Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Less volatile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tin promoted platinum catalyst for carbonylation of lower alkyl alcohols

InactiveUS6903045B2Not volatileLess solubleIsocyanic acid derivatives preparationOrganic compound preparationSolid componentGas phase

A carbonylation catalyst useful for producing esters and carboxylic acids in a vapor phase carbonylation process, wherein the catalyst includes a solid component having a catalytically effective amount of platinum and tin associated with a solid catalyst support material and a vaporous halide promoter component.

Owner:EASTMAN CHEM CO

Polyarylene sulfide and process for producing the same

In a production process of a poly(arylene sulfide), a mixture containing an organic amide solvent, an alkali metal hydrosulfide and an alkali metal hydroxide in a proportion of 0.95 to 1.05 mol per mol of the alkali metal hydrosulfide is heated and dehydrated in a dehydration step. After the dehydration step, as needed, an alkali metal hydroxide and water are added to control the total number of moles of the alkali metal hydroxide, and the number of moles of water so as to amount to 1.00 to 1.09 per mol of a sulfur source including the alkali metal hydrosulfide existing in the system and to 0.5 to 2.0 per mol of the charged sulfur source, respectively. A polymerization step is conducted by a two-stage process.

Owner:KUREHA KAGAKU KOGYO KK

Polyarylene sulfide and process for producing the same

In a production process of a poly(arylene sulfide), a mixture containing an organic amide solvent, an alkali metal hydrosulfide and an alkali metal hydroxide in a proportion of 0.95 to 1.05 mol per mol of the alkali metal hydrosulfide is heated and dehydrated in a dehydration step. After the dehydration step, as needed, an alkali metal hydroxide and water are added to control the total number of moles of the alkali metal hydroxide, and the number of moles of water so as to amount to 1.00 to 1.09 per mol of a sulfur source including the alkali metal hydrosulfide existing in the system and to 0.5 to 2.0 per mol of the charged sulfur source, respectively. A polymerization step is conducted by a two-stage process.

Owner:KUREHA KAGAKU KOGYO KK

Method for synthesizing high activity rigid foam polyether polyatomic alcohol for spraying

The invention discloses a synthetic method of a high-activity rigid foam polyether polyol. In the method, a mixed initiator is polymerized with an epoxy compound at the pressure of 0-0.5MPa and the temperature of 50-150 DEG C by taking an amine compound as a catalyst to obtain the polyether polyol; the mixed initiator consists of a polyol compound and a urea compound or consists of the polyol compound, a polyamine compound and the urea compound, and the urea compound accounts for 30-70% of the total weight of the mixed initiator in the mixed initiator. The polyether polyol synthesized by the method is characterized by high activity, low viscosity and low cost, can be used for the preparation of rigid polyurethane foam, and is especially applicable to the preparation of spraying polyurethane.

Owner:SHANDONG BLUSR DONGDA CHEM

Preparation of partially cross-linked polymers and their use in pattern formation

InactiveUS6262181B1Less shrinkage of the resistReduce the amount requiredPhotosensitive materialsSemiconductor/solid-state device manufacturingCross-linkPolymer science

Owner:FUJIFILM ELECTRONICS MATERIALS US

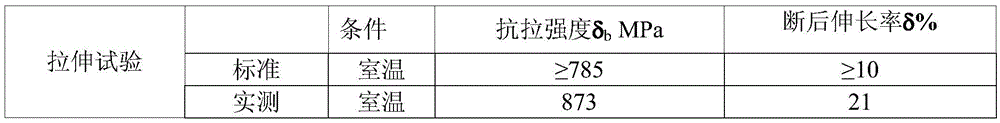

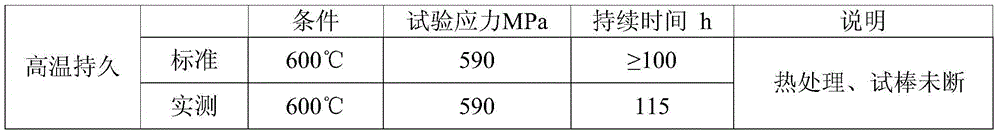

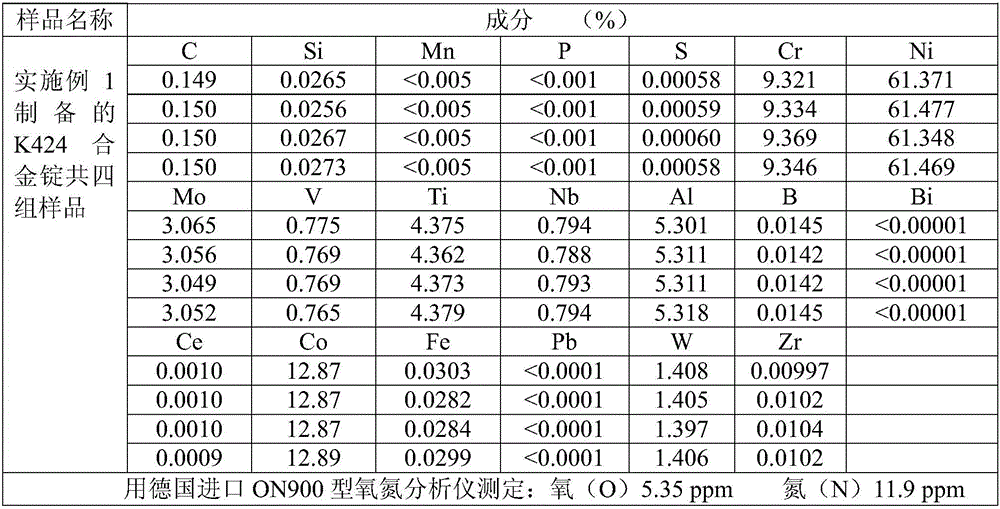

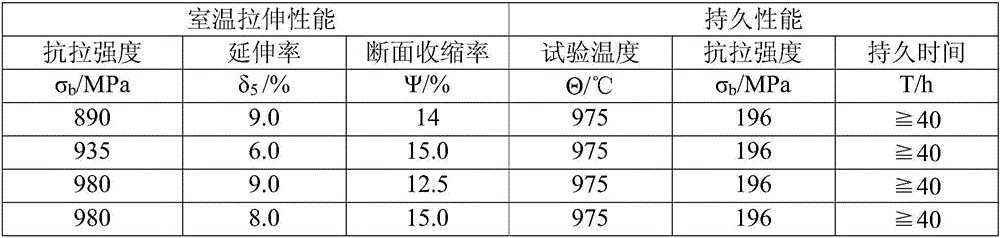

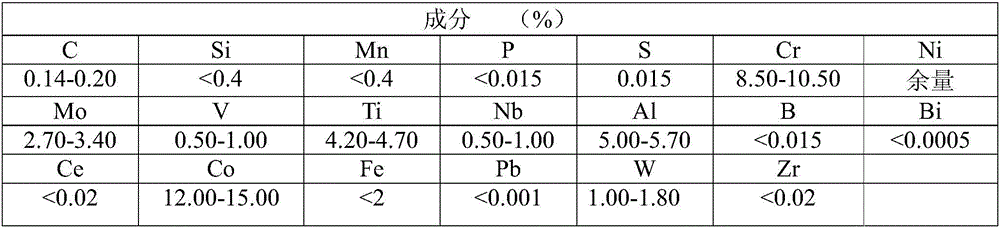

Smelting method of nickel-based high-temperature alloy

The invention relates to alloy smelting methods, in particular to a smelting method of nickel-based high-temperature alloy. The smelting method includes following steps: adding graphite accounting for 50% of total carbon content of the high-temperature alloy into a vacuum furnace crucible, placing at the downmost bottom of the crucible, and adding all elements, except for aluminum, titanium, boron and nickel, in the high-temperature alloy into the vacuum furnace crucible for smelting; heating, adding remaining graphite into the crucible, refining, and then cooling; adding metal calcium, and heating for refining after the metal calcium is smelted completely; cooling, adding aluminum and titanium, and heating until aluminum and titanium are smelted fully; adding nickel-boron alloy, and heating the nickel-boron alloy is smelted; cooling, freezing metal melt, heating, and tapping for pouring. By using the smelting method, content of harmful gas and low-smelting-point harmful impurities in the high-temperature alloy is lowered, pure alloy melt is obtained, alloy element segregation is reduced, and alloy performance is guaranteed.

Owner:SHANDONG ROITIE NEW MATERIAL SCI & TECH

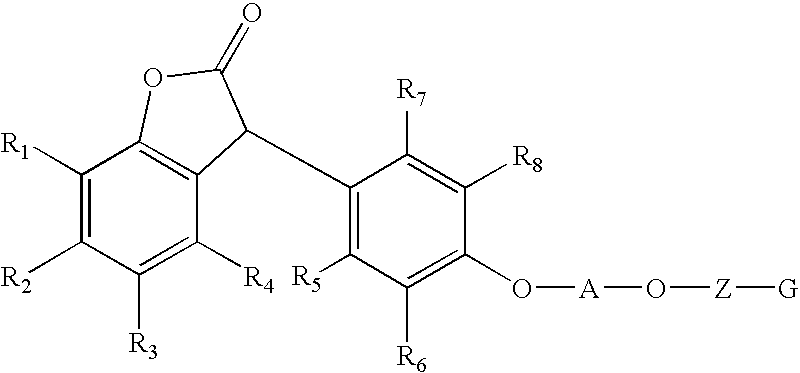

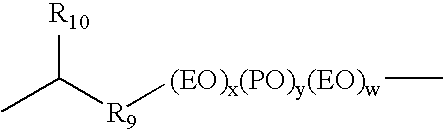

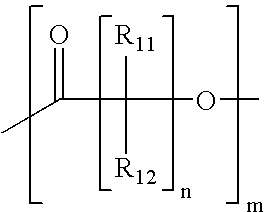

Lactone stabilizing compositions

This invention provides a novel class of compounds and compositions and synthetic methods related to lactone antioxidant 3-arylbenzofuranones. The compounds may be useful to prevent yellowing and deterioration of organic materials preferably polymers, such as polyurethane foams as one example. The lactone antioxidants may be polymeric, and may also be liquid or paste in physical form at room temperature. Although it is not necessary for its stabilizing properties, the compositions may, in some species, bear one or more reactive primary OH groups on the polymer chains. The chains may also contain oligomeric oxyalkylene ether and aliphatic ester functional groups, in one embodiment of the invention.

Owner:MILLIKEN & CO

Binder for manufacturing inorganic sintered body

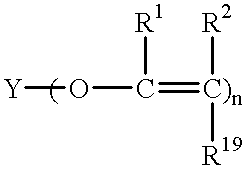

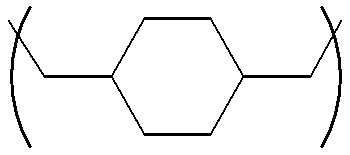

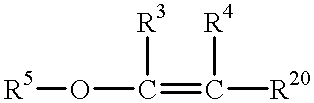

ActiveUS20160053039A1Not volatileStay flexibleFixed capacitor dielectricCeramic layered productsPolyvinyl butyralVitrification

The present invention provides a binder for manufacturing an inorganic sintered body that has excellent adhesiveness upon heat pressing and thermal decomposability and, especially when used as a binder for a ceramic green sheet, provides a ceramic green sheet having sufficient mechanical strength and flexibility. The present invention also provides a paste for manufacturing an inorganic sintered body, a ceramic green sheet, and a ceramic laminate individually manufactured using the binder for manufacturing an inorganic sintered body. The present invention provides a binder for manufacturing an inorganic sintered body containing a graft copolymer having a unit including polyvinyl butyral and a unit including a poly(meth)acrylic compound, the polyvinyl butyral having a polymerization degree of 800 to 5000, a hydroxy group content of 20 to 40 mol %, and a butyralization degree of 60 to 80 mol %, the unit including a poly(meth)acrylic compound having a glass transition temperature of 0 to 110° C.

