Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73 results about "Normal concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Normal concentration of an ionic solution is intrinsically connected to the conductivity (electrolytic) through the equivalent conductivity. Examples. Normality can be used for acid-base titrations. For example, sulfuric acid (H 2 SO 4) is a diprotic acid.

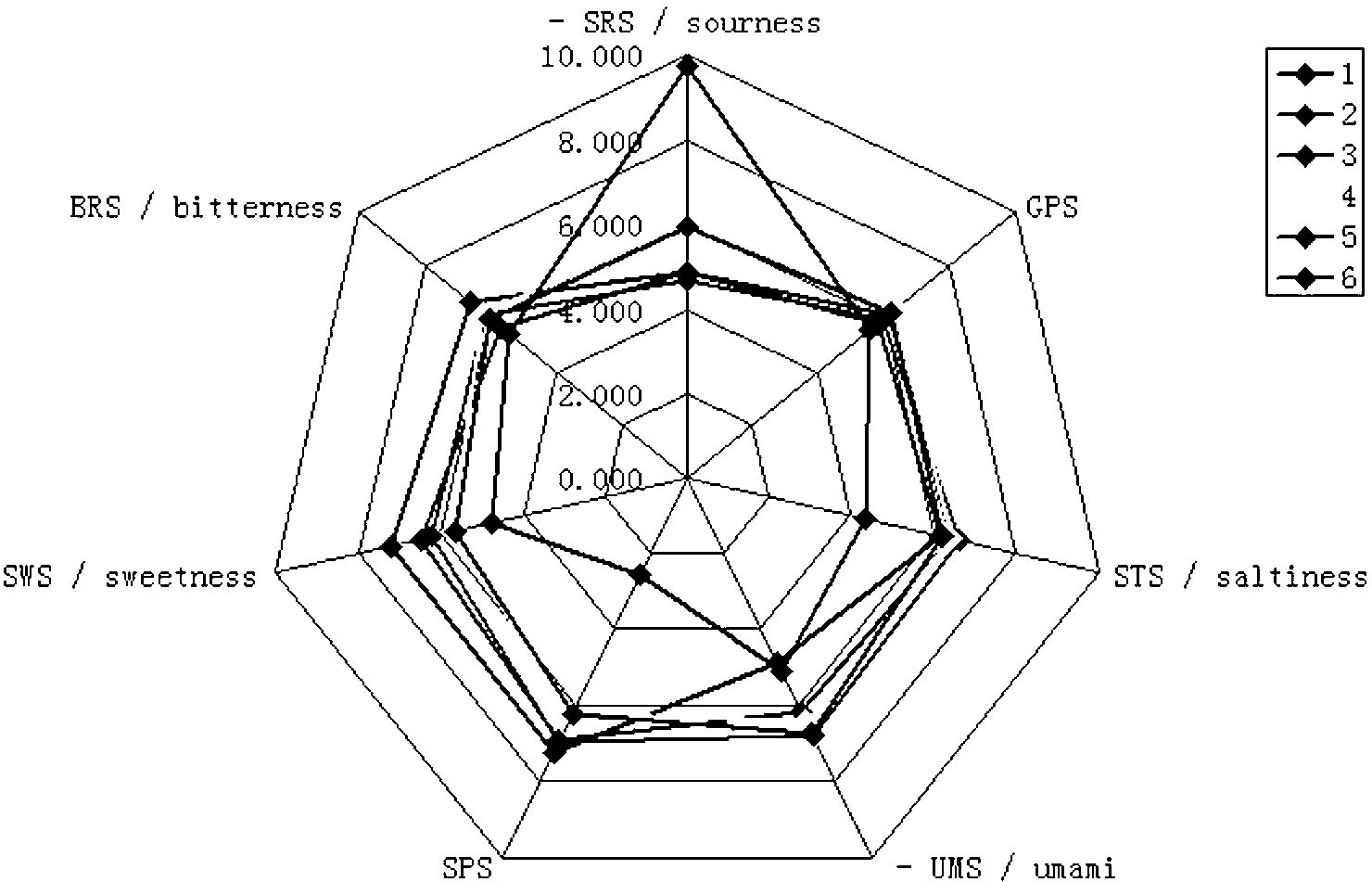

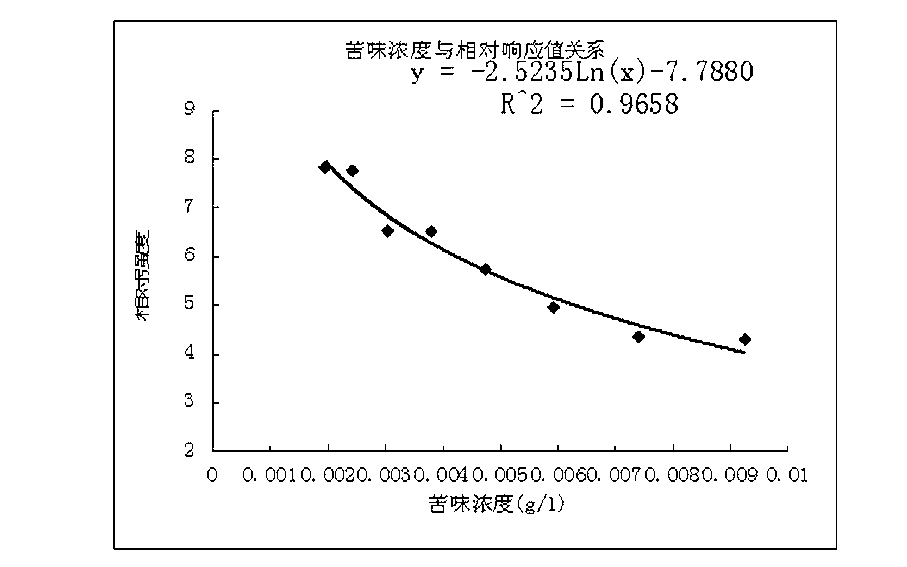

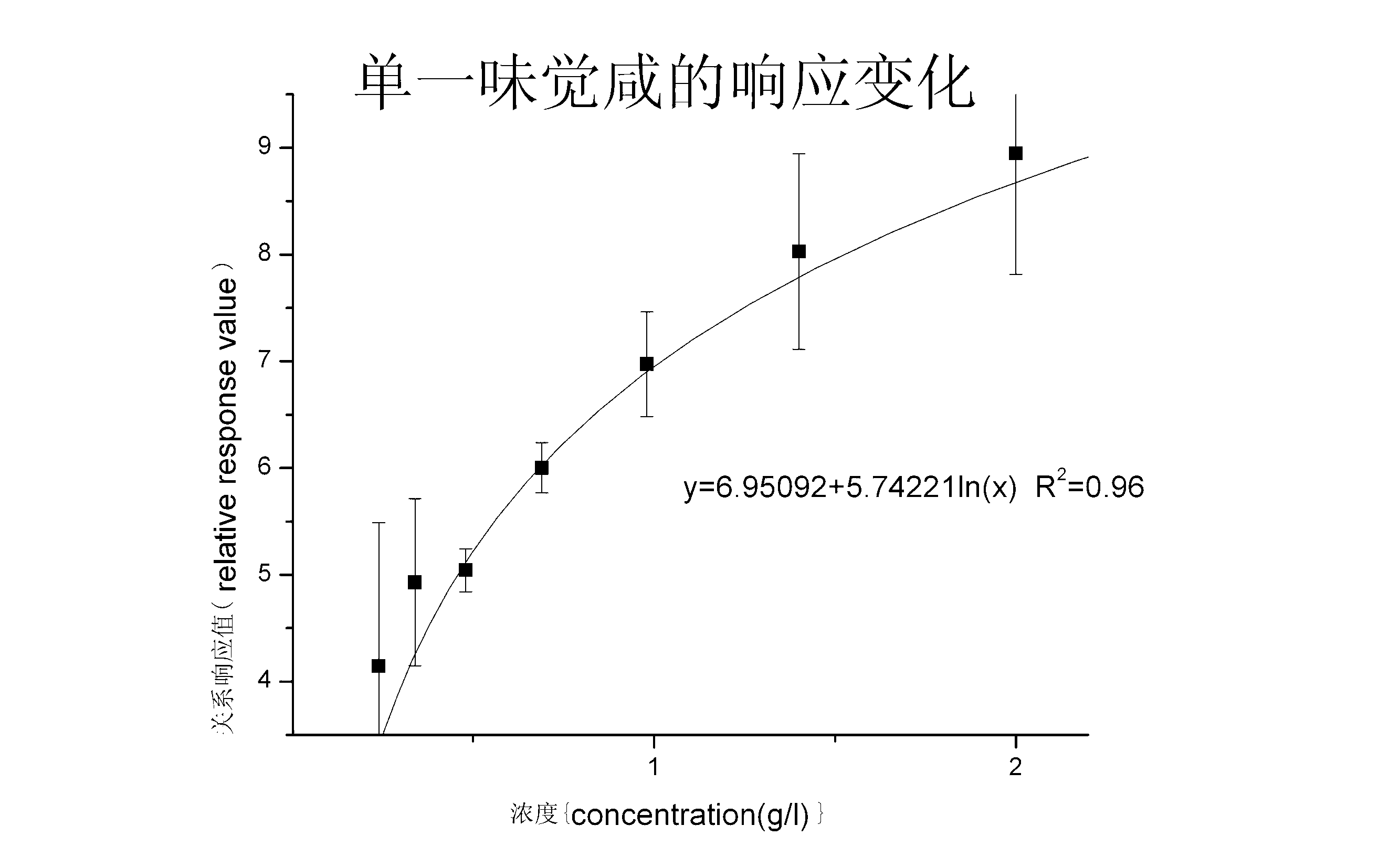

Method for quickly detecting intensity of four basic tastes in liquid food by using electronic tongue

