Multi-hole superfine denier polyamide 6 POY/FDY interlacing composite fiber, its preparation method and its device

A composite fiber and polyamide technology, which is applied in the field of chemical fibers, can solve the problems of poor dyeing performance and effect, complicated processing procedures, and high production costs, and achieve the effects of low production costs, good drapability, and low investment in equipment transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

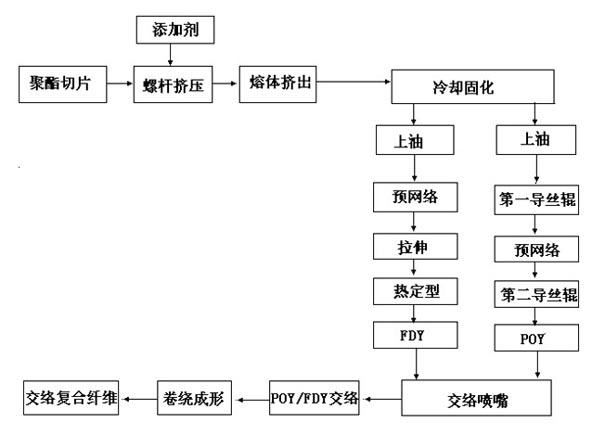

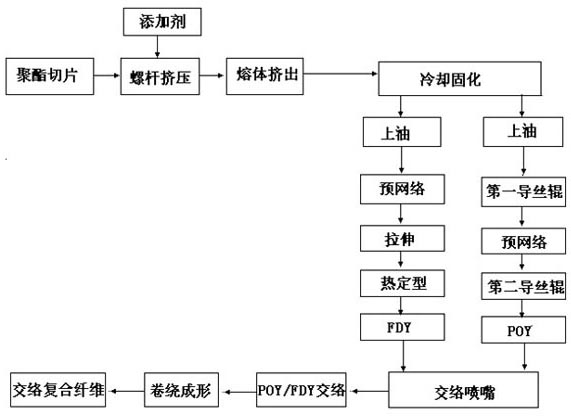

[0022] See attached figure 1 , which is a process flow diagram for the preparation of a porous ultrafine polyamide 6 POY / FDY interlaced composite yarn provided in this example, and provides a new type of porous ultrafine polyamide 6 POY / FDY with excellent production performance Preparation method of entangled composite fiber. The production process is as follows:

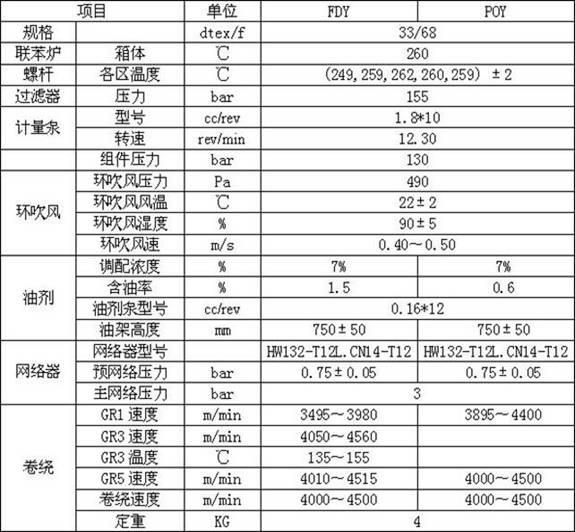

[0023] The relative viscosity of polyamide 6 slices is 2.70-3.10, and the relative molecular weight is 16000-18000. The slices are pre-crystallized at 145°C for about 30 minutes, and sent to the drying tower for 6-8 hours. The drying temperature is 155°C to ensure the moisture content of the slices. Less than 30ppm, the dry polyamide 6 slices after drying enter the screw, and an additive with a mass fraction of 5.0% is added to the polyamide 6 slices, and the additive is a nano-random copolymer of methacrylate, maleic anhydride and styrene , by weight percent, the content of methacrylate is 80%, the content of mal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com