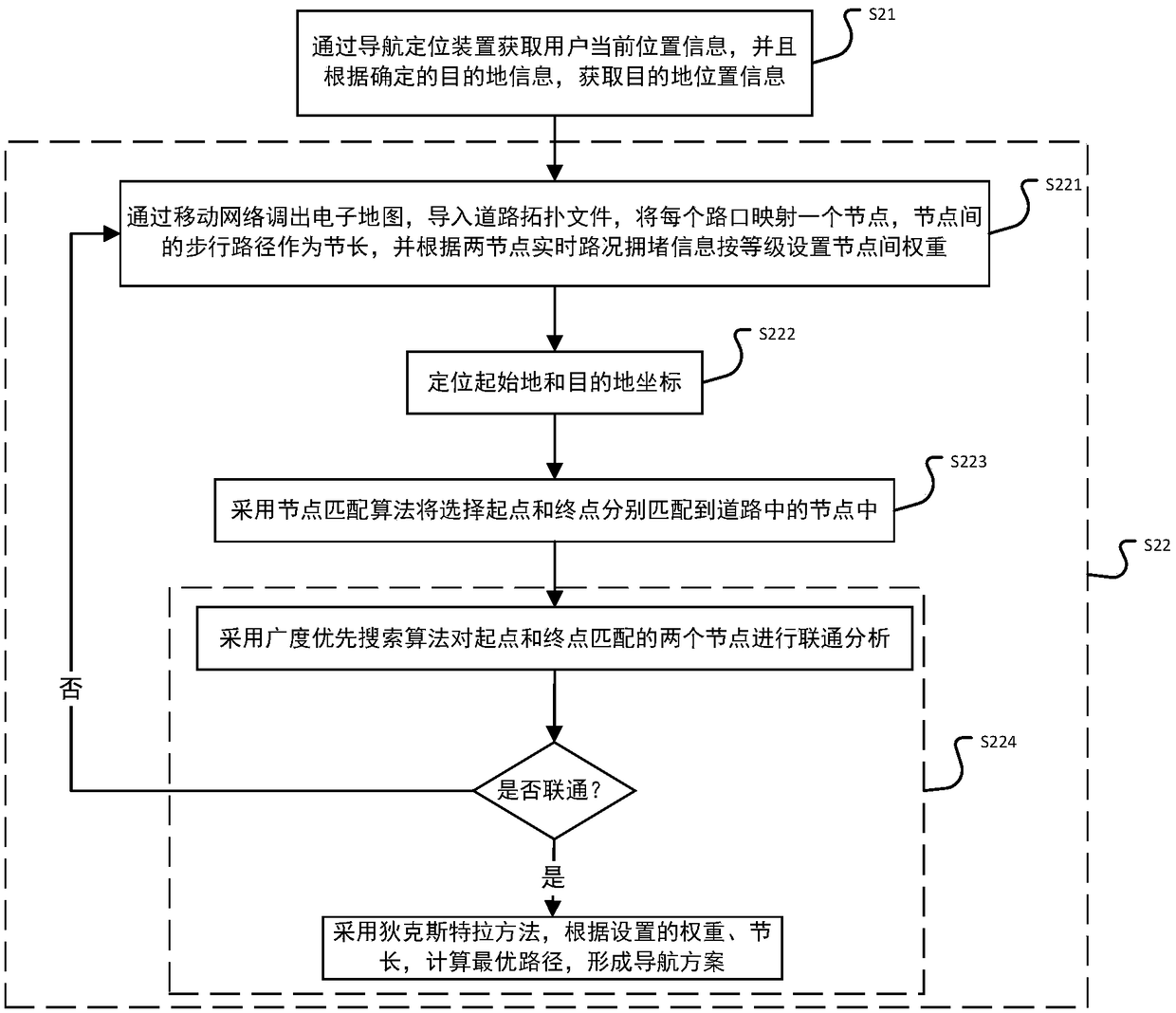

Intelligent navigation method and intelligent navigation system for traffic safety monitoring for the blind

InactiveCN109059920ATimely, efficient and accurate travelComprehensive and effective active navigationNavigational calculation instrumentsInformation transmissionReal time navigation

The invention discloses an intelligent navigation method and system for traffic safety monitoring for the blind. The method comprises the steps such as voice collection and analysis, route planning design, real-time navigation information determination, and timely navigation broadcast. The system comprises a storage module, a voice collection module, a voice data processing module, a positioning device module, a communication module, a route design determination algorithm module, a real-time navigation information determination module, and an information transmission broadcast module. The invention is stable and reliable, good in anti-interference performance and wide in application range, can conveniently and timely guide the blind to travel in a complex environment, and has the advantages such as high system intelligence, advanced method and safe and accurate travel route, which greatly improves freedom of movement of the blind, and the advantages of practicability and realizability,and high practical value and broad application prospects.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