ActiveCN103018293AQuick checkGood reproducibilityMaterial electrochemical variablesHuman mouthNormal concentration

The invention relates to a method for quickly detecting the intensity of four basic tastes (sour, sweet, bitter, and salty) in a liquid food by using an electronic tongue. The method comprises the following steps: preparing an HCl solution with a concentration of 0.01mol / L from distilled water as the activating solution of the electronic tongue (five tastes) sensor; using distilled water of the cleaning solution (pay attention to replacing new distilled water); adding the HCl solution with a concentration of 0.01mol / L as the calibration solution, so that the electronic tongue sensor can be used for analyzing samples after calibration; selecting four kinds of substances with four basic tastes with a concentration suitable for the normal concentration level in the human mouth as the basic samples; determining the number of cleaning beakers according to the number of the samples, wherein each sample is cleaned in the specific cleaning beaker, and the samples are cleaned according to the natural sequence; placing the electronic tongue sensor in each beaker for 120 seconds to detect the taste of the sample, and detecting for six times for each sample to obtain that the taste of the sample has a semi-logarithmic relationship with the response strength on the electronic tongue sensor; and carrying out macro operation by electronic tongue software on the results to obtain the relative intensity relationship between different concentrations of the basic taste substances on the electronic tongue.

Owner:HONGTA TOBACCO GRP

Method for improving the accuracy of the semi-quantitative determination of analyte in fluid samples

InactiveUS6306660B1Microbiological testing/measurementBiological testingAnalyteQuantitative determination

Disclosed is an improved method for determining the concentration of a first analyte in a fluid test sample as a function of a second analyte also present in the sample whose concentration in the fluid sample is clinically related to that of the first analyte. The method involves determining the concentration of the first analyte, and, if this concentration is outside of its useful analytical range, dividing this concentration by the normal concentration of the second analyte. This method of ratioing the concentrations of the first and second analyte is advantageous because accuracy is increased with fewer false positive and false negative results being reported.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

Varied concentration mixed working medium auto-cascade refrigerator

ActiveCN101776358AReduce boot pressureImproved dynamic running characteristicsFluid circulation arrangementRefrigeration safety arrangementVapor–liquid separatorLiquid storage tank

Owner:ZHEJIANG UNIV

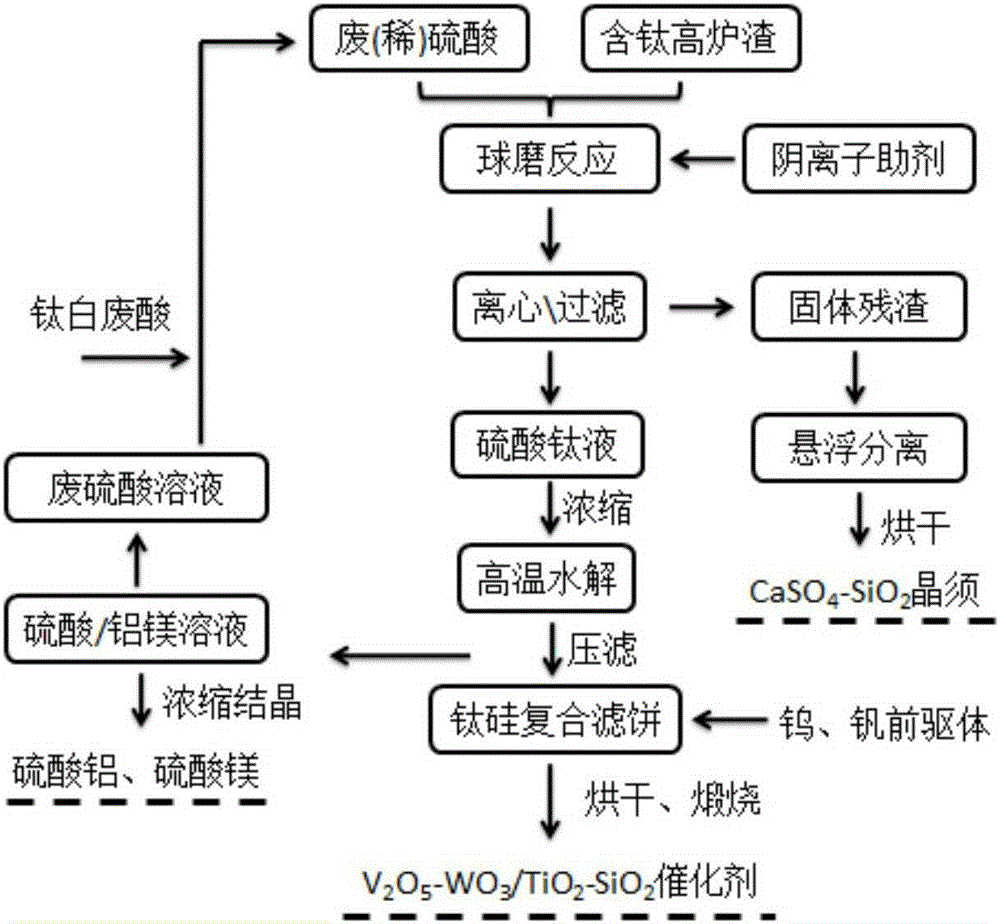

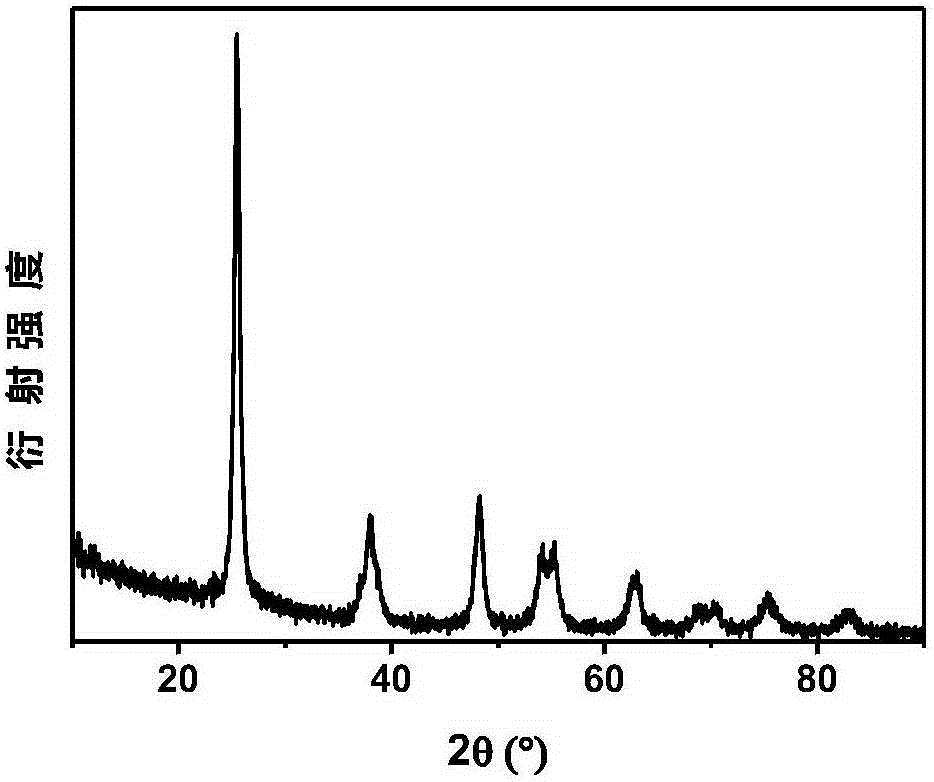

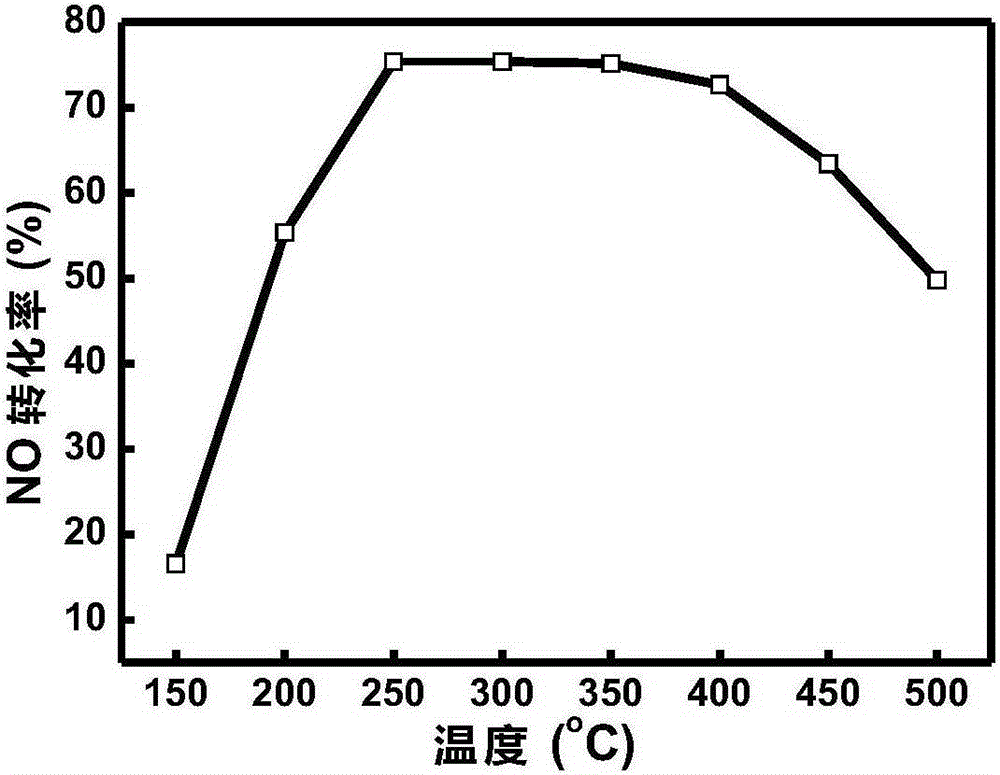

Treating and using method for titanium-containing blast furnace slag

InactiveCN105217664AReduce manufacturing costRelieve stressPhysical/chemical process catalystsChemical industrySilicic acidSlag

