Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Less investment in transformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

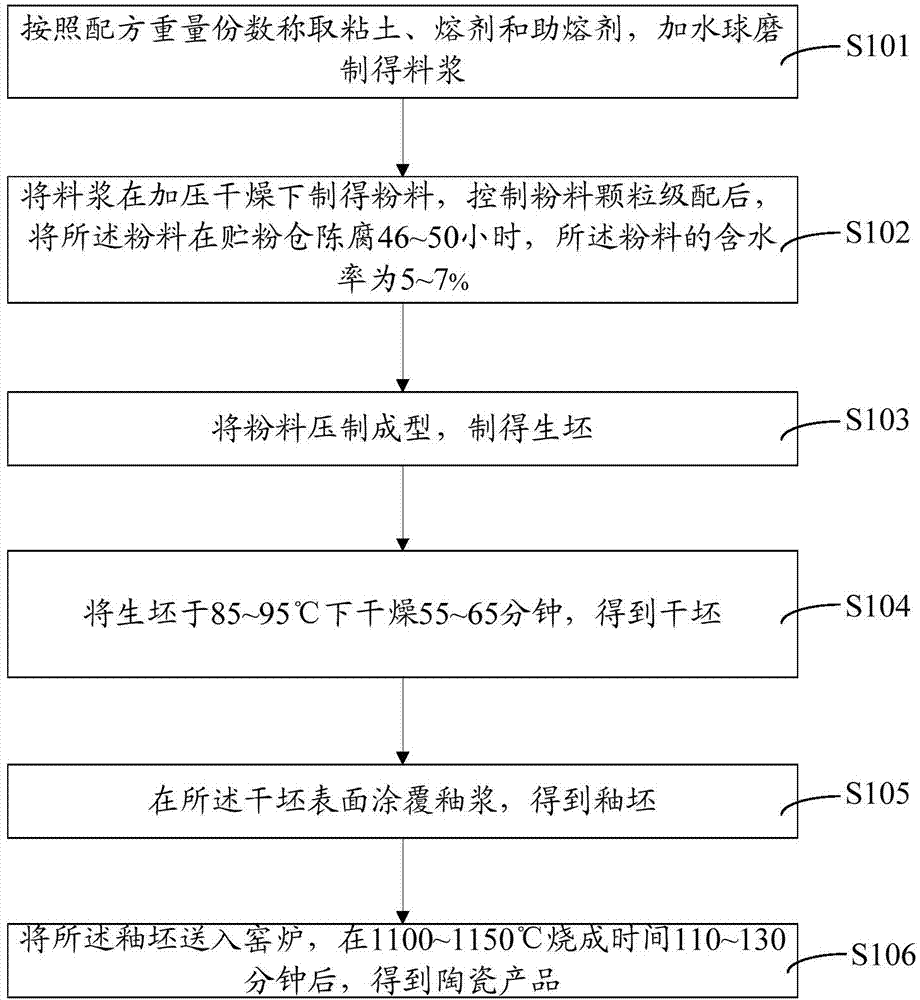

Ceramic formula and preparation method for ceramic product

The invention provides a ceramic formula, comprising, by weight, 55 to 65 parts of clay, 20 to 30 parts of a flux and 15 to 23 parts of a fluxing agent, wherein the clay is a mixture of purple sandshale and china clay mixed according to a weight ratio of 0.67 to 2.0, the flux is shale, and the fluxing agent is one or more selected from the group consisting of limestone, calcite, diopside, wollastonite, dolomite, talcum and industrial waste residue. A preparation method for a ceramic product comprises the following steps: weighing the clay, the flux and the fluxing agent according to the formula, carrying out crushing and screening with a 250-mesh sieve, wherein the weight of screen residue is 1 to 1.5%, adding water, carrying out blending to obtain slurry and then carrying out drying and granulation so as to obtain powder; grading particles and then carrying out molding so as to prepare a green body; carrying out drying so as to prepare a dry body; and carrying out firing so as to prepare a seasonal ceramic body. According to the ceramic formula and the preparation method for the ceramic product in the invention, raw materials are cheap, process is simple, firing temperature is reduced, production cost is decreased, investment for production equipment is lowered down, production efficiency is improved, and energy consumption is reduced.

Owner:怀化市亿智陶瓷有限公司

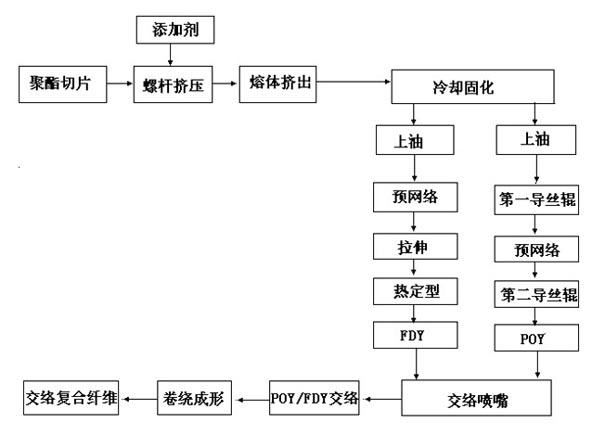

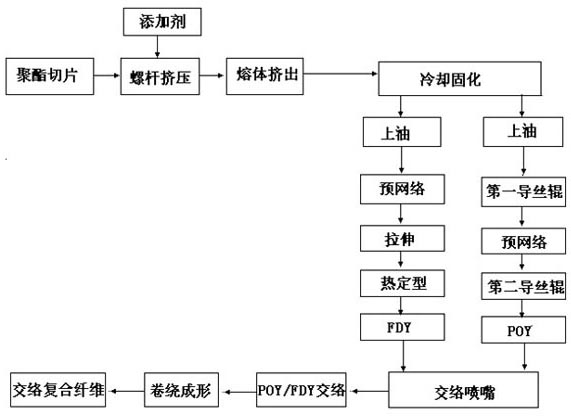

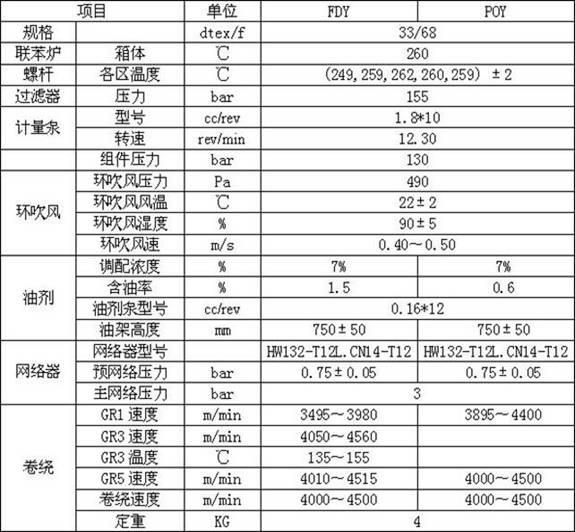

Multi-hole superfine denier polyamide 6 POY/FDY interlacing composite fiber, its preparation method and its device

InactiveCN102517680AImprove the comprehensive performance of fibersSmall shrinkageArtificial thread manufacturing machinesMelt spinning methodsPolyamideMelt extrusion

The invention discloses a multi-hole superfine denier polyamide 6 POY / FDY interlacing composite fiber, its preparation method and its device. The invention is characterized in that a current FDY production device is used, a raw material polyamide 6 is sliced and dried, an additive is on-line added, the sliced polyamide 6 is subjected to screw extrusion and melt extrusion, strand which is subjected to annealing and circular-blow wind cooling solidification is divided in to two beams, one beam of the strand is subjected to oiling, pre-networking, stretching and thermosetting to obtain FDY; another beam of the strand is subjected to oiling and then is input to a first godet roller, and then subjected to pre-networking and input to a second godet roller to obtain POY, then simultaneously input in an interlacing nozzle for compositing, a process of winding formation is carried out to prepare the multi-hole superfine denier polyamide 6 POY / FDY interlacing composite fiber. According to the fiber molecular structure performance design and the fiber form control, a process optimization scheme is determined to obtain the composite silk fiber with differential linear density, differential elongation and differential shrinkage, the fiber has the advantages of moisture absorption, breathability, good drapability, high color rendering, good comfortableness and the like.