Owner:SEKISUI CHEM CO LTD

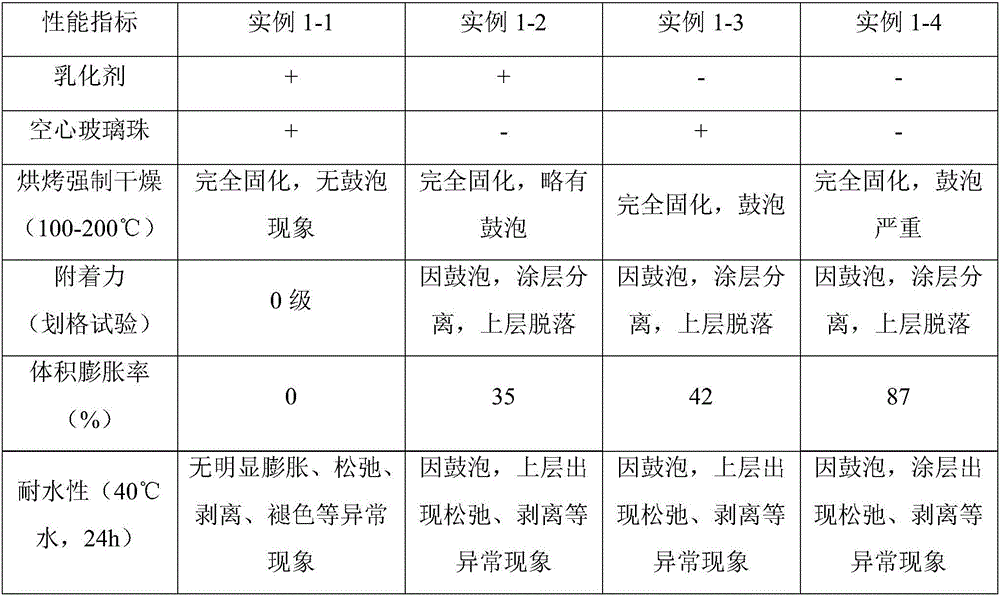

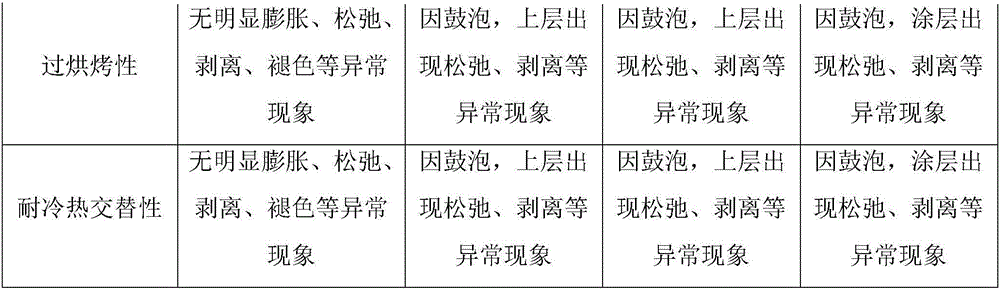

Sprayable baking type water soluble damping coating and preparation method thereof

The invention relates to the field of damping materials, in particular to a sprayable baking type water soluble damping coating and a preparation method thereof. The sprayable baking type water soluble damping coating is prepared from, by weight, 10-50 parts of acrylic emulsion, 5-20 parts of emulgator, 0.1-10 parts of neutralizer, 1-20 parts of a dispersing agent, 1-15 parts of cosolvent, 10-80 parts of pigment filler and 1-50 parts of water. By means of a high-pressure spraying means, the thickness of a coating layer is fixed to be about 0.5-5 mm, sagging does not exist, after baking at the high temperature of 100-200 DEG C, curing can be achieved quickly, bubbling and disengaging do not occur, and the functions of vibration and noise reduction can be enhanced; water serves as a main solvent, so that the coating does not contain benzene volatile matter and does not seriously hurt the human health, and adopted equipment and tools can be washed through water; the needed raw materials are easy to get, the production process is simple, construction is convenient, operation is easy, the added value of products is high, the domestic blank is filled, and the coating can be greatly applied to the industries of automobiles, locomotives and the like.

Owner:QINGDAO AIR NEW MATERIALS

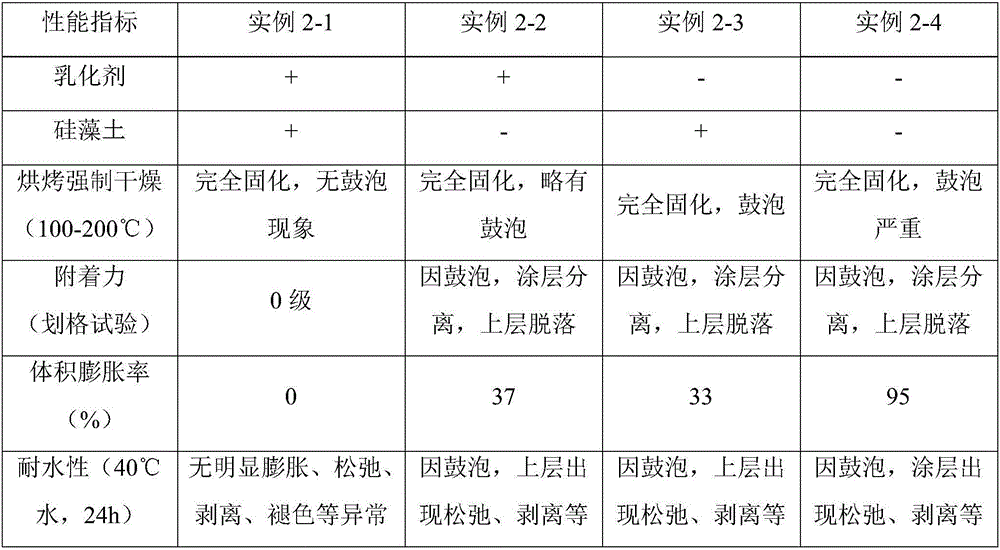

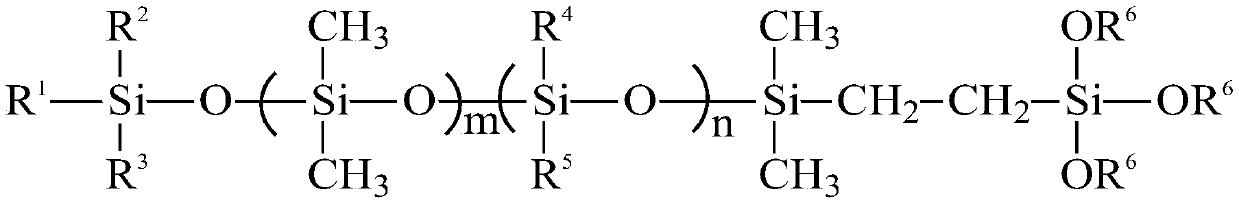

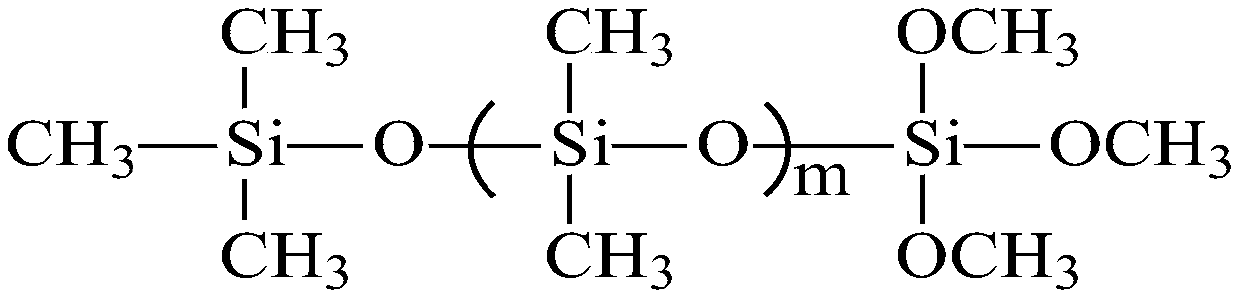

Active silicone oil and low-pollution heat-conducting silicone grease composition

InactiveCN109762340AEliminate pollutionAvoid pollutionHeat-exchange elementsHeat conductingDimethyl siloxane

The invention discloses active silicone oil, and further discloses a low-pollution heat-conducting silicone grease composition. The active silicone oil can control the oil content sigma D3-D10 of a volatile low molecular organic silicone ring body to be less than 200ppm. The active silicone oil is structurally characterized in that one end is of a hydrolyzable trimethoxysilane or triethoxysilane structure, and the other end is of any structure of methyl or vinyl or butyl methyl silicone oil or phenyl silicone oil, or all the ends are of a hydrolyzable alkoxysilane structure, and a molecule chain structure is a high temperature resistant dimethyl siloxane polymer or methyl phenyl siloxane liquid polymer. The low-pollution heat-conducting silicone grease composition is prepared from the components in parts by weight: 10-100 parts of active silicone oil, 100-3000 parts of heat-conducting filler and 0-90 parts of non-active silicone oil, wherein the sum of the content of the two types of silicone oil is 100 parts. According to the active silicone oil and the low-pollution heat-conducting silicone grease composition, the silicone oil of the specific alkoxy structure is adopted, the content of the volatile organic silicone ring body is greatly reduced, the effective binding force of the silicone oil and the filler is improved, the migration of the silicone oil and the diffusion of the ring body are avoided, and the advantages such as low pollution and good heat resistance are achieved.

Owner:东莞优邦材料科技股份有限公司

Stereolithography rapid protoyping photosensitive resin prepared by using polypropylene glycol diglycidyl ether diacrylate as prepolymer, and preparation method for stereolithography rapid protoyping photosensitive resin

The invention discloses a stereolithography rapid protoyping photosensitive resin prepared by using polypropylene glycol diglycidyl ether diacrylate as prepolymer, and a preparation method for the stereolithography rapid protoyping photosensitive resin. The resin is characterized by being prepared from the following raw materials in percentage by mass: 10 to 70 percent of polypropylene glycol diglycidyl ether diacrylate, 5 to 75 percent of epoxy resin, 5 to 55 percent of oxacyclobutane compound, 1 to 12 percent of cationic initiator, and 1 to 10 percent of free radical photopolymerization initiator. The method comprises the following steps of: mixing the raw materials in the mass ratio, and stirring at the temperature of between 20 and 80 DEG C for 5 to 120 minutes to ensure that a mixture becomes transparent faint yellow uniform liquid. The prepared photosensitive resin is low in irritation and volatile matter content, and is easy and convenient to prepare, and is high in photosensitiveness; and the critical exposure capacity Ec of the resin is less than 16.0mJ / cm<2>; formed parts are high in precision, and the camber factor CF(6) of the formed parts is + / -0.01, and CF (11) is + / -0.03. Parts with any complex shape and high precision can be directly prepared from the resin and the preparation cost of the resin is much lower than that of the photosensitive resins of the same kind.