The invention belongs to the field of solid waste resource utilization. The treating and using method for titanium-containing blast furnace slag provided by the invention comprises: adding titanium-containing blast furnace slag into waste dilute sulfuric acid to be leached and separating the mixture to obtain a filter residue and a leaching liquid; after controlling the normal concentration of TiO2 in the leaching liquid through reduction vaporization, further carrying out oxidative hydrolysis reaction; filtering, washing and drying the hydrolyzed product to obtain a metatitanic acid-silicic acid compound; further loading tungsten on the product; and calcining the product to obtain titanium tungsten silicon powder; carrying out simple suspended separation and drying and roasting on the ball-milled filter residue to obtain a calcium sulfate-SiO2 composite whisker material; and crystallizing and separating the hydrolyzed liquid to obtain an aluminum sulfate chemical. The method not only realizes effective use of titanium, silicon, calcium and aluminum of blast furnace slag, and solves the problem that a titanium product extracted from the blast furnace slag is hard to separate and purify and the product quality is hard to reach the standard, but also greatly lowers the titanium-extracting cost, reduces the energy consumption, and realizes high value utilization of calcium and silicon.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

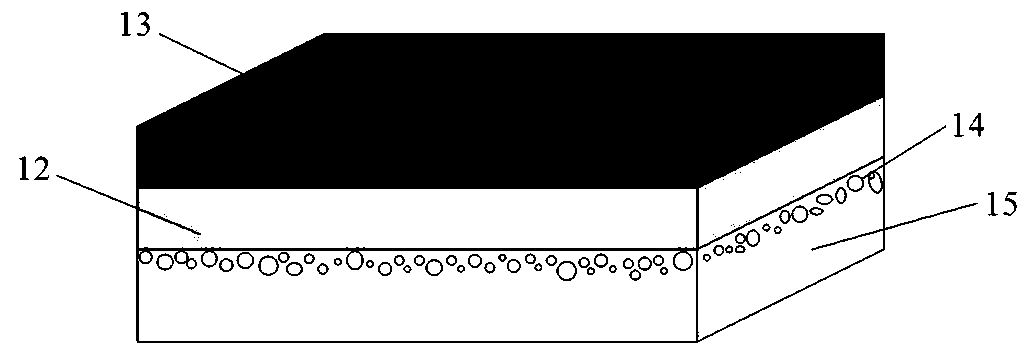

Technique for coating fluorescent powder on LED chip

InactiveCN101369623ASolve precipitationGood color temperature uniformitySemiconductor devicesColor rendering indexFluorescence

This invention provides a technique of coating fluorescent powder an LED chip, including following steps: (1) fixing an LED chip on a bracket bowl, at the same time, preparing a fluorescent glue with low concentration based on the proportion that the mass ratio of the glue and fluorescent powder of 15:1 to 25:1, and coating to the bowl, wherein the coating depth is 1 / 2-2 / 3 of the bowl depth; (2) roasting and solidifying; (3) preparing a fluorescent glue with normal concentration based on the proportion that the mass ratio of the glue and fluorescent powder of 4:1 to 15:1 and coating to the bowl, roasting; (4) if the coated fluorescent glue in the bowl forms a concave surface after roasting, then repeatedly processing the step (3) until the mixture of the coated glue and the fluorescent powder is level with the edge of the bowel after solidifying and with out the dent. This invention adopts the technical method of multiple coating, which effectively solves influences such as the fluorescent powder deposition and aggregation in the solidifying process after coating the fluorescent powder about one time, improves parameters of the LED using the fluorescent powder, such as the color temperature evenness, color rendering index and color evenness and so on.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

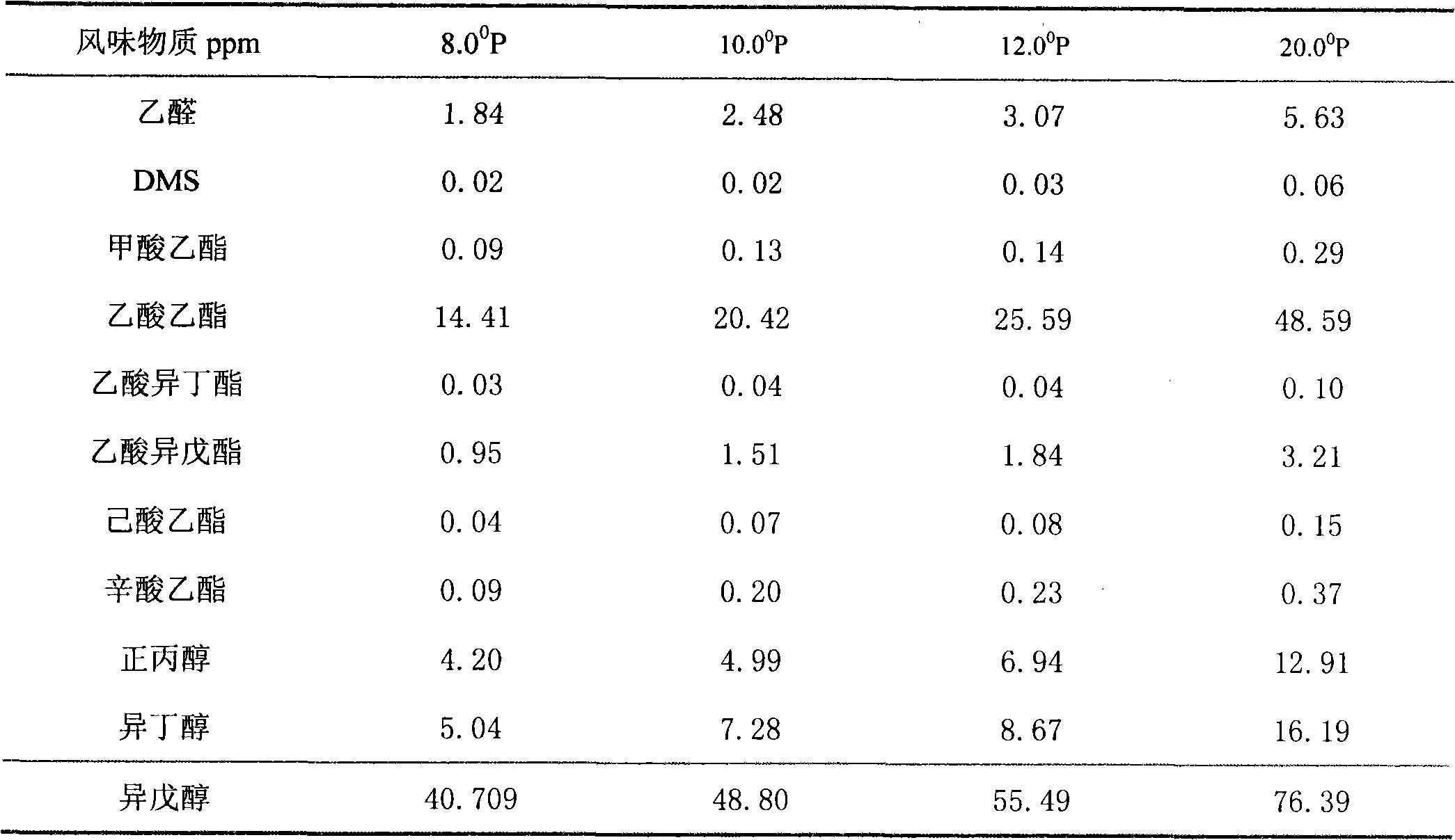

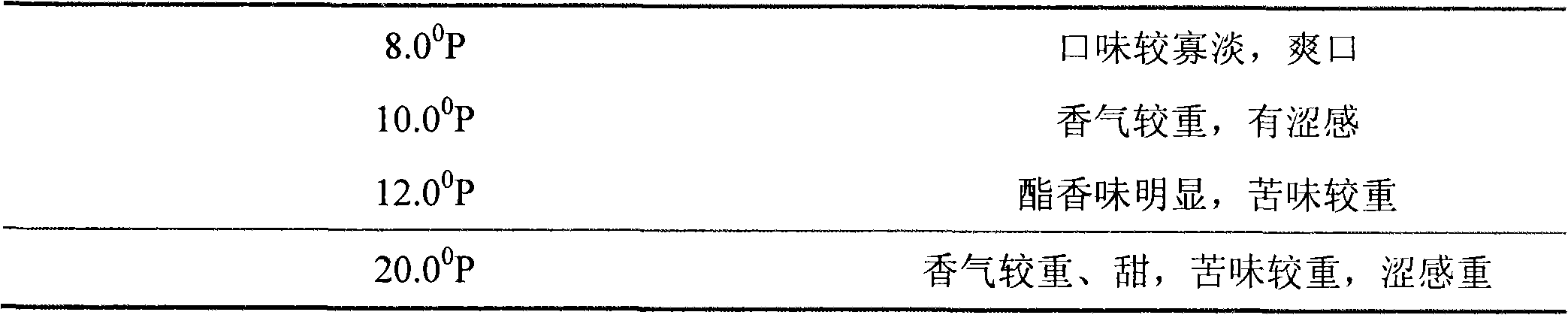

Ultrahigh-concentration beer brewing strain and culture medium for screening same

