Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Improve water management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

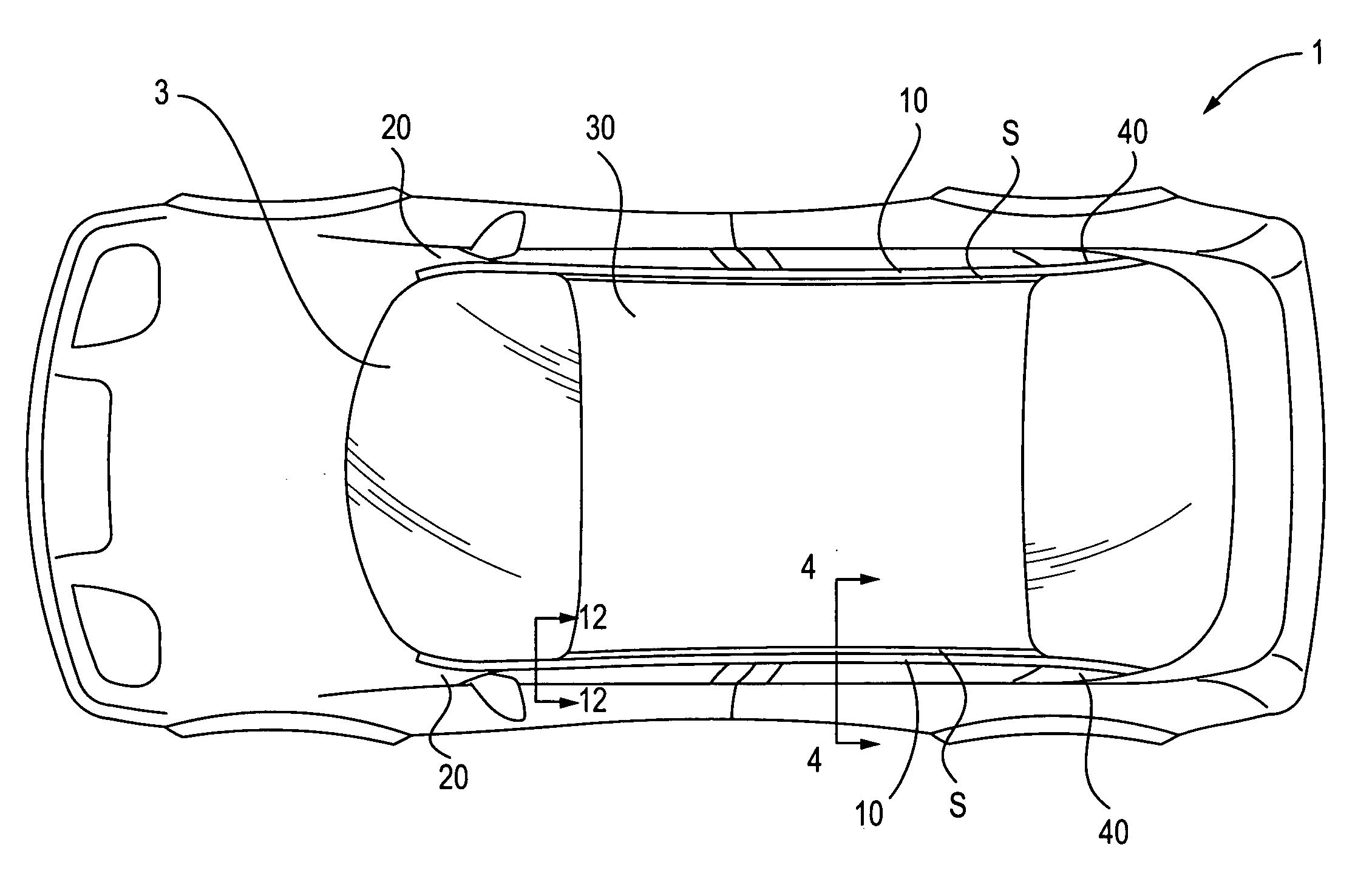

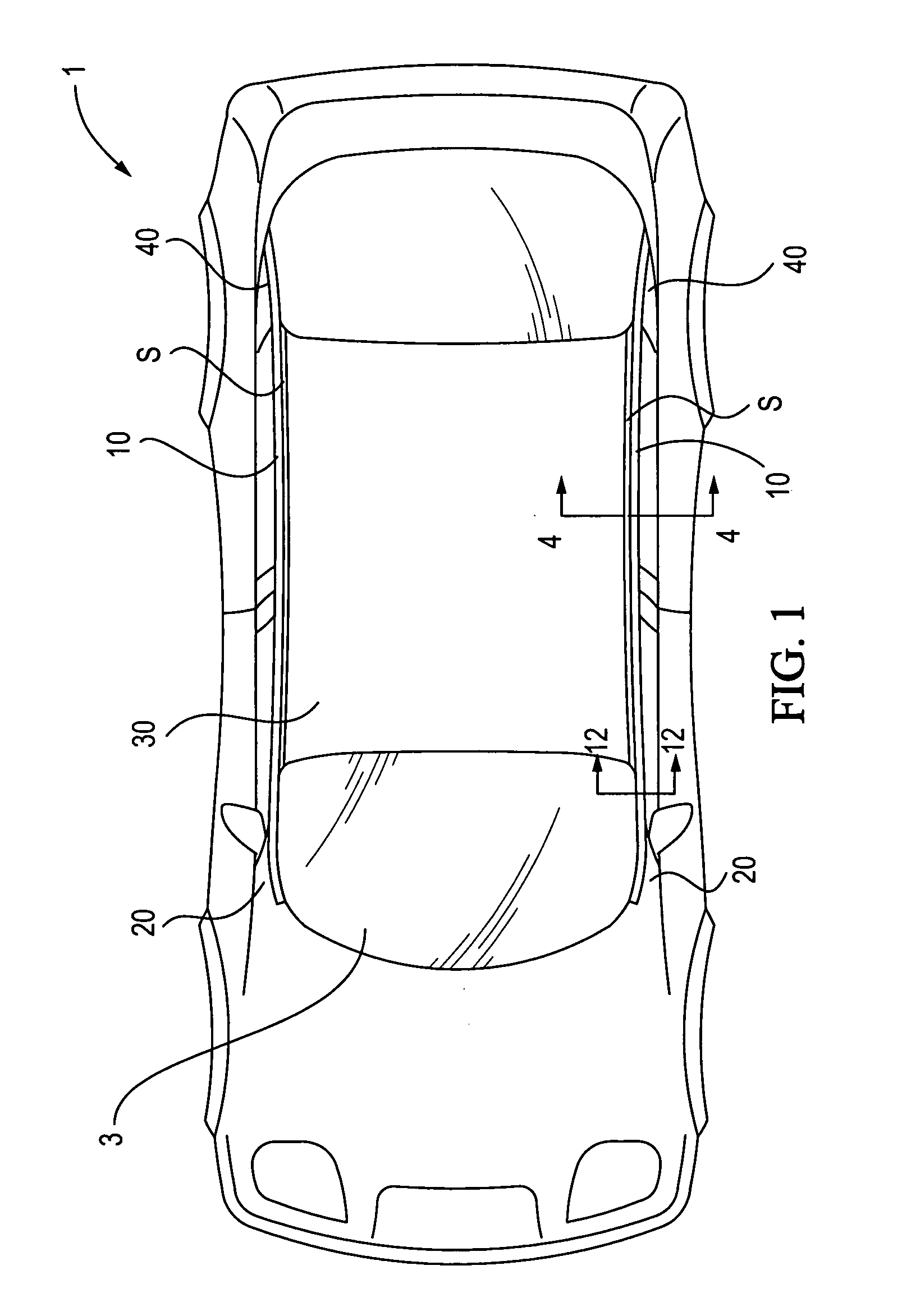

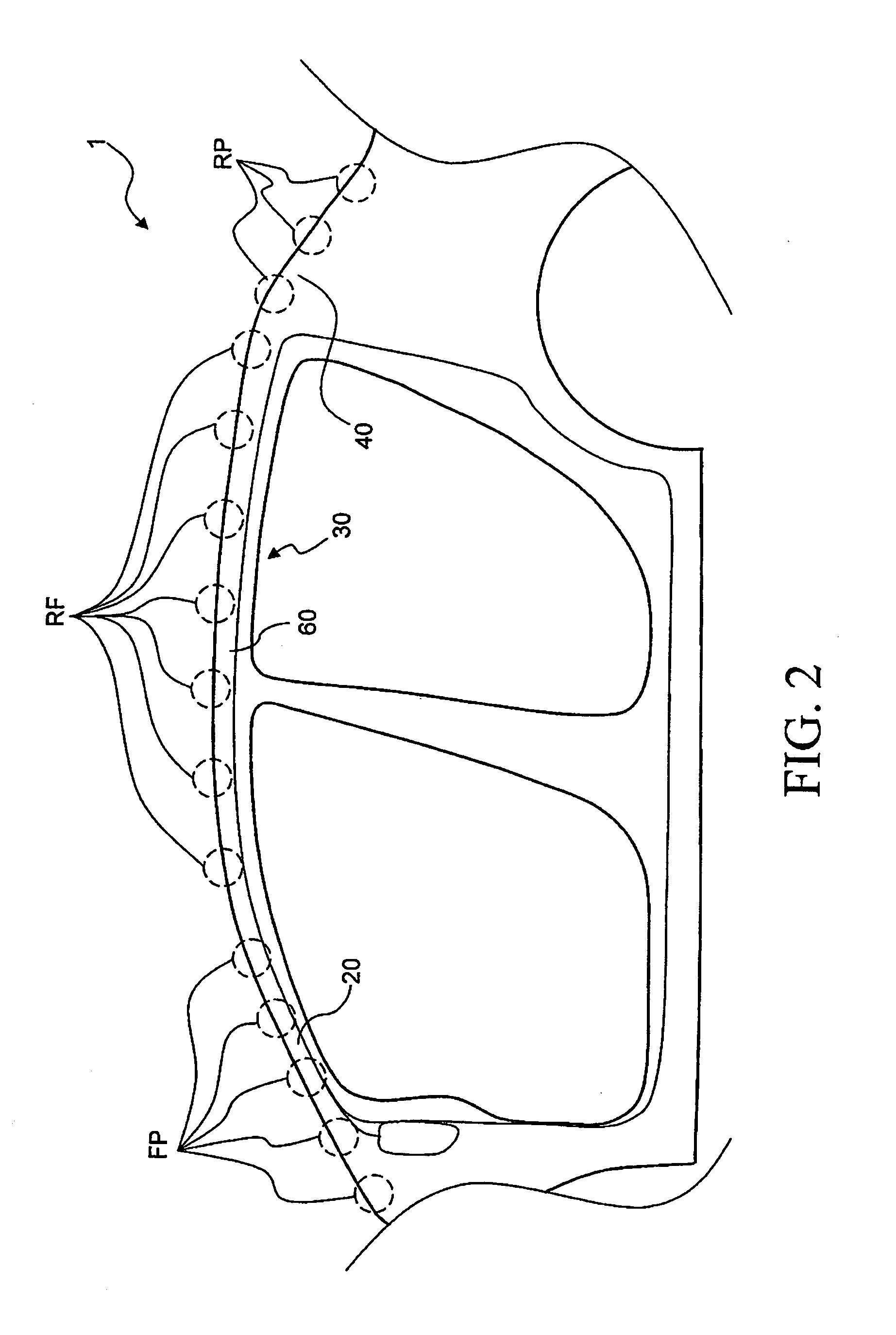

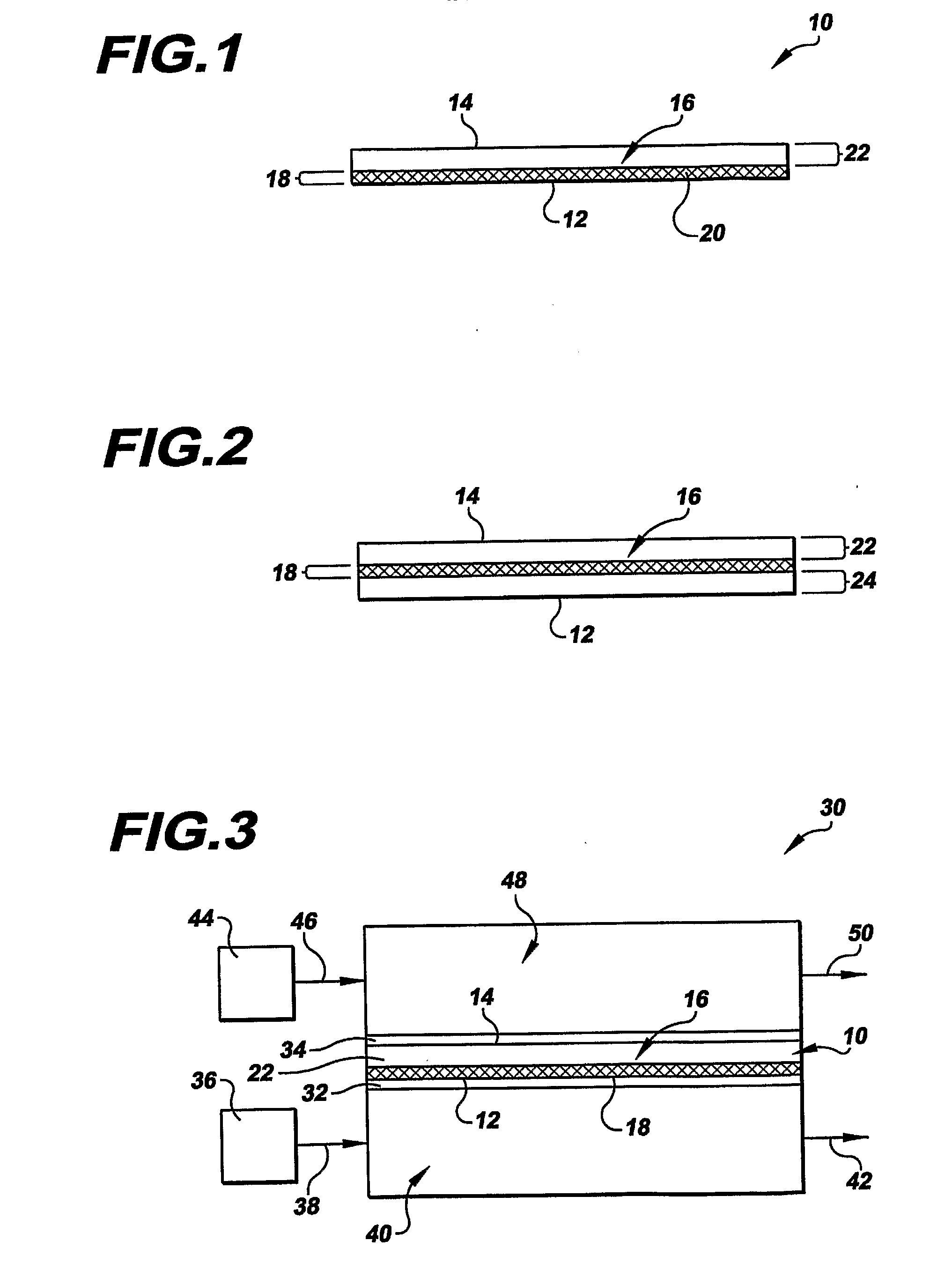

Roof ditch molding structure

ActiveUS7029060B1Good lookingImprove water managementVehicle seatsSuperstructure subunitsDitchEngineering

A roof ditch molding structure is provided with a body member having a drainage groove that receives a roof ditch molding which is preferably coupled thereto by a double sided tape formed of thermally cured urethane. The roof ditch molding has a rigid carrier member and a resilient cover member that substantially covers an outer surface of the carrier member. The rigid carrier member has a first transverse free end disposed between first and second vertical portions of the body member, and a second transverse free end disposed between the first transverse free end and the second vertical portion of the body member. The first transverse free end has a step portion extending substantially toward the second vertical portion of the body member. The cover member has first and second lip portions extending from the first and second transverse free ends of the carrier member, respectively, to form seals between the roof ditch molding and the drainage groove.

Owner:NISSAN MOTOR CO LTD

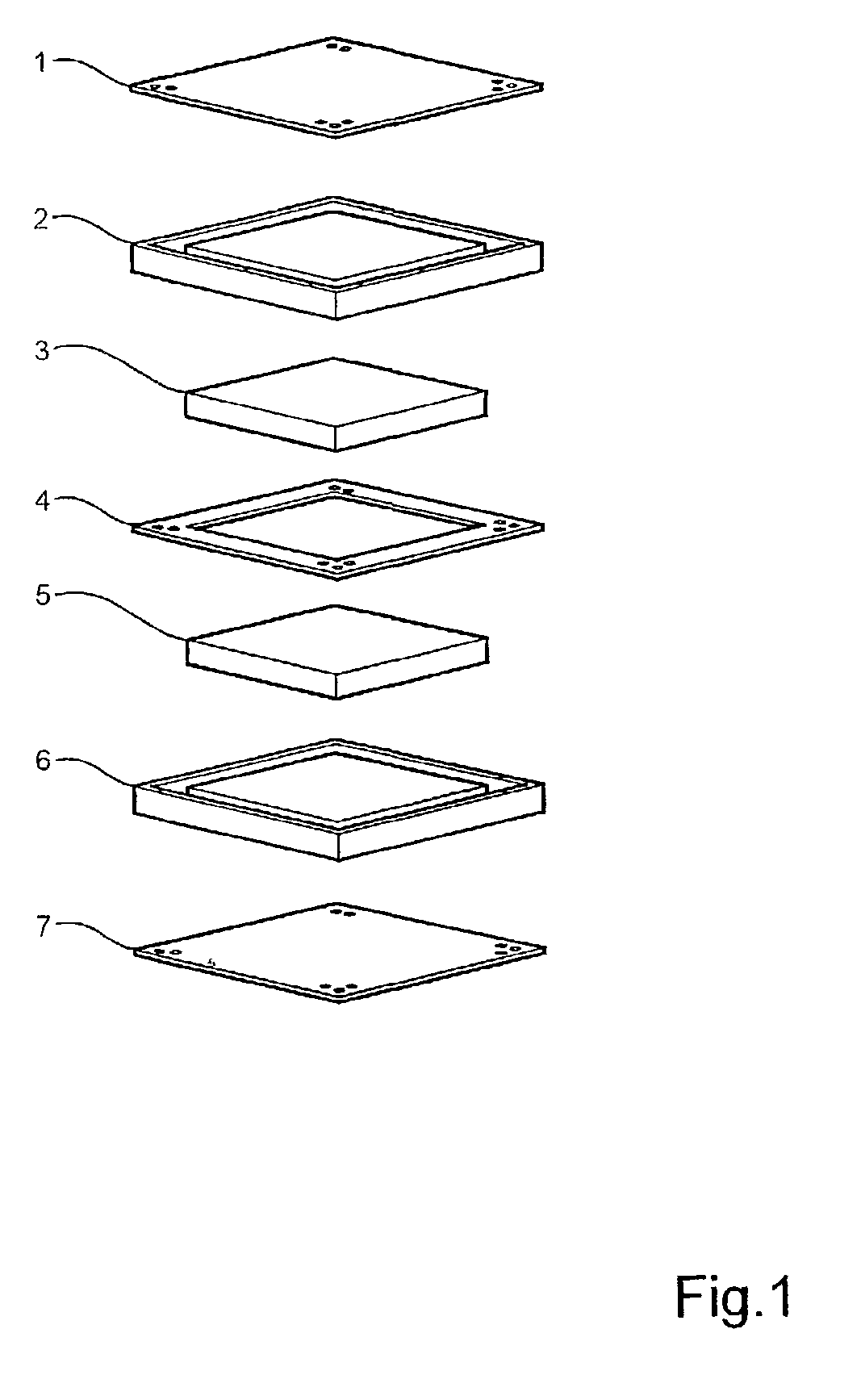

Water management in a direct methanol fuel cell system

ActiveUS20050008923A1Avoids bulky and power consumingImprove efficiencyRegenerative fuel cellsFuel cell auxillariesFuel cellsWater vapor

A compact water management module for a direct methanol fuel cell (DMFC) system is provided. The module is a set of plates, typically two or more plates. Two of the plates are sandwiched together and enclose a membrane. The membrane is permeable to air or to water vapor. In another embodiment, both membranes are utilized. The cathode output stream of the DMFC stack feeds into one of the plates. One output of the module is water that is re-used as anode input stream to the DMFC stack. Another output of the module is the unused air that is vented out. The module is an elegant solution that improves the overall efficiency of a DMFC system. In addition, the module is small in size and can easily be stacked and integrated with a DMFC stack, a mixing device, a carbon dioxide separation device and / or a methanol source.

