Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Increase the phenolic hydroxyl content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing lignin sulfonate dye dispersant

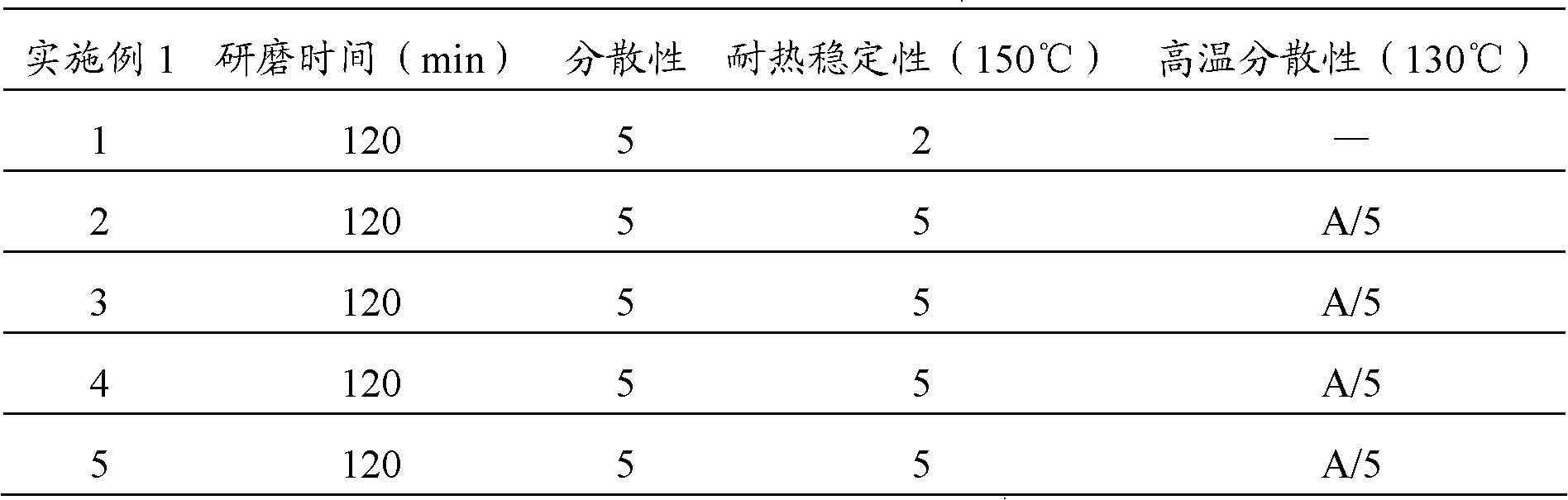

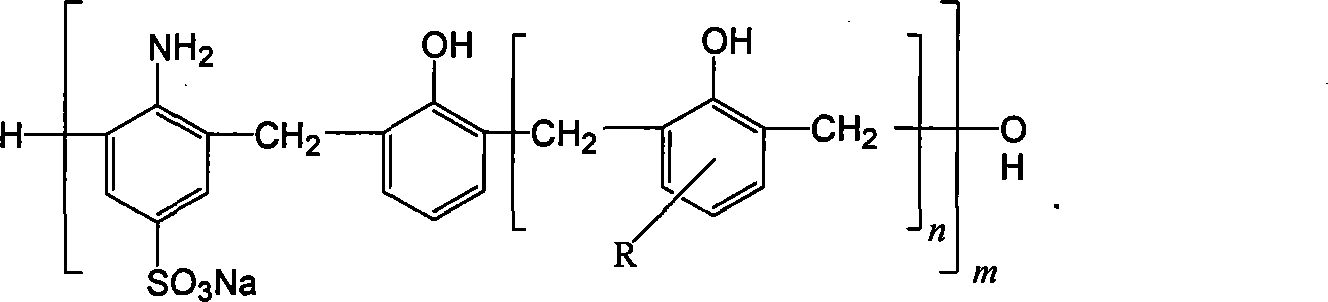

The invention provides a method for preparing lignin sulfonate dye dispersant. The method comprises the following step of carrying out condensation reaction on sodium lignin sulfonate, formaldehyde and a compound containing hydroxyls to generate the lignin sulfonate dye dispersant, wherein the compound containing hydroxyls is one or more of the sulfonic acid methyl naphthalene, naphthalene sulfonic acid, phenol, naphthol, benzyl alcohol and lignin, both the sodium lignin sulfonate and the compound containing hydroxyls can be subjected to the condensation reaction together with the formaldehyde to generate the lignin sulfonate with high molecular weight. The capacity of absorbing the dye molecular of the lignin sulfonate can be enhanced and the activity of the lignin sulfonate can be improved so that the lignin sulfonate has good heat-resistant stability and high-temperature dispersibility. Experiments show that the dye composite, which is obtained by singly using the lignin sulfonate dye dispersant prepared by adopting the method provided by the invention for the C. I disperse blue 79, has 5-grade stability and 5-grade high-temperature dispersibility at 150 DEG C.

Owner:延边石岘双鹿实业有限责任公司

Method for preparing biodegradable polyurethane foam by liquefied modification of bark powder and lignin

InactiveCN102675581AIncrease the phenolic hydroxyl contentIncrease responsivenessApparent densityPolymer science

The invention relates to a method for preparing biodegradable polyurethane foam by liquefied modification of bark powder and lignin. The method comprises the following steps: 1. adding phenol into alkaline solution, heating, then adding larch bark powder and the lignin, stirring evenly, carrying out reaction adequately, and cooling for use; 2. heating liquefied product, adding formaldehyde and catalyst to obtain methylolated lignin, phenolic hydroxyl lignin and methylolated tannin; 3. mixing above modified product, polyether, a foam homogenizing agent and catalyst according to a certain proportion, and mixing with isocyanate for foaming. The rigid foam material foamed by mixing, provided by the invention, has an apparent density of 0.03-0.05g / cm<3>, compressive strength greater than 0.15MP, thermal conductivity of 0.023W / (M.K), and water absorption of 3%. The method provided by the invention can improve the utilization of lignin, save resources, does not cause environmental pollution, and is high in production efficiency. The foam is good in lame retardant property.

Owner:BEIHUA UNIV

Alkali lignin modified sulfamate high-effective water reducer and preparation method thereof

The invention discloses a preparation method of alkali lignin modified sulfamate highly effective water reducing agent, which includes the steps that: firstly, alkali lignin, phenol and water are evenly mixed, and an alkaline regulator is used to adjust the pH value of a reaction system to 8.0-10.0 and heat the temperature to 80-100 DEG C for half an hour to two hours; secondly, the pH value is adjusted to 9.0-11.0, and aminobenzene sulfonic acid sodium is added to react under the temperature of 60 to 80 degrees for half an hour to one hour; thirdly, the temperature is heated to 75-95 DEG C, and condensing agent is dropped. After that, the reaction continues for three to six hours and then the temperature is lowered. The obtained water reducing preparation, having low cost and small content of free formaldehyde and phenol, can improve the fluidity of concrete and compressive strength significantly. The preparation method is a simple technique without the discharge of three wastes in production.

Owner:SOUTH CHINA UNIV OF TECH

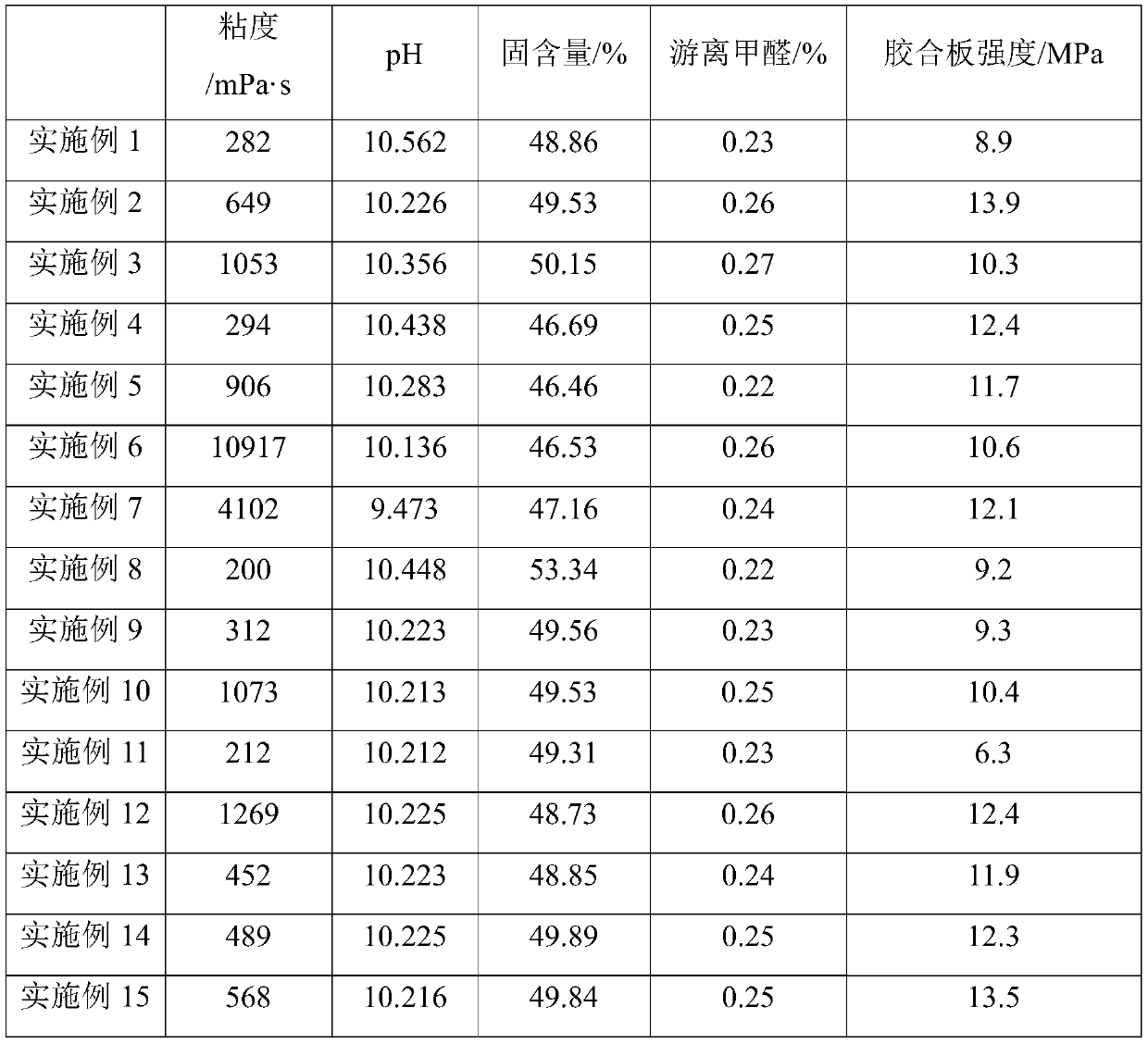

Preparation method of enzymolysis lignin-based phenolic resin

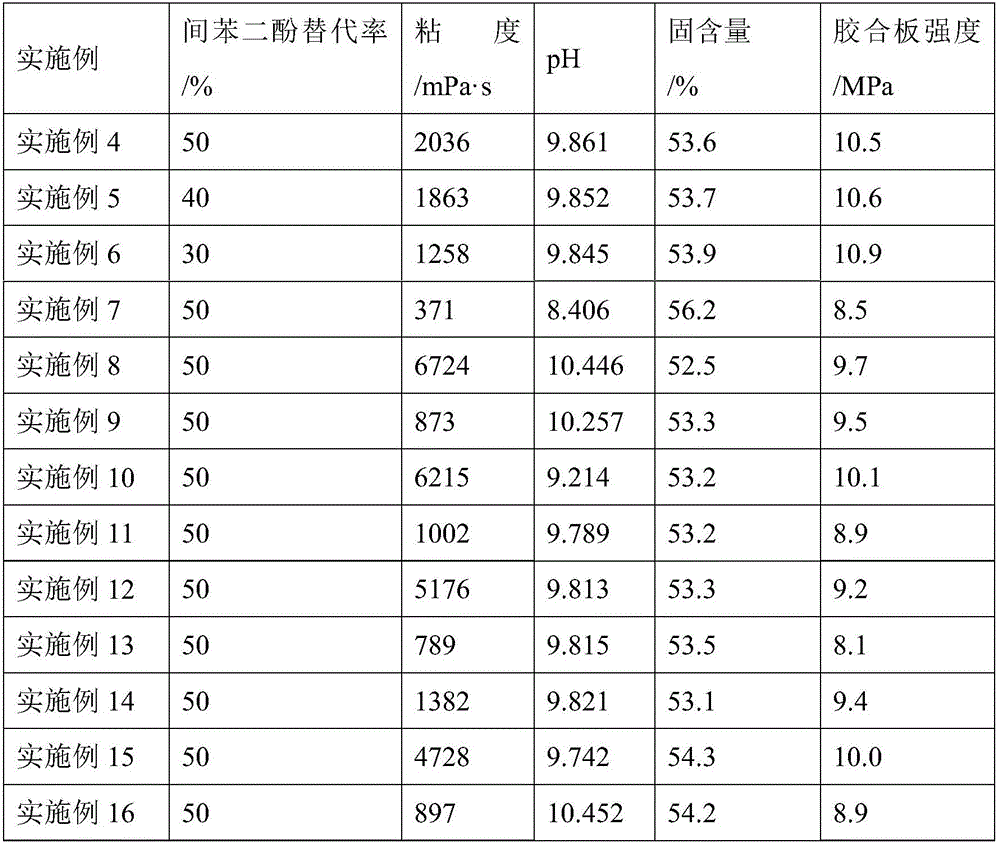

ActiveCN104140508AIncrease the phenolic hydroxyl contentHigh reactivityNational standardBonding strength