Owner:NANCHANG UNIV

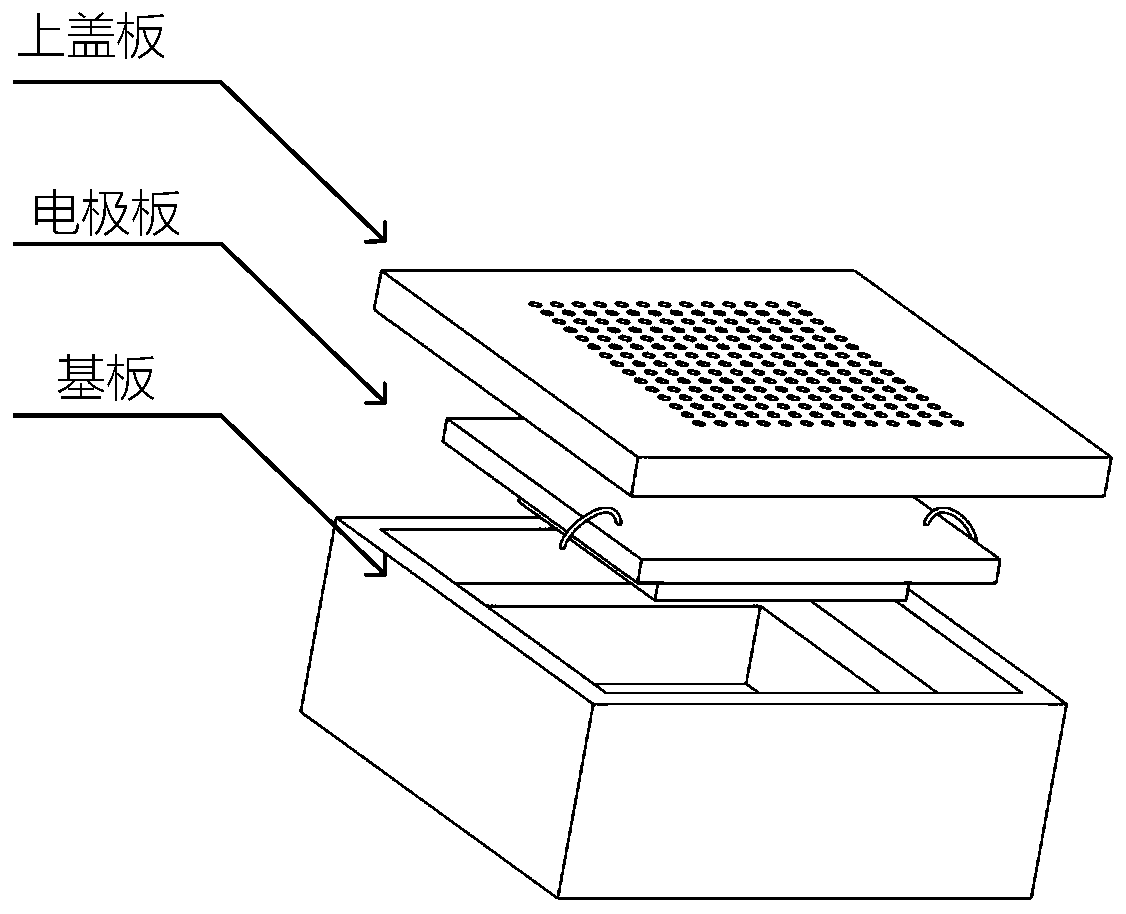

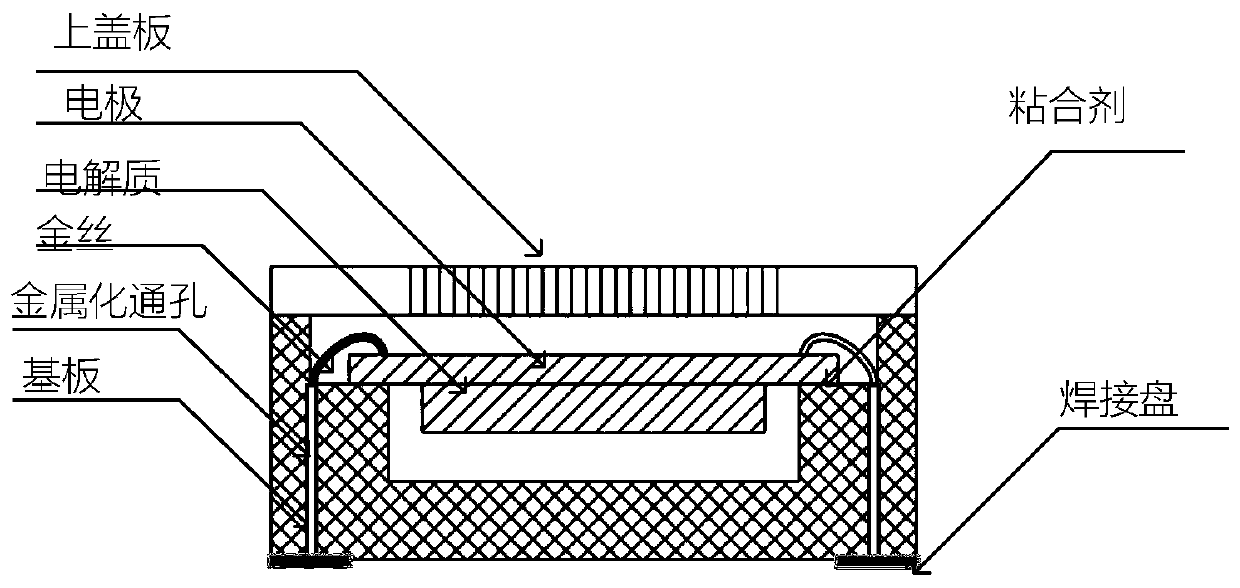

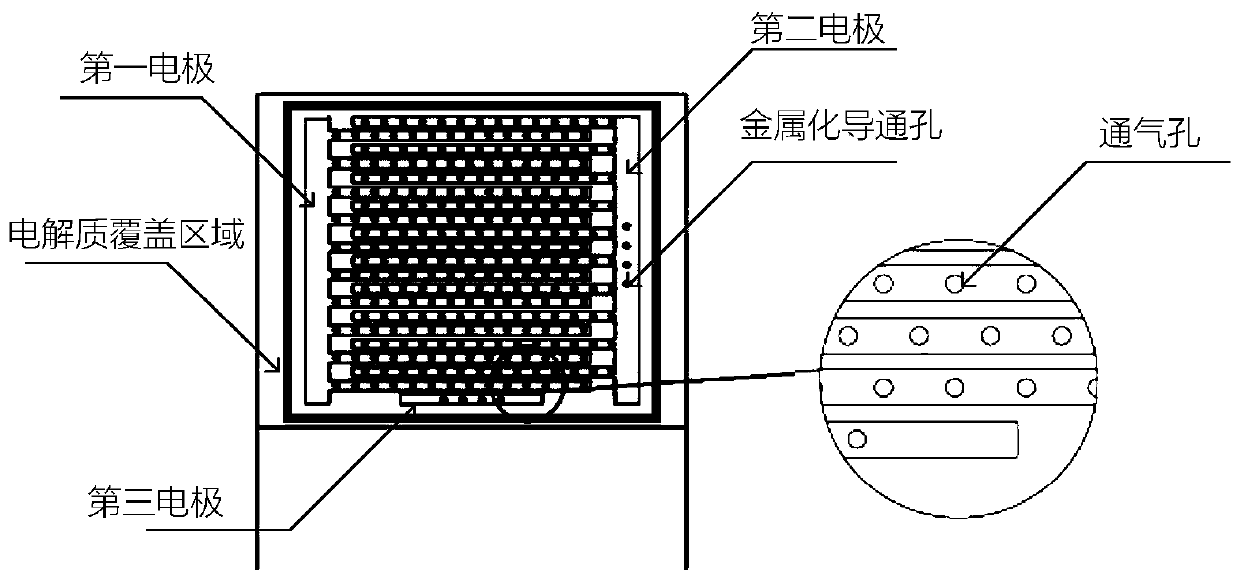

Electrochemical gas sensor and device packaging method thereof

InactiveCN110455899ALess package componentsSimple packaging processMaterial analysis by electric/magnetic meansSolid state electrolyteElectrochemical gas sensor

The invention relates to an electrochemical gas sensor and a device packaging method thereof. The electrochemical gas sensor comprises an upper cover plate, an electrode plate and a substrate; the upper cover plate adopts a porous ceramic material, and to-be-measured gas can enter the sensor through ceramic micro pores; the back surface of the electrode plate is equipped with a micro-spacing sensor electrode of a three-electrode coplanar system, wherein the electrode is covered with a solid electrolyte layer and is sealed in a groove of the substrate; and the electrode plate is coupled to thesubstrate through an adhesive and is electrically connected with the substrate through gold wire binding. The sensor is less in components, small in size, high in sensitivity and long in service life.

Owner:广州钰芯传感科技有限公司

Vacuum smelting process for nickel-based alloy containing aluminium, titanium, boron and zirconium

The invention relates to an alloy smelting process, and specifically relates to a vacuum smelting process for a nickel-based alloy containing aluminium, titanium, boron and zirconium. The vacuum smelting process comprises the following steps: adding all elements in the nickel-based alloy except aluminium, titanium, boron, zirconium and nickel into a vacuum furnace crucible, and smelting; cooling molten metal to 1370-1390 DEG C, adding aluminium and titanium into the molten metal, and heating until the aluminium and titanium are completely fused; keeping a temperature of 1410-1430 DEG C, adding a nickel-boron alloy and zirconium into the molten metal, and heating until the nickel-boron alloy and zirconium are completely fused to obtain molten metal; and cooling, freezing the molten metal, and while lowering the temperature to 1360-1380 DEG C and then heating to 1450-1470 DEG C, carrying out steel-tapping pouring. According to the vacuum smelting process disclosed by the invention, the contents of harmful gases and low-melting-point impurities in the molten metal are reduced, the molten alloy is pure, the chemical ingredients of the alloy are uniform, and the comprehensive mechanical properties and quality of the alloy achieve the level of domestic and international high-quality alloys.

Owner:SHANDONG ROITIE NEW MATERIAL SCI & TECH

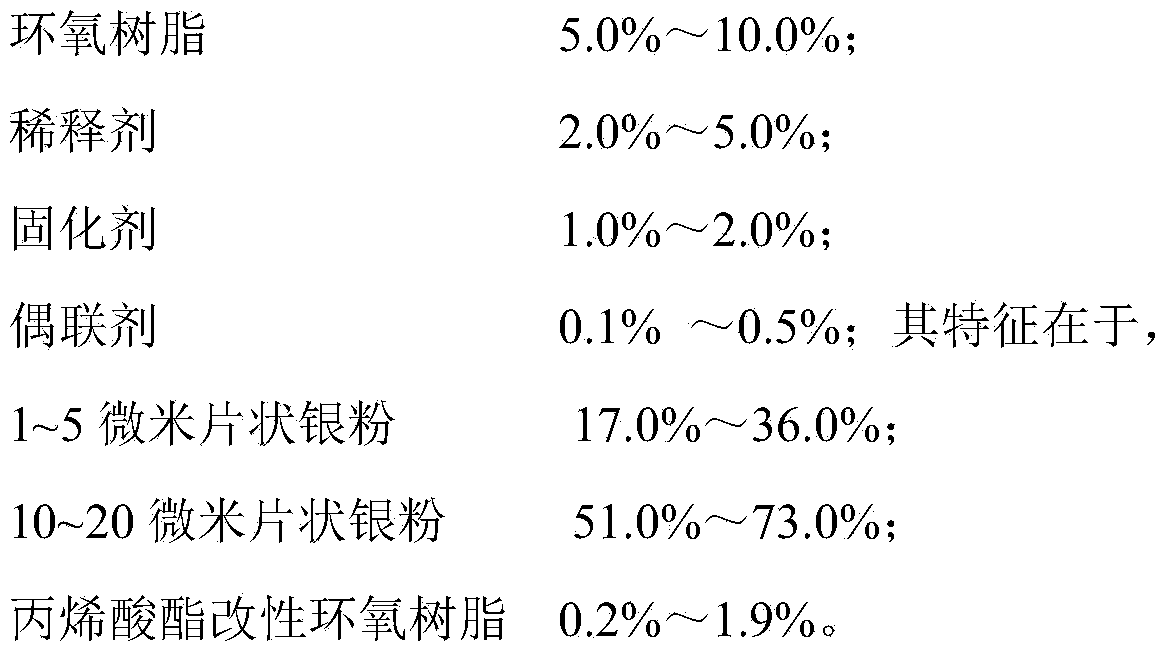

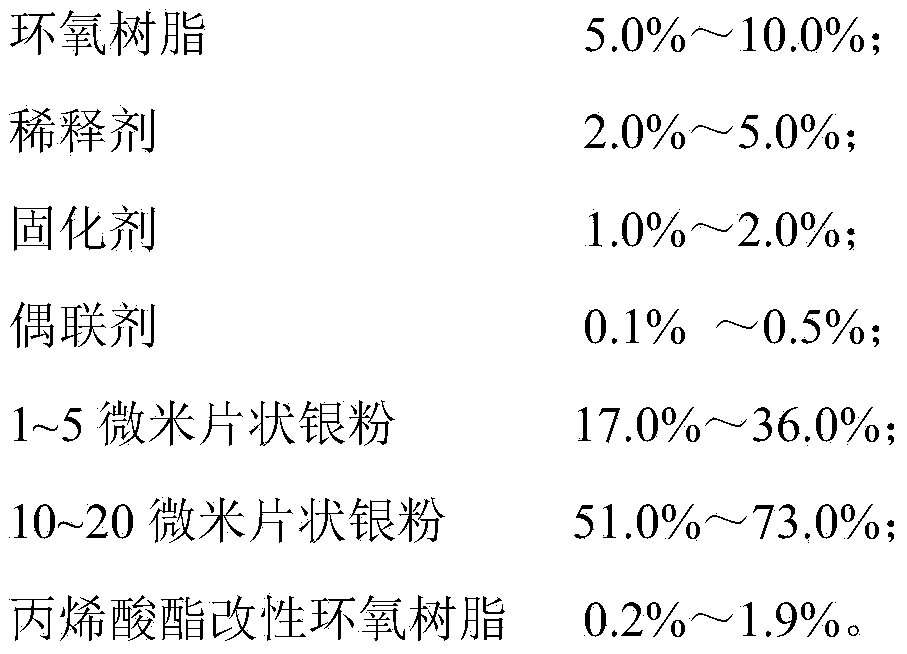

Large-power conductive chip adhesive

InactiveCN103627357AEnsure operabilityImprove thermal conductivityNon-macromolecular adhesive additivesEster polymer adhesivesEpoxyGlycidyl methacrylate

The invention relates to a large-power conductive chip adhesive, belonging to the technical field of an adhesive applied to microelectronic packaging. The conductive chip adhesive consists of flake silver powder, epoxy resin, acrylate-modified epoxy resin, a curing agent, a coupling agent and a diluting agent. By adopting two-peak distribution of micrometer silver powder, the filling capacity of silver can be improved, and the large-power modified epoxy resin conductive chip adhesive with high electrical conductivity and high heat conductivity can be realized; the acrylate-modified epoxy resin is a copolymerization product of glycidyl methacrylate and two to three acrylic ester monomers and / or olefin monomers. The large-power conductive chip adhesive has the effects that the high-temperature resistance and high-humidity resistance and aging resistance property of the epoxy resin adhesive can be improved, the volume resistivity is low, and the bonding strength is high; the large-power conductive chip adhesive is applicable to electronic packaging requirements on lead-free and high-temperature and high-humidity environments, the packaging reliability can be enhanced, and the service lives of packaged devices can be prolonged.