Owner:OORJA CORP

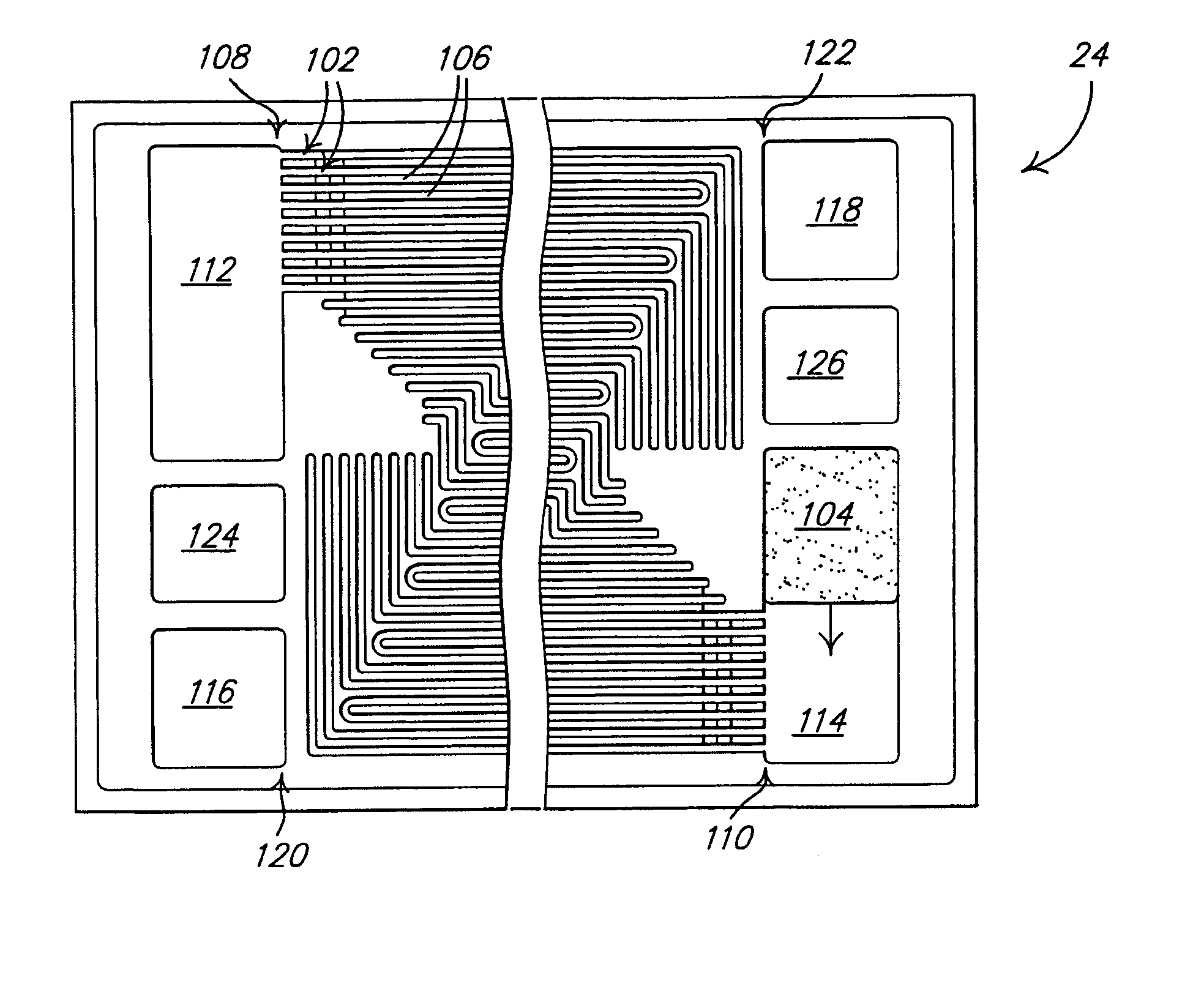

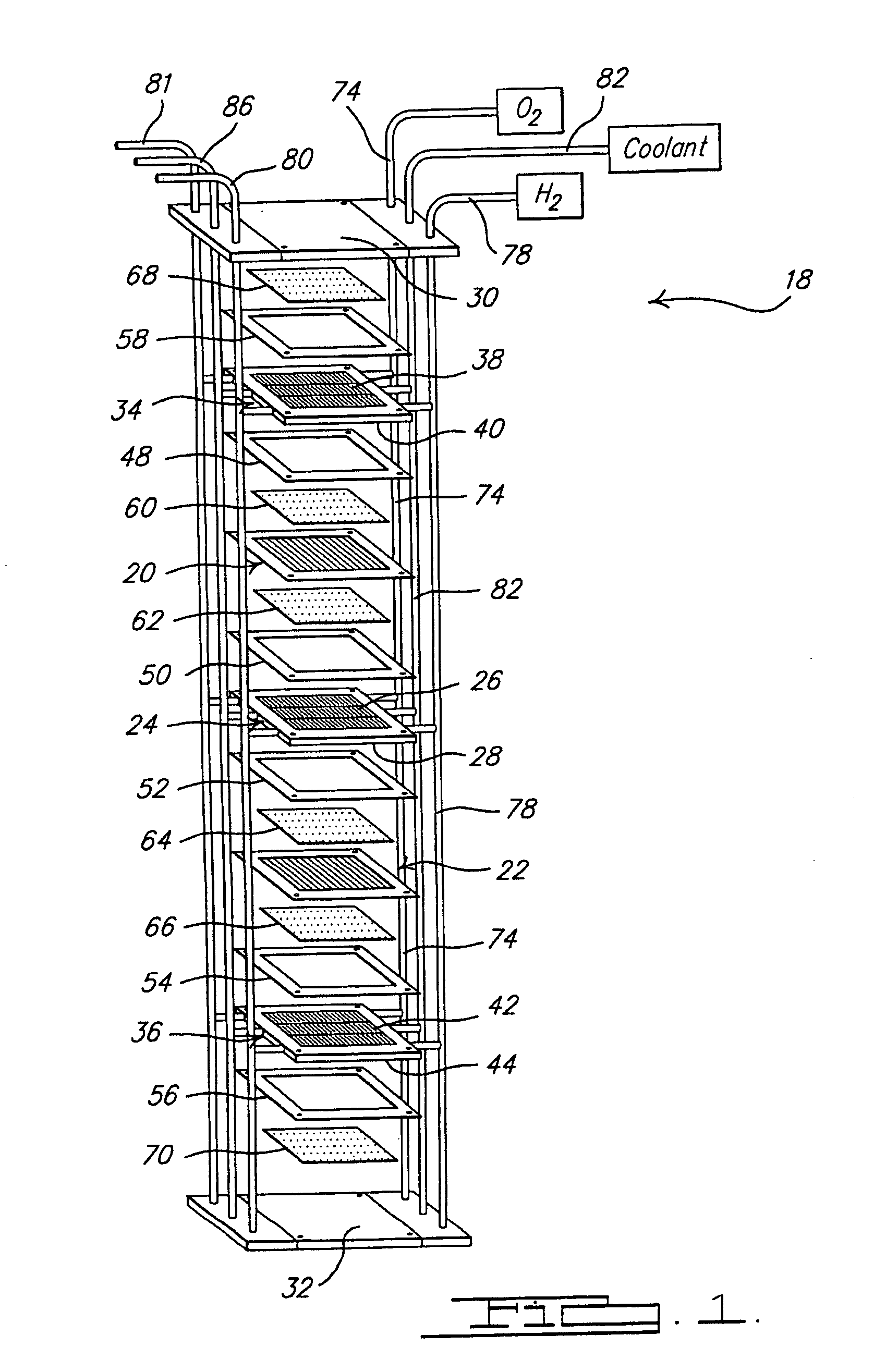

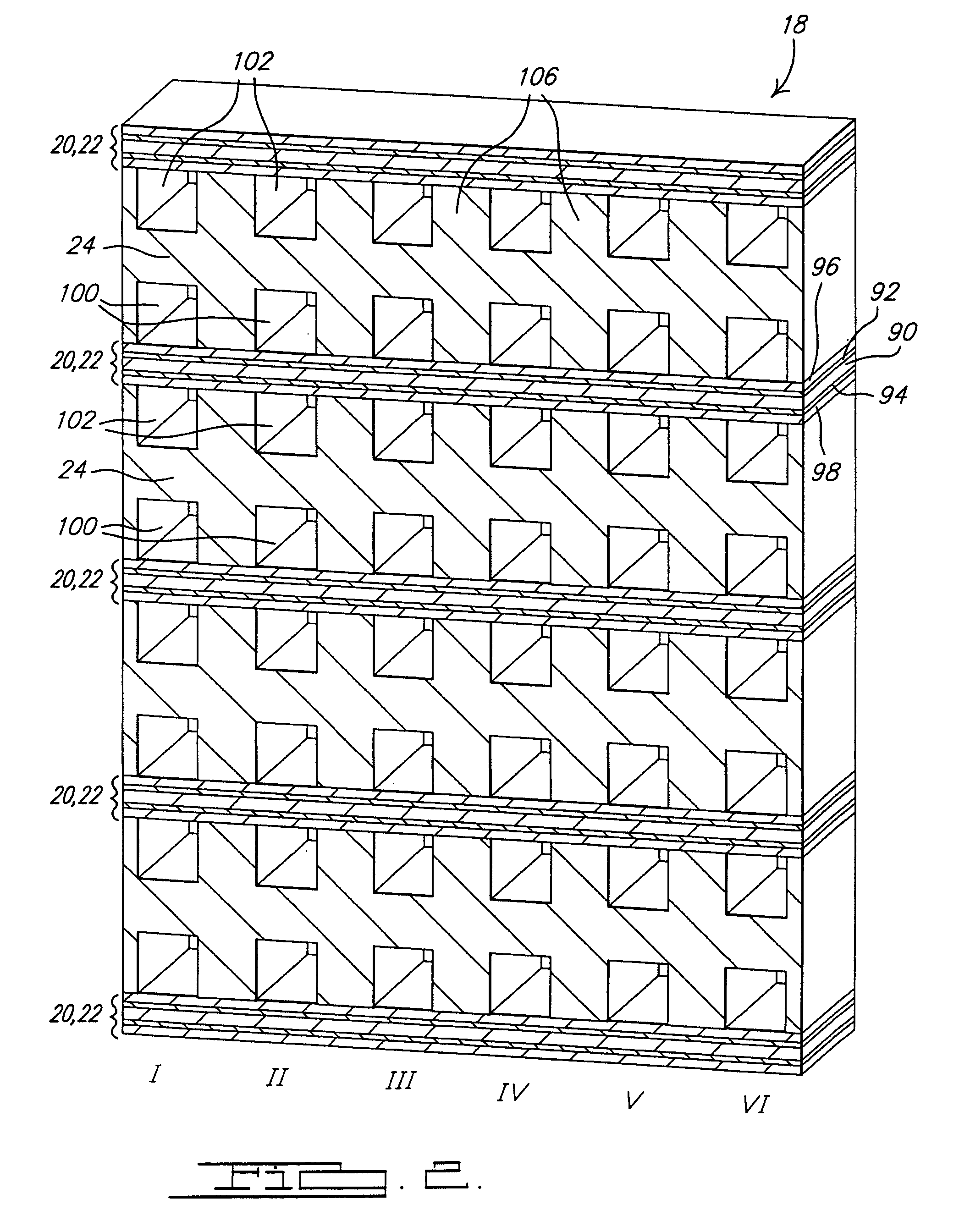

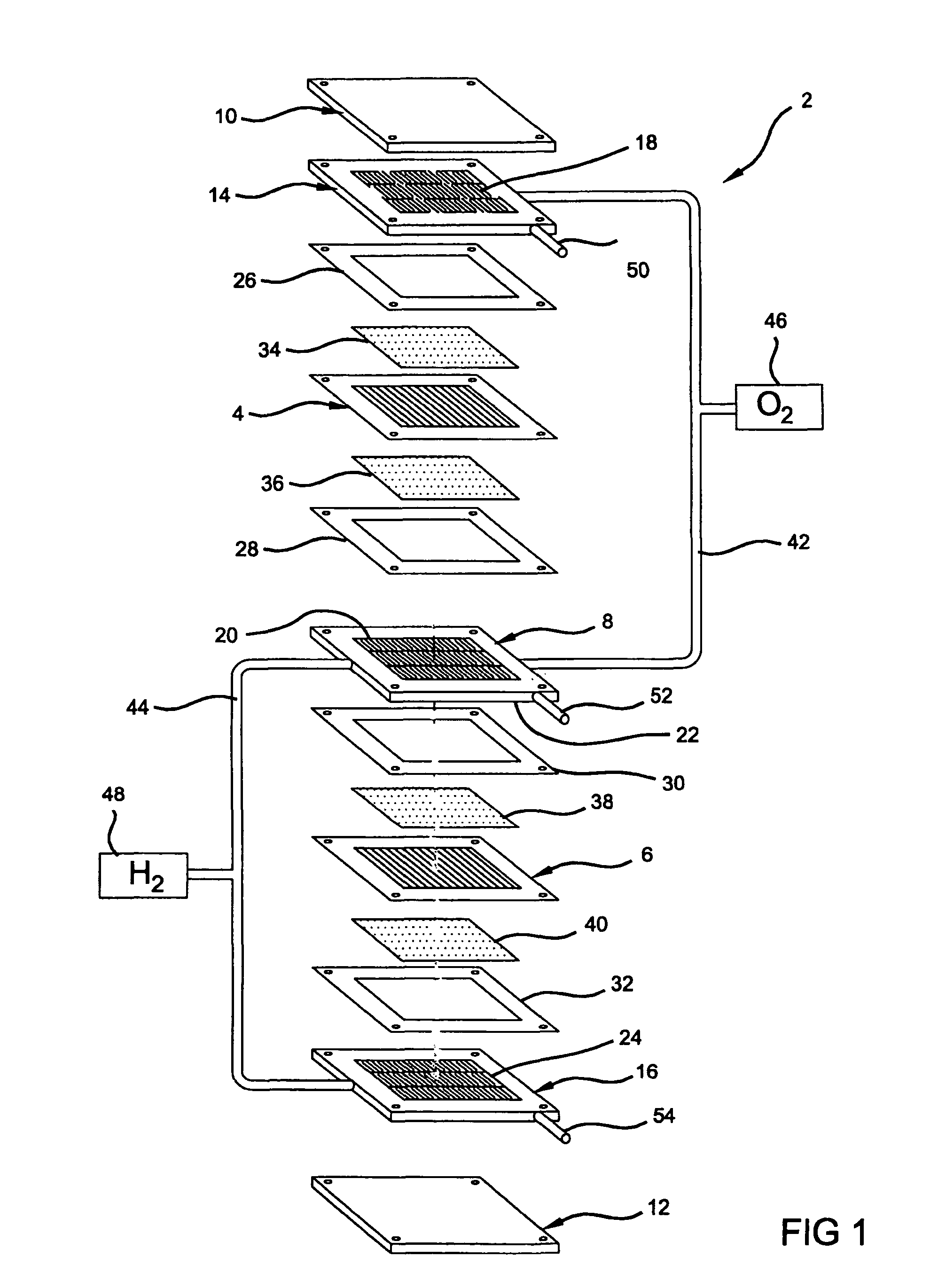

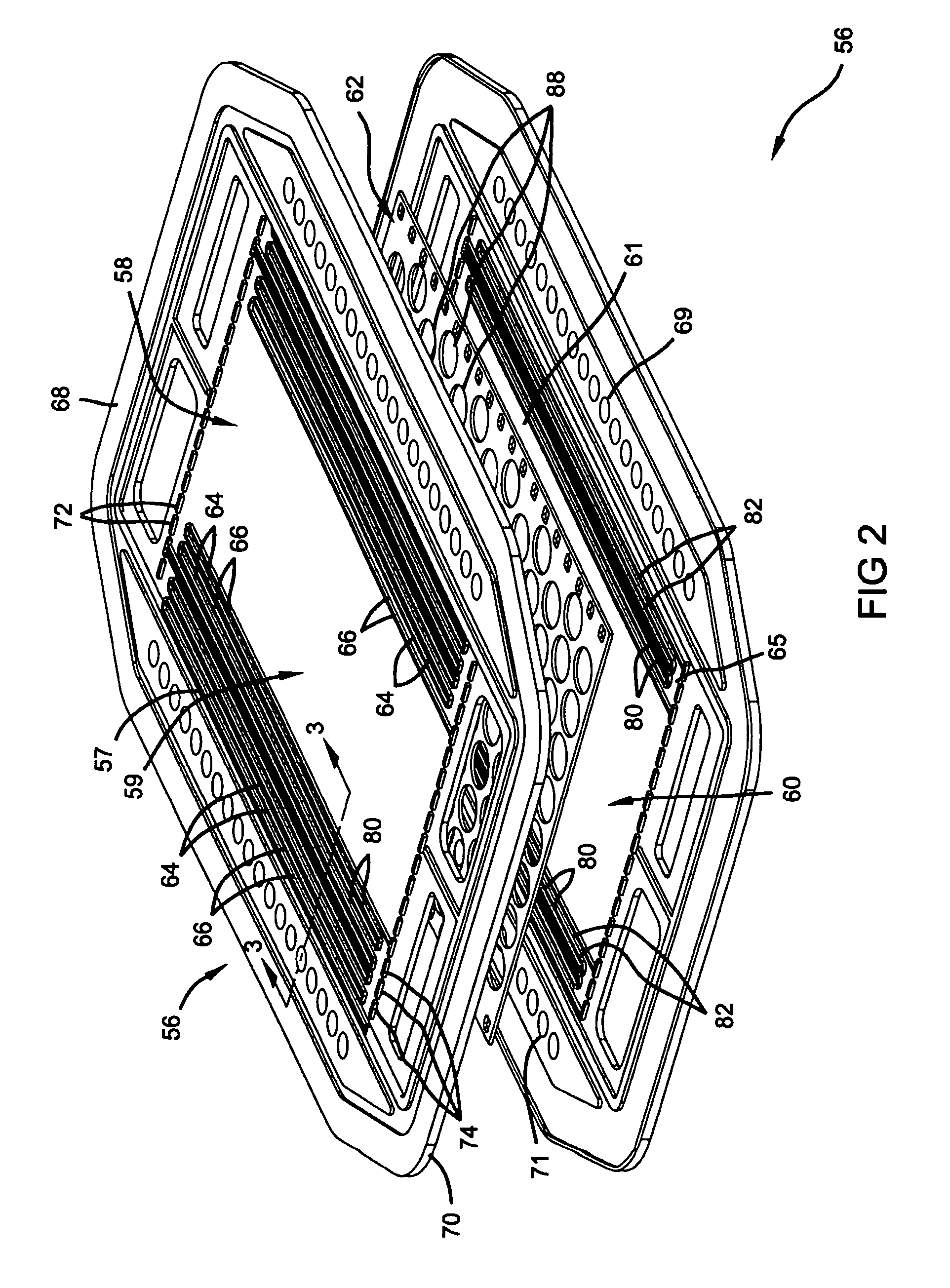

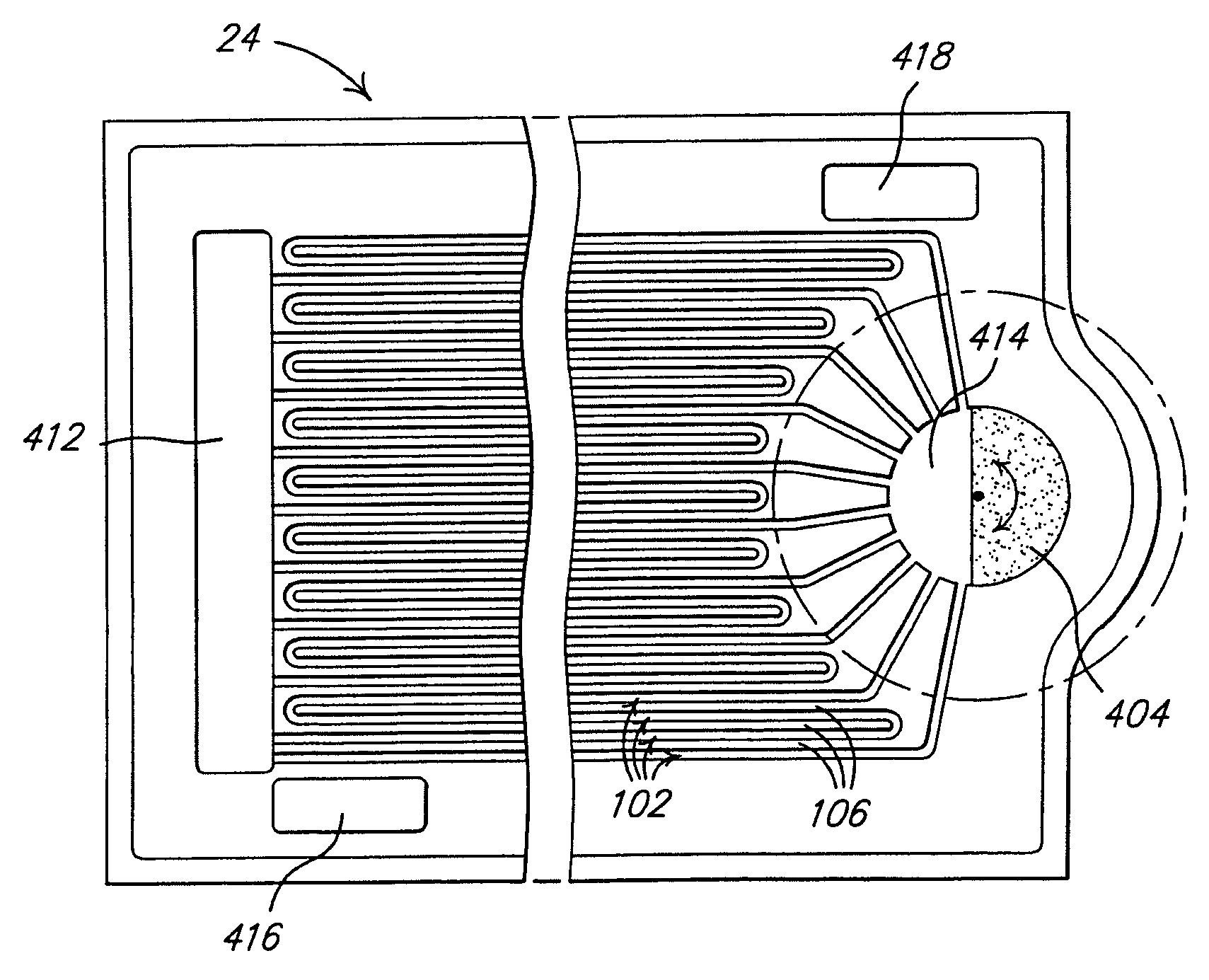

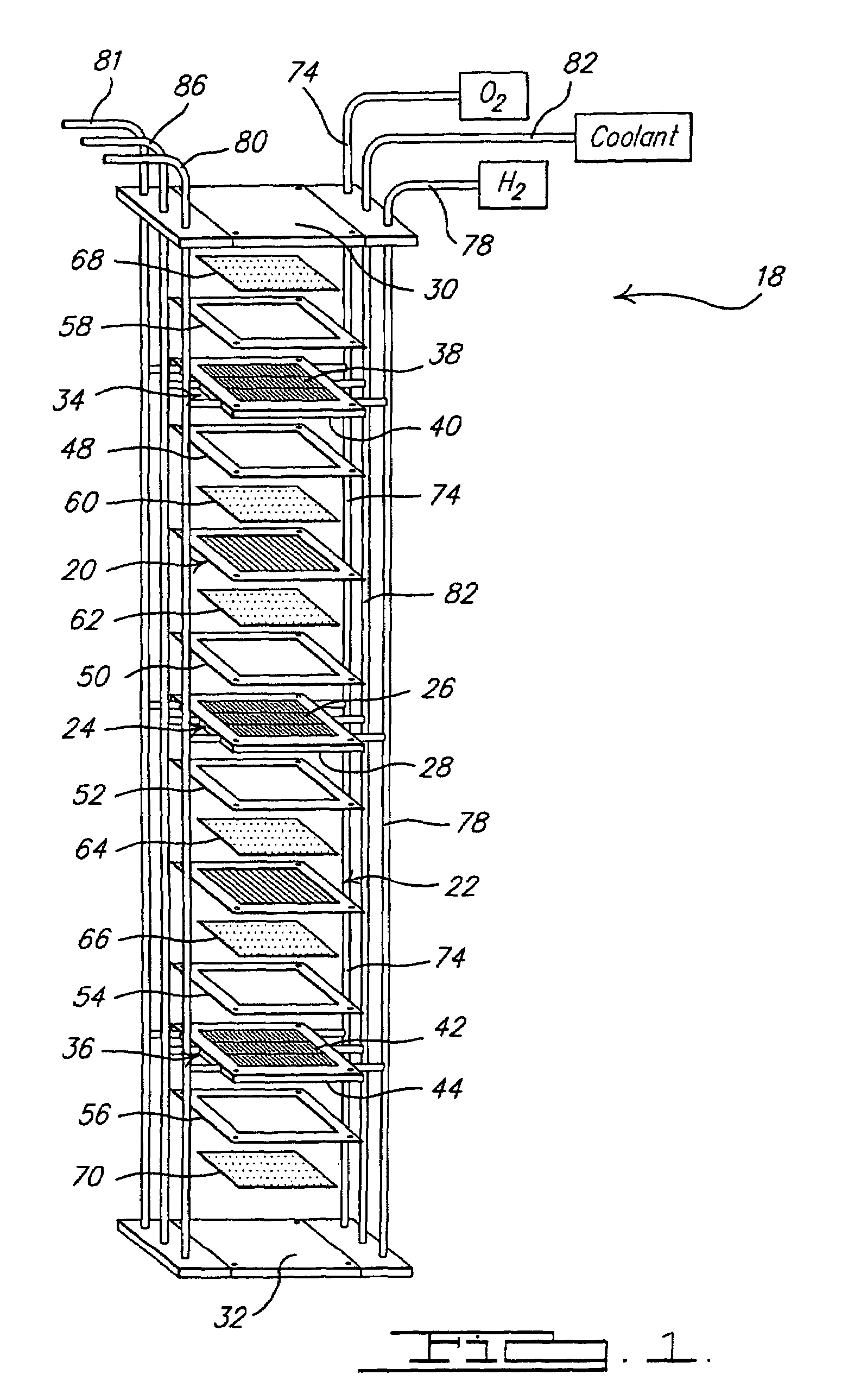

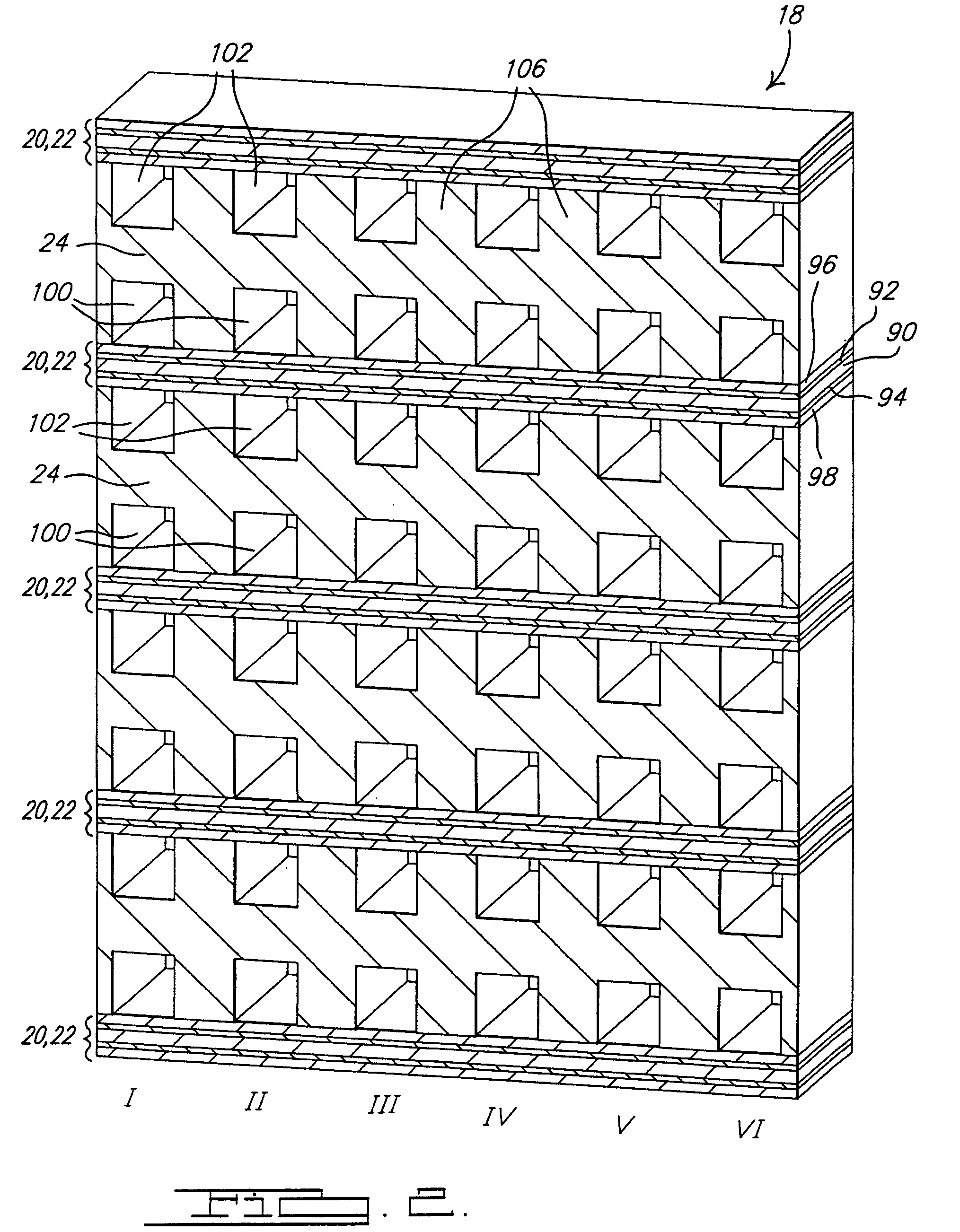

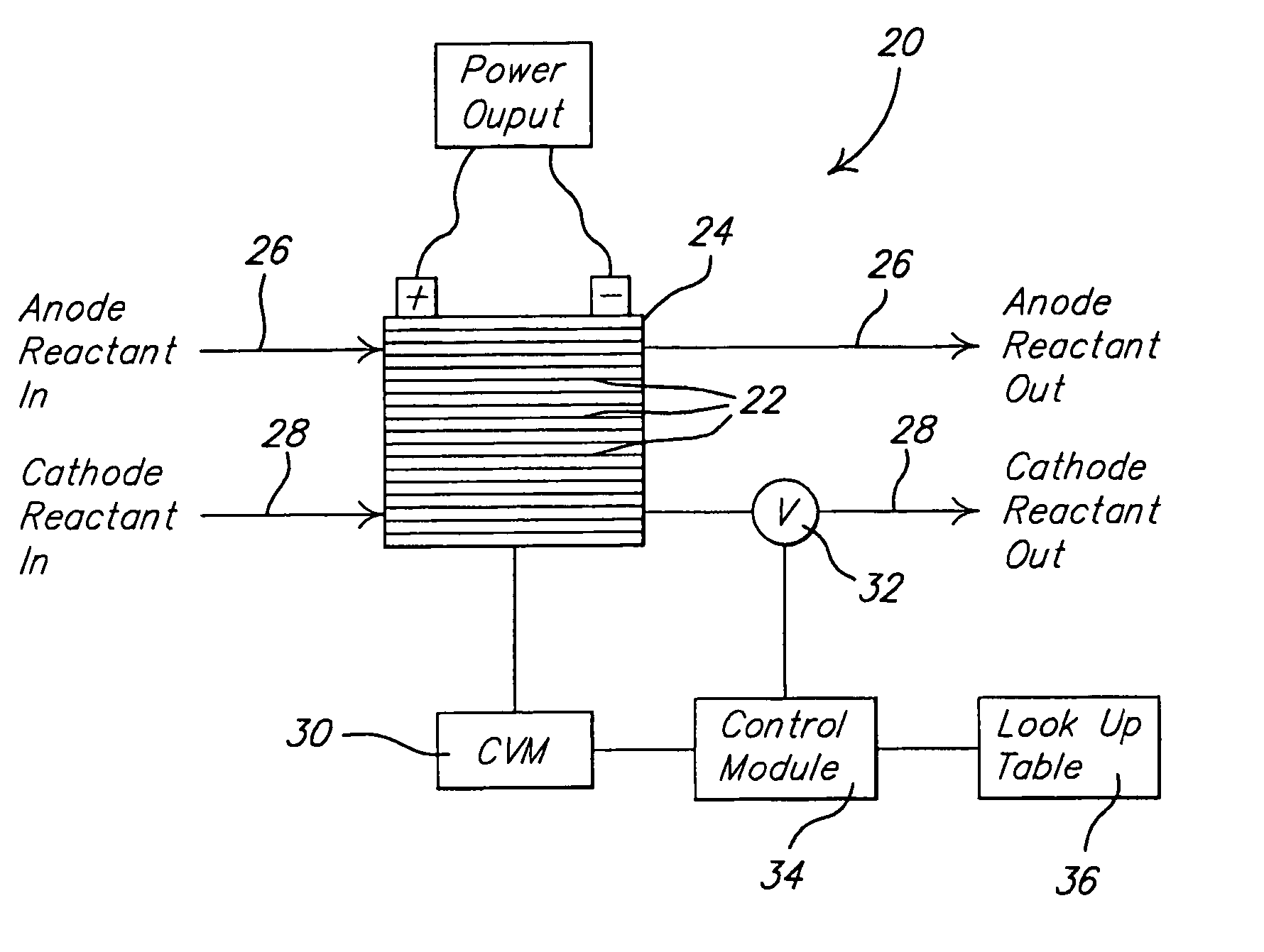

Variable active area for fuel cell

InactiveUS20050255366A1Improve water managementFuel cells groupingFuel cell auxillariesFuel cellsCathode

An electrochemical fuel cell stack assembly having a variable active area. The fuel cell stack uses a blocking member to selectively block the flow of reactants through channels of the flow fields of the anode and / or cathode flow paths. Blocking portions of the flow paths allows the fuel cell stack to maintain reactant flow velocities in a desired predetermined range. This enables the control and variation of the active area of the fuel cell, enhancing water management of the fuel cell stack.