InactiveCN101851589ALight tasteClean tasteFungiBeer fermentationScreening methodNormal concentration

The invention offers a culture medium for ultrahigh-concentration beer brewing strains, a method for screening the strains by using the culture medium, the strains screened by the method and a method for brewing beer with the ultrahigh-concentration beer brewing strains. The culture medium for screening the strain contains components 2-Deoxy-D-glucose. The screening method comprises the steps of acclimatization, cultivation, continuous separation, screening and process evaluation. The strains which are suitable for 20 DEG P ultrahigh-concentration wort and have the abilities of resisting 2-Deoxy-D-glucose and alcohol and deoxidizing diacetyl can be screened. By using the strains and method provided by the invention, the utilization rate of equipment can be greatly improved, and the production cost can be reduced. Compared with the beer fermented at normal concentration, the beer produced in the invention has better flavour and better taste.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

Vehicle system for detecting oxygen, carbon monoxide and carbon dioxide

InactiveCN104553980AAvoid suffocation deathsSignalling/lighting devicesMaterial electrochemical variablesOxygen sensorComputer module

The invention discloses a vehicle system for detecting oxygen, carbon monoxide and carbon dioxide. The system comprises an oxygen sensor, a carbon monoxide sensor, a carbon dioxide sensor, a signal amplification circuit module, a filtering circuit module, a controller module, a warning module and a display module, wherein weak signals detected by the oxygen sensor, the carbon monoxide sensor and the carbon dioxide sensor are input into the controller module after being amplified by the signal amplification circuit module and filtered by the filtering circuit module; and the controller module is synchronously connected with the warning module and the display module. The system can detect the concentrations of oxygen, carbon monoxide and carbon dioxide in a vehicle in real time; and once the concentrations in the vehicle are not in a normal concentration range, an alarm is immediately given to prompt persons in the vehicle so as to effectively prevent the generation of death with asphyxia in the closed vehicle.

Owner:DANYANG CITY FEIYUE VEHICLE ACCESSORY

Safe and environment-friendly method for removing explosive oil gas of large-scale emptying oil tank

InactiveCN102302831AIncrease temperatureSpeed up evaporationFire rescueBoring toolsFlammability limitProduct gas

The invention relates to a safe and environment-friendly method for removing explosive oil gas of a large-scale emptying oil tank. The method comprises the following steps of: (1) carrying out an inert gas replacement treatment on the large-scale emptying oil tank or other large-scale limited spaces which are full of the oil gas and are located within the explosive limit, so as to lower the oxygen concentration of the large-scale emptying oil tank or the other large-scale limited spaces to 10-13%; (2) enabling the inert oil gas to pass through a heat exchanger and a preheater and then to enter a catalytic reactor, introducing high-temperature gas with the oil gas concentration which is lower than 0.1% into a wall-dividing type heat exchanger after the catalytic combustion is carried out so as to transfer heat quantity to new-entered inert gas, and then continuously carrying out replacement through circularly entering the oil gas into the oil tank or the other large-scale limited spaces; and (3) directly carrying out an air replacement emission treatment until the whole oxygen concentration recovers to an air normal concentration range when the oxygen concentration is lower than 0.5%. The method has the advantages of safety, high efficiency and environment protection, and the efficiency of hypoxia catalytic combustion processing under an inerting condition reaches 99%.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Pharmaceutical compound containing silymarin and carbopol, production method thereof and use of same as a regenerator of tissue and pancreatic cells with endogenous secretion damaged by diabetes mellitus

The present invention refers to a new compound containing Silymarin with Carbopol for the treatment of Diabetes Mellitus. This compound morphologically and structurally regenerates the damage that occurs in the pancreatic tissue in Diabetes Mellitus, and regenerates the insulin-producing pancreatic cells (β cells). It therefore regulates the serum levels of this hormone. Furthermore, it restores and maintains the normal concentrations of the blood glucose.

Owner:SOTO PEREDO CLAUDIA ANGELICA

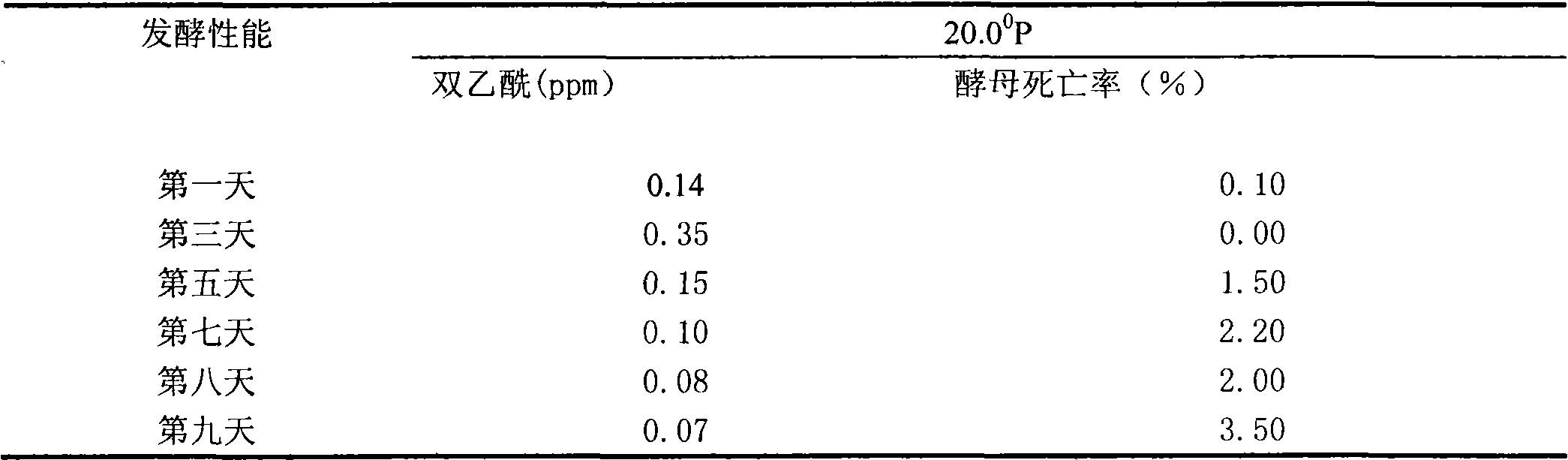

Magnetic relaxation switch for detecting glycoprotein

InactiveCN101858964AEasy to operateNo repeated changesMeasurements using NMR imaging systemsBiological testingAgglutinin-BNMR - Nuclear magnetic resonance

The invention belongs to the technical field of nuclear magnetic resonance, and particularly discloses a magnetic relaxation switch for detecting glycoprotein. A probe of the magnetic relaxation switch adopts a super-paramagnetic nano particle which uses a ferroferric oxide particle as a core, uses glucan as a shell and has average particle size of no more than 60 nanometers. A method for detecting the glycoprotein by using the magnetic relaxation switch comprises two mixing steps and one detecting step, wherein the mixing steps comprises mixing of agglutinin and mixing of target substance, the agglutinin is concanavalin, and the target substance is a1-acid glycoprotein. The linear concentration range of the detection is 0 to 7.0nmol / L, and the detection limit is 0.40nmol / L and is far lower than the normal concentration of AGP in blood plasma.

Owner:FUDAN UNIV

Synthetic urine and method of making same

A synthetic urine formulation, a kit including the synthetic urine formulation and a method of preparing synthetic urine are described. The urine formulation includes urine components in dried form, concentrated form or normal concentration and a compound that, when added to water, increases the temperature of the water (a “heat activator”). When the urine components are present in dried form, the synthetic urine can be provided in one or two parts. When present in concentrated form or in normal concentration, the heat activator must be provided separately. Lithium chloride is a preferred heat activator. The components can be provided in kit form, including a measuring cup with a fill line, the powdered, concentrated or normal concentration synthetic urine components, and the heat activator. Optionally, but preferably, the kit also includes a temperature measuring device to ensure that the appropriate temperature is reached. The synthetic urine formulation includes an appropriate amount of individual components of human urine such that the sample can appear to be a genuine human urine sample, with components testing within normal limits.