Owner:CHANGCHUN YONGGU TECH

Light alkyd resin for interior decoration and furniture coating and preparation method thereof

The invention discloses light alkyd resin for interior decoration and furniture coating, which is formed by the following raw materials: glycerol, palmitoleic acid, benzoic acid, hexanedioic acid, neopentyl glycol, phthalic anhydride, tetramethylolmethane and dimethylbenzene; the preparation method comprises the following steps: a. the palmitoleic acid, the benzoic acid, the hexanedioic acid, the glycerin, the neopentyl glycol, the phthalic anhydride, the tetramethylolmethane and the dimethylbenzene are thrown in a reactor one time, are heated and are stirred; b. carbon dioxide gas flows in the reactor to protect temperature rise, when the temperature is raised to 130-180 DEG C and kept for 1-3 hours, at the moment, the dimethylbenzene flows back, and then the temperature is raised to 200 plus / minus 5 DEG C at the temperature raising speed with 8-12 DEG C per hour, and then the temperature is kept for 4-8 hours; c. a sample is taken out in the step b for measuring viscosity, when the viscosity reaches desired value, the temperature is cooled to 130-180 DEG C, so as to obtain the modified alkyd resin; d. the alkyd resin in the step c is transferred to another reactor, and then 2.5-8.5 percent of dimethylbenzene is added, the mixture is mixed uniformly to obtain the water-white alkyd resin liquid.

Owner:四川巴德士新材料有限公司

Binder for manufacturing inorganic sintered body

ActiveUS9447218B2Stay flexibleNot volatileFixed capacitor dielectricCeramic layered productsVitrificationGlass transition

Owner:SEKISUI CHEM CO LTD

Preparation method of glaze isolated color-printed chinaware

The invention relates to a preparation method of glaze isolated color-printed chinaware, which belongs to the technical field of ceramic preparation. The preparation method comprises the following steps: preparing basic glaze powder, surface layer glaze, bottom layer glaze and a chinaware clay body, performing color printing on the surface of the mud clay body by using a transfer color printing machine conventionally used by ceramics for daily use and using the bottom layer glaze to obtain a pattern composed of strips, drying, manually glazing the color-printed and oven-dried product, storing the glazed product in a cool and dry place for 8-16 hours, and burning the glazed product in a kiln to obtain the glaze isolated color-printed chinaware. The product prepared by using the preparation method of the invention has a slightly concaved-convexed and colored pattern on the surface thereof, and has a good three-dimensional effect; the glaze isolated color-printed chinaware has regular appearance and smooth glaze, and the strip-like motif pattern in the glaze is clear; and the method has high efficiency and low cost.

Owner:GUANGDONG SITONG GROUP

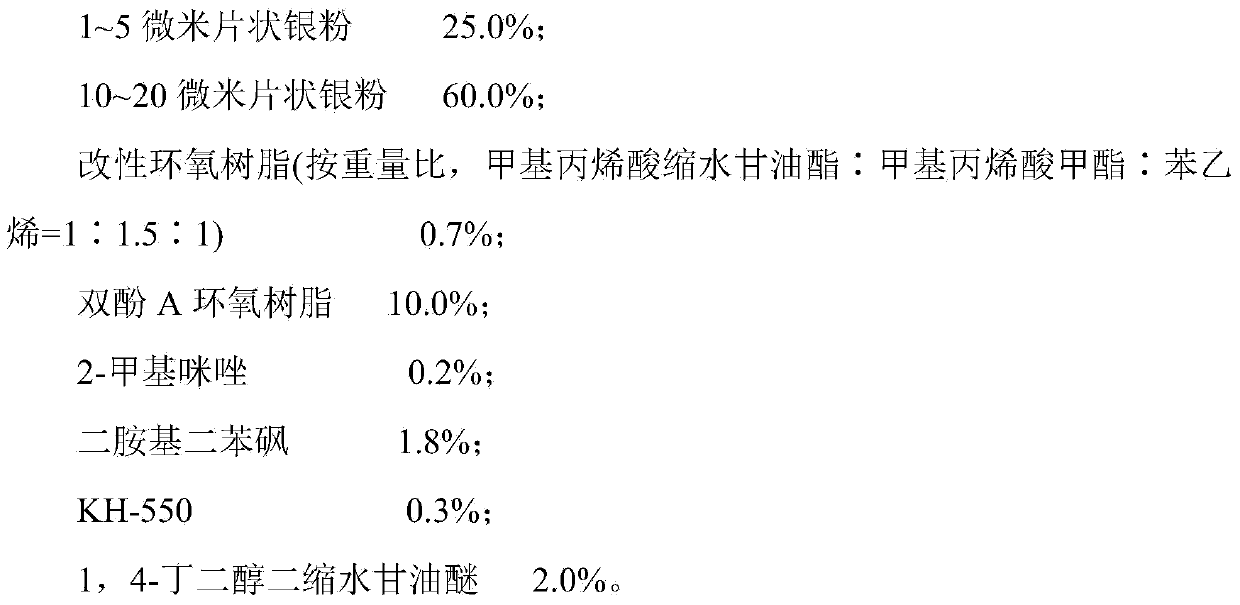

Preparation method of adhesive for recombined material

ActiveCN106336839ALess volatilePromote environmental protectionStarch adhesivesMacromolecular adhesive additivesFiberMicro nano

The invention relates to a preparation method of an adhesive for a recombined material. The preparation method comprises the following steps: preparing modified micro-nano cellulose, preparing aqueous polymer, preparing biomass composite emulsion, preparing a main agent, preparing a stress type crosslinking agent and preparing the adhesive, wherein the micro-nano cellulose is prepared by performing acid treatment, low-temperature ultrasonic pretreatment, high-pressure homogenization treatment and surface modification on wood or straw fibers which lignin and hemicelluloses are removed from; and the biomass composite emulsion is prepared by performing vegetable protein modification and active monomer grafting on soybean powder. According to the preparation method provided by the invention, formaldehyde is not added, so high environmentally-friendly property is achieved; the synergistically toughening effect of the biomass composite emulsion and the modified micro-nano cellulose is exerted, so that the prepared adhesive for the recombined material has a good toughening effect. The adhesive prepared by the method is very suitable for adhesion of the recombined material and effectively solves the problems that the existing recombined material has low environmentally-friendly property and low toughness.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

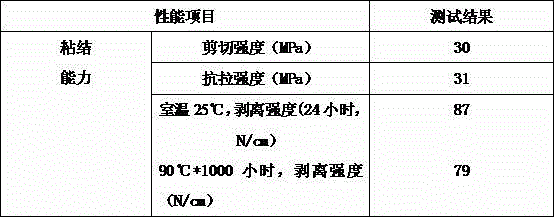

Epoxy resin and nitrile rubber adhesive and preparing method thereof

InactiveCN103059750AHigh strengthHigh impact strengthNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyPolyvinyl chloride

The invention discloses an epoxy resin and nitrile rubber adhesive and a preparing method thereof. The epoxy resin and nitrile rubber adhesive is prepared from raw materials comprising, by weight part ratio, 100-120 parts of styrene, 100-150 parts of ethyl acetate, 20-25 parts of nitrile rubber N230S, 15-20 parts of dimethylbenzene, 1-2 parts of 4,4`-diphenylmethane diisocyanate, 8-12 parts of polyisobutene, 2-3 parts of 3-aminopropyltrimethoxysilane, 2-3 parts of polytetramethylene ether glycol, 3-5 parts of SG-2 type polyvinyl chloride (PVC) resin, 1-2 parts of ferrocene, 15-20 parts of modified epoxy resin, 5-8 parts of ethylene propylene diene monomer, 2-5 parts of phthalic acid ester and the like. The adhesive has excellent heat resistance and impact resistance, and is high in bonding strength, water-proof and damp-proof, good in storage stability, low in number of volatile matters during the solidification process, good in environmental protection property and using effect, convenient and wide in range of application.