Owner:GM GLOBAL TECH OPERATIONS LLC

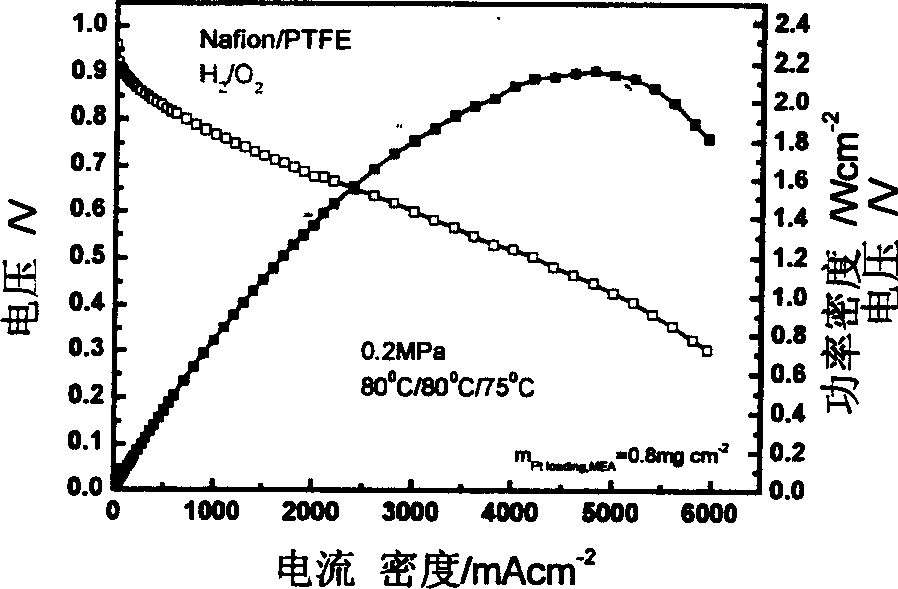

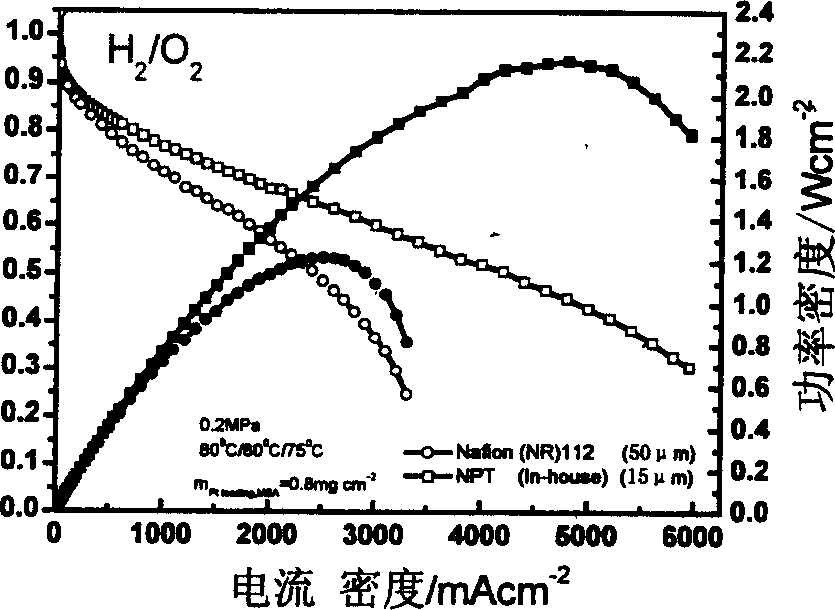

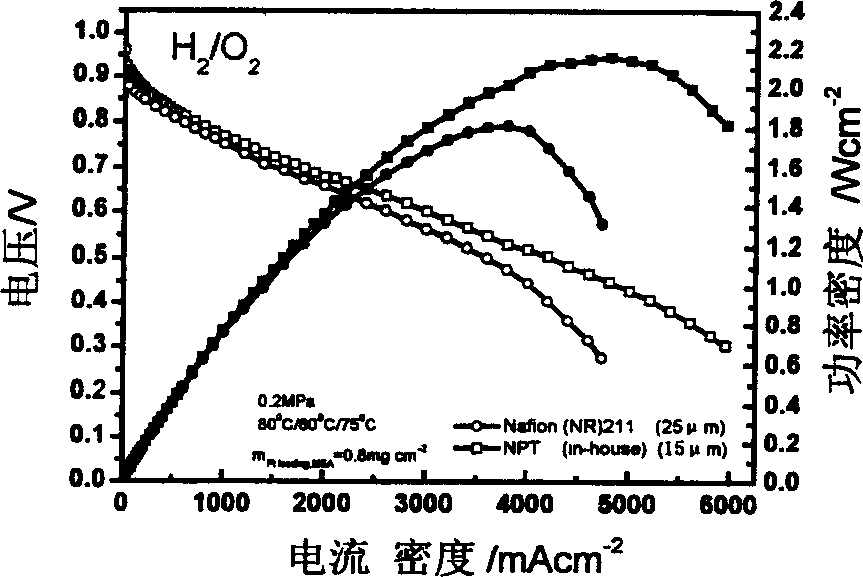

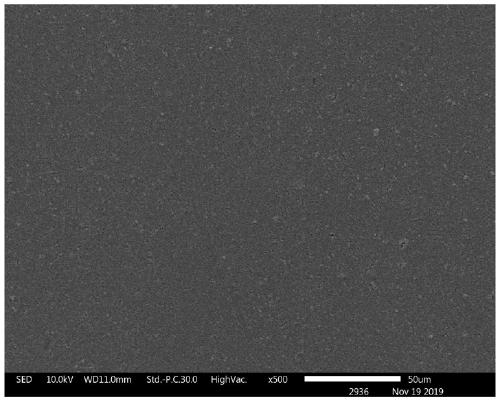

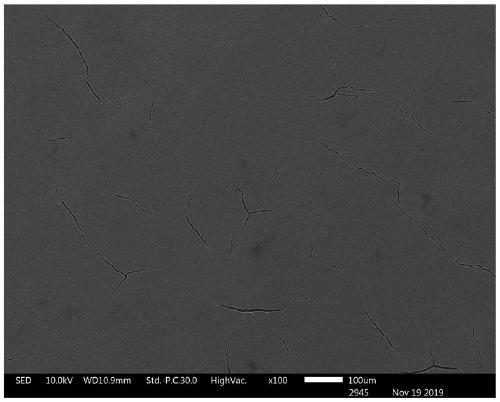

Composite proton exchange membrane synthesizing method for fuel cell

ActiveCN1845363AThe synthesis method is simpleSimple methodCell electrodesElectrolysisSynthesis methods

The related synthesis method for composite proton exchange membrane on fuel cell comprises: taking surface modification to the porous teflon membrane to reduce water contact angle and enhance wettability, and dipping into mid / low-boiling point solvent for standby; sealing and heating the solid macromolecular electrolyte with high-boiling point solvent, and adding mid / low boiling point solvent to prepare solution; casting on the film, and heating to volatilize the solvent for crystallizing heat treatment. This invention has well physical and chemical performance.

Owner:SUNRISE POWER CO LTD

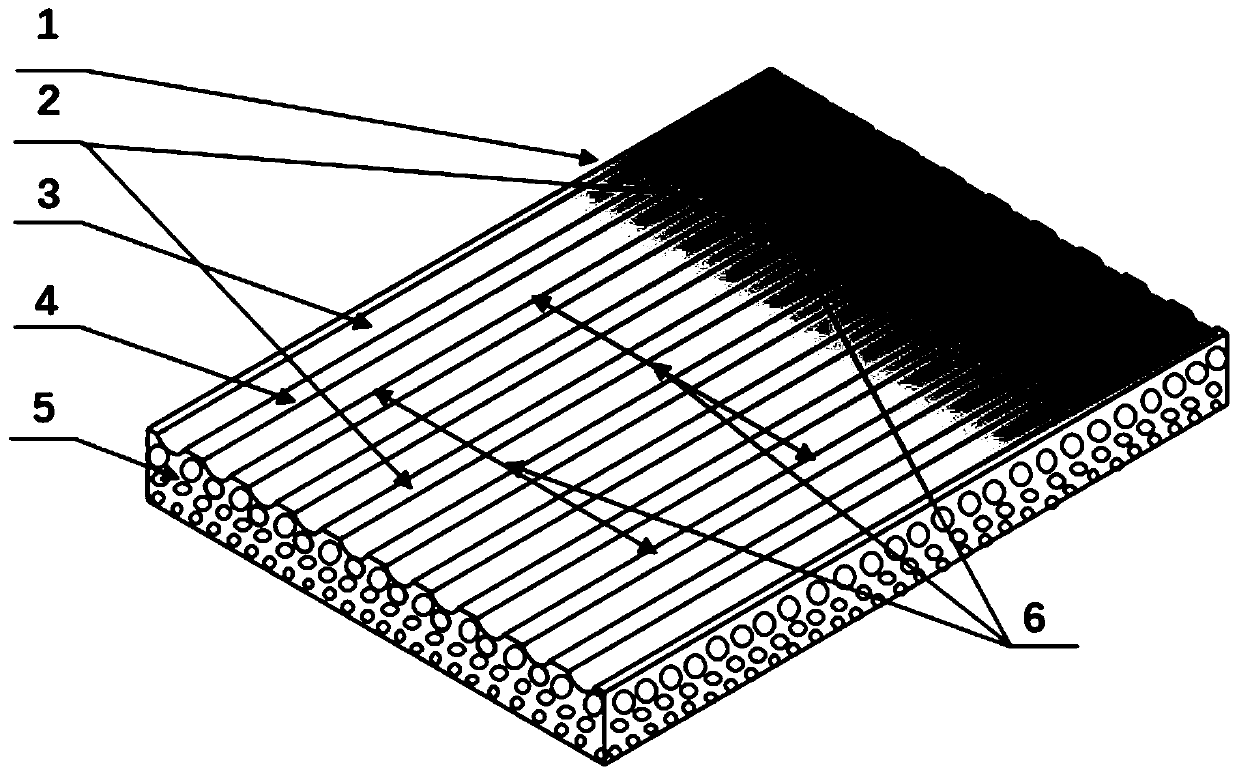

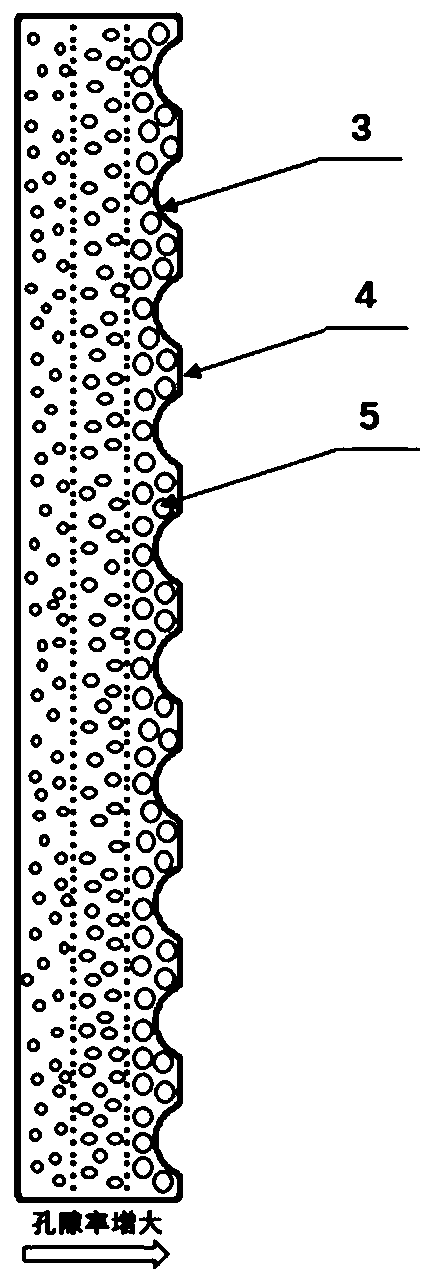

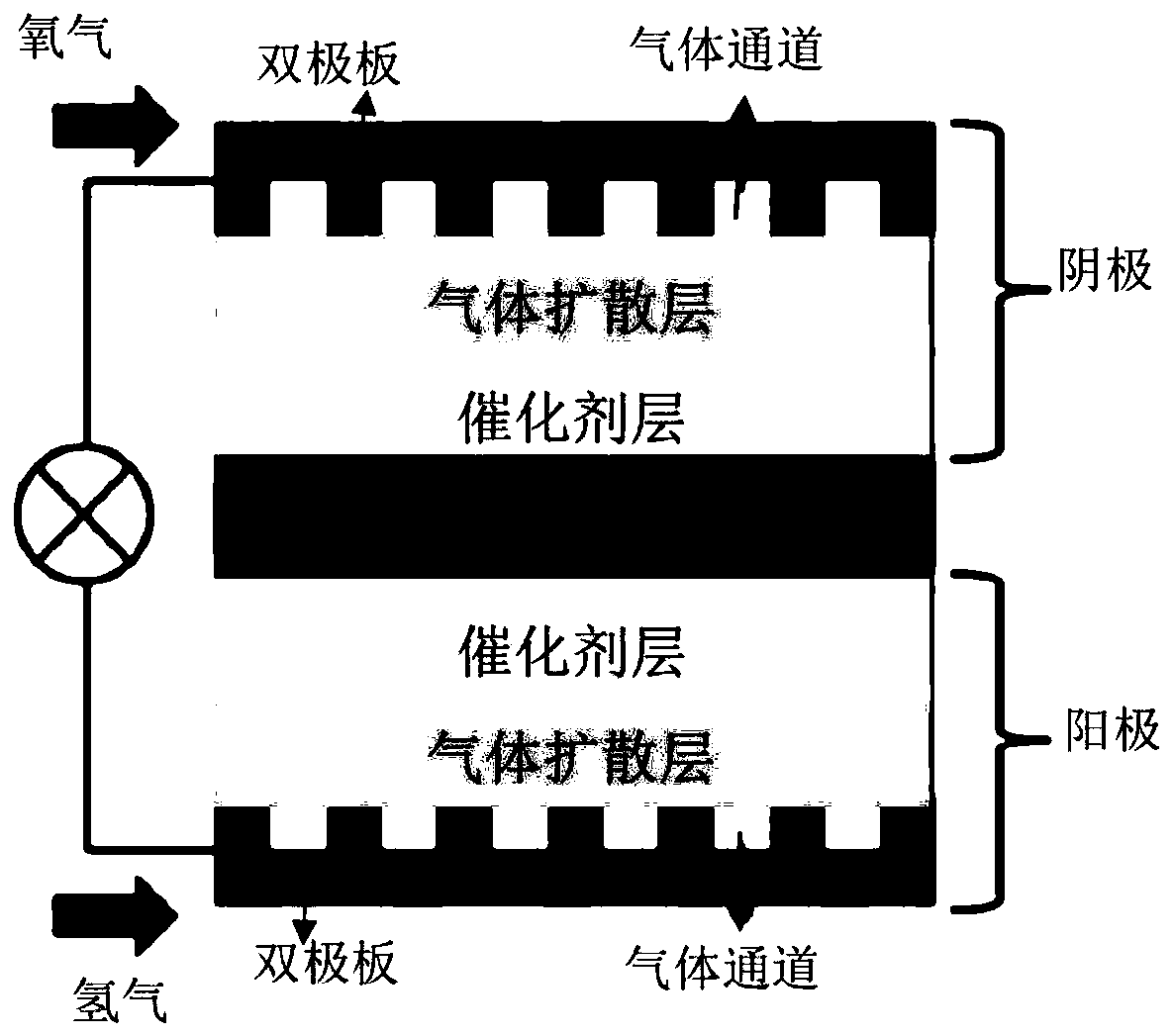

Gas diffusion layer of proton exchange membrane fuel cell

ActiveCN110112425AOptimal water and thermal managementEnsure consistencyCell electrodesFuel cellsThermal conductivityChemistry

The invention relates to a gas diffusion layer of a proton exchange membrane fuel cell. The gas diffusion layer comprises a hydrophobic medium in a gradient distribution in the direction of a flow channel in a plane, and the uniformity of water distribution in the gas diffusion layer during the reaction of a cell is ensured. The fiber arrangement in a direction perpendicular to the flow channel direction in the plane can improve the thermal conductivity ability between the gas diffusion layer and an electrode plate. The porosities in plane penetrating direction are in a gradient arrangement, and the transfer of cell reaction water from a lower surface to an upper surface of the gas diffusion layer is facilitated. The designs of electrode plate ridge lower and flow channel lower gas diffusion layer structures are different, the ridge lower gas diffusion layer structure is concave, the too small porosity in the gas diffusion layer caused by excessive compression is prevented, and the water accumulation in a ridge lower gas diffusion layer is reduced. Compared with the prior art, the consistency of water and heat in the gas diffusion layer can be effectively ensured, the water drainage and heat dissipation capacity of the fuel cell are enhanced, the mass transfer of reaction gas in the cell is increased, and the reaction efficiency of the cell is improved.

Owner:SHANGHAI JIAO TONG UNIV

Gas diffusion layer with controlled diffusivity over active area

InactiveUS20080206615A1Improve fuel cell performanceImprove water managementCell electrodesWater management in fuel cellsDiffusionPorous substrate

A diffusion medium for use in a PEM fuel cell comprising a thin perforated layer having variable size and frequency of perforation patterns incorporated into a microporous layer on a first side of a porous substrate layer, wherein the diffusion medium is adapted to improve water management and performance of the fuel cell.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