Owner:WOODSTOCK ENTERPRISES

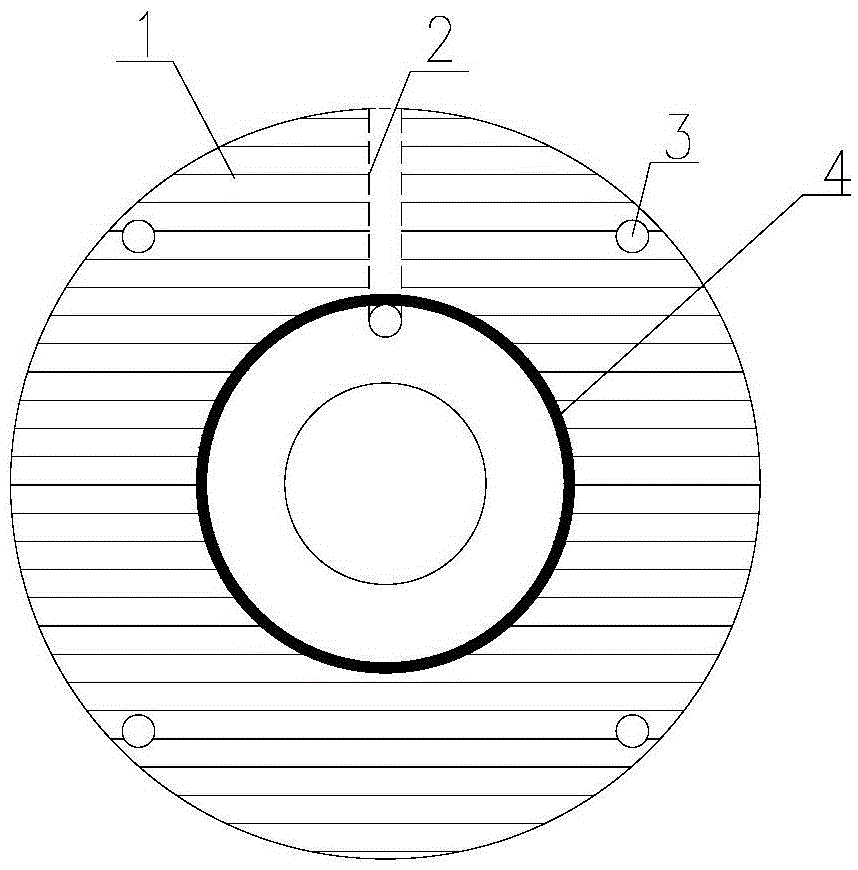

Method for measuring communicating porosity of concrete by using non-contact impedance method and testing device

ActiveCN105424578AThe principle is clearSimple methodPreparing sample for investigationPermeability/surface area analysisPorosityContact impedance

The invention relates to a method for measuring the communicating porosity of concrete by using a non-contact impedance method and a testing device. The method for measuring the communicating porosity of concrete comprises the following steps: measuring the resistivity of a salt solution in normal concentration, preprocessing a piece to be tested, installing a concrete test piece to be tested and an ion migration system, measuring the resistivity of the concrete test piece and calculating the communicating porosity of concrete according to an Archie equation. The testing device comprises the ion migration system, a resistivity measuring system and a data processing system, wherein the ion migration system mainly comprises a flange pressure plate, a liquid adding pipe, a liquid supplementing water channel, the piece to be tested and an opposite-pull screw; the resistivity measuring system comprises a signal generator, a coil, a magnetic core and a current sensor; and the data processing system comprises a signal processor and a central controller. The method for measuring the communicating porosity of concrete and the testing device have the beneficial effects that the limit to the size of the test piece in the traditional testing method is broken through, so as to realize the testing for the communicating porosity of concrete; the method for measuring the communicating porosity of concrete and the testing device can not only be suitable for testing the communicating porosity of concrete freshly mixed indoors, but also be suitable for testing the communicating porosity of concrete obtained through core boring sampling in the existing building structure.

Owner:ZHEJIANG UNIV OF TECH

Method for improving working stability of glass substrate heating coating

The invention relates to a method for improving the working stability of a glass substrate heating coating. The invention aims at improving the thermal stability on the basis of ensuring the excellentradiation efficiency of quartz glass. The method is characterized by comprising the following steps: firstly pre-irradiating a quartz glass substrate by using plasma, forming a micropore on the surface of the quartz substrate, coating a heating coating slurry on the surface, baking for half an hour in the nitrogen-containing atmosphere, finally, evenly coating one or more layers of heating coating slurry with the normal concentration, and drying for half an hour. The method enlarges the contact area between the slurry and the substrate, the processed substrate material does not change the macroscopic optical property of the quartz glass; in addition, the thermal radiation efficiency is improved by 30%, the preparation method is simple and reliable and is easy to implement industrially ona large scale.

Owner:陕西日禾嘉新能源科技有限公司

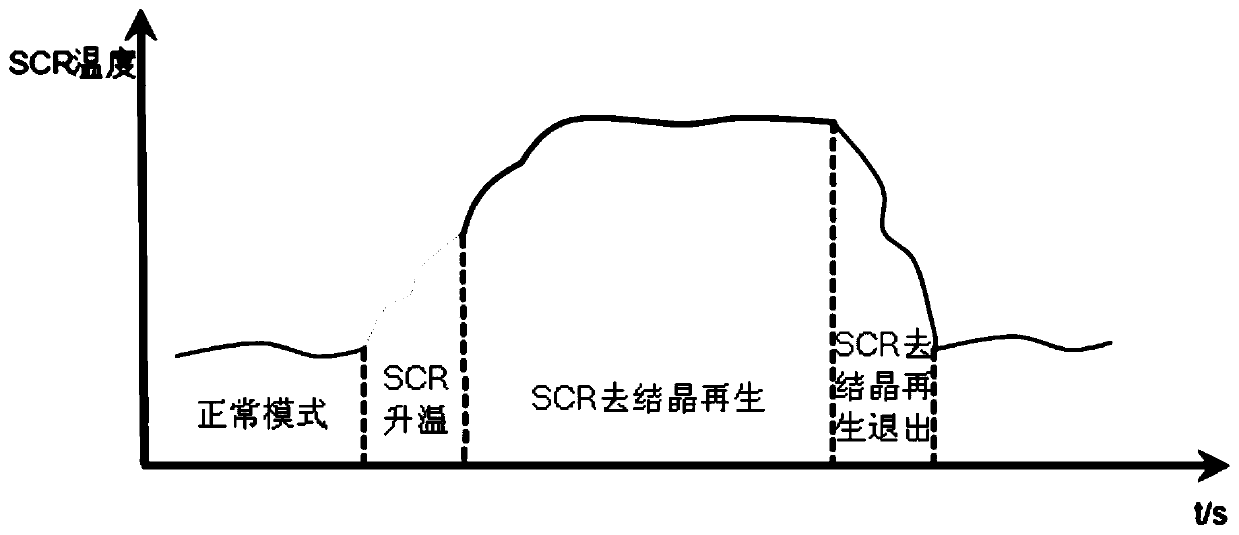

Control method for SCR efficiency recovery

ActiveCN110630361AImprove reliabilitySCR efficiency recoveryElectrical controlInternal combustion piston enginesEngineeringNormal concentration

The invention discloses a control method for SCR efficiency recovery. The control method for the SCR efficiency recovery comprises the following steps that A, if the SCR efficiency is low due to low urea concentration, the normal concentration of urea is replaced; B, if the SCR efficiency is low due to the large deviation of a urea injection control model, the deviation of the urea injection control model is corrected; C, if the SCR efficiency is low due to SCR crystallization, SCR de-crystallization regeneration is started; D, if the SCR efficiency is low due to SCR sulfur poisoning, SCR desulfurization regeneration is started; and E, if the SCR efficiency is low due to a deactivated SCR catalyst, SCR is replaced. According to the control method, the SCR efficiency can be restored, and the control method is high in reliability.

Owner:DONGFENG COMML VEHICLE CO LTD

Production method of composite phosphate

InactiveCN106082152ANo significant increase in production costsDisperse fastPhosphatesProduction lineHigh concentration

The invention discloses a production method of composite phosphate. The production method includes: using monomer phosphate or physically-mixed phosphate as the raw material, controlling the temperature to be at 200-40 DEG C, adding a certain proportion of water under a stirring state, controlling the temperature of the phosphate in different ranges, and using the hydrolysis of the phosphate to produce the composite phosphate of different proportions and properties according to different water adding proportions and temperatures. The production method has the advantages that the dissolving speed of the produced composite phosphate can reach the dissolving speed of chemical mixing, caking of the produced composite phosphate in water is avoided, the high-concentration composite phosphate is fast in dispersing, and the normal-concentration composite phosphate is fast in dissolving; the phosphate production cost of factories is not increased evidently, and only the cooling equipment of an original phosphate production line needs to be slightly modified.

