Control method for SCR efficiency recovery

A control method and efficiency technology, applied in electrical control, engine control, fuel injection control, etc., can solve the problem of unable to restore SCR efficiency, and achieve the effect of high reliability and recovery of SCR efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

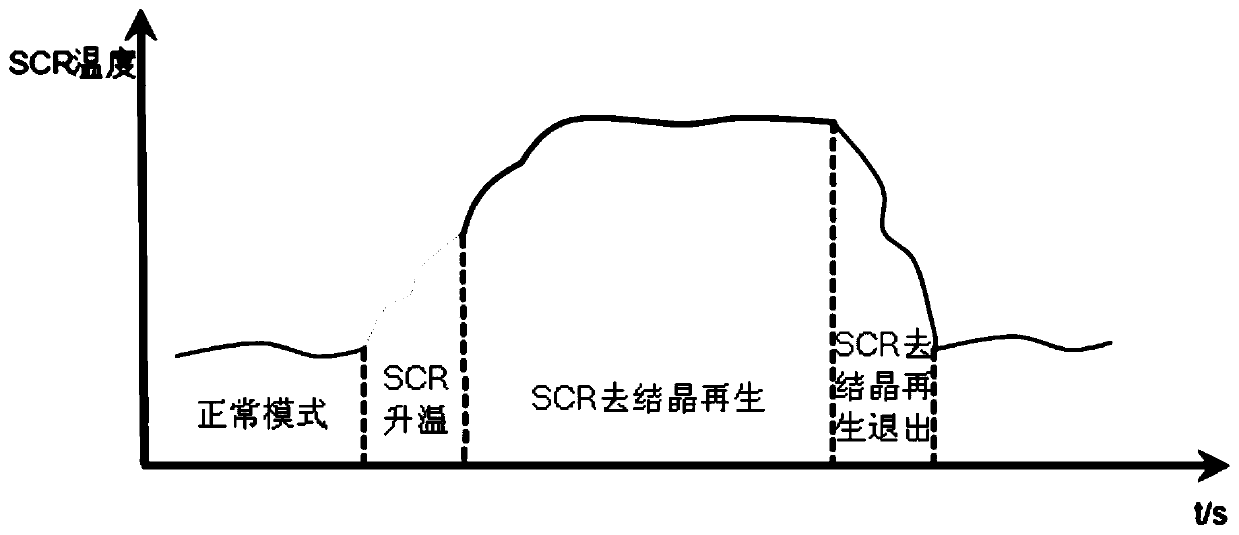

[0110] see figure 1 , figure 2 , a control method for recovering SCR efficiency, the control method comprising the following steps:

[0111] A. If the reason for the low efficiency of SCR is the low concentration of urea, replace it with normal concentration of urea;

[0112] B. If the reason for the low efficiency of SCR is that the urea injection control model has a large deviation, stop the injection of urea to make the original machine NOx react all the ammonia storage of the SCR, and the deviation between the measured value of the subsequent NOx sensor and the original machine NOx valueε= (Original NOx value - rear NOx sensor measurement value) / Original NOx value is less than the set value, and the range of the set value is 0% to 30%. It is considered that the ammonia storage in the SCR has completely reacted. At this time, The urea injection control model is restored to the initial state, the control parameters of the urea injection control model are all changed to 0,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com