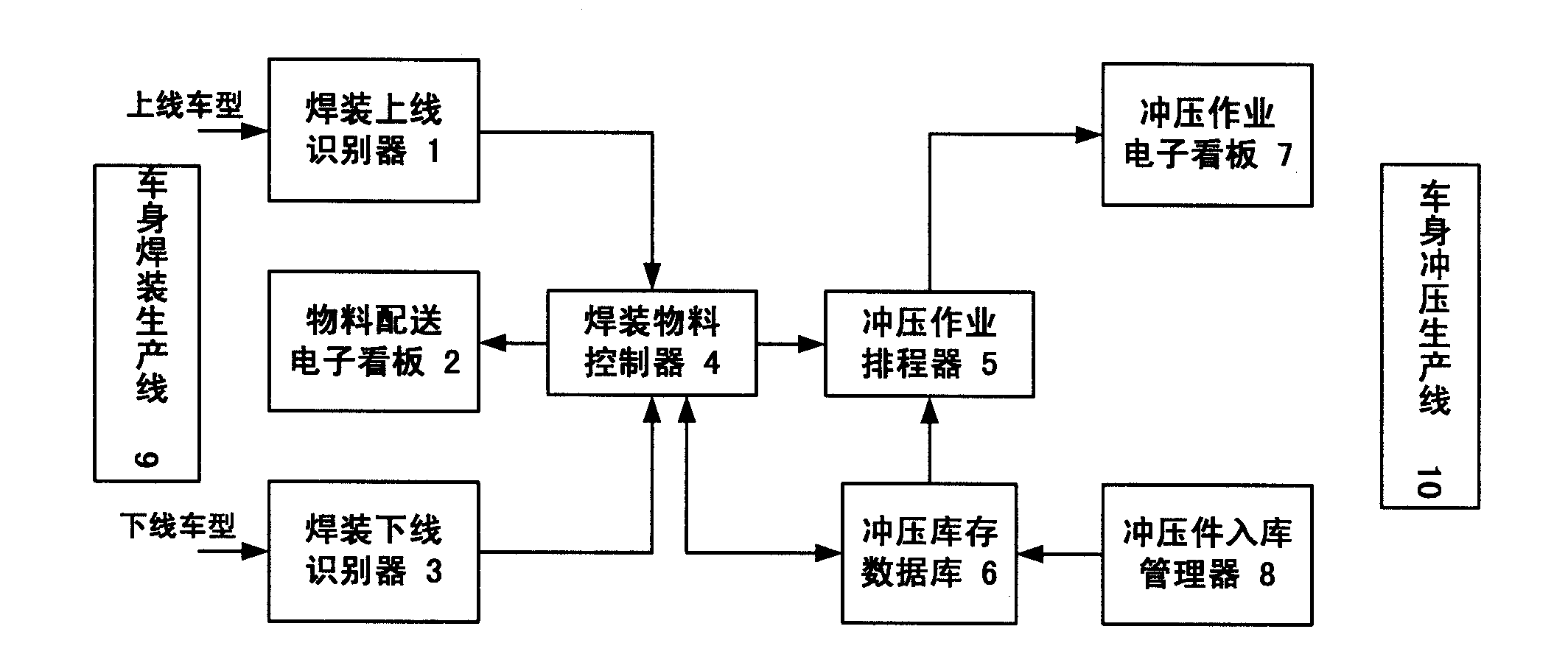

Vehicle body soldering, and drop forging shop work integration control system

A technology of integrated control system and stamping workshop, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problems of lack of materials and materials, difficult production scheduling, excessive production, etc. for body welding, so as to ensure timely The effect of supply, ensuring smooth production and reducing inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