Owner:苏州闻达食品配料有限公司

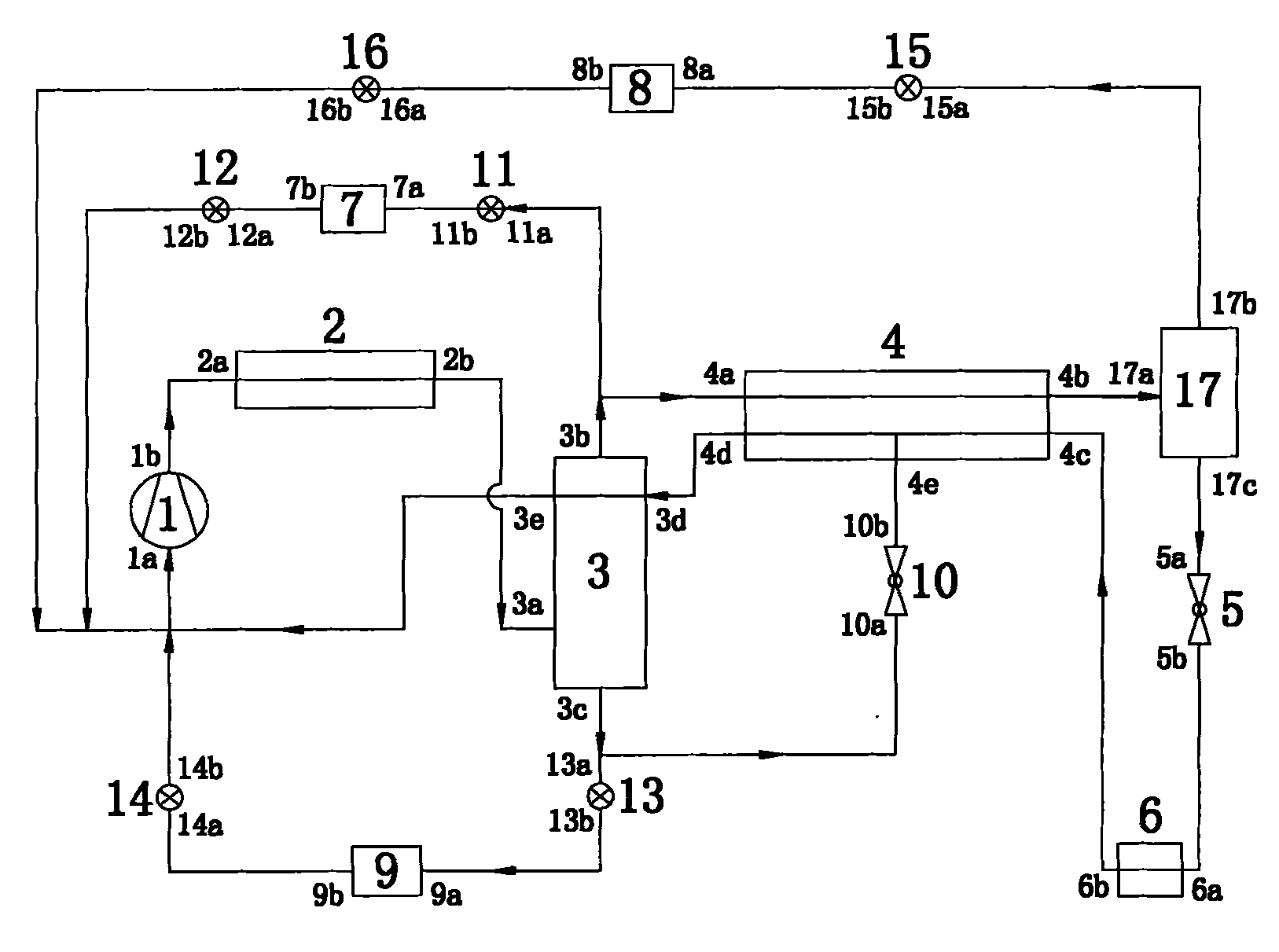

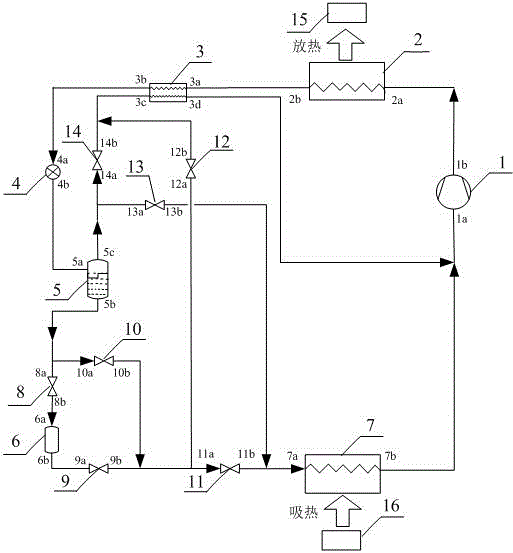

Non-azeotropic mixed working medium heat pump air-conditioning system with concentration adjustable

ActiveCN105972864AImprove energy efficiencyGood temperature matchingMechanical apparatusHeat pumpsVapor–liquid separatorHigh energy

The invention discloses a non-azeotropic mixed working medium heat pump air-conditioning system with the concentration adjustable in a variable condenser and a variable evaporator. The non-azeotropic mixed working medium heat pump air-conditioning system comprises a normal concentration circuit, a variable condenser concentration bypass and a variable evaporator concentration bypass. The normal concentration circuit comprises a compressor, the condenser, a supercooler, a throttling device, a main gas-liquid separator and an evaporator. The variable condenser concentration bypass comprises an auxiliary gas-liquid separator and regulating valves. The variable evaporator concentration bypass comprises the main gas-liquid separator, the supercooler and regulating valves. According to the non-azeotropic mixed working medium heat pump air-conditioning system with the concentration adjustable in the variable condenser and the variable evaporator, the energy efficiency of the heat pump air-conditioning system can be further improved on a given working condition; the concentration of a mixed working medium in the condenser is firstly changed, then the concentration of a mixed working medium in the evaporator is changed, good temperature matching can be generated in the condenser and the evaporator on variable working conditions, and the relatively high energy efficiency of the heat pump air-conditioning system can be guaranteed; and the structure is simple, operation is convenient, modification cost is low, and the concentration of the mixed working medium in the condenser and the concentration of the mixed working medium in the evaporator can be independently regulated by controlling the opening-closing and the opening degree of the additionally arranged regulating valves.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for measuring concentrations of dopants in a liquid carrier on a wafer surface

InactiveUS6373576B1X-ray/infra-red processesSemiconductor/solid-state device testing/measurementHigh concentrationNon destructive

A method for non-destructively testing for the concentration of a component of a film that is used for doping a region of a semiconductor wafer uses an image histogram of the light reflected from an array of points on the film and the underlying substrate. The image histogram has peaks that are characteristic of the composition of the film. Tests are run to establish the image histogram peaks for a film with a normal concentration of the components and for films with low and high concentrations. When the same test is made for the film of a production wafer, the concentration of the component is readily classified as normal, high, or low.

Owner:TAIWAN SEMICON MFG CO LTD

Manihot esculenta crantz rapid propagation method based on atomization nutrient solutions

ActiveCN106577027AHigh reproductive rateImprove survival rateClimate change adaptationGrowth substratesNutrient solutionManihot esculenta

Owner:GUANGXI SUBTROPICAL CROPS RES INST GUANGXI SUBTROPICAL AGRI PROD PROCESSING RES INST +1

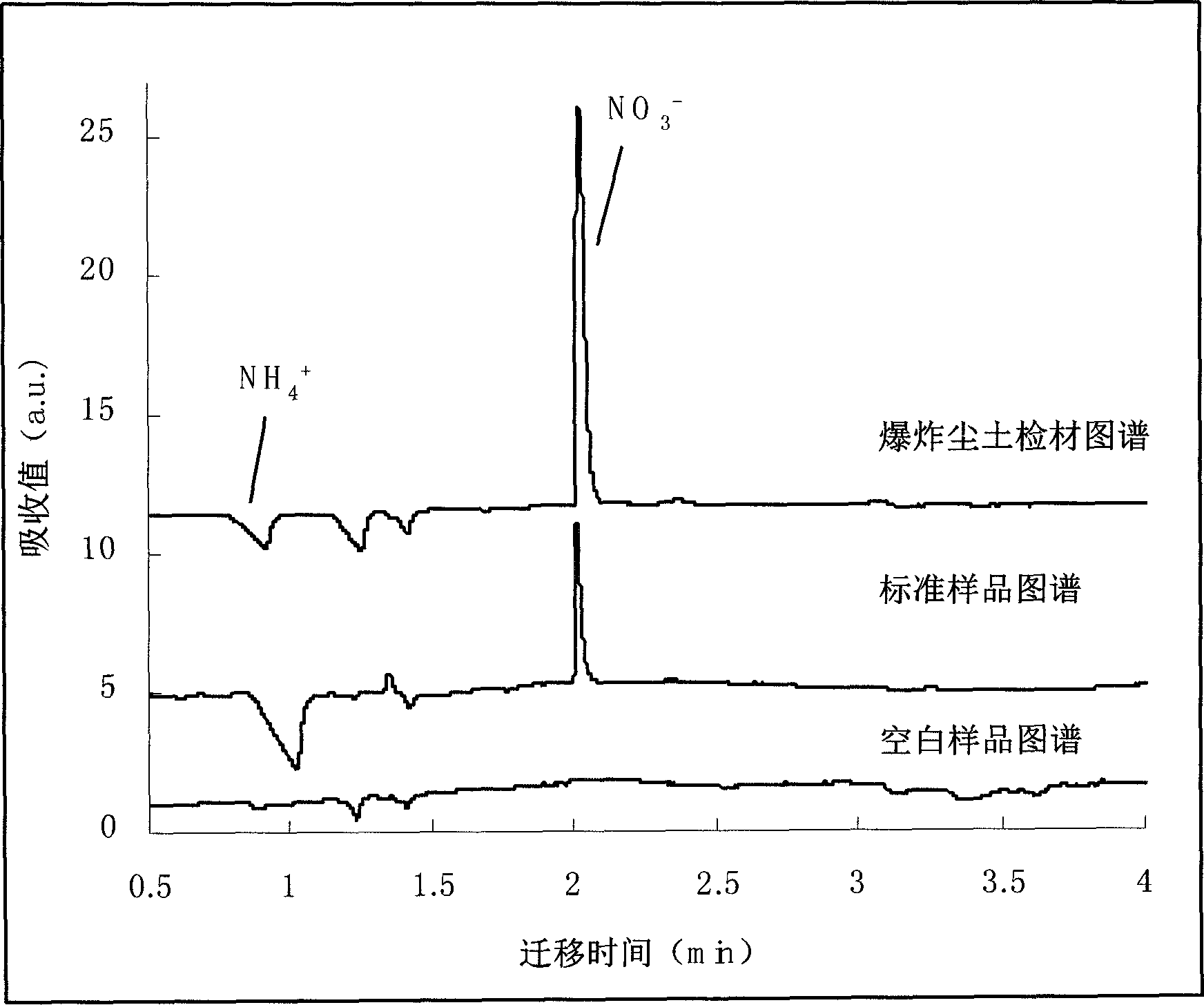

Rapid and accurate detection method for ammonium nitrate explosive

InactiveCN104111280ADisadvantages of Avoiding PollutionReduce dosageMaterial analysis by electric/magnetic meansAdditive ingredientUltraviolet