Owner:吴江赴东扬程化纤有限公司

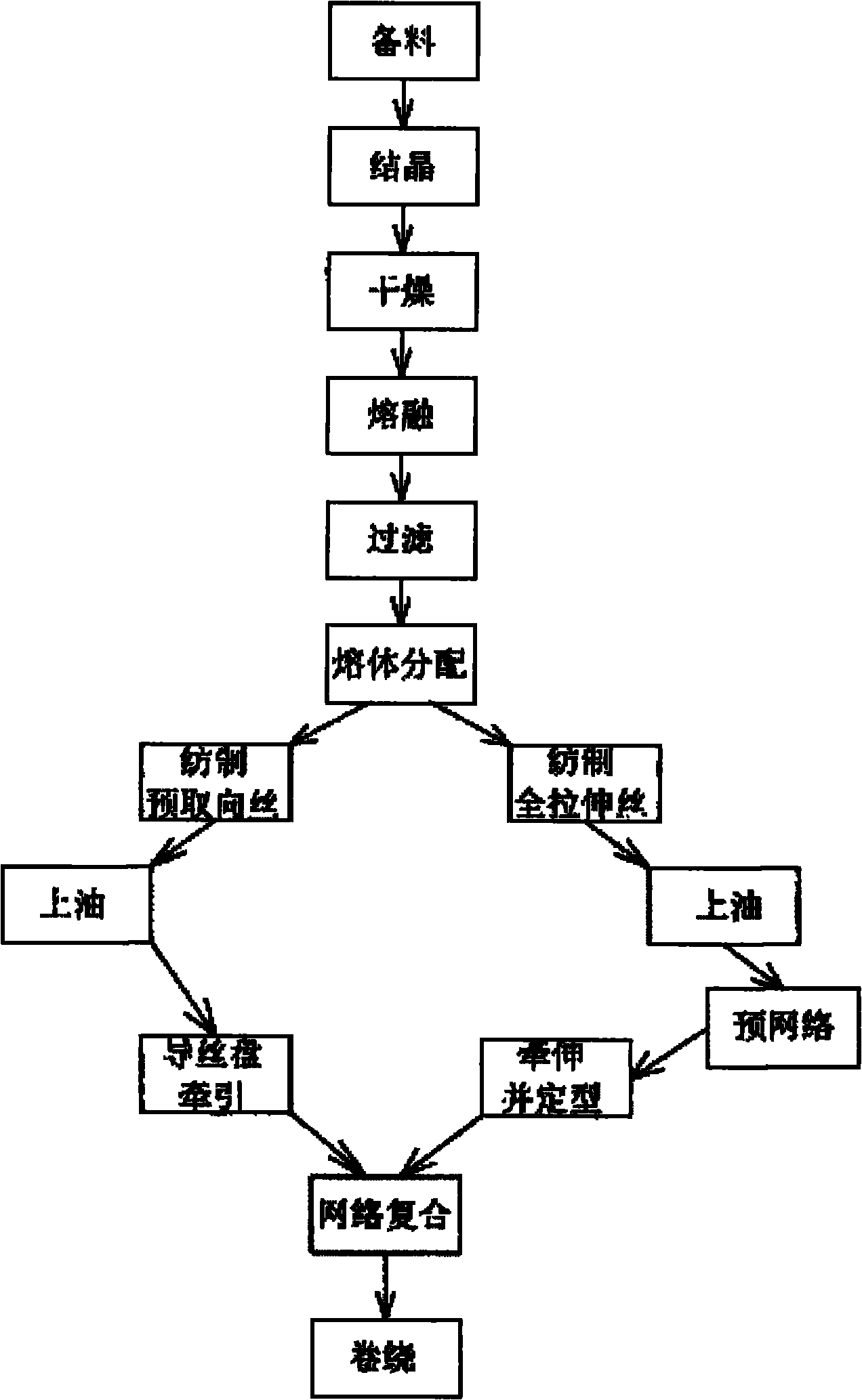

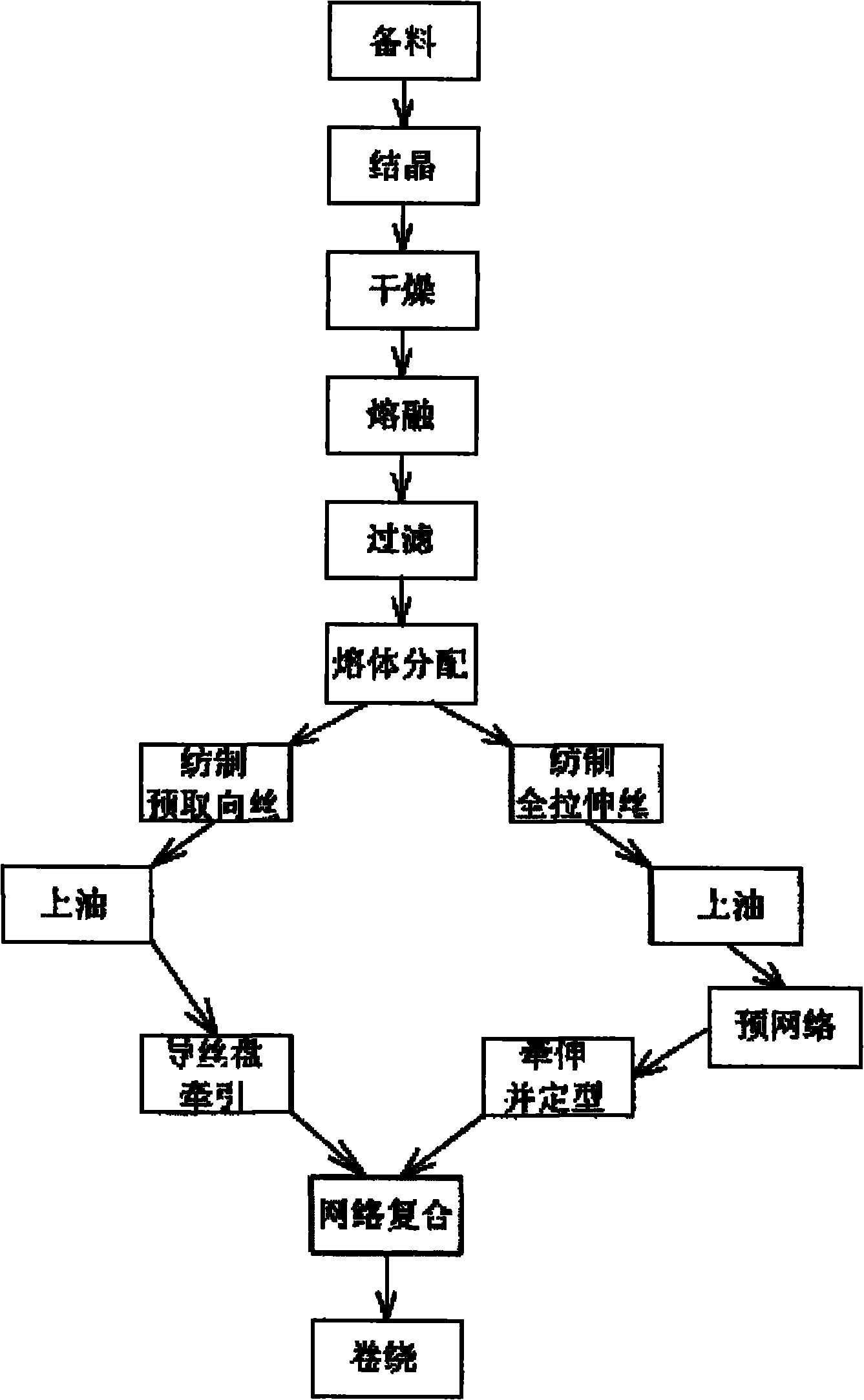

One-step spinning and winding combined manufacturing process for 24-head/position multi-heterogeneous hybrid yarn composite fiber

The invention discloses a one-step spinning and winding combined manufacturing process for 24-head / position multi-heterogeneous hybrid yarn composite fiber. The process comprises the steps of material preparation, crystallization and drying, melting and filtering, melt distribution, spinning of pre-oriented yarns and fully-drawn yarns, oiling, pre-meshing of the fully-drawn yarns, drawing and sizing of the fully-drawn yarns, composite meshing and winding (fixed length and fixed weight) in turn. The process fully utilizes and reforms the existing spinning and winding equipment to integrate spinning and winding at one time, and can produce 24 spinning cakes with fixed length and fixed weight at each position simultaneously so as to improve the production efficiency and economic benefit; and the produced multi-heterogeneous hybrid yarn composite fiber has high quality.

Owner:XUZHOU SILK FIBER TECH

Differential shrinkage composite fiber and processing method thereof

InactiveCN102747474AIncrease productivityHigh yieldFilament/thread formingMonocomponent polyesters artificial filamentYarnConductor Coil

The invention relates to a differential shrinkage composite fiber and a processing method thereof. The processing method includes the sequential steps of subjecting to raw materials, namely pure terephthalic acid and glycol, to esterification to obtain polyester melt, delivering the melt, simultaneously spinning pre-oriented yarns and full-drawn yarns, oiling, pre-interlacing the full-drawn yarns, drafting the full-drawn yarns, interlacing and complexing, and winding to produce the differential shrinkage composite fiber of 47dtex / 48f. Existing equipment is fully modified, spinning and winding are integrated, 20 fixed-length constant-weight spinning cakes can be produced at each station, production efficiency is high, yield is increased, product quality is stable, the produced fiber has differential shrinkage, post-processing gigging is effective, the differential shrinkage composite fiber feels nice, is thick and is widely applicable to production of chiffon and printed fabrics.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

Intelligent coal yard control system of thermal power plant and it control method

PendingCN108196506APrevent spontaneous combustion of stored coalImprove the level of intelligenceProgramme control in sequence/logic controllersSpontaneous combustionSystems design

The invention discloses an intelligent coal yard control system of thermal power plant and its control method and belongs to the technical field of coal yard management and control system. The systemcomprises a data server is connected with an application server and an interface server. The application server is connected with a client. The interface server is connected with a coal conveying system PLC, an SIS system, a fuel whole process management platform, a three-dimensional laser scanner and a stacker-taking system PLC. The PLC of the coal handling system is connected with the PLC of thedumper system. The coal yard environmental monitoring system and the stacker-taking system PLC. The system has the advantages of reasonable design, fully exerting the advantages of the existing control system of the coal conveying system, reducing the investment of transformation, improving the intelligent level of the coal conveying system of the power plant and the equipment operation efficiency, avoiding the occurrence of spontaneous combustion of coal in the coal yard, improving the precision of the coal blending through the intelligent coal blending control and improving economic benefitof the unit.

