Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Low cost and energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for using bulk sintered neodymium iron boron (NdFeB) machining waste to prepare high-performance regenerated NdFeB magnet

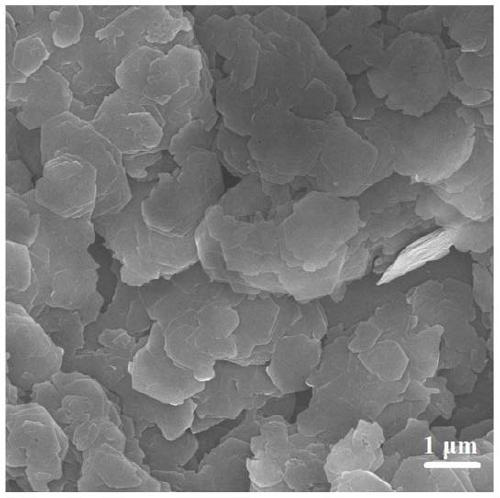

InactiveCN104036942ASmall particle sizeEvenly distributedInductances/transformers/magnets manufactureMagnetic materialsGas phaseRare earth

The invention relates to a method for using bulk sintered neodymium iron boron (NdFeB) machining waste to prepare a high-coercivity regenerated NdFeB magnet and belongs to the technical field of magnetic materials. The rare earth praseodymium hydride nano powder doping technology is used to regenerate the sintered NdFeB machining waste so as to prepare the high-performance regenerated sintered NdFeB permanent magnet. The method includes: using hydrogen explosion and air flow milling to prepare NdFeB powder; using the physical gas phase deposition technology to prepare praseodymium hydride nano powder; mixing the two kinds of powder, and performing magnetic field orientation and compression moulding; performing dehydrogenation, sintering and thermal treatment on the compressed base at different temperatures to obtain the sintered magnet. The method has the advantages that various magnetic performances of the regenerated magnet prepared by the method can restore to the level an original magnet, and the coercivity of the regenerated magnet is higher than that of the original magnet, and the method is short in process flow, low in cost and energy consumption and resource saving.