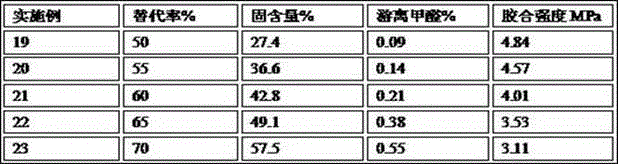

Preparation of enzymolysis lignin-based phenolic resin relates to a method for carrying out activated modification on enzymolysis lignin so as to further synthesize phenolic resin by replacing phenol with the modified enzymolysis lignin. According to the method, pilot-base fuel ethanol production residue is used as a raw material; the pilot-base fuel ethanol production residue is extracted to obtain refined enzymolysis lignin; and after the refined enzymolysis lignin undergoes activated modification, phenol is replaced with the modified enzymolysis lignin to synthesize the phenolic resin. By the method, utilization rate of enzymolysis lignin is high; substitution rate of phenol reaches 60%; and bonding strength of the phenolic resin still can meet the national standard, and the phenolic resin has a wide application prospect.

Owner:NORTHEAST FORESTRY UNIVERSITY

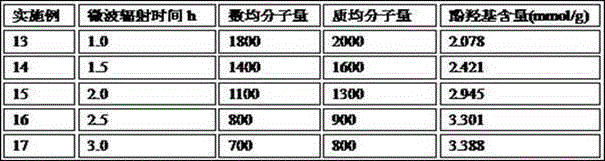

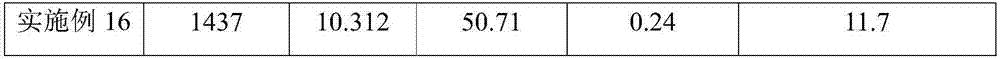

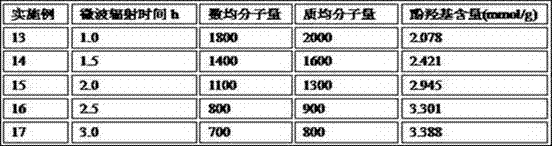

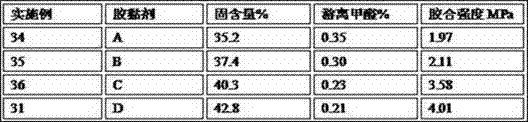

Method for preparing lignin phenolic resin adhesive by using microwave-CuO to treat papermaking waste liquid

ActiveCN104910341AHigh activityIncrease replacement rateAldehyde/ketone condensation polymer adhesivesPhenol formaldehyde resinPhenolic aldehyde

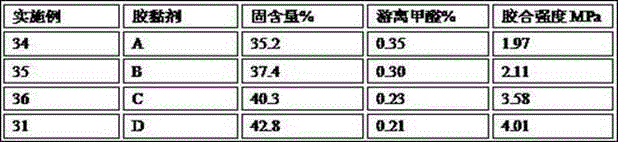

The invention discloses a preparation method for preparing a lignin phenolic resin adhesive by using activated lignin to replace part of phenol to react with formaldehyde. The preparation method comprises the following steps: treating papermaking waste liquid with microwave and CuO, then filtering, adjusting the pH value to be about 2-3 by using hydrochloric acid, putting into a drying oven, standing for a period of time at a set temperature, filtering while the liquid is hot, washing to be neutral, and drying to obtain acidified lignin for later use; and taking the dried lignin to replace part of phenol, and performing phenolization, hydroxymethylation and phenolic reaction to prepare the lignin phenolic resin adhesive. By using the method disclosed by the invention, the replacement rate of phenol by lignin is improved, the cost is reduced, the pollution to the environment is reduced, the adhesive is high in bonding strength and low in free formaldehyde content, and various properties of the adhesive accord with national standards.

Owner:湖南恒旺新材料科技有限公司

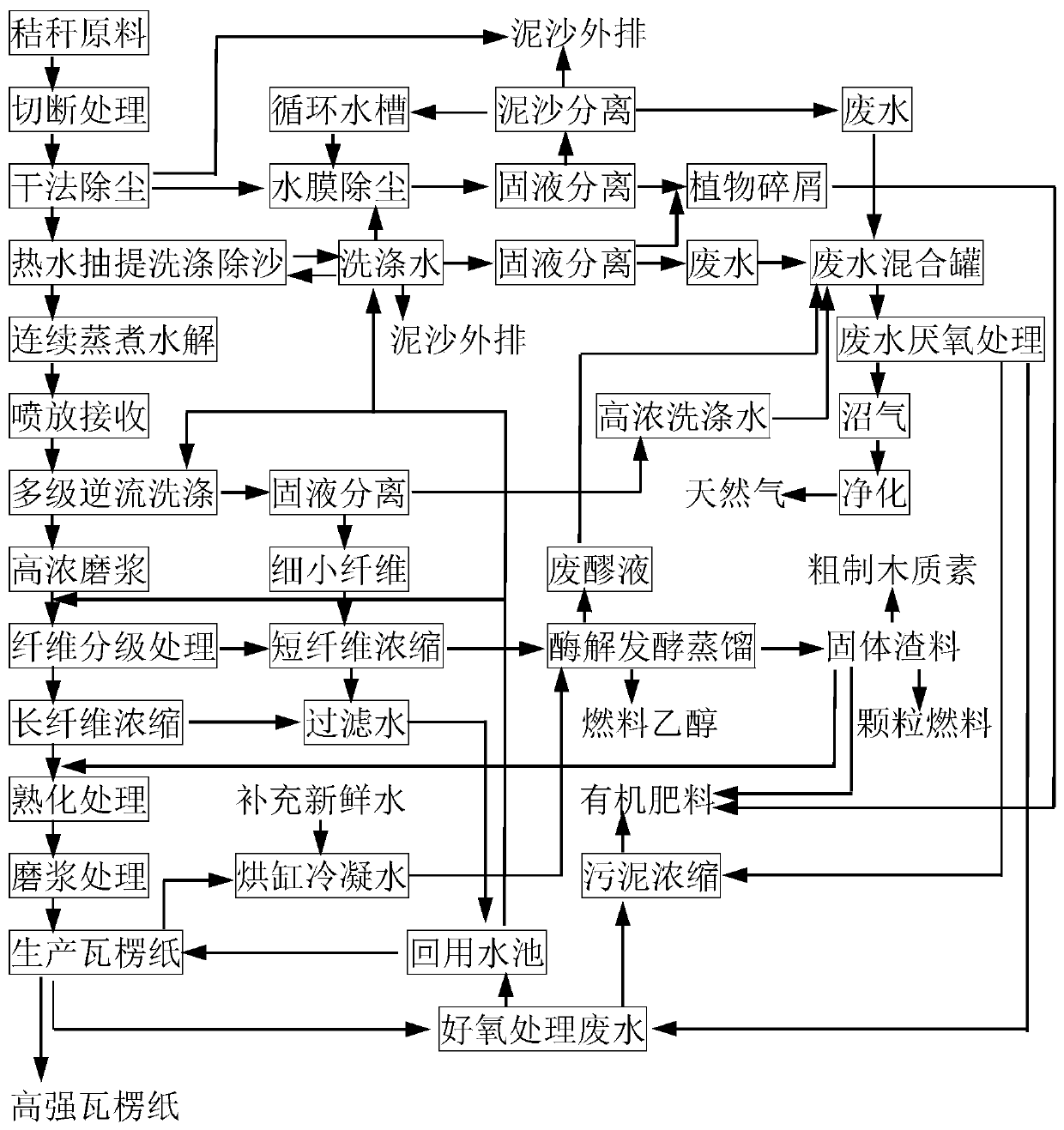

Method of utilizing straw to produce biomass fuel, corrugated paper and organic fertilizer

InactiveCN110129380AImprove water filtration performancePromote degradationPretreatment with water/steamSludge treatment by de-watering/drying/thickeningDistillationHigh concentration

The invention relates to a method of utilizing straw to produce biomass fuel, corrugated paper and organic fertilizer. The method includes: cutting the straw, dusting through a dry process and a waterfilm, washing through hot water extraction for desanding, continuously boiling for hydrolysis, blowing and receiving, performing multistage countercurrent washing, jordaning at high concentration, treating fiber in a staged manner, concentrating long fiber, curing the long fiber, jordaning the long fiber, and using the long fiber to produce the corrugated paper; concentrating the short fiber, subjecting fine and broken fiber to enzymolysis, fermentation and distillation to produce cellulose alcohol, and separating waste mash for utilization. By the method, high-value comprehensive utilizationof each component of the straw is realized, wastewater COD biochemical degradability is high, inorganic salt accumulation is avoided, biogas is produced by high-concentration wastewater in the process and purified as natural gas, and low-concentration wastewater is recycled after being treated, so that a water system is a closed cycle, and there is no wastewater emission; a fine and broken fibercomponent is large in specific surface area and high in enzymolysis efficiency; the corrugated paper produced by a long fiber component is high in strength and quality, and cost of the cellulose alcohol can be lowered; biological natural gas and biomass particle fuel can reduce consumption of mineral fuel.

Owner:吴学军 +5

Preparation method of lignin-based resorcinol-phenol-formaldehyde resin adhesive

ActiveCN107099010AAdaptableExtensive sources of raw materialsAldehyde/ketone condensation polymer adhesivesAdhesivePhenols

The invention discloses a preparation method of a lignin-based resorcinol-phenol-formaldehyde resin adhesive. The preparation method comprises dissolving a basic catalyst in water, heating the solution to 70 to 75 DEG C, adding lignin and phenol into the solution, carrying out uniform mixing, heating the mixture to 90-95 DEG C for a phenolization reaction for 1-1.5h, cooling the mixed solution to 70-85 DEG C, supplying a basic catalyst aqueous solution, adding a formaldehyde aqueous solution into the catalyst aqueous solution, carrying out a primary polycondensation reaction process at 70-85 DEG C for 45-60min, cooling the prepared solution to 55-65 DEG C, adding a resorcinol aqueous solution into the cooled solution, carrying out a secondary polycondensation reaction at 55-65 DEG C for 60-150min and cooling the product to the room temperature. The preparation method pretreats lignin through phenolization and improves phenolic hydroxyl group content of lignin. The preparation method utilizes high activity resorcinol. The lignin-based resorcinol-phenol-formaldehyde resin adhesive has a low curing temperature and short curing time.