Owner:HUANENG YINGKOU THERMAL POWER CO LTD

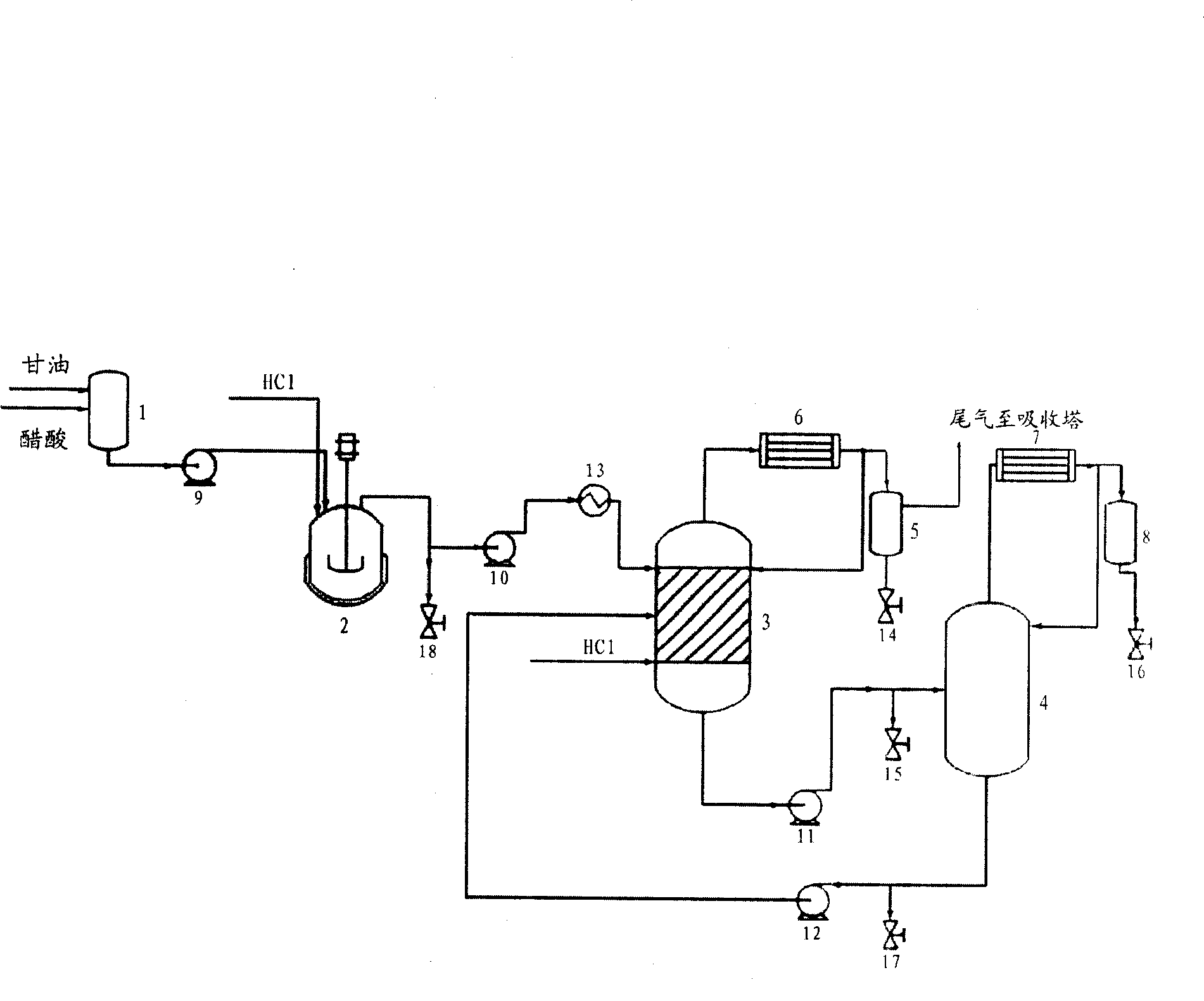

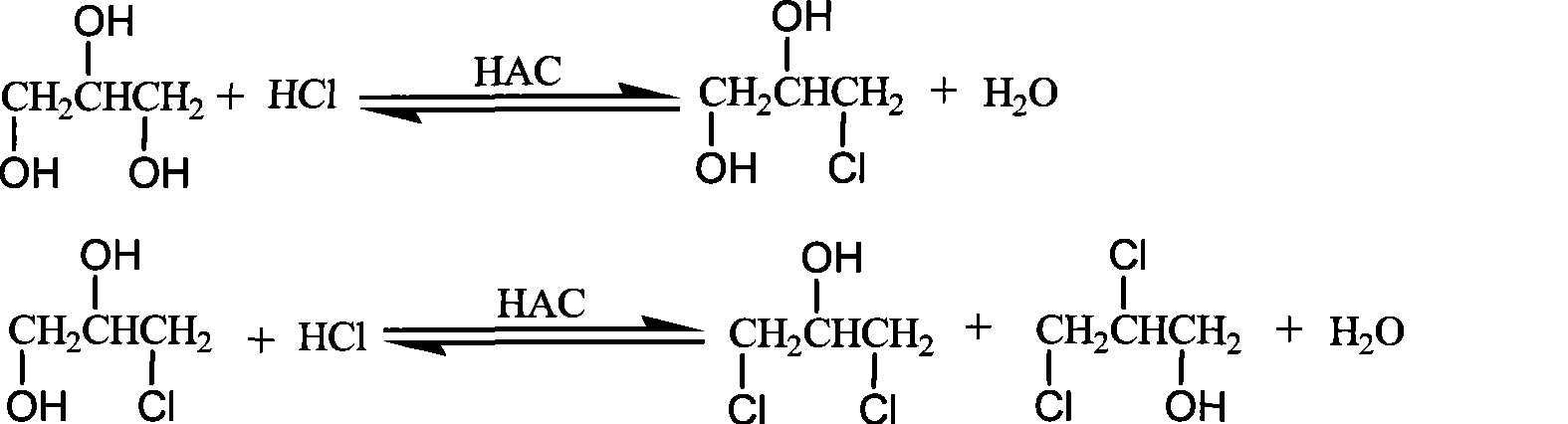

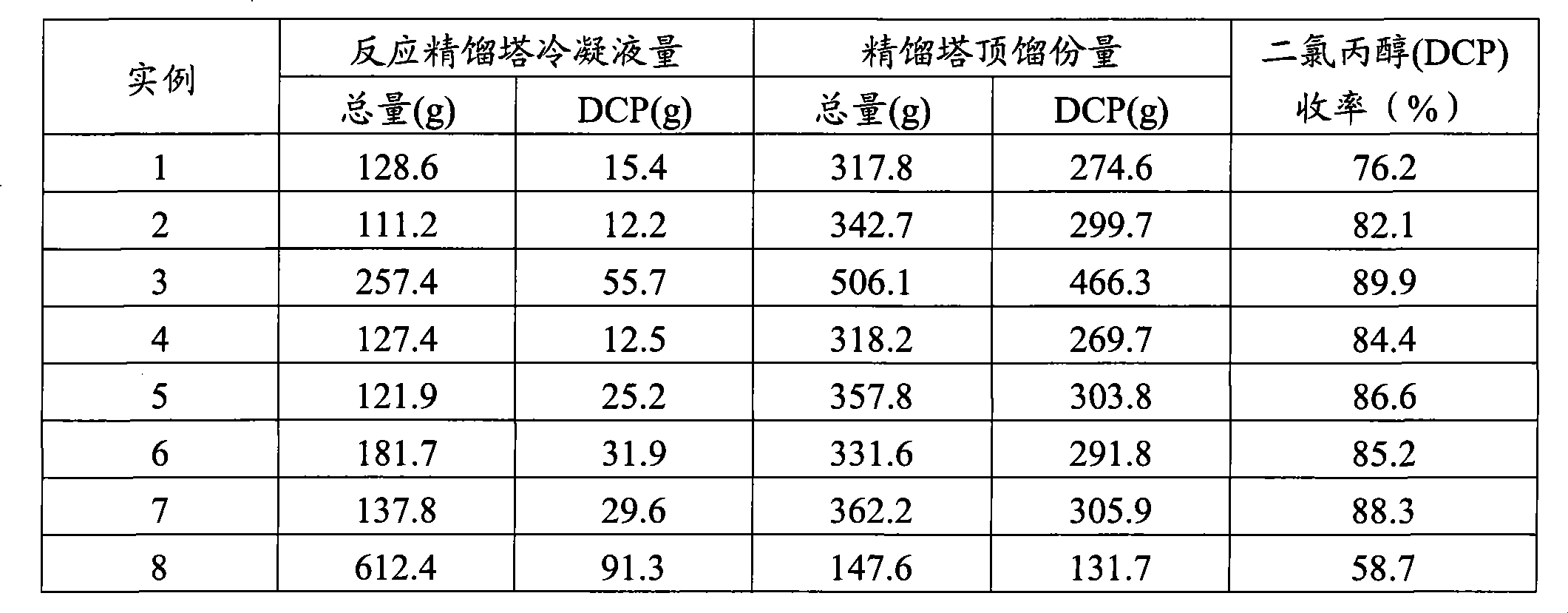

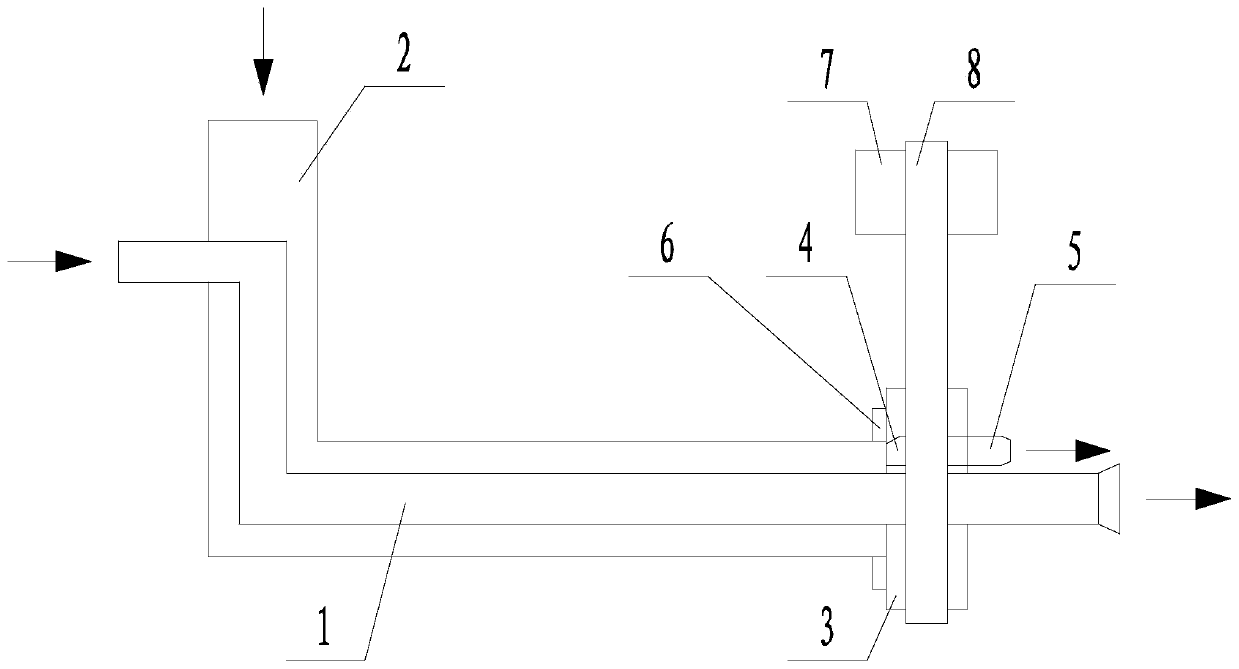

Method for producing dichlorohydrin with glycerol

InactiveCN101429099AImprove responseReduce construction costsPreparation by halogen introductionReaction rateGlycerol