Owner:TONGLING TONGYUN MACHINERY

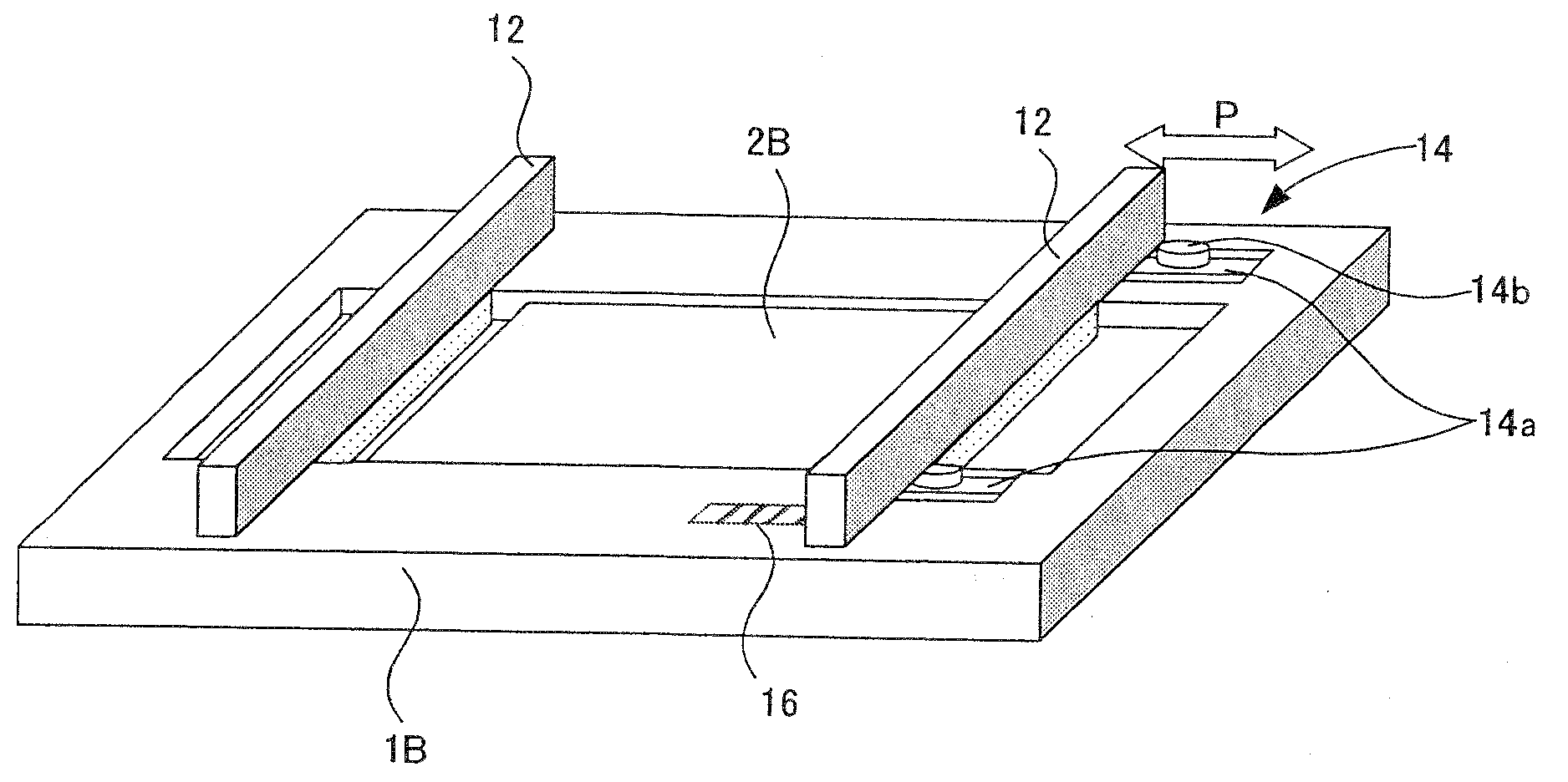

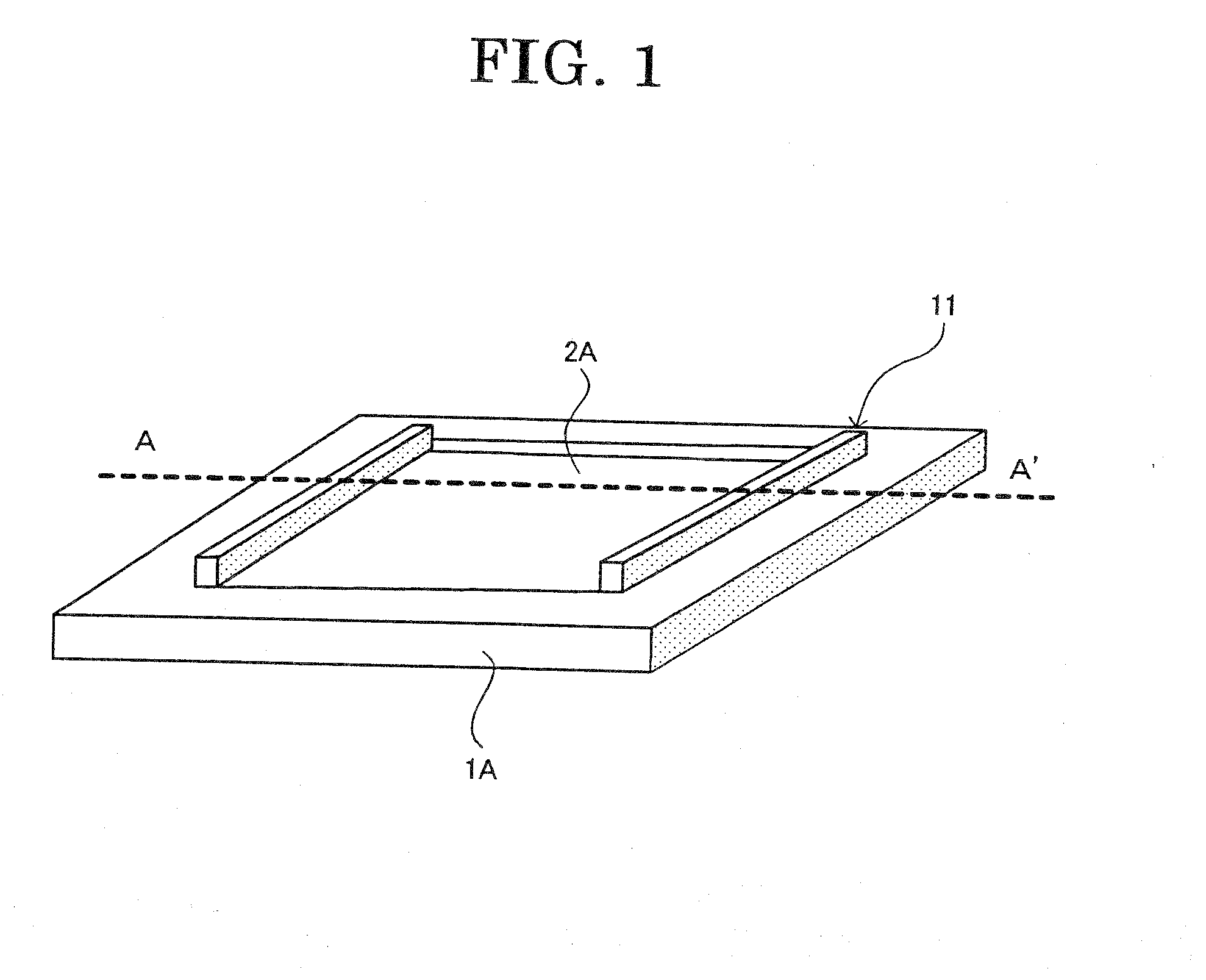

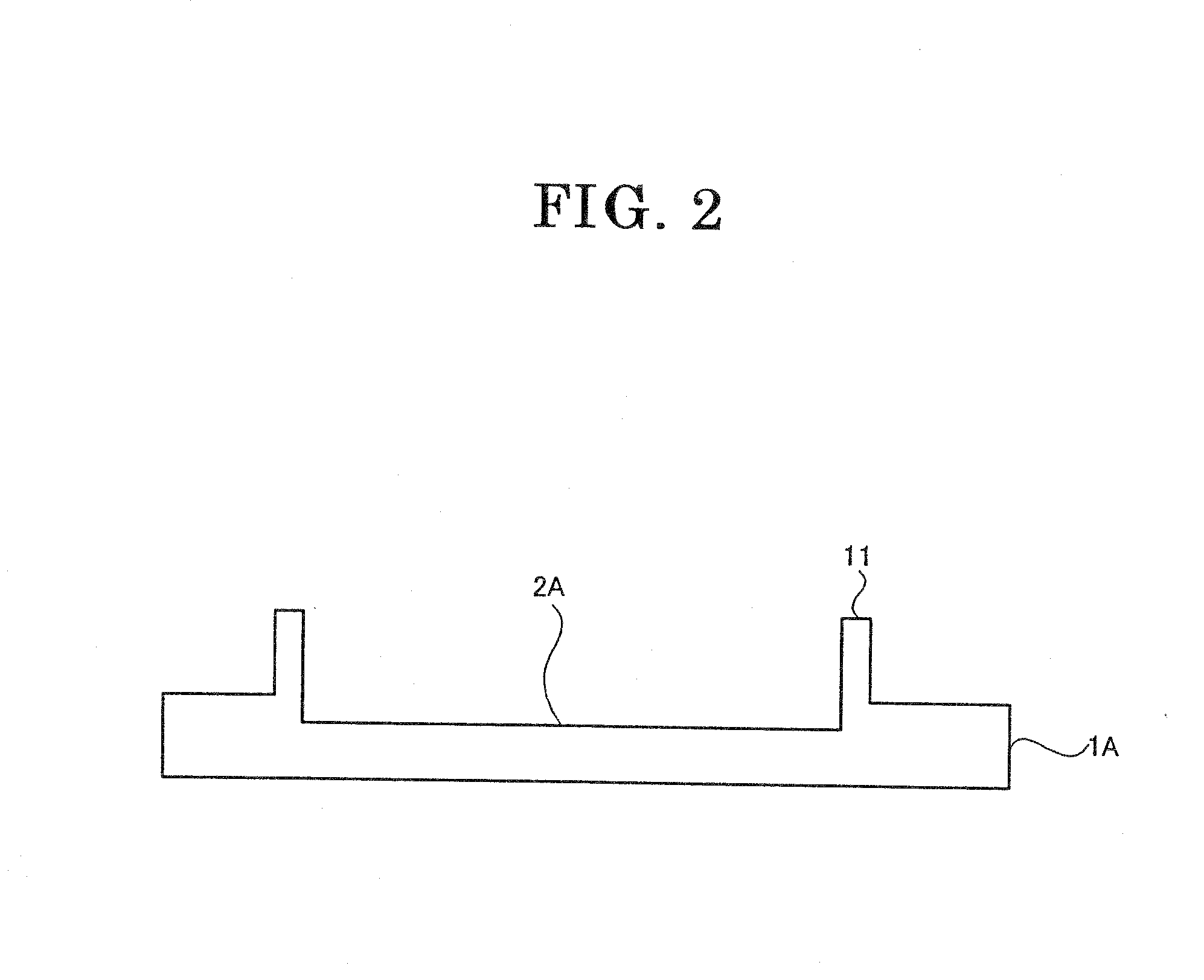

Liquid crystal plate, liquid crystal injection apparatus and liquid crystal injection method

InactiveUS20080178961A1Uniform characteristicLess volatilePackaging under special atmospheric conditionsLiquid bottlingLiquid crystalEngineering

A liquid crystal plate for storing a liquid crystal material for simultaneously injecting it into a plurality of liquid crystal panels and liquid crystal injection apparatus and method using such liquid crystal plate are disclosed. The liquid crystal plate has a recess for storing the liquid crystal material and a pair of raised members such as ribs, baffles or the like at both end portions of the recess in parallel with the outermost liquid crystal panels. The raised members have the height at least equal to the top surface of the liquid crystal material filled in the recess for maintaining the liquid crystal characteristics of the liquid crystal material injected into the plurality of liquid crystal panels substantially uniform regardless of the location in a cassette.

Owner:NEC LCD TECH CORP

Rubber floor prepared with rubber powder of junked tires as raw material and preparation method thereof

InactiveCN105330923AIncreased activationHigh strengthPlastic recyclingBulk chemical productionPolymer sciencePotassium

The invention relates to the technical field of recycle of rubber powder of junked tires, in particular to a rubber floor prepared with the rubber powder of the junked tires as a raw material and a preparation method thereof. Through selection and raw material matching of the rubber powder of the junked tires, PVC powder, ferric oxide powder, potassium-bearing rock powder, polypropylene powder and polyurethane curing agents, all the raw materials interact with one another to enhance the strength of the rubber floor, reduce volatile substances in the rubber floor, lower the emission of peculiar smells of the rubber floor, lower the environmental pollution rate and increase the sound insulation rate of the rubber floor; particularly through selection of potassium-bearing rock, sylvite in the potassium-bearing rock reacts with the rubber powder of the junked tires, and then the purpose of activating the rubber powder of the junked tires is achieved; in combination with the ferric oxide powder, the activation degree of the rubber powder is increased; in combination with the PVC powder, the polypropylene powder and the polyurethane curing agents, the strength of the rubber powder in the curing and shaping process is guaranteed, and the performance of the rubber floor is improved.

Owner:贵州安泰再生资源科技有限公司

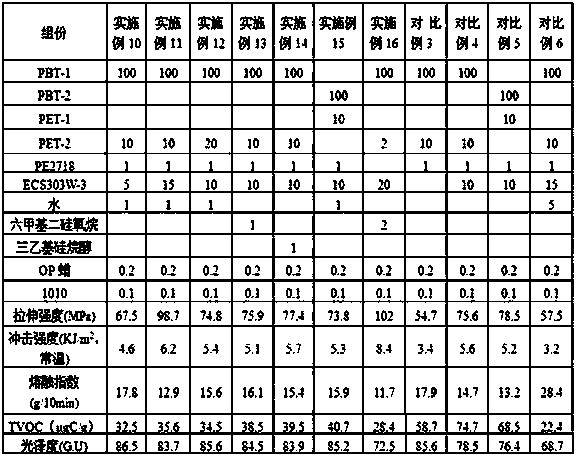

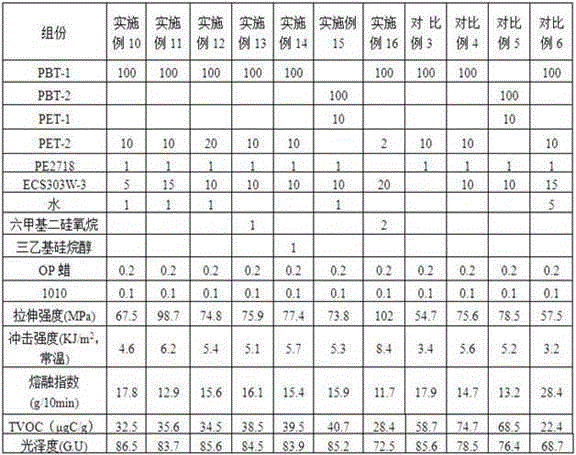

Highlight low-volatile polybutylene terephthalate (PBT) composition as well as preparation method and application of composition

The invention discloses a highlight low-volatile polybutylene terephthalate (PBT) composition as well as a preparation method and application of the composition. The highlight low-volatile PBT composition comprises the following components: 100 parts of PBT resin, 2-20 parts of PET (polyethylene terephthalate) resin, 0-20 parts of glass fiber, 0.5-2 parts of highlight auxiliary, 0.5-2 parts of black seeds and 0.1-2 parts of auxiliary. The preparation method comprises the steps of mixing the PBT resin, the PET resin, the highlight auxiliary, the black seeds and the auxiliary in a high-speed mixer for 1-2min to obtain a premix; melting and extruding the premix by using a double screw extruder; laterally feeding the glass fiber; carrying out two-stage vacuum granulation to obtain a finished product. The highlight auxiliary is introduced to the PBT composition, so that the glossiness of the material and the output rate of a highlight product can be effectively increased on the premise that the mechanical performance and processability of the composition are not affected, and the prepared PBT composition is high in glossiness, good in flowability, few in volatile matters, favorable in mechanical performance and processability and suitable for products such as electronic and electrical products, automobile lamp ornaments and the like with highlight requirements.

