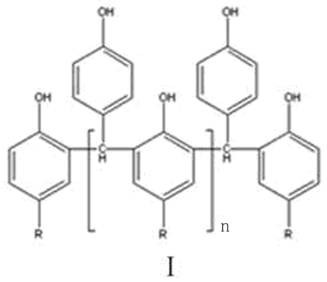

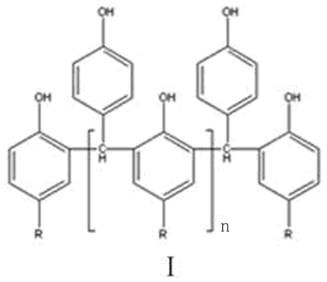

A kind of 4-tert-alkylphenol-(phenol-based) formaldehyde resin and its preparation method and application

A technology of tertiary alkylphenol and phenolic resin, which is applied in the field of phenolic resin, can solve problems such as decreased adhesion, poor production safety, high temperature and high pressure required for production, etc., achieves improved initial viscosity and sticky durability, high safety, and improved production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

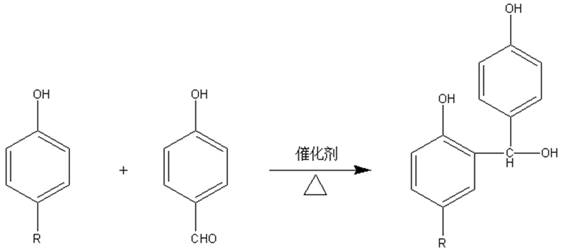

Method used

Image

Examples

Embodiment 1

[0046] Weigh 158.13g of 95 wt% p-tert-butylphenol, 103.8g of 99.7 wt% p-hydroxybenzaldehyde and 300g of toluene into the reaction kettle, raise the temperature to dissolve the raw materials, add 4.7g of oxalic acid and stir evenly. Reflux condensation reaction for 2.5 hours, add liquid caustic soda to neutralize to neutrality, then raise the temperature to distill out toluene and water, basically anhydrous and then raise the temperature to 160-180°C for polycondensation reaction, the polycondensation reaction time is 2.5 hours, after the reaction Pour out the product in the reaction kettle, and cool to obtain the 4-tert-alkylphenol-(phenol-based) formaldehyde resin of the present invention. The softening point detected by the ring and ball softening point instrument is 142 ° C, and the free phenol detected by the high performance liquid chromatography is 0.08 %, the weight average molecular weight detected by gel chromatography is 1240.

Embodiment 2

[0048] Weigh 158.13g of 95 wt% p-tert-butylphenol, 97.7g of 99.7 wt% p-hydroxybenzaldehyde and 270g of toluene into the reaction kettle, heat up to dissolve the raw materials, add 3.2g of concentrated sulfuric acid and stir evenly, at 98~102℃ Under reflux condensation reaction for 2.0 hours, add liquid caustic soda to neutralize to neutrality, then raise the temperature to distill toluene and water out, basically anhydrous and then raise the temperature to 150-170°C for polycondensation reaction, the polycondensation reaction time is 2.0 hours, the reaction After that, the product in the reaction kettle is poured out, cooled to obtain the 4-tert-alkylphenol-(phenol-based) formaldehyde resin of the present invention, and the softening point is 134°C as detected by a ring and ball softening point instrument, and the free phenol is detected by a high-performance liquid chromatography. It was 0.13%, and the weight average molecular weight detected by gel chromatography was 970.

Embodiment 3

[0050] Weigh 158.13g of 95 wt% p-tert-butylphenol, 109.91g of 99.7 wt% p-hydroxybenzaldehyde and 350g of toluene into the reaction kettle, heat up to dissolve the raw materials, add 3.5g of p-toluenesulfonic acid and stir evenly, at 100~ Reflux condensation reaction at 105°C for 3.5 hours, then raise the temperature to distill out toluene and water, then heat up to 160-180°C for polycondensation reaction, the reaction time is 3.5 hours, after the reaction is completed, the product in the reactor is Pour out and cool to obtain 4-tert-alkylphenol-(phenol-based) formaldehyde resin of the present invention. The softening point detected by the ring and ball softening point instrument is 141° C., and the free phenol detected by high performance liquid chromatography is 0.10%. Instrument detection weight average molecular weight is 1580.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com