Owner:NANJING UNIV OF TECH

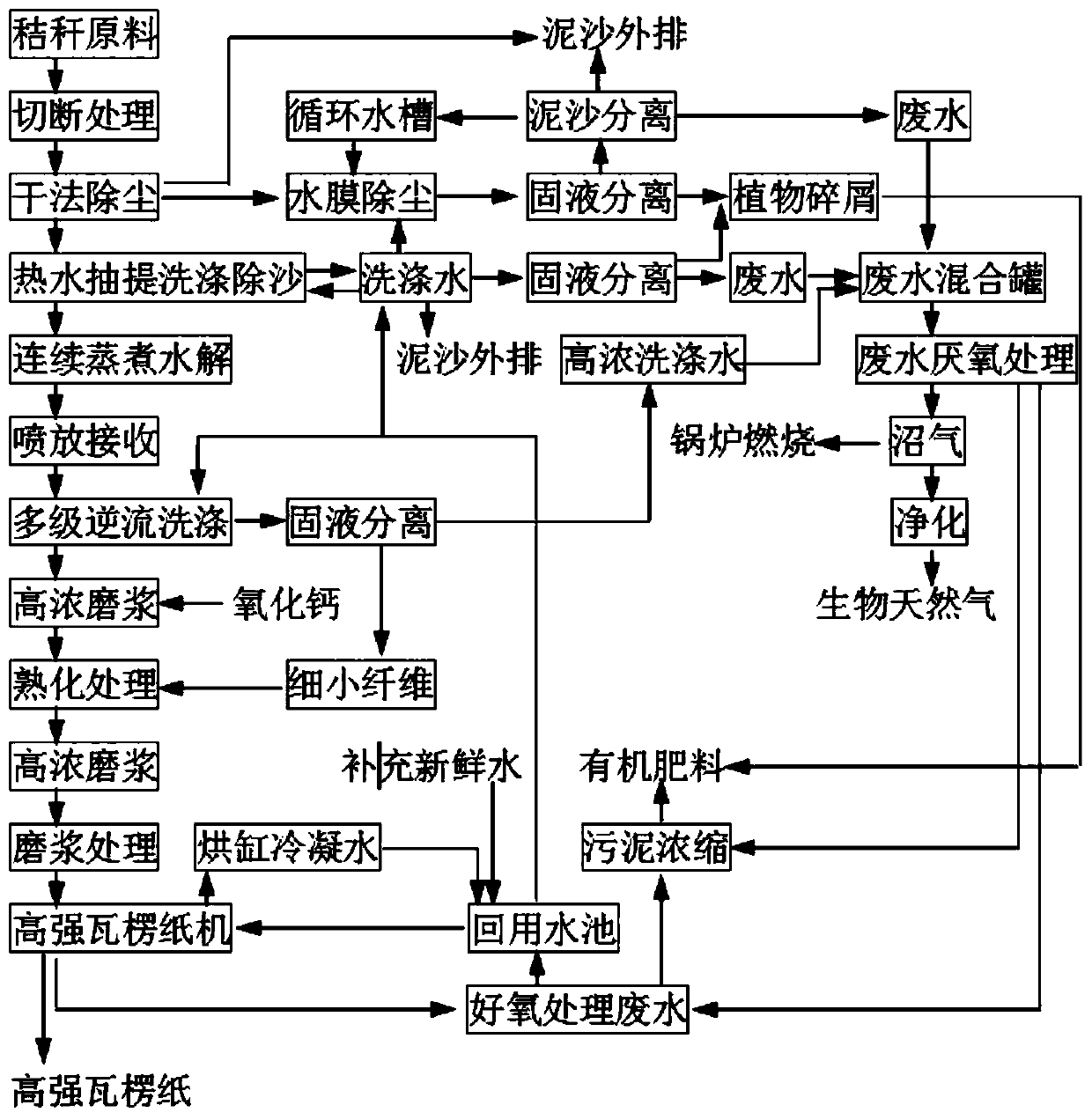

Methods for producing corrugated paper, natural gas and organic fertilizer from straws

InactiveCN110318288AImprove water filtration performanceReduce consumptionCalcareous fertilisersWashing/displacing pulp-treating liquorsHigh concentrationFiber

The invention discloses methods for producing corrugated paper, natural gas and organic fertilizer from straws. The method for producing the corrugated paper includes: (1) cutting the straws; (2) dedusting by a dry method; (3) dedusting by a water membrane; (4) extracting and washing with hot water to remove sand; (5) hydrolyzing by continuous steaming; (6) sprinkling and collecting; (7) backwashing in multiple stages; (8) grinding into high-concentration liquid firstly; (9) ripening; (10) grinding into high-concentration liquid and low-concentration liquid; (11) producing the corrugated paper. The method for producing the natural gas includes the steps of: (1) subjecting high-concentration wastewater to anaerobic treatment; (2) subjecting the treated wastewater to aerobic treatment; (3) purifying marsh gas obtained from anaerobic treatment to obtain the natural gas. The method for producing the organic fertilizer is also provided. The methods for producing the corrugated paper, the natural gas and the organic fertilizer from straws are environmentally friendly, the wastewater obtained in the processes can be recycled, self-producing capability of pulp for industrial packing paperincluding the corrugated paper and the like can be improved, the difficulty of fibrous material shortage in our country can be alleviated, and reliance on imported waste paper can be reduced.

Owner:吴学军 +4

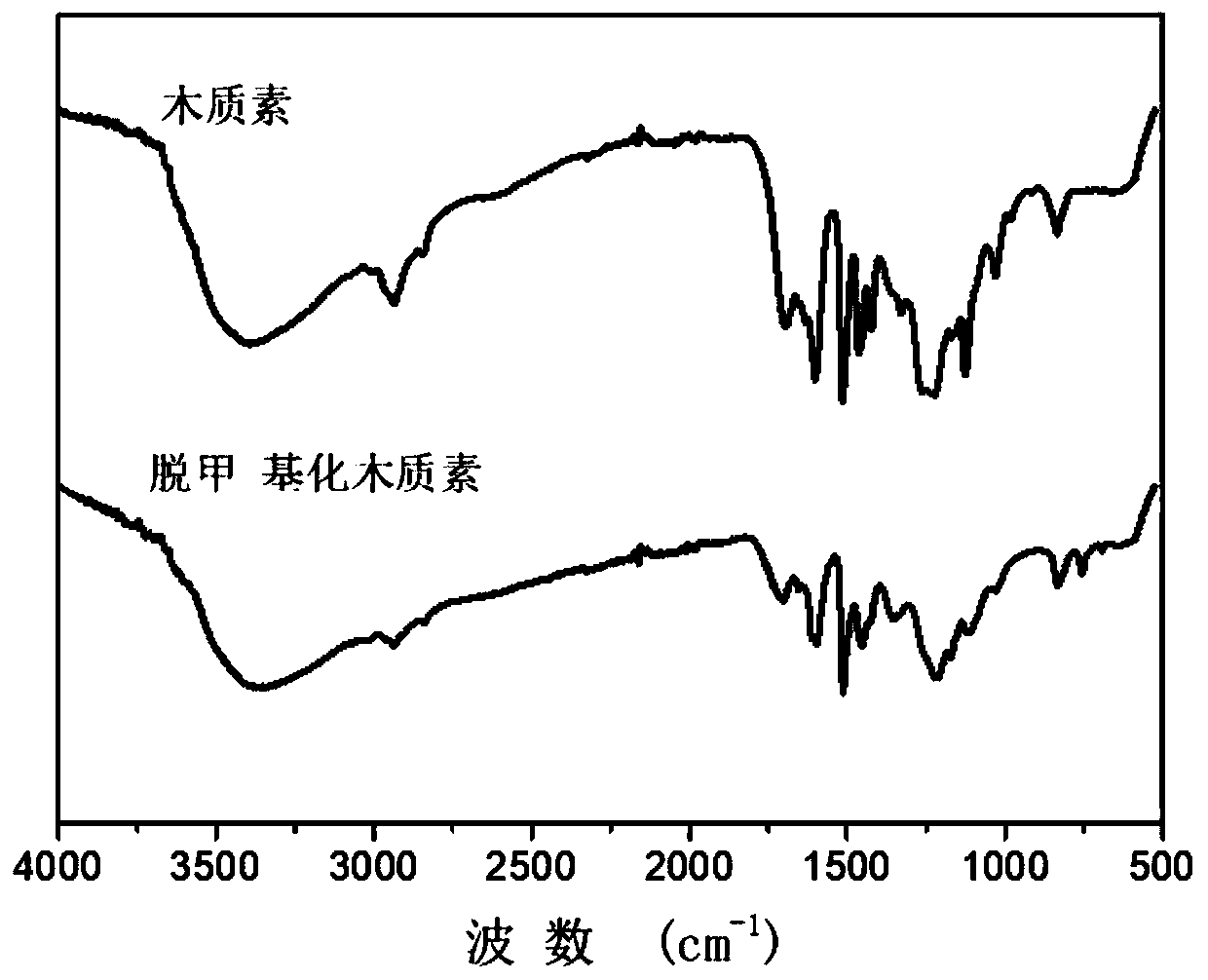

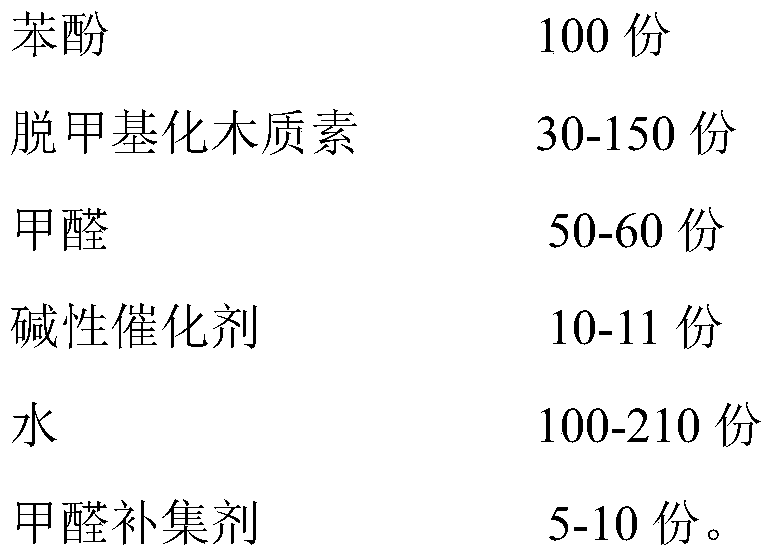

Demethylated lignin-based resorcinol-phenol-formaldehyde resin adhesive and preparation method thereof

ActiveCN107177026ATake advantage ofLow costAldehyde/ketone condensation polymer adhesivesAdhesiveAlkaline catalyst

The invention discloses a demethylated lignin-based resorcinol-phenol-formaldehyde resin adhesive and a preparation method thereof. The preparation method comprises the steps: add lignin into an aqueous solution of sodium sulfide, raising the temperature to be 90 to 110 DEG C, adding sulfur, N-dodecyl mercaptan and sodium borohydride, conducting thermal reaction for 1 to 3 hours, preparing demethylated lignin; dissolving an alkali catalyst in water, raising the temperature to be 60 to 65 DEG C, adding phenol and a formaldehyde aqueous solution, stirring and mixing heating to 85 to 95 DEG C, and reacting for 1 to 1.5 hours; cooling a mixed solution to 60 to 75 DEG C, adding alkaline catalyst aqueous solution, adding the demethylated lignin, and carrying out an initial polycondensation reaction at 60 to 75 DEG C for 1 to 1.5 hours; adding a resorcinol aqueous solution, carrying out the second polycondensation reaction at 60 to 75 DEG C for 1 to 2 hours, and cooling to room temperature to obtain a product. According to the invention, the lignin is demethylated at first to increase the content of phenolic hydroxyl groups in the lignin, and the high active resorcinol is added. The prepared adhesive has low curing temperature, short curing time, good performance and low cost. The replacement rate of demethylated lignin to the resorcinol is 30 to 50%.

