Method for measuring communicating porosity of concrete by using non-contact impedance method and testing device

A connected porosity, non-contact technology, applied in the field of non-contact impedance method to measure the connected porosity of concrete, to achieve the effect of good stability, clear principle and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 The method for measuring the connected porosity of concrete by the non-contact impedance method of the present invention comprises the following steps:

[0044] 1) Preparation of concrete to be tested:

[0045] Pouring and forming the concrete specimen to be tested or taking core samples on site, soaking in a standard concentration salt solution or vacuum saturating with salt until the pores are saturated, the concentration of the standard sodium chloride solution is 0.1-2mol / L;

[0046] 2) Preparation before measurement:

[0047] Before the experiment, ensure that the temperature of the standard concentration salt solution is the same as that of the concrete test block saturated with salt. Butt and seal the two flange pressure plates, pour standard saline solution into the liquid filling pipe to calibrate the instrument, and determine the resistivity ρ of the standard concentration saline solution 0 ;After the calibration, drain the standard salt solutio...

Embodiment 2

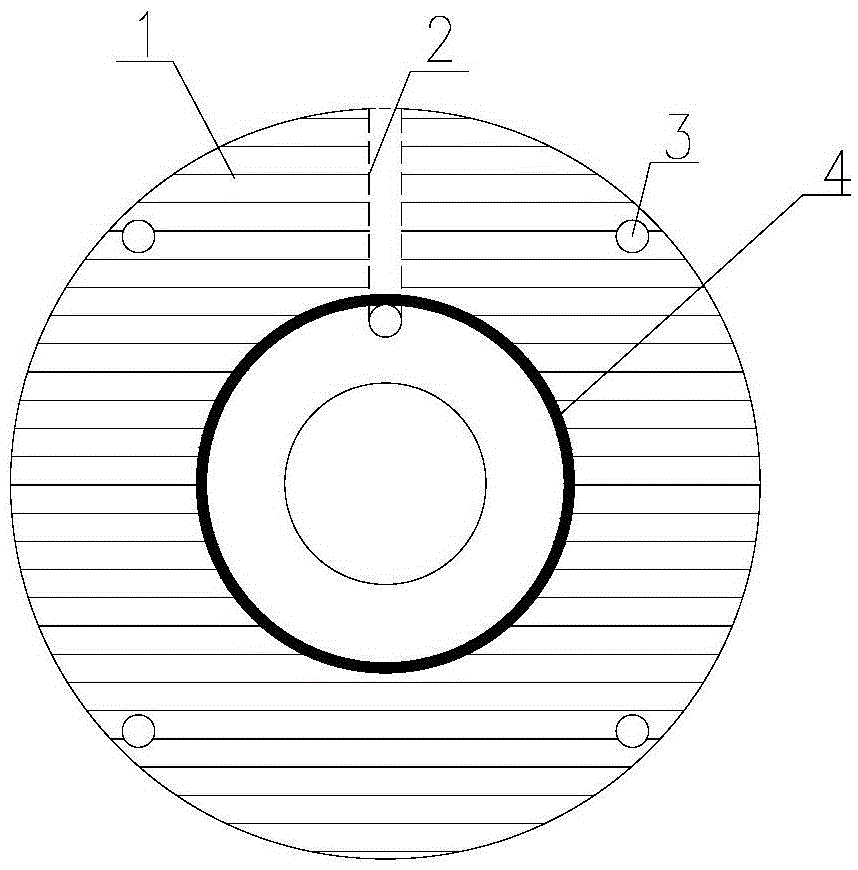

[0056] Embodiment 2 The test device constructed according to the method described in Example 1 includes an ion migration unit, a resistance measurement unit and a data processing unit. The ion migration unit includes two flange pressure plates 1 with through holes, a liquid filling Pipe 7, replenishment water tank 10 and pull screw 5, each port of the described liquid feeding pipe 7 corresponds to a flange pressure plate 1; The outer end faces are inserted into the through holes and sealed at the junction of the two; the inner end faces of the two flange pressure plates 1 face each other and form a test chamber for clamping the test piece through the pull screw 5, and the flange pressure plate 1 and The parts to be tested 11 are sealed by rubber gaskets 4; the rehydration water tank 10 is in communication with the liquid feeding pipe 7;

[0057] The resistance measurement unit includes a signal generator 14, a coil 13, a magnetic core 12 and a current sensor 15, and the liquid...

Embodiment 3

[0069] Embodiment 3 Taking the measurement of the concrete connected porosity of measuring the water-cement ratio 0.53 and the mix ratio as cement:water:sand:coarse aggregate=1:0.53:2.0:3.0 as an example, the work of the present invention is described in detail.

[0070] The raw material of this embodiment mixing concrete is: cement is P.I525 grade portland cement, and sand adopts the river sand of fineness modulus 2.6, and coarse aggregate adopts the crushed stone (maximum particle diameter 25mm) of continuous gradation, water Use tap water. Concrete specimens with a size of 100mm×100mm×100mm were poured in a standard mold, and after 28 days of standard curing in the curing room, 50mm of the two ends of the specimen along the length direction were cut off, and a concrete specimen with a thickness of 50mm in the middle was cut for testing. Trial test.

[0071] Dry the newly prepared concrete specimen with a size of 100mm×100mm×50mm in an oven at 105°C to a constant weight, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com