The invention relates to a method for preparing dichlorohydrin from glycerin. The method comprises the following steps: the glycerin is mixed with carboxylic acid catalyst, and mixture obtained and HCl are subjected to chlorination reaction in a chlorination reactor; reaction mixture obtained is sent into a reaction rectification tower (3), contacts the HCl and is subjected to chlorination reaction continuously; water, a hydrochloric acid and partial dichlorohydrin generated after reaction are rectified from the top of the reaction rectification tower (3), and products are reclaimed after condensation; and tower bottoms of the reaction rectification tower (3) enter into a purification and rectification tower (4) for purification and separation. The method is simple and convenient to operate, can improve the reaction rate and the HCl utilization rate, and can improve the dichlorohydrin yield to more than 80 percent.

Owner:WANHUA CHEM GRP CO LTD +2

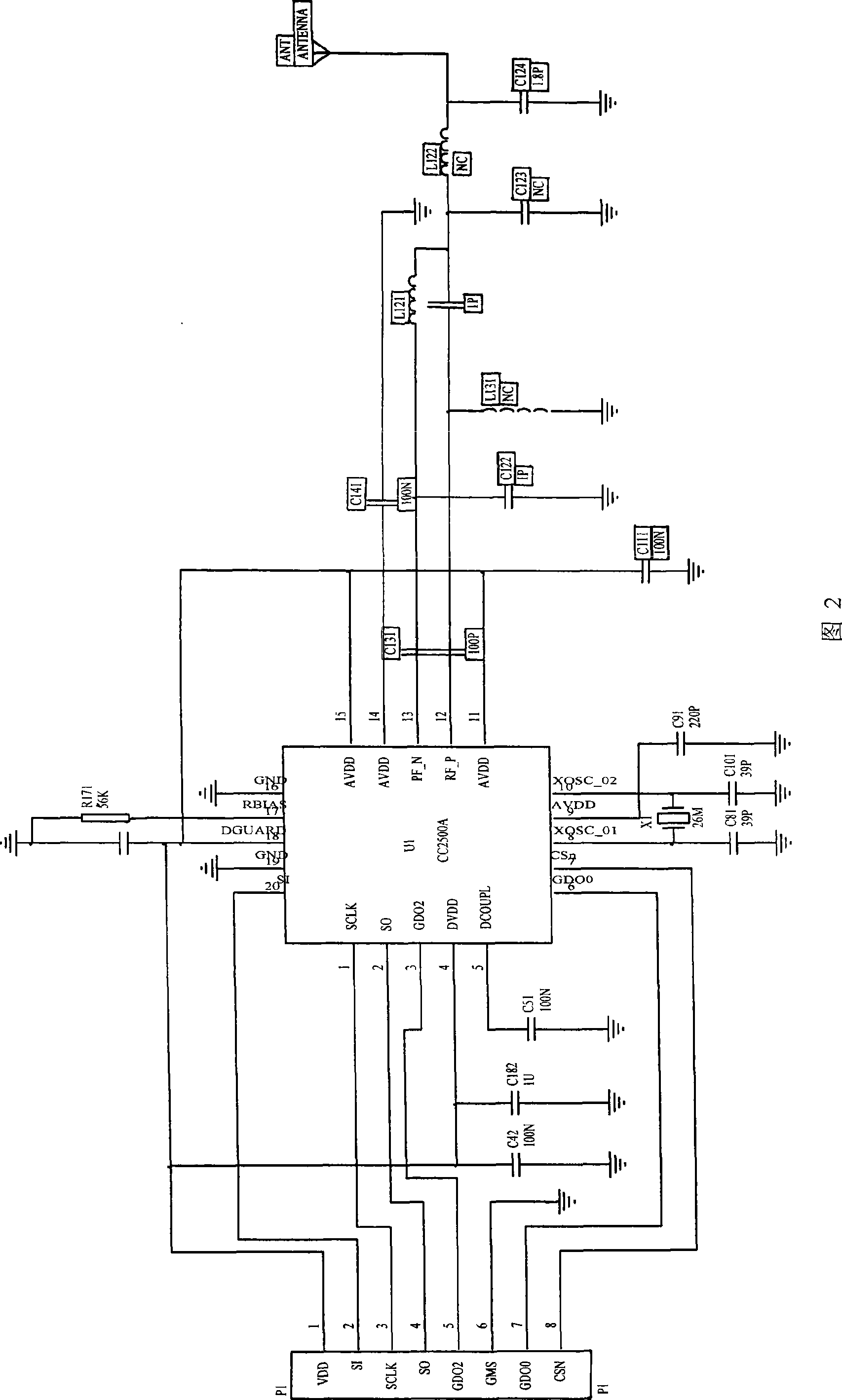

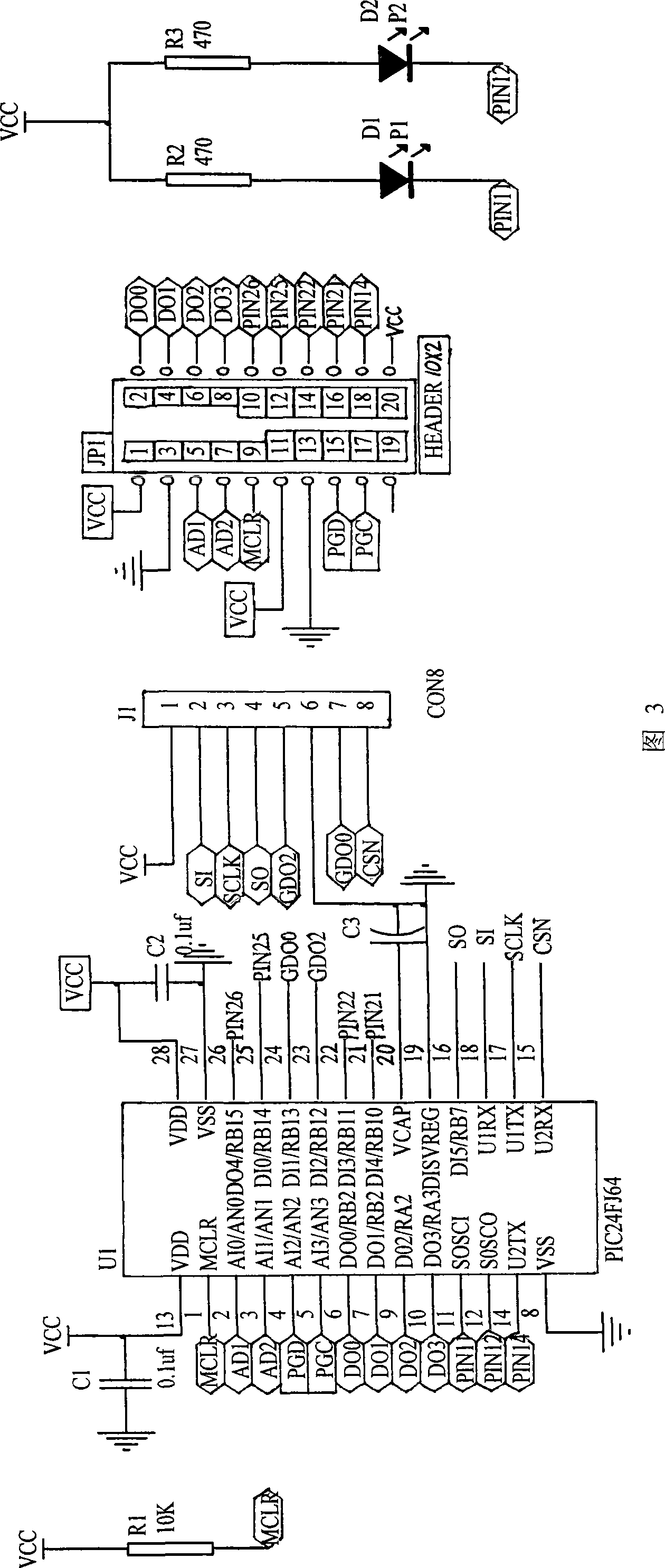

Urban road lamp energy saving control and management system based on WSN

InactiveCN101420807ARealize single light controlReduce energy consumptionEnergy efficient ICTTransmission systemsTransformerEffect light

The invention provides a WSN-based urban street light energy-saving control and management system. The system comprises node modules, control modules and coordinators, one node module and one control module are arranged on each street light, each node module comprises a radio frequency module and a microprocessor, the radio frequency module and the microprocessor are connected on the control module by plugging pins in, the various node modules on the street lights and one coordinate in a region adopt the wireless relay mode for communication and connection, each control module comprises a transformer and a relay and is provided with two output control circuits, one circuit controls the switch amount of lighting of a secondary road, the other circuit is the dimming output for controlling the dimming of a main road, and all the coordinators are communicated and connected by a GPRS and a universal RTU. The system has convenient control implementation and can effectively reduce the energy consumption of the street lights, realize the initiative alarm of street light faults and street light aging and effectively reduce the workload of patrol officers of the street lights, has small size and can greatly facilitate the installation of working staff.