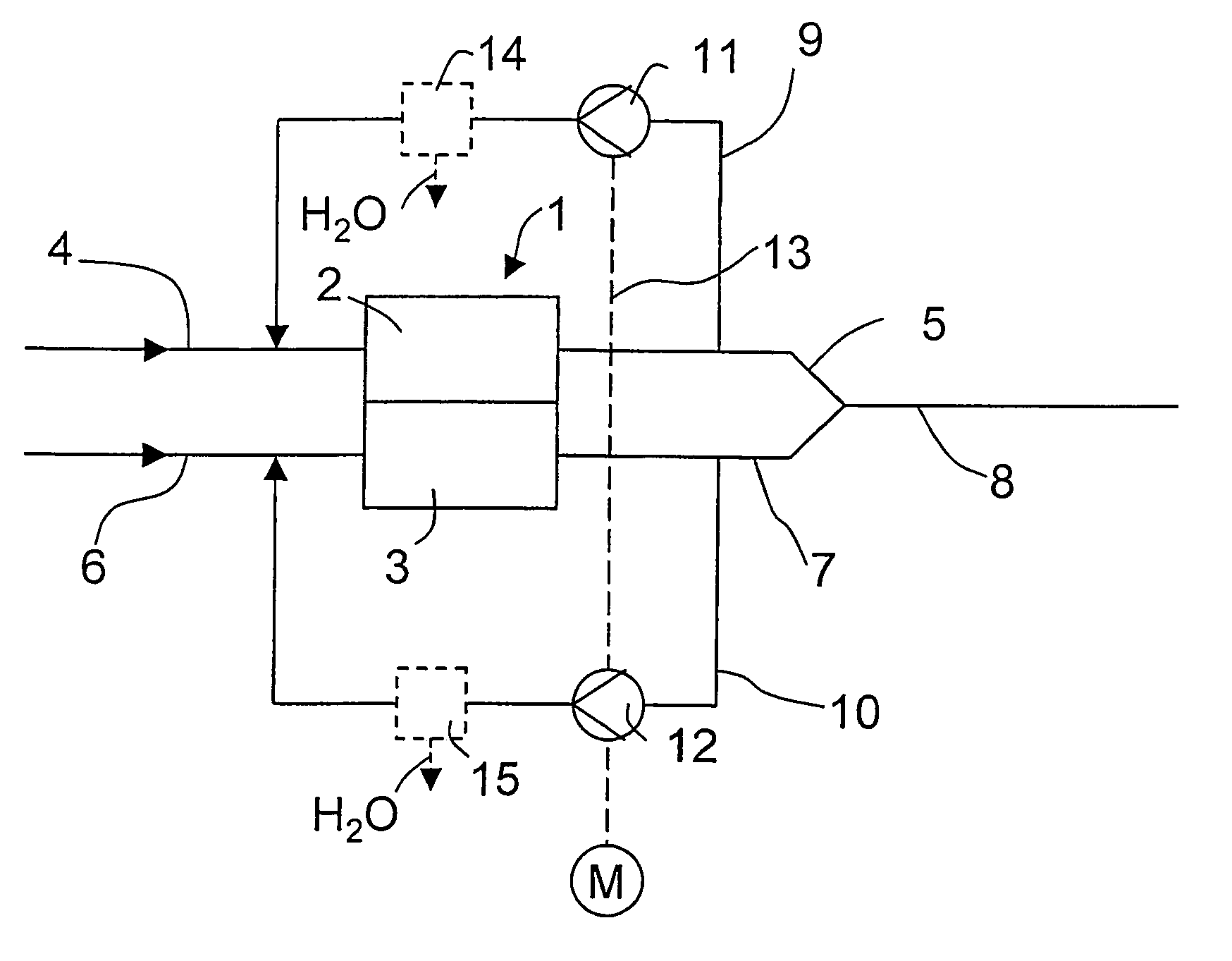

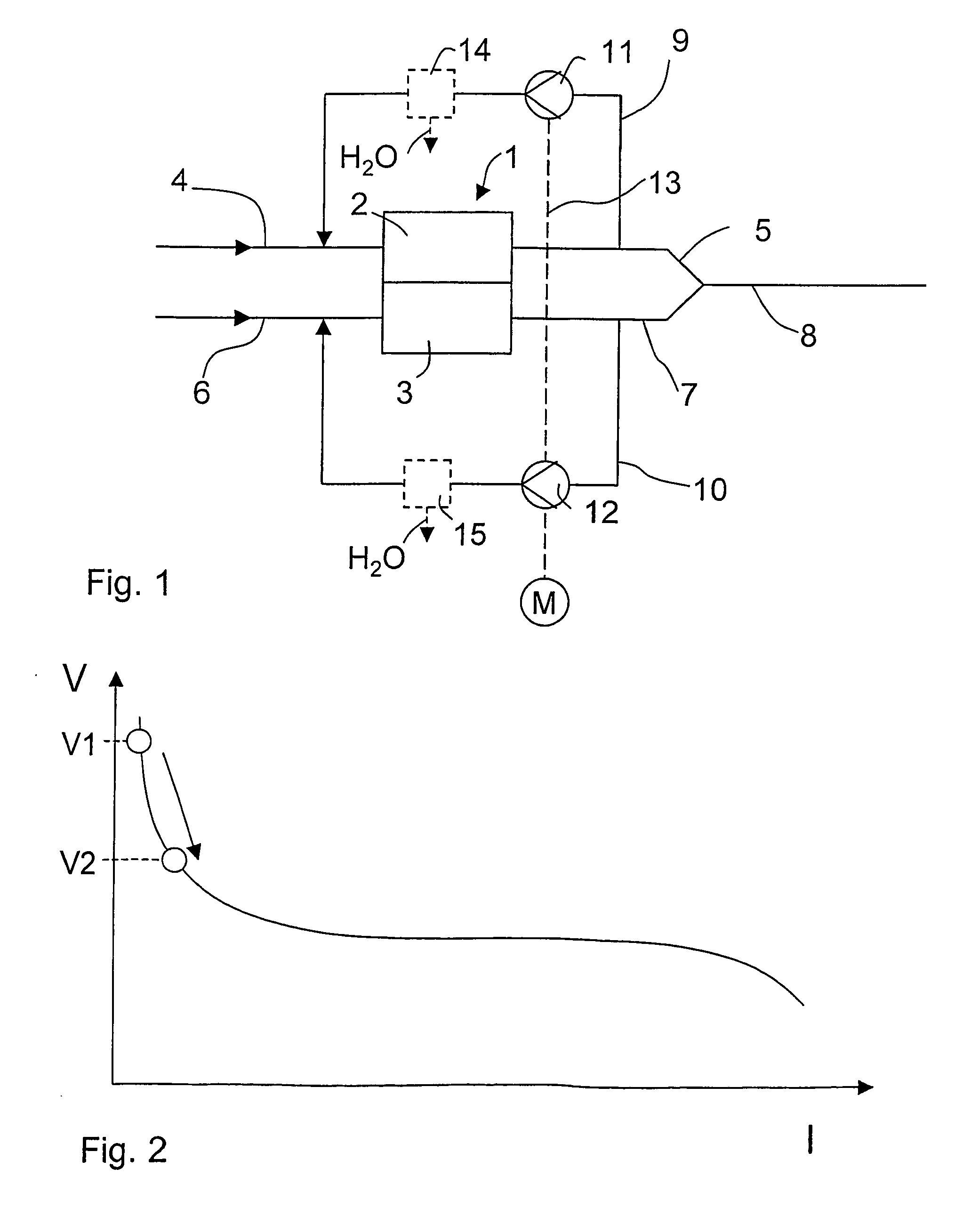

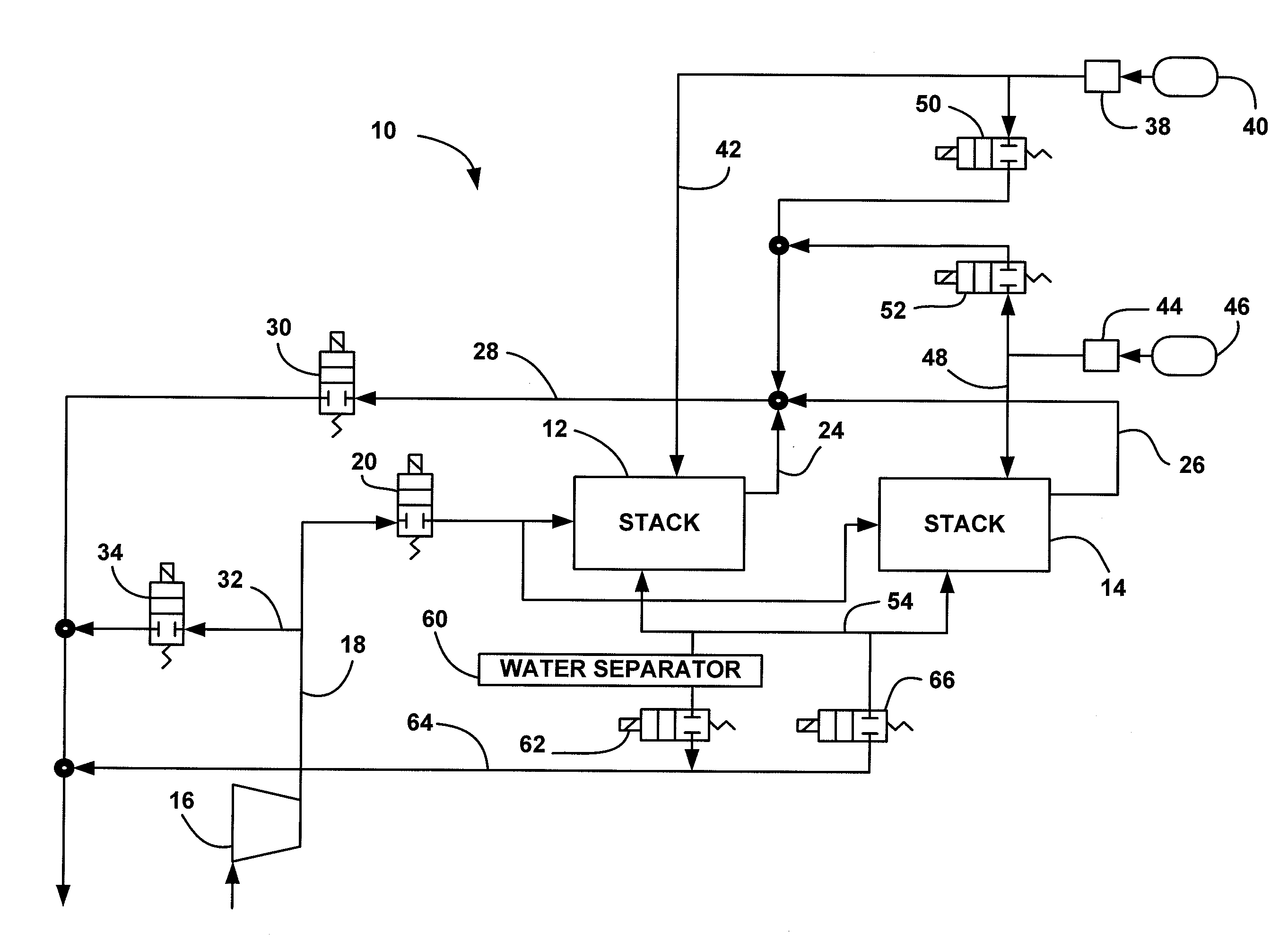

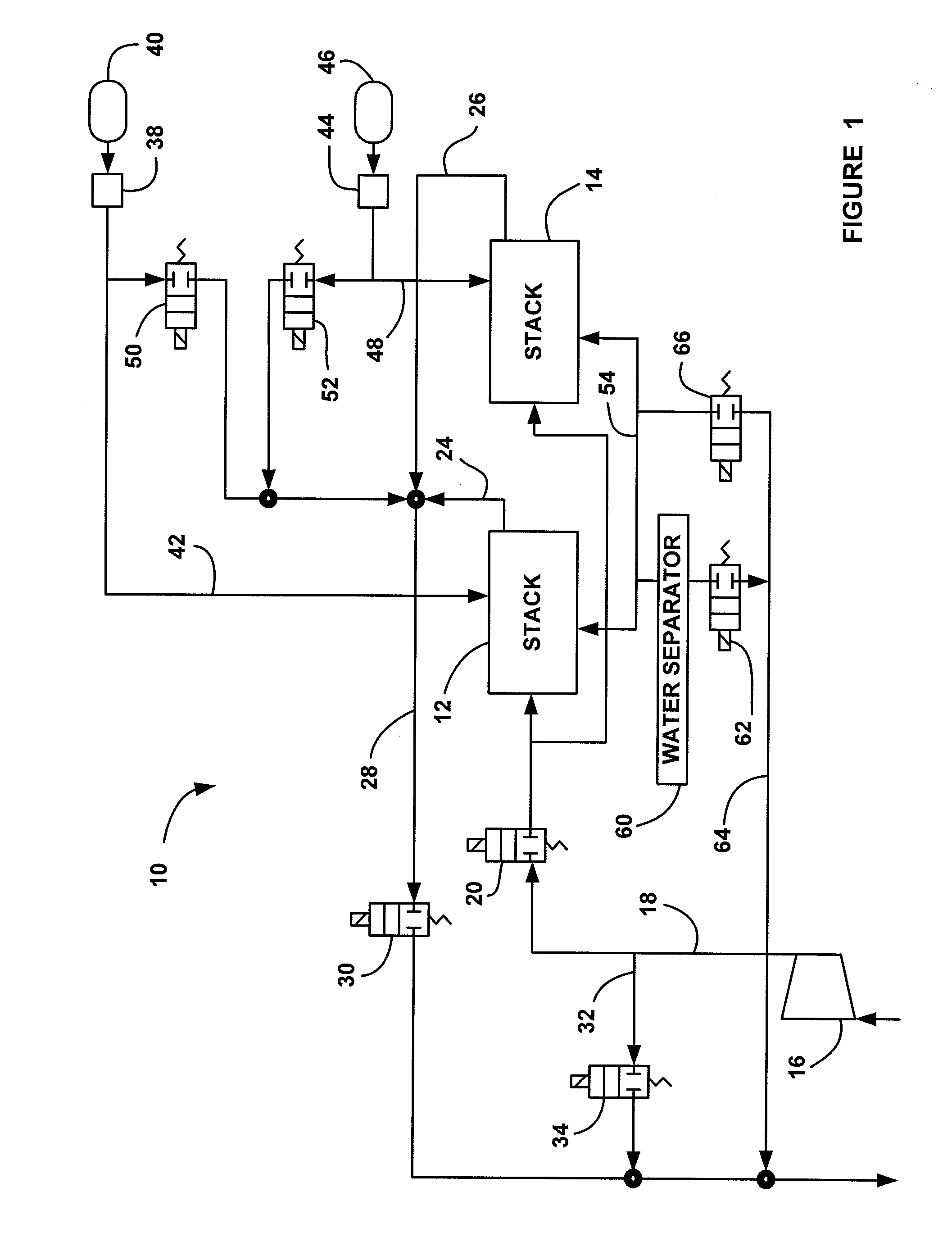

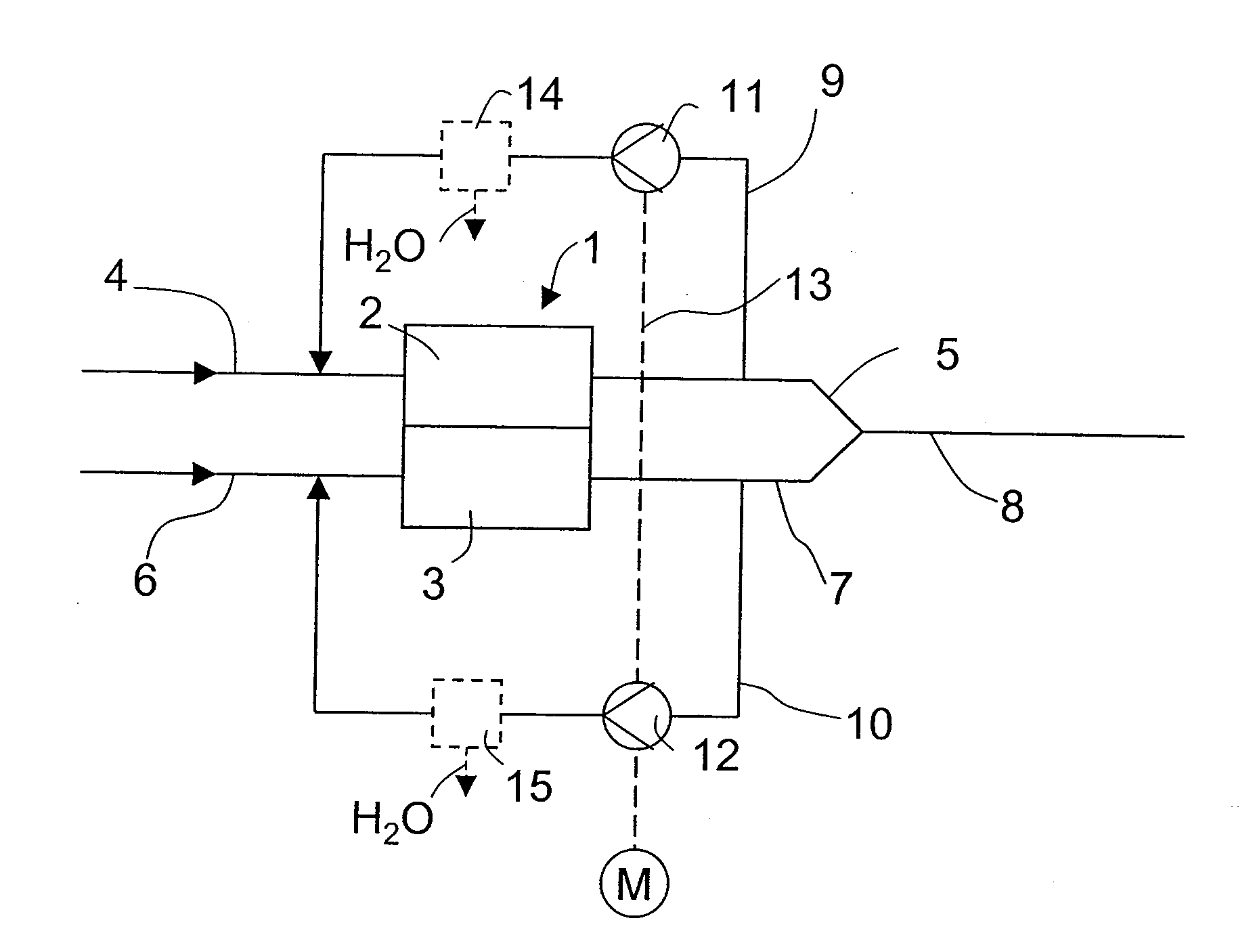

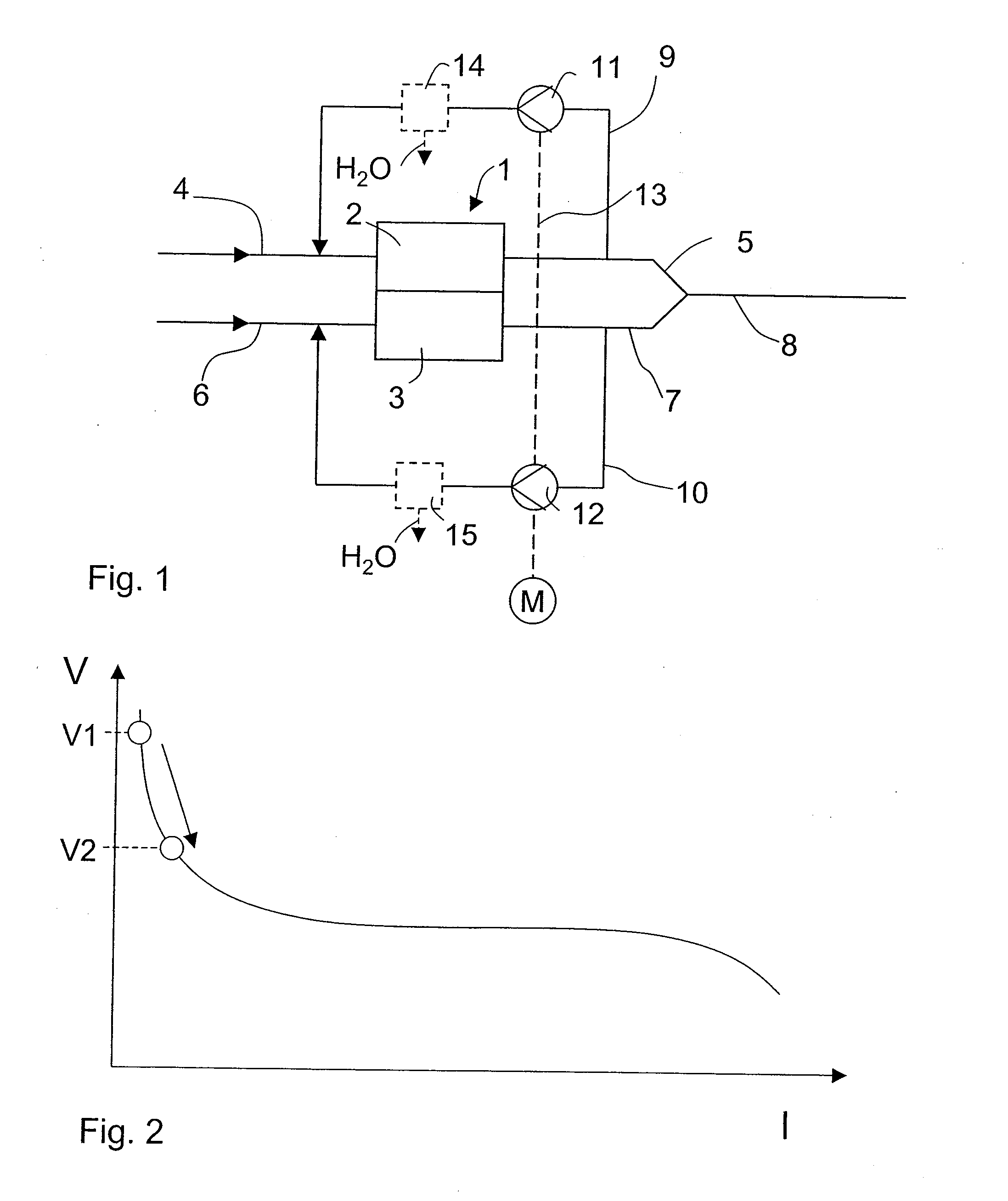

Fuel cell system and method for operating same

InactiveUS20050147862A1High power outputIncrease pressure dropFuel cells groupingFuel cell auxillariesFuel cellsDrive motor

A fuel cell system has recycle lines for recycling exhaust from the cathode and exhaust from the anode, with a recirculation device in each of the recycle lines. The recirculation devices are operated by a drive, such as a drive motor, with the drive and the two recirculation devices arranged on a common shaft.

Owner:BDF IP HLDG

Novel approach to make a high performance membrane electrode assembly (MEA) for a PEM fuel cell

ActiveUS20050260484A1Improve water managementReduction and elimination of needLayered productsFuel cell auxillariesFuel cellsPorous medium

An electrically conductive fluid distribution element for use in a fuel cell having a conductive non-metallic porous media having a surface with an electrically conductive metal deposited along one or more metallized regions. The metallized regions are arranged to contact a membrane electrode assembly (MEA) in a fuel cell assembly, and thus improve electrical conductance at contact regions between the MEA and the fluid distribution media. Methods of making such a fluid distribution element and operating fuel cell assemblies are also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

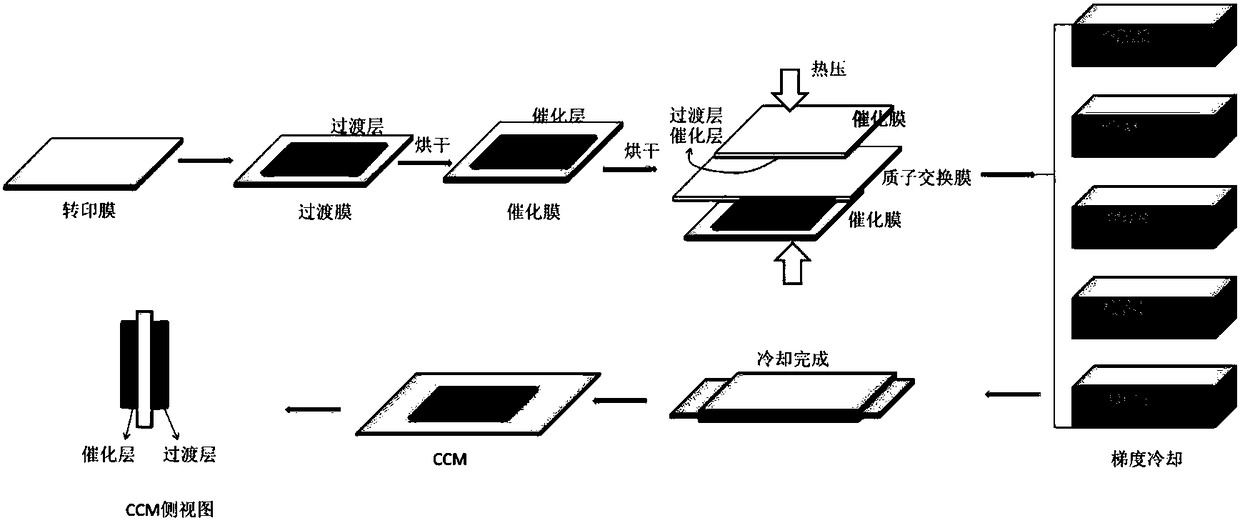

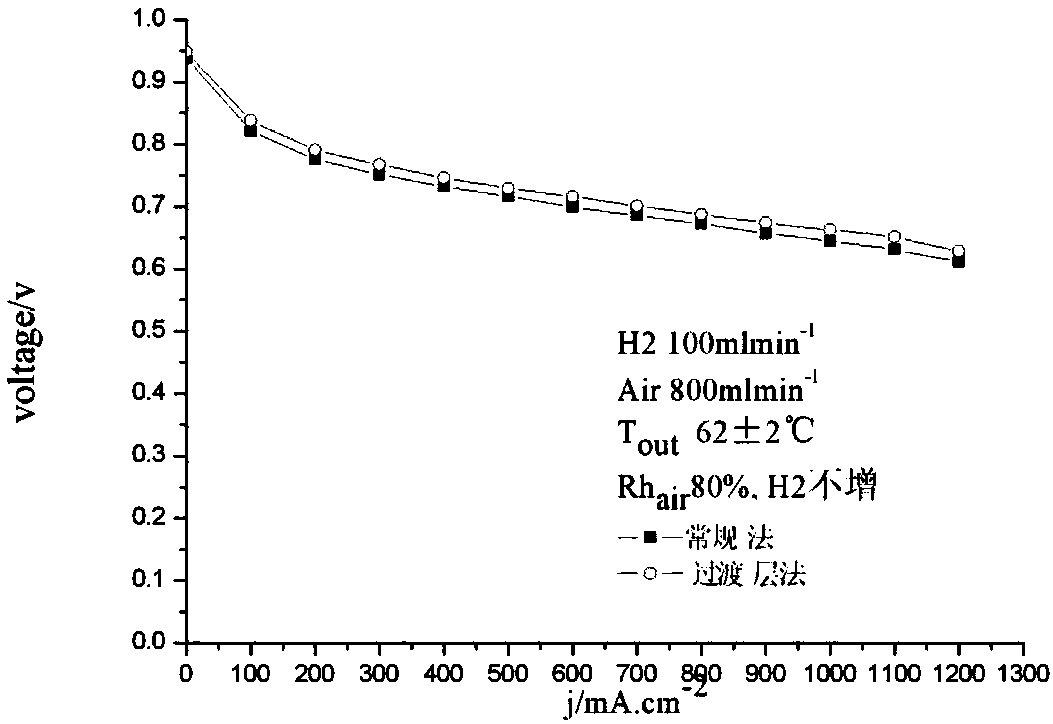

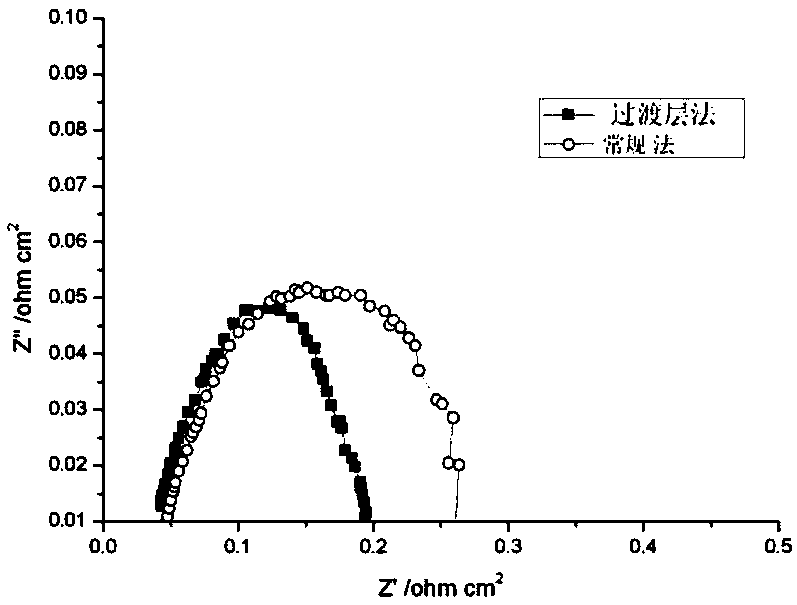

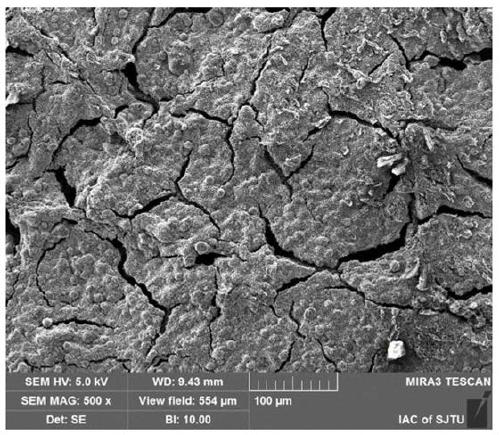

Preparation method of fuel cell CCM membrane electrode

The invention provides a preparation method of a fuel cell CCM membrane electrode. The preparation method comprises the following specific steps: spraying / screen-printing catalyst slurry on a transfermembrane to form a catalyst layer, and transferring the catalyst layer on a proton exchange membrane by adopting a hot pressing mode to form a CCM electrode. The preparation method provided by the invention is a common preparation method of fuel cell membrane electrodes. In the process of preparing the CCM by a transfer method, because the bonding force between the catalyst layer and the transfermembrane is larger, the prepared catalyst layer is uneven, the hot pressing temperature and pressure are uneven and the environmental temperature and humidity are uneven and the like, the transfer isincomplete, and then the preparation of the CCM fails. The method provided by the invention adopts a transition layer, so that the bonding force between the catalyst layer and the transfer membrane can be reduced, the transfer efficiency of the catalyst layer can be enhanced, the problem of water management between the catalyst layer and a micro-porous layer can be improved, and the subsequent problems of mass transfer and the like can be solved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Multilayered composite proton exchange membrane and a process for manufacturing the same

InactiveUS20090176141A1High mechanical strengthLow production costFinal product manufactureSolid electrolyte fuel cellsPolymer electrolytesFuel cells

A multilayered membrane for use with fuel cells and related applications. The multilayered membrane includes a carrier film, at least one layer of an undoped conductive polymer electrolyte material applied onto the carrier film, and at least one layer of a conductive polymer electrolyte material applied onto the adjacent layer of polymer electrolyte material. Each layer of conductive polymer electrolyte material is doped with a plurality of nanoparticles. Each layer of undoped electrolyte material and doped electrolyte material may be applied in an alternating configuration, or alternatively, adjacent layers of doped conductive polymer electrolyte material is employed. The process for producing a multilayered composite membrane includes providing a carrier substrate and solution casting a layer of undoped conductive polymer electrolyte material and a layer of conductive polymer electrolyte material doped with nanoparticles in an alternating arrangement or in an arrangement where doped layers are adjacent to one another.