Owner:NANJING UNIV OF TECH

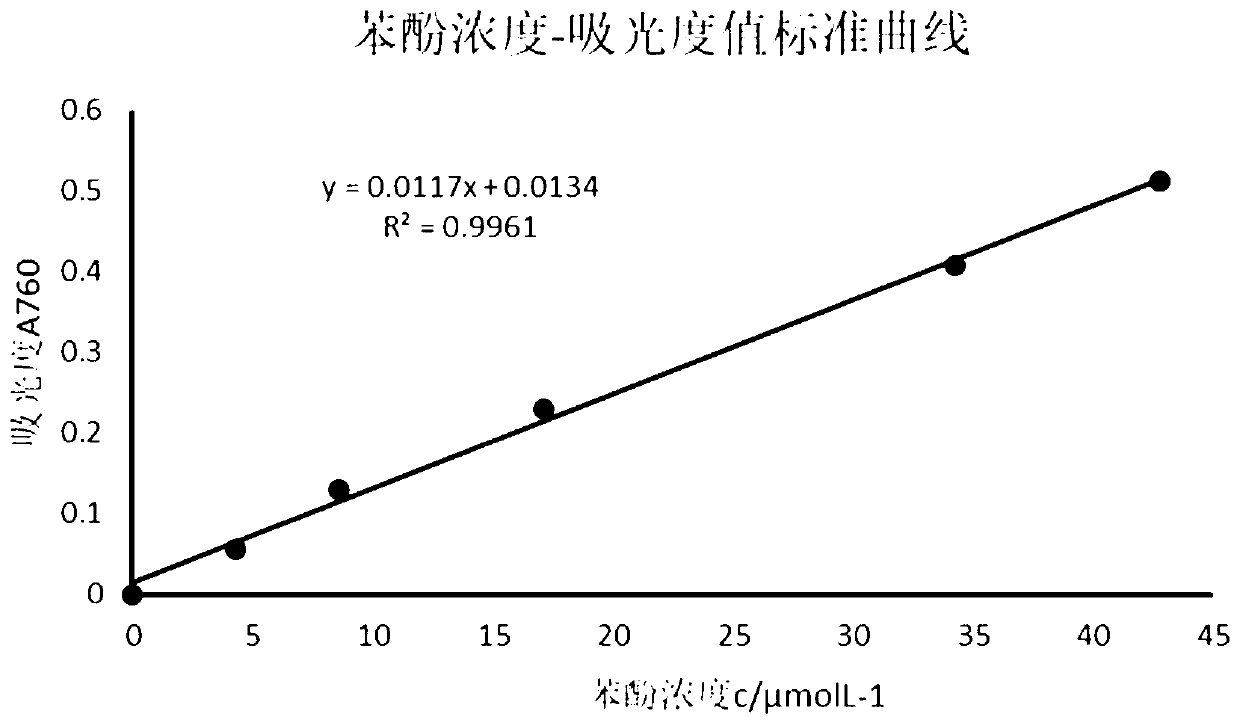

Demethylated lignin, preparation method thereof and application of the demethylated lignin in phenolic resin adhesive

ActiveCN111286041AIncrease the phenolic hydroxyl contentHigh activityAldehyde/ketone condensation polymer adhesivesMaterials scienceDemethylation

The invention discloses demethylated lignin as well as a preparation method and application thereof in a phenolic resin adhesive. The demethylated lignin is obtained by reacting lignin with laccase ina solvent. The lignin is demethylated through the laccase, so that the content of phenolic hydroxyl groups on lignin molecules is increased, activation sites reacting with formaldehyde in the ligninmolecular structure are increased, the activity is higher, and the reactivity with formaldehyde is higher. Meanwhile, the laccase used in the lignin demethylation process is a biocatalyst, has the advantages of being easy and convenient to operate and environmentally friendly, avoids the use of high-temperature and high-pressure reaction conditions and environment-friendly reagents, and is beneficial to production of downstream phenolic aldehyde adhesives. Moreover, due to the fact that the reaction activity of the demethylated lignin is improved, compared with a phenolic resin adhesive prepared from unmodified lignin, the modified phenolic resin adhesive prepared from the demethylated lignin has the advantages that the gelation time is shortened, the resin activity is improved, the formaldehyde release amount is reduced, and the bonding strength is improved.

Owner:NANJING UNIV OF TECH

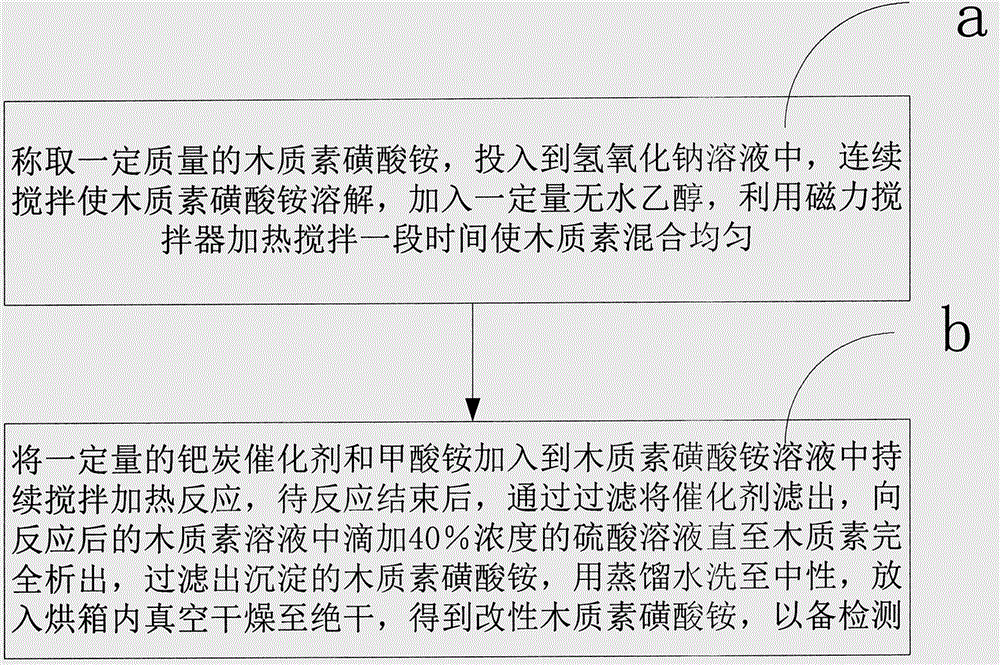

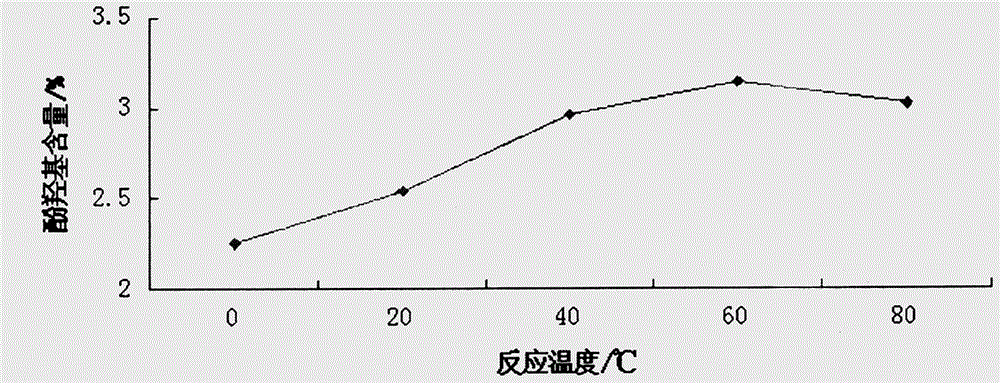

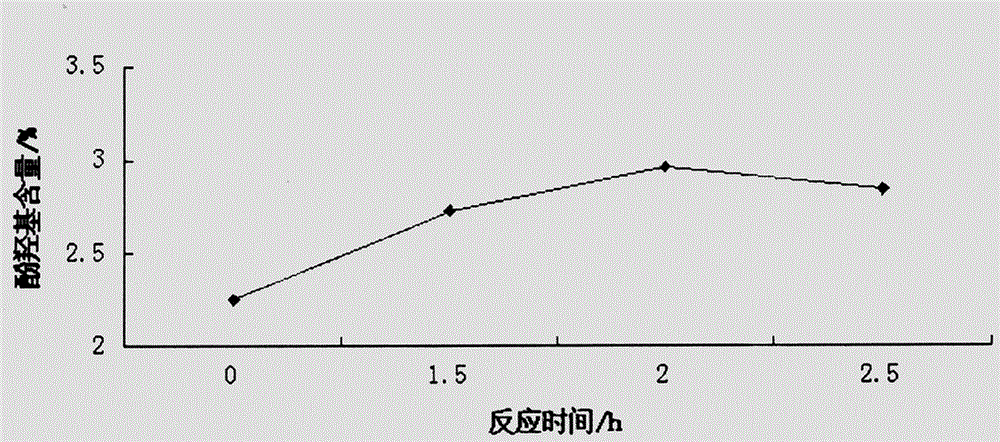

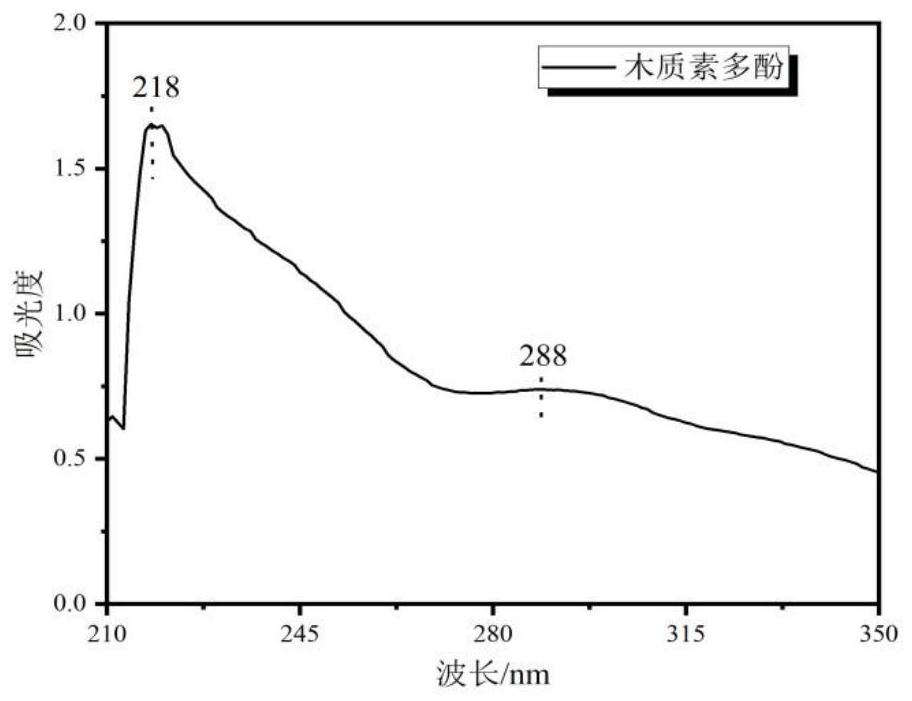

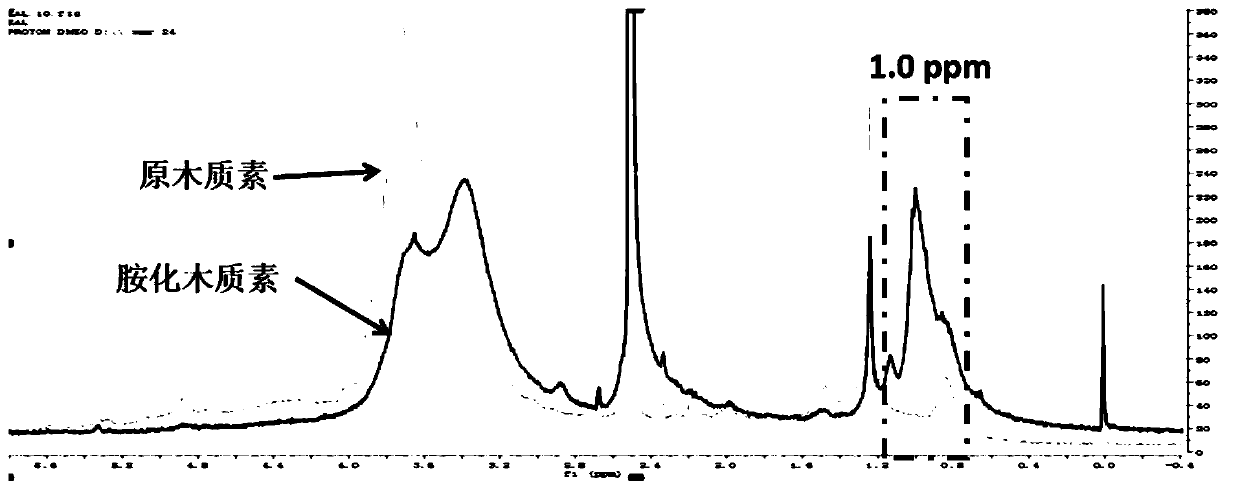

Modification method for improving industrial lignin activity

The invention relates to a modification method for improving industrial lignin activity. According to the invention, ammonium formate and palladium carbon catalysts are utilized; and with a catalytic transfer hydrogenation method, industrial lignin is subjected to a modification treatment. The adopted reagents are environment-friendly and non-toxic. Mainly, the industrial lignin phenolic hydroxyl group content is improved, such that lignin activity is improved, and the lignin added value is increased. With the method, the industrial lignin phenolic hydroxyl group content is improved by approximately 40% when compared with the content before modification.

