Modifier for reducing methyl mercury pollution in acidic rice field and method thereof

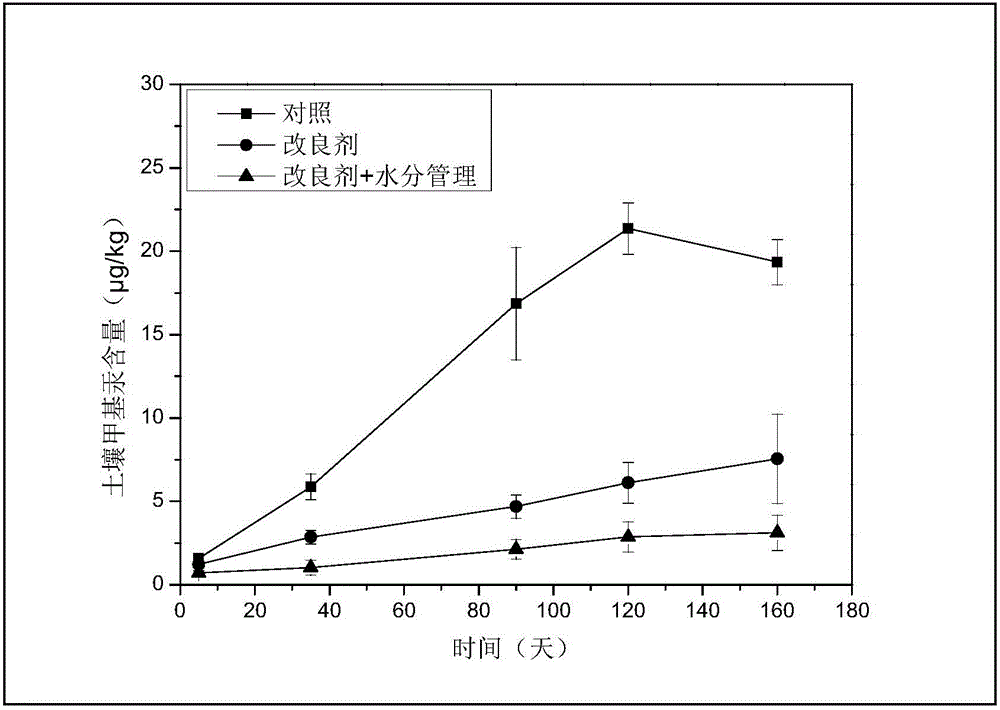

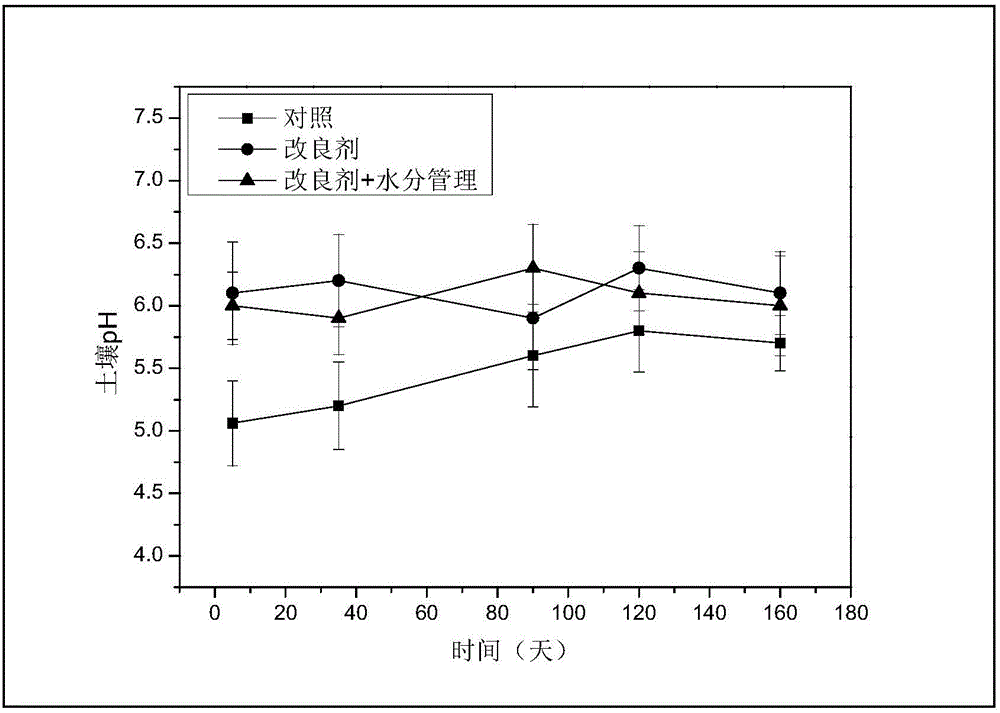

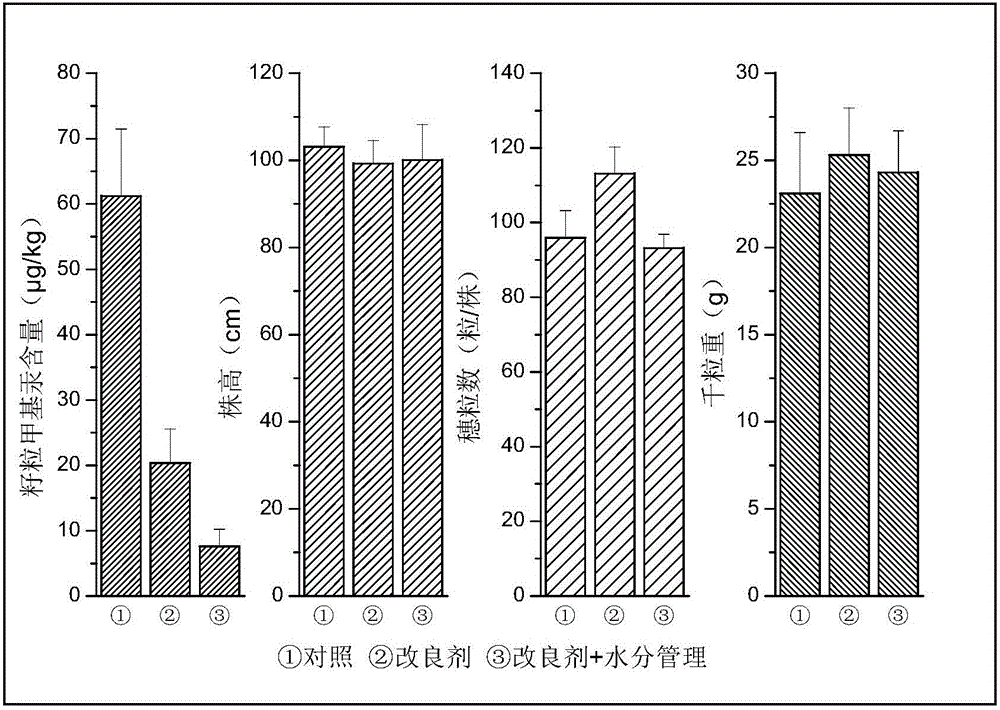

A technology of methylmercury and modifier, applied in the restoration of polluted soil, chemical instruments and methods, organic fertilizers, etc., can solve the problem of impossible to know the actual content of sulfate, difficult to meet the needs of pollution control, organic carbon production procedures Complicated problems, to achieve the effect of not reducing rice yield and plant biomass, reducing methylmercury content in rice, and improving soil pH and mercury adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: the improver that reduces acid rice field methylmercury pollution

[0045] The weathered coal was taken from an open-pit coal mine in Huozhou, Shanxi, with a humic acid content of 623g / kg and a Hg content of 0.012mg / kg.

[0046] Prepared by the following steps:

[0047] Remove sundries from the weathered coal, grind it and pass it through a 1mm sieve. According to the water-to-coal ratio (mass ratio) of 10:1, add clean water to the weathered coal powder, stir evenly, and in the treatment pool of an ultrasonic cleaning machine (KQ-500DE, Kunshan Ultrasonic Instrument Co., Ltd.), according to the ultrasonic power of 500W and ultrasonic time of 40 minutes for ultrasonic activation. After the activation is completed, air-dry the weathered pulverized coal at room temperature. Add 0.1mol / L HCl according to the volume ratio of 1:2, soak for 72 hours, fully stir or shake during soaking. The soaked material was filtered with a bamboo drying mat, rinsed with wat...

Embodiment 2

[0049] Embodiment 2: the improver that reduces acid rice field methylmercury pollution