Owner:BEIJING UNIV OF TECH

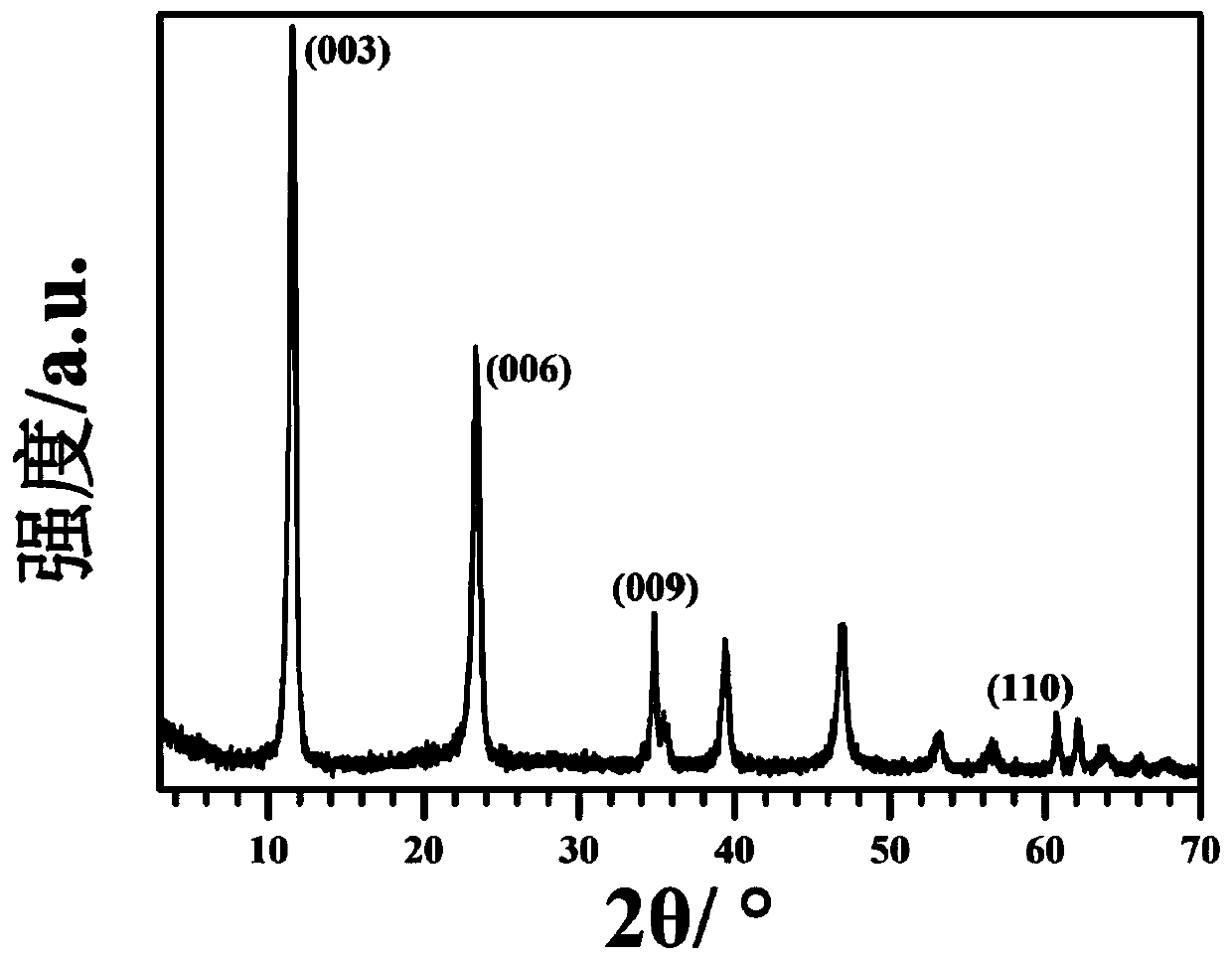

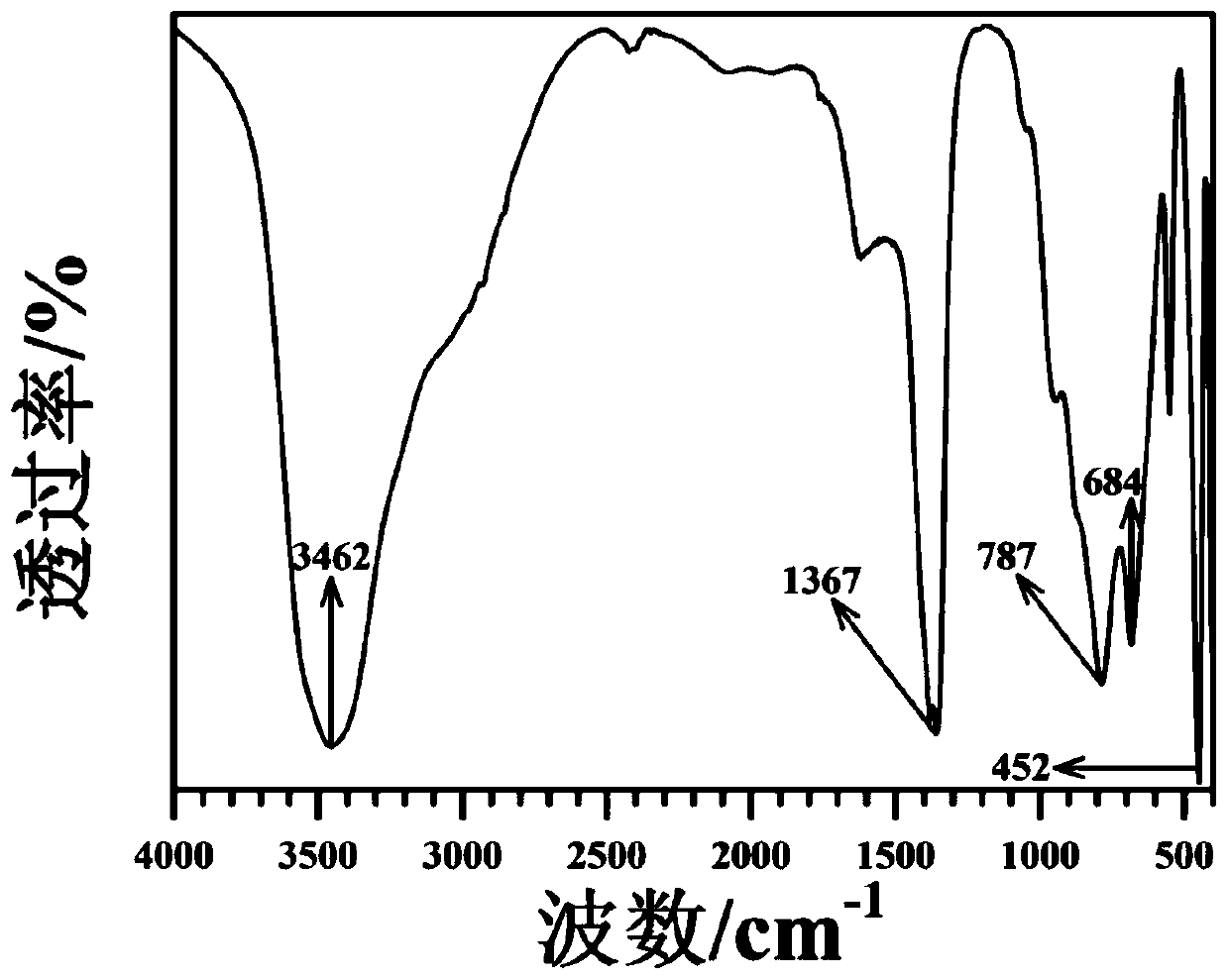

Cleaning preparation method of laminated composite metal hydroxide

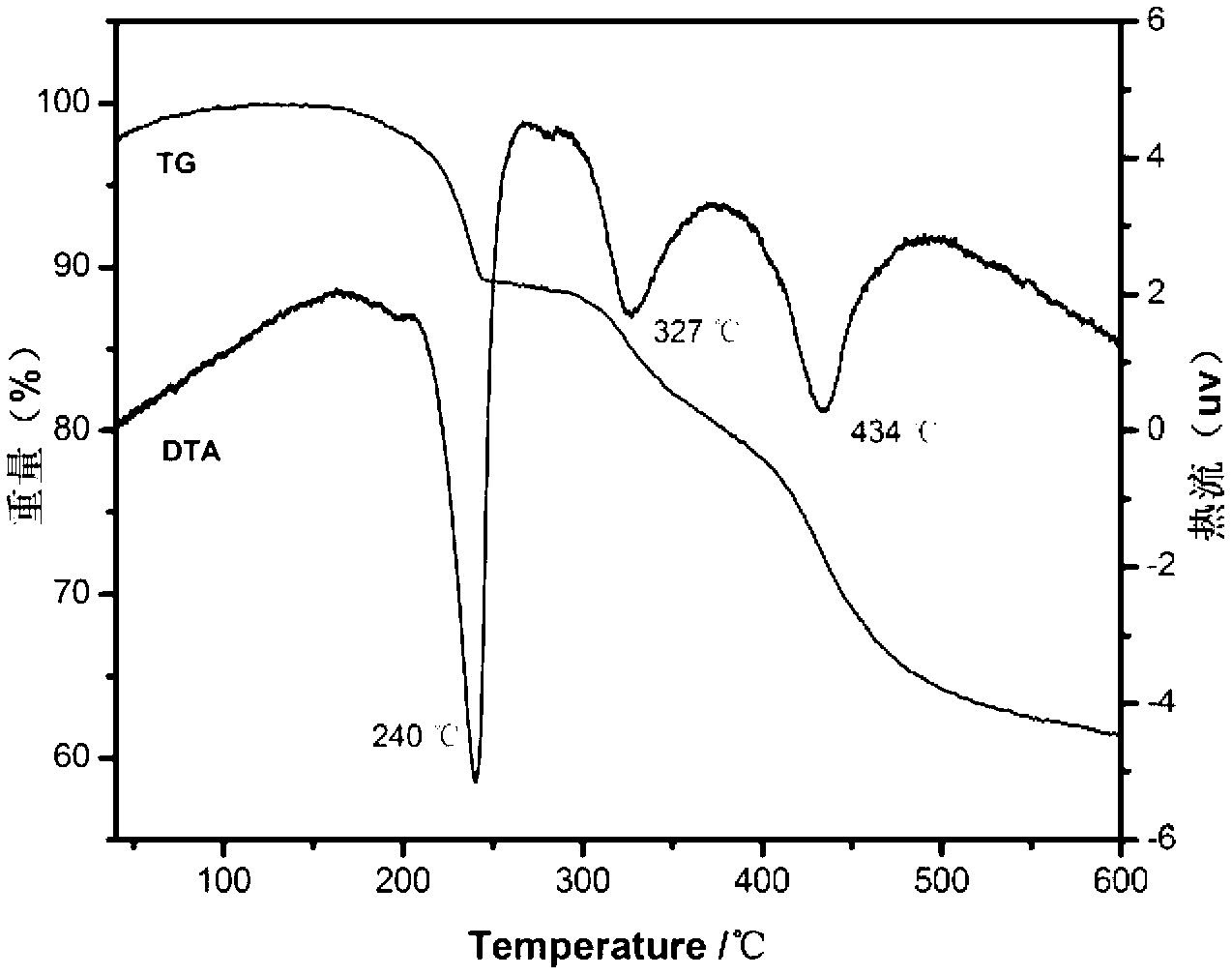

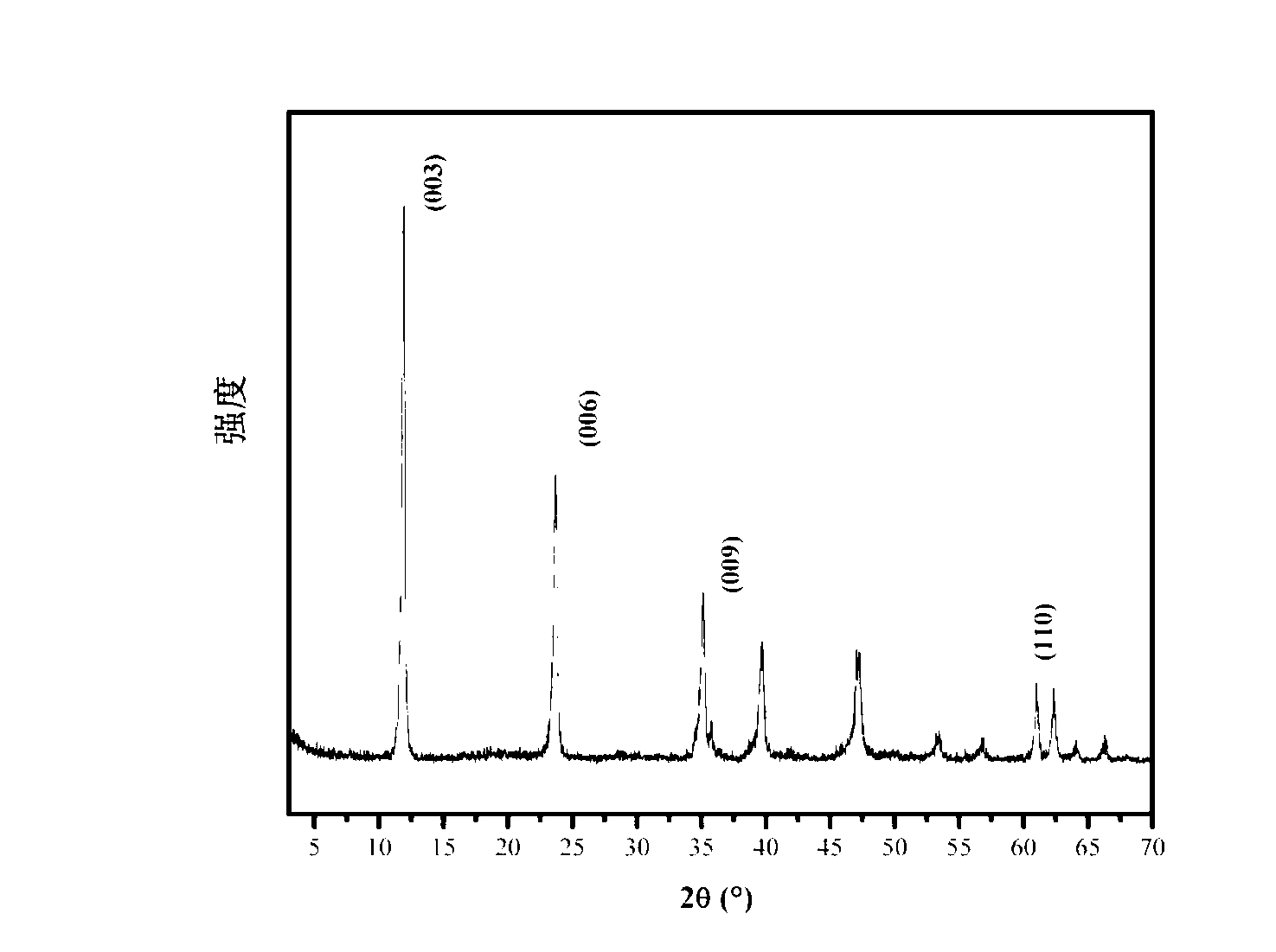

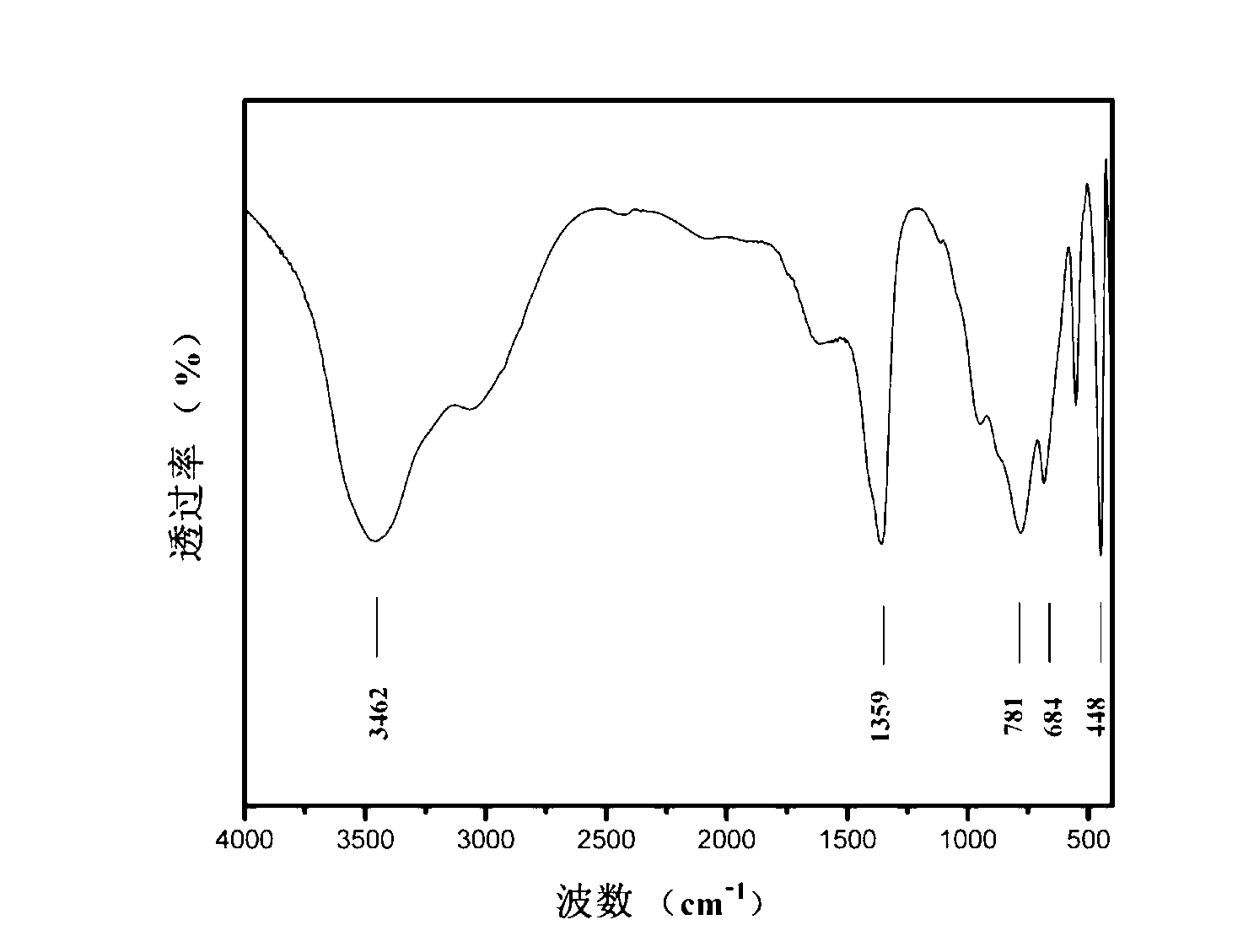

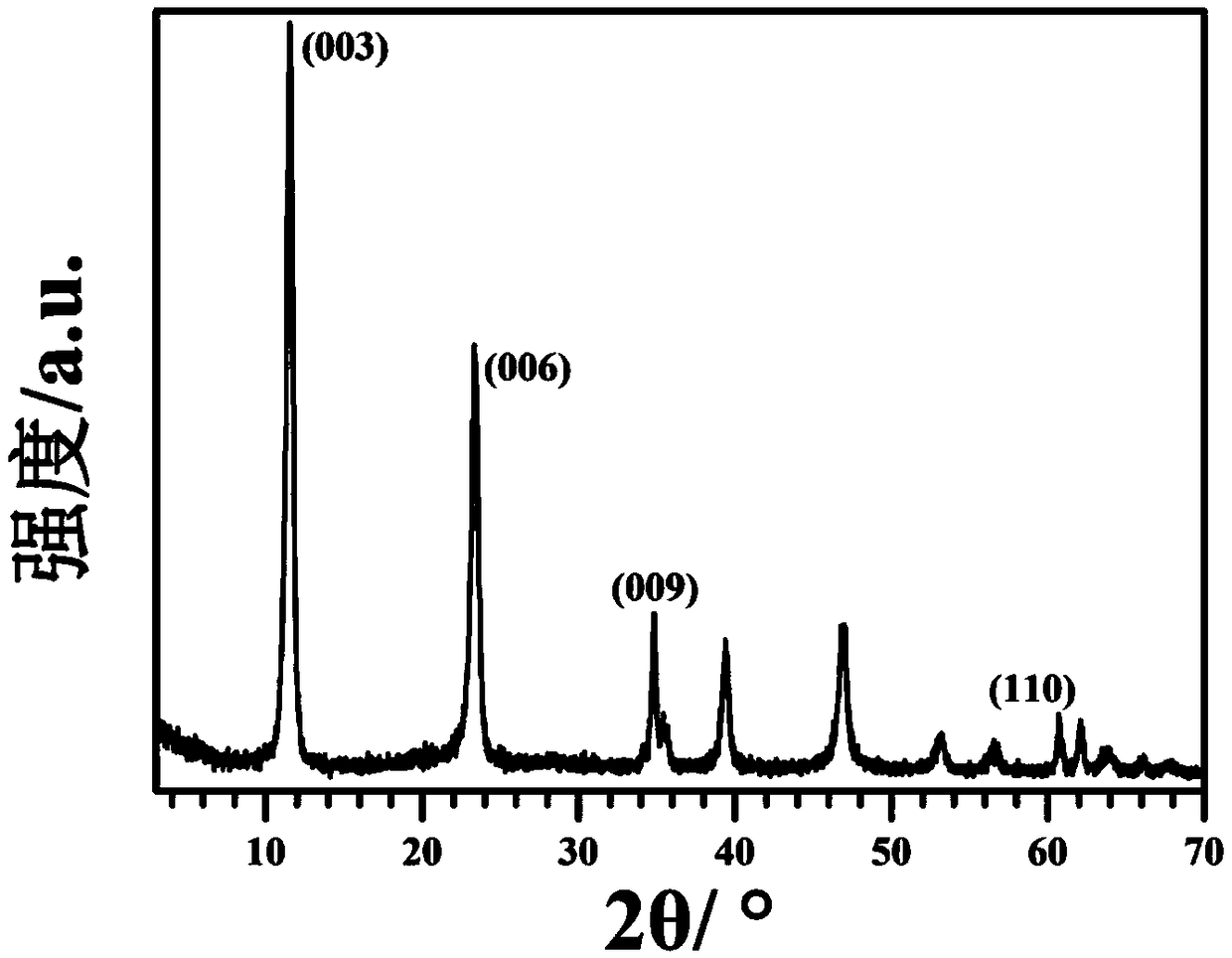

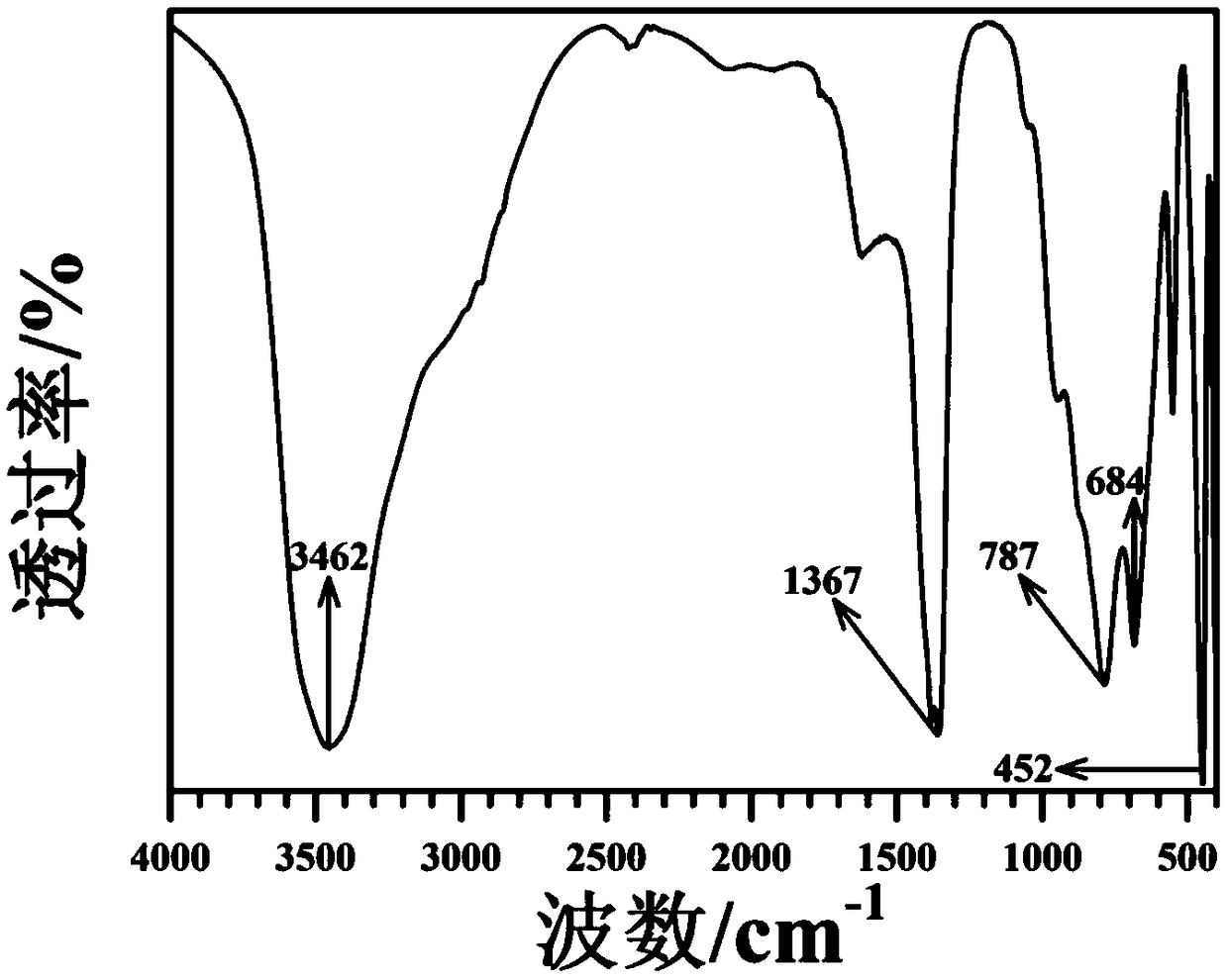

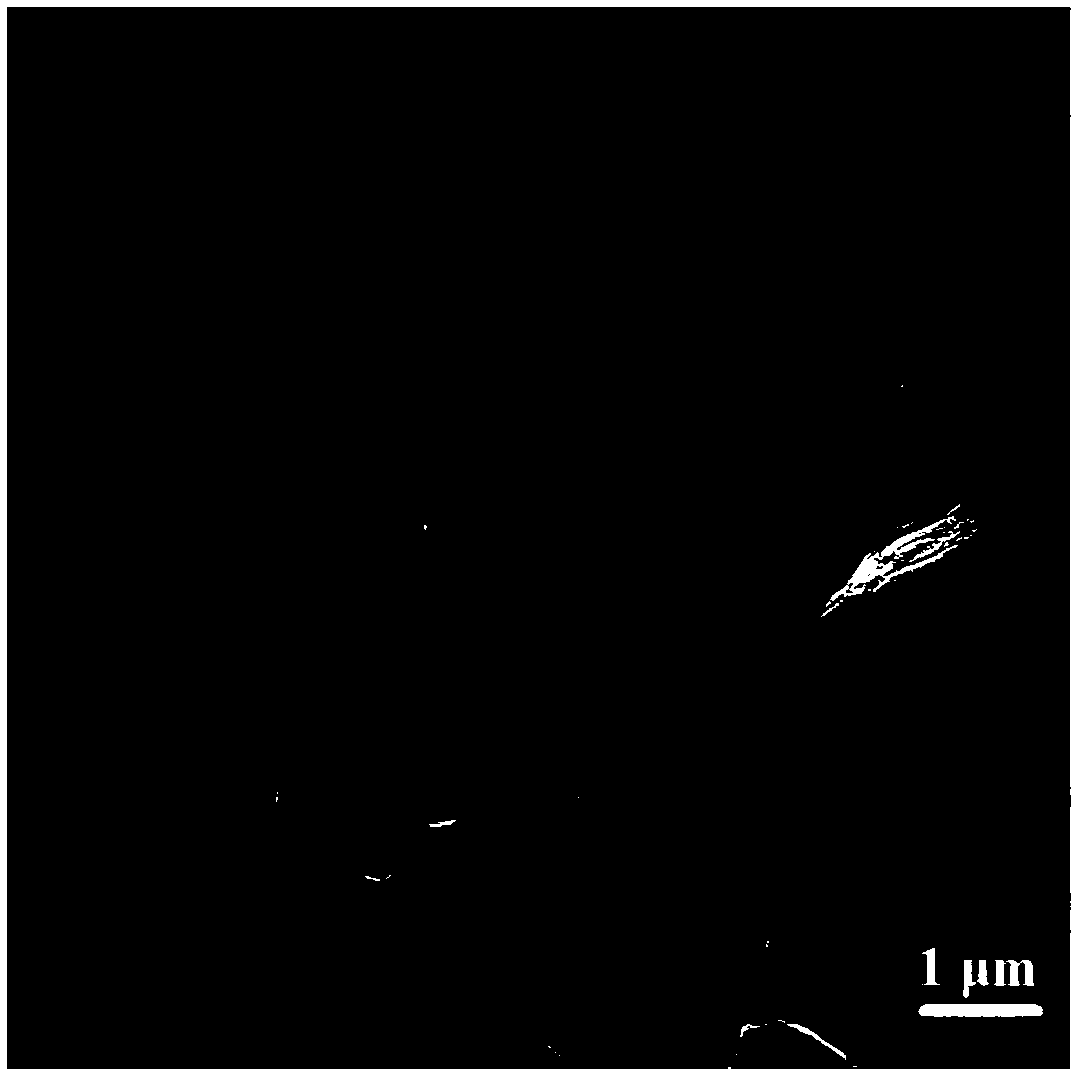

InactiveCN102701241ANo pollution in the processSave waterAluminium compoundsCalcium/strontium/barium compoundsChemical compositionDivalent metal

The invention provides a cleaning preparation method of laminated composite metal hydroxide, wherein a general formula of chemical composition of the laminated composite metal hydroxide is M2+1-xM3+x(OH)2(An-)x / n.mH2O. The method uses hydroxide of divalent metal, basic carbonate or carbonate and the hydroxide of trivalent metal as raw materials to directly synthesize and prepare the laminated composite metal hydroxide with a regular structure by one step, wherein all the materials take part in the reaction to generate the target product without a by-product; the drying treatment can be carried out directly and the water resource is greatly saved. The method has the advantages of simple technological process, little device investment, low cost and energy consumption and no environmental pollution, and belongs to an environment-friendly technique.

Owner:BEIJING UNIV OF CHEM TECH

Method for using magnetic steel of waste permanent magnet motor to prepare high-performance high-coercivity regenerated sintered neodymium iron boron (NdFeB) magnet

InactiveCN104036946ASmall particle sizeEvenly distributedInductances/transformers/magnets manufactureMagnetic materialsGas phaseResource saving

The invention relates to a method for using magnetic steel of a waste permanent magnet motor to prepare a high-performance high-coercivity regenerated sintered neodymium iron boron (NdFeB) magnet and belongs to the technical field of magnetic materials. The rare earth praseodymium hydride nano powder doping technology is used to regenerate the magnetic steel of the waste rare earth permanent magnet motor so as to prepare the high-performance regenerated sintered NdFeB permanent magnet. The method includes: using hydrogen explosion and air flow milling to prepare NdFeB powder; using the physical gas phase deposition technology to prepare praseodymium hydride nano powder; mixing the two kinds of powder, and performing magnetic field orientation and compression moulding; performing dehydrogenation, sintering and thermal treatment on the compressed base at different temperatures to obtain the sintered magnet. The method has the advantages that various magnetic performances of the regenerated magnet prepared by the method can restore to the level of the original magnetic steel, and the coercivity of the regenerated magnet is higher than that of the original magnetic steel, and the method is short in process flow, low in cost and energy consumption and resource saving.

Owner:BEIJING UNIV OF TECH

Method for using magnetic steel of waste permanent magnet motor to prepare high-performance regenerated sintered neodymium iron boron (NdFeB) magnet

InactiveCN104036948ASmall particle sizeEvenly distributedInductances/transformers/magnets manufactureMagnetic materialsMetallurgyGas phase

The invention relates to a method for using magnetic steel of a waste permanent magnet motor to prepare a high-coercivity regenerated sintered neodymium iron boron (NdFeB) magnet and belongs to the technical field of magnetic materials. The rare earth dysprosium hydride nano powder doping technology is used to regenerate the magnetic steel of the waste rare earth permanent magnet motor so as to prepare the high-coercivity regenerated sintered NdFeB permanent magnet. The method includes: using hydrogen explosion and air flow milling to prepare NdFeB powder; using the physical gas phase deposition technology to prepare dysprosium hydride nano powder; mixing the two kinds of powder, and performing magnetic field orientation and compression moulding; performing dehydrogenation, sintering and thermal treatment on the compressed base at different temperatures to obtain the sintered magnet. The method has the advantages that the coercivity of the regenerated magnet can be higher than that of the original magnetic steel, and the residual magnetism and magnetic energy product of the regenerated magnet are close to those of the original magnetic steel, and the method is short in process flow, low in cost and energy consumption and resource saving.