Owner:NORTHEAST FORESTRY UNIVERSITY

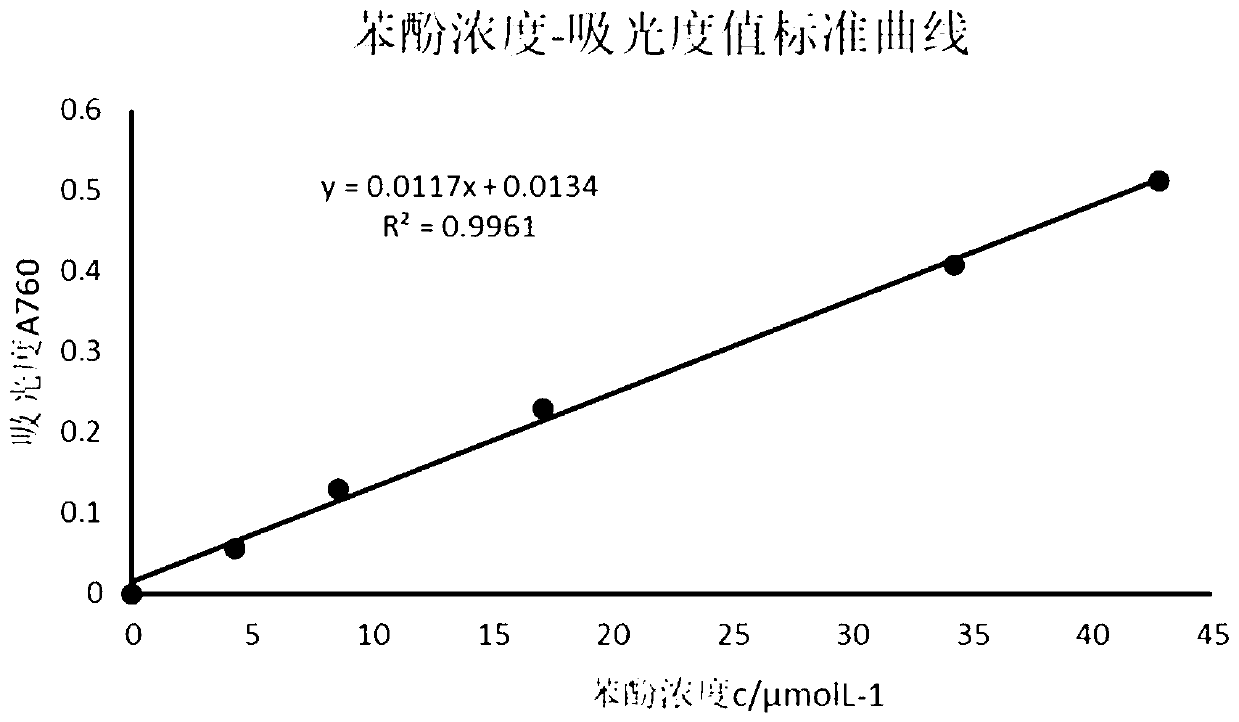

Method for increasing content of phenol hydroxyl of lignosulfonate by ultrasonic waves and application

The invention discloses a method for increasing the content of a phenol hydroxyl of lignosulfonate by ultrasonic waves and application. The method comprises the steps that lignosulfonate is dissolved in water, the pH value of lignosulfonate is regulated to be 0-4, and stirring is performed, so that lignosulfonate is dispersed or dissolved fully, and a lignosulfonate solution is obtained; the ultrasonic waves with a service power ranging between 150W and 300W and a frequency ranging between 20kHz and 40kHz at the temperature ranging between 20 DEGC and 30 DEG C act on the lignosulfonate solution for 60-120min, and natural cooling is performed; and the cooled ultrasonic reaction solution is subjected to reduced pressure distillation and constant-temperature drying, so that lignosulfonate with increased content of the phenol hydroxyl is obtained. The method is mild in reaction condition, low in cost and environment-friendly, can be operated easily, and has a broad application prospect.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

Environment-friendly anti-radiation photovoltaic cable used for solar energy power generation

InactiveCN106221264AGood water solubilityHigh reactivityInsulated cablesOrganic insulatorsBenzoyl peroxideEngineering

The invention discloses an environment-friendly anti-radiation photovoltaic cable used for solar energy power generation, which includes a cable core and a sheath layer coating the cable core, wherein the sheath layer includes, by weight, 20-40 parts of EVA resin, 15-25 parts of chloroprene rubber, 15-30 parts of hydrogenated nitrile butadiene rubber, 15-35 parts of micro powder of silicon carbide, 8-12 parts of bentonite, 10-20 parts of zeolite powder, 10-20 parts of lignin, 45-65 parts of rice hull powder, 10-20 parts of barite powder, 15-22 parts of modified sodium lignin sulfonate, 1-1.5 parts of white oil, 0.8-1.6 parts of an anti-aging agent 2246, 0.8-1.6 parts of an anti-aging agent SP, 3-6 parts of benzoyl peroxide, 2-5 parts of an anti-coking agent CTP, 0.4-0.8 parts of an accelerator PZ, 0.3-0.7 parts of an accelerator TMTD, 1-1.8 parts of zinc oxide, 1.5-2.2 parts of disproportionated rosin, 1.5-3.5 parts of a softener DOP, 1.5-2.5 parts of epoxy soybean oil and the like.

Owner:吴显峰

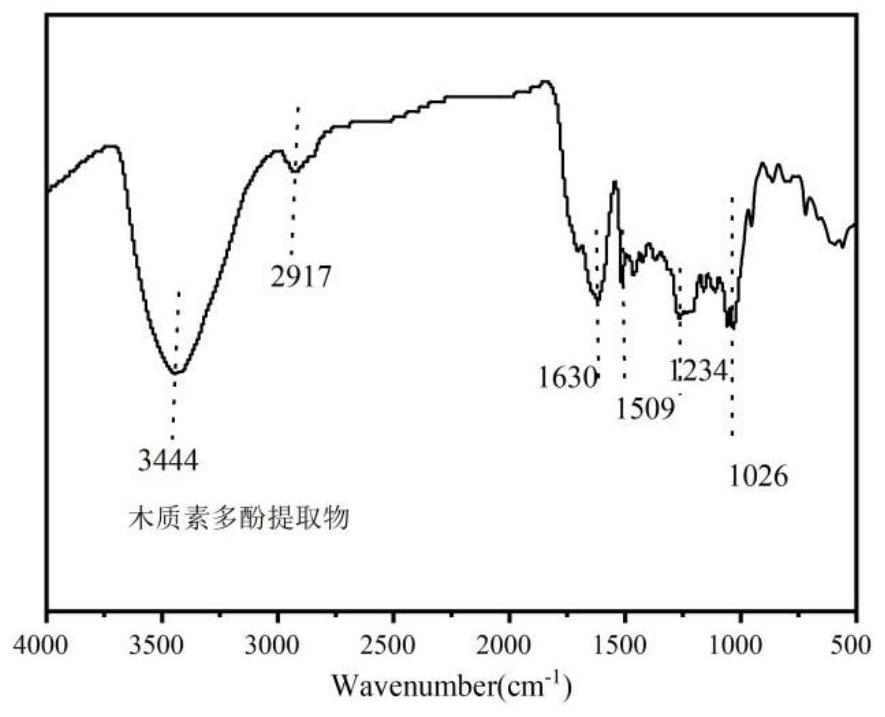

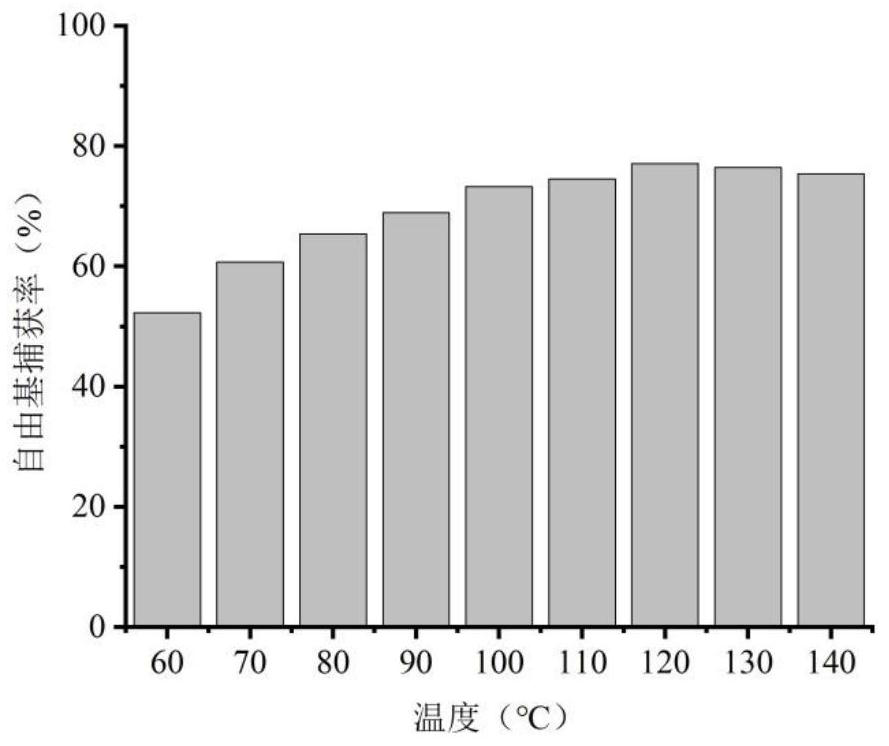

Method for extracting multifunctional active biological polyphenol from waste wood fiber, and application of multifunctional active biological polyphenol

The invention provides a method for extracting multifunctional active biological polyphenol from waste wood fiber, and application of the multifunctional active biological polyphenol.The method comprises the following steps: 1) preparing a green extraction solution: mixing choline chloride, polybasic organic acid, a penetrant and a catalyst, and stirring for at least 1 hour to obtain a solution A; 2) dissolving biomass polyphenol: putting the wood fiber raw material into the solution A, fully dissolving, then adding an ethanol solution and fully oscillating, and then filtering to obtain a filtrate, namely a solution B; and 3) purifying the biomass polyphenol: adding pure water into the solution B, and standing for at least 24 hours until the biomass polyphenol is completely separated out, so as to obtain a separated solid and a residual solution which is a solution C; and carrying out oscillation washing on the precipitated solid with ultrapure water, fully drying at 60 DEG C, then grinding to obtain the solid biomass polyphenol active substance, and filtering the solution C for recycling. The biomass polyphenol extracted by the method is high in purity and strong in activity, and integrates antibacterial, anti-oxidation and anti-ultraviolet properties.

Owner:ZHEJIANG SCI-TECH UNIV

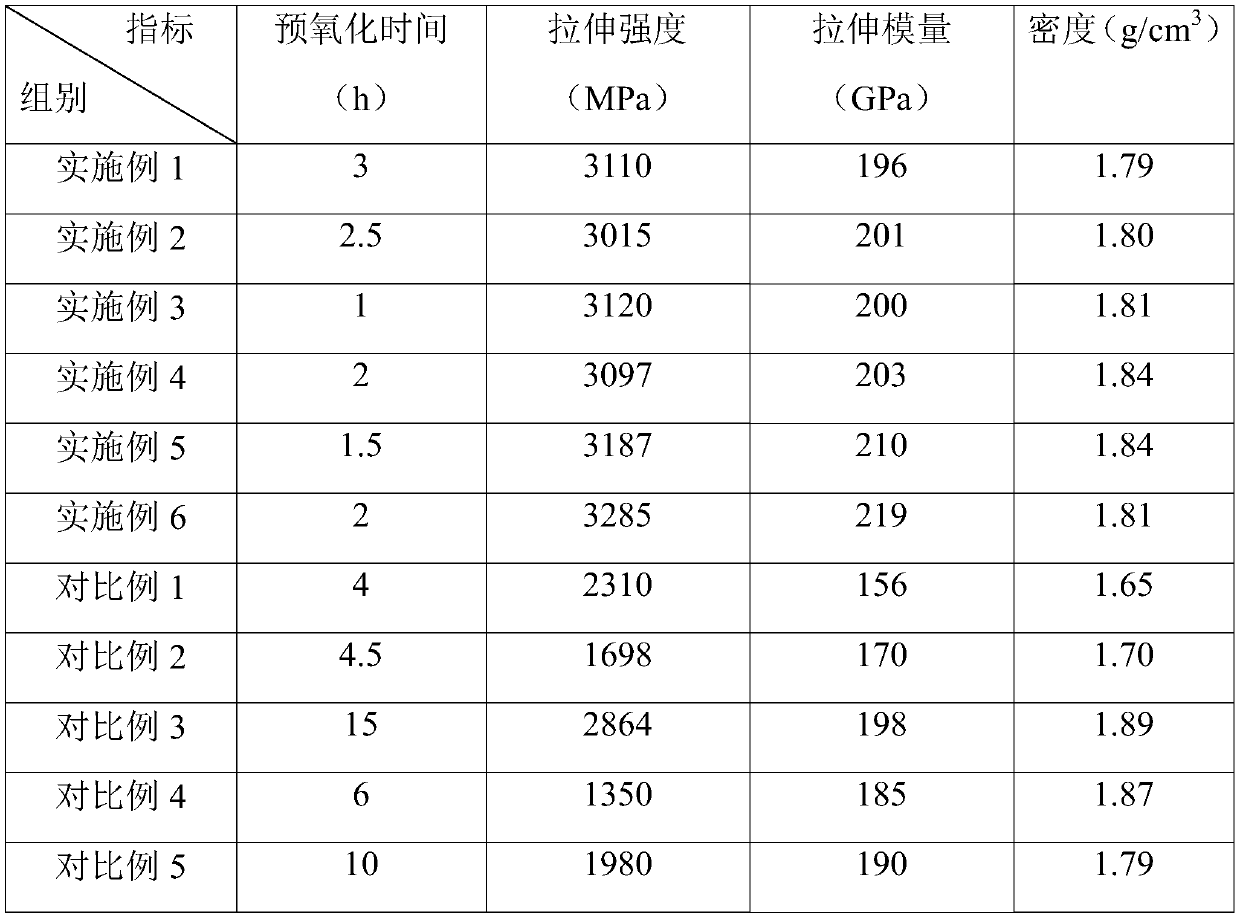

Preparation method of high-stretch lignin-based carbon fiber

InactiveCN109853088AHigh tensile strengthIncrease profitFibre chemical featuresPaper material treatmentFiberCellulose