Owner:CHEMSULTANTS INT

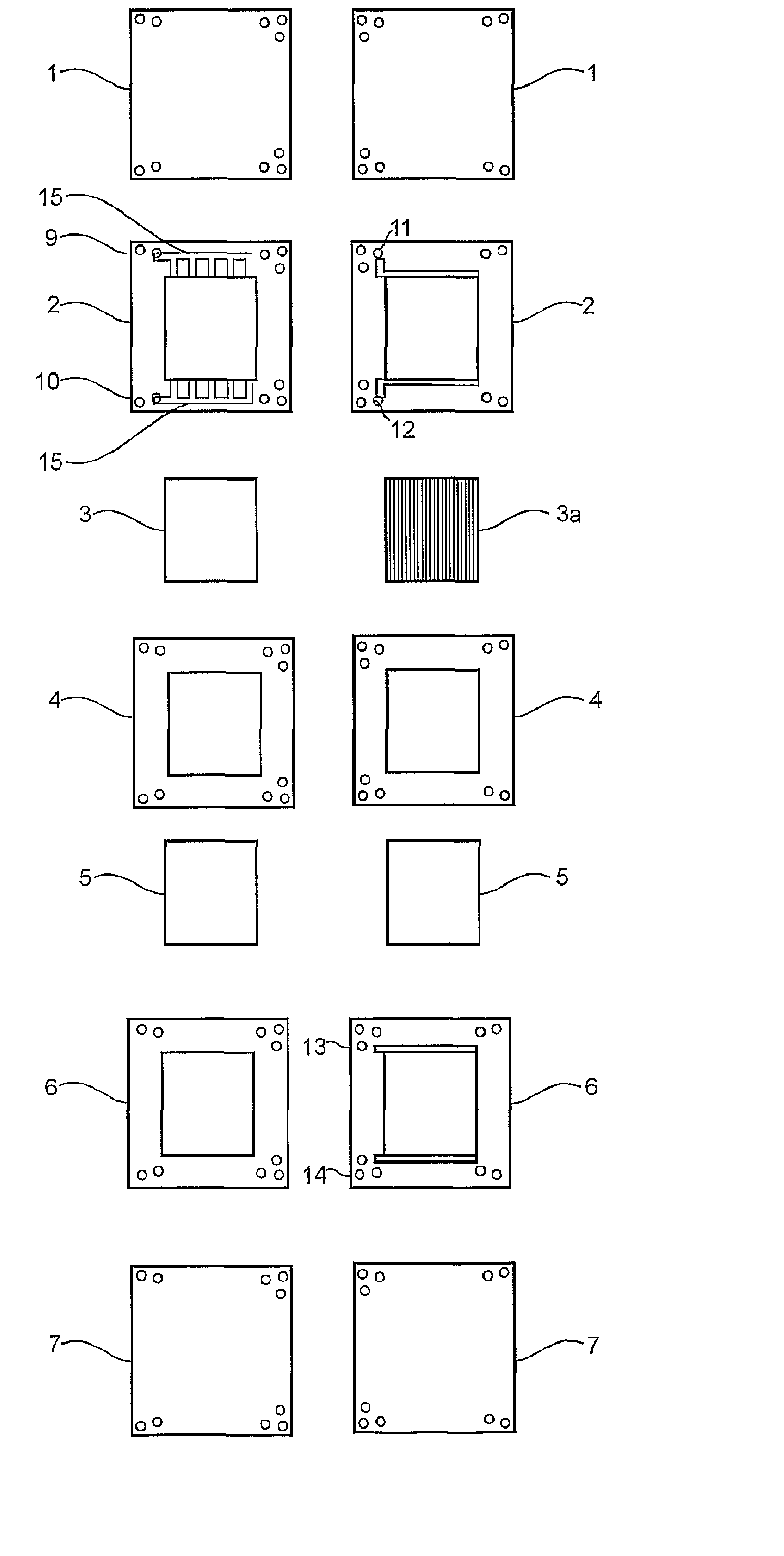

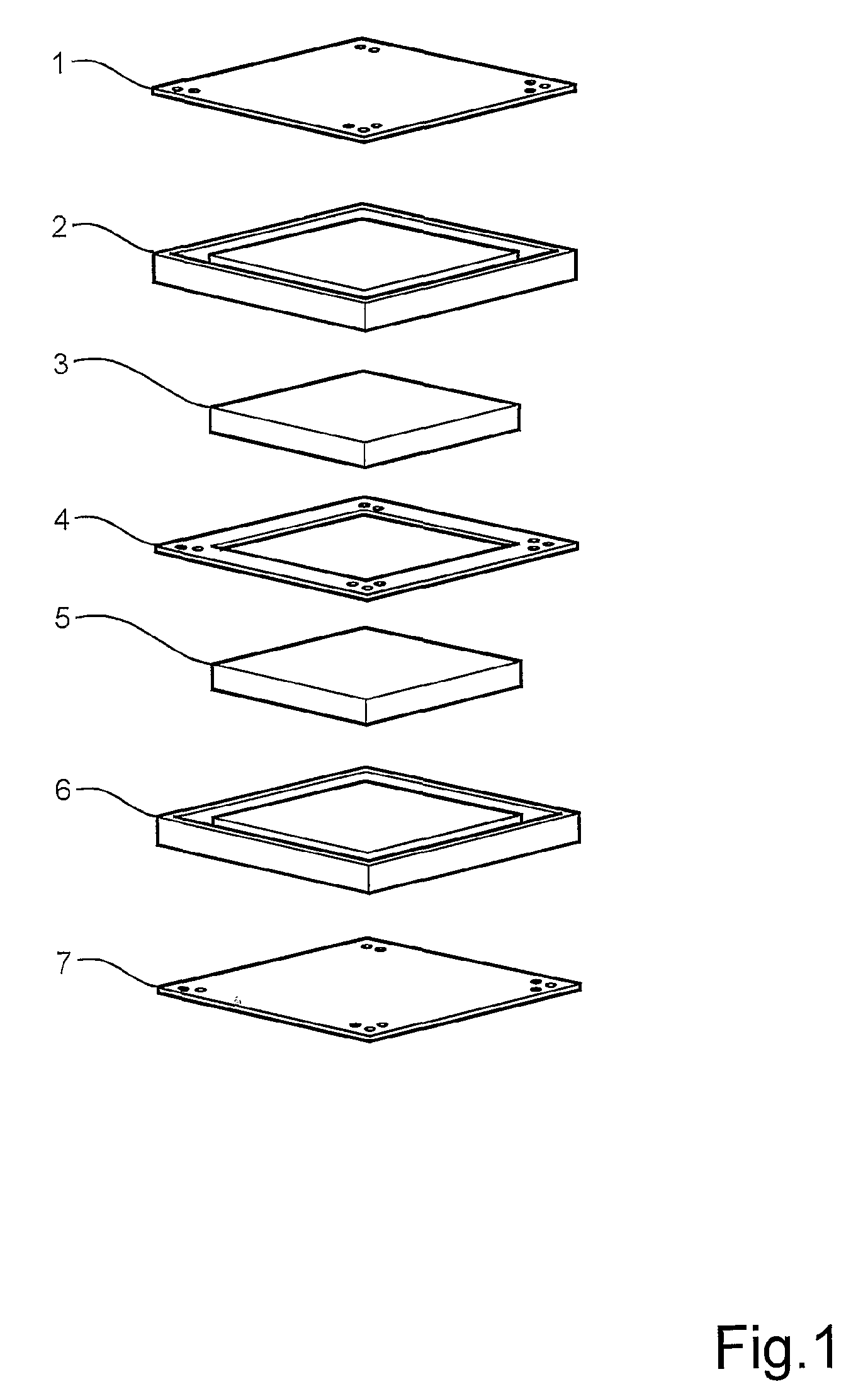

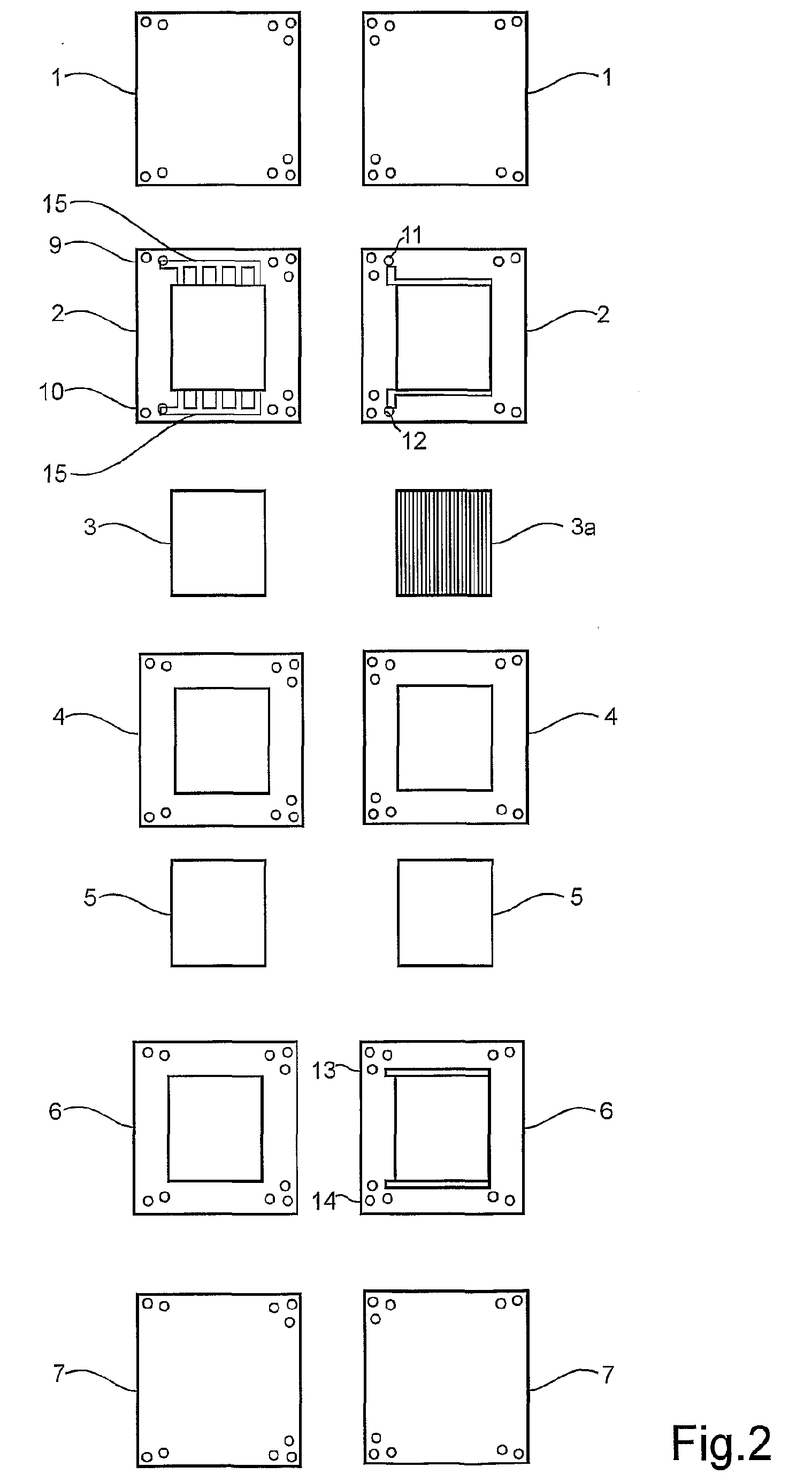

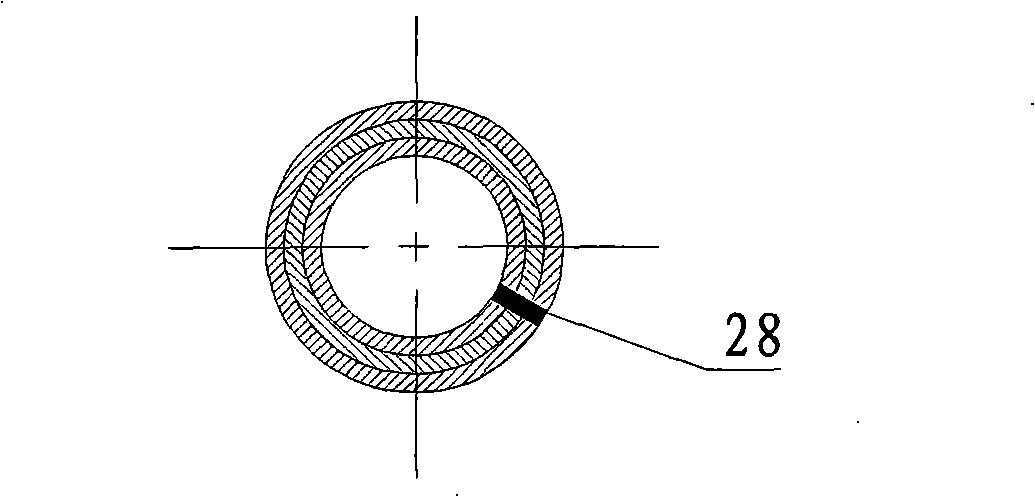

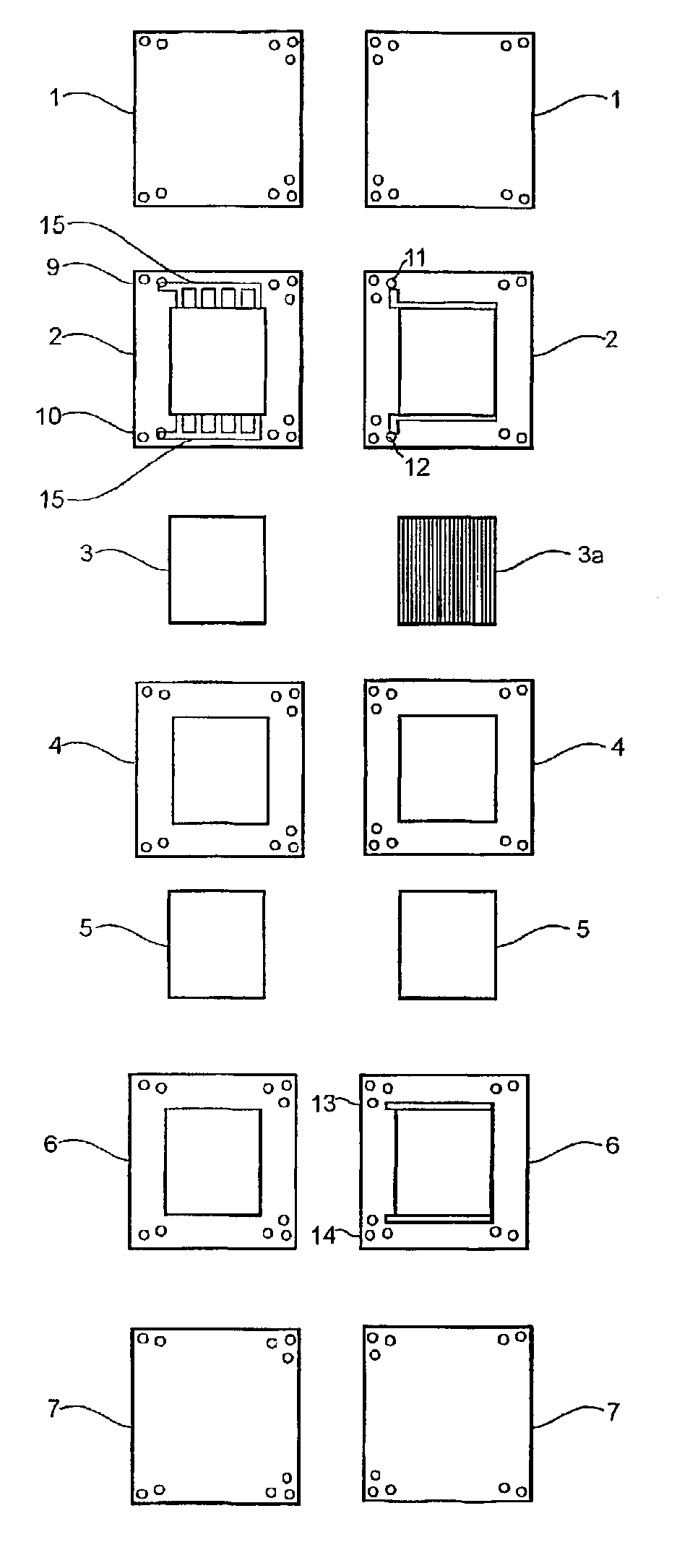

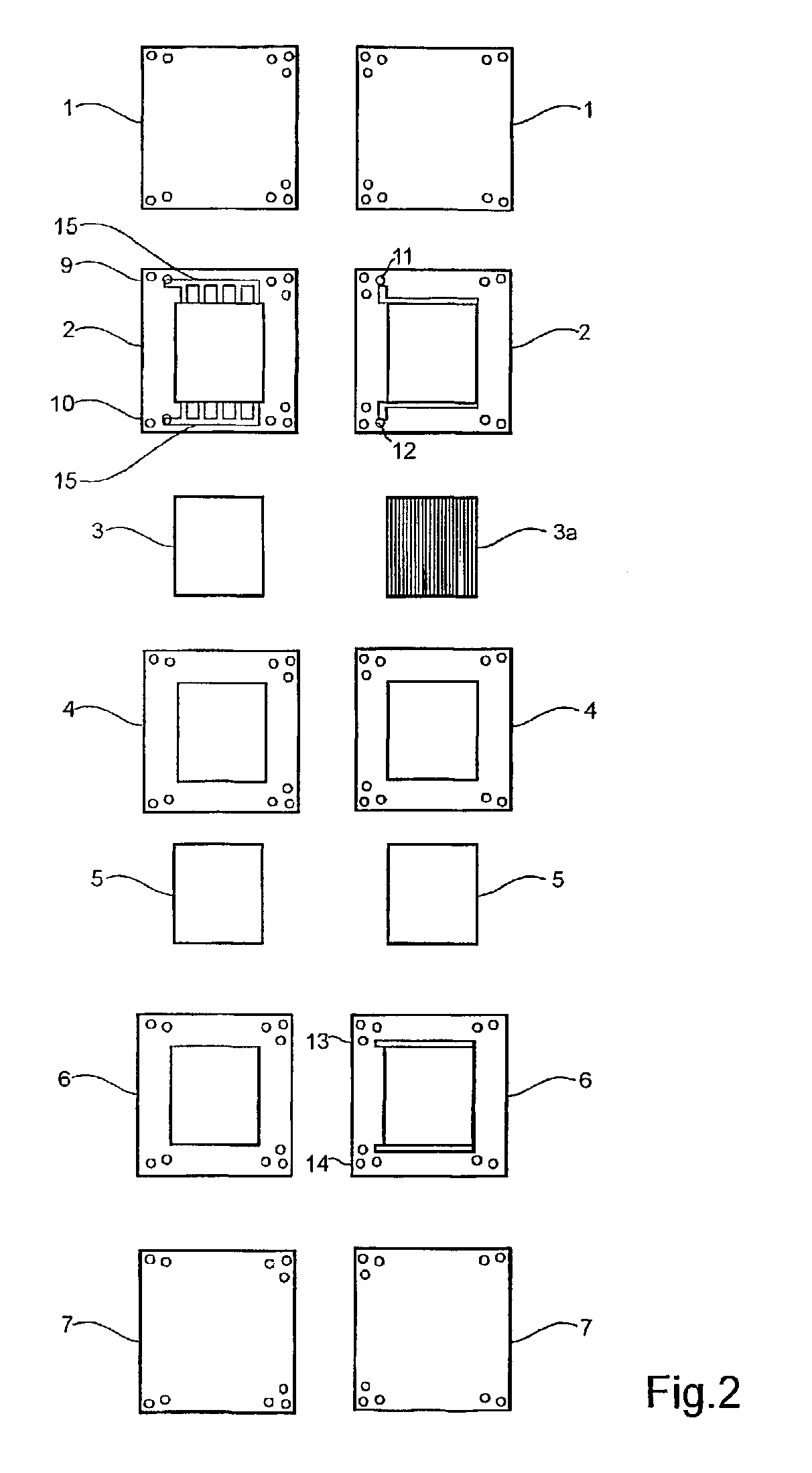

Polymer fuel cell structure

InactiveUS20030091887A1Improve water managementEasy to humidifyWater management in fuel cellsActive material electrodesInlet channelProton

Abstract of Disclosure A polymer electrolyte fuel cell structure includes a proton exchange membrane (4). An anode catalyst layer (1,16) is located on one side of the proton exchange membrane. A cathode catalyst layer (7) is located on the opposite side of the proton exchange membrane, and a gas distribution layer (3,5) is arranged on each side of the proton exchange membrane (4). The anode side gas distribution layer (3) is a flat, porous structure having water channels (3a) formed in the surface facing the membrane (4). The anode side gas distribution layer (3) is enclosed by a coplanar, sealing plate (2) with water inlet channels coupled to the water channels (3a) in the gas distribution layer.

Owner:POWERCELL SWEDEN AB

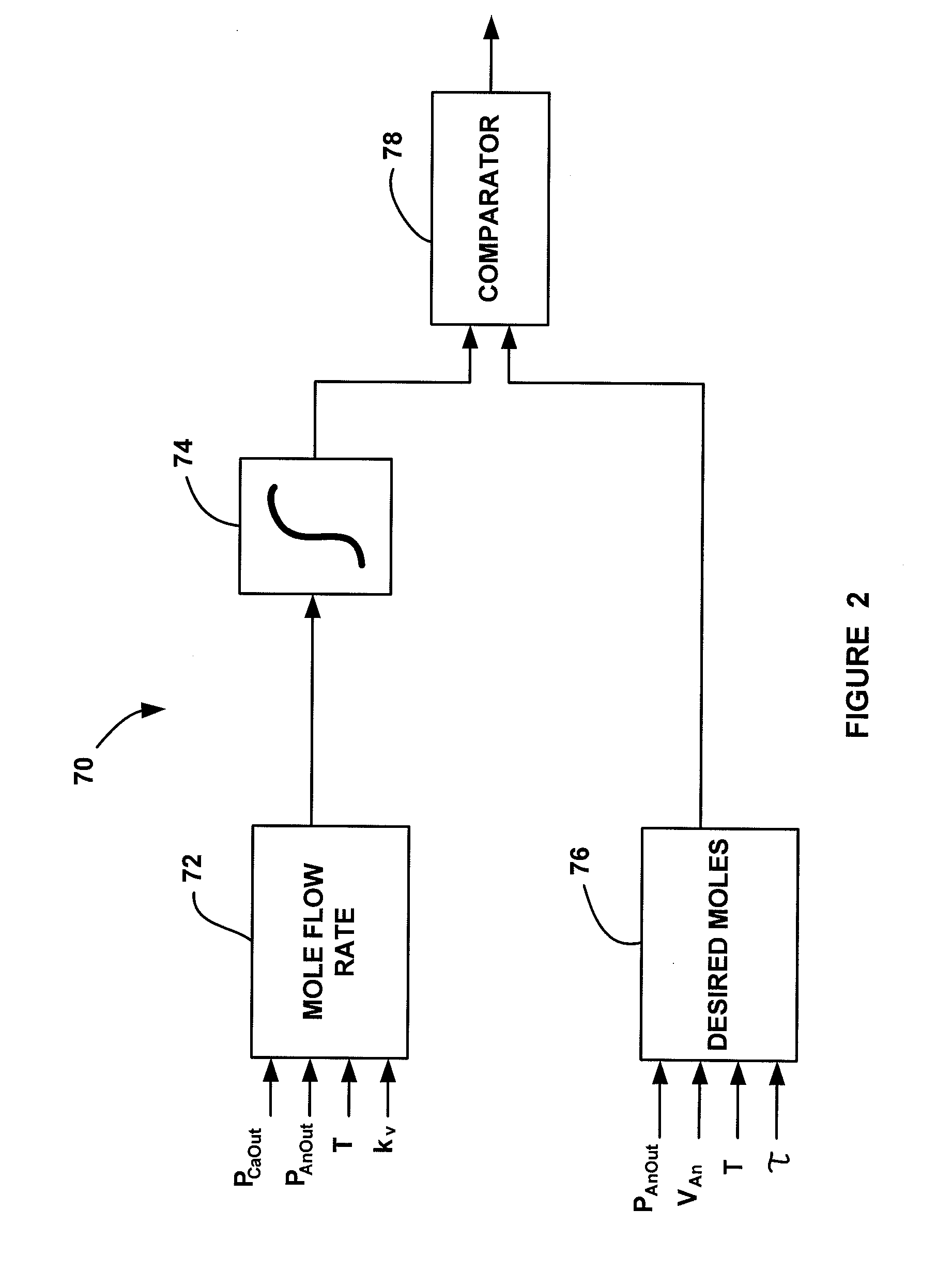

Anode Bleed Control Strategy for Improved Water Management and Hydrogen Utilization

ActiveUS20080312849A1Improve water managementSolve the durability problemVolume flow measuring devicesVolume/mass flow by differential pressureHydrogenFuel cells

A control strategy for bleeding an anode side of fuel cell stack in a fuel cell system that improves water management and addresses durability and performance concerns. The method includes determining when to begin the anode bleed, typically by estimating or measuring the amount of nitrogen in the anode side of the stack. The method also includes determining when to end the anode bleed based on the volume of gas that has been bled. The method determines the mole flow rate of the anode gas flowing through a bleed valve, integrates the mole flow rate to get the number of moles of the gas that have passed through the bleed valve, determines a desired amount of moles to be bled, and ends the bleed when the actual number of moles of the gas equals the desired number of moles of the gas.