Owner:BEIJING UNIV OF TECH

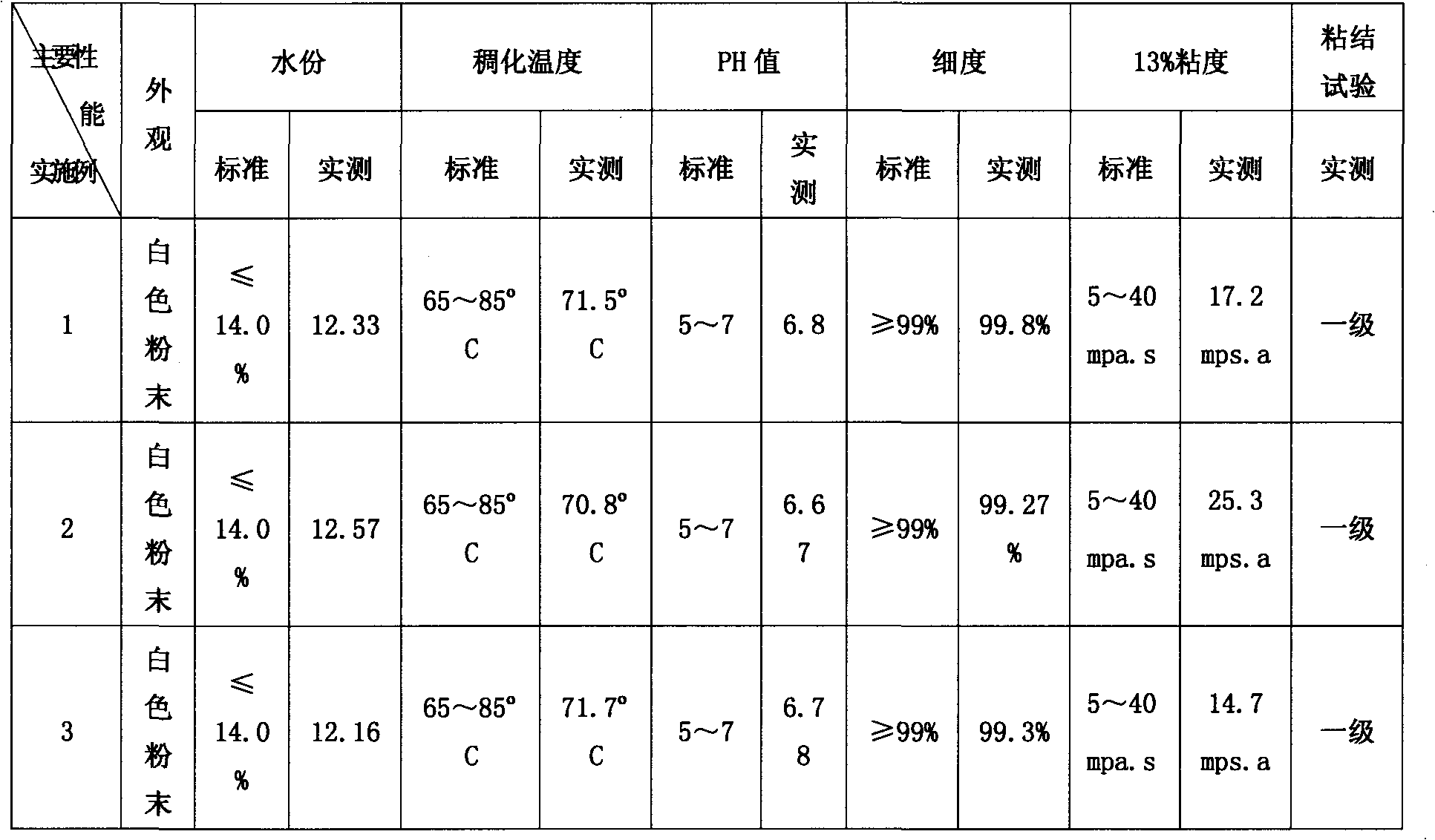

Production technology of plasterboard modified starch

The invention discloses a production technology of plasterboard modified starch, comprising the following steps of mixing, degeneration reaction, neutralization reaction, physical synergism, screening, weighing and packaging. The invention combines the advantages of various modified starches, has the advantages of strong size film strength, transparency, good water absorption, good dispersion, good gliding property, low gelatinization temperature, strong paste liquid bond force, good adsorbability, easy dissolution, good film forming ability, weak retrogradation, good elasticity, smoothness, flexibility, tough and elastic size film, nontoxicity, tastelessness, safe use, convenient operation, large production scale, little investment, low energy consumption, less pollution, high production efficiency, stable and reliable product quality and the like and is widely applied to gypsum products.

Owner:四川省蓬溪县弘桥实业有限公司

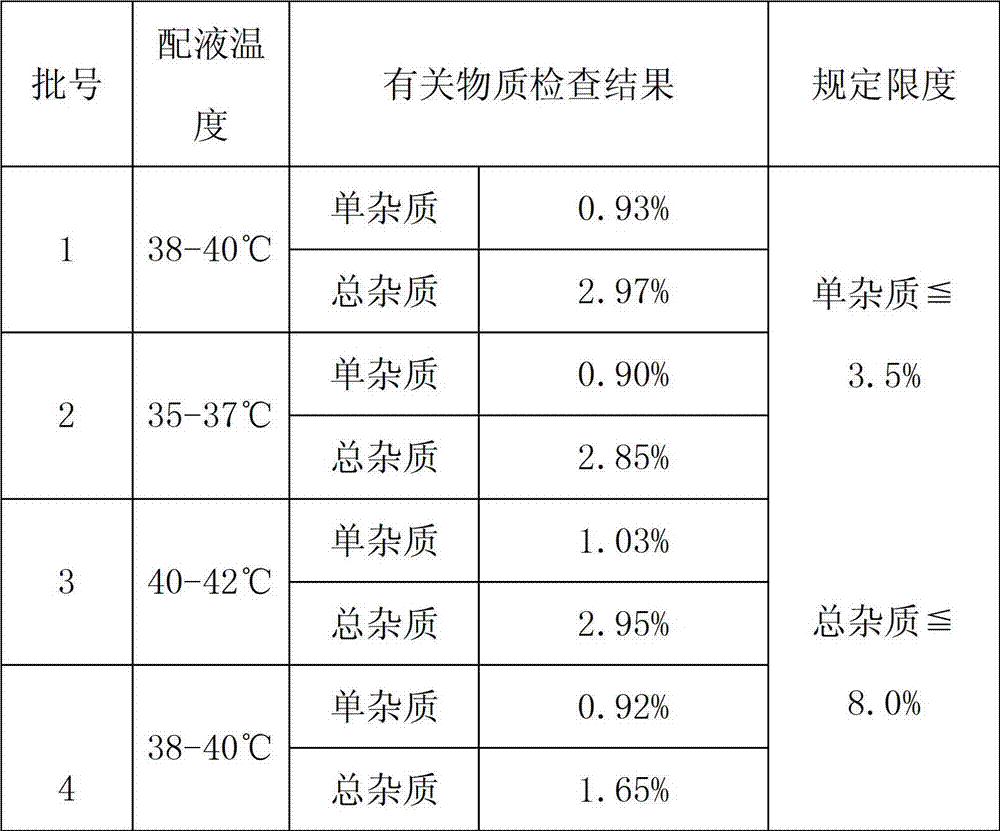

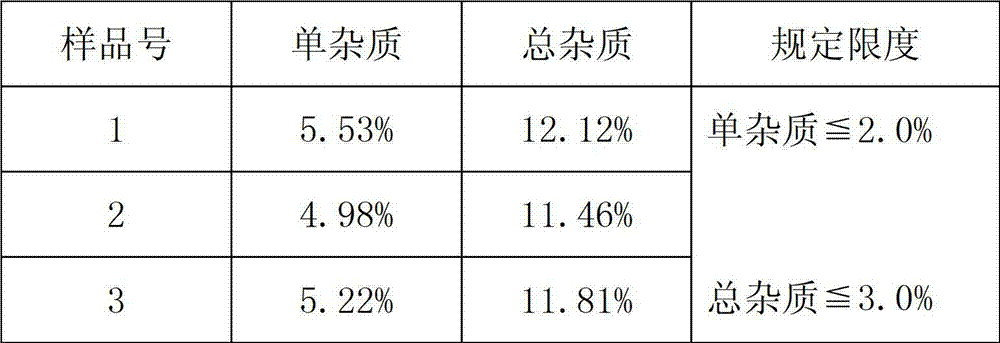

Preparation method of deslanoside injection

InactiveCN102961326ALow costQuality improvementOrganic active ingredientsPharmaceutical delivery mechanismEnergy consumptionChinese pharmacopoeia

The invention provides a preparation method of deslanoside injection. According to the preparation method, the temperature of water for injection of liquor is lowered to 35-42 DEG C, heat treatment is carried out at 100 DEG C for 30 minutes or is not adopted, and ethanol (re-steaming) is changed into ethanol (medicinal) and is directly used without re-steaming, so that the re-steaming time and cost are saved, and the quality can be ensured. According to an experimental study, the related substance indexes of the product prepared by the method are obviously reduced, the product quality is improved, and the product risk is lowered. A complete inspection according to the standard of Chinese Pharmacopoeia 2010 shows that all indexes of the deslanoside injection produced by the new method meet the standard requirements. The preparation method is simple, the product quality is ensured without increasing new cost, and the cost and energy consumption can be lowered. The preparation method is suitable for large-scale industrial production.

Owner:SHANGHAI ZHAOHUI PHARMA

Process for producing bright thin-wall copper pipe through up-draw method

The invention discloses a process for producing a bright thin-wall copper pipe through an up-draw method. The process comprises the steps of cathode copper smelting, up-drawing and continuous castingof oxygen free copper tube, tube rolling, bull block drawing, compound wound cleaning, annealing and drawing. The invention provides the process for producing the bright thin-wall copper pipe throughthe up-draw method. A copper-tube bus produced through the process has the advantages of small dimension error, high electric conductivity, good thermal diffusivity and strong mechanical capacity, hasthe copper content higher than or equal to 99.99 percent, the oxygen content lower than or equal to 10 PPM, and dimension error less than or equal to + / -0.05m, and the electric conductivity higher than or equal to 100 percent IACS.