Owner:KINGFA SCI & TECH CO LTD

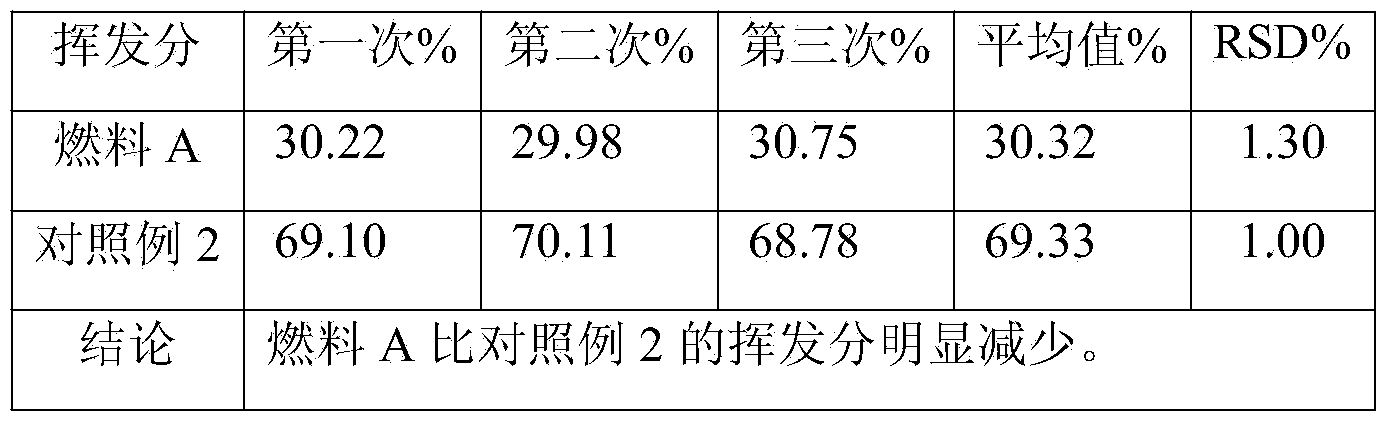

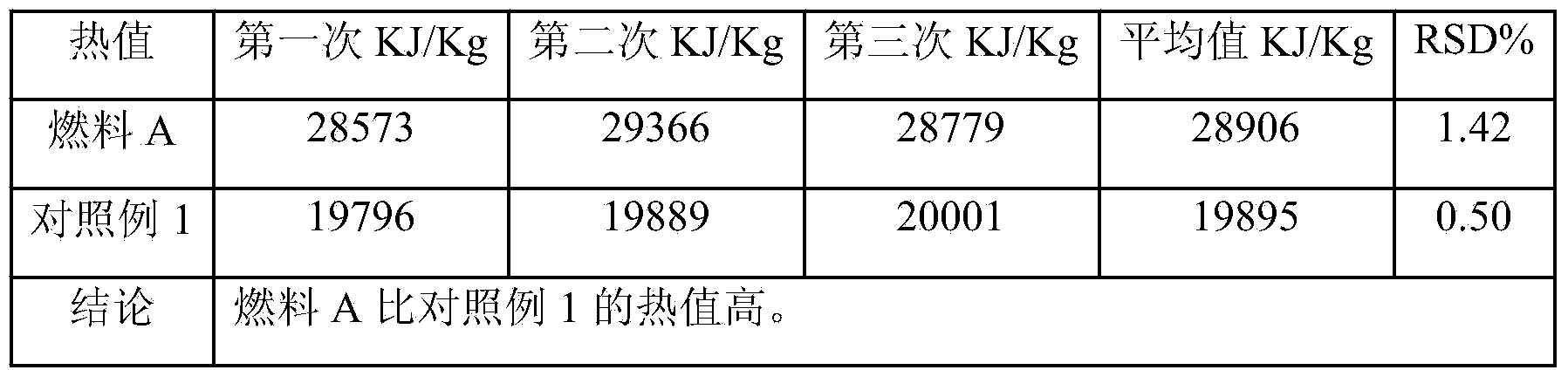

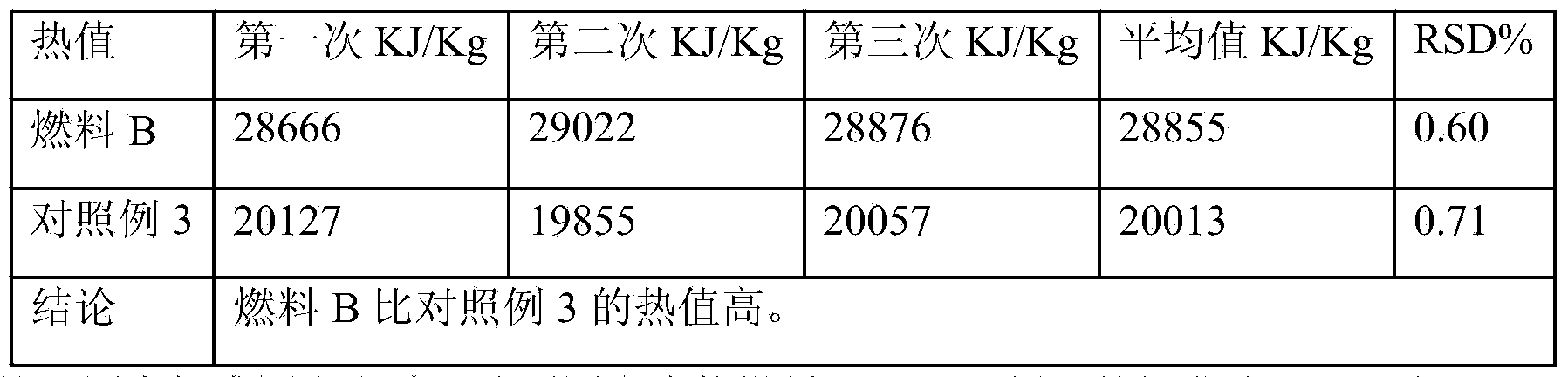

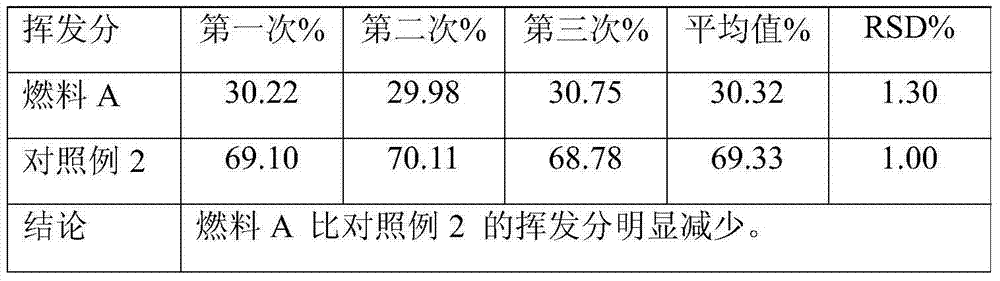

Environment-friendly and energy-saving biological fuel

The invention discloses an environment-friendly and energy-saving biological fuel which comprises the materials in parts by weight: 70-80 parts of a biomass briquette fuel, 10-15 parts of coal, 6-7 parts of hexamine, 3-5 parts of ethyl alcohol and 1-3 parts of stearic acid. A preparation method comprises the steps of smashing the biomass briquette fuel, uniformly mixing the smashed biomass briquette fuel with the solid ethyl alcohol and the stearic acid, then smashing the coal blocks, adding the coal, continuing to fully stir the materials, and finally adding the hexamine. According to the biofuel obtained by the technical scheme, the carbon content is increased; due to the characteristic of high oxygen content, the combustion heat value of the fuel is increased; volatile matters generated in the beginning of combustion can be effectively reduced by adjusting formula, and environment protection is facilitated.

Owner:福建泰和生物质能源科技有限公司

Alpha-amino acid salt absorbent for capturing carbon dioxide

The invention relates to the field of carbon dioxide capture, and relates to an alpha-amino acid salt absorbent for capturing carbon dioxide. The absorbent comprises the following components in percentage by volume: 15 to 40 percent of alpha-amino acid salt, 5 to 15 percent of dissolution promoter, and 2 to 8 percent of absorption promoter. The brand-new alpha-amino acid salt absorbent is formed by mixing the specific main absorbent alpha-amino acid salt, the absorption promoter, the dissolution promoter and water according to a proper ratio. Compared with the prior art, the absorbent has thefollowing beneficial effects and effects: the amino acid salt has extremely low vapor pressure and low volatilization and operation loss; good anti-oxidative degradation performance is realized, and the service life is greatly prolonged; and the dissolution promoter is added, so that the solubility of the amino acid salt is greatly improved, and the carbon dioxide saturated absorption capacity ofthe solvent is greatly improved.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD +1

A high light and low volatility polybutylene terephthalate composition and its preparation method and application

The invention discloses a high-gloss and low-volatility polybutylene terephthalate composition, its preparation method and application, which includes components: 100 parts of PBT resin; 2 to 20 parts of PET resin; 0 to 20 parts of glass fiber; high gloss 0.5~2 parts of additives; 0.5~2 parts of black seeds; 0.1~2 parts of additives. The preparation method is to mix PBT resin, PET resin, high-gloss additives, black seeds and additives in a high-speed mixer for 1-2 minutes to obtain a premix. The premix is melted and extruded through a twin-screw extruder, and the glass fiber Side feeding, using two-stage vacuum granulation to obtain the finished product. The present invention introduces a high-gloss additive into the polybutylene terephthalate composition, which can effectively improve the glossiness of the material and the output rate of high-gloss products without affecting the mechanical and processing properties of the composition. Preparation The obtained polybutylene terephthalate composition not only has high gloss, good fluidity and low volatile matter, but also has excellent mechanical and processing properties, and is suitable for products with high gloss requirements such as electronic appliances and car lamp decorative rings.