Owner:GM GLOBAL TECH OPERATIONS LLC

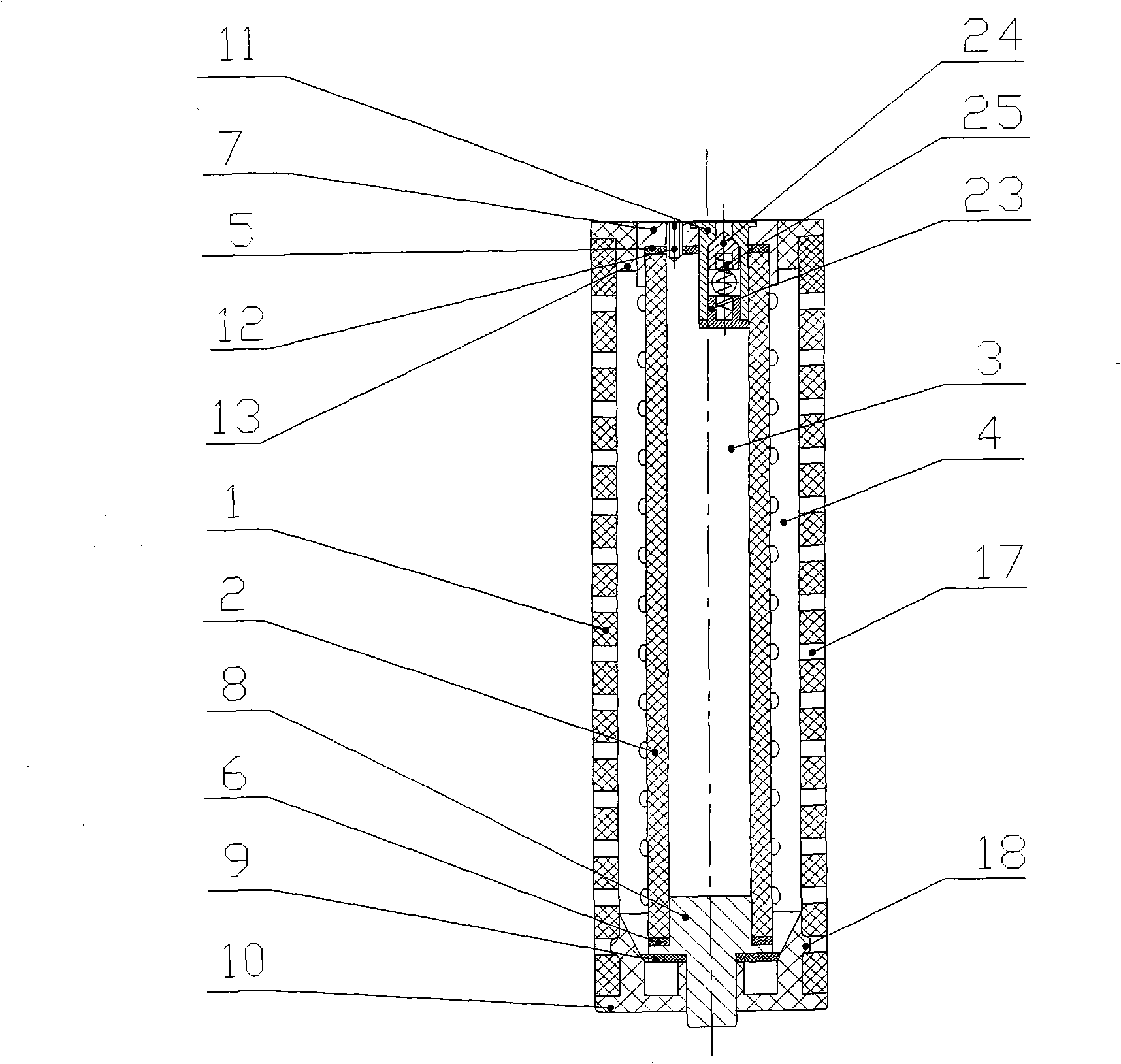

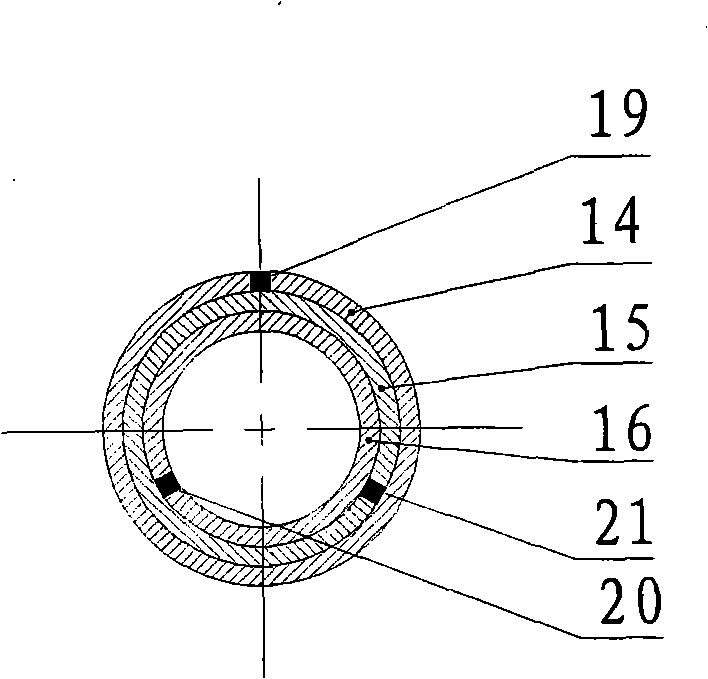

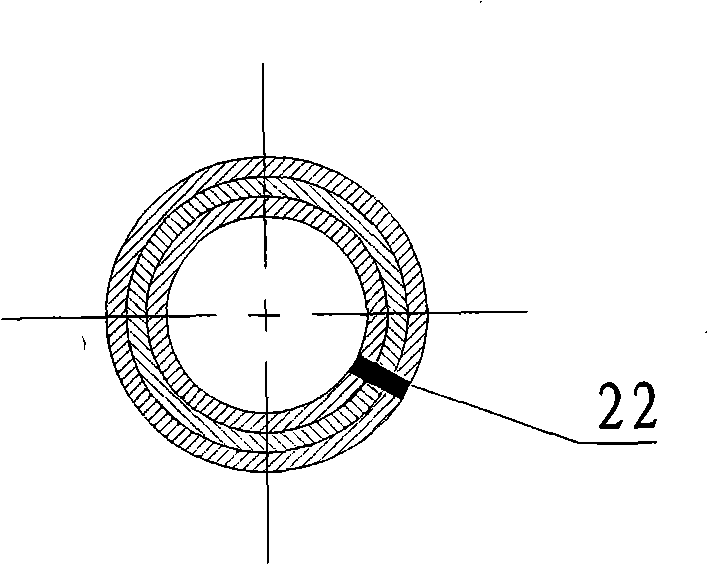

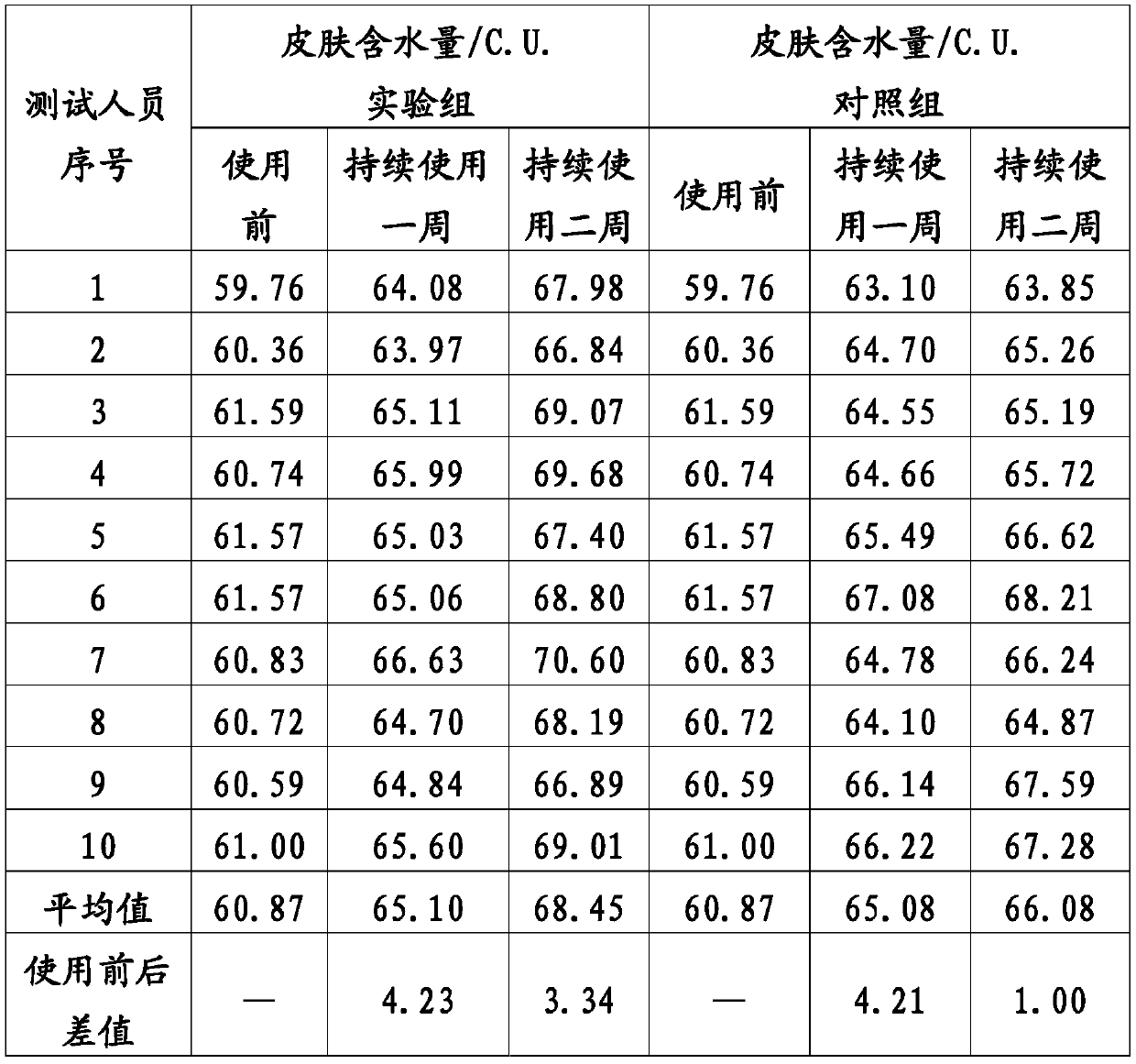

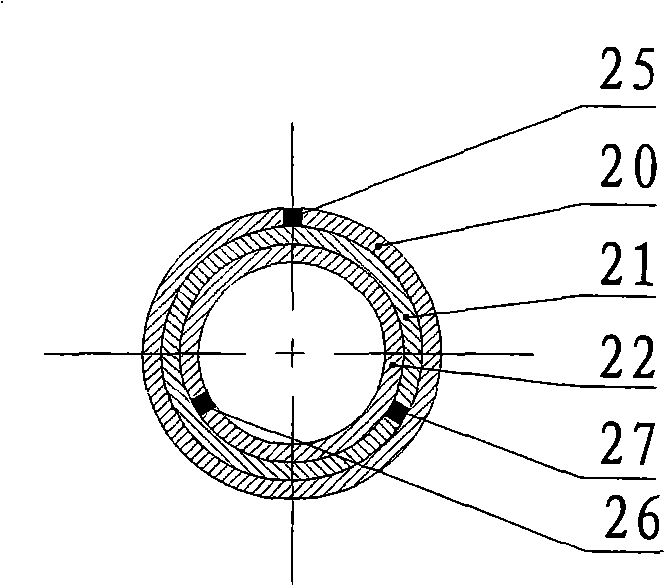

Circular direct methanol fuel cell of high performance and low cost

InactiveCN101335362AEasy to cleanEasy maintenanceFuel cells groupingCell electrodesFuel cellsBiochemical engineering

The invention discloses a column direct methanol fuel cell with good performance and low cost. The cell comprises a shell, wherein, a membrane electrode is arranged in the shell. A battery liquid compartment is arranged in the membrane electrode, an air chamber is arranged between the shell and the membrane electrode, insulating sealing rings are arranged on both ends of the membrane electrode, and a cathode output device and an anode output device are respectively arranged on the cathode end and the anode end of the cell group, a water-diversion gas-barrier membrane is arranged on the exterior of the anode output device, a water collector is arranged on the exterior of the water-diversion gas-barrier membrane, and the cathode output device is provided with a check valve which is communicated with the cell liquid compartment and a pollutant output bolt device. The cell has the advantages of reasonable structure and good working performance.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH

Approach to make a high performance membrane electrode assembly (MEA) for a PEM fuel cell

ActiveUS8101319B2Improve water managementReduction and elimination of needLayered productsFuel cell auxillariesFuel cellsPorous medium

Owner:GM GLOBAL TECH OPERATIONS LLC

Fuel cell system and method for operating same

InactiveUS20090075130A1High power outputIncrease pressure dropFuel cell auxillariesCell component detailsFuel cellsDrive motor

A fuel cell system has recycle lines for recycling exhaust from the cathode and exhaust from the anode, with a recirculation device in each of the recycle lines. The recirculation devices are operated by a drive, such as a drive motor, with the drive and the two recirculation devices arranged on a common shaft.

Owner:KNOOP ANDREAS +1

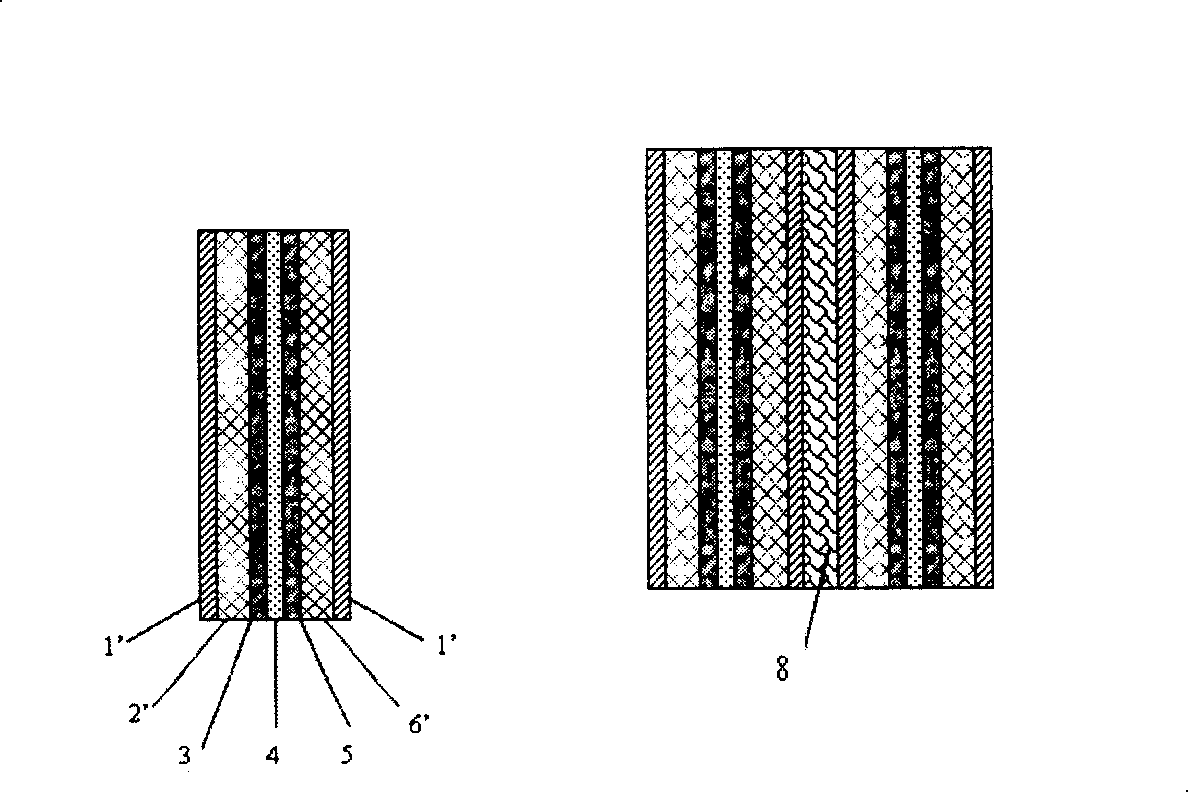

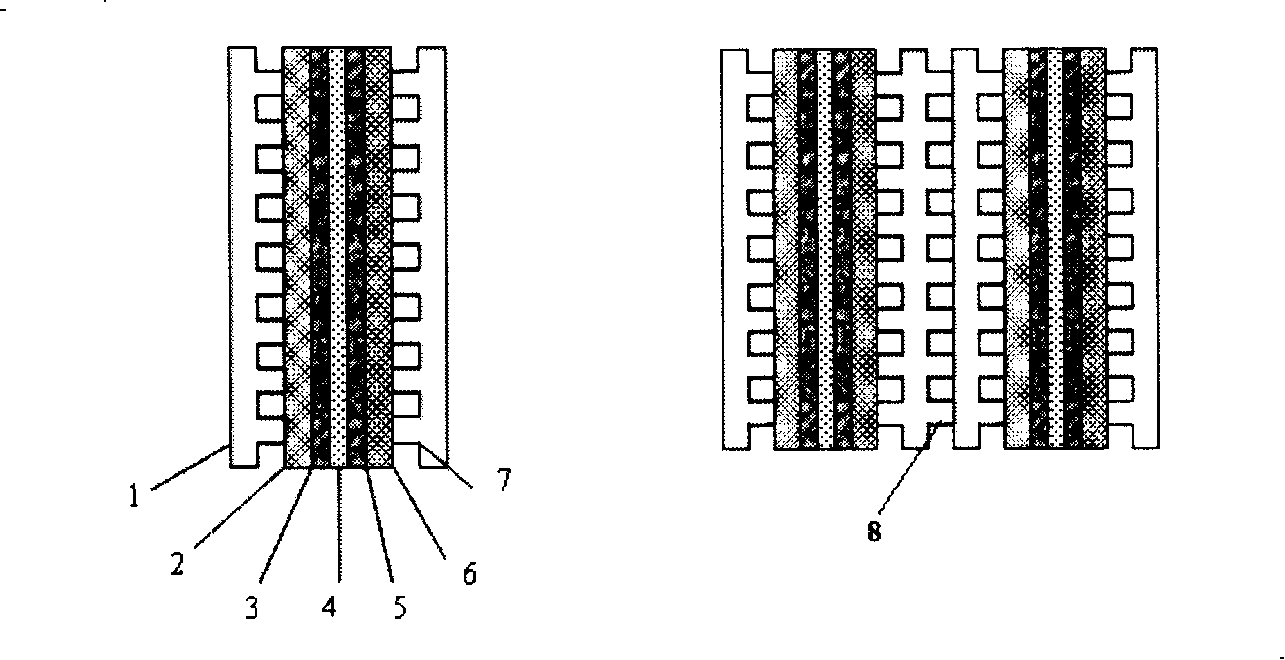

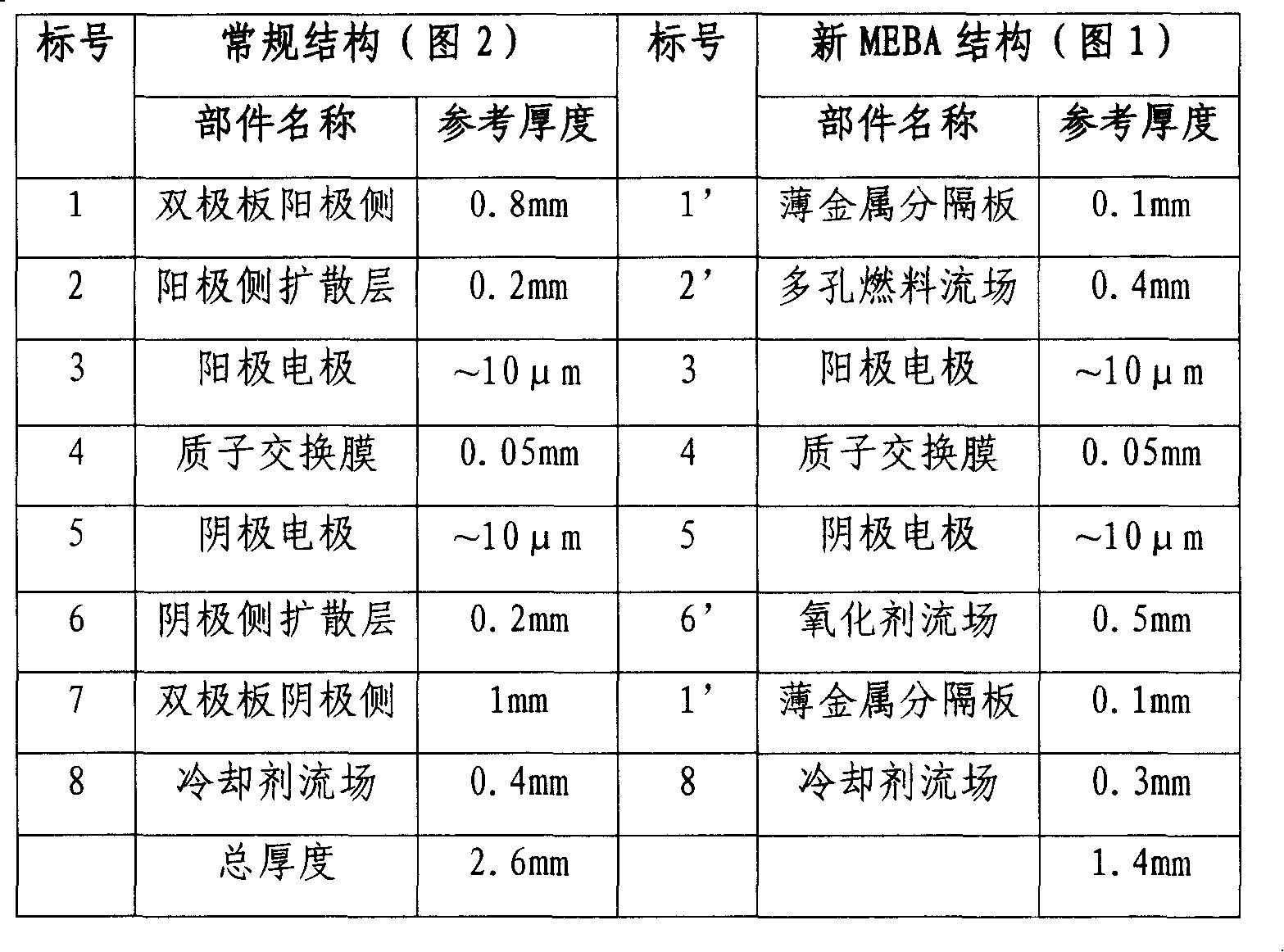

Proton exchange membrane fuel cell structure applicable to high temperature operation

InactiveCN101212057AReduce volumeSimple structureCell electrodesSolid electrolyte fuel cellsThin metalProton

The invention relates to a fuel cell, in particular a structure of the fuel cell having a proton exchange membrane applicable to high temperature operation, which comprises a fuel flow field, a CCM, an oxidizer flow field, and thin metal separating boards arranged on two sides of the oxidizer flow field. Inner sides of the thin metal separating boards are provided with poriferous layers of conductive material which are taken as flow fields and diffusing layers. The structure of the invention can simplify the structure of the fuel cell and greatly reduce the size.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

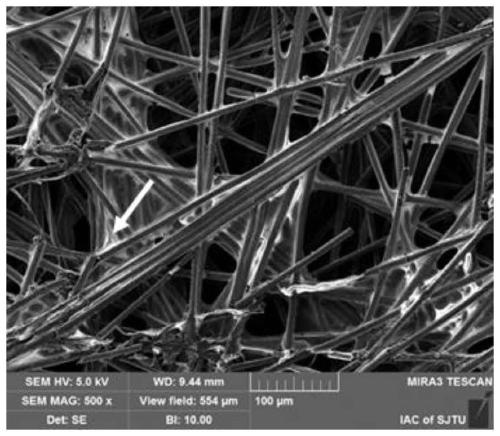

Gas diffusion layer of fuel cell and preparation method thereof and fuel cell

ActiveCN111193040AEasy to prepareEasy to operateCell electrodesWater management in fuel cellsDischarge efficiencyFuel cells

The invention discloses a preparation method of a gas diffusion layer of a fuel cell. The method comprises the following steps of: (1) performing hydrophobic treatment on two sides of a carbon substrate material by using a hydrophobic material, and performing curing to obtain a hydrophobic carbon substrate material; (2) coating slurry on one side of the hydrophobic carbon substrate material, and forming a microporous layer after curing, wherein the slurry comprises conductive carbon powder, a dispersing agent, a hydrophobic binder and an emulsifying agent, the mass ratio of the conductive carbon powder to the dispersing agent to the hydrophobic binder to the emulsifying agent is 1:(10-20):(0.2-4):(0.1-2), and the emulsifying agent comprises one or more of Tween 80, triton x-100 and dipolyglycerol. The gas diffusion layer of the fuel cell is good in hydrophobic property, the contact angle can be 160 degrees or above, the water management condition of the fuel cell can be improved, the discharge voltage, the discharge efficiency and the output performance under high current density of the membrane electrode are improved, and the current operation stability and the long-time operationstability of the fuel cell under high voltage can also be improved.

Owner:SHANGHAI ELECTRICGROUP CORP

Variable active area for fuel cell

InactiveUS7601451B2Improve water managementFuel cells groupingFuel cell auxillariesFuel cellsEngineering

An electrochemical fuel cell stack assembly having a variable active area. The fuel cell stack uses a blocking member to selectively block the flow of reactants through channels of the flow fields of the anode and / or cathode flow paths. Blocking portions of the flow paths allows the fuel cell stack to maintain reactant flow velocities in a desired predetermined range. This enables the control and variation of the active area of the fuel cell, enhancing water management of the fuel cell stack.

Owner:GM GLOBAL TECH OPERATIONS LLC

Hydrogel-containing catalyst slurry, catalyst layer prepared from same and fuel cell electrode

ActiveCN111261878AExcellent battery characteristicsGuaranteed output performanceCell electrodesPtru catalystFuel cells

The invention relates to hydrogel-containing catalyst slurry, a catalyst layer prepared from the same and a fuel cell electrode. The catalyst slurry comprises an organic solvent, as well as a catalyst, an ion conductor and hydrogel which are dissolved in the organic solvent, wherein the hydrogel is selected from lignosulfonate hydrogel or acrylic acid hydrogel. The catalyst layer can be obtained by coating the catalyst slurry. The preparation method of the fuel cell electrode includes the following steps that: (a) weighing a catalyst, an ion conductor and hydrogel, sequentially dissolving thecatalyst, the ion conductor and the hydrogel in an organic solvent, and performing uniform dispersing to obtain catalyst slurry; and (b) uniformly coating the catalyst slurry obtained in the step (a)on a gas diffusion layer or a proton exchange membrane, and then carrying out drying treatment to obtain the fuel cell electrode. Compared with the prior art, the fuel cell electrode can assist in solving a water management problem possibly occurring in high-temperature and low-humidity operation of a traditional fuel cell electrode and guaranteeing the output performance of a fuel cell.

Owner:TONGJI UNIV

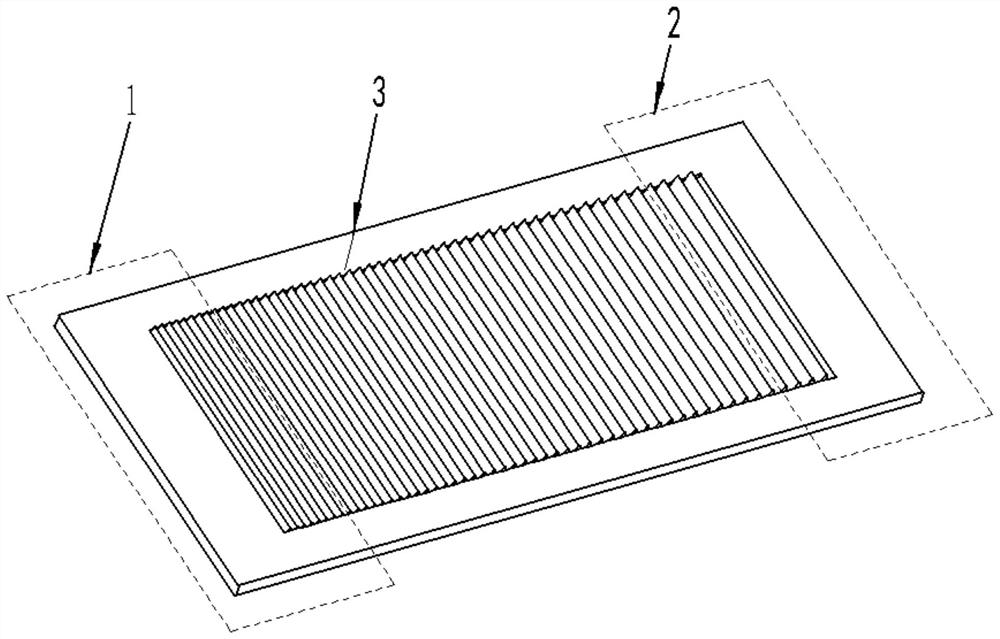

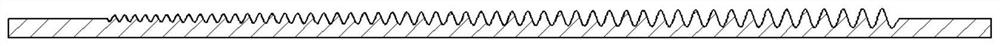

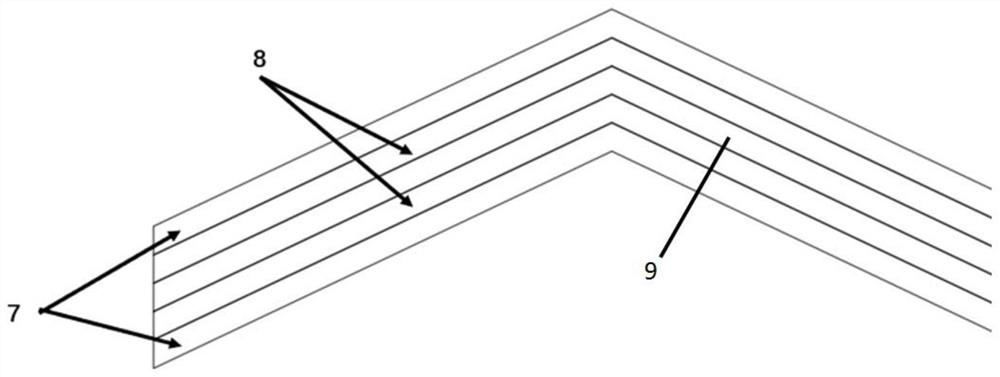

Gas diffusion layer for proton exchange membrane fuel cell and processing technology of gas diffusion layer

ActiveCN113178591AImprove performanceImprove cooling effectCollectors/separatorsChemical physicsEngineering

The invention provides a gas diffusion layer for a proton exchange membrane fuel cell and a processing technology of gas diffusion layer, gradient wavy micro-groove structures are distributed on the surface of one side of the gas diffusion layer close to a bipolar plate, and the wavy micro-groove structures are located between an inlet section of the gas diffusion layer and an outlet section of the gas diffusion layer. The gradient wavy micro-groove structures are characterized in that the amplitude and the wavelength of the wavy micro-groove structures are increased in a synchronous gradient manner along the gas flowing direction. The grooves distributed according to the gradient can achieve the effect that different water contents correspond to drainage capacities of different strengths, and the consistency of water distribution in the gas flowing direction is guaranteed.