The invention discloses a preparation method of a high-stretch lignin-based carbon fiber. By enzymatic degradation and fermentation treatment of by-products obtained during cellulose production, the impurity content of raw materials is reduced, a benzene ring structure is not degraded, but a benzene ring side chain is modified and more easily dissolved in a solvent, the content of phenolic hydroxyl groups in lignin is increased, and therefore cross-linking of ferulic acid and the phenol structure of the lignin is promoted; under the further curing function of polyethylene, the spinnability ofa spinning solution is improved, the strength of a carbon fiber precursor is improved under the function of physical force between chopped fibers and viscose fibers and the lignin, and therefore the carbon fiber has more excellent strength and stretchability; in addition, the waste reuse of the lignin is achieved, the utilization rate of the lignin is high, the pre-oxidation time of the preparation process is short, the process is simple, the cost is reduced accordingly, and the mass production can be achieved.

Owner:佛山市石金科技有限公司

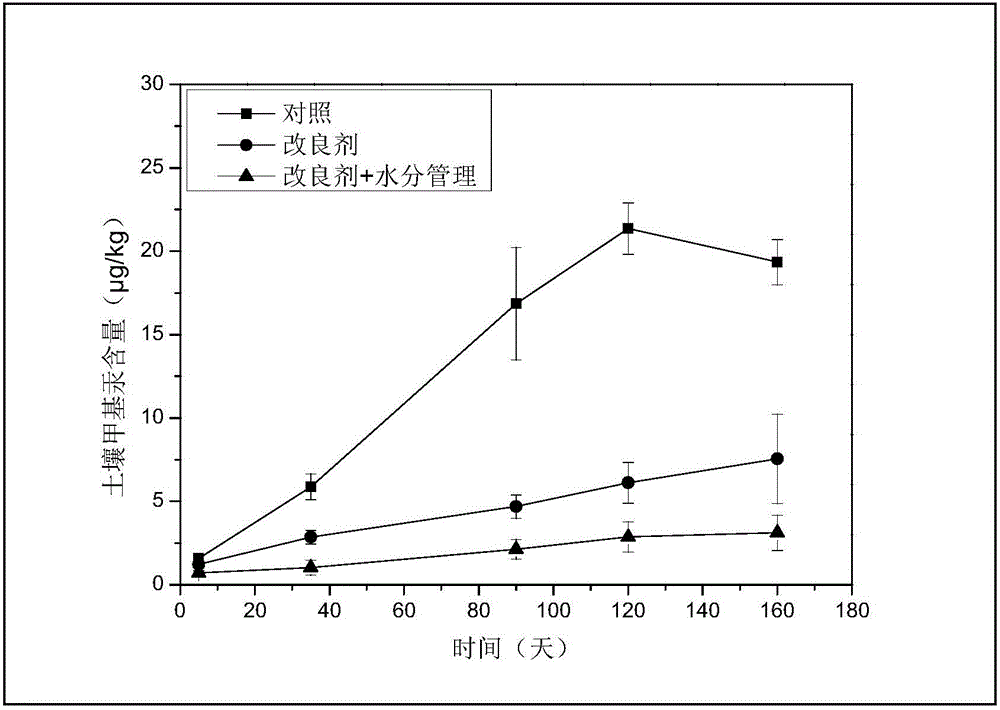

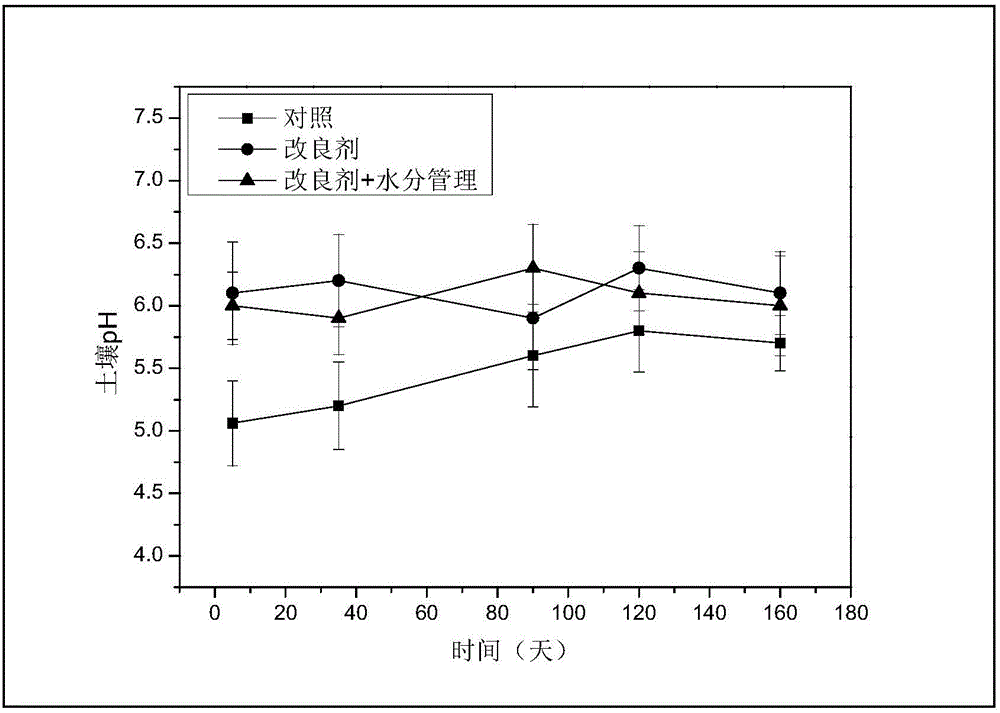

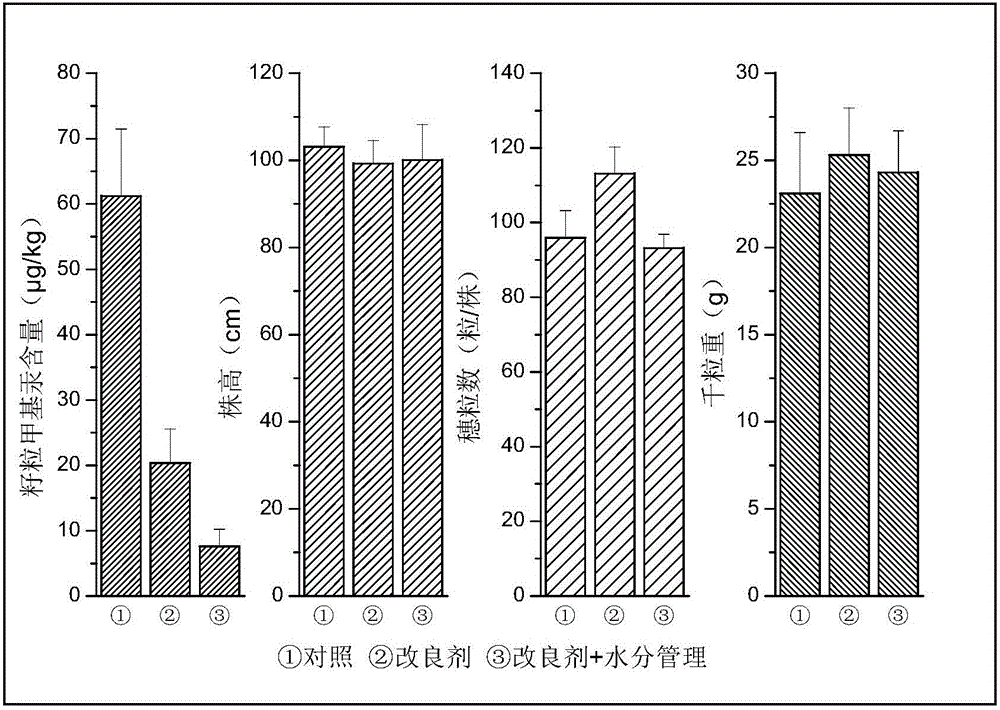

Modifier for reducing methyl mercury pollution in acidic rice field and method thereof

InactiveCN106520137AImprove soil pH and mercury adsorption capacityReduced effectivenessAgriculture tools and machinesOther chemical processesHumic acidBiomass

The invention discloses a modifier for reducing methyl mercury pollution in an acidic rice field and a method thereof, which mainly relates to the field of agriculture pollution prevention and treatment. The method comprises basal application of the modifier and moisture management. The preparation method of the modifier is characterized in that weathered coal is prepared to coal-based humic acid, according to the weight percentage, 0.1-0.2% of sodium selenite is added and aged, calcium carbonate with the weight ratio of 1:1.2-1:1.5 is added, and the materials are uniformly mixed. The modifier has the beneficial effect that the modifier is used for the acidic rice field with pH value of 4-6 and the mercury pollution degree of lower than 6 mg / kg, compared with the contrast group, the methyl mercury content of soil and rice is reduce to 60% and more, the pH value of the soil is obviously increased, the modifier has good reappearance, and has the advantages of low cost, high efficiency and easy operation, the paddy rice output and plant biomass are not reduced, and the modifier has high economic effect.

Owner:农业部农业生态与资源保护总站

A method for preparing lignin phenolic resin adhesive by treating papermaking waste liquid with microwave-cuo

ActiveCN104910341BIncrease replacement rateReduce the degree of polymerizationAldehyde/ketone condensation polymer adhesivesLiquid wasteMicrowave

The invention discloses a preparation method for preparing a lignin phenolic resin adhesive by using activated lignin to replace part of phenol to react with formaldehyde. The preparation method comprises the following steps: treating papermaking waste liquid with microwave and CuO, then filtering, adjusting the pH value to be about 2-3 by using hydrochloric acid, putting into a drying oven, standing for a period of time at a set temperature, filtering while the liquid is hot, washing to be neutral, and drying to obtain acidified lignin for later use; and taking the dried lignin to replace part of phenol, and performing phenolization, hydroxymethylation and phenolic reaction to prepare the lignin phenolic resin adhesive. By using the method disclosed by the invention, the replacement rate of phenol by lignin is improved, the cost is reduced, the pollution to the environment is reduced, the adhesive is high in bonding strength and low in free formaldehyde content, and various properties of the adhesive accord with national standards.

Owner:湖南恒旺新材料科技有限公司

Method for improving amination modification efficiency or phenolic hydroxyl group content of alkali lignin

The invention belongs to the field of improvement of reaction activity of alkali lignin, and discloses a method for improving the amination modification efficiency or phenolic hydroxyl group content of alkali lignin, which comprises the following preparation steps: adding lignin into a deep eutectic solvent system (a choline chloride / urea system, a choline chloride / glycerol system and a choline chloride / acetic acid system), uniformly mixing, carrying out heating treatment, adjusting the pretreatment temperature, adding deionized water to terminate the reaction after stirring treatment is conducted for a period of time, then performing centrifugation and freeze drying to obtain the pretreated alkali lignin, carrying out reduced pressure distillation to recover the deep-eutectic solvent system, or transferring the reaction system treated by the deep-eutectic solvent system into a dilute acid solution, continuing to mechanically stir for a period of time, and then centrifuging and vacuum drying to obtain the pretreated industrial alkali lignin. The solvent used in the pretreatment method is green and environment-friendly, can be recycled, and is free of pollution, and the method is simple in process, is easy to operate, is suitable for industrial production, and has a good application prospect.

