Alkali lignin modified sulfamate high-effective water reducer and preparation method thereof

A technology of sulfamate and high-efficiency water reducer, which is applied in the field of sulfamate high-efficiency water reducer, can solve the problems of unfavorable durability of concrete, many bleeding channels of concrete, poor water retention of concrete, etc., and achieve slump The effect of small loss over time, easy availability of raw materials, and large slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

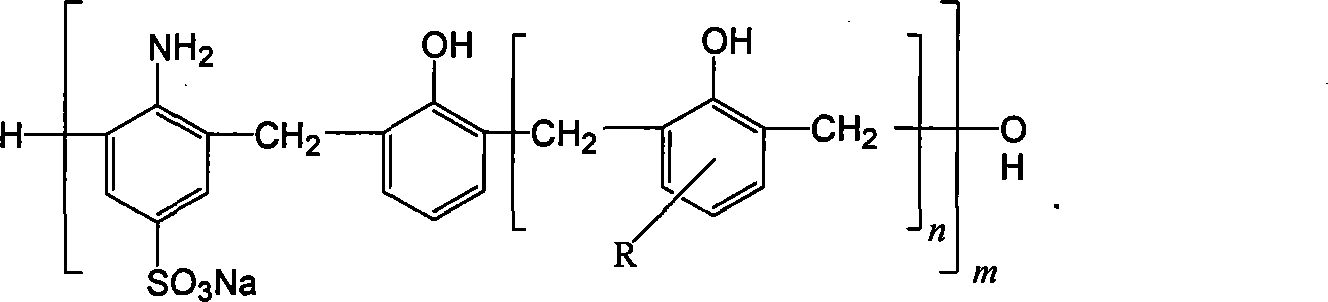

Image

Examples

Embodiment 1

[0033] Example 1: First, take 200g of acid-analyzed alkali lignin, 200g of phenol and 2000g of water and mix well, adjust the pH value of the system to 8.0 with 30g of sodium hydroxide and 10g of potassium hydroxide, heat to 90°C while stirring, and react for 1.0h ; Then add 20g of sodium hydroxide, adjust the pH of the system to 10.0, add 200g of sodium p-aminobenzenesulfonate, 100g of sodium methylsulfanilate, react at 60°C for 1.0h; finally raise the temperature to 95°C, add formaldehyde dropwise (37% solution) 1000g, continue to react for 5 hours after dripping, then cool down and discharge to obtain superplasticizer liquid product, and then dry to obtain powdery product.

Embodiment 2

[0034] Example 2: First, take 400g of acid-analyzed alkali lignin, 200g of phenol, 100g of α-naphthol and 2500g of water and mix well, adjust the pH value of the system to 10.0 with 60g of sodium hydroxide, heat to 95°C while stirring, and react 0.5 h; then add 30g of sodium hydroxide, adjust the pH of the system to 11.0, add 900g of sodium diaminobenzenesulfonate, and react at 70°C for 0.5h; finally heat up to 85°C, dropwise add formaldehyde (37% solution) 1000g and more 200g of polyoxymethylene, continue to react for 6 hours after dropping, then cool down and discharge to obtain liquid product of high-efficiency water reducer, and then dry to obtain powder product.

Embodiment 3

[0035] Example 3: Take 300g of acid-analyzed alkali lignin, 200g of mixed cresols, 200g of bisphenol A and 1500g of water and mix well, adjust the pH value of the system to 9.0 with 20g of sodium hydroxide, 20g of triethanolamine, and 10g of diethanolamine, while stirring Heat to 80°C, react for 2.0h; then add 30g of triethanolamine, adjust the pH of the system to 10.0, add 300g of sodium diaminobenzenesulfonate, 200g of sodium methylaminobenzenesulfonate, and 100g of sodium p-aminobenzenesulfonate, at 80 React at ℃ for 0.8h; finally raise the temperature to 95℃, add dropwise 200g of formaldehyde (37% solution), 200g of acetaldehyde, and 200g of furfural. Powdered product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com