Owner:JIANGSU UNIV

Catalyst layer for a fuel cell and method for the production thereof

ActiveUS20170084927A1Safer to produceSafe handlingFinal product manufactureCell electrodesFuel cellsPolymer chemistry

A catalyst layer (20) for a fuel cell and to a method suitable for producing the catalyst layer (20). The catalyst layer (20) includes a catalyst material (22) containing a catalytic material (24) and optionally porous carrier material (23) on which the catalytic material (24) is supported. The catalyst layer also includes mesoporous particles (21) made from hydrophobic material.

Owner:AUDI AG

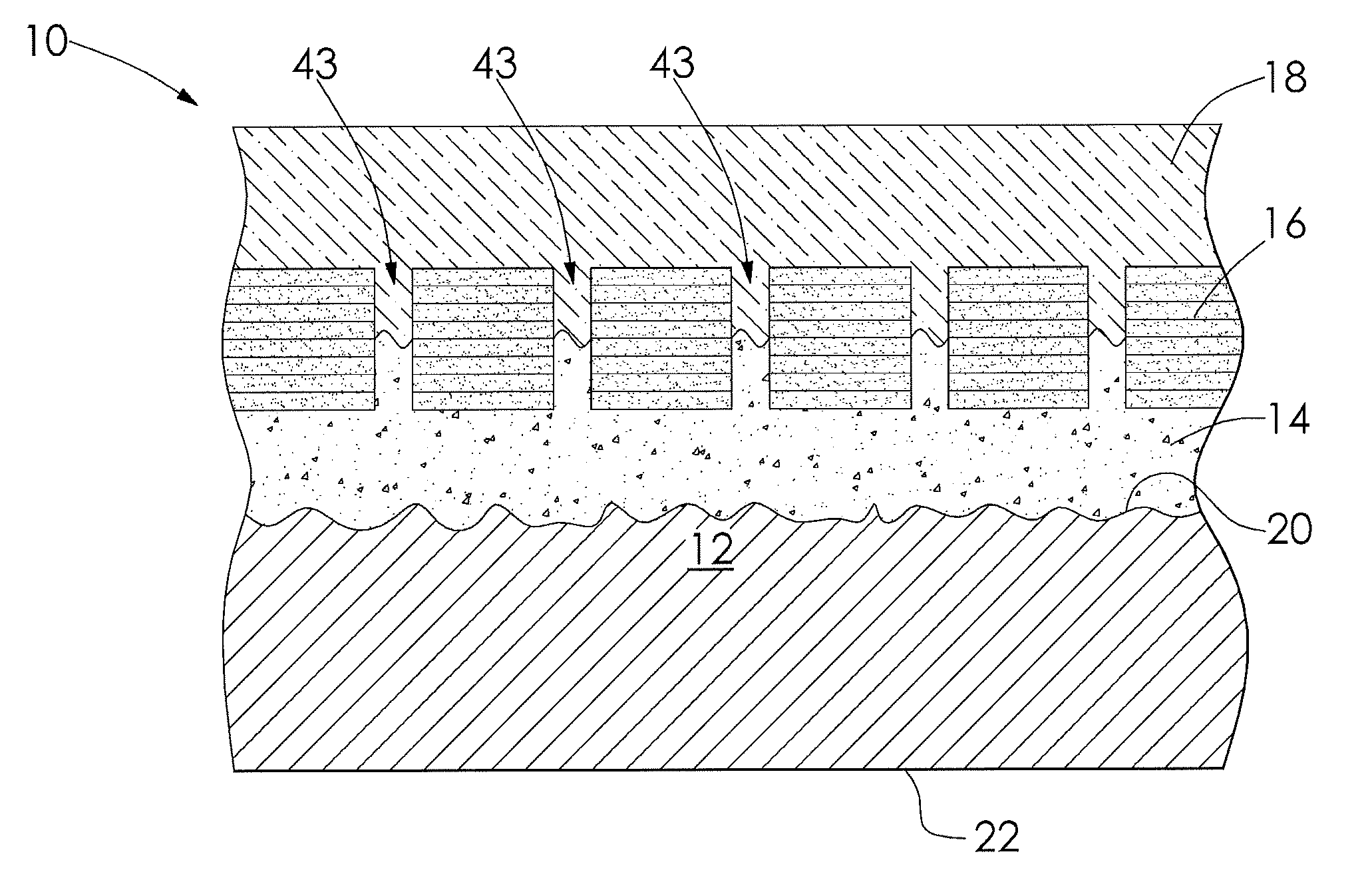

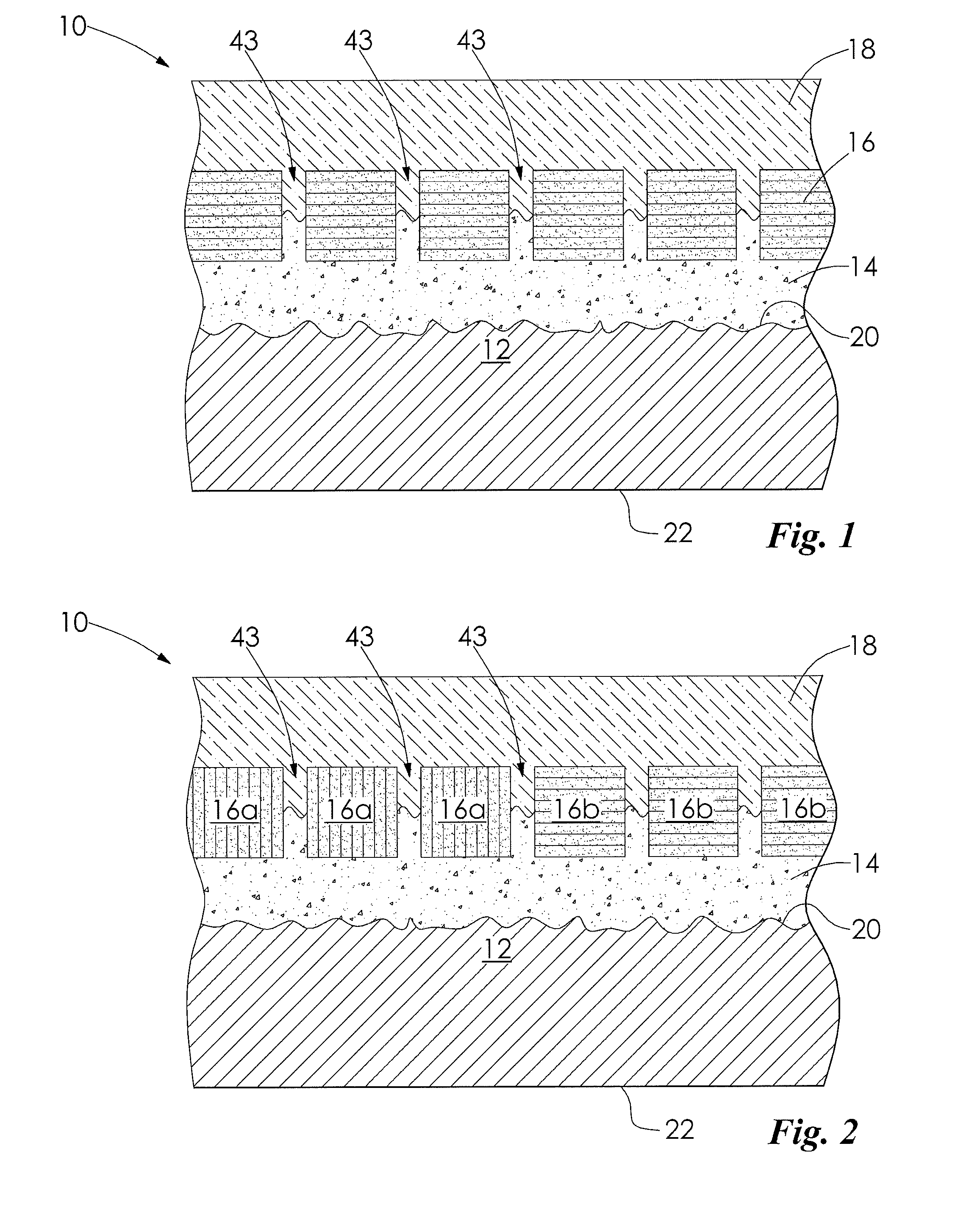

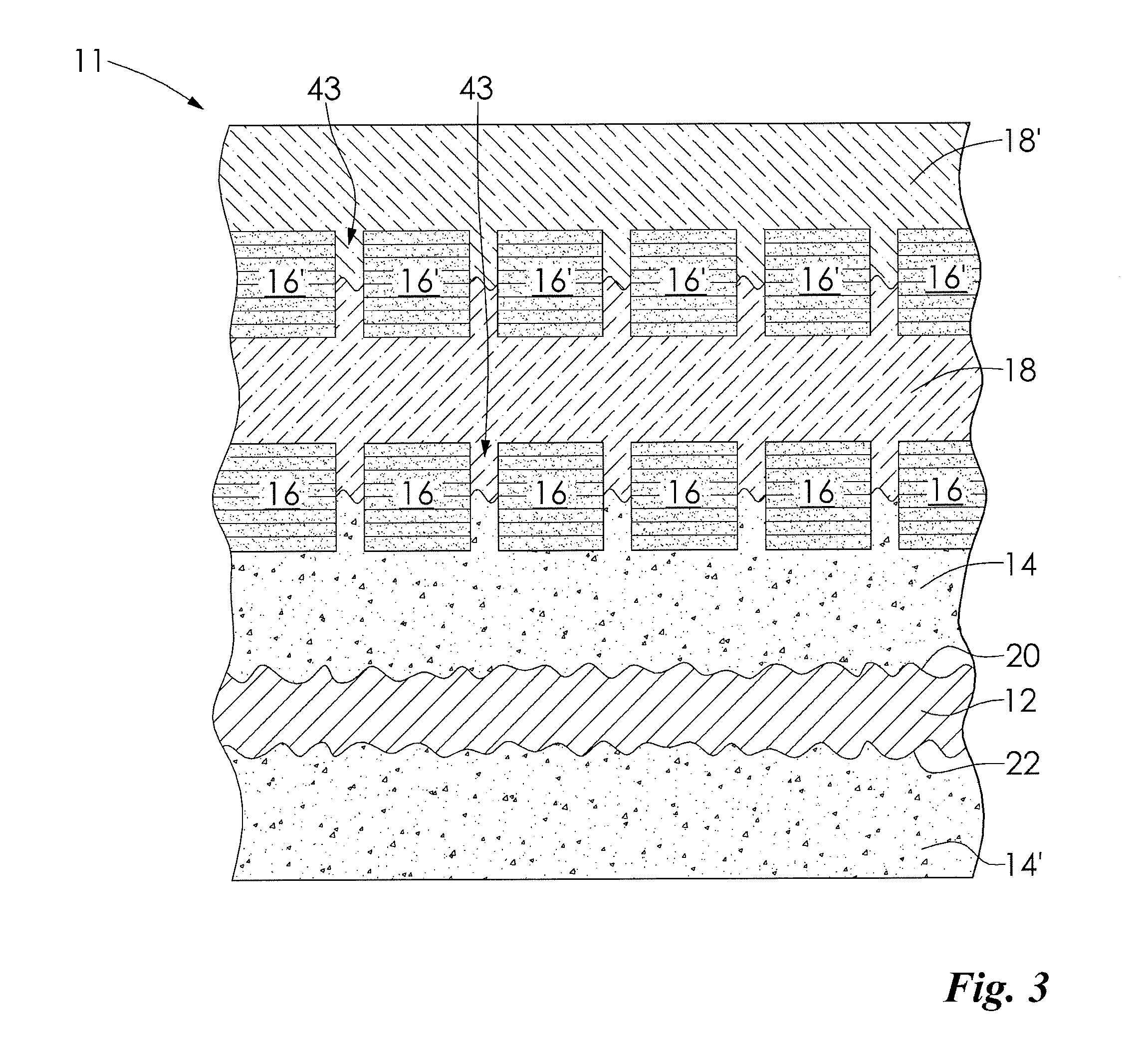

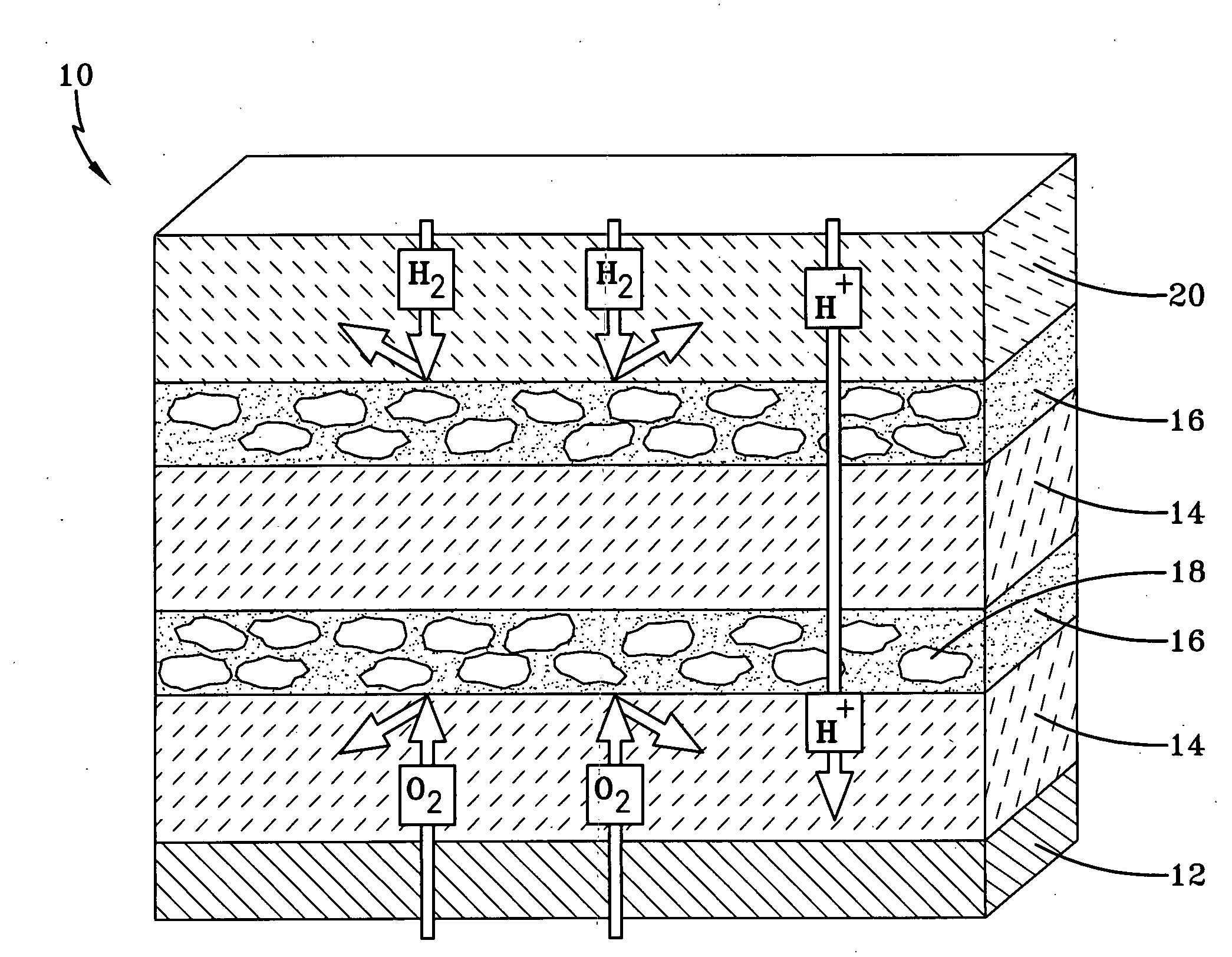

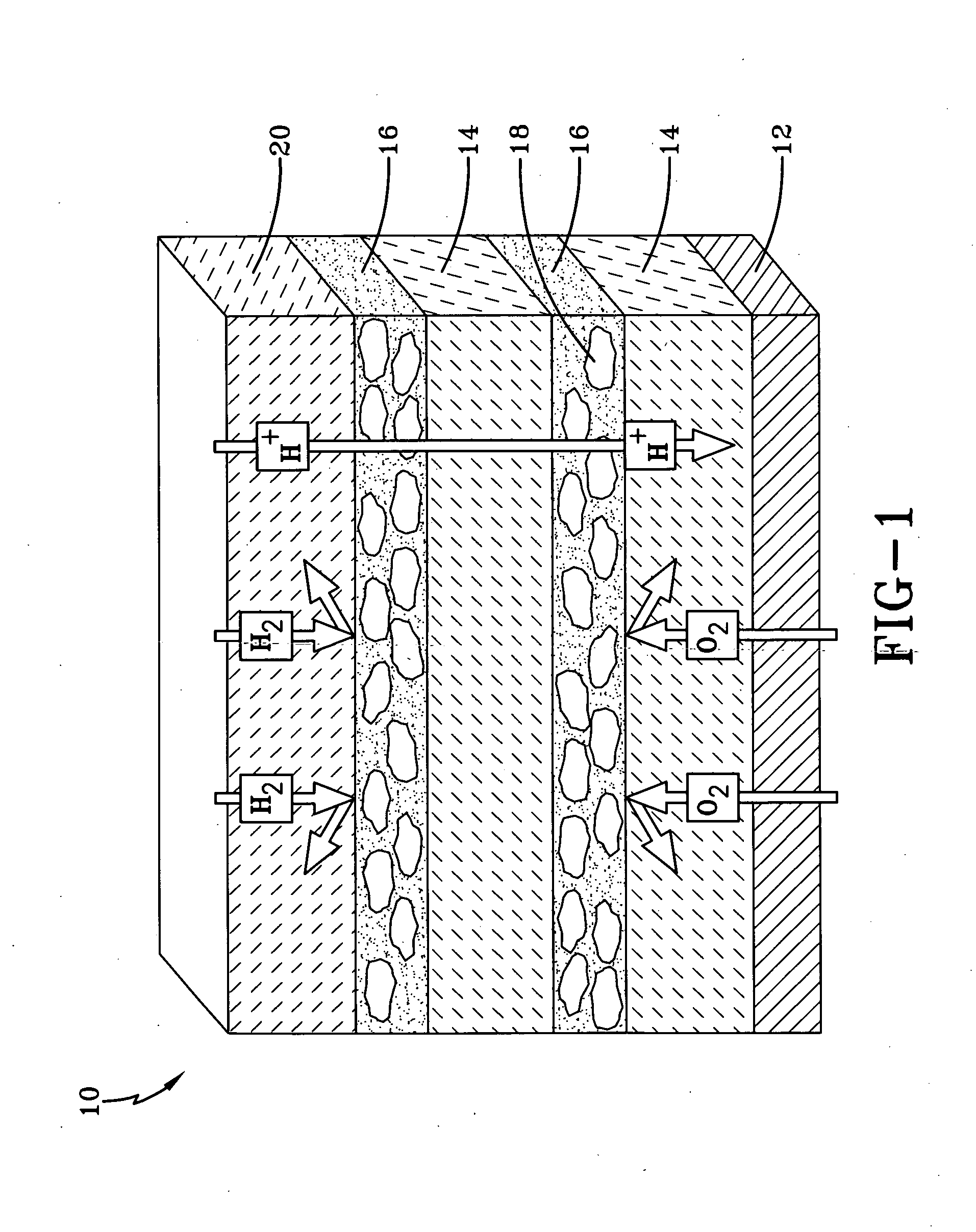

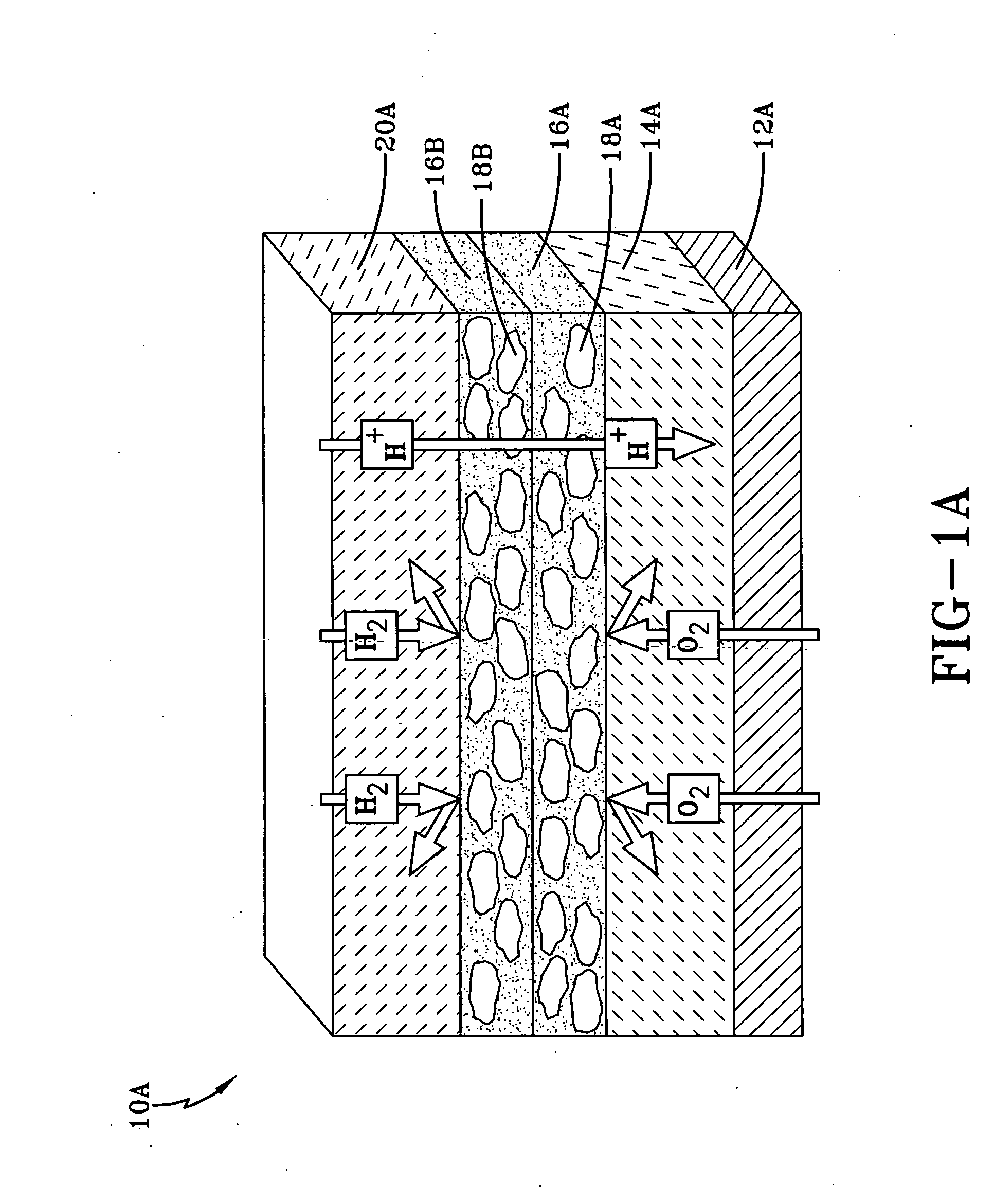

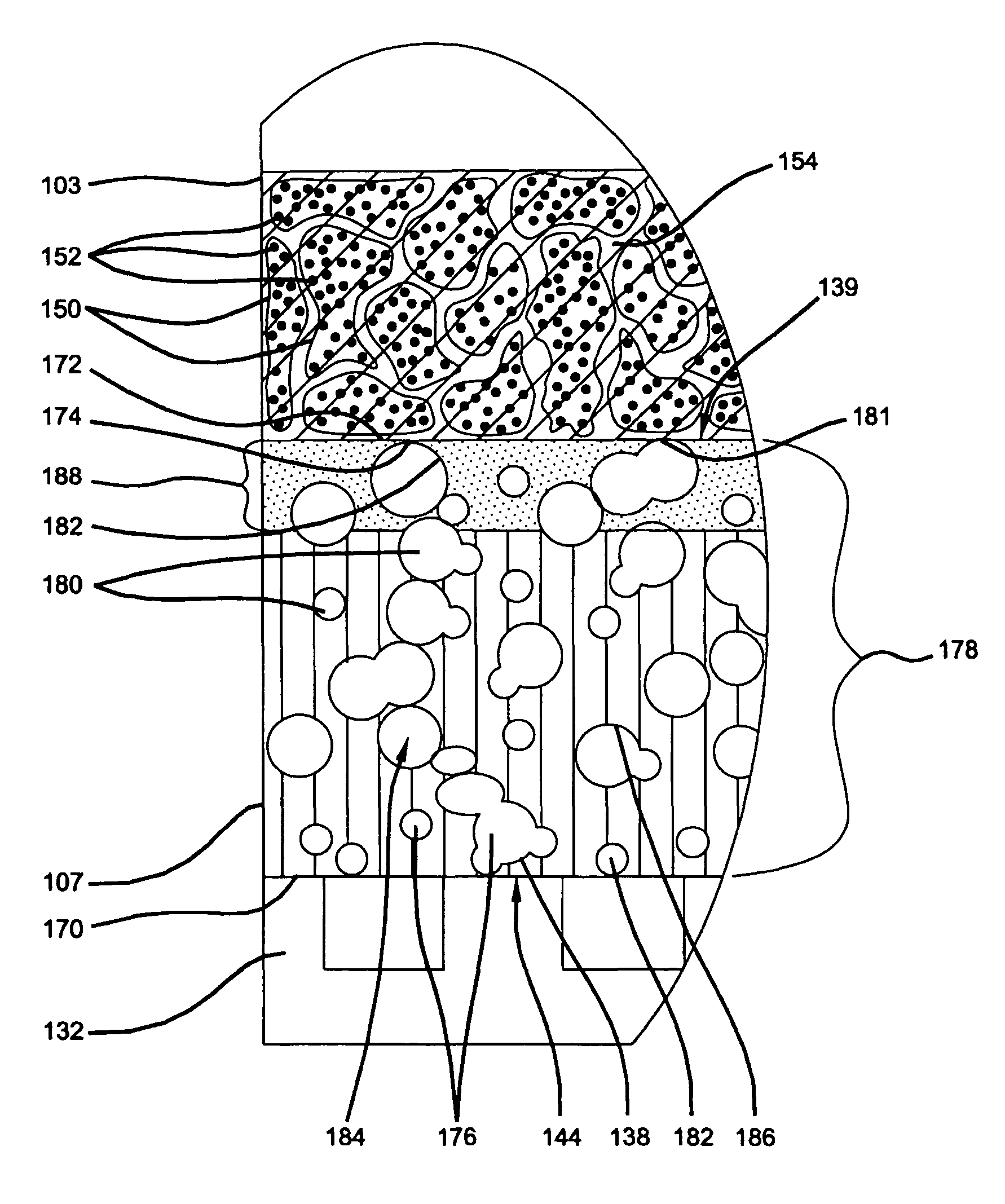

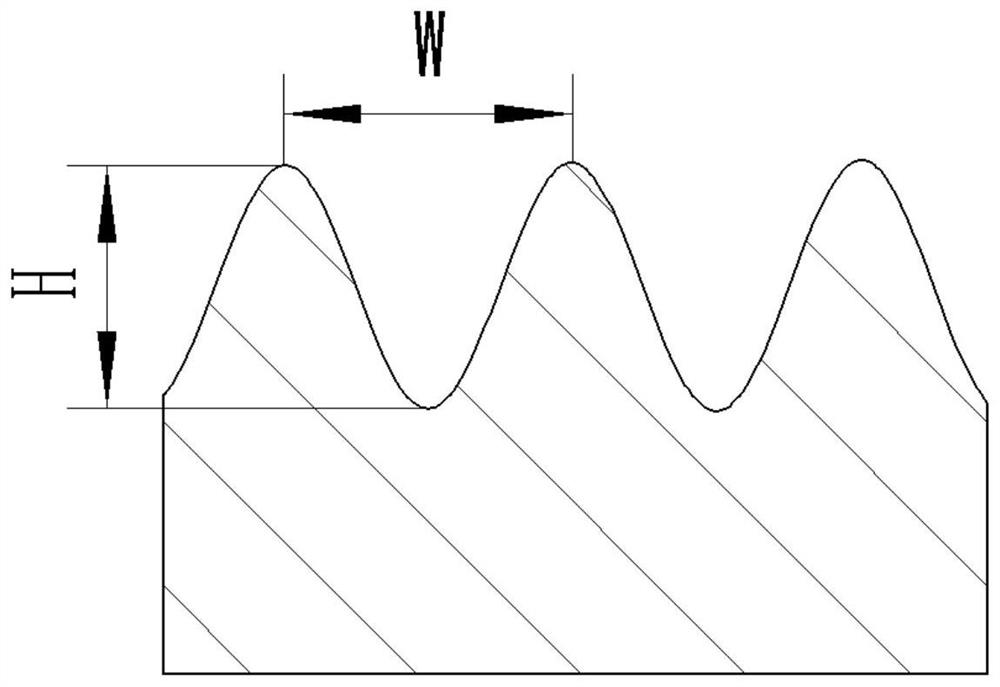

Composite Water Management Electrolyte Membrane For A Fuel Cell

InactiveUS20090017344A1Promote hydrationEffectively remove waterCell electrodesWater management in fuel cellsIonomerFuel cells

A composite electrolyte membrane (10) for a fuel cell (30) includes an ionomer component (16) extending continuously between opposed first and second contact surfaces (12, 14) defined by the membrane (10). The ionomer component is a hydrated nanoporous ionomer consisting of a cation exchange resin. The membrane (10) also includes a microporous region (18) consisting of the ionomer compound (16) and a structural matrix (20) dispersed through region (18) within the ionomer compound (16) to define open pores having a diameter of between 0.3 and 1.0 microns. The microporous region (18) does not extend between the contact surfaces (12, 14), and facilitates water management between the electrode catalysts (32, 34).