Optimal tracking method and system for automatic identification image of remote education teacher

InactiveCN108876672AAccurate extractionGuaranteed accuracy and validityData processing applicationsCharacter and pattern recognitionData compressionData modeling

The invention discloses an optimal tracking method and system for an automatic identification image of a remote education teacher. The method comprises the following steps of video data acquisition, target framing, foreground extraction target identification, adjustment parameter determination, video simplified compression and the like; the system comprises a video acquisition module, a storage module, a teacher target framing processing module, a foreground extraction module, a data modeling module, a pixel classification module, a teacher target generation module, a position calibration module, an adjustment parameter generation module, a video data compression processing module and a communication module. According to the method and the system, a teacher target in a video image can be accurately extracted, the acquisition angle and the direction of a video are synchronously adjusted according to the movement of the target, and the image of the teacher target can be clearly and completely acquired all the time, so that the data volume in the video transmission is reduced, the accurate effectiveness of the teacher target information is ensured, and the higher practical value and the wide application prospect are provided.

Owner:HEFEI SIBOT SOFTWARE DEV CO LTD

Security monitoring dynamic target optimization locked tracking method and system

InactiveCN108805073AAccurate extractionGuaranteed accuracy and validityTelevision system detailsImage analysisData compressionHuman body

The invention discloses a security monitoring dynamic target optimization locked tracking method and system. The method comprises the steps of collecting video data, framing a target, identifying a foreground extraction target, determining an adjusting parameter, and simplifying and compressing the video; the system comprises a video collection module, a storage module, a human body target framingprocessing module, a foreground extraction module, a data modelling module, a pixel classification module, a human body target generation module, a location calibration module, an adjusting parametergeneration module, a video data compressing processing module and a communication module. Through the tracking method and system disclosed by the invention, the human body target in the video image can be accurately extracted, and the collection angle and direction of the video can be synchronously adjusted according to the movement of the target, thereby clearly and completely collecting the human body target image at any time; the data size in the video transmission is reduced, and the accurate effectiveness of the human body target information is guaranteed; and the method and system havehigh practical value and extensive application prospect.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Multifunctional foaming system used in air foam flooding

The invention discloses a multifunctional foaming system used in air foam flooding, relates to the technical field of oilfield development and is used for increasing oil recovery efficiency. The multifunctional foaming system is composed of following components, by weight: 0.1-0.5% of fatty alcohol polyoxyethylene ether sodium sulphate, 0.05-0.2% of silicon resin polyether emulsion, 0.05-0.2% of anionic polyacrylamide, 0.5-2% of molasses, 0.01-0.1% of yeast extraction, 0.0005-0.005% of ferrous sulfate, 0.00005-0.0002% of manganese sulfate, 0.05-0.5% of sodium nitrate and the balanced being water. The sum of weight percentages of all components is 100%. The multifunctional foaming system can solve a problem of requirements of a ground oxygen reducing apparatus and the profile control for plugging gas passages during conventional air foam flooding construction, and can enable the air foam flooding to be safe, more high-efficient and more low-cost.

Owner:SOUTHWEST PETROLEUM UNIV

Technology and system for removing dust and sulfur by using coal ash

InactiveCN103599691AAchieve emission standardsAchieve recyclingSolid waste disposalDispersed particle separationChemical reactionSurface-active agents

The invention discloses a technology for removing dust and sulfur by using coal ash. The technology mainly comprises the following steps: (1) leading flue gas with the coal ash, which is generated after burning, into a cyclone dust collector, wherein the coal ash mainly comprises glass bead bodies, spongy porous particles and calcium oxide powder; (2) separating the glass bead bodies and the spongy porous particles adsorbing SO2, which are contained in the flue gas, from the flue gas by using the cyclone dust collector; and (3) feeding the flue gas sent out from the cyclone dust collector into a desulfurizing tower, so that the flue gas and a water circulating liquid containing a surface active agent are subjected to physical and chemical reactions so as to realize the removal of sulfur in the flue gas. The system for removing dust and sulfur by using coal ash comprises the cyclone dust collector, the desulfurizing tower and a circulating pool. The removal of sulfur in the flue gas is realized by using activating oxides contained in the flue gas through the related physical and chemical reactions, so that the up-to-standard release of the treated clean flue gas is realized. The whole technological process is concise, extremely reasonable and optimal; and the desulfurized coal ash can be reused, so that the comprehensive cyclic utilization of the coal ash is realized, and the utility value of the coal ash is fully exerted.

Owner:JINJIANG MEICHUANG ENVIRONMENTAL PROTECTION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com