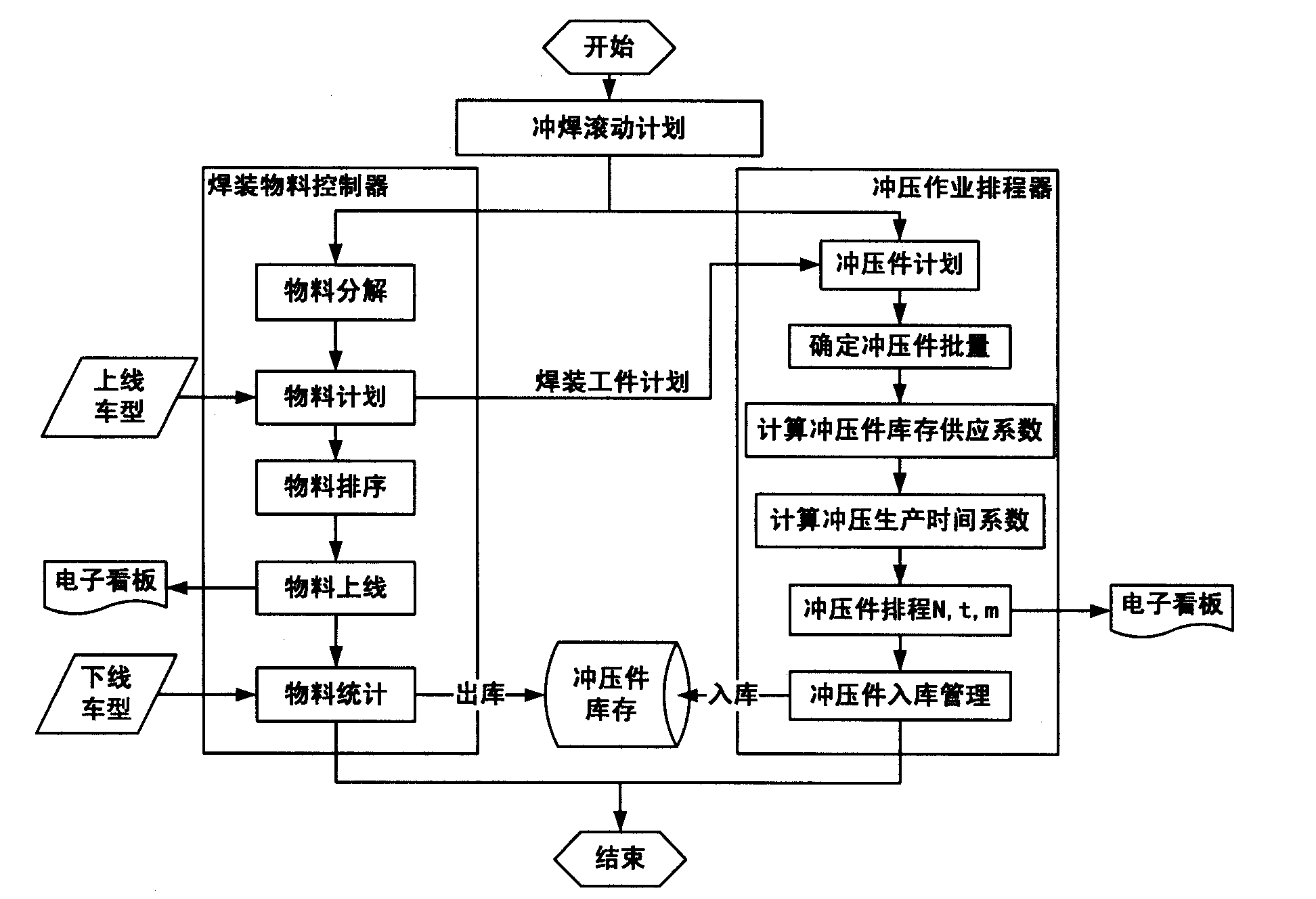

Method used

Image

Examples

example

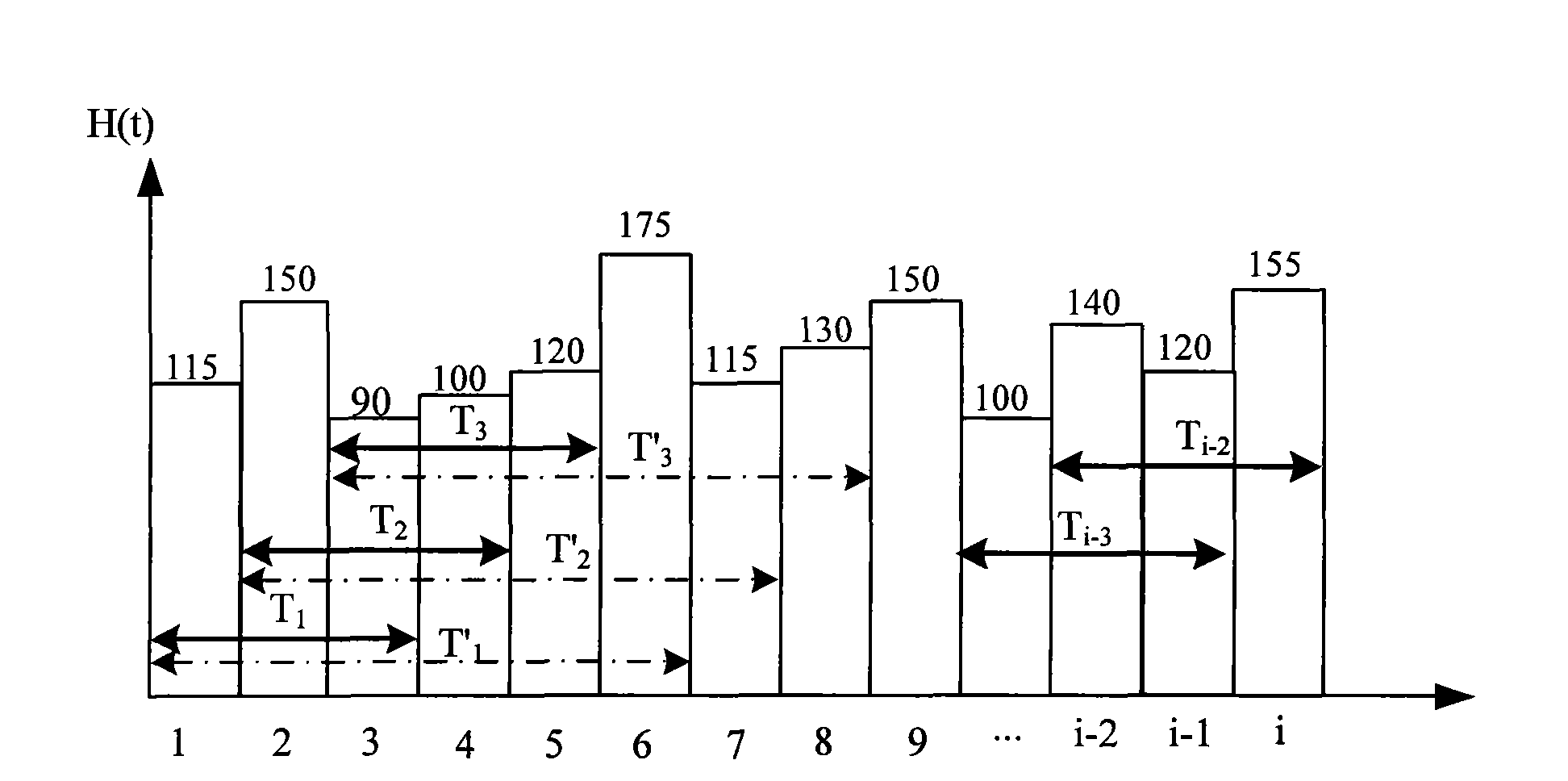

[0053] Example: The following is a simple example to illustrate, without loss of generality, assuming that there is only one model in the welding plan.

[0054] 1. If Figure 3.1 As shown, the daily welding planning quantity of the welding workshop is the number above the box, which is 115, 150, 90, 100, 120...etc. If the rolling time window is selected as 3 days, the rolling demand plan of the stamping shop can be obtained as Figure 3.1 , and their numbers are 355, 340, 310, 395... in turn.

[0055] 2. Calculate the batch and batch processing time of all stamping workpieces, such as Figure 4 As shown, the number on the box is the batch quantity, and the number in the box is the batch processing time.

[0056] 3. According to the bill of materials BOM, decompose the stamping demand plan to obtain the demand quantity of each stamping part, and compare it with the actual stock and safety stock of stamping parts, such as Figure 5.1 As shown, the number on the dotted line r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com