Owner:AUDI AG +2

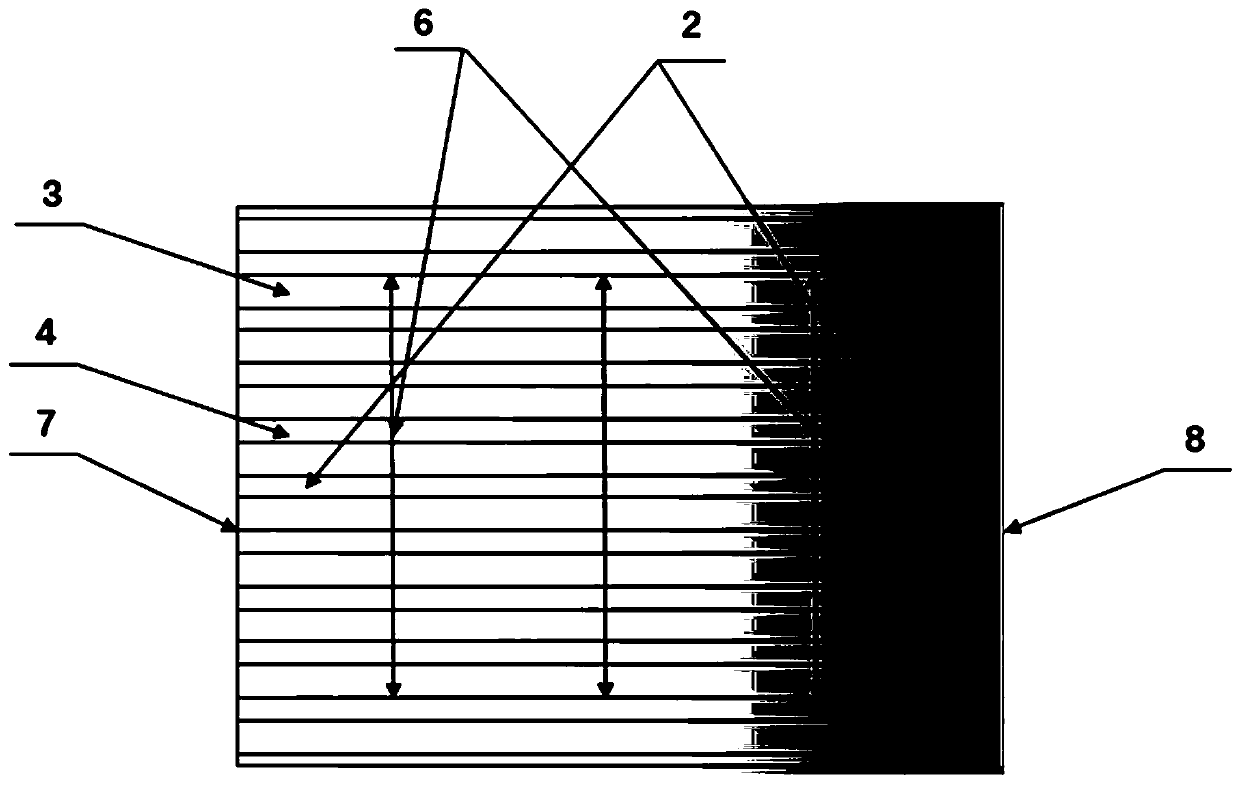

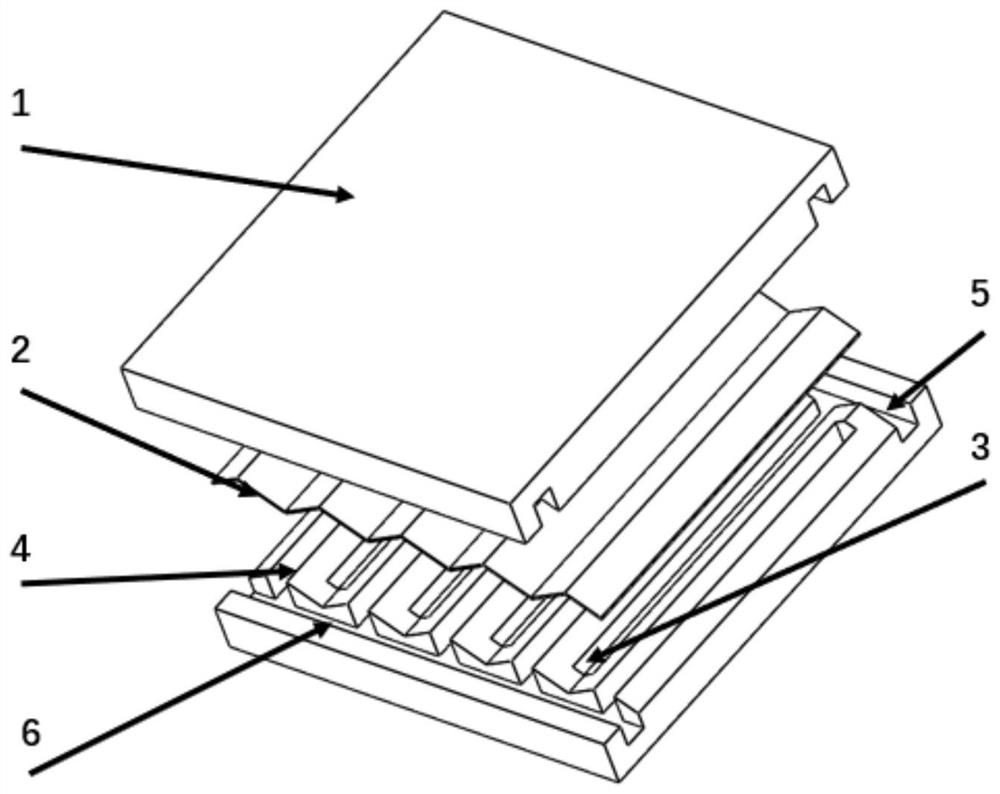

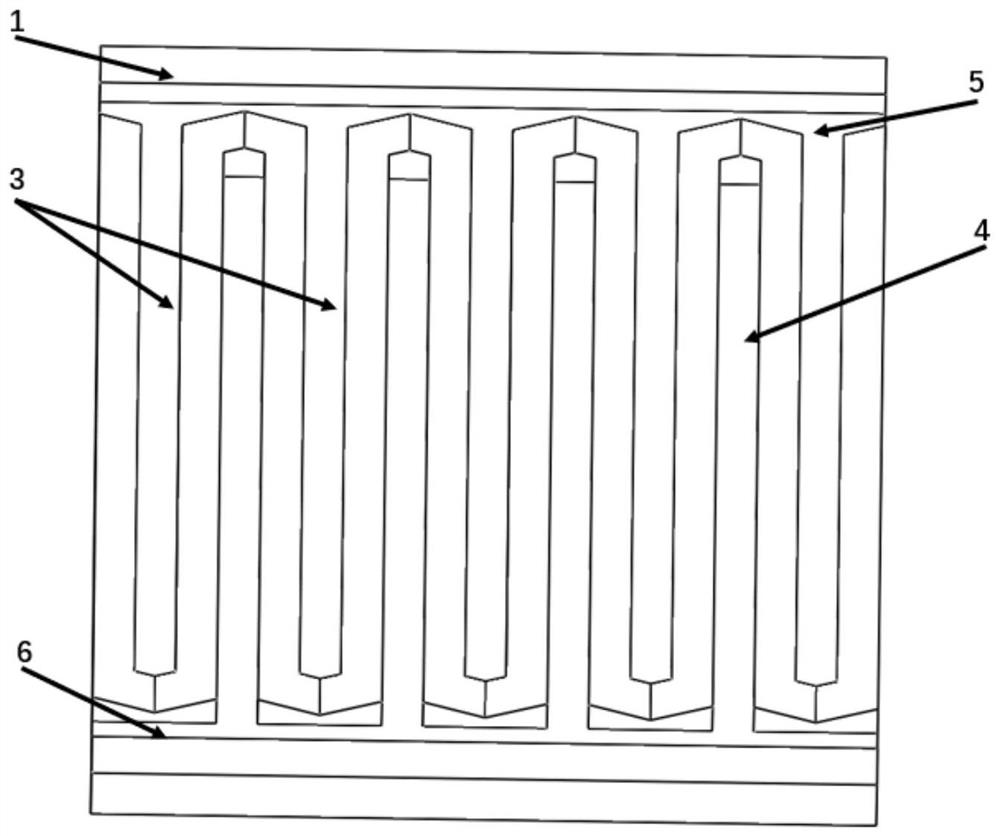

Integrated reversible fuel cell water-gas separation structure and reversible fuel cell

The invention relates to an integrated reversible fuel cell water-gas separation structure, which comprises a gravity-driven water-gas separation flow channel and a membrane electrode assembly (2), and the water-gas separation flow channel comprises a downward concave water flow channel (3) and an upward convex gas flow channel (4); the upper convex gas flow channels (4) and the lower concave water flow channels (3) are arranged in a staggered manner; the membrane electrode assembly (2) corresponds to the flow channel walls of the upper convex gas flow channel (4) and the lower concave water flow channel (3) to form a broken line shape; the upper convex gas flow channels (4) are connected through a gas distribution area (6), and the lower concave water flow channels (3) are connected through a water distribution area (5). Compared with the prior art, the reversible fuel cell has the advantages that water and gas flow channels are separated, the water management and reaction catalysis efficiency of the reversible fuel cell is effectively improved, and efficient bidirectional reversibility of the cell is really realized.

Owner:SHANGHAI JIAO TONG UNIV

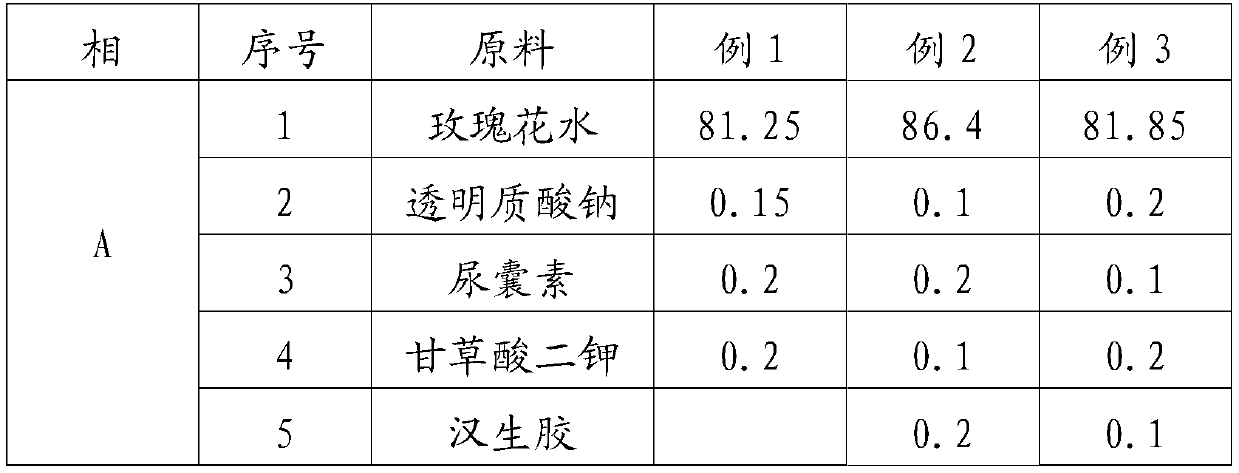

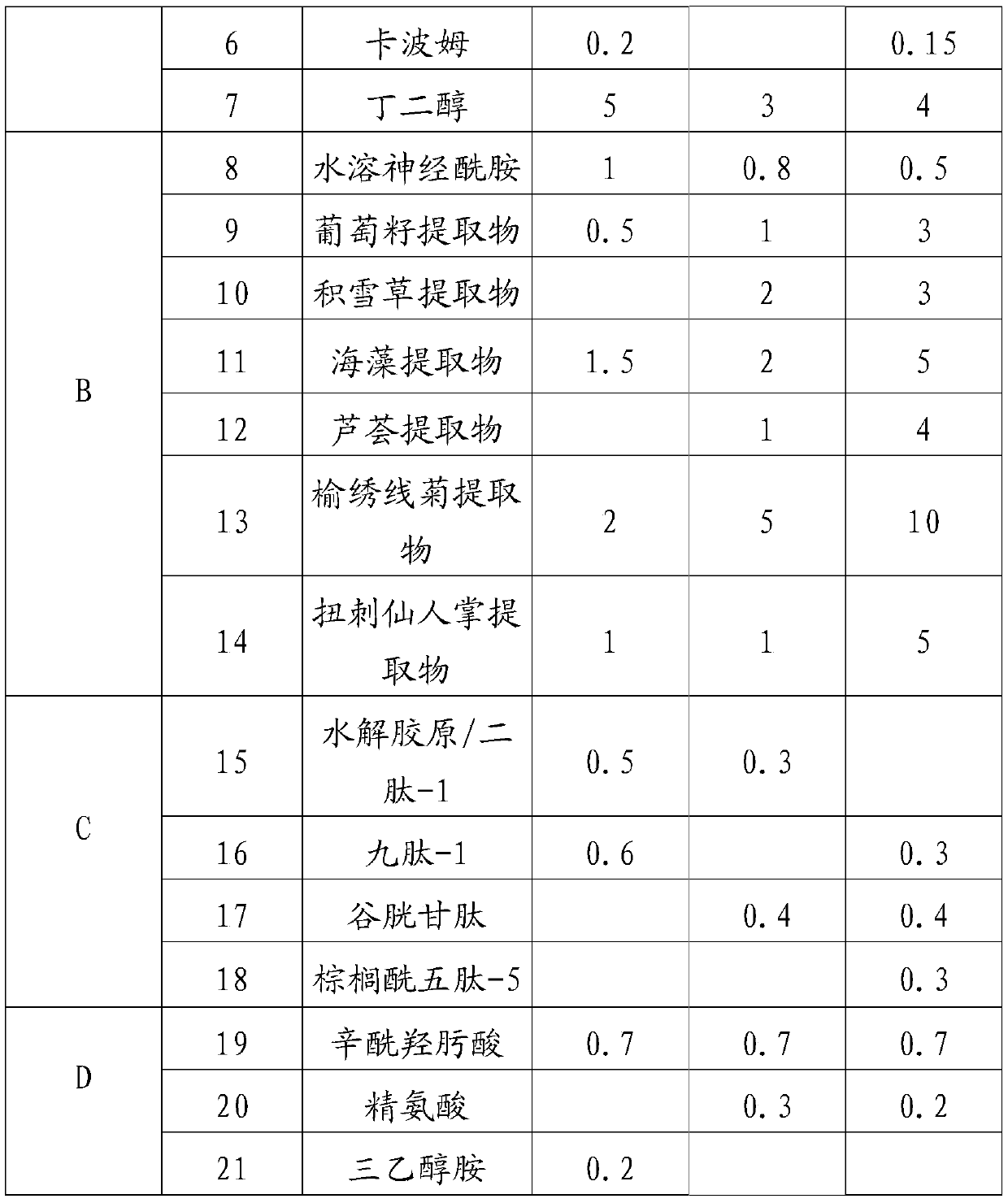

High-moisture-keeping composition capable of improving skin dryness

InactiveCN110025550AAvoid stimulationEasy to synthesizeCosmetic preparationsToilet preparationsCentella asiatica extractExtracted grape seeds

The invention discloses a high-moisture-keeping composition capable of improving skin dryness. The high-moisture-keeping composition comprises the following components in parts by mass of 40-95 partsof solvents, 0.1-10 parts of polypeptide, 5-30 parts of a plant extract, 0.1-1 part of a rheologic adjusting agent and 0.1-8 parts of an additive, wherein the plant extract is one or a mixture of twoor more of an aloe extract, a grape seed extract, a kelp seaweed extract, a centella asiatica extract, a spiraea ulmaria extract and an opuntia streptacantha extract in any proportion, and preferablythe spiraea ulmaria extract. The high-moisture-keeping composition disclosed by the invention has good moisture keeping effects.

Owner:GUANGZHOU KEEN BIOTECH CO LTD

Circular direct methanol fuel battery set with high performance and low cost

InactiveCN101330157AEasy to cleanEasy maintenanceFuel cells groupingCell electrodesMethanol fuelEngineering

The invention discloses a high-performance low-cost round direct methanol fuel battery pack, which comprises a casing. An outer membrane electrode and an inner membrane electrode are disposed in the casing. An air chamber is in the inner membrane electrode, an air chamber is between the casing and the outer membrane electrode, and a battery electrolyte chamber is between the inner membrane electrode and the outer membrane electrode. The insulating sealing rings are disposed at two ends of the membrane electrodes. A cathode output member and an anode output member are respectively disposed at the cathode terminal and the anode terminal of the battery pack. A water-guide air-blocking membrane is disposed on the outer side of the anode output member. A water collector is disposed on the outer side of the water-guide air-blocking membrane. A one-way valve communicating with the battery electrolyte chamber and a blow-down bolt device are disposed on the cathode output member. The battery pack has the advantages of reasonable structure and good operation performance.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH

Polymer fuel cell structure

InactiveUS7790330B2Improve water managementEasy to humidifyWater management in fuel cellsActive material electrodesInlet channelProton

A polymer electrolyte fuel cell structure includes a proton exchange membrane (4). An anode catalyst layer (1,16) is located on one side of the proton exchange membrane. A cathode catalyst layer (7) is located on the opposite side of the proton exchange membrane, and a gas distribution layer (3,5) is arranged on each side of the proton exchange membrane (4). The anode side gas distribution layer (3) is a flat, porous structure having water channels (3a) formed in the surface facing the membrane (4). The anode side gas distribution layer (3) is enclosed by a coplanar, sealing plate (2) with water inlet channels coupled to the water channels (3a) in the gas distribution layer.

Owner:POWERCELL SWEDEN AB

A kind of preparation method of fuel cell CCM membrane electrode

The invention provides a method for preparing a fuel cell CCM membrane electrode, specifically spraying / screen printing catalyst slurry onto a transfer membrane to form a catalytic layer, and then transferring the catalytic layer onto a proton exchange membrane by hot pressing , to form a CCM electrode, which is a common preparation method for fuel cell membrane electrodes. However, in the process of preparing CCM by transfer printing, there are often problems such as the large adhesion between the catalytic layer and the transfer film, the uneven preparation of the catalytic layer, the uneven temperature and pressure of hot pressing, and the uneven temperature and humidity of the environment. The transfer is not complete, which leads to the failure of CCM preparation. The present invention proposes a transition layer method, which can reduce the adhesion between the catalytic layer and the transfer film, improve the transfer efficiency of the catalytic layer, and improve the water management problem between the catalytic layer and the microporous layer, and The resulting mass transfer problems, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Active control strategy for PEM fuel cell liquid water evacuation

InactiveUS7858252B2Minimize impactImproves chemical kinetics and currentFuel cells groupingFuel cell auxillariesFuel cellsNuclear engineering

The present invention provides a fuel cell stack and a method of operating the same that allows for removal of liquid water and minimizes the impact of liquid water on the performance of the fuel cells. By selectively blocking the cathode reactant flow from exiting the fuel cell stack improved water management can be achieved. The selective blocking of the cathode reactant from exiting the fuel cell stack also helps to increase the partial pressure of the oxygen toward the exit side of the fuel cell stack which improves the chemical kinetics and the voltage produced by the fuel cells.

Owner:GM GLOBAL TECH OPERATIONS LLC

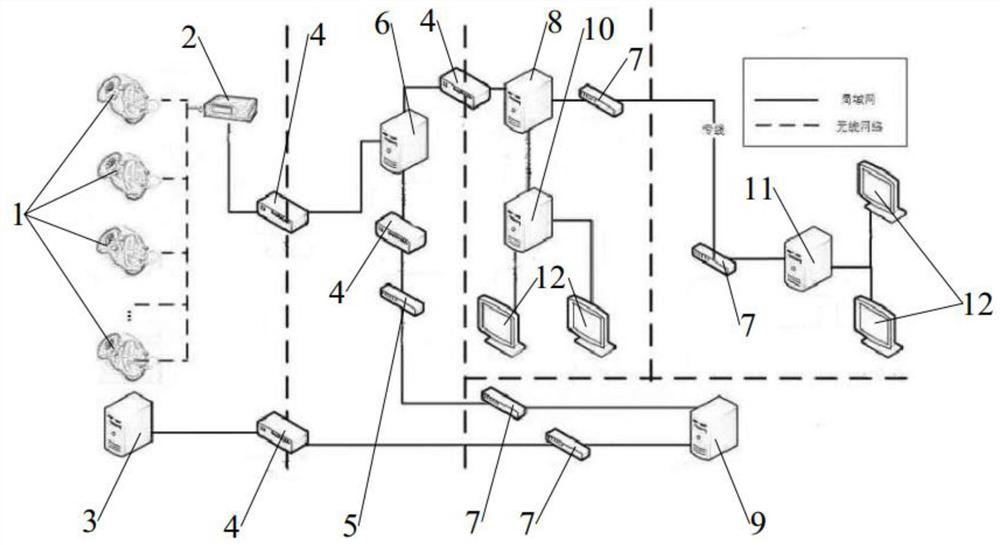

Management system and method for water resource regulation and operation

PendingCN113902288ALow costSave water resources and sewage costsGeneral water supply conservationResourcesWater balanceEnvironmental geology

The invention provides a management system and method for water resource regulation and operation, and the management system comprises: a data collection module, which is used for detecting the water affair information and equipment information of the system; a data service module, which is used for counting, analyzing and storing water affair data and equipment data in the system and outputting a management report; a water balance detection module, which is used for monitoring and calculating the water unbalance rate of the system in real time; a salt balance detection module, which is used for monitoring the salt balance condition in real time; and a regulation and control module, which is used for data transmission, analysis, monitoring, early warning, diagnosis and regulation and control of water resources. Through on-line monitoring and regulation of water balance and salt balance, water resources and pollution discharge cost are saved, the situation that water resources are insufficient in the place where a plant is located is relieved, meanwhile, due to the arrangement of the regulation and control module, fault discovery time is greatly shortened, an operator can obtain fault treatment measures in the first time, fault removal time is greatly shortened, and comprehensive water consumption of power generation of the whole plant is reduced.

Owner:北京京能能源技术研究有限责任公司

Method for preparing fuel cell metal bipolar plate flow field through electrochemical etching

ActiveCN110931819AImprove corrosion resistanceImprove water managementFinal product manufactureFuel cellsFuel cellsTriethoxysilane

The invention discloses a fuel cell metal bipolar plate flow field manufacturing method, belongs to the field of fuel cells, and particularly relates to a manufacturing process of a fuel cell metal bipolar plate. According to the method, a required flow channel is etched on the surface of the metal bipolar plate mainly according to the principle of electrochemical anodic dissolution, and a hydrophobic film is plated in a groove after a flow field is etched, so that water management is improved, and the corrosion resistance of the flow field plate is enhanced. And the metal bipolar plate flow field is subjected to electrochemical etching, and a hydrophobic protective film is plated in the flow field groove. And the hydrophobic protective film is any one of a PTFE film, a tridecafluorooctyltriethoxysilane film and a heptadecafluorodecyltriethoxysilane film. The method has the advantages of low cost, short time period, easiness in template modification, convenience in manufacturing and the like. According to the method, continuous manufacturing of different sample bipolar plate flow fields can be achieved, so that continuous fine adjustment of the flow fields is achieved, and the optimal flow field performance is obtained.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com