Owner:QILU UNIV OF TECH

Aminated lignin as well as preparation method and application thereof

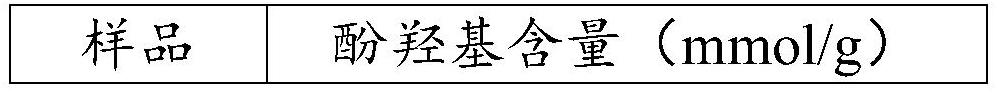

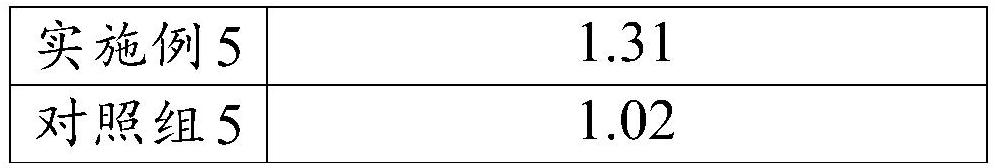

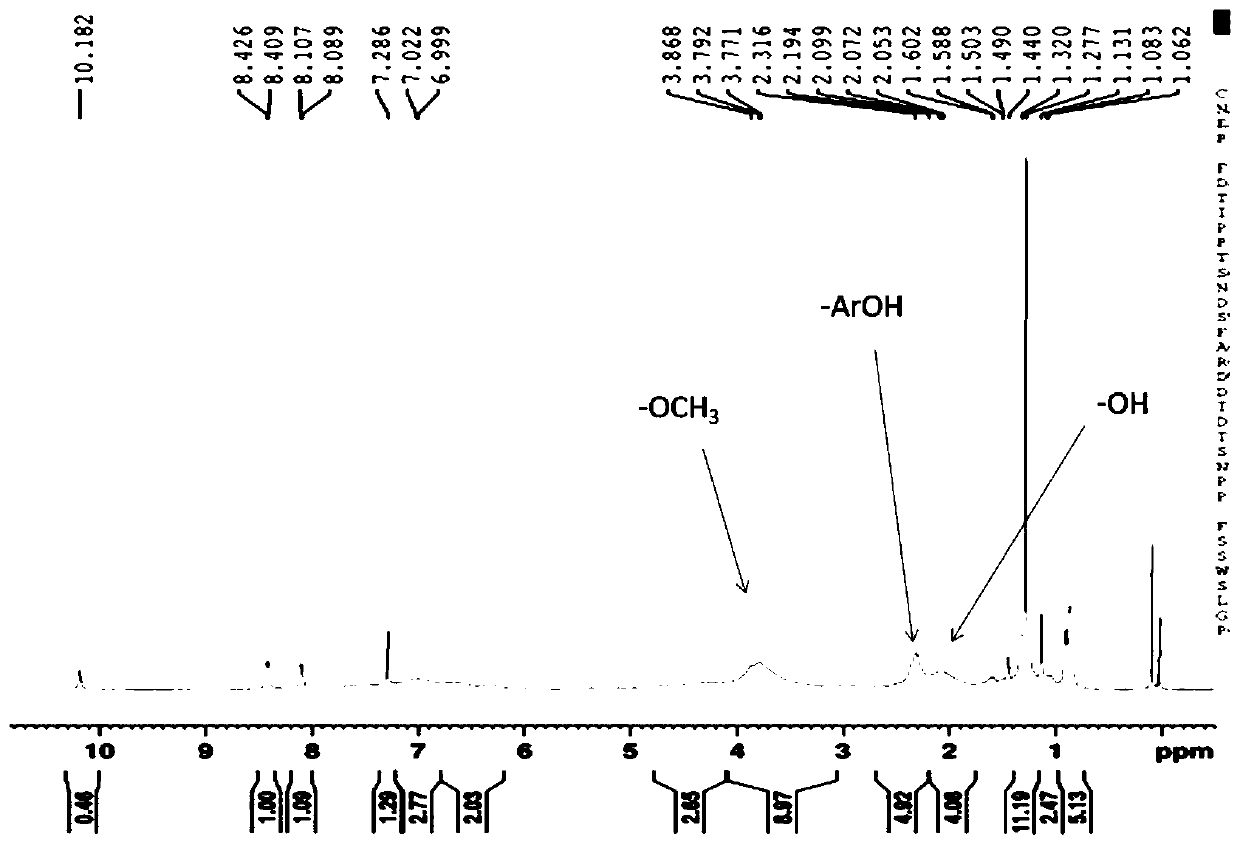

PendingCN111333859ASmall molecular weightIncrease the phenolic hydroxyl contentWorking-up pitch/asphalt/bitumenBuilding insulationsMicroreactorReactive site

The invention discloses aminated lignin as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) respectively pumping an epoxy chloropropane aqueous solution and an amination reagent aqueous solution into a first micro-mixer in a micro-channel reaction device at the same time, mixing, and introducing the mixture into a first micro-reactor in the micro-channel reaction device; and (2) while the step (1) is carried out, simultaneously pumping an alkali solution of the degraded lignin and the effluent of the first micro-reactor into a second mixer in the micro-reaction device, mixing, introducing the mixture into a second micro-reactor in the micro-reaction device, and collecting the effluent of the second micro-reactor, thereby obtaining the product. The method has the following advantages: (1) after pretreatment, the molecular weight is reduced, the phenolic hydroxyl group content is increased, and the reaction active sites are increased; and (2) the preparation process disclosed by the invention not only can realize continuous production, but also can shorten the amination reaction time, is low in energy consumption and improves the production efficiency.

Owner:NANJING UNIV OF TECH

Modified lignin as well as preparation method thereof and application of modified lignin in phenolic resin adhesive

ActiveCN111393667AIncrease the phenolic hydroxyl contentIncreased activation sitesAldehyde/ketone condensation polymer adhesivesReactive siteResin adhesive

The invention discloses modified lignin as well as a preparation method and application thereof in a phenolic resin adhesive, and the preparation method of the modified lignin comprises the followingsteps: mixing lignin and a biocatalyst in a solvent, and reacting to obtain the modified lignin. The method has the advantages of mild reaction conditions, simple post-treatment, strong operability and environmental protection. Besides, phenolic hydroxyl is introduced into the modified lignin through biological catalytic hydroxylation, so that the number of active sites is increased, the activityof the modified lignin is enhanced, and the modified lignin can be used for preparing a phenolic resin adhesive and has important significance in efficient utilization of lignin and relief of petroleum resource pressure.

Owner:NANJING UNIV OF TECH

Method and application of increasing phenolic hydroxyl content of lignosulfonate by using ultrasonic waves

The invention discloses a method for increasing the content of a phenol hydroxyl of lignosulfonate by ultrasonic waves and application. The method comprises the steps that lignosulfonate is dissolved in water, the pH value of lignosulfonate is regulated to be 0-4, and stirring is performed, so that lignosulfonate is dispersed or dissolved fully, and a lignosulfonate solution is obtained; the ultrasonic waves with a service power ranging between 150W and 300W and a frequency ranging between 20kHz and 40kHz at the temperature ranging between 20 DEGC and 30 DEG C act on the lignosulfonate solution for 60-120min, and natural cooling is performed; and the cooled ultrasonic reaction solution is subjected to reduced pressure distillation and constant-temperature drying, so that lignosulfonate with increased content of the phenol hydroxyl is obtained. The method is mild in reaction condition, low in cost and environment-friendly, can be operated easily, and has a broad application prospect.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

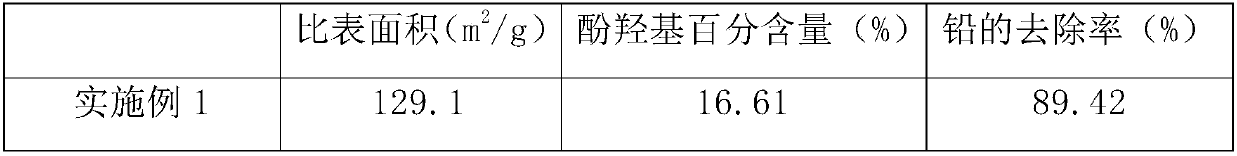

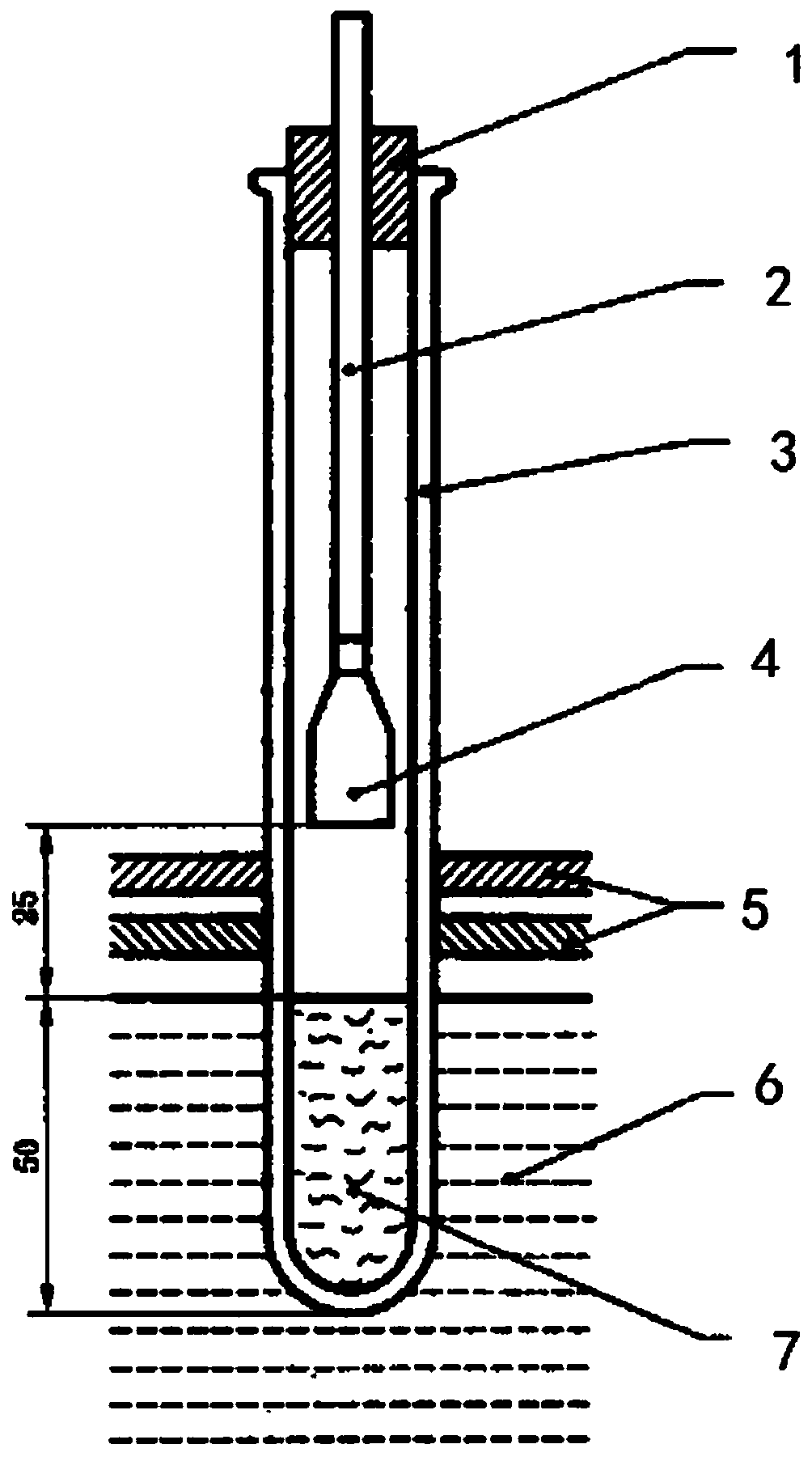

Charcoal and preparation method thereof as well as method for removing lead in water by using charcoal

InactiveCN107661743AWide variety of sourcesLow costOther chemical processesWater contaminantsCellulosePollution

The invention relates to charcoal and a preparation method thereof and a method for removing lead in water by using the charcoal. The method comprises the following steps: 1) washing caragana microphylla, drying, crushing, extruding molding, and thus obtaining caragana microphylla sections; 2) under an atmosphere protection condition, heating, pyrolysing and cooling the caragana microphylla sections to obtain a crude product; crushing the crude product, and sieving to obtain charcoal, wherein the pyrolysis temperature is 550 to 680 DEG C. The charcoal prepared in the invention is wide in source of raw material caragana microphylla, low in cost, capable of converting waste into treasure and reducing the production cost and simple and easy in preparation method; the raw material caragana microphylla in the invention is rich in cellulose and lignin, so that the adsorption performance of the prepared charcoal for the lead in water is high, and the lead removal rate is 89.42 to 99.87 percent; moreover, the charcoal of the invention is convenient to recover and free from causing secondary pollution.