Owner:ZHONGTIAN ALLOY TECH

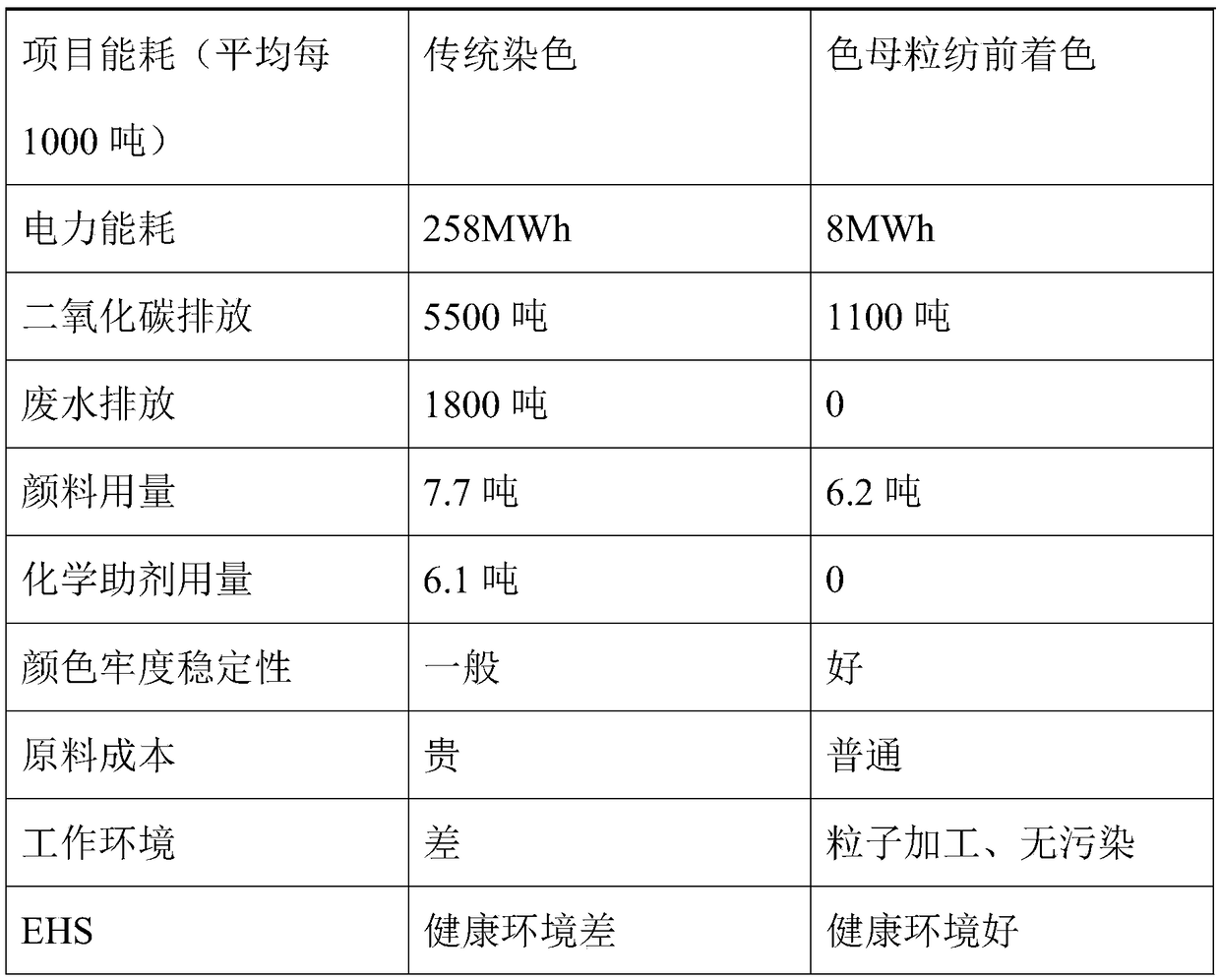

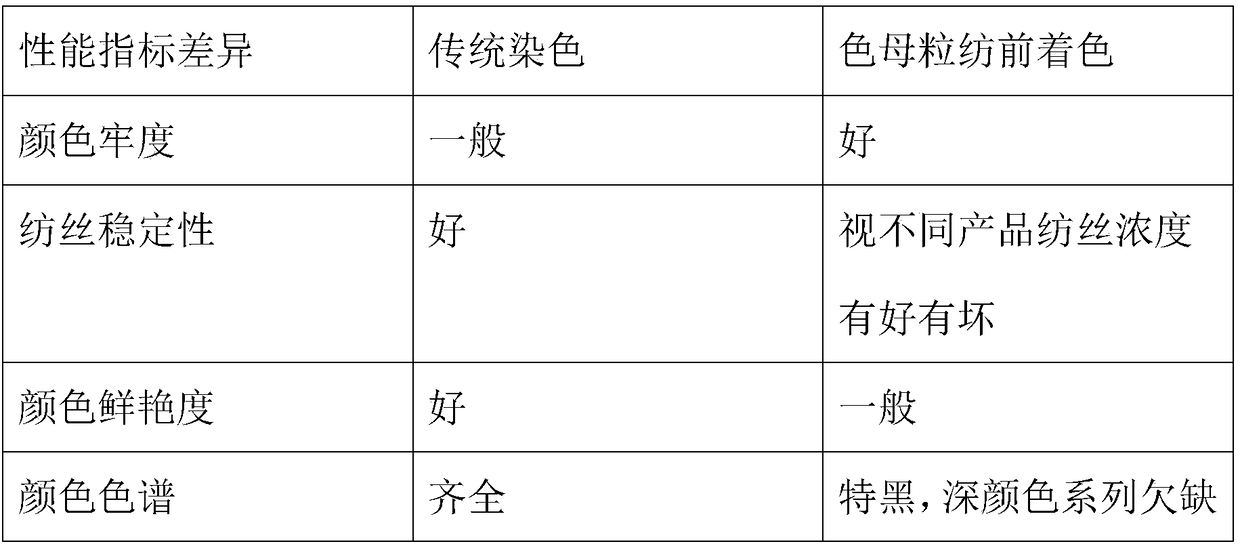

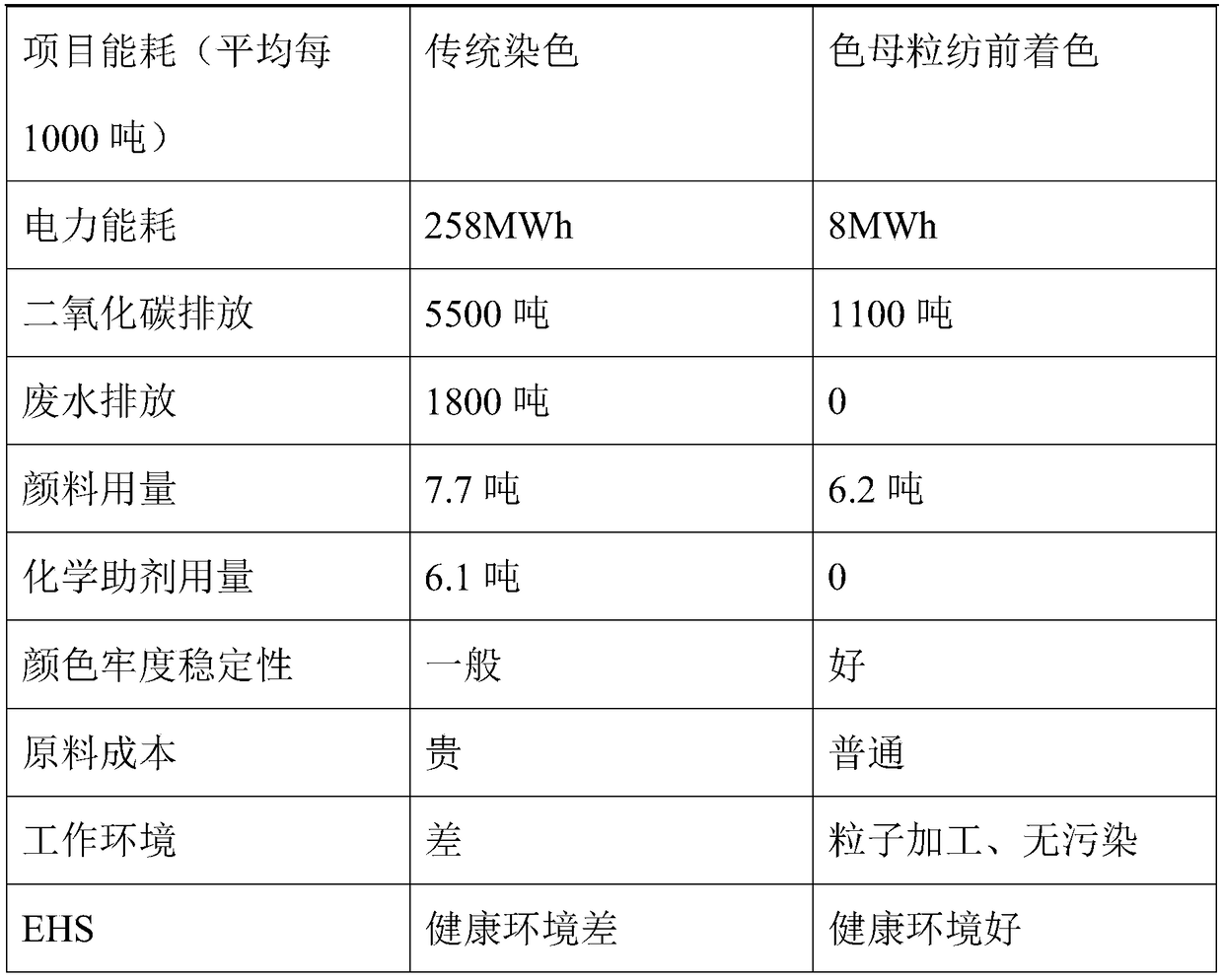

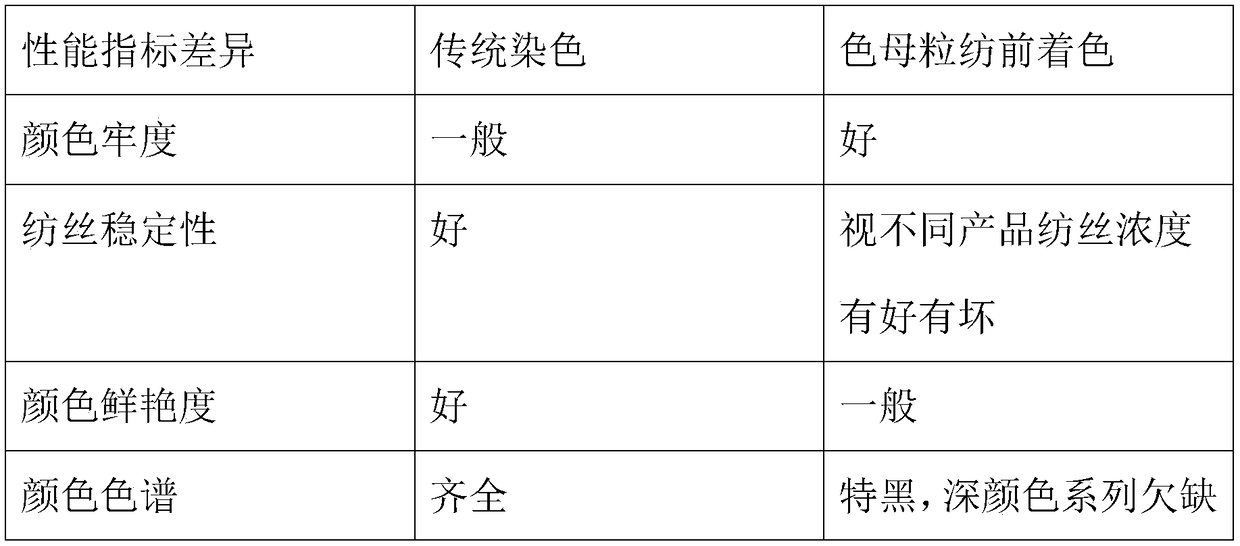

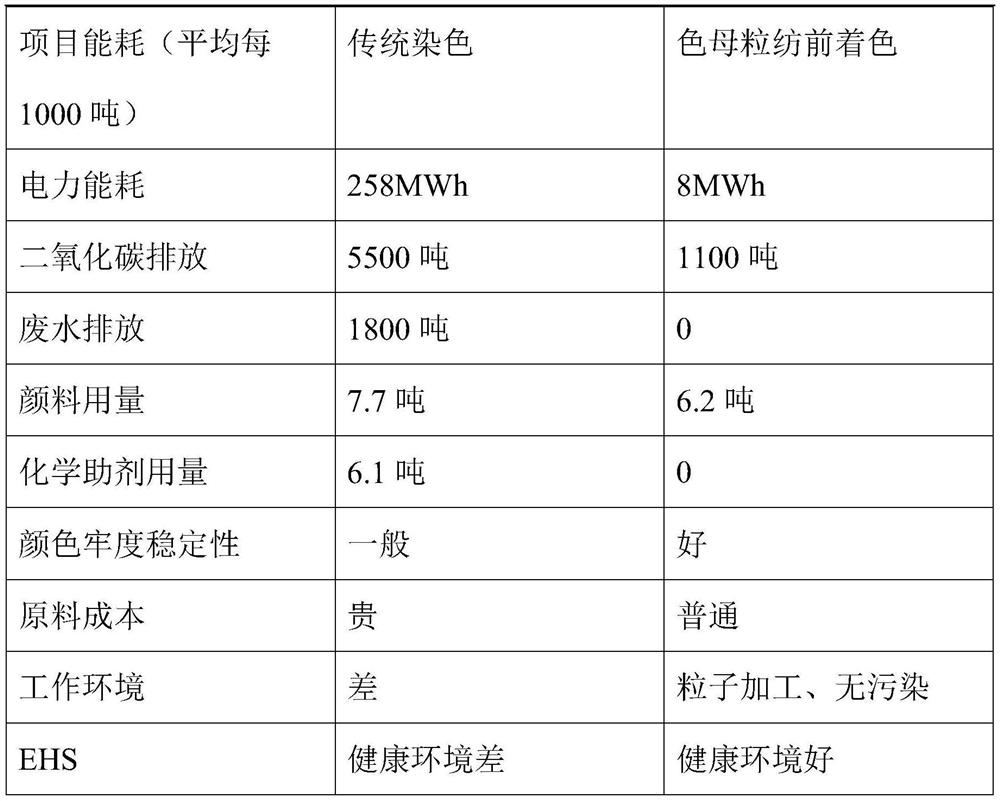

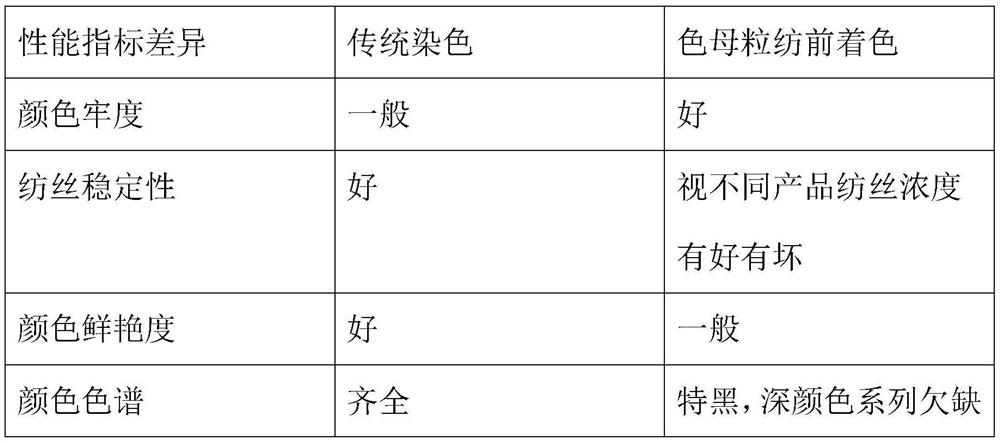

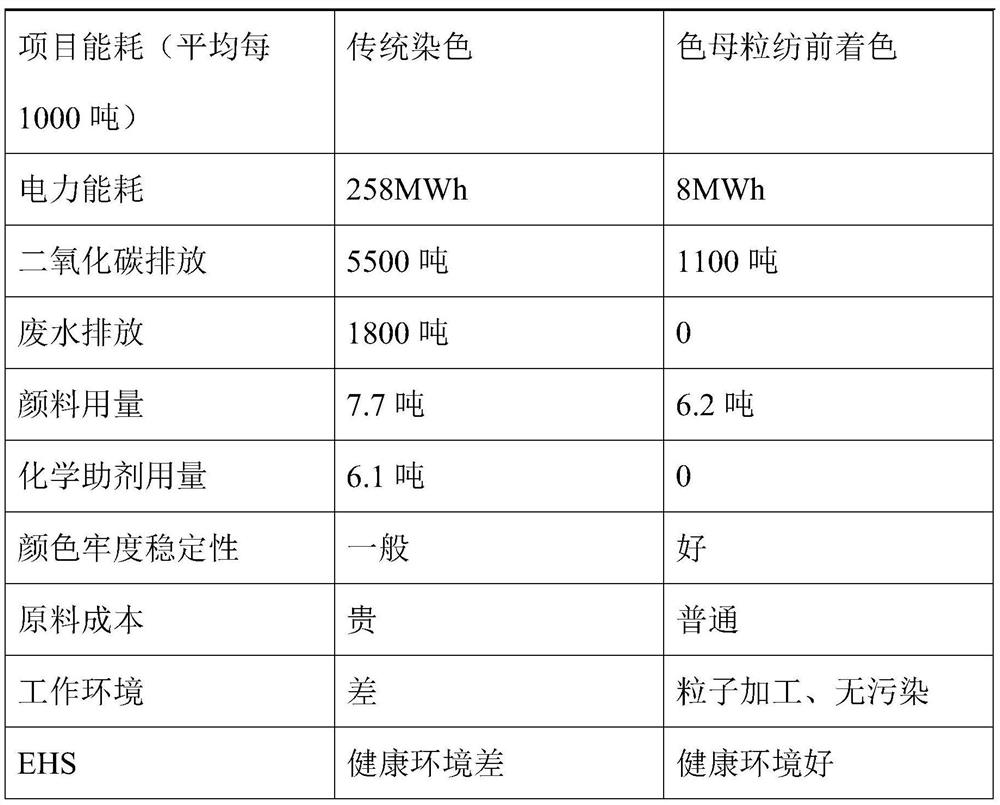

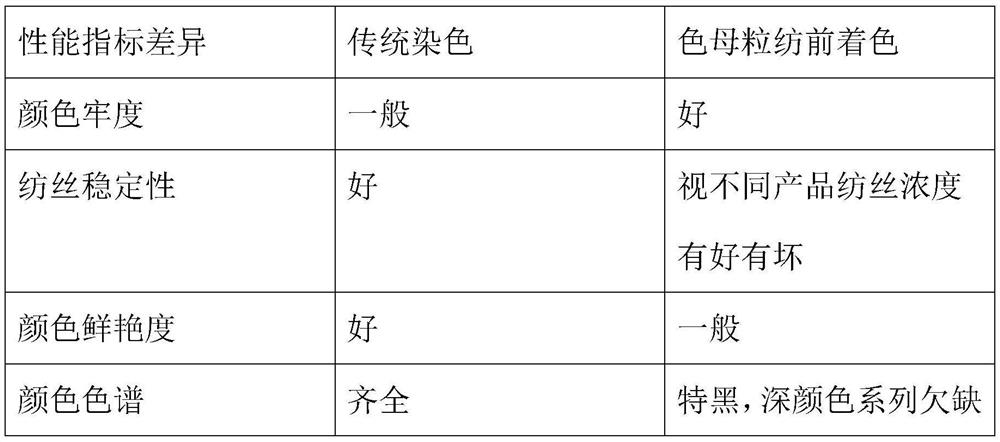

Method for improving brilliance and tinting strength of polyester fiber

InactiveCN108866672AImprove vividnessHigh tinting strengthPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses a method for improving brilliance and tinting strength of polyester fiber. The method comprises the following step: S1, preparing coloring master batch, wherein the prepared coloring master batch is prepared from 20 to 30% of pigment, 5 to 10% of ethylene acrylate copolymer, 2 to 5% of dispersing agent and the balance of carrier resin; S2, mixing the coloring master batch with PET slices and drying, wherein the weight proportion of the coloring master batch is 5 to 20%; S3, putting the coloring master batch and the PET slices which are evenly mixed into a spinning machine to be molten and extruding into silk by a spinneret plate to form polyester fiber. According to the method for improving brilliance and tinting strength of the polyester fiber disclosed by the invention, the coloring master batch containing pigment and the ethylene acrylate copolymer is used, so that brilliance and the tinting strength of the prepared polyester fiber is improved, and the brilliance of the polyester fiber is improved by 20%; meanwhile, spinning stability is improved, pressure is stable, and a spinning period is improved by 20%; furthermore, in an assembly cleaning process, residues are less, more convenience is brought to cleaning, and cost and energy consumption are obviously reduced.

Owner:浙江恒烨新材料科技有限公司

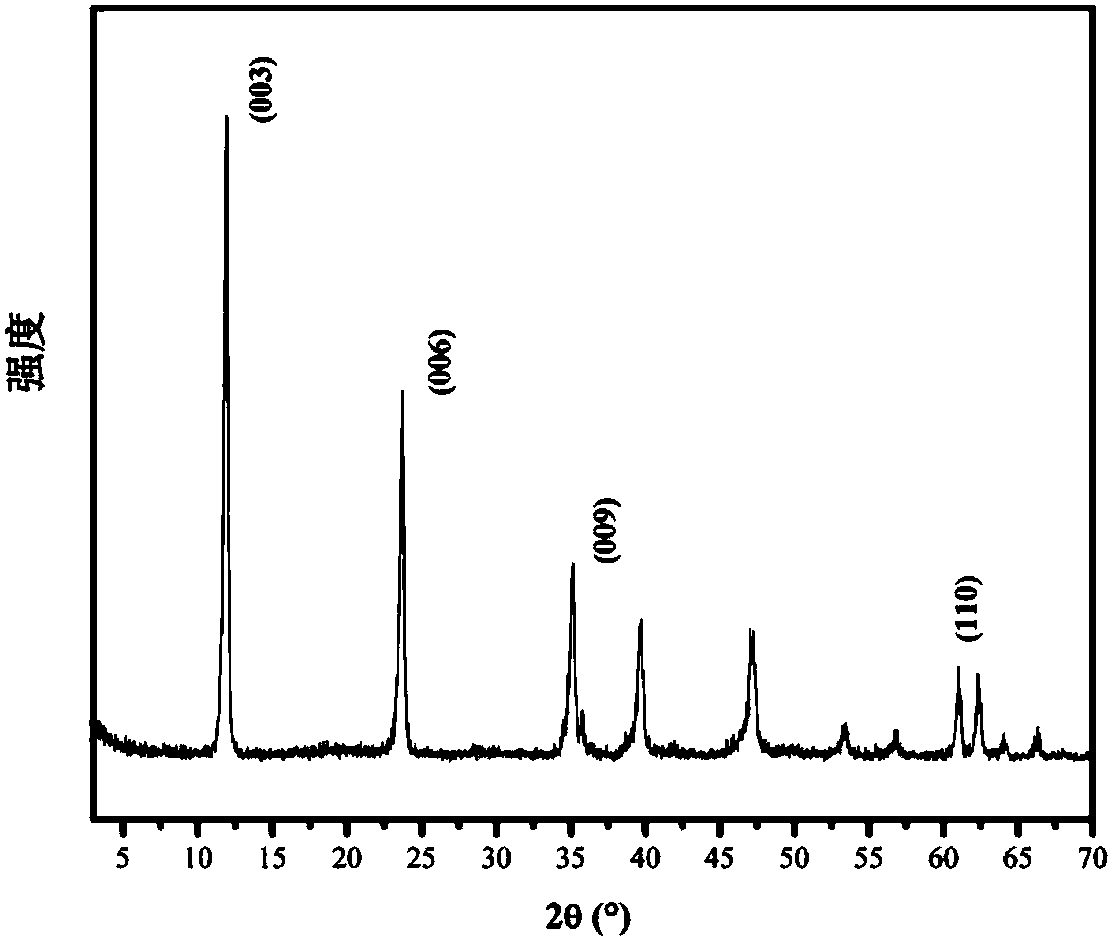

Clean preparation method of layered double hydroxides

ActiveCN108751237ANo pollution in the processHigh value availableHydrotalciteAlkalinityReaction temperature

The invention provides a clean preparation method of layered double hydroxides (LDHs). According to the invention, a metal hydroxide, metal soluble salt and metal basic carbonate are used as reactionraw materials, and the layered double hydroxides which are high in purity and well-defined in structure are directly synthesized in one step. Since only the metal hydroxide, the metal soluble salt andthe metal basic carbonate are used as the raw materials in a reaction process, and alkali materials such as NaOH or Na2CO3 which are commonly used in a conventional technology are not used, the alkalinity of reaction products is greatly reduced, washing with a large amount of water is avoided, a lot of water resources are saved and the environment is protected; at the same time, because the metalsoluble salt is used as the reaction raw material, compared with clean preparation methods by only using poorly soluble metal hydroxides or oxides as the reaction raw material, the method provided bythe invention is reduced in reaction temperature, shortened in reaction time, mild in reaction conditions, low in production cost and energy consumption, low in requirements on a reaction device, less in equipment investment and simple in process flow, has basically no environmental pollution, and is an environmentally-friendly process.