[0050] The weathered coal was taken from the Guozhuang Coal Mine in Tengzhou, Shandong, with a humic acid content of 743g / kg and a Hg content of 0.016mg / kg.

[0051] Prepared by the following steps:

[0052] Remove sundries from the weathered coal, grind it and pass it through a 0.8mm sieve. According to the water-to-coal ratio (mass ratio) of 12:1, add clean water to the weathered coal powder, stir evenly, and in the treatment pool of an ultrasonic cleaning machine (KQ-500DE, Kunshan Ultrasonic Instrument Co., Ltd.), according to the ultrasonic power of 650W and ultrasonic time of 35 minutes for ultrasonic activation. After the activation is completed, air-dry the weathered pulverized coal at room temperature. Add 0.1mol / L HCl according to the volume ratio of 1:3, soak for 78 hours, fully stir or shake during soaking. The soaked material was filtered with a bamboo drying mat, rinsed r...

Embodiment 3

[0054] Embodiment 3: the improver that reduces acid rice field methylmercury pollution

[0055] The weathered coal was taken from Jinan Lifu Coal Mine, with a humic acid content of 574g / kg and a Hg content of 0.019mg / kg.

[0056] Prepared by the following steps:

[0057] Remove sundries from the weathered coal, grind it and pass it through a 1.5mm sieve. According to the water-to-coal ratio (mass ratio) of 9:1, add clean water to the weathered coal powder, stir evenly, and in the treatment pool of an ultrasonic cleaning machine (KQ-500DE, Kunshan Ultrasonic Instrument Co., Ltd.), according to the ultrasonic power of 450W and ultrasonic time of 50 minutes for ultrasonic activation. After the activation is completed, air-dry the weathered pulverized coal at room temperature. Add 0.1mol / L HCl according to the volume ratio of 1:1.5, soak for 70 hours, fully stir or shake during soaking. The soaked material was filtered with a bamboo drying mat, rinsed with water for 4 times re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com