An alkali liquor control system

A control system and lye technology, applied in the direction of processing textile materials equipment configuration, etc., can solve the problem of high cost, achieve low-cost operation, and realize the effect of cost-effective operation

Active Publication Date: 2016-11-16

江苏欧化纺织有限公司

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If this part of waste water is recycled, but according to the equipment (such as soda distillat

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

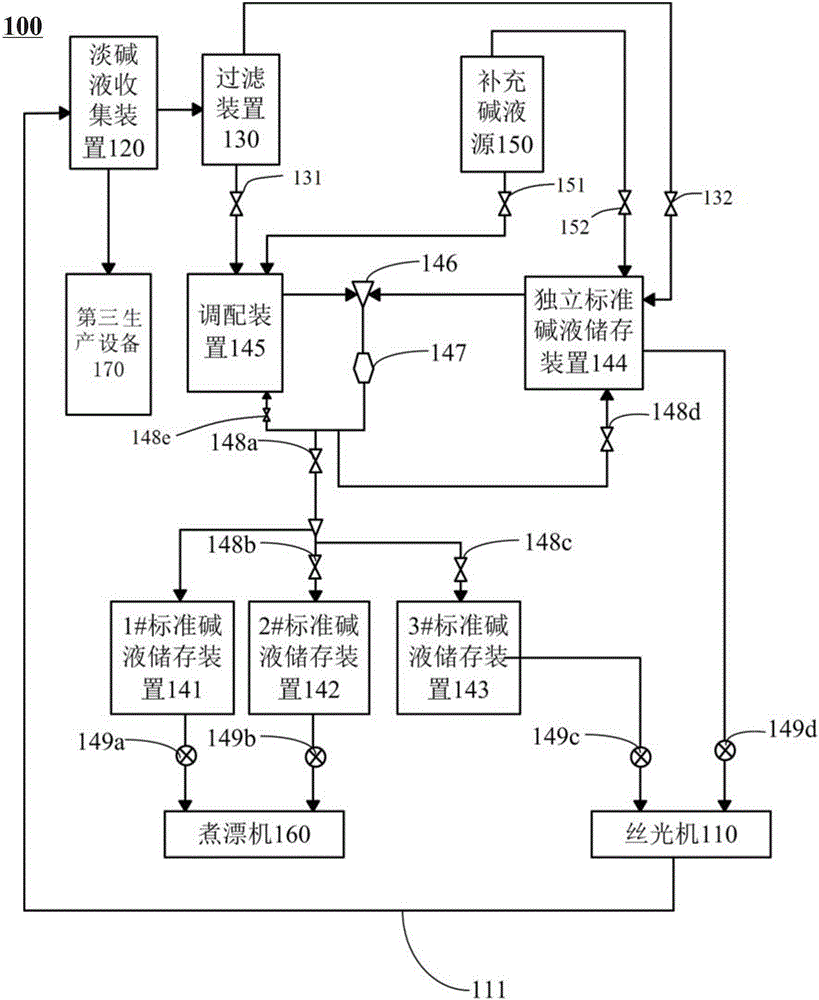

The invention provides an alkali liquor control system comprising a first production apparatus, a weak alkali liquor collection device, a filter device, a normal concentration configuration unit, a supplementing alkali liquor source, and a second production apparatus. With the structural design of the whole system, the effect of low-cost operation is achieved, collected weak alkali liquor and commercial alkali can be mixed to prepare alkali liquor with a required concentration effectively according to production requirements and the alkali liquor can be conveyed to a specified production machine bench automatically. With the system, weak alkali liquor can be recovered and utilized to the greatest extent and low-cost operation is achieved.

Description

technical field [0001] The invention relates to the field of chemical equipment for textile printing and dyeing, in particular to an lye control system. Background technique [0002] For pure cotton printing and dyeing production lines, caustic soda is the main auxiliary agent for pretreatment, and the cost of use accounts for nearly 40% of the cost of pretreatment auxiliary agents. The mercerizing machine is the machine with the largest proportion of caustic soda consumption (usually, the caustic soda consumption of the mercerizing machine accounts for about 80% of the total caustic soda consumption), and the main component of the waste water it produces is 35-45g / L light lye. If the waste water containing light lye is not recovered, in addition to the increase in the cost of additives, if the sewage is directly discharged, it will take a large amount of acid agents such as sulfuric acid for neutralization. In this way, not only will the operating cost be increased, but al...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06B23/20

CPCD06B23/20

Inventor 全亦然王华坤刘忠

Owner 江苏欧化纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com