Owner:BEIJING UNIV OF CHEM TECH

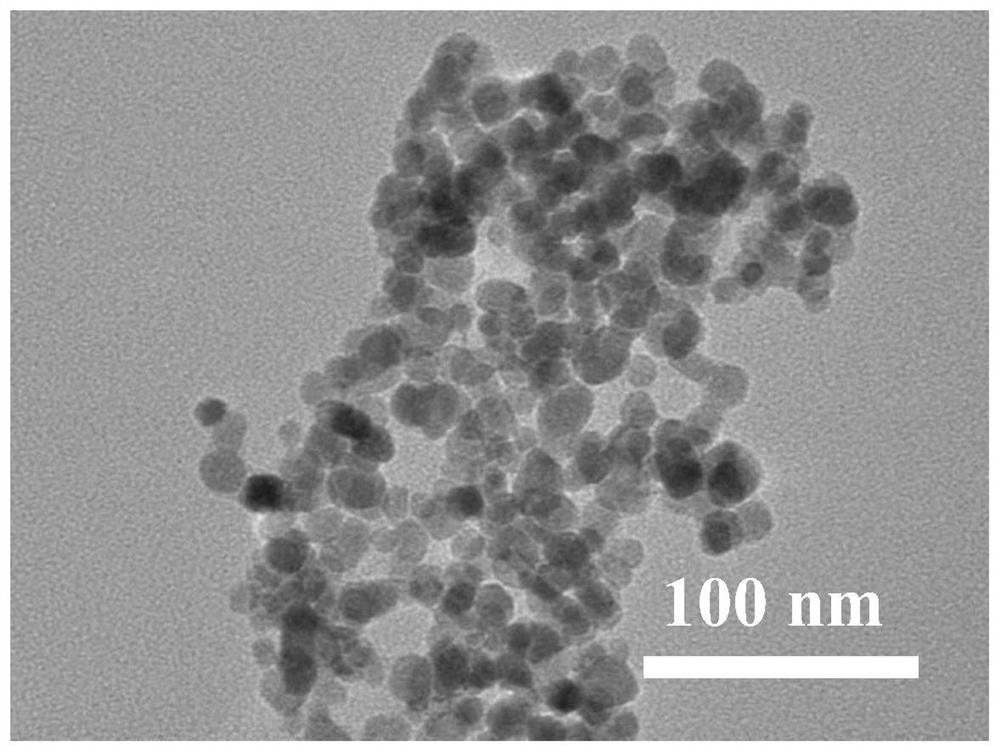

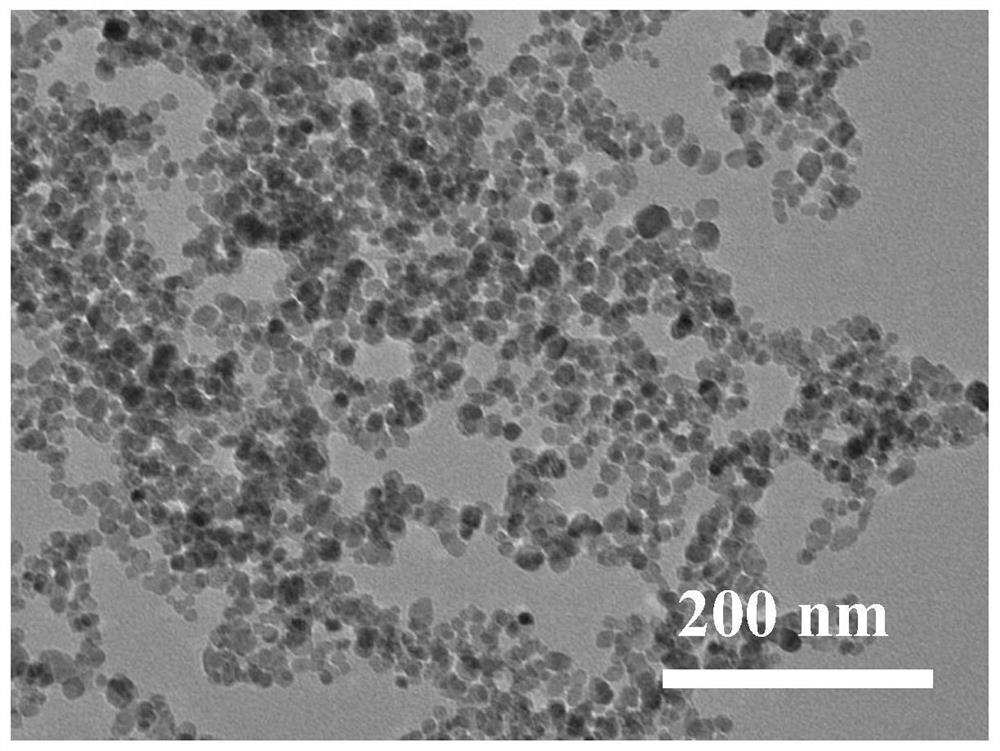

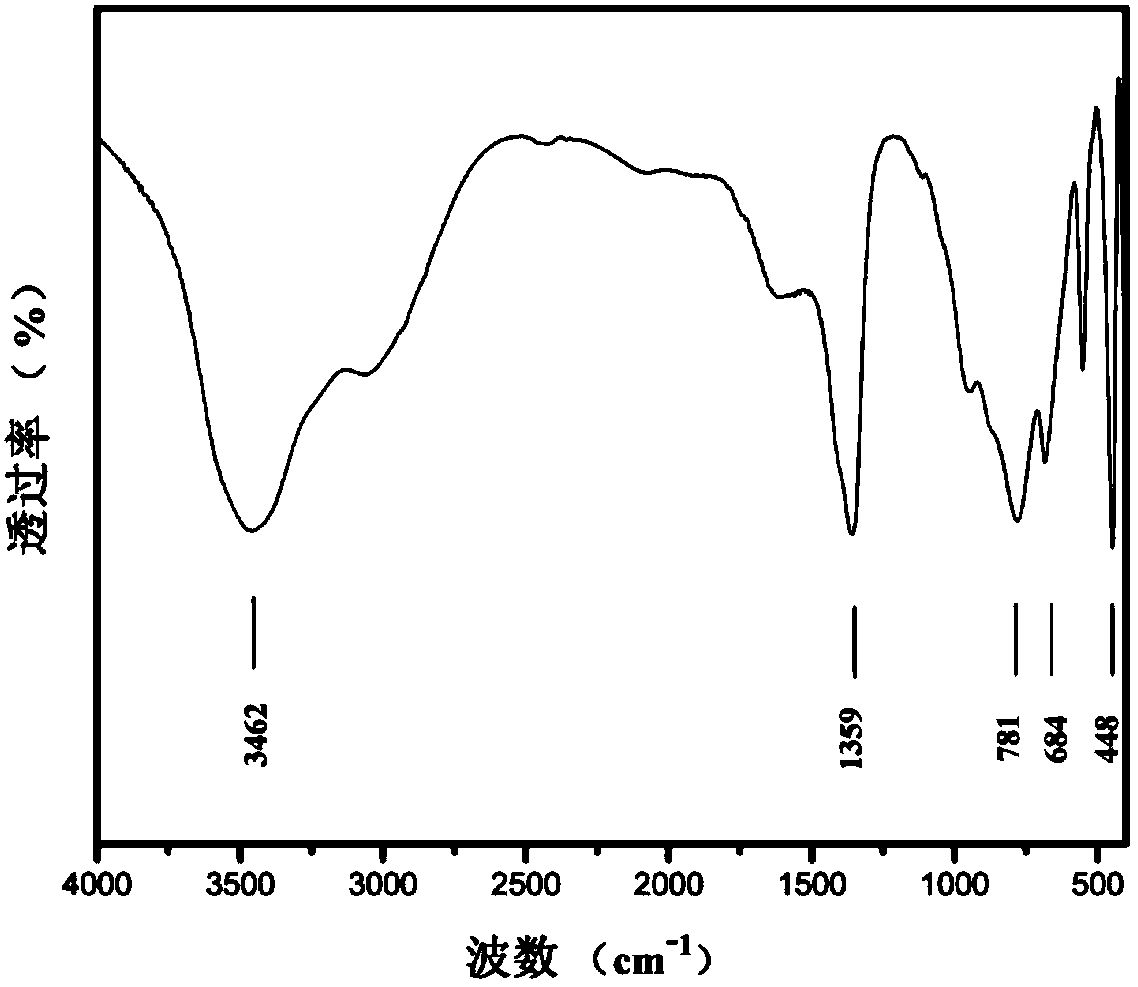

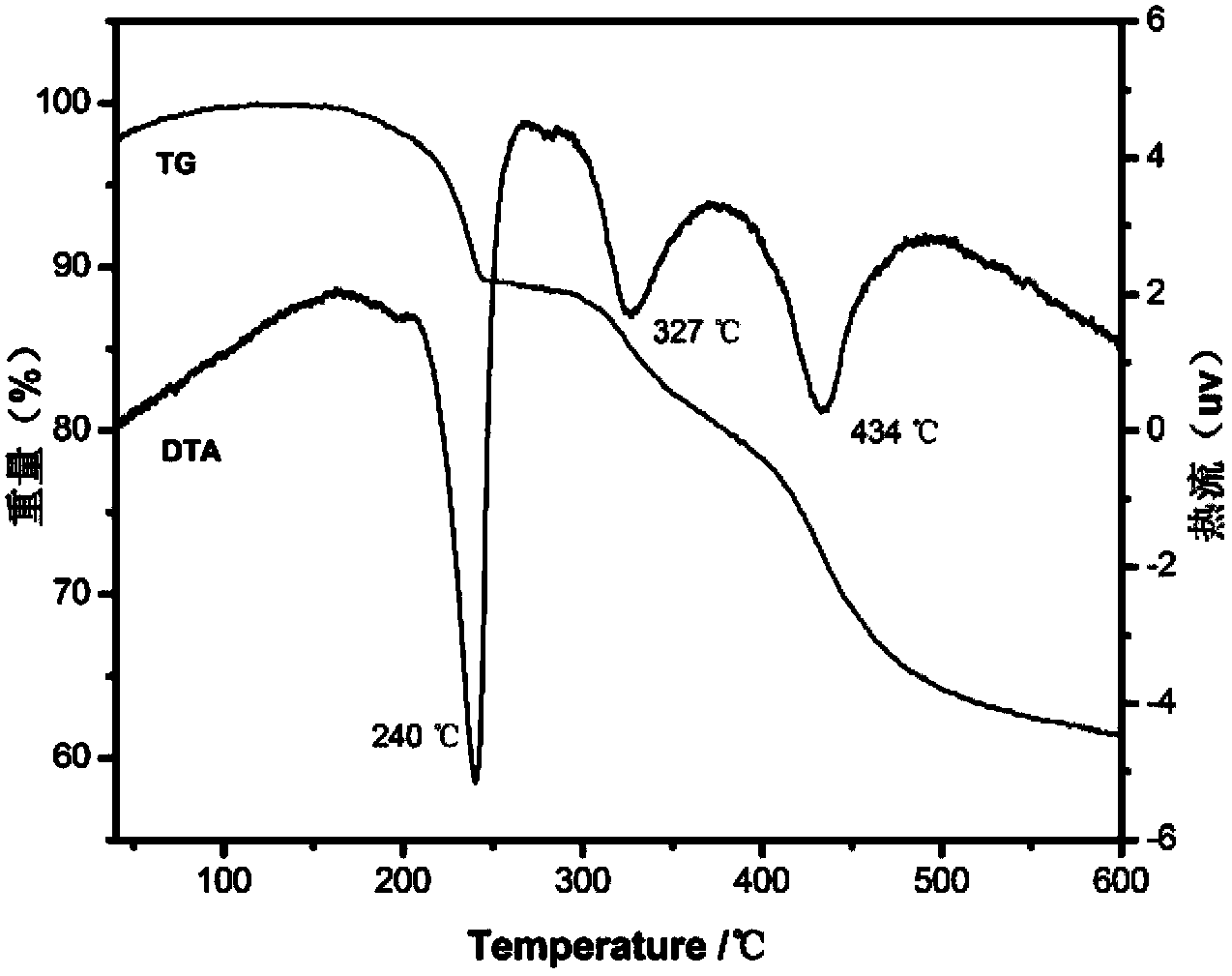

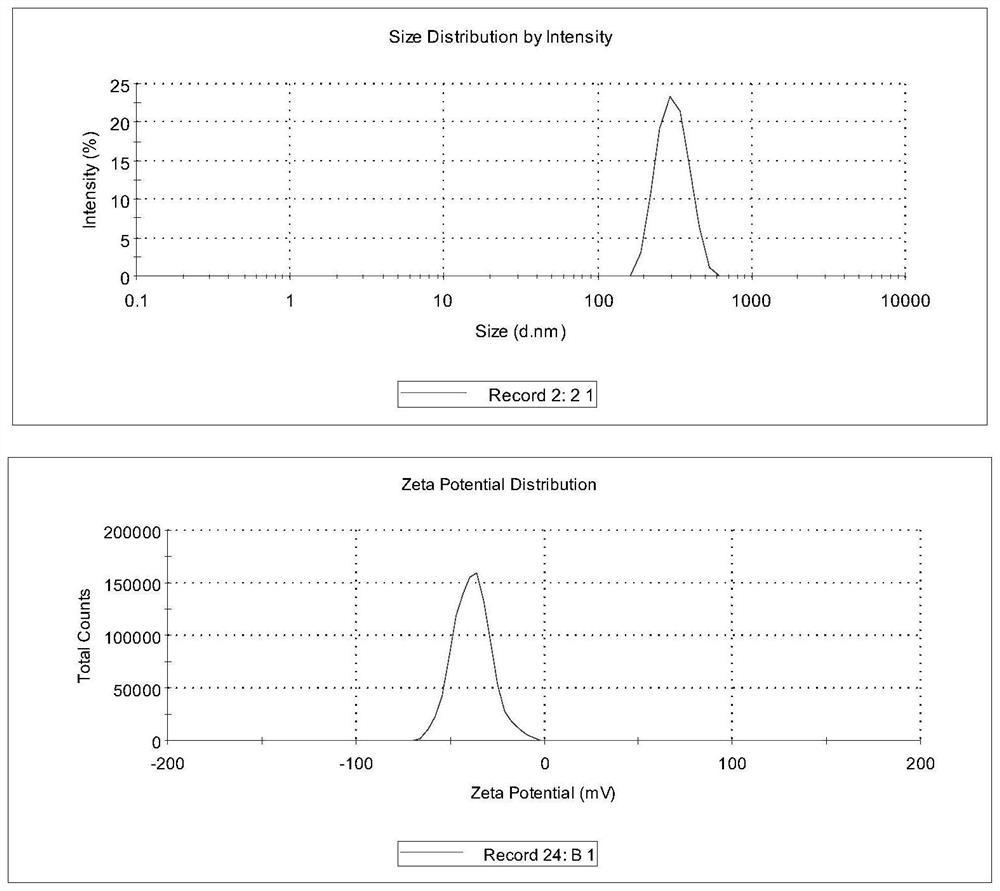

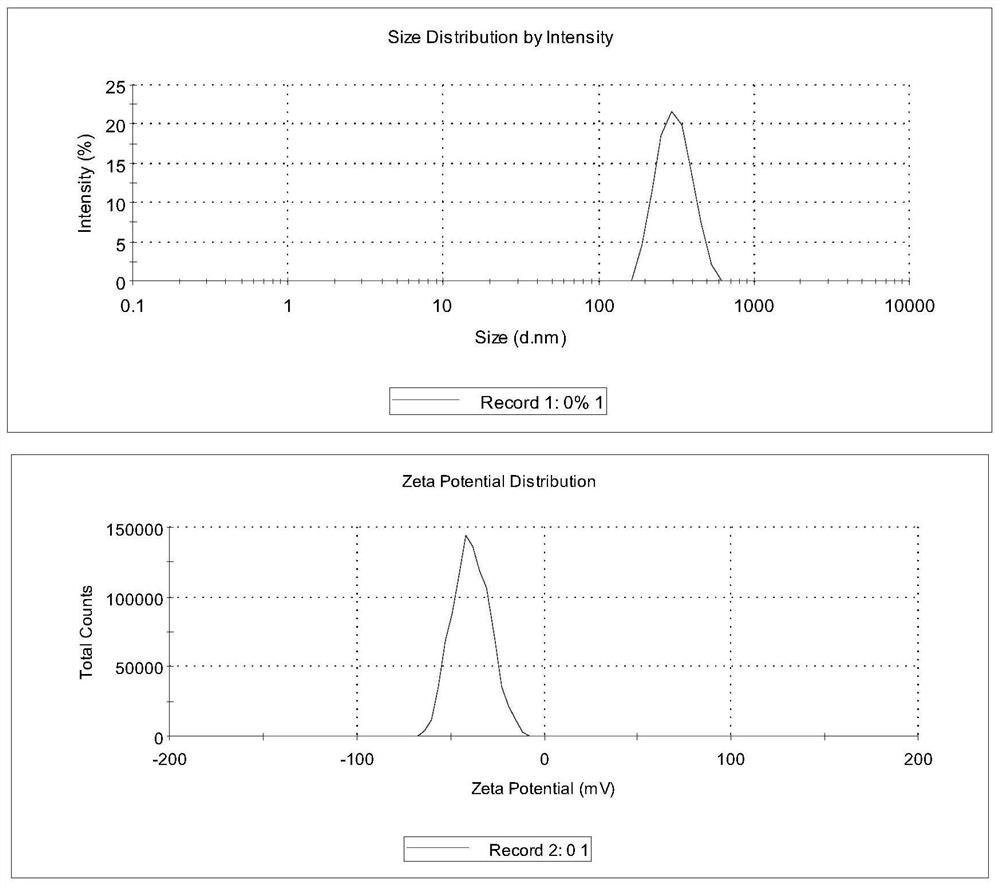

Preparation method of water-based nano magnetic fluid

PendingCN112309669AGood dispersionSingle phaseMagnetic liquidsInductances/transformers/magnets manufactureFerrous saltsActive agent

The invention discloses a preparation method of a water-based nano magnetic fluid. The method comprises the following steps of: dissolving ferrous salt and ferric salt in an acidic solution to preparea ferric salt mixed solution, and marking the ferric salt mixed solution as a feed liquid A; dissolving an alkali source in deionized water to prepare alkali liquor, and marking the alkali liquor asfeed liquid B; under the reaction condition of introducing inert gas N2, mixing the feed liquid B with the feed liquid A, heating the mixed solution in a water bath, and performing stirring to carry out a full reaction; adding a surfactant, heating an obtained mixed solution in a water bath, performing stirring, generating black precipitated nano ferroferric oxide particles after finishing the reaction, continuously introducing N2, and cooling to room temperature; collecting the black precipitates, and carrying out centrifugal washing by using a mixed solution of an organic solvent and water;and dispersing the precipitates in deionized water, removing the organic solvent, and carrying out ultrasonic dispersion to obtain the water-based nano magnetic fluid. The water-based magnetic fluid product is uniform in size, and the average particle size of the product is 5-25 nm; the water-based magnetic fluid product is good in dispersion, single in phase and good in stability; and stable dispersion of the product for more than or equal to 6 months can be realized after the product is modified.

Owner:BEIJING UNIV OF CHEM TECH +1

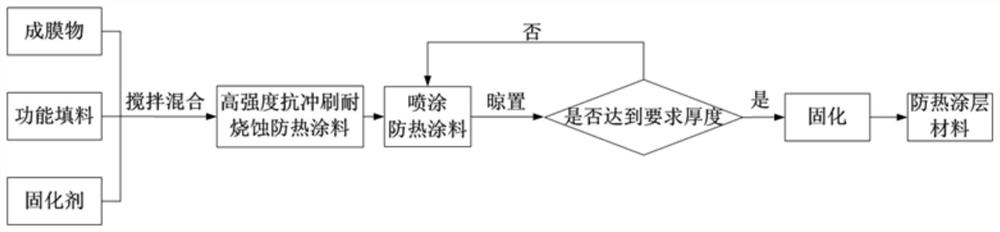

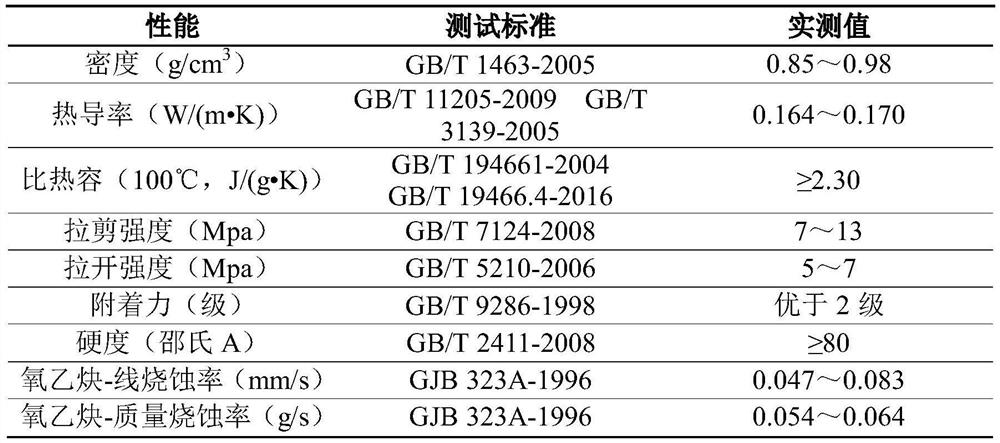

High-strength anti-scouring ablation-resistant heatproof coating material and preparation method thereof

InactiveCN112480789AHigh bonding strengthHigh hardnessEpoxy resin coatingsOrganic solventThermal insulation

The invention provides a high-strength anti-scouring ablation-resistant heatproof coating material and a preparation method thereof. The high-strength anti-scouring ablation-resistant heatproof coating material comprises a film forming matter, a curing agent and functional filler, the film forming matter, the curing agent, the functional filler and an organic solvent are mixed and stirred evenly to prepare heatproof paint, and the heatproof paint is sprayed to the surface of a base material through an air spraying technology; and curing is conducted to obtain the high-strength anti-scouring ablation-resistant heatproof coating. The material is good in thermal insulation performance, low in ablation rate, light in weight, high in strength and excellent in process performance, can be widelyapplied to surface heat protection of aircrafts such as various rocket boats and ships, and can also be popularized and applied to other civil fields.