Owner:王雷

A production process of enameled wire for compressor

ActiveCN102280221ADestruction coefficient zeroImprove thermal stabilityInsulating conductors/cablesLacquerCopper wire

The invention discloses a process for producing an enameled wire for a compressor. The process comprises the following steps of: an extrusion procedure: extruding an oxygen-free copper rod produced by the continuous casting and rolling process to obtain a bare copper wire; cleaning the bare copper wire, removing oil stain and attachments on the surface of the bare copper wire to achieve the surface cleanness required by a painting procedure; and a painting and baking procedure: painting the bare copper wire in a manner of supplying paint by a metering pump and painting by a plurality of moulds, wherein the primer is polyesterimide and the finish paint is polyamideimide composite insulation paint; carrying out secondary baking by using hot air circulation and catalytic combustion, and sufficiently combusting solvent in the insulation paint; and gathering the wire to obtain the enameled wire for a compressor. The process disclosed by the invention has simple process, small investment and short time for refitting the current equipment; and the produced enameled wire can fully meet the requirements of the R134a compressor.

Owner:JIANGSU ZHONGRONG ELECTRIC

ETD high-shrinkage type elastic double-color fiber and preparation method thereof

InactiveCN107829165AIncrease elasticityImprove shrinkageArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsFiberMaterials science

The invention discloses an ETD high-shrinkage type elastic double-color fiber and a preparation method thereof, and is characterized in that the ETD high-shrinkage type elastic double-color fiber is formed by compositing a first filament body and a second filament body, the ratio of the first filament body to the second filament body is 3:7-7:3, the first filament body is a cationic POY filament,the second filament body is prepared by compositing a component A and a component B, the component A is one of PET, PA and PBT, the component B is one of PET, PA and PBT, and the component A is different from the component B; the preparation method comprises the steps: 1, heating and texturing the first filament body; and 2, stranding the first filament body and the second filament body, to obtainthe high-elasticity double-color fiber. The elastic double-color fiber can be produced, and the production cost can be reduced.

Owner:WUJIANG JIALI ADVANCED FIBER CO LTD

Recycling method of unfused zircon sand in technical process for preparing zirconium oxychloride by alkaline fusion method

The invention relates to a recycling method of unfused zircon sand in a technical process for preparing zirconium oxychloride by an alkaline fusion method, and belongs to the field of preparation methods of zirconium compounds. The technical process for preparing zirconium oxychloride by the alkaline fusion method comprises the following steps of alkaline fusion, water washing, transformation, acidification, crystallization, acid pickling, centrifugation and drying. The recycling method is characterized in that a working procedure of recycling unfused zircon sand is added after the steps of water washing and transformation and before the step of acidification so as to precipitate and separate the unfused zircon from a dilute hydrochloric acid solution of a water transformation material. The working procedure of recycling unfused zircon sand comprises the following steps: (1) dissolving the water transformation material by a diluted hydrochloric acid; (2) leaving the obtained solution to stand for precipitation; (3) performing solid-liquid separation; (4) repetitively washing unfused sand collected in the step (3) with clean water until the washing water is clear; (5) drying the washed unfused sand in the step (3), and supplying the dried unfused sand for alkaline fusion. Through the adoption of the recycling method disclosed by the invention, the recycling rate of the unfused zircon sand reaches 97%, and the recycled zircon sand can be recycled as raw zircon sand, so that the productive rate of zirconium oxychloride products is increased, and the production cost is reduced.