Owner:KINGFA SCI & TECH CO LTD

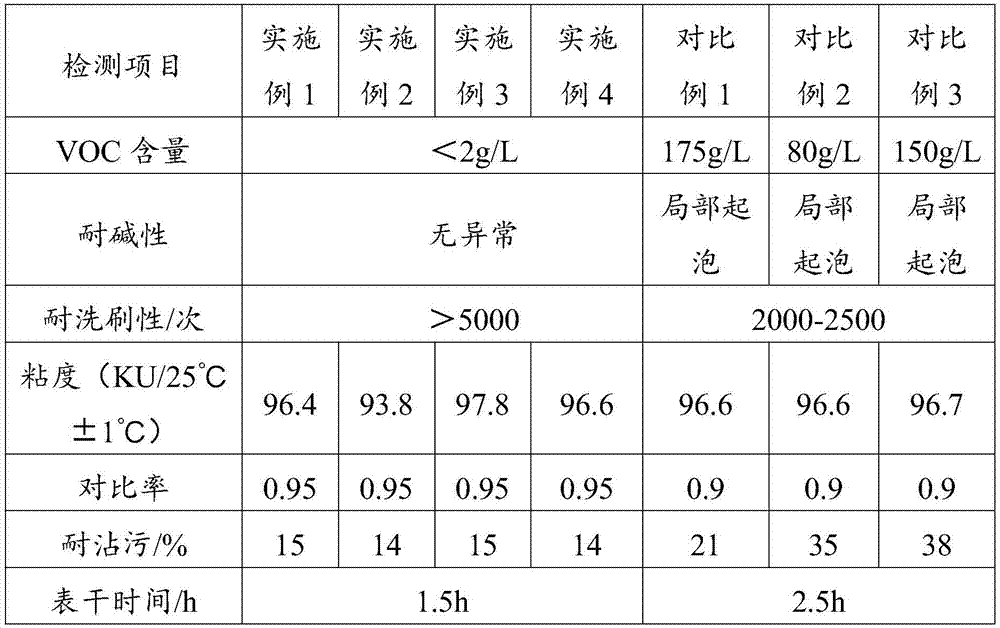

Environment-friendly EVA emulsion paint and preparation method thereof

PendingCN107459879ALow scrub resistanceImprove stain resistanceAntifouling/underwater paintsPaints with biocidesWater basedCellulose

The invention discloses environment-friendly EVA emulsion paint and a preparation method thereof. The emulsion paint is prepared from the following ingredients in parts by mass: 15 to 20 parts of EVA emulsion, 8 to 14 parts of spurrite powder, 35 to 45 parts of filling materials, 1 to 2 parts of propanediol, 0.2 to 0.4 part of cellulose ether, 0.6 to 0.8 part of water-based defoamers, 0.4 to 0.6 part of water-based dispersants, 0.3 to 0.5 part of water-based pH regulators, 0.2 to 0.4 part of water-based moisturizing agents, 1 to 1.5 parts of coalescing agents, 0.5 to 1 part of thickening agents, 0.2 to 0.4 part of preservatives and 22 to 30 parts of deionized water. The spurrite powder is added into the environment-friendly EVA emulsion paint, so that the defects of low scrub resistance and poor water resistance performance of the EVA emulsion paint are obviously overcome; the preparation method is simple; the adding sequence of the ingredients is used, so that the performance of each ingredient achieves the optimum; the scrub resistance performance, the water-resistant performance and the alkali resistance of the emulsion paint are improved.

Owner:北京宝辰联合科技股份有限公司

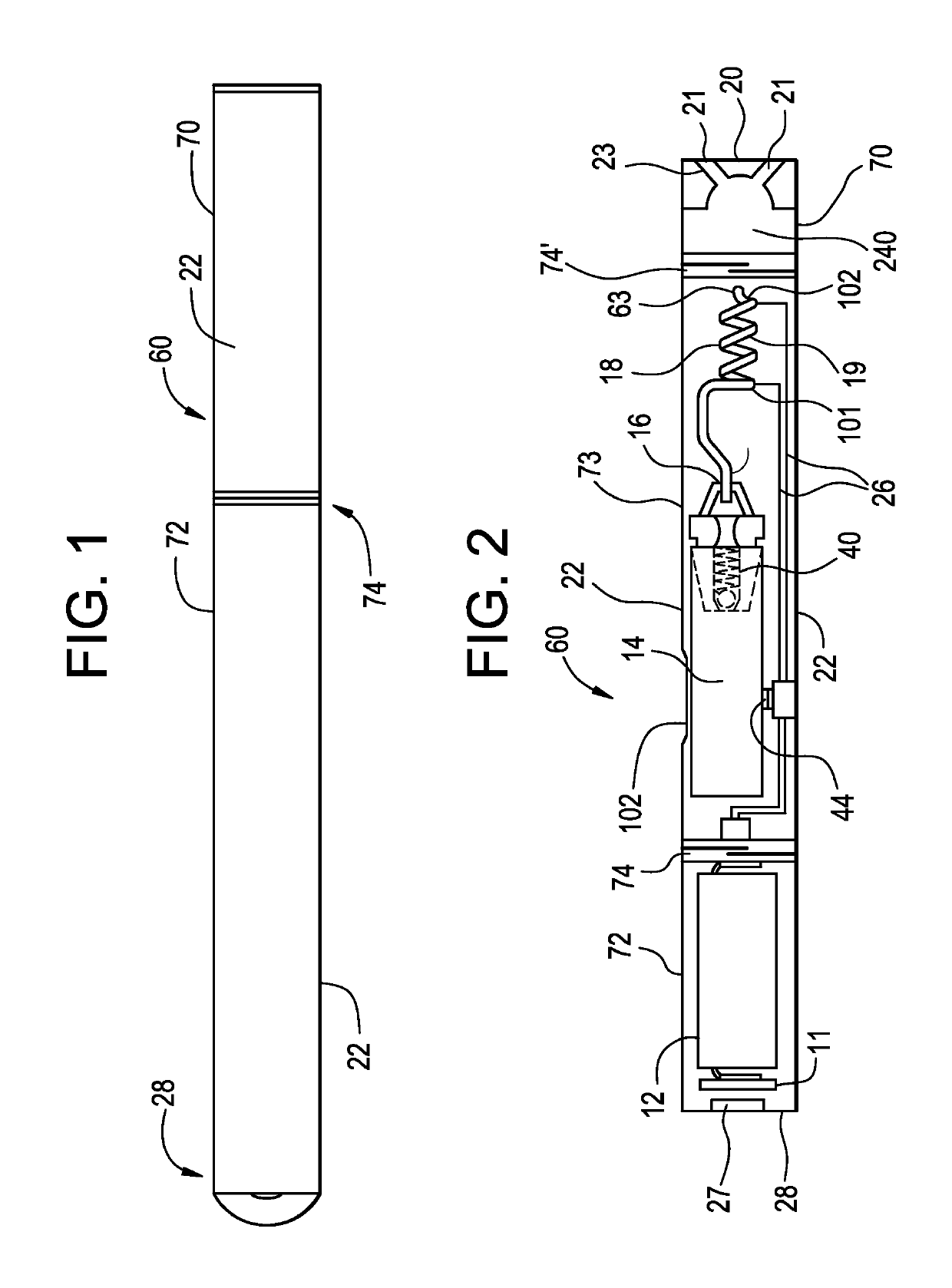

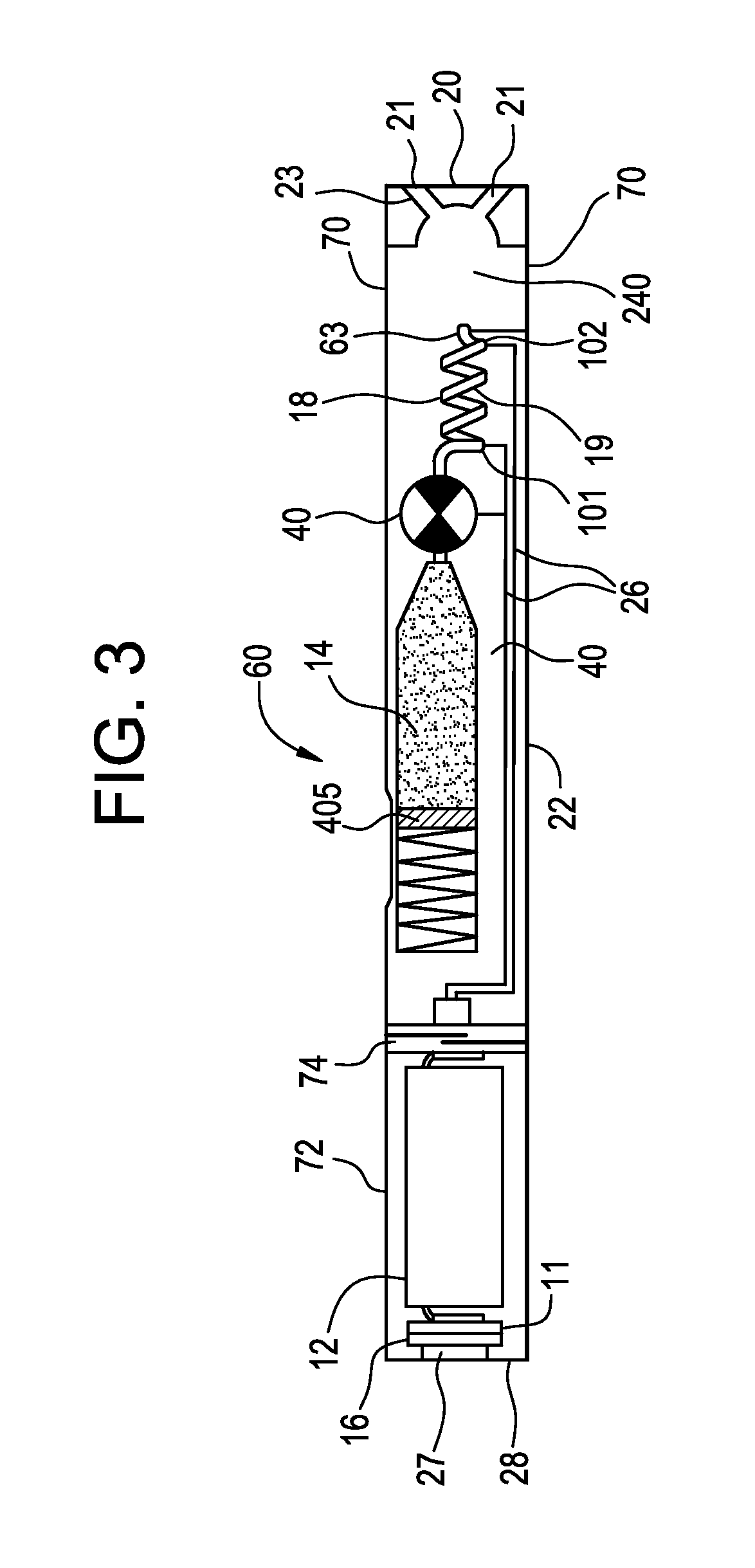

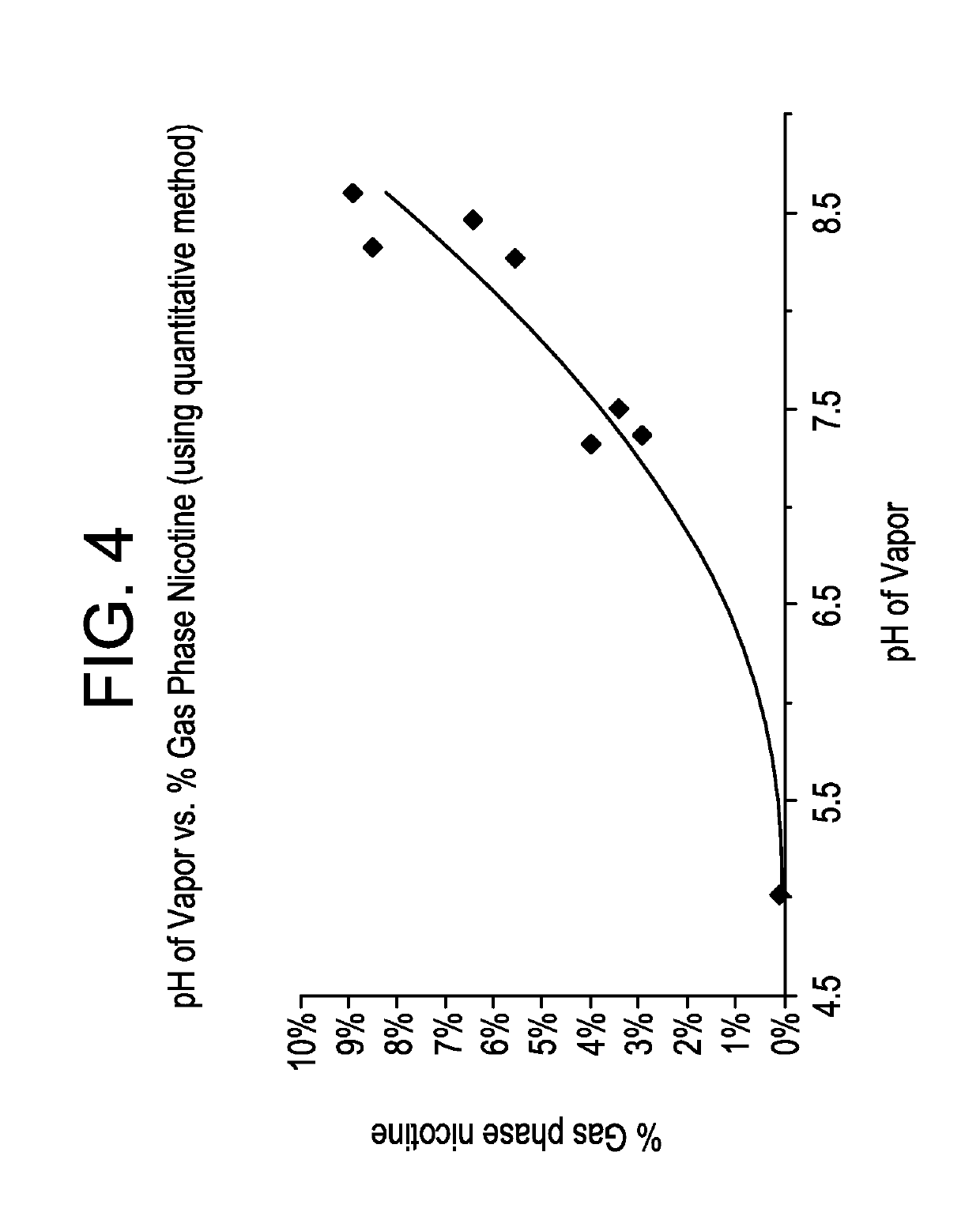

Pre-vaporization formulation for controlling acidity in an e-vaping device

ActiveUS10327472B2Increase acidityGreat proportionTobacco treatmentPharmaceutical delivery mechanismBenzoic acid4-pentenoic acid