Owner:西安长峰机电研究所

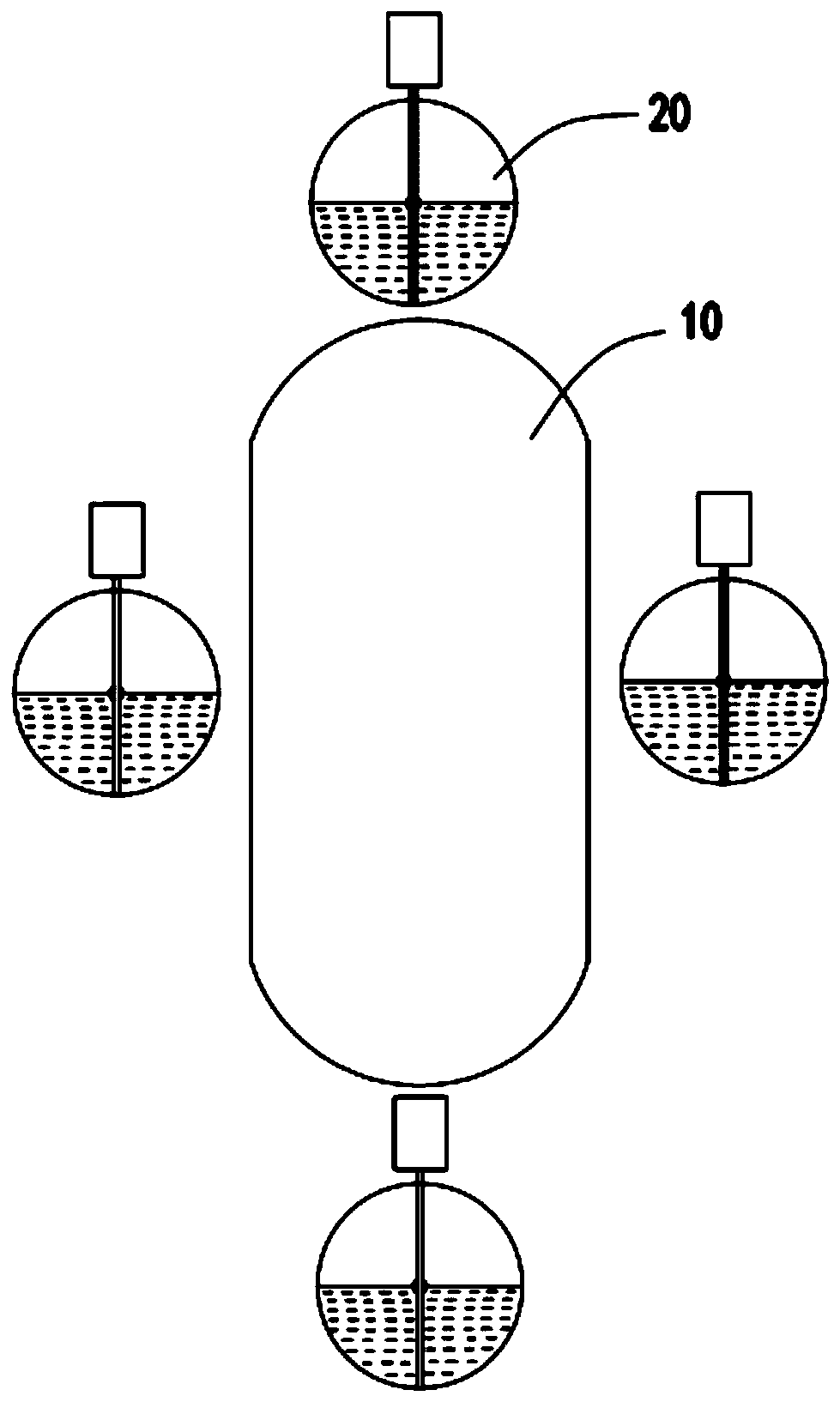

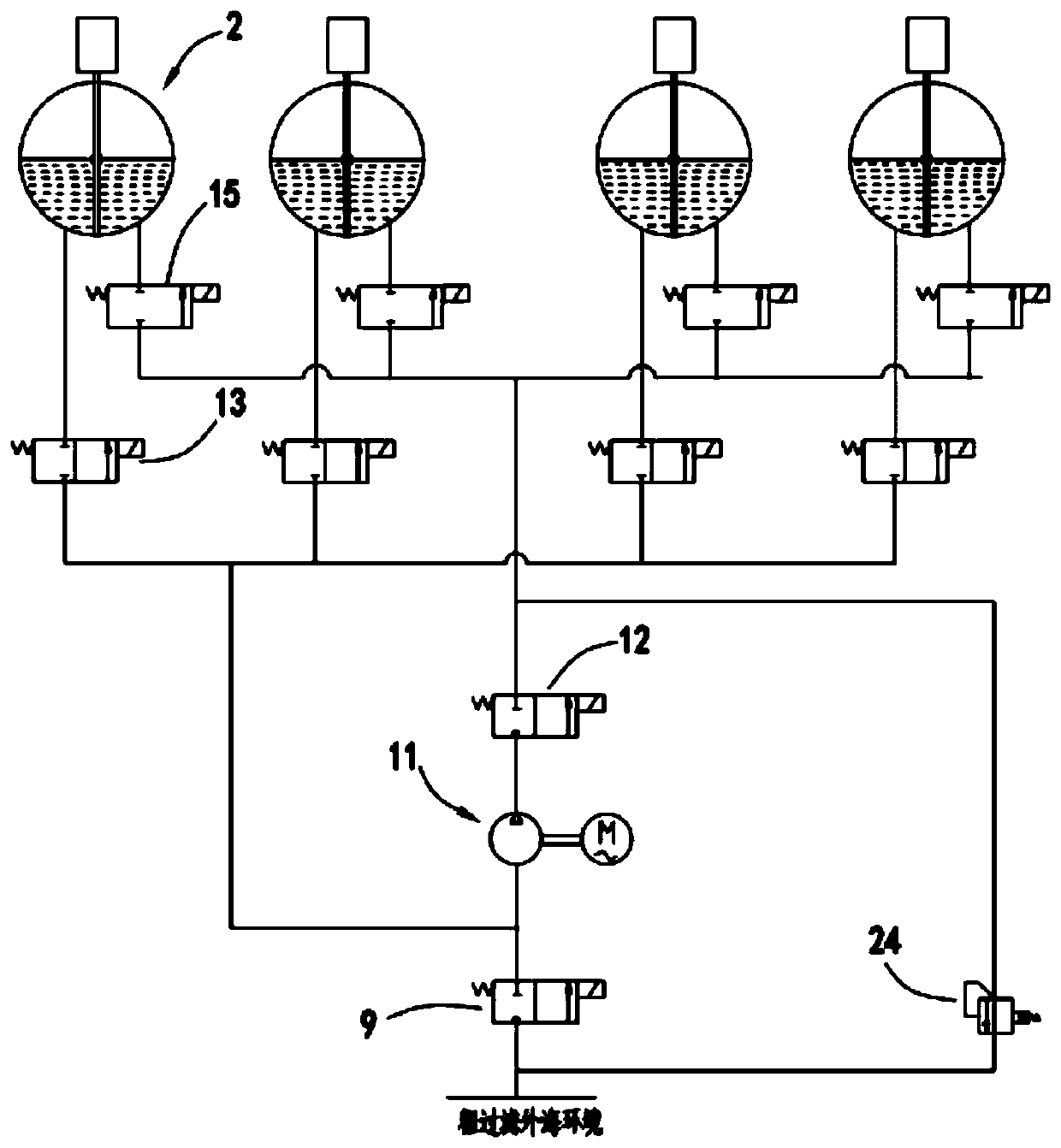

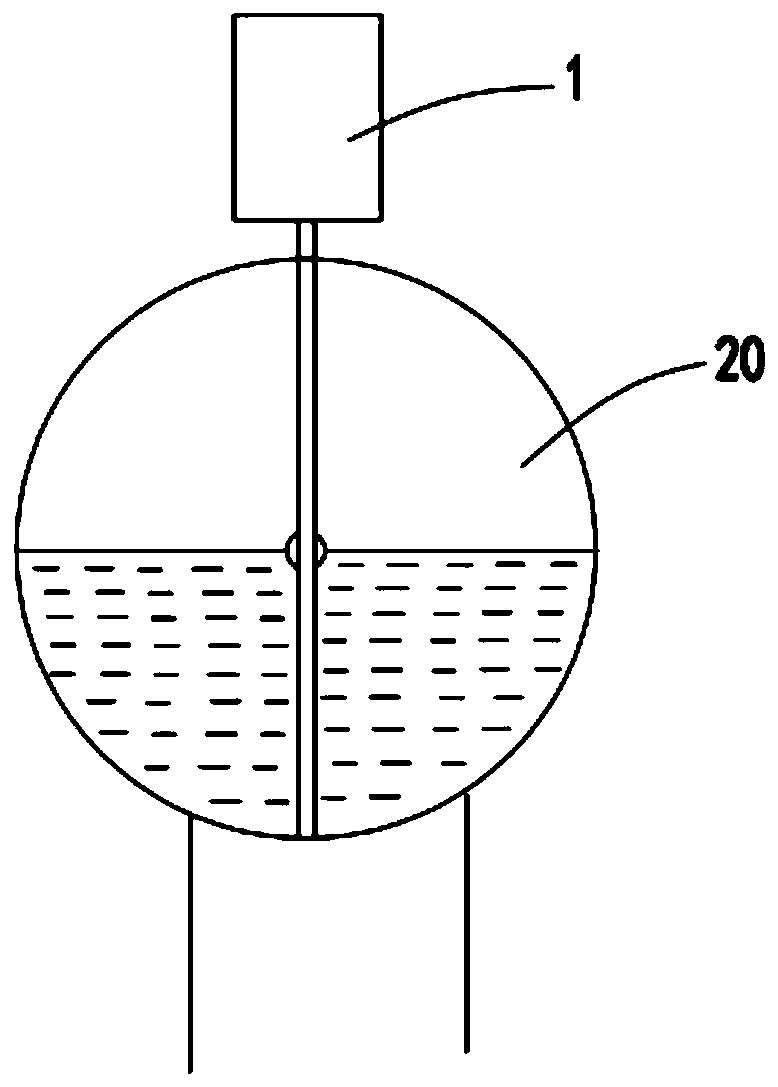

Buoyancy and attitude adjustment integrated system of manned submersible

PendingCN110979601AReduce complexityReduce the difficulty of integrationUnderwater vesselsUnderwater equipmentOpen seaMarine engineering

The invention relates to a buoyancy and attitude adjustment integrated system of a manned submersible. The system comprises the manned submersible, ballast tank units, a main pumping assembly, outer circulation switch valves and a first switch valve, one ends of the outer circulation switch valves are connected with the ballast tank units in a one-to-one correspondence mode, the other ends of theouter circulation switch valves are connected with the main pumping assembly, the other end of the main pumping assembly is connected with the first switch valve, and the other end of the first switchvalve communicate with the open sea environment; the system further comprises inner circulation switch valves, one ends of the inner circulation switch valves are connected with the ballast tank units in a one-to-one correspondence mode, and the other ends of the inner circulation switch valves are connected with pipelines between the main pumping assembly and the first switch valves; the outer circulation switch valves are matched with the main pumping assembly and the first switch valves to inject or discharge seawater into or out of the ballast tank units; and the inner circulation switchvalves are matched with the main pumping assembly, the first switch valves and the outer circulation switch valves to complete water injection and water drainage among the ballast tank units. The problems that the buoyancy and attitude adjustment system is complex in design, high in cost, high in energy consumption, short in endurance time and low in reliability are solved.

Owner:浙江横海科技有限公司

Cleaning preparation method of laminated composite metal hydroxide

InactiveCN102701241BNo pollution in the processSave waterAluminium compoundsCalcium/strontium/barium compoundsChemical compositionDivalent metal

The invention provides a cleaning preparation method of laminated composite metal hydroxide, wherein a general formula of chemical composition of the laminated composite metal hydroxide is M2+1-xM3+x(OH)2(An-)x / n.mH2O. The method uses hydroxide of divalent metal, basic carbonate or carbonate and the hydroxide of trivalent metal as raw materials to directly synthesize and prepare the laminated composite metal hydroxide with a regular structure by one step, wherein all the materials take part in the reaction to generate the target product without a by-product; the drying treatment can be carried out directly and the water resource is greatly saved. The method has the advantages of simple technological process, little device investment, low cost and energy consumption and no environmental pollution, and belongs to an environment-friendly technique.

Owner:BEIJING UNIV OF CHEM TECH

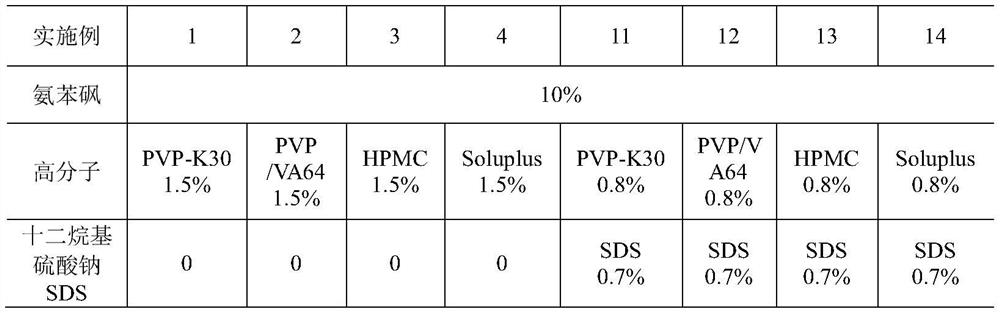

Dapsone compound suspension as well as preparation method and application thereof

ActiveCN113577022AEffective control of key quality attributesLarge particle sizeAntibacterial agentsOrganic active ingredientsPolyethylene glycolPyrrolidinones

The invention discloses a dapsone compound suspension as well as a preparation method and application thereof, the suspension comprises a dapsone compound and a polymer, and the polymer is selected from one or more of the following components: polyvinylpyrrolidone, hydroxypropyl methyl cellulose, hydroxyethyl cellulose, PVP / VA, Soluplus and polyethylene glycol. Compared with the prior art, the suspension disclosed by the invention has the advantages of large drug loading capacity, narrow particle size distribution, good stability, easiness in production and preparation, industrial applicability and the like.

Owner:NANJING XINTONG RUIYI MEDICINE SCI & TECH

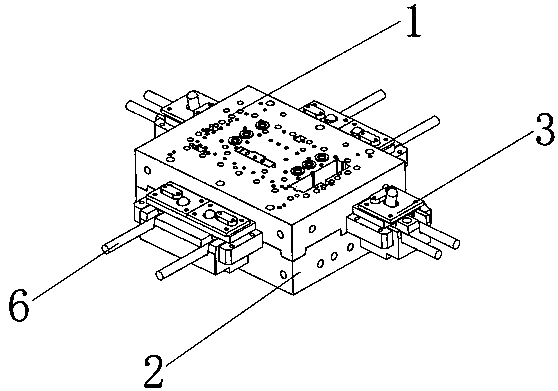

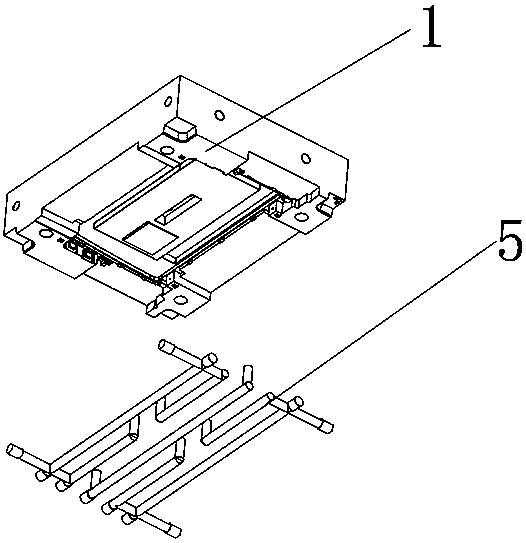

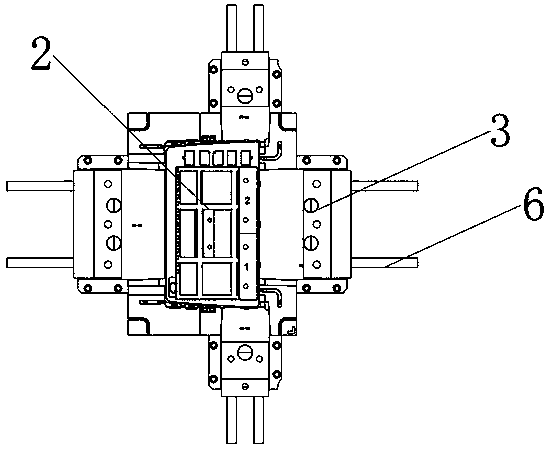

Injection molding process for ultrahigh-flatness liquid crystal screen supporting panel

InactiveCN110480937ALow cost and energy consumptionReduce surface defectsFlat articlesInjection molding machineInjection molding process

The invention discloses an injection molding process for an ultrahigh-flatness liquid crystal screen supporting panel. The process comprises the following steps of composite drying stage: drying a PC-ABS composite; melting stage: feeding the dried composite into an injection molding machine; injection molding stage. In the injection molding process for the ultrahigh-flatness liquid crystal screensupporting panel, for an injection molded part panel, special temperature setting is adopted, a mold fixing mold is connected with a refrigerator with a temperature of a fixed mold being set to be 25DEG C, a mold moving mold is connected with an oil temperature machine with a temperature of a moving mold being set to be 95 DEG C, and sliders on the two sides of the moving mold are connected witha water temperature machine with a temperature of each slider being set to be 60 DEG C, so that cooling speeds of different areas of the injection molding part panel are different, and the deformationquantity of the final injection molding part panel after being completely cooled is controlled to be at a low degree; and in addition, the one-step forming flatness of the PC / ABS material injection molding panel with the area of the positive surface being 390cm^2 is within 0.2mm, secondary processing such as subsequent shaping is not needed, and the injection molding process has the technical characteristics of less surface defects, high qualified rate, low cost, low energy consumption and the like.

