Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Improve spinning stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titania fiber, method for producing the fiber and method for using the fiber

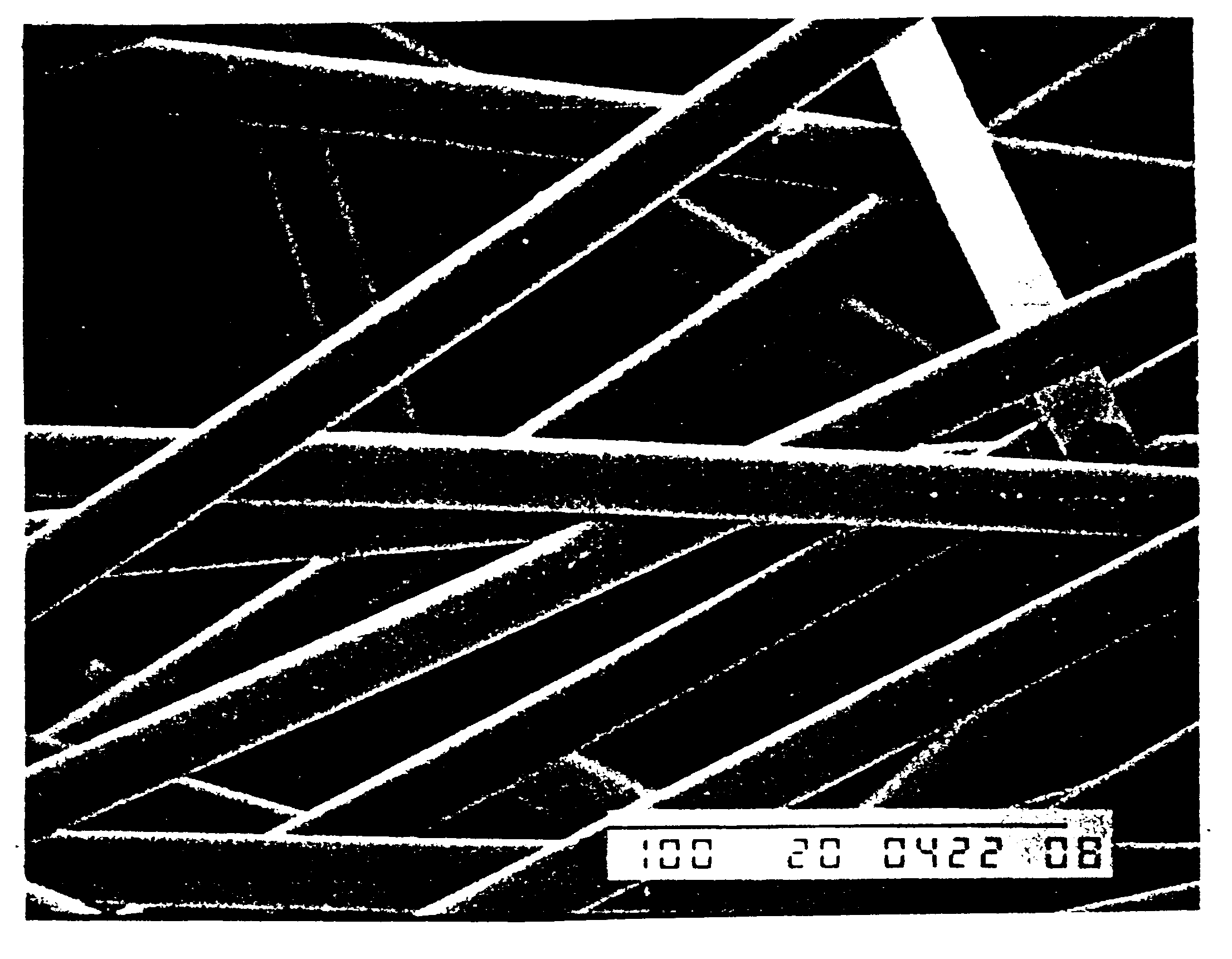

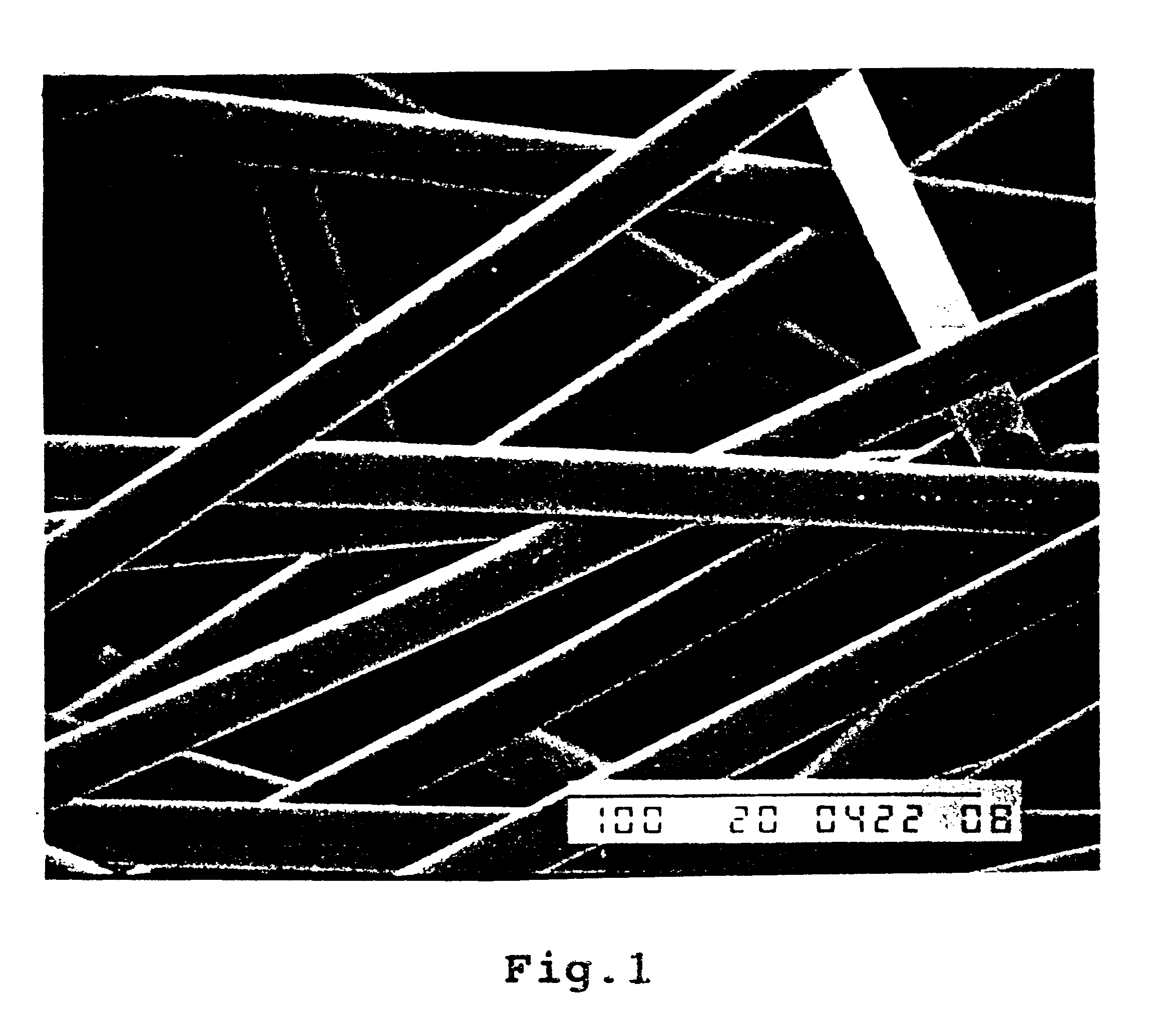

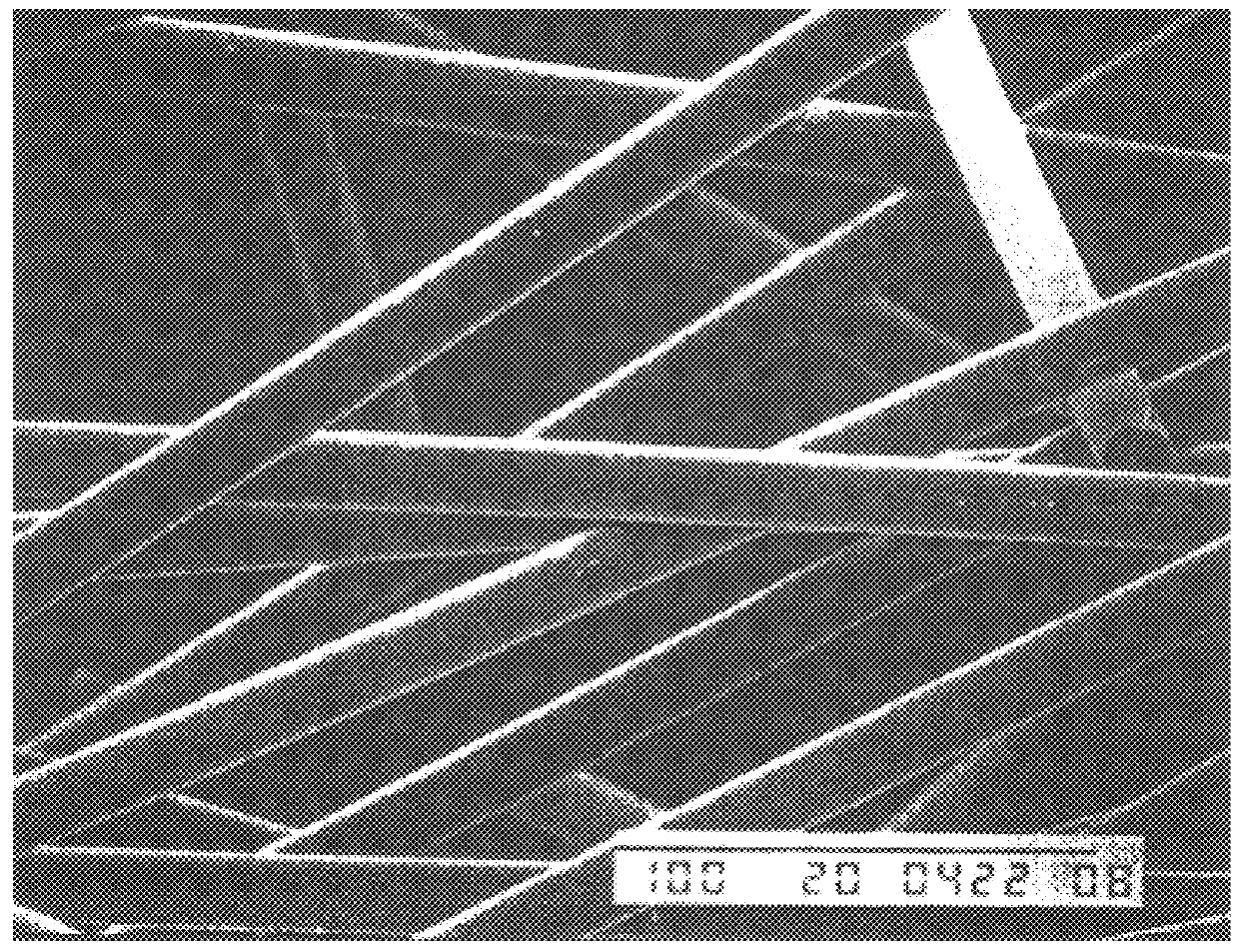

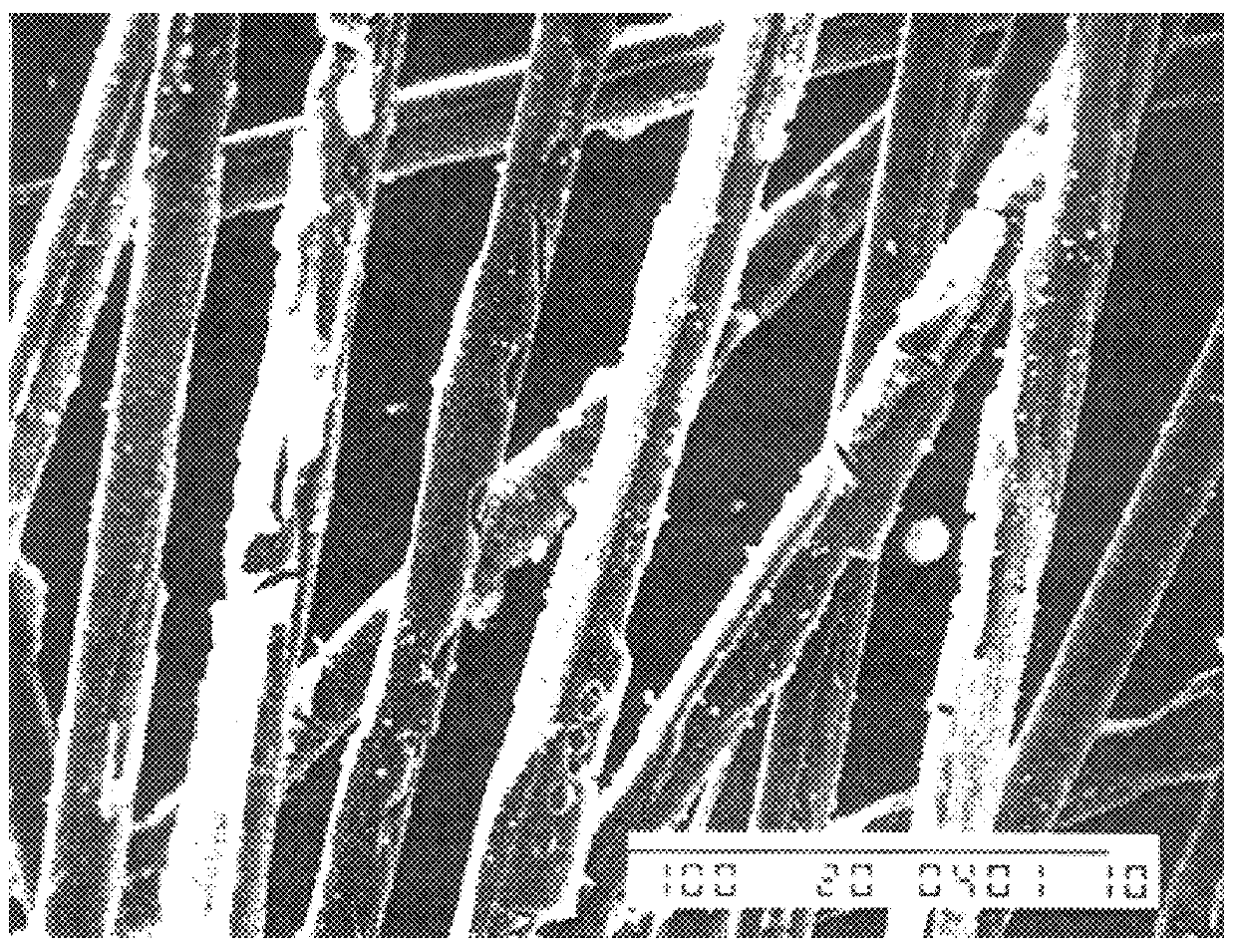

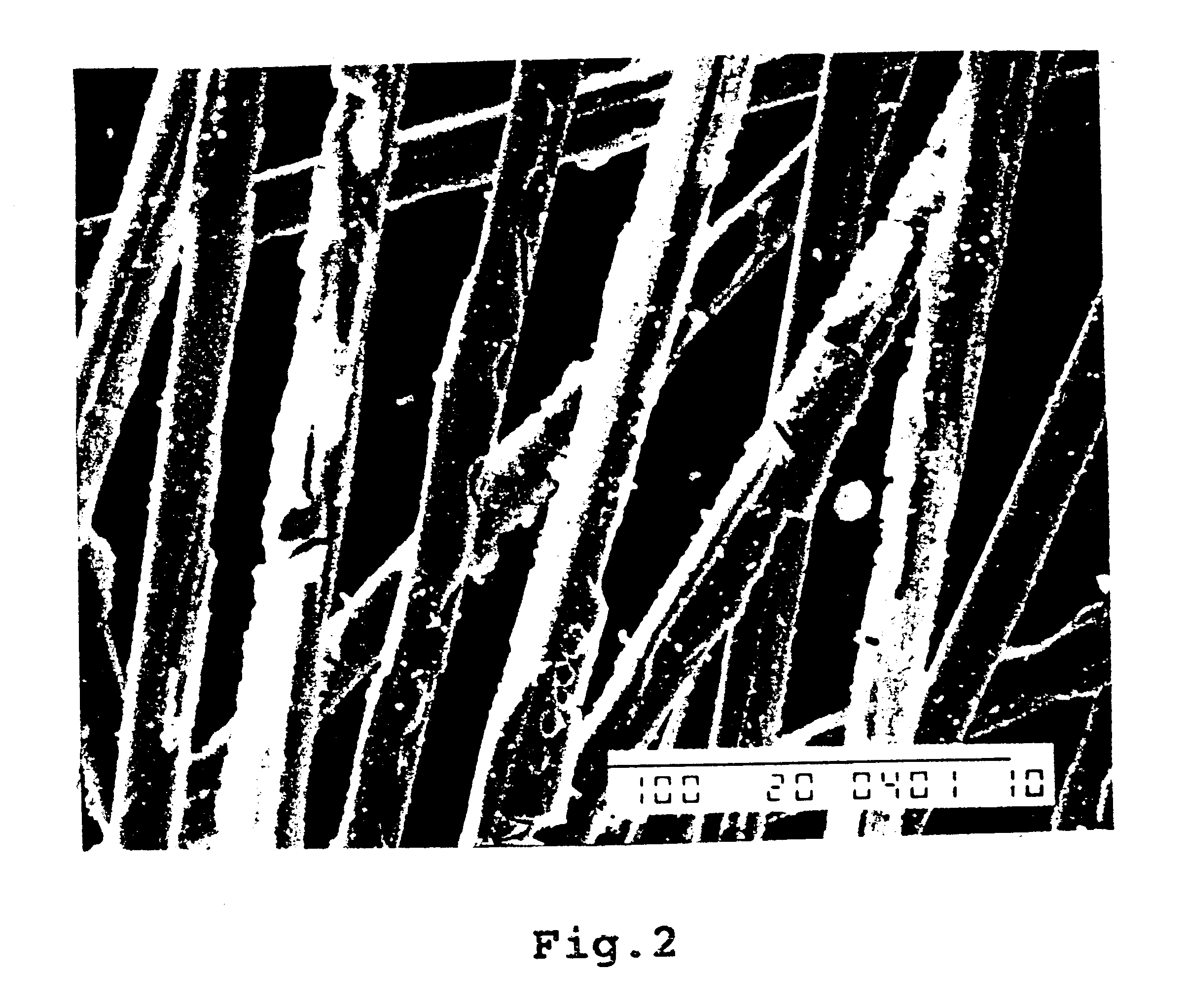

InactiveUS6191067B1Improve spinning stabilityHigh mechanical strengthAluminium compoundsOther chemical processesFiberPore diameter

