Method for producing ammonium sulfate by removing sulfur through ammonia method

A technology of ammonia desulfurization and ammonium sulfate, applied in separation methods, chemical instruments and methods, ammonia compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

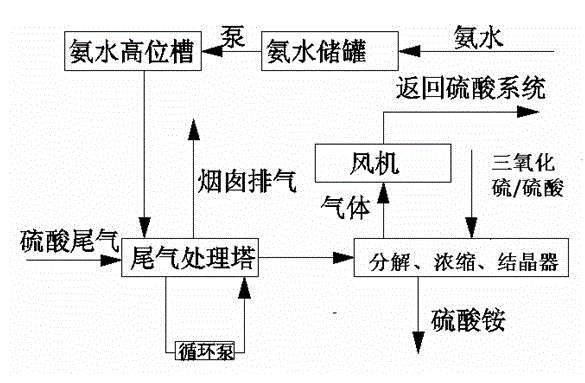

[0044] A method for ammonia desulfurization to produce ammonium sulfate, the flow chart is as figure 1 shown, including the following steps:

[0045] (1) Send the ammonia water with an ammonia concentration of 17.8% in the ammonia water storage tank into the ammonia water high-level tank with a circulating pump, and then pass the waste ammonia water with an ammonia concentration of 17.8% in the ammonia water high-level tank into the tail gas treatment tower. The amount of ammonia water is 0.18% t / h; At the same time, the tail gas produced during the production of sulfuric acid, the concentration of SO2 in the tail gas is 1700mg / Nm3, is passed into the tail gas treatment tower, and after the sulfur dioxide and ammonia water in the tail gas are desulfurized by reaction, the SO2 in the tail gas 2 The absorption rate is 95.06%, and it is discharged after demisting with a demister, and the SO in the exhaust gas 2 The concentration dropped to 84mg / Nm 3 , NH 3 The concentration i...

Embodiment 2

[0051] A method for ammonia desulfurization to produce ammonium sulfate, comprising the following steps:

[0052] (1) Send the waste ammonia water with an ammonia concentration of 13.3% in the ammonia water storage tank into the ammonia water high-level tank with a fan, and then pass the waste ammonia water with an ammonia concentration of 13.3% in the ammonia water high-level tank into the tail gas treatment tower. The amount of waste ammonia water is 0.261t / h; at the same time, the SO in the tail gas produced during the production of sulfuric acid 2 The concentration is 1920mg / Nm 3 , the tail gas is passed into the tail gas treatment tower, after the tail gas is desulfurized, the SO in the tail gas 2 The absorption rate is 95.05%, and it is discharged after defogging with a mist eliminator. The exhaust gas contains SO 2 The concentration of 95mg / Nm 3 , NH 3 The concentration is 2.14mg / Nm 3 , to obtain a circulating absorption liquid containing ammonium bisulfite, ammon...

Embodiment 3

[0058] A method for ammonia desulfurization to produce ammonium sulfate, comprising the following steps:

[0059] (1) Send the waste ammonia water with an ammonia concentration of 7.7% in the ammonia water storage tank to the high level tank of ammonia water with a circulating pump, and then pass the waste ammonia water with an ammonia concentration of 7.7% in the high level tank of ammonia water into the tail gas treatment tower. The amount of waste ammonia water is 0.43t / h; at the same time, the SO in the tail gas produced during the production of sulfuric acid 2 The concentration is 1850mg / Nm 3 , the tail gas is passed into the tail gas treatment tower, after the tail gas is desulfurized, the SO in the tail gas 2 The absorption rate is 95.14%, and it is discharged after demisting with a demister, and the SO in the tail gas 2 The concentration of 90mg / Nm 3 , NH 3 The concentration is 7.52mg / Nm 3 , to obtain a circulating absorption liquid containing ammonium bisulfite,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com