Owner:江阴市羽项汽车饰件有限公司

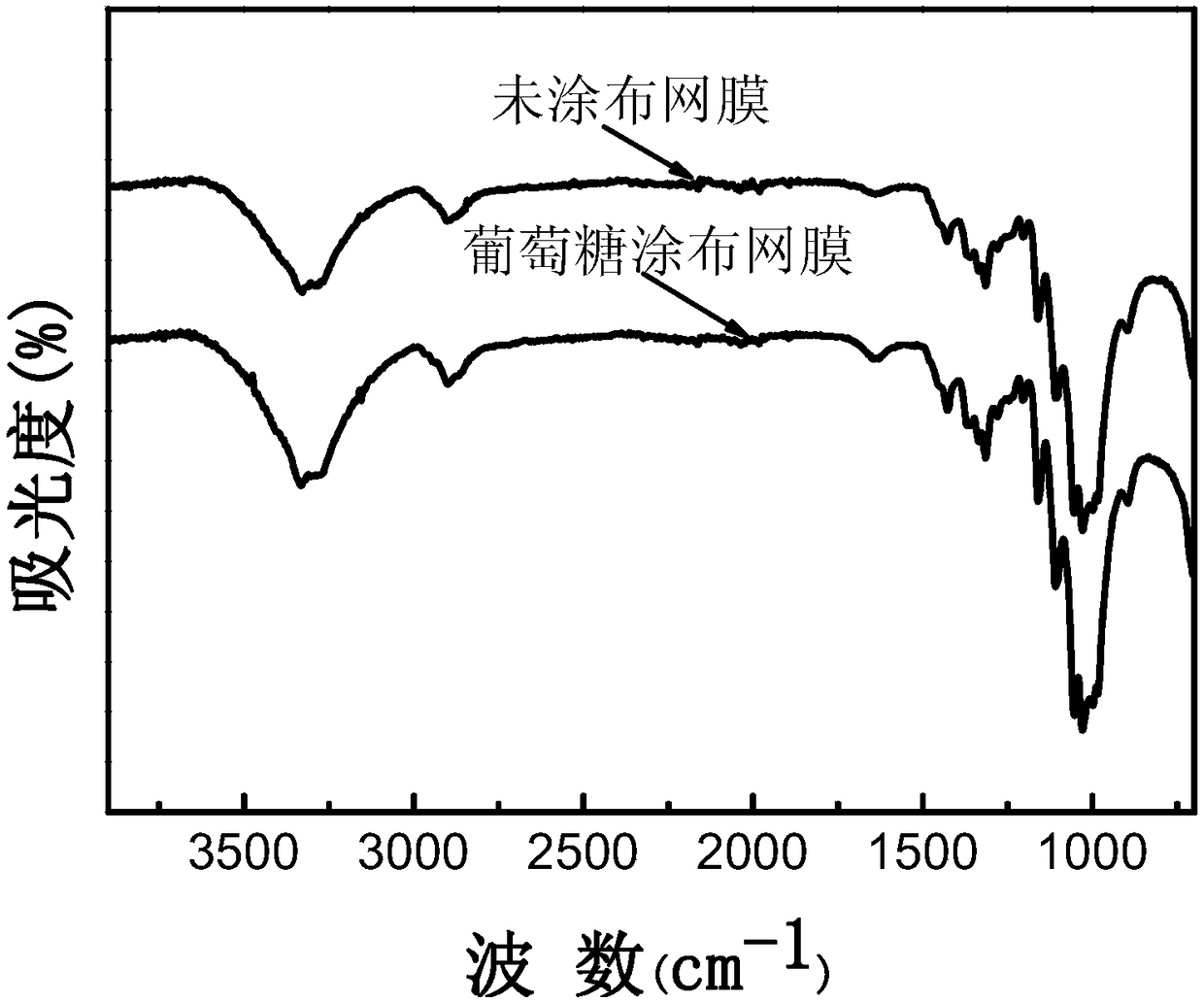

Preparation method and application of glucose coated oil-water separation membrane

InactiveCN108176243AHigh water flowEasy to operateMembranesSemi-permeable membranesChemistryAqueous solution

Belonging to the technical field of chemistry and chemical engineering and functional materials, the invention in particular relates to a preparation method and application of a glucose coated oil-water separation membrane. The preparation method includes: adding glucose into deionized water and fully stirring the substances to obtain a glucose aqueous solution; adjusting the pH value of the glucose solution, and then putting a cellulose net membrane into the solution for soaking; then taking the cellulose net membrane out and putting it in a glutaraldehyde aqueous solution for soaking; and then taking the cellulose net membrane out, and conducting full washing and drying, thus obtaining the glucose coated oil-water separation membrane. The prepared glucose coated oil-water separation membrane can be applied to oil-water separation or oil-water emulsion separation.

Owner:CHANGZHOU UNIV

Composite material injection molding forming technology

ActiveCN108481654AImprove mechanical propertiesReduce surface defectsCoatingsSprayerInjection moulding

The invention relates to a composite material injection molding forming technology. An existing injection molding forming technology is optimized and improved, metal powder of Ti, Mg, Al, Ni, Mo and other components and matrix resin are utilized as composite material raw materials, the multi-sprayer intermittent injection molding manner is adopted, under the technology conditions of the injectionmolding pressure, the temperature, the time and the like obtained through repeated tests, finally-obtained plastic products have good mechanical performance, and the technical characteristics that fewsurface defects exist, the glossiness at 60 DEG C is larger than 80%, and cost and energy consumption are low are achieved.

Owner:昆山益兴荣电子科技有限公司

Tinting master batch capable of improving polyester fiber brightness and tinting strength

ActiveCN109054310AImprove vividnessHigh tinting strengthPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses tinting master batch capable of improving brightness and tinting strength of polyester fibers. The tinting master batch is prepared from 20-30% of pigment, 5-10% of ethylene acrylate copolymer, 2-5% of dispersion agent and the balance of carrier resin. According to the tinting master batch capable of improving the polyester fiber brightness and tinting strength, the pigmentand the ethylene acrylate copolymer are used, so that the brightness and the tinting strength of the polyester fibers using the tinting master batch are improved, wherein the brightness of the polyester fibers is improved by 20%; meanwhile, the spinning stability is improved, pressure is stable, a spinning cycle is prolonged by 20%, moreover, in an assembly cleaning process, the tinting master batch is remained less, cleaning is more convenient, and the cost and energy consumption are obviously reduced.

Owner:汕头市科彩新材料有限公司

A coloring masterbatch for improving the vividness and tinting strength of polyester fibers

ActiveCN109054310BImprove vividnessHigh tinting strengthPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses a coloring masterbatch for improving the vividness and tinting strength of polyester fiber, which comprises 20-30% of pigment, 5-10% of ethylene acrylate copolymer, 2-5% of dispersant, and the balance is carrier resin. The present invention relates to a kind of coloring masterbatch that improves the brightness and coloring strength of polyester, which uses pigments and ethylene acrylate copolymers, so that the brightness and coloring strength of polyester fibers using the coloring masterbatch can be improved, so that The brightness of polyester fiber is increased by 20%, while the spinning stability is improved, the pressure is stable, the spinning cycle is increased by 20%, and in the process of cleaning components, there are less residues, cleaning is more convenient, and cost and energy consumption are significantly reduced.

Owner:汕头市科彩新材料有限公司

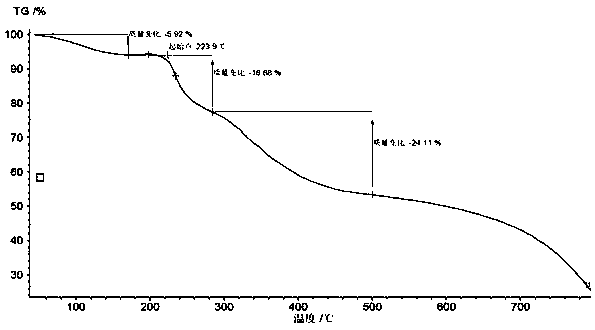

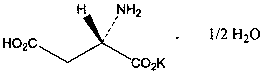

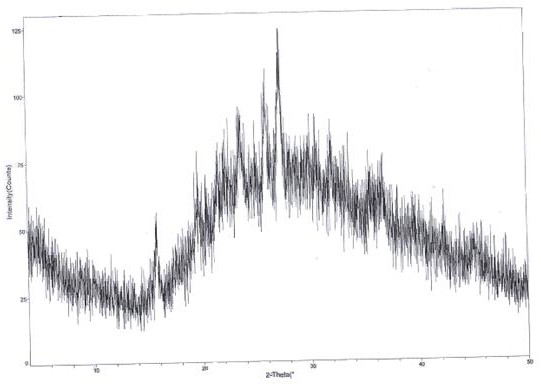

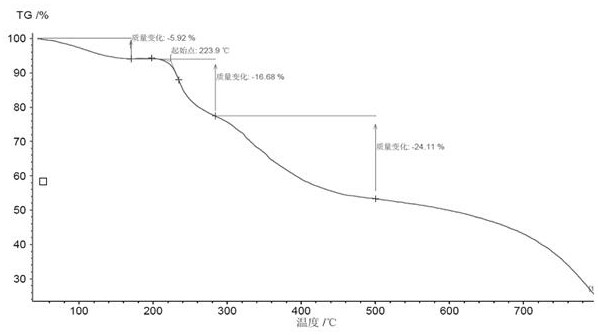

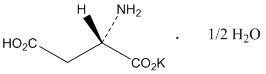

Preparation method of potassium aspartate crystals

ActiveCN108546236AEmission reductionStable storageOrganic compound preparationAmino-carboxyl compound preparationSolventN-Butyl Alcohol

The invention discloses a preparation method of potassium aspartate crystals. The method comprises the following steps of (1) adding pure water being 0.25 times the mass of aspartic acid into a reaction container; in the stirring state, adding the aspartic acid and potassium carbonate; preparing a potassium aspartate aqueous solution; (2) after reaction clarification, regulating the pH value to 6.5 to 6.8 by potassium carbonate; (3) adding medical active carbon into the obtained solution for decoloration filtering; (4) adding organic solvents into filter liquid; (5) controlling the crystal separation temperature at 0 to 20 DEG C; performing cooling crystal separation for separating the crystals for 8 to 12 hours; performing vacuum drying on filter cake to obtain a product. The 0.25 times of pure water (relative to the mass of the aspartic acid) is used as the reaction solvents; the discharge of a great amount of waste water is reduced; then, the energy consumption is reduced by controlling the crystallization temperature; the solvents such as isopropanol, n-butyl alcohol and methylisobutylketone are reasonably used for obtaining a potassium aspartate finished product capable of being more stably stored; the operation in the whole crystal preparation process is simple; the cost and the energy consumption are low; the product can be easily stored; the method is very suitable forindustrialized production.

Owner:ANHUI HEALSTAR PHARM CO LTD

A kind of preparation method of potassium aspartate crystal

ActiveCN108546236BEmission reductionStable storageOrganic compound preparationAmino-carboxyl compound preparationOrganosolvPotassium carbonate

The invention discloses a preparation method of potassium aspartate crystals. The method comprises the following steps of (1) adding pure water being 0.25 times the mass of aspartic acid into a reaction container; in the stirring state, adding the aspartic acid and potassium carbonate; preparing a potassium aspartate aqueous solution; (2) after reaction clarification, regulating the pH value to 6.5 to 6.8 by potassium carbonate; (3) adding medical active carbon into the obtained solution for decoloration filtering; (4) adding organic solvents into filter liquid; (5) controlling the crystal separation temperature at 0 to 20 DEG C; performing cooling crystal separation for separating the crystals for 8 to 12 hours; performing vacuum drying on filter cake to obtain a product. The 0.25 times of pure water (relative to the mass of the aspartic acid) is used as the reaction solvents; the discharge of a great amount of waste water is reduced; then, the energy consumption is reduced by controlling the crystallization temperature; the solvents such as isopropanol, n-butyl alcohol and methylisobutylketone are reasonably used for obtaining a potassium aspartate finished product capable of being more stably stored; the operation in the whole crystal preparation process is simple; the cost and the energy consumption are low; the product can be easily stored; the method is very suitable forindustrialized production.

Owner:ANHUI HEALSTAR PHARM CO LTD

Production technology of plasterboard modified starch

The invention discloses a production technology of plasterboard modified starch, comprising the following steps of mixing, degeneration reaction, neutralization reaction, physical synergism, screening, weighing and packaging. The invention combines the advantages of various modified starches, has the advantages of strong size film strength, transparency, good water absorption, good dispersion, good gliding property, low gelatinization temperature, strong paste liquid bond force, good adsorbability, easy dissolution, good film forming ability, weak retrogradation, good elasticity, smoothness, flexibility, tough and elastic size film, nontoxicity, tastelessness, safe use, convenient operation, large production scale, little investment, low energy consumption, less pollution, high productionefficiency, stable and reliable product quality and the like and is widely applied to gypsum products.

Owner:四川省蓬溪县弘桥实业有限公司

A method for improving the brightness and tinting strength of polyester fibers

InactiveCN108866672BImprove vividnessHigh tinting strengthPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses a method for improving brilliance and tinting strength of polyester fiber. The method comprises the following step: S1, preparing coloring master batch, wherein the prepared coloring master batch is prepared from 20 to 30% of pigment, 5 to 10% of ethylene acrylate copolymer, 2 to 5% of dispersing agent and the balance of carrier resin; S2, mixing the coloring master batch with PET slices and drying, wherein the weight proportion of the coloring master batch is 5 to 20%; S3, putting the coloring master batch and the PET slices which are evenly mixed into a spinning machine to be molten and extruding into silk by a spinneret plate to form polyester fiber. According to the method for improving brilliance and tinting strength of the polyester fiber disclosed by the invention, the coloring master batch containing pigment and the ethylene acrylate copolymer is used, so that brilliance and the tinting strength of the prepared polyester fiber is improved, and the brilliance of the polyester fiber is improved by 20%; meanwhile, spinning stability is improved, pressure is stable, and a spinning period is improved by 20%; furthermore, in an assembly cleaning process, residues are less, more convenience is brought to cleaning, and cost and energy consumption are obviously reduced.

Owner:浙江恒烨新材料科技有限公司

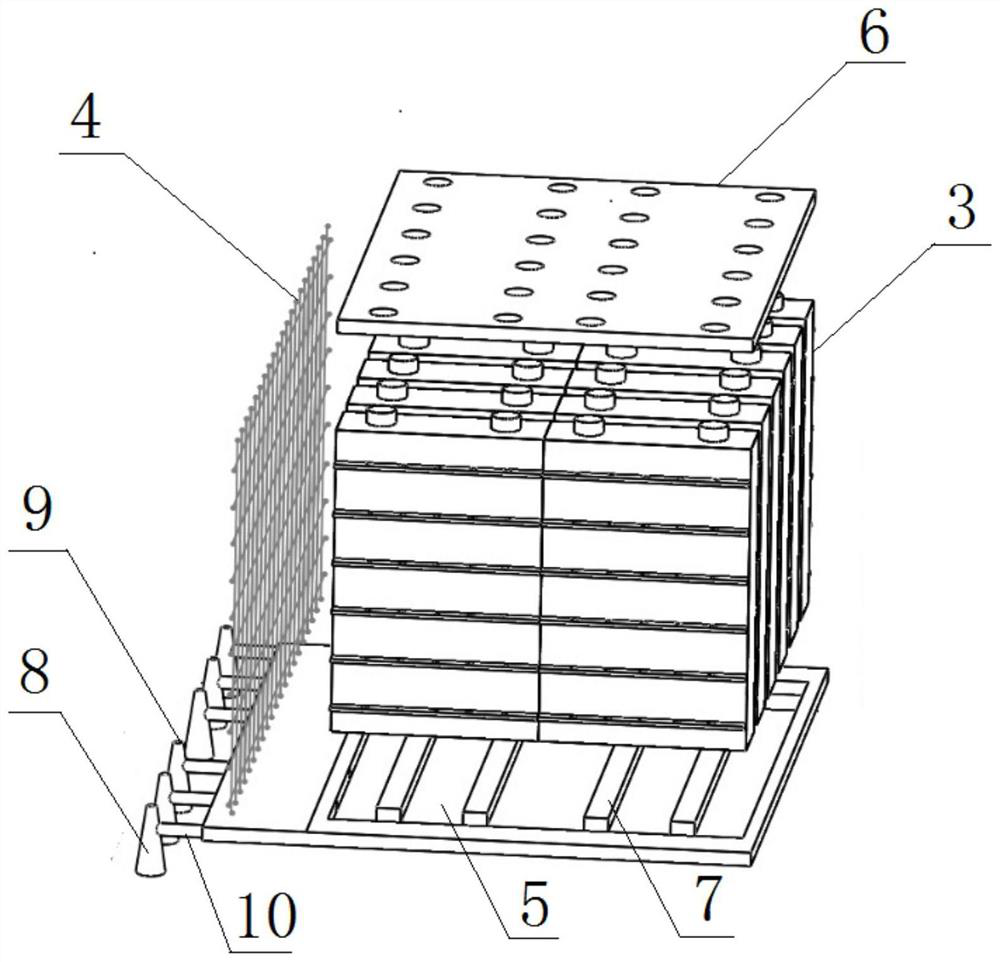

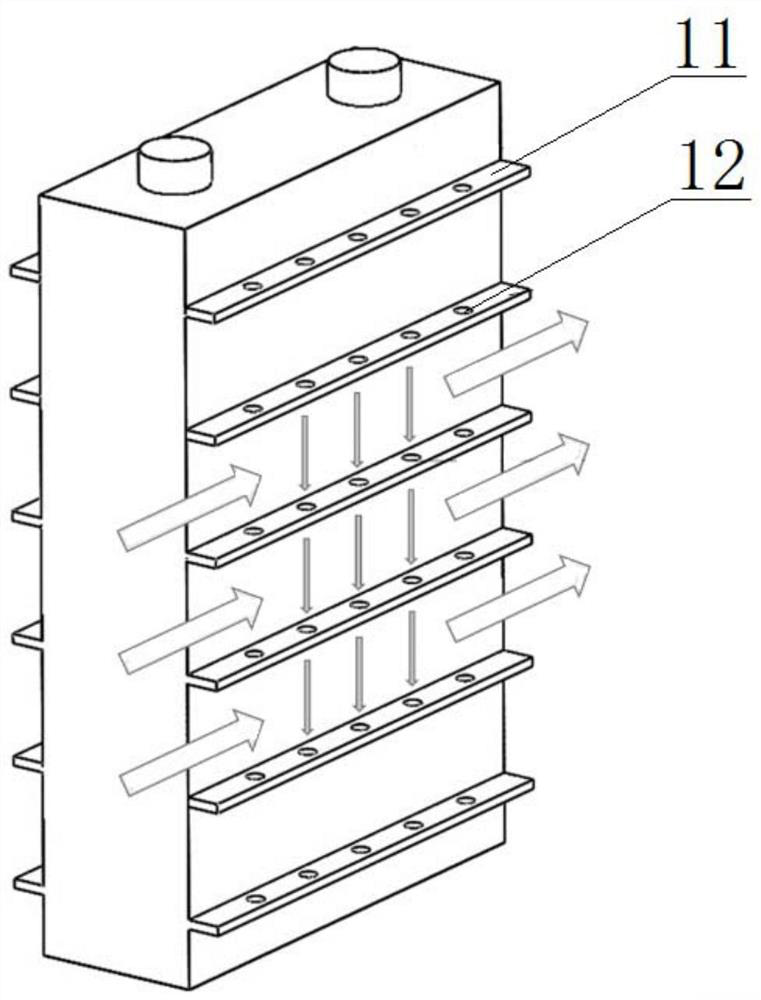

Battery thermal management system

PendingCN113437376AImprove cooling efficiencyLow cost and energy consumptionSecondary cellsCell component detailsThermodynamicsElectrical battery

The invention provides a battery thermal management system, which comprises a battery box body used for loading a battery, and further comprises a heat dissipation unit arranged on the outer wall of the battery, a battery support is arranged at the bottom in the battery box body, a condensation tank is arranged at the bottom of the battery support, an aerial fog generator is arranged on the condensation tank, a temperature detection module for detecting the temperature of a battery is arranged on the battery box body, a fan is arranged on the wall surface of the battery box body, an electric heating wire net is arranged between the battery in the battery box body and the fan, a nozzle of the aerial fog generator is arranged between the fan and the electric heating wire net, the battery thermal management system further comprises an upper computer for controlling the temperature detection module, the fan, the aerial fog generator and the electric heating wire net. The structure is simpler, a worker can maintain the battery conveniently, and meanwhile, the temperature of the battery is effectively managed.

