Method and device of automatic control for sequencing batch type treatment process at non-DO state

An automatic control device and treatment process technology, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. The same problems, to achieve the effect of improving sewage treatment capacity, saving energy consumption, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

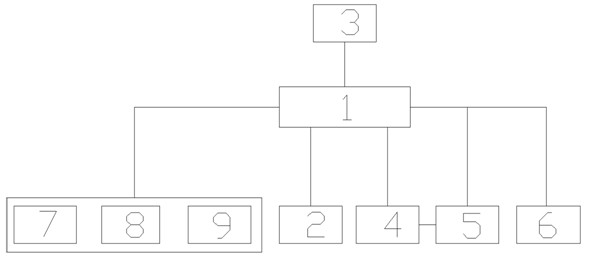

Image

Examples

Embodiment Construction

[0033]Embodiments of the present invention: the automatic control method of sequence batch type treatment process under non-DO state, it is characterized in that: real-time collection this influent water quality parameter and influent quantity parameter, influent water quality parameter is COD value, BOD value and ammonia nitrogen content; the influent volume is the volume flow rate of influent water; and it is sent to the aeration automatic control device together with the effluent water quality parameters of the previous cycle. The effluent water quality parameters of the previous cycle are COD, BOD, NH3-N, SS; after aeration After the automatic calculation of the preset program of the automatic air control device, various parameters of the influent water treatment process are obtained, including the start time of aeration, the end time of aeration, the operating frequency and number of aeration fans, the settling time, and the decanting time. Time and discharge time of retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com