Owner:山东广通新材料有限公司

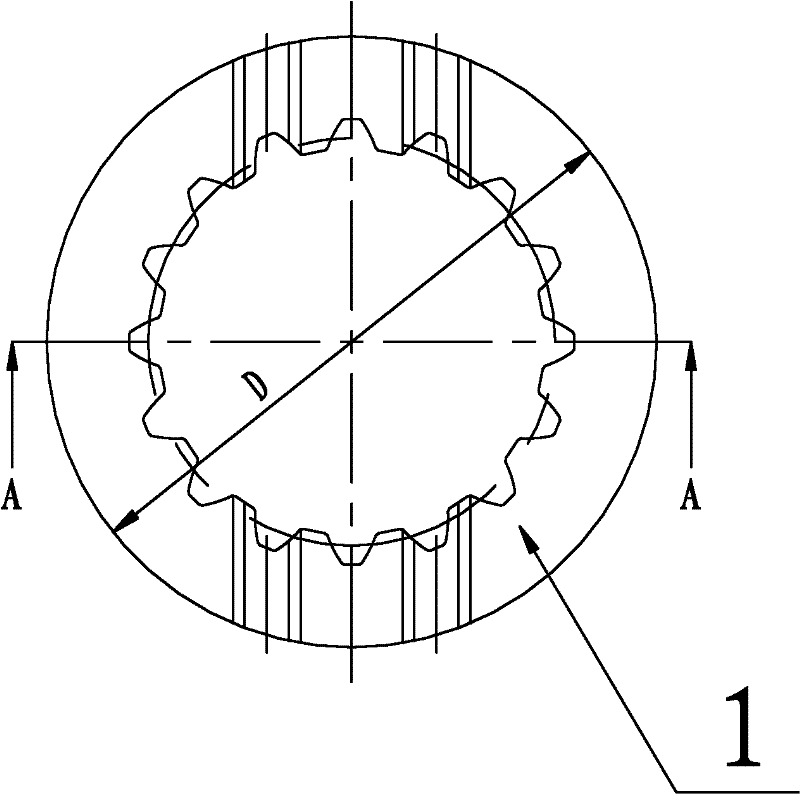

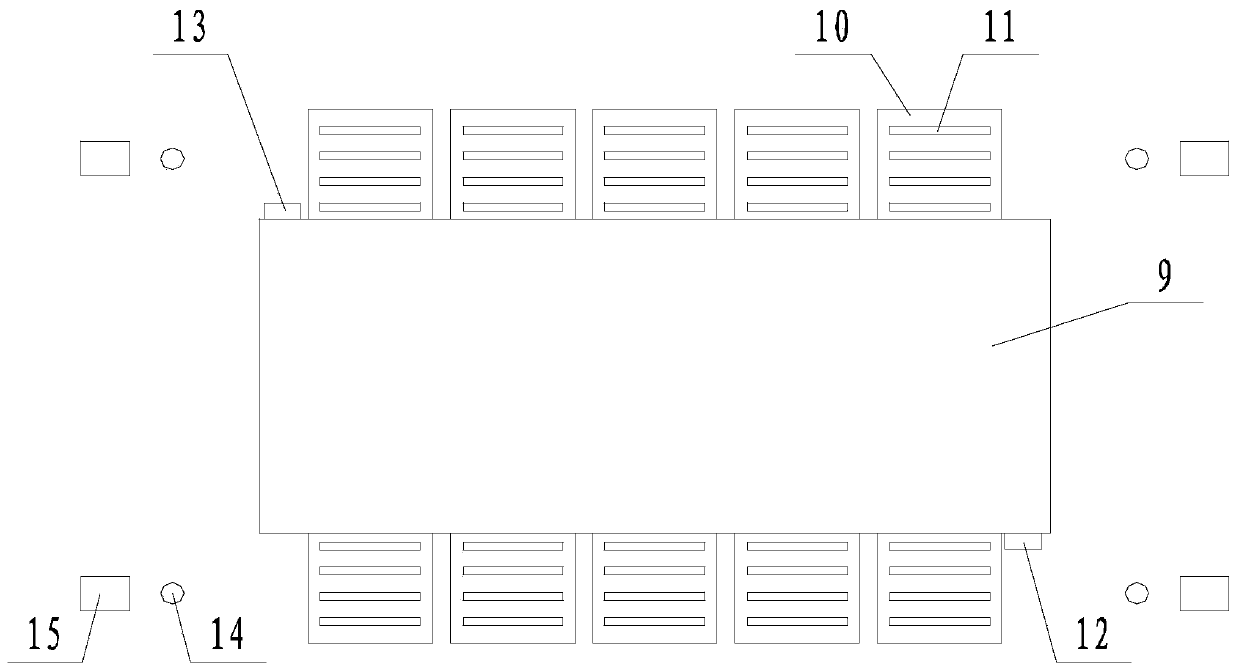

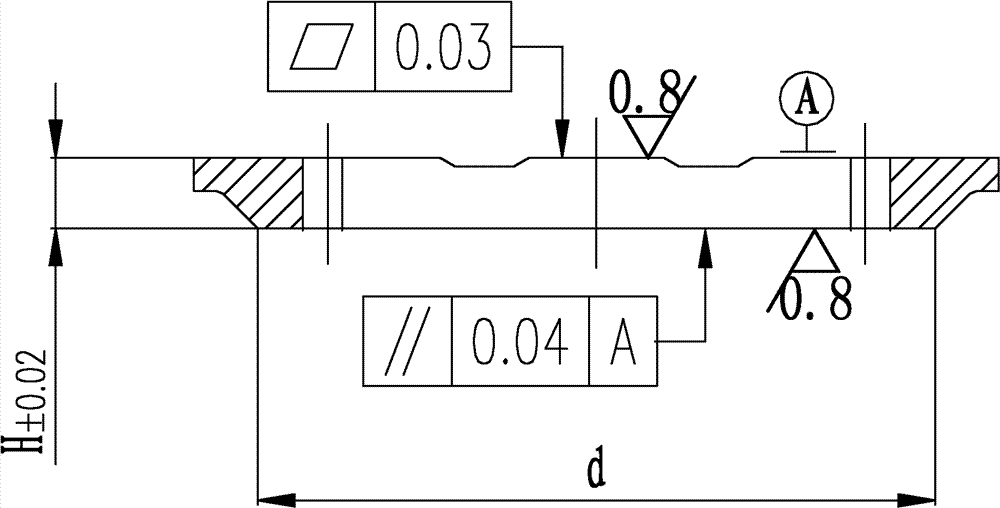

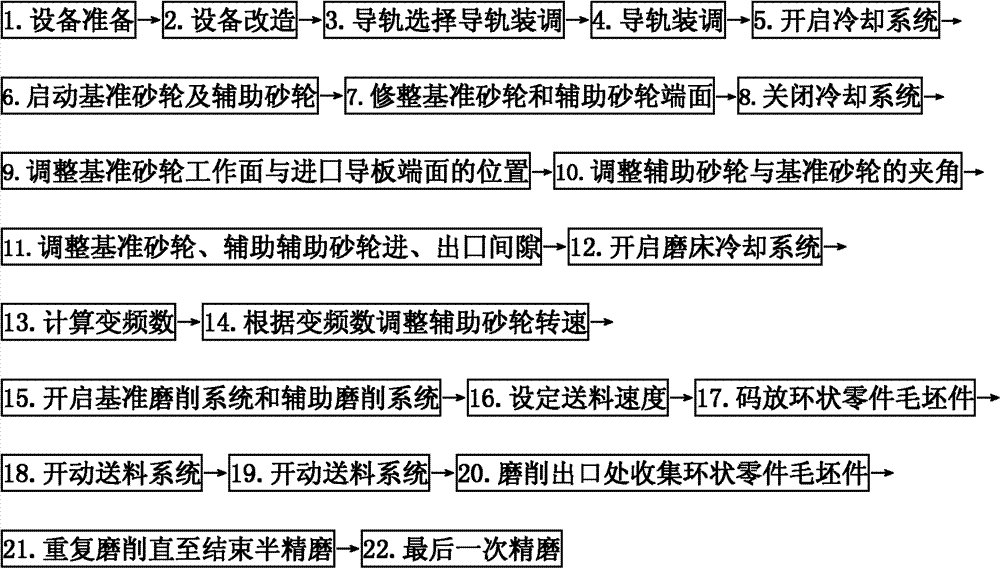

High-precision double-sided grinding method and machine of annular parts with unequal areas of two end surfaces

ActiveCN102229077ARealize mass productionStable at or above thicknessPlane surface grinding machinesHigh volume manufacturingFrequency ratio

The invention relates to a high-precision double-sided grinding method and machine of annular parts with unequal areas of two end surfaces. According to a rule that the rotating speed and the grinding amount of a grinding wheel of a grinding machine are proportionable, a motor transducer is additionally arranged on a circuit of an assisted grinding system of the grinding machine, the area ratios of two different end surfaces of different parts are converted into different grinding amount ratios so that the frequency ratio and the rotating speed ratio are further adjusted; an appropriate rotating speed ratio of a reference grinding wheel and an assisted grinding wheel is reached by changing and controlling the frequency of the assisted grinding wheel circuit; requirements on thickness, roughness, planarity, parallelism and the like can be stably reached or exceeded finally; the production efficiency is greatly increased and is 28 times that of the common M7160; the production cost is effectively reduced; and the batch production of the parts is realized.

Owner:武汉华夏精冲技术有限公司

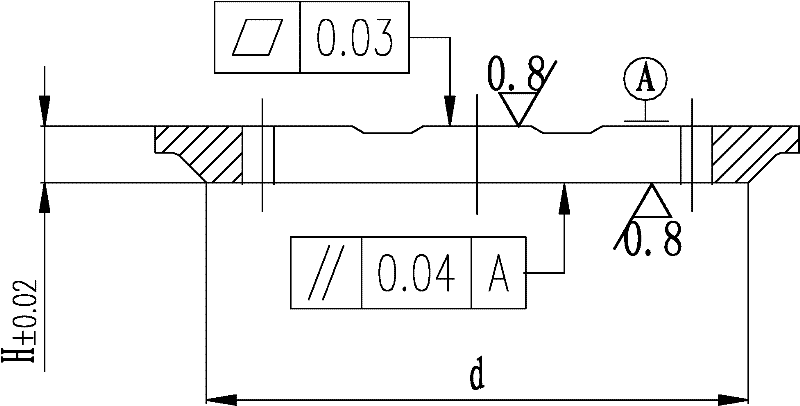

POY (polyester pre-oriented yarn) spinning method and device by using FDY (fully drawn yarn) spinning device

InactiveCN102660786AQuality improvementRealize flexible productionArtificial thread manufacturing machinesMelt spinning methodsPolyesterYarn

The invention relates to a POY (polyester pre-oriented yarn) spinning method and device by using a FDY (fully drawn yarn) spinning device. The POY spinning method is realized by using the FDY spinning device, wherein the FDY spinning device comprises a box body, a cross air blasting window, a chimney, a first hot roll, a second godet and a winding head. When the POY spinning is preceded, an oil tanker of the original FDY spinning device is stopped using, an oil nozzle is additionally arranged above the chimney for feeding oil, and a guide wire hook and combtype wire-dividing device of the first hot roll are provided with extension rods for moving outwards in a pre-network so as to move the spinning central line outwards; meanwhile, a second hot roll of the original FDY spinning device is stopped using, the first hot roll and the second godet are reserved, the filament bundling passes through the first hot roll for one time and winds 4-5 circles on the second godet for further moving the spinning central line outwards, and then enters into a wiring head for realizing winding. The method provided by the invention can produce high-quality POY on hot-roll type FDY equipment with the advantages of less transformation investment, simple method and fast transformation speed, thus realizing flexible production between the FDY and POY products at any time.

Owner:ZHEJIANG HUAXIN CHEM FIBER

Automatic interstation blocking control method and system under heavy-load movable blocking

ActiveCN109649450AImprove operational efficiencyLess investment in transformationRailway traffic control systemsVehicle route interaction devicesEngineeringHeavy load

The invention provides an automatic interstation blocking control method and system under heavy-load movable blocking. The method includes: arranging an axle counter between a first state and a secondstation; determining interstation state between the first station and the second station according to interstation occupation condition between the first station and the second station and collectedby the axle counter by interlocking equipment of the first station or that of the second station; when the first station applies an outgoing route to the second station, determining interstation statebetween the first station and the second station by the interlocking equipment of the first station and that of the second station by means of mutual communication, and performing control managementon interstation blocking between the first station and the second station according to the interstation state between the two. By the method, the characteristic that mutual communication can be realized during interlocking under movable blocking is utilized fully, the axle counter is arranged to collect the interstation occupation condition on the basis of interlocking communication, automatic interstation blocking is realized, and running efficiency after heavy-load movable blocking degradation is improved effectively.

Owner:TRAFFIC CONTROL TECH CO LTD

High-elasticity extinction TSF composite fiber chip fabric and preparation method for same

InactiveCN107385528AIncrease elasticityPermanentArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsYarnFiber

The invention discloses a high-elasticity extinction TSF composite fiber chip fabric which is characterized in that the high-elasticity extinction TSF composite fiber chip fabric is made through extrusion, metering, yarn recombination, filament spraying, cooling, oiling, stretching and shaping, and winding of an extinction PTT constituent melt and an extinction PET constituent melt; the ratio of the extinction PTT constituent to the extinction PET constituent is 6:4-4:6; the extinction PET constituent contain PET and ash; the ratio of PET to ash is 98:2; the extinction PTT constituent contains PTT and ash; and the ratio of PTT to ash is 98.5:1.5. According to the invention, elasticity of the high-elasticity extinction TSF composite fiber chip fabric can be enhanced; certain light shielding effects can be achieved; production efficiency and production quality can be increased; and production cost can be reduced.

Owner:WUJIANG JIALI ADVANCED FIBER CO LTD

A system and method for controlling heavy metals in the effective state of rice rhizosphere

ActiveCN105425850BReduce blindnessRefine the required range of flooding depthControlling ratio of multiple fluid flowsWatering devicesControl systemWater content

The invention discloses a rice rhizosphere available heavy metal control system, comprising a rice field simulation device and a fine rice field water management device, wherein the rice field simulation device comprises a shell of which the upper end is opened and surface soil fed into the shell and used for planting rice, the surface soil is formed by collecting metal contaminated rice field soil layer by layer and backfilling the shell with the soil, the shell is filled with water till exceeding the surface of the surface soil to form overlying water, and a rhizosphere water collector as well as an Eh probe and a pH probe connected with rhizosphere Eh and pH monitoring equipment are inserted into the surface soil; and the fine rice field water management device comprises field Eh and pH supervision equipment and intelligent irrigation and drainage equipment connected with the field Eh and pH supervision equipment. The invention further provides a rice rhizosphere available heavy metal control method. The system and the method can reduce the blindness in field water management of current heavy metal contaminated rice fields, improve the scientificity of field water content management and gain maximum benefits of field water management for inhibiting rice from absorbing available heavy metals.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

POY (polyester pre-oriented yarn) spinning method and device by using FDY (fully drawn yarn) spinning device

InactiveCN102660786BQuality improvementRealize flexible productionArtificial thread manufacturing machinesMelt spinning methodsYarnPolyester

The invention relates to a POY (polyester pre-oriented yarn) spinning method and device by using a FDY (fully drawn yarn) spinning device. The POY spinning method is realized by using the FDY spinning device, wherein the FDY spinning device comprises a box body, a cross air blasting window, a chimney, a first hot roll, a second godet and a winding head. When the POY spinning is preceded, an oil tanker of the original FDY spinning device is stopped using, an oil nozzle is additionally arranged above the chimney for feeding oil, and a guide wire hook and combtype wire-dividing device of the first hot roll are provided with extension rods for moving outwards in a pre-network so as to move the spinning central line outwards; meanwhile, a second hot roll of the original FDY spinning device is stopped using, the first hot roll and the second godet are reserved, the filament bundling passes through the first hot roll for one time and winds 4-5 circles on the second godet for further moving the spinning central line outwards, and then enters into a wiring head for realizing winding. The method provided by the invention can produce high-quality POY on hot-roll type FDY equipment with the advantages of less transformation investment, simple method and fast transformation speed, thus realizing flexible production between the FDY and POY products at any time.

