Rapid and accurate detection method for ammonium nitrate explosive

A technology of ammonium nitrate explosives and a detection method, applied in the field of analytical chemistry, to achieve the effects of high detection sensitivity, good reproducibility, and rapid analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

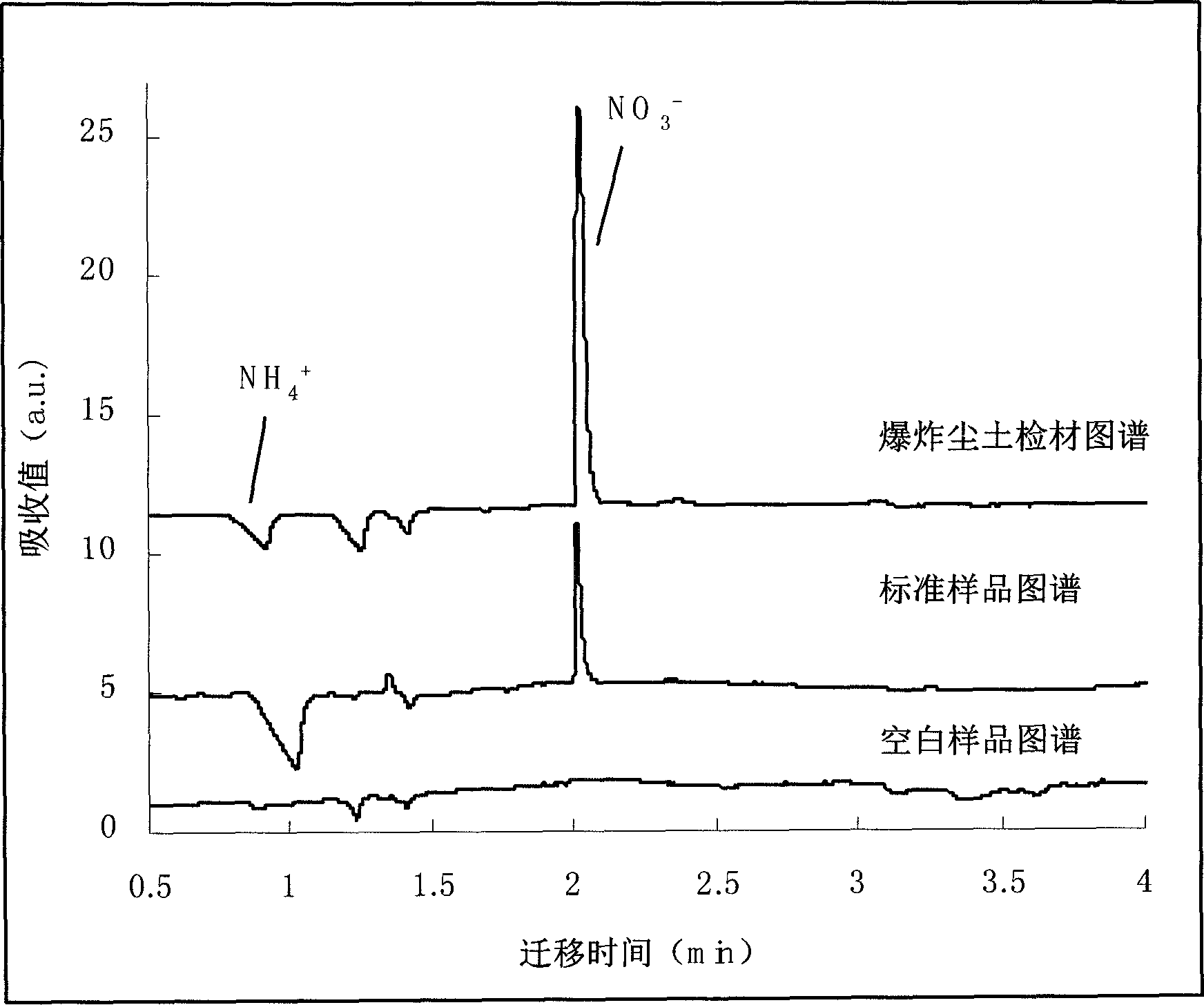

Image

Examples

Embodiment 1

[0028] A fast and accurate detection method for ammonium nitrate explosives, comprising the steps of:

[0029] Step (1), preparing an ionic liquid stock solution: adding 1-ethyl-3-methylimidazolium tetrafluoroborate into deionized water to a concentration of 20 mM to obtain an ionic liquid stock solution;

[0030] Step (2), prepare standard NH 4 + and NO 3 - Stock solution: Weigh ammonium chloride and magnesium nitrate hexahydrate respectively, dissolve in deionized water, dilute to 1000ppm as standard NH 4 + and NO 3 - stock solution;

[0031] Step (3), preparing ionic liquid capillary electrophoresis buffer solution: diluting the ionic liquid stock solution in step (1) to 6 mM, adding 4 μl of ethanolamine diluted 400 times to each 1 ml of ionic liquid, and mixing evenly to obtain a buffer solution;

[0032] Step (4), capillary pretreatment: cut off a 50cm long capillary, burn a window of 2-3mm at 10cm, wash the capillary with 0.1 M sodium hydroxide and water respecti...

Embodiment 2

[0036] A fast and accurate detection method for ammonium nitrate explosives, comprising the steps of:

[0037] Step (1), preparing an ionic liquid stock solution: adding 1-butyl-3-methylimidazolium tetrafluoroborate into deionized water to a concentration of 20 mM to obtain an ionic liquid stock solution;

[0038] Step (2), prepare standard NH 4 + and NO 3 - Stock solution: Weigh ammonium chloride and magnesium nitrate hexahydrate respectively, dissolve in deionized water, dilute to 1000ppm as standard NH 4 + and NO 3 - stock solution;

[0039] Step (3), preparing ionic liquid capillary electrophoresis buffer solution: diluting the ionic liquid stock solution in step (1) to 6 mM, adding 4 μl of ethanolamine diluted 400 times to each 1 ml of ionic liquid, and mixing evenly to obtain a buffer solution;

[0040] Step (4), capillary pretreatment: cut off a 50cm long capillary, burn a window of 2-3mm at 10cm, wash the capillary with 0.1M sodium hydroxide and water respectiv...

Embodiment 3

[0044] A fast and accurate detection method for ammonium nitrate explosives, comprising the steps of:

[0045] Step (1), preparing an ionic liquid stock solution: adding 1-butyl-3-methylimidazolium hexafluorophosphate to deionized water to a concentration of 20 mM to obtain an ionic liquid stock solution;

[0046] Step (2), prepare standard NH 4 + and NO 3 - Stock solution: Weigh ammonium chloride and magnesium nitrate hexahydrate respectively, dissolve in deionized water, dilute to 1000ppm as standard NH 4 + and NO 3 - stock solution;

[0047] Step (3), preparing ionic liquid capillary electrophoresis buffer solution: diluting the ionic liquid stock solution in step (1) to 6 mM, adding 4 μl of ethanolamine diluted 400 times to each 1 ml of ionic liquid, and mixing evenly to obtain a buffer solution;

[0048] Step (4), capillary pretreatment: cut off a 50cm long capillary, burn a window of 2-3mm at 10cm, wash the capillary with 0.1M sodium hydroxide and water respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com