Owner:GUANGDONG UNIV OF TECH

Synthetic fiber preparation method for inhibiting production of fine wool

The invention discloses a synthetic fiber preparation method for inhibiting production of fine hair. The synthetic fiber preparation method comprises the following preparation steps: 1, selecting synthetic fibers with the length of 1-6cm; 2, mechanically crushing synthetic fibers, adding the crushed synthetic fibers into water to form a suspension, carrying out ultrasonic dispersion, and filtering to obtain a synthetic fiber suspension; 3, adding a treating agent into the synthetic fiber suspension prepared in the step 2, wherein the mass ratio of the synthetic fibers to the treating agent is (6-20): (1-4); and 4, continuing to mechanically stir and crush the synthetic fiber suspension treated by the treating agent in the step 3, filtering, and drying to obtain the synthetic fiber provided by the invention. The preparation method is simple, low in cost and energy consumption, capable of effectively inhibiting the generation of fine hair and improving the practicability, and capable of being popularized and used in a large range.

Owner:东恩高分子材料(宿迁)股份有限公司

A kind of clean preparation method of layered composite metal hydroxide

ActiveCN108751237BNo pollution in the processHigh value availableHydrotalciteReaction temperaturePhysical chemistry

Owner:BEIJING UNIV OF CHEM TECH

A composite material injection molding process

ActiveCN108481654BImprove mechanical propertiesReduce surface defectsCoatingsInjection molding processInjection moulding

The invention relates to a composite material injection molding forming technology. An existing injection molding forming technology is optimized and improved, metal powder of Ti, Mg, Al, Ni, Mo and other components and matrix resin are utilized as composite material raw materials, the multi-sprayer intermittent injection molding manner is adopted, under the technology conditions of the injectionmolding pressure, the temperature, the time and the like obtained through repeated tests, finally-obtained plastic products have good mechanical performance, and the technical characteristics that fewsurface defects exist, the glossiness at 60 DEG C is larger than 80%, and cost and energy consumption are low are achieved.

Owner:昆山益兴荣电子科技有限公司

Oil displacement composition, multi-component thermal fluid oil displacement composition containing same, and displacement method

ActiveCN103289665BImprove oil displacement efficiencyEnhanced overall recoveryFluid removalDrilling compositionWater vaporMass ratio

Owner:PETROCHINA CO LTD

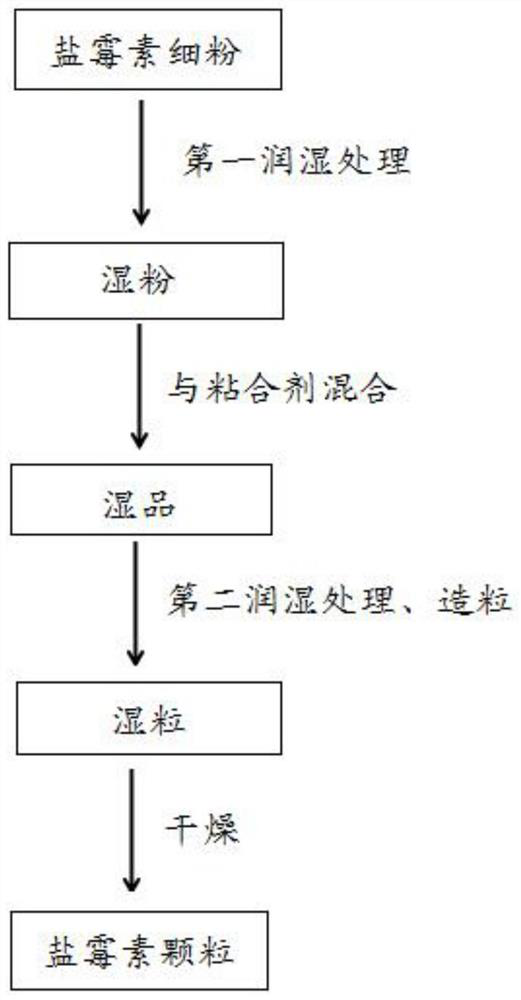

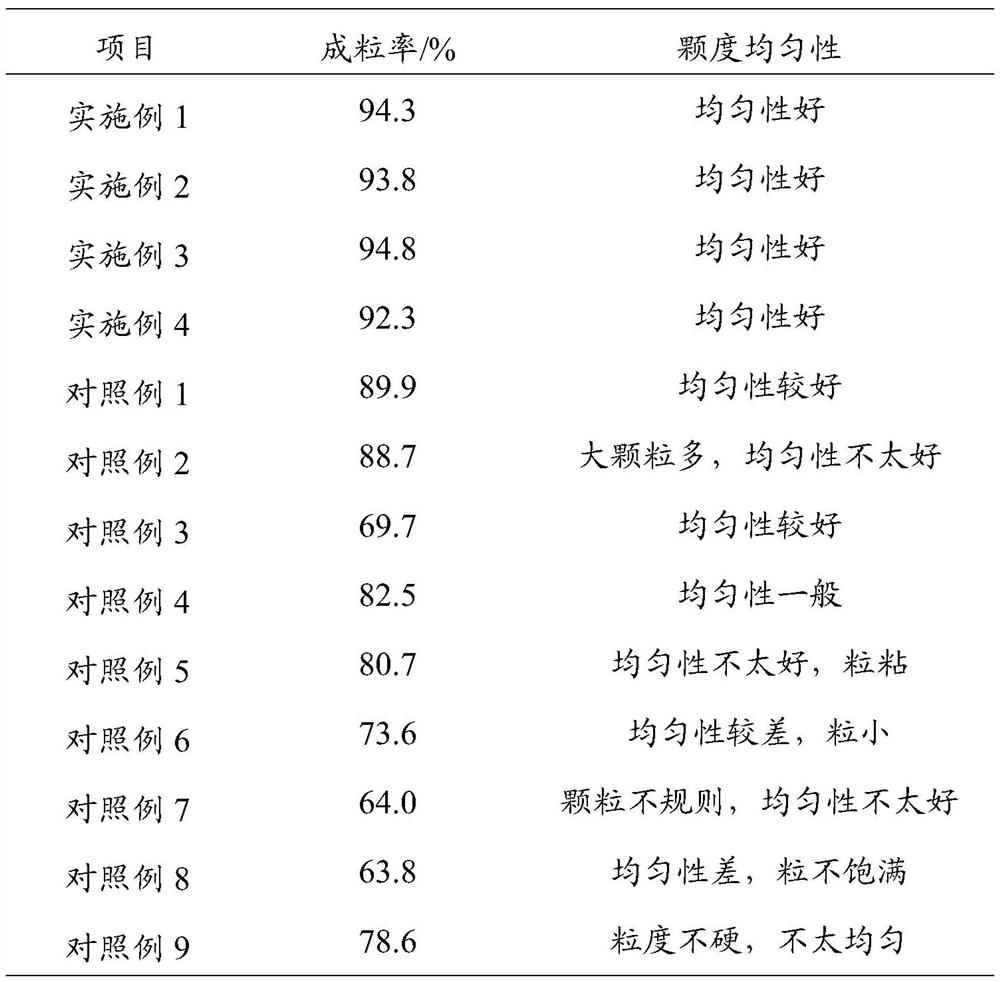

A kind of preparation method of salinomycin granule

ActiveCN110025582BHigh granulation rateImprove uniformityAntibacterial agentsOrganic active ingredientsBiotechnologySalinomycin sodium

The invention provides a preparation method of salinomycin sodium granules, and belongs to the technical field of the production of antibiotics for livestock. The preparation method of salinomycin sodium granules provided by the invention comprises the following steps of mixing salinomycin sodium fine powder with water, and performing first wetting treatment so as to obtain wet powder; mixing thewet powder with an adhesive so as to obtain wet products; mixing the wet products with water, performing second wetting treatment, and performing granulation so as to obtain wet granules; and drying the obtained wet granules so as to obtain the salinomycin sodium granules. According to the preparation method provided by the invention, the granulation rate of the salinomycin sodium fine powder is high, the granules are good in uniformity, the preparation method provided by the invention is low in repeated granulation frequency, high in production efficiency, simple in technology and low in costand energy consumption, and clean production can be realized.

Owner:PUCHENG CHIA TAI BIOCHEM

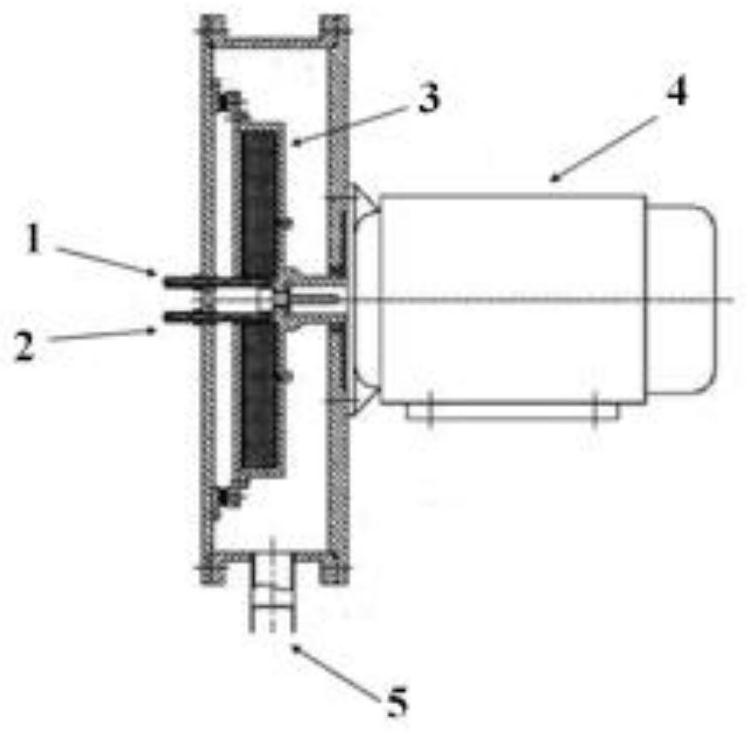

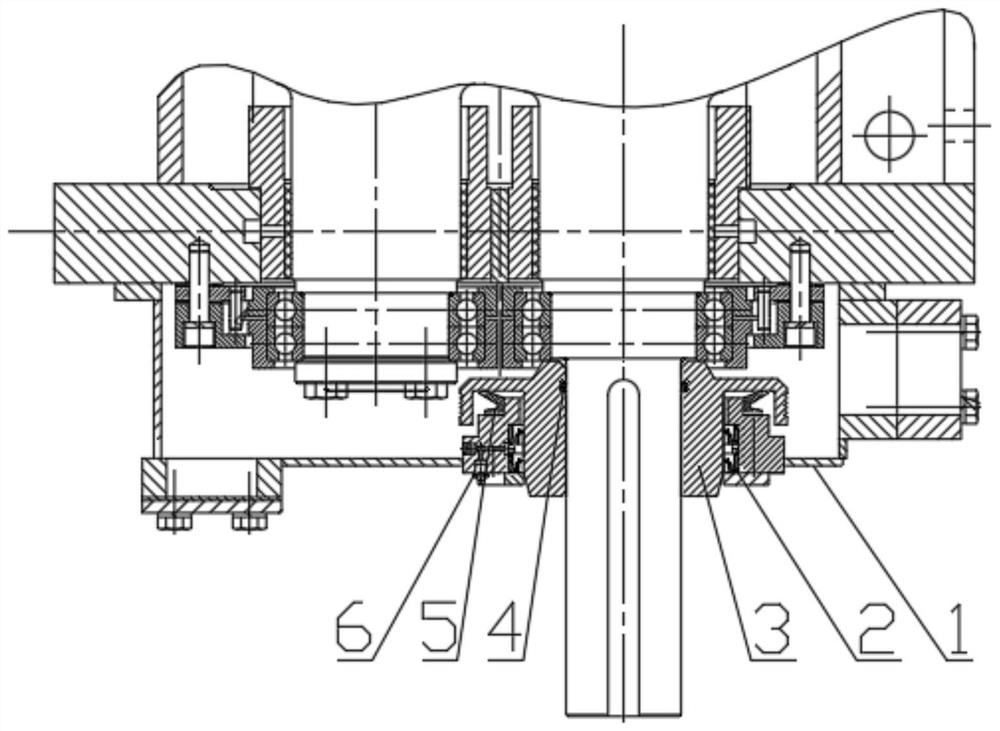

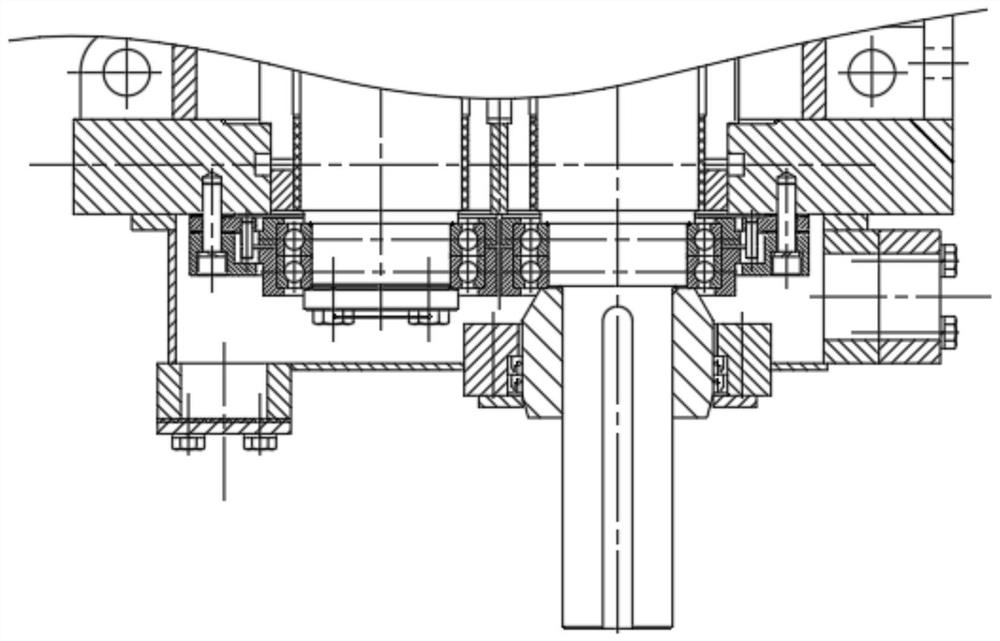

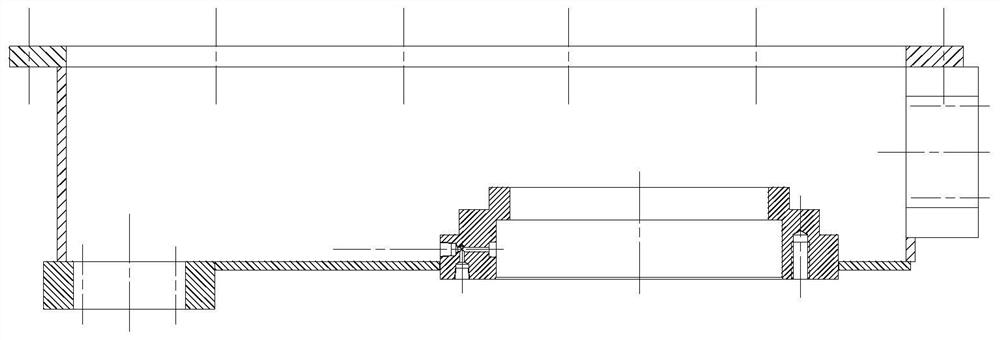

Leakage-free rolling mill workstation shaft seal device

InactiveCN113775760AExtend your lifeReasonable structural designEngine sealsControl engineeringProcess engineering

The invention discloses a leakage-free rolling mill workstation shaft seal device. The device comprises a rolling mill workstation body, an oil seal device is arranged on the rolling mill workstation body, the oil seal device comprises an oil pan, a framework oil seal, a shaft sleeve with an oil slinger, an O-shaped sealing ring, a sealing lip and a grease nipple, an input shaft is arranged on the rolling mill workstation body, and the shaft sleeve with the oil slinger is arranged on the input shaft through a coupler. The leakage-free rolling mill workstation shaft seal device is reasonable in structural design, simple and easy to operate, good in lubricating and sealing effect, convenient to install, small in overhaul and maintenance workload and free of leakage.

Owner:江西铜业铜材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com