Sprayable baking type water soluble damping coating and preparation method thereof

A damping paint, water-based technology, applied in the field of damping materials, can solve the problems of loss of vibration reduction and noise reduction, bubbling, falling off, etc., to achieve the effect of reducing viscosity, convenient construction, and enhancing smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

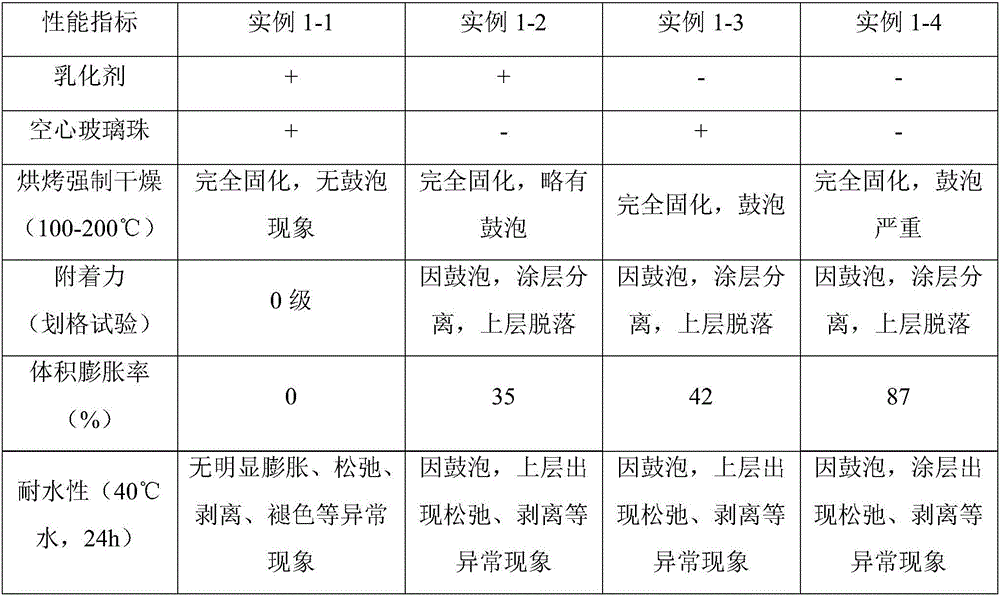

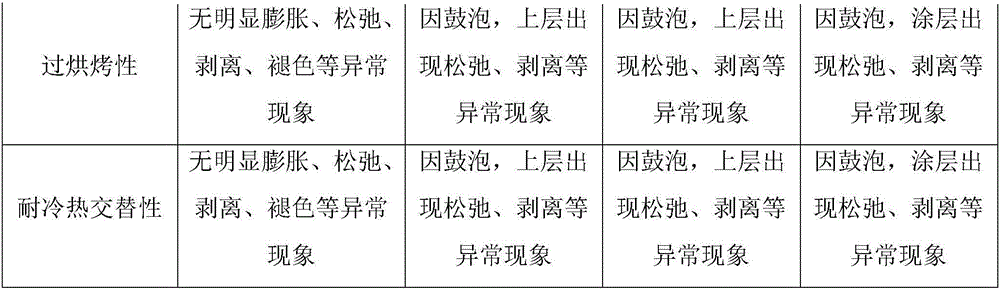

Embodiment l

[0026] This embodiment discloses a spray-baking water-based damping paint and its preparation method. The damping paint contains by mass: 20 parts of acrylic emulsion, 6.8 parts of emulsifier, 0.2 parts of neutralizer, 1.5 parts of dispersant, 1.5 parts of co-solvent, 1 part of iron oxide pigment, 10 parts of mica powder, 4 parts of hollow glass beads, 10 parts of talc powder, 15 parts of aluminum hydroxide, 20 parts of quartz powder, and 10 parts of water.

[0027] The water-based damping paint is prepared according to the following method: Step 1: filter 20 parts of acrylic emulsion and add it to the mixer, add 0.2 parts of neutralizer while stirring, and stir for 5-10 minutes; Step 2: Add 6.8 parts of emulsifier, stir for 5 minutes, add 1.5 parts of dispersant and 1.5 parts of co-solvent, stir for 5-10 minutes; the third step: put in 1 part of iron oxide pigment, disperse at high speed, after the pigment is fully developed, slowly add hollow glass beads 4 parts, 10 parts of...

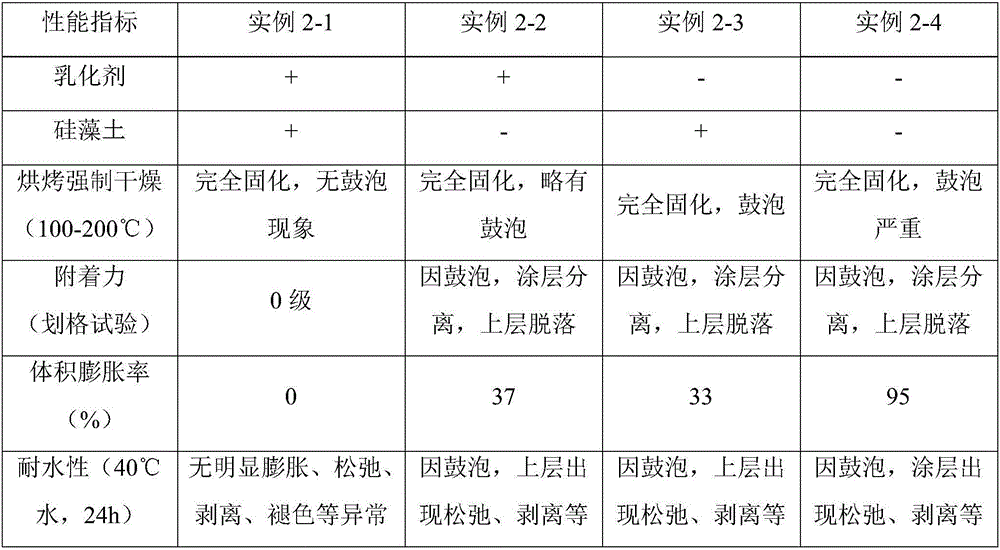

Embodiment 2

[0033] This embodiment discloses a spray-baking water-based damping paint and its preparation method. The damping paint contains by mass: 25 parts of acrylic emulsion, 7.9 parts of emulsifier, 0.1 part of neutralizer, 2 parts of dispersant, 2 parts of co-solvent, 2 parts of titanium dioxide, 4 parts of kaolin, 5 parts of diatomaceous earth, 10 parts of talcum powder, 20 parts of calcium carbonate, 20 parts of barium sulfate, and 2 parts of water.

[0034] The water-based damping paint is prepared according to the following method: Step 1: Filter 25 parts of acrylic emulsion and add it to the mixer, add 0.1 part of neutralizer while stirring, and stir for 5-10 minutes; Step 2: Add 7.9 parts of emulsifier, after stirring for 5 minutes, add 2 parts of dispersant and 2 parts of co-solvent, and stir for 5-10 minutes; the third step: add 2 parts of titanium dioxide, disperse at high speed, after the pigment is fully developed, slowly add 4 parts of kaolin, 5 parts of diatomite, 10 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com