Treating and using method for titanium-containing blast furnace slag

A technology for waste acid treatment and blast furnace slag, applied in chemical instruments and methods, magnesium sulfate, aluminum sulfate, etc., can solve the problems of difficult product quality, high cost, and high energy consumption in the extraction process, so as to reduce production costs and alleviate Huge pressure to achieve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

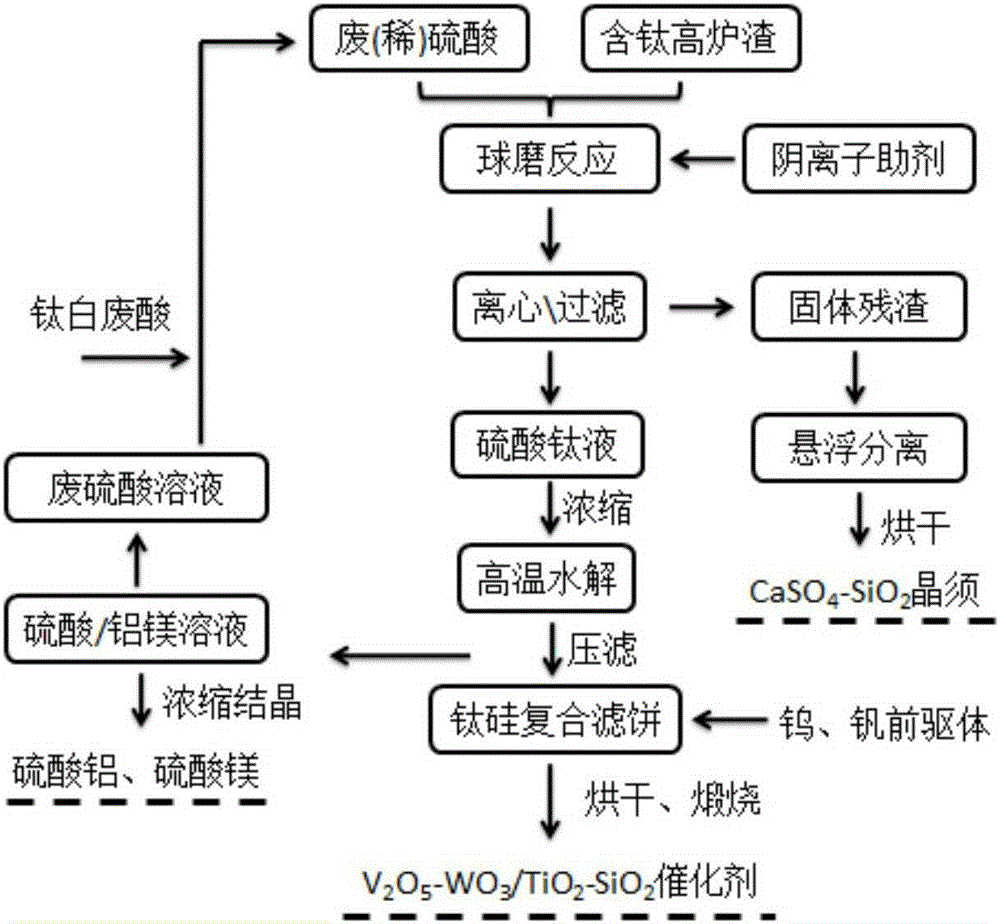

Method used

Image

Examples

Embodiment 1

[0046] After mixing 1000g of titanium-containing blast furnace slag (20-50 mesh) (see attached table 1 for composition), 5kg (20% mass concentration of waste sulfuric acid), it was added to a 10L ball mill tank, and corundum balls were added for ball milling reaction. The ball milling speed is controlled to be 120 rpm, and the ball milling time is 600 min. After the reaction is completed, the slurry is poured into a centrifuge tank for high-speed centrifugation and washed with waste sulfuric acid to obtain leachate and solid residue.

[0047] After the leaching liquid was concentrated to 2.5L at 60°C and -0.8atm (TiO 2 Equivalent concentration 50g / L), warming up to 110 ℃, at 30mL / L (with H 2 o 2 Oxygen was introduced into the filter press for oxidative hydrolysis reaction for 10 hours. After the liquid-solid separation was carried out by a small filter press, it was washed twice with dilute sulfuric acid and ammonia water respectively, maintained at 80°C for 1h and 100°C for...

Embodiment 2

[0057] After mixing 1000g of titanium-containing blast furnace slag (20-50 mesh) (see attached table 1 for composition), 50kg (10% waste sulfuric acid in mass concentration), put it into a 10L ball mill tank, add corundum balls, and carry out ball milling reaction. The ball milling speed is controlled to be 30 rpm, and the ball milling time is 600 min. After the reaction is completed, the slurry is poured into a centrifuge tank for high-speed centrifugation and washed with waste sulfuric acid to obtain leachate and solid residue.

[0058] After the leaching liquid was concentrated to 8.33L at 30°C and -0.5atm (TiO 2 Equivalent concentration 15g / L), under the condition of raising the temperature to 90°C, add H at 60mL / L 2 o 2, carry out oxidative hydrolysis reaction for 20 hours, after liquid-solid separation by small filter press, wash twice with dilute sulfuric acid and ammonia water respectively, maintain at 80°C for 2h, maintain at 100°C for 2h, and then dry at 150°C to o...

Embodiment 3

[0061] After mixing 1000g of titanium-containing blast furnace slag (20-50 mesh) (see attached table 1 for composition), 1.67kg (60% mass concentration of waste sulfuric acid), put it into a 10L ball mill tank, add corundum balls, and carry out ball milling reaction. The ball milling speed was controlled to be 1000 rpm, and the ball milling time was 15 minutes. After the reaction is completed, the slurry is poured into a centrifuge tank for high-speed centrifugation and washed with waste sulfuric acid to obtain leachate and solid residue.

[0062] After the leaching liquid was concentrated to 1.25L at 70°C and -0.01atm (TiO 2 Equivalent concentration 100g / L), add nitric acid (with H 2 o 2 10mL / L), carry out oxidative hydrolysis reaction for 5 hours, after liquid-solid separation by small-scale filter press, wash twice with dilute sulfuric acid and ammonia water respectively, maintain 1.5h at 80°C, 1.5h at 100°C, and then store at 120°C Dry to obtain a composite filter cake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com