Owner:AKRIA CLIENT SERVICES LLC

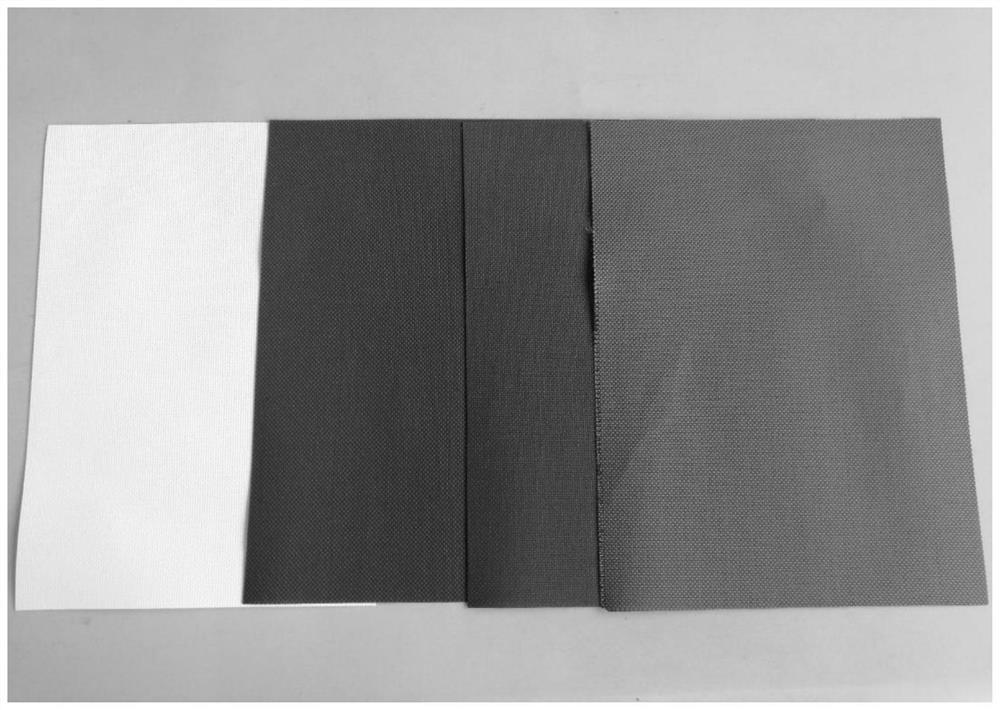

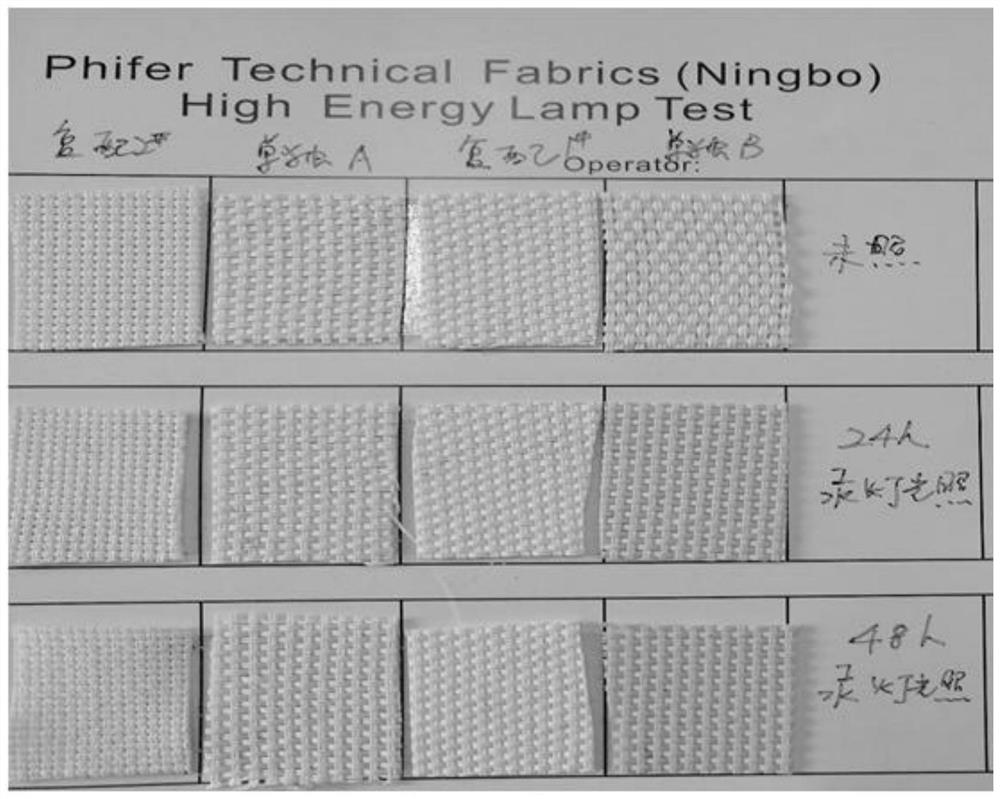

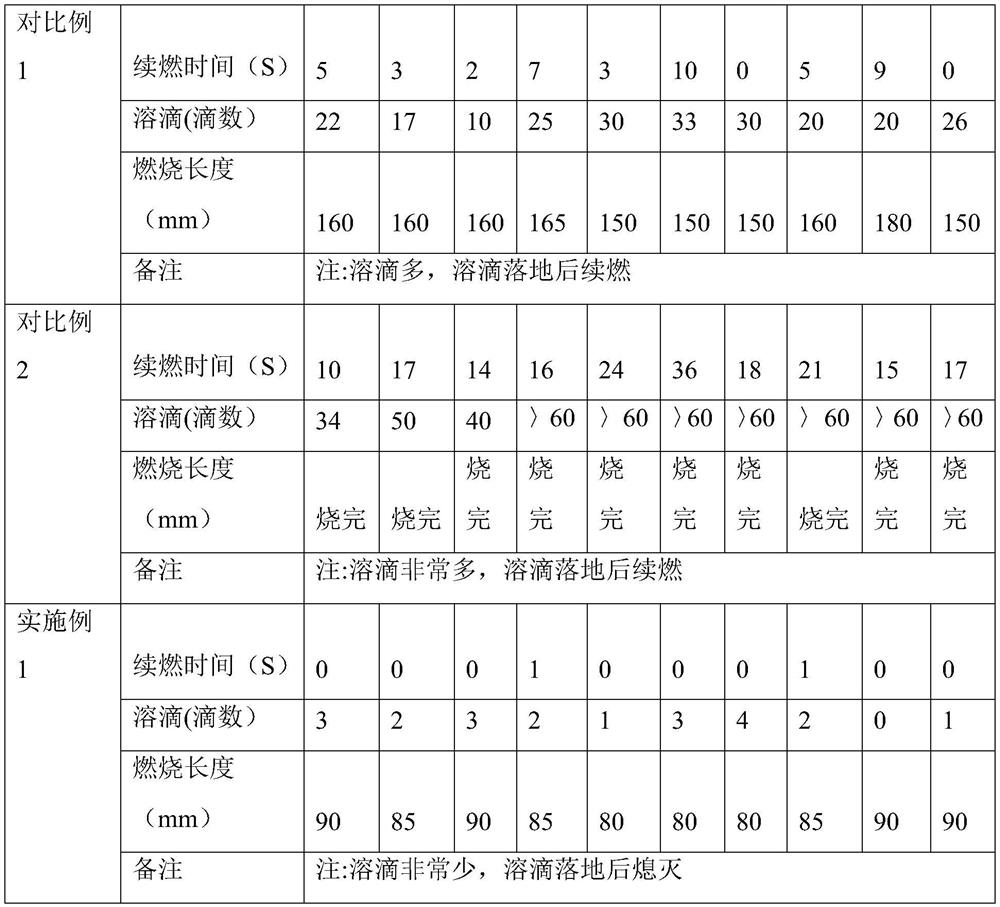

TPO environment-friendly particle for sunlight fabric

ActiveCN112111106AGood anti-smoke effectVariety of material choicesFlame-proof filament manufactureFilament/thread formingElastomerPlasticizer

The invention relates to a TPO environment-friendly particle for a sunshine fabric. The particle is prepared from the following raw materials in parts by weight: 40-50 parts of copolymerized PP, 40-50parts of an ethylene propylene elastomer, 0.3-0.5 part of a compound antioxidant, 0.6-1.0 part of a compound light stabilizer, 0.2-0.3 part of a compound antibacterial agent and 0-12 parts of a compound synergistic flame retardant. The particle is environment-friendly, does not need to add a large number of plasticizers and lubricants, reduces volatile matter and odor, is particularly suitable for indoor products of sunshine fabrics, can be made into materials with different hand feelings by properly adjusting the content of the elastomer, and is better in flame-retardant effect and environment-friendly by adopting the compounded flame retardant.

Owner:PHIFER INC

Loquat fruit jelly

InactiveCN101133784AGood anti-inflammatory effectEnhance immune functionFood preparationSugarAmygdalin

The present invention discloses a loquat fruit jelly. Its composition contains (by wt%) 50-80% of loquat extract, 0.6-1.2% of edible gelatin, 12-16% of edible sugar and 0.07-0.10% of edible essence, and the rest is pure water. In the loquat extract 0.008-0.0125% of amygdalin is contained, said amygdalin has the effects of resolving sputum, relieving cough and resisting senility.

Owner:NINGBO UNIV

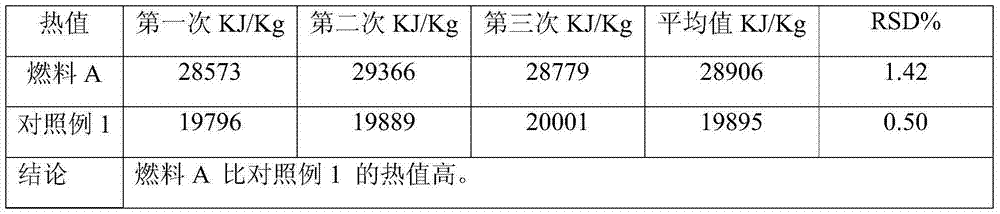

An environmentally friendly and energy-saving biofuel

InactiveCN103773541BMake up for the problem of low carbon contentHigh calorific valueBiofuelsSolid fuelsCombustionAlcohol

The invention discloses an environment-friendly and energy-saving biological fuel which comprises the materials in parts by weight: 70-80 parts of a biomass briquette fuel, 10-15 parts of coal, 6-7 parts of hexamine, 3-5 parts of ethyl alcohol and 1-3 parts of stearic acid. A preparation method comprises the steps of smashing the biomass briquette fuel, uniformly mixing the smashed biomass briquette fuel with the solid ethyl alcohol and the stearic acid, then smashing the coal blocks, adding the coal, continuing to fully stir the materials, and finally adding the hexamine. According to the biofuel obtained by the technical scheme, the carbon content is increased; due to the characteristic of high oxygen content, the combustion heat value of the fuel is increased; volatile matters generated in the beginning of combustion can be effectively reduced by adjusting formula, and environment protection is facilitated.

Owner:福建泰和生物质能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com