Owner:ZHEJIANG HUAXIN CHEM FIBER

A kind of method preparing dichloropropanol by glycerol

InactiveCN101429099BImprove responseReduce construction costsPreparation by halogen introductionReactive distillationGlycerol

A method for preparing dichloropropanol from glycerol, the method comprising the steps of: mixing glycerin with a carboxylic acid catalyst, and carrying out chlorination reaction of the obtained mixture with HCl in a chlorination reactor; sending the obtained reaction mixture to into the reactive distillation tower (3) to contact with HCl to continue the chlorination reaction; the water, hydrochloric acid and part of dichlorohydrin produced by the reaction are steamed from the top of the reactive distillation tower (3), and the product is recovered after condensation The still liquid of reactive distillation column (3) enters purifying distillation column (4) and carries out purification and separation. The method is easy to operate, can increase the reaction rate and the utilization rate of HCl, and the yield of dichloropropanol can reach more than 80%.

Owner:WANHUA CHEM GRP CO LTD +2

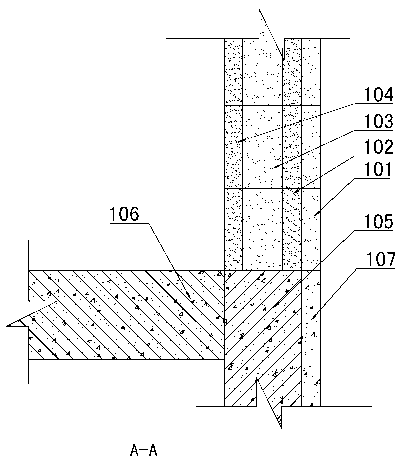

Equal-lifetime self-insulation exterior wall and beam column structure, and construction method thereof

InactiveCN103290946AOutward center of gravity loweredSolve the defects of unreasonable structural stressWallsBuilding material handlingInsulation layerBuilding energy

The invention relates to an equal-lifetime self-insulation exterior wall and beam column structure, and a construction method thereof and belongs to the technical field of building energy conservation. The equal-lifetime self-insulation exterior wall and beam column structure comprising a frame-embedded wall is characterized in that the wall comprises an outer insulation layer (101), an outer bearing layer (102), a central layer (103) and an inner bearing layer (104) sequentially from outside to inside; the outer bearing layer (102), the central layer (103) and the inner bearing layer (104) are located on the upper portion of a frame beam (105); an interface between the outer insulation layer (101) and the outer bearing layer (102) is level to the outer surface of the frame beam (105) and the outer surface of a frame column (105); the outer insulation layer (101) projects out of the frame beam (105), and the outer surface of the outer insulation layer (101) is level to the outer surface of an insulation plate (107) added to the frame beam (105) and the frame column (108). The equal-lifetime self-insulation exterior wall and beam column structure has the advantages that the exterior wall is large in heat resistance, the target of saving energy by 65% is satisfied, the wall is large in bending resistance, the stress structure is reasonable, and the equal-lifetime self-insulation exterior wall and beam column structure is convenient to construct and equal in lifetime.

Owner:DONGHUA CONSTR COMPANY LTD OF YANKUANG GRP +2

Surface runoff initial rainwater control structure

PendingCN109518787ANo energy consumptionNo secondary pollutionFatty/oily/floating substances removal devicesSewerage structuresDynamic balanceWater block

The invention discloses a surface runoff initial rainwater control structure which can be used for collecting initial rainwater and includes an initial rainwater collecting trough and an automatic water blocking device. The initial rainwater collecting trough comprises a water inlet and a permeable paving structure. The rainwater enters the initial rainwater collecting trough through the water inlet and can be infiltrated underground through the permeable paving structure. The water inlet of the initial rainwater collecting trough is provided with the automatic water blocking device capable ofbeing automatically closed when the initial rainwater collecting trough is full of the rainwater. The automatic water blocking device is provided with a continuous small flow water supply channel, and the water supply flow of the water supply channel and the infiltration water volume of the initial rainwater collecting trough can maintain dynamic balance. The control structure has the function ofpreprocessing pollutants like suspended solids contained in rainwater runoff, especially the comprehensive function of permeable paving and movable floating boards, and is free of mechanical device,chemical agent, energy consumption and secondary pollution, small in occupied area and convenient and quick to clean later. The control structure has the advantages of low transformation investment and low operating cost.

Owner:中铁四川生态城投资有限公司

Area positioning navigation system based on traffic sign information line and working method thereof

PendingCN113362629ALess investment in transformationLow costTicket-issuing apparatusRoad vehicles traffic controlElectronic mapVideo recognition

The invention discloses an area positioning navigation system based on traffic sign information lines and a working method thereof, and belongs to the field of positioning and navigation. The positioning navigation system comprises a traffic sign information line containing distance and position information, a video acquisition unit, a control unit and a mobile unit, wherein the traffic sign information line is laid on an area road, and the video acquisition unit and the control unit are installed on the mobile unit; when the mobile unit moves, the video acquisition unit acquires an image of the traffic sign information line, the control unit identifies and calculates the position information and the moving distance of the point, and the navigation of the mobile unit is realized in combination with an electronic map. The method overcomes the current situation of high cost of vehicle positioning navigation in the prior art, realizes high-precision and low-cost positioning navigation in an area by combining a large number of traffic marker lines laid in a city with a video recognition technology which is maturely applied at present, and can be applied to the fields of automatic driving, automatic parking and the like.

Owner:张铂虎

Multi-hole superfine denier polyamide 6 POY/FDY interlacing composite fiber, its preparation method and its device

InactiveCN102517680BImprove performanceBeyond SpinnabilityArtificial thread manufacturing machinesMelt spinning methodsProcess optimizationPolyamide

The invention discloses a multi-hole superfine denier polyamide 6 POY / FDY interlacing composite fiber, its preparation method and its device. The invention is characterized in that a current FDY production device is used, a raw material polyamide 6 is sliced and dried, an additive is on-line added, the sliced polyamide 6 is subjected to screw extrusion and melt extrusion, strand which is subjected to annealing and circular-blow wind cooling solidification is divided in to two beams, one beam of the strand is subjected to oiling, pre-networking, stretching and thermosetting to obtain FDY; another beam of the strand is subjected to oiling and then is input to a first godet roller, and then subjected to pre-networking and input to a second godet roller to obtain POY, then simultaneously input in an interlacing nozzle for compositing, a process of winding formation is carried out to prepare the multi-hole superfine denier polyamide 6 POY / FDY interlacing composite fiber. According to the fiber molecular structure performance design and the fiber form control, a process optimization scheme is determined to obtain the composite silk fiber with differential linear density, differential elongation and differential shrinkage, the fiber has the advantages of moisture absorption, breathability, good drapability, high color rendering, good comfortableness and the like.

Owner:吴江赴东扬程化纤有限公司

Dielectric protective film of plasma display panel, preparation method of dielectric protective film, plasma display panel

InactiveCN103762137AHigh crystallinitySimple processAlternating current plasma display panelsCold cathode manufactureDielectricProcess equipment

The invention provides a dielectric protective film of a plasma display panel, a preparation method of the dielectric protective film, and a plasma display panel comprising the dielectric protective film. According to the preparation method of the dielectric protective film, an intermittent oxygen aeration technique is adopted in the manufacture process of the dielectric protective film, such that a dielectric protective film with a plurality of magnesium oxide layers can be obtained. According to the preparation method of the invention which is simple in process, only a system for controlling oxygen flow and ventilation time is required to be additionally arranged on existing equipment, and the preparation method can be realized under the premise that the structure of the equipment is not modified basically, and therefore, modification investment on processing equipment can be low. The dielectric protective film obtained through adopting the preparation method of the invention has the plurality of magnesium oxide layers, and the degree of crystallinity of magnesium oxide layers which are formed under an oxygen aeration condition is high, and magnesium oxide layers which are formed under an anaerobic condition are compact, and therefore, the plasma display panel comprising the dielectric protective film can have high luminous efficiency under low voltage.

Owner:SICHUAN COC DISPLAY DEVICES

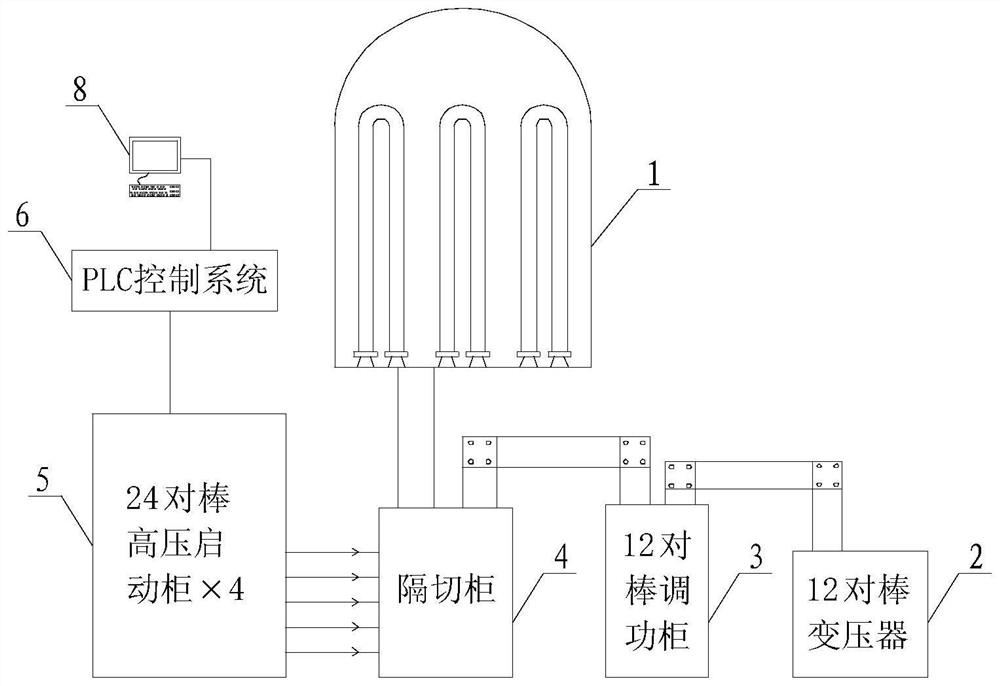

System and method for high-pressure start-up of reduction furnace

ActiveCN110482554BLess investment in transformationReduce startup timeSilicon compoundsEngineeringThree-phase

