Method for improving amination modification efficiency or phenolic hydroxyl group content of alkali lignin

A technology of alkali lignin and lignin amine, which is applied in the field of improving the reactivity of alkali lignin, can solve the problems of increased water pollution treatment pressure, does not conform to green environmental protection, is not green environmental protection, etc., and achieves improved amination efficiency and easy operation. , the effect of increasing the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

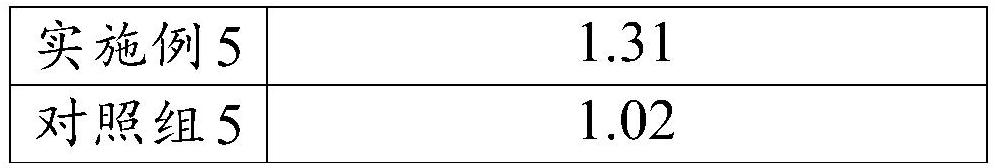

Embodiment 1

[0054] Get the alkali lignin (purity is 80%, water content is 3%, particle diameter is 100 orders, molecular weight is 4500) that wheat straw caustic soda anthraquinone method pulping black liquor extracts, adds deep eutectic solvent system (choline chloride / urea system) mixed evenly for heat treatment, adjusting the pretreatment temperature, stirring for a period of time, adding deionized water to terminate the reaction, followed by centrifugation and freeze drying to obtain the pretreated alkali lignin. Carry out vacuum distillation recovery deep eutectic solvent system (choline chloride / urea system). The treatment conditions are: the molar ratio of choline chloride and urea in the deep eutectic solvent system is 1:1.9, the purity of choline chloride is 90%, the purity of urea is 90%, and the choline chloride and urea are mixed evenly Then heat treatment, the mass volume ratio of alkali lignin and choline chloride / urea system is 1g:15mL, the pretreatment temperature is 55°C...

Embodiment 2

[0063] Get the alkali lignin (purity is 85%, water content is 2.6%, particle diameter is 120 orders, molecular weight is 4200) that poplar alkaline sulphite pulping black liquor extracts, adds deep eutectic solvent system (chole chloride Alkali / glycerin system) mixed evenly for heat treatment, adjusting the pretreatment temperature, stirring for a period of time, adding deionized water to terminate the reaction, and then centrifuging and freeze drying to obtain the pretreated alkali lignin. Carry out vacuum distillation recovery deep eutectic solvent system (choline chloride / glycerol system). The treatment conditions are: the molar ratio of choline chloride and glycerin in the deep eutectic solvent system is 1:2.5, the purity of choline chloride is 95%, the purity of glycerin is 95%, and the choline chloride and glycerin are mixed evenly Then heat treatment, the mass volume ratio of alkali lignin and choline chloride / glycerin system is 1g:25mL, the pretreatment temperature is ...

Embodiment 3

[0072] Take commercial alkali lignin (purity is 90%, water content is 4%, particle size is 100 mesh, molecular weight is 5000), add deep eutectic solvent system (choline chloride / acetic acid system) and mix evenly and heat treatment, Adjust the pretreatment temperature, stir for a period of time, add deionized water to terminate the reaction, and then perform centrifugation and freeze drying to obtain the pretreated alkali lignin. Carry out vacuum distillation recovery deep eutectic solvent system (choline chloride / acetic acid system). The treatment conditions are: the molar ratio of choline chloride and acetic acid in the deep eutectic solvent system is 1:2.6, the purity of choline chloride is 95%, the purity of acetic acid is 95%, and the choline chloride and acetic acid are mixed evenly Then heat treatment, the mass volume ratio of alkali lignin and choline chloride / acetic acid system is 1g:20mL, the pretreatment temperature is 65°C, the pretreatment time is 60min, the spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com