Owner:NORTHWEST A & F UNIV

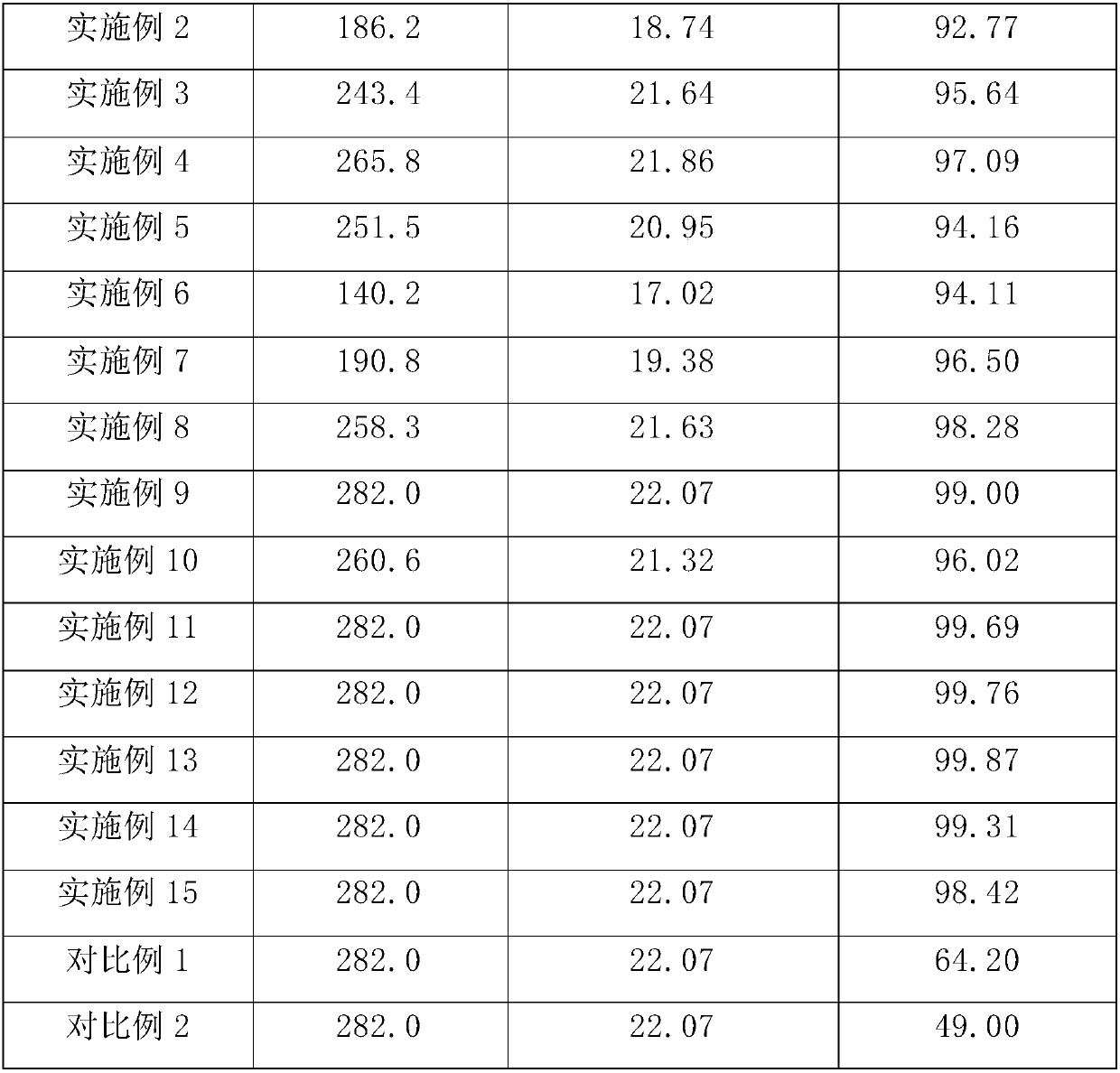

Biomass synthetic resin filtrate reducer for drilling fluid as well as preparation method and application thereof

PendingCN113621116ASmall molecular weightImprove molecular chemical reactivityDrilling compositionPhenolSynthetic resin

The invention provides a preparation method of a biomass synthetic resin filtrate reducer for drilling fluid, which comprises the following steps of: carrying out a reaction on lignin, phenol, hydrochloric acid and temperature-controlled ionic liquid to obtain liquefied lignin; and reacting the liquefied lignin with paraformaldehyde, a sulfonating agent and water to obtain a biomass synthetic resin filtrate reducer. The temperature-controlled ionic liquid is used as a solvent, so that the solubility and the reaction activity of a lignin compound in the ionic liquid can be improved, and isotropic cracking of lignin compound molecules at beta-O-4 is facilitated; and generated free radicals are combined with phenol, the molecular weight and the spatial steric hindrance of the lignin compound are reduced, the chemical reaction activity of lignin molecules is improved, subsequent sulfonation and condensation polymerization are facilitated, and an environment-friendly biomass synthetic resin filtrate reducer is obtained. The invention further provides a biomass synthetic resin filtrate reducer for drilling fluid and application thereof. The filtrate reducer is environmentally friendly, resistant to temperature and salt and easy to biodegrade.

Owner:中石化石油工程技术服务有限公司 +2

Straw comprehensive utilization method

InactiveCN109989285AImprove COD valueImprove water filtration performanceBioreactor/fermenter combinationsBiological substance pretreatmentsFiberHigh concentration

The invention relates to a straw comprehensive utilization method, and belongs to the technical field of biomass raw material comprehensive utilization. The method mainly comprises the following key steps: straw cutting treatment, dry-process dedusting, hot-water washing for sand removing, continuous cooking, spraying and receiving, multi-stage countercurrent washing, multi-stage high-concentration pulp grinding, fiber classification treatment, long-fiber concentration, long-fiber curing treatment, long-fiber pulp grinding and production of corrugated paper through long fibers, short-fiber concentration, and enzymolysis, fermentation and distillation of short fibers for production of fuel ethanol and solid granular fuel. The method has the beneficial effects that high-value comprehensive utilization of all components of the straw material is realized, chemicals are not added, a water system is closed and circulated, and the zero discharge of wastewater is realized; the specific surfacearea of a fine fiber component is large, and the enzymolysis efficiency is high; corrugated paper produced by the long fiber component is high in strength and good in quality; when the fine fiber component is used for an enzymolysis system, not only is the enzymolysis property of the material improved, but also the cost of enzymolysis sugar is greatly reduced, so that the development of a biomasscomprehensive utilization technology is promoted.

Owner:吴学军 +5

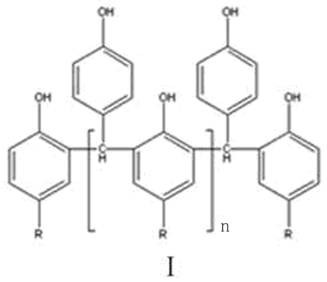

Preparing method for phenol series substances

InactiveCN1255367CLow costLow molecular weightOrganic chemistryOrganic compound preparationSolventPhenol

Owner:KUNMING UNIV OF SCI & TECH

Antistatic high-strength polyacrylonitrile fiber and preparation method thereof

PendingCN114525596AIncrease crosslink densityHigh tensile strengthElectroconductive/antistatic filament manufactureTextile/flexible product manufacturePolymer scienceSpinning

The invention discloses an antistatic high-strength polyacrylonitrile fiber and a preparation method thereof, and relates to the technical field of fiber modification. When the anti-static high-strength polyacrylonitrile fiber is prepared, a polyacrylonitrile fiber matrix prepared through electrostatic spinning and irradiation crosslinking is hydrolyzed, then phosphorylated polyvinyl alcohol is introduced, then poly (3-thiopheneacetic acid) hydrogel is coated, and finally freeze drying is conducted to obtain the anti-static high-strength polyacrylonitrile fiber. Phenolated lignin is added into an electrostatic spinning solution, so that the tensile strength of the polyacrylonitrile fiber is enhanced; the phosphorylated polyvinyl alcohol can form a film on the surface of the polyacrylonitrile fiber to enhance the tensile strength of the polyacrylonitrile fiber, the poly (3-thiopheneacetic acid) hydrogel coats the surface of the polyacrylonitrile fiber to enhance the air permeability of the fiber, and then freeze drying is performed, so that the fiber has antistatic property and the air permeability is enhanced.

Owner:吕建刚

Low-smoke halogen-free non-toxic high-oil-resistance ultrathin locomotive cable

InactiveCN106279856APromote cross-linking and curingGood water solubilityRubber insulatorsInsulated cablesAcrylonitrileSilicon dioxide

The invention discloses a low-smoke halogen-free non-toxic high-oil-resistance ultrathin locomotive cable which comprises a cable core and a sheath layer, wherein the cable core is coated with the sheath layer; the sheath layer comprises the following raw materials in parts by weight: 15 to 35 parts of ethylene propylene diene monomer rubber, 10 to 20 parts of hydrogenated butadiene-acrylonitrile rubber, 10 to 18 parts of chloric ether rubber, 0.1 to 0.5 part of an accelerant D, 0.1 to 0.5 part of an accelerant NS, 1 to 2 parts of an accelerant MZ, 2 to 5 parts of sulfur, 1 to 4 parts of an antiscorching agent CTP, 0.5 to 1.5 parts of zinc oxide, 0.5 to 1.2 parts of 202 resin, 10 to 20 parts of modified sodium lignin sulfonate, 5 to 15 parts of calcined clay, 10 to 30 parts of nano-silica, 40 to 60 parts of nano-titanium dioxide, 5 to 15 parts of lignin, 5 to 10 parts of graphene nanosheets, 5 to 15 parts of fir carbon, 0.5 to 1.5 parts of an anti-ageing agent 1010-A, 0.5 to 1.2 parts of an anti-ageing agent 616, 1 to 3 parts of a softening agent DOP, 1 to 2 parts of disproportionated rosin and the like.

Owner:吴显峰

Method capable of improving thermostability and flame retardance of PVC

ActiveCN110054847AImprove thermal stabilityImprove flame retardant performancePlasticizerMixed materials

The invention discloses a method capable of improving thermostability and flame retardance of PVC through a nano magnesium borate / lignin composite material. The method includes following steps: (1), using dioctyl phthalate (DOP) as a plasticizer to hydrophobically modify the composite material; (2), well mixing the hydrophobically modified composite material with PVC powder, and performing plasticizing modification; (3), banburying a mixed material obtained by plasticizing modification in a banbury mixer; (4), performing hot-press forming on a mixed material obtained by banbury to obtain a PVCformed material. The composite material synthesized in situ and DOP are used as an enhancer and a plasticizer respectively, so that thermostability and flame retardance of the PVC formed material areimproved remarkably.

Owner:GUANGXI UNIV

A kind of preparation method of lignin-based resorcinol-phenol-formaldehyde resin adhesive

ActiveCN107099010BTake advantage ofAdaptableAldehyde/ketone condensation polymer adhesivesAdhesiveHigh activity

Owner:NANJING TECH UNIV

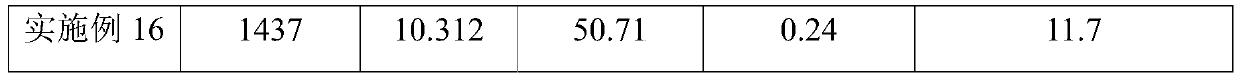

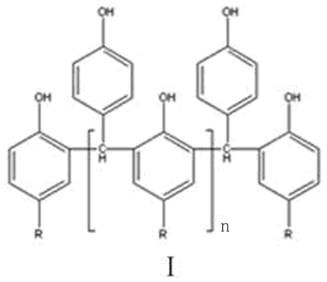

A kind of 4-tert-alkylphenol-(phenol-based) formaldehyde resin and its preparation method and application

ActiveCN109810231BImprove qualityIncrease the phenolic hydroxyl contentSocial benefitsPolymer science

Owner:SHANDONG YANGGU HUATAI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com