The invention provides a reduction furnace high-voltage starting system. A 12-rod-pair power adjusting cabinet and a 24-rod-pair high-voltage starting system are connected to a silicon core of a reduction furnace through a separation switching cabinet respectively. After the 24-rod-pair high-voltage starting system is connected with a single-phase silicon core under switching by the separation switching cabinet, the 24-rod-pair high-voltage starting system is used for applying a breakdown voltage to the single-phase silicon core until breakdown of the single-phase silicon core. The 12-rod-pairpower adjusting cabinet is used for connection with the single-phase silicon core in preset time after breakdown of the silicon core and under switching by the separation switching cabinet, and is used for applying a preset voltage to the silicon core to keep the silicon core in a conducting state. The 12-rod-pair power adjusting cabinet, the separation switching cabinets and the 24-rod-pair high-voltage starting system cooperate with each other to perform high-voltage breakdown and switching of a next single-phase silicon core until silicon cores in three phases are all connected to the 12-rod-pair power adjusting cabinet. Correspondingly, a high-voltage starting method for the reduction furnace high-voltage starting system is provided. The reduction furnace high-voltage starting systemand method can ensure rapid breakdown of the silicon cores and do not damage elements of the 12-rod-pair power adjusting cabinet.

Owner:XINTE ENERGY

Process for producing enameled wire for compressor

ActiveCN102280221BDestruction coefficient zeroImprove thermal stabilityInsulating conductors/cablesCooking & bakingCopper wire

The invention discloses a process for producing an enameled wire for a compressor. The process comprises the following steps of: an extrusion procedure: extruding an oxygen-free copper rod produced by the continuous casting and rolling process to obtain a bare copper wire; cleaning the bare copper wire, removing oil stain and attachments on the surface of the bare copper wire to achieve the surface cleanness required by a painting procedure; and a painting and baking procedure: painting the bare copper wire in a manner of supplying paint by a metering pump and painting by a plurality of moulds, wherein the primer is polyesterimide and the finish paint is polyamideimide composite insulation paint; carrying out secondary baking by using hot air circulation and catalytic combustion, and sufficiently combusting solvent in the insulation paint; and gathering the wire to obtain the enameled wire for a compressor. The process disclosed by the invention has simple process, small investment and short time for refitting the current equipment; and the produced enameled wire can fully meet the requirements of the R134a compressor.

Owner:JIANGSU ZHONGRONG ELECTRIC

Manufacture method of non-aqueous printing ink wet underglaze colour self-sharpening polishing ceramic glazed tile

The invention relates to a manufacture method of a non-aqueous printing ink wet underglaze colour self-sharpening polishing ceramic glazed tile. The manufacture method is characterized by comprising the following steps of proportioning raw materials, ball milling, iron removal, spraying pulverizing, compacting for moulding, biscuiting, wet underglaze colour decoration, glaze firing, self-sharpening polishing and edging. The self-polishing is as below: in order to prevent passivation of a resin polishing grinding head on a smooth glaze, during normal polishing operation, a ceramic glazed tile product to be polished is added with a rough surface body to be polished; the rough surface body to be polished rubs the polishing grinding head to keep the grinding head sharp. The method has advantages that produced polishing ceramic glazed tile has high strength, brilliant color, rich pattern texture of a ceramic tile as well as high surface flatness and good glossiness of a polishing product. Meanwhile, a production technology has advantages of simple process, low production cost, short sintering period, low energy consumption and simple polishing technology, and is suitable for large-scale production and demand of common consumers.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +2

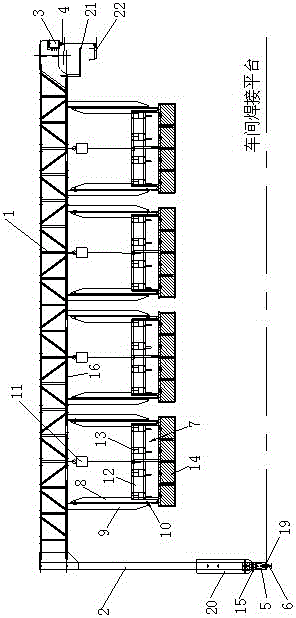

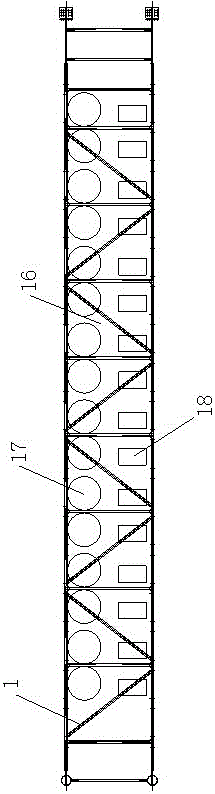

A gantry type automatic fillet welding vehicle

InactiveCN104439638BWelding process parameters are stableImprove welding qualityWelding accessoriesFillet weldVehicle frame

The invention relates to the technical field of ship structure construction, in particular to a gantry type automatic angle welding vehicle used for fillet weld welding of a plane flat rack unit element sectional material of a ship steel structure. The gantry type automatic angle welding vehicle comprises a gantry walking mechanism, a plurality of welding trolley frame lifting mechanisms, an electrical control system, a flexible drag chain power system and a CO2 gas shield welding device. The welding trolley frame lifting mechanisms are hung below the gantry walking mechanism, the electrical control system controls the gantry walking mechanism, the CO2 gas shield welding device and the welding trolley frame lifting mechanisms to operate, and the flexible drag chain power system supplies power to the electrical control system and provides a gas source needed in work by the CO2 gas shield welding device. According to the gantry type automatic angle welding vehicle, the welding quality of a fillet weld can be ensured, the labor intensity of constructors can be relieved, the welding efficiency is greatly improved, and the production cost is reduced.

Owner:广州黄船海洋工程有限公司

Cooling system of oil-immersed self-cooling transformer

InactiveCN110957109AAvoid long-term high temperature alarm stateDistribute in timeTransformers/inductances coolingElectric component structural associationProcess engineeringAlarm state

The invention discloses a cooling system of an oil-immersed self-cooling transformer. The system comprises a winding temperature monitoring unit, an oil surface temperature monitoring unit, a humidifying unit, an air supply unit and a control module, the control module controls starting and stopping of the humidifying unit according to signals of the winding temperature monitoring unit, and the control module controls starting and stopping of the air supply unit according to signals of the oil surface temperature monitoring unit. The invention aims to provide the cooling system for the oil-immersed self-cooling transformer, so as to solve the problems that the oil-immersed self-cooling transformer in the prior art is poor in heat dissipation capability and is in a high-temperature alarm state for a long time, and achieve the purposes of reducing manpower consumption and improving heat dissipation efficiency.

Owner:GUANGAN POWER SUPPLY COMPANY STATE GRID SICHUANELECTRIC POWER

Preparation method of ceramic formula and ceramic product

Owner:怀化市亿智陶瓷有限公司

High-precision double-sided grinding method of annular parts with unequal areas of two end surfaces

ActiveCN102229077BRealize mass productionStable at or above thicknessPlane surface grinding machinesHigh volume manufacturingFrequency ratio

The invention relates to a high-precision double-sided grinding method and machine of annular parts with unequal areas of two end surfaces. According to a rule that the rotating speed and the grinding amount of a grinding wheel of a grinding machine are proportionable, a motor transducer is additionally arranged on a circuit of an assisted grinding system of the grinding machine, the area ratios of two different end surfaces of different parts are converted into different grinding amount ratios so that the frequency ratio and the rotating speed ratio are further adjusted; an appropriate rotating speed ratio of a reference grinding wheel and an assisted grinding wheel is reached by changing and controlling the frequency of the assisted grinding wheel circuit; requirements on thickness, roughness, planarity, parallelism and the like can be stably reached or exceeded finally; the production efficiency is greatly increased and is 28 times that of the common M7160; the production cost is effectively reduced; and the batch production of the parts is realized.

Owner:武汉华夏精冲技术有限公司

Method for recycling unmelted zircon sand in the process of preparing zirconium oxychloride by alkali fusion method

The invention relates to a recycling method of unfused zircon sand in a technical process for preparing zirconium oxychloride by an alkaline fusion method, and belongs to the field of preparation methods of zirconium compounds. The technical process for preparing zirconium oxychloride by the alkaline fusion method comprises the following steps of alkaline fusion, water washing, transformation, acidification, crystallization, acid pickling, centrifugation and drying. The recycling method is characterized in that a working procedure of recycling unfused zircon sand is added after the steps of water washing and transformation and before the step of acidification so as to precipitate and separate the unfused zircon from a dilute hydrochloric acid solution of a water transformation material. The working procedure of recycling unfused zircon sand comprises the following steps: (1) dissolving the water transformation material by a diluted hydrochloric acid; (2) leaving the obtained solution to stand for precipitation; (3) performing solid-liquid separation; (4) repetitively washing unfused sand collected in the step (3) with clean water until the washing water is clear; (5) drying the washed unfused sand in the step (3), and supplying the dried unfused sand for alkaline fusion. Through the adoption of the recycling method disclosed by the invention, the recycling rate of the unfused zircon sand reaches 97%, and the recycled zircon sand can be recycled as raw zircon sand, so that the productive rate of zirconium oxychloride products is increased, and the production cost is reduced.

Owner:山东广通新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com