The invention relates to a rapid and accurate detection method for an ammonium nitrate explosive and belongs to the technical field of analytical chemistry. The method comprises the following six steps of preparing an ionic liquid stock solution, preparing standard NH4<+> and NO3<-> stock solutions, preparing an ionic liquid capillary electrophoresis buffer solution, preprocessing a capillary tube, measuring a normal concentration curve and analyzing exploding remnants. The detection method has the beneficial effects that a novel green solvent, namely ionic liquid, simultaneously serves as the electrophoresis buffer solution and an indirect ultraviolet detection back-ground electrolyte, so that the disadvantages that multiple reagents need to be used, the operation is complex, and the environment is polluted in a conventional method are overcome; furthermore, main ingredients, namely NH4<+> and NO3<-> ions of the exploding remnants of the ammonium nitrate explosive can be simultaneously separated and detected by virtue of the method, and the method is specific to the detection of the ammonium nitrate explosive; meanwhile, by combining an efficient capillary electrophoresis-ultraviolet detection technique, the analysis is accurate and rapid, the detection sensitivity is high, the reproducibility is good, the dosage of the reagent is low, and the method is easy to popularize and apply.

Owner:杨丽

A method for quantitative determination of content of triglyceride in pulp resin

InactiveCN1952650ACorrespondence is accurateEasy to prepareMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationGlycerolColor reaction

A method of quantitative detecting the content of the triglyceride in pulp resin is disclosed, a solution of triolein with normal concentration is formulated with the dissolvent of isopropanol, and the triglyceride is hydrolyzed to glycerin and aliphatic acid by reaction with the solution of KOH or NaOH, the glycerin is oxygenated with oxygenant co-operating with the chloride ion, the chromogenic reaction is occurred between the resultant and the color reagent to generate yellow organic materials, the max spectral behavior absorption peak of the yellow organic materials is at 412nm, the color strength of the chromogenic reaction is proportional to the content of the triglyceride. With this method, the content of the triglyceride in pulp resin can be detected quickly and precisely, the operation is convenient, the cost of detecting is low, it is adapted for the monitoring and optimization of pitch control in course of paper making.

Owner:SOUTH CHINA UNIV OF TECH

Method for automatic detection of concentration of heavy metal ions in soil and soil remediation

InactiveCN104407041ASimple methodEasy to implementMaterial electrochemical variablesCharge currentSoil remediation

The invention discloses a method for automatic detection of concentration of heavy metal ions in soil and soil remediation. The method comprises the following steps: presetting a normal heavy metal ion concentration threshold value parameter; using an electrochemical transducer to acquire voltage signals generated by ion electrodes, and further obtaining membrane potential; according to the actual value of the membrane potential, obtaining the ion concentration, meanwhile displaying the ion concentration by a display unit, comparing the calculated ion concentration with the set normal heavy metal concentration threshold value, if the calculated ion concentration is higher than the normal concentration threshold value, giving an alarm by a control and alarm unit, and meanwhile starting an electric soil remediation device. The method disclosed by the invention can measure, display and store the ion concentration; the method charges current to the soil to enable the metal ions in the soil to be conveyed to the electrodes, and then intensively collects and processes the conveyed metal ions, so as to achieve the pollution control purpose.

Owner:SUZHOU OUBORI AUTOMATION TECH

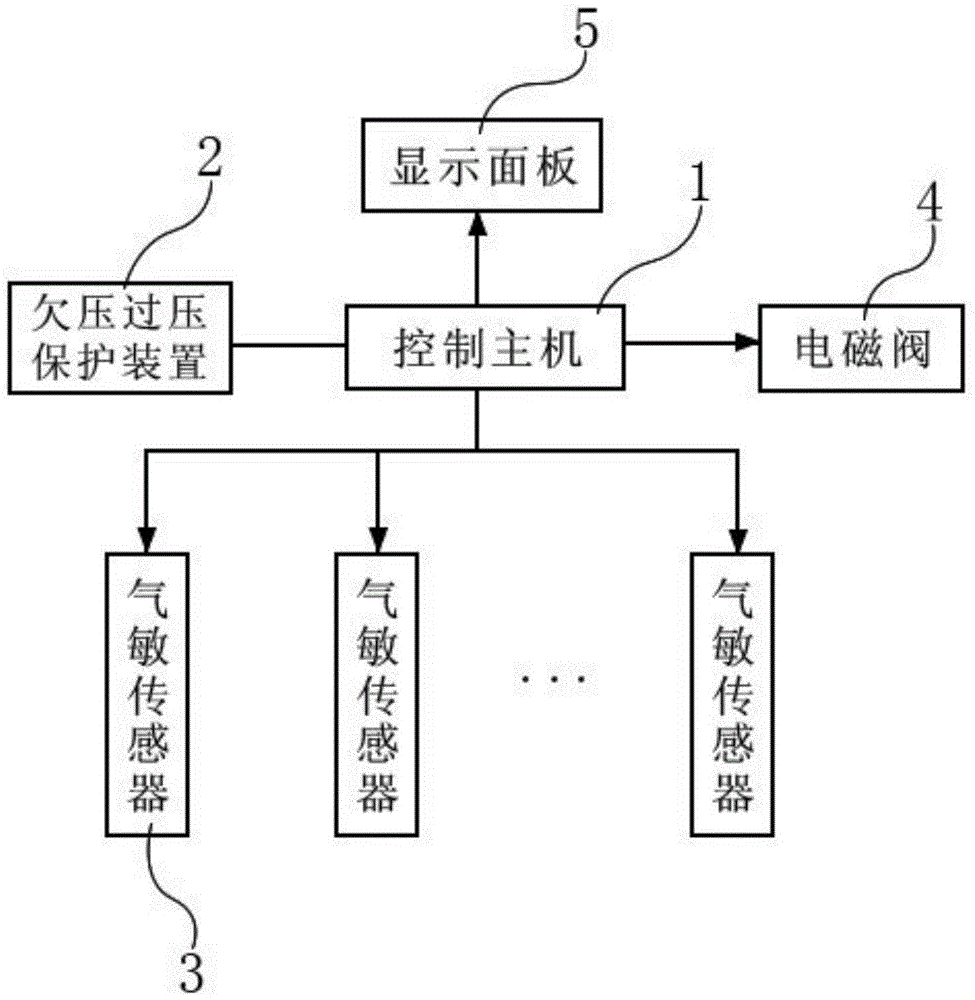

Gas leakage alarm device for gas car

InactiveCN105096538AImprove anti-interference abilityQuick response to alarmAlarmsElectric transmission signalling systemsOvervoltageGas detector

The invention discloses a gas leakage alarm device for a gas car. The alarm device comprises a control host, a solenoid valve and a plurality of gas-sensitive sensors. The gas-sensitive sensors are connected with the control host for sensing the concentration of the natural gas in the environment. The solenoid valve is arranged at the gas outlet pipeline of a gas bottle and connected with the control host through a signal line. After the natural gas concentration exceeds the normal concentration value, the gas-sensitive sensor is used to transmit the sensing signal to the control host, and the control host is used to send a valve turn-off execution signal to the solenoid valve to make the solenoid valve execute the valve turn-off action to close the gas bottle. The control host is provided with a display panel and connected with an undervoltage and overvoltage protection device. The display panel is provided with a reset button, a mute button and alarm indicating lamps corresponding to the gas-sensitive sensors. The undervoltage and overvoltage protection device can be used to perform undervoltage and overvoltage detection on a car storage battery. According to the invention, advantages of fast alarm response speed, good sensitivity and good anti-interference performance can be realized, and an alarm signal can be given when the storage battery is in the undervoltage or overvoltage condition.

Owner:ZHEJIANG DAOWEIER TECH

Transmitting method of ozone with normal concentration

InactiveCN106501202AEasy to operateReduce mistakesColor/spectral properties measurementsNormal concentrationOzone concentration

The invention provides a transmitting method of ozone with a normal concentration. According to the transmitting method, an ozone calibration instrument, an ozone analysis meter and a dynamic calibration instrument are used, wherein the ozone calibration instrument, the ozone analysis meter and the dynamic calibration instrument are calibrated by a SRP state ozone normal calibration instrument. The method comprises the steps of 1, confirming that the ozone calibration instrument has been calibrated by the SRP state ozone normal calibration instrument and is in force; 2, transmitting ozone with the normal concentration to the ozone analysis meter through the ozone normal calibration instrument; 3, using the transmitted ozone analysis meter to carry out a reverse calibration on the dynamic calibration instrument; 4, conducting reexamination after the reverse calibration, wherein the reexamination is usually conducted on the second day after the calibration and the reexamination usually needs to be conducted twice, introducing ozone to the ozone analysis meter through the dynamic calibration instrument, and continuously observing for 1-2 hours under the same ozone concentration, wherein a product of which concentration fluctuation is within an allowable range is the good product; 5, comparing the ozone concentrations of the ozone calibration instrument and the dynamic calibration instrument when the ozone calibration instrument and the dynamic calibration instrument are connected to the ozone analysis meter respectively under the same concentration, wherein if a concentration discrepancy is within 0.5% of a transmitting value, transmitting is proved to be ok. According to the transmitting method of ozone with the normal concentration, the transmitting is convenient and the error is small.

Owner:深圳市赛宝伦科技有限公司

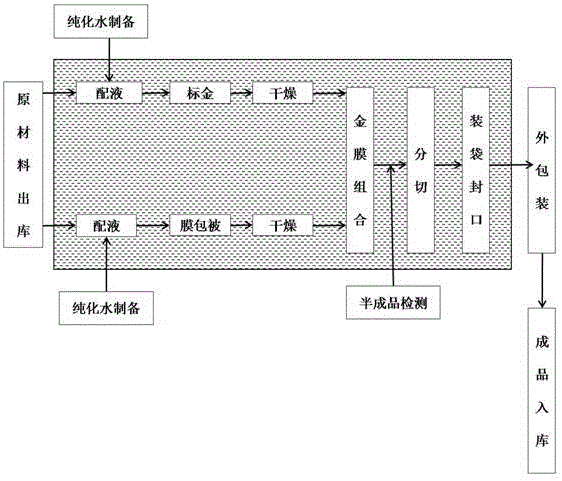

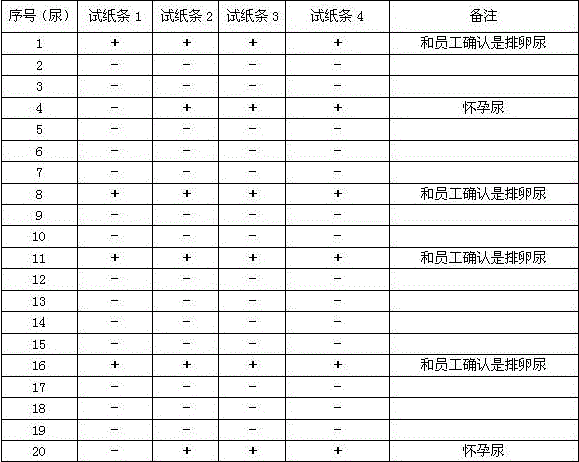

Ovulation test paper and processing technology thereof

InactiveCN106324264AWill not affect test resultsBiological material analysisBiological testingNitrocelluloseColloid

The invention relates to the field of medical detection, in particular to ovulation test paper and a processing technology thereof. The ovulation test paper comprises a sample pad, a colloidal gold bonding pad, a NC nitrocellulose membrane, a water absorption plate and a PVC plate, and is characterized in that the sample pad and the colloidal gold bonding pad at the lower portion of the sample pad, the colloidal gold bonding pad and the NC nitrocellulose membrane at the lower portion of the colloidal gold bonding pad and the NC nitrocellulose membrane and the water absorption plate at the upper portion of the NC nitrocellulose membrane are partly overlapped and connected respectively, and the overlapped width is 1mm to 4mm respectively; a jhkLH-alpha antibody marked by colloidal gold is sprayed to the colloidal gold bonding pad; two parallel antibody capture lines are marked on the NC nitrocellulose membrane respectively, a jhkLH-beta antibody close to the colloidal gold bonding pad serves as a detection line, and the other antibody capture line containing a goat anti mouse IgG antibody with the determined concentration serves as a normal-concentration color-developing quality control line. By means of the ovulation test paper and the processing technology thereof, the problem that the HCG sample false positive exists when detection is carried out through the ovulation test paper is solved.

Owner:BEIJING JINHUAKE BIOLOGICAL TECH

Detection method of vitamin B12 content in vitamin complex additive

InactiveCN104330484APrecipitation is effectiveConducive to on-board measurementComponent separationFood additiveVitamin B12

The invention relates to a detection method of the vitamin B12 content in a vitamin complex additive, which belongs to the fields of food additives and detection methods of the food additives. The detection method comprises the following steps: (1) preparing a vitamin B12 stock solution with the concentration of 1 mg / ml, then preparing serial solutions with the normal concentrations of 0.5, 1.0, 2.0, 3.0, 4.0 and 5.0mu g / ml, putting on an instrument to measure under certain chromatographic conditions, and calculating a regression equation and correlation coefficients; and (2) weighing a test sample, putting on the instrument to measure under the same chromatographic conditions, and calculating the concentration of the test sample according to the peak height of a standard sample, the concentration of the standard sample and the peak height of the test sample. According to the detection method, the measuring precision and accuracy can meet the requirement of dairy product analysis, and the detection method has the characteristics of high accuracy, high repeatability, simplicity and convenience in operation, low detection limit and the like and can be used as a conventional detection method to be applied.

Owner:XIAN MIYI BIOTECH

Surface processing method for construction drill

The invention discloses a surface processing method for a construction drill. The method includes the steps that (1) an oil stain removal washing agent is used for removing oil; (2) acid pickling is carried out to remove rust; (3) sand blasting is carried out; (4) rough washing is carried out through a washing agent; (5) fine washing is carried out through water to make the drill clean; (6) preheating is conducted, the cleaned drill is placed in a steel wire mesh type container, then the container is placed in a preheating furnace to dry the drill at the temperature of 160+ / -5 DEG C, and after heat preservation is carried out for five minutes, the container is cooled along with the furnace and then is taken out; (7) stove charging is carried out, the dried drill and the steel wire mesh type container are placed in a well type electric stove with a stirring fan, and an open steel bottle is placed at the bottom of the stove and contains anti-rust oil of the one-quarter normal concentration; and (8) the well type electric stove is started for heating, heat preservation is conducted for ten minutes when the temperature is increased to 240+ / -5 DEG C, and then the drill and the steel wire mesh type container are cooled along with the stove and taken out. The anti-rust oil of the one-quarter normal concentration also can be injected from the outside in a saturated vapor form. The surface of the construction drill has the standard metal amber color, and the construction drill is low in cost, capable of being stored for a long time, resistant to abrasion and attractive.

Owner:湖南奇力工具有限公司

Yield increasing type plant growth regulator and its preparation

InactiveCN101103730ALow costRaw materials are easy to getBiocidePlant growth regulatorsGrowth plantPotassium hydroxide

The invention relates to a production increase type plant growth regulator and the preparation method, which is characterized in that: an acetamide and a potassium hydroxide are chosen for being made into acetamide solution and potassium hydroxide solution respectively according to the proportion by weight, and the two solutions are mixed together, and then some water is added for being regulated in a normal concentration; wherein the potassium hydroxide can be replaced by plant ash in 1.5 to 5 times, firstly the plant ash solution can be made, and then the preparation can be implemented. The invention can be used in seed soaking, the leaf spraying and the root application, so the crop yield can be increased significantly.

Owner:马恩芳

Fluorescent probe for detecting high-concentration gamma-Glutamyl Transpeptidase and preparation method thereof

ActiveCN108893106AGood luminous propertiesThe synthesis process is simplePeptide preparation methodsGroup 3/13 element organic compoundsHigh concentrationFluorescence

The invention provides a fluorescent probe for detecting high-concentration gamma-Glutamyl Transpeptidase, which solves the problem of selective response to abnormally high-concentration gamma-Glutamyl Transpeptidase in vivo. The fluorescent probe of the invention starts to produce obvious fluorescence changes after the gamma-Glutamyl Transpeptidase is higher than the normal concentration of humanbody, and as the concentration of gamma-Glutamyl Transpeptidase increases, the fluorescent probe solution of the invention produces large fluorescence enhancement and obvious color change. At the same time, after the fluorescent probe of the invention reacts with gamma-Glutamyl Transpeptidase, the permeability of the cell membrane is greatly enhanced, and when applied to cell imaging, the fluorescent probe can selectively image ovarian cancer cells with high expression of gamma-Glutamyl Transpeptidase. According to the invention, the synthesis process is simple and feasible, the raw materialsare cheap and easy to obtain, the preparation cost is low, and the preparation method is easy to popularize.

Owner:川北医学院

Method for preventing indoor swimming pool with concrete structure from being eroded by chlorine gas

Owner:林州建总建筑工程有限公司 +1

Pharmaceutical compound containing silymarin and carbopol, its manufacturing process and its use as a regenerator of the pancreatic tissue and cells of endogenous secretion damaged by diabetes mellitus

The present invention refers to a new compound containing Silymarin with Carbopol for the treatment of Diabetes Mellitus. This compound morphologically and structurally regenerates the damage that occurs in the pancreatic tissue in Diabetes Mellitus, and regenerates the insulin-producing pancreatic cells (β cells). It therefore regulates the serum levels of this hormone. Furthermore, it restores and maintains the normal concentrations of the blood glucose.

Owner:UNIV AUTONOMA METROPOLITANA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com