A continuous fiber of titania are made having an average diameter per a monofilament of from 5 to 50 mum, which has a BET specific surface area of 10 m2 / g or more, a pore volume of 0.05 cc / g or more, a volume of pores having a pore diameter of not less than 10 angstroms being 0.02 cc / g or more and an average tensile strength per a monofilament of 0.1 GPa or more, or which has an average tensile strength per a monofilament of 0.5 GPa or more.

Owner:SUMITOMO CHEM CO LTD

Titania fiber, method for producing the fiber and method for using the fiber

InactiveUS6086844AImprove spinning stabilityHigh mechanical strengthOther chemical processesTitanium dioxideFiberPore diameter

A continuous fiber of titania are made having an average diameter per a monofilament of from 5 to 50 mu m, which has a BET specific surface area of 10 m2 / g or more, a pore volume of 0.05 cc / g or more, a volume of pores having a pore diameter of not less than 10 angstroms being 0.02 cc / g or more and an average tensile strength per a monofilament of 0.1 GPa or more, or which has an average tensile strength per a monofilament of 0.5 GPa or more.

Owner:SUMITOMO CHEM CO LTD

Polyphenylene sulfide fiber spinning technology

ActiveCN102776601AHigh crystallinityGood light stabilityArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentPolymer scienceVacuum drying

The invention relates to a polyphenylene sulfide fiber spinning technology which comprises the steps as follows: (1) pre-processing materials: mixing graphite powder with a silane coupling agent to obtain modified graphite, and mixing the modified graphite and polyphenylene sulfide resin at a high speed so as to obtain a mixture, and finally pre-crystallizing and drying the mixture in a vacuum drying box to obtain dried powder with less than 50 ppm of water; (2) melting and spinning: feeding the dried powder into a double-screw extruder for melting and spinning so as to obtain a melt; (3) slowly cooling and cooling: thermally forming the smelt after forming silk through a spinneret plate, and then transferring to a slow cooling area, and finally transferring to a cooling area to solidify and form; and (4) drafting and finalizing: carrying out oil applying and silk guiding on the solidified and finalized fiber, and then drafting and finalizing at three times so as to obtain the short fiber with the linear density of 11 dte x. The polyphenylene sulfide fiber spinning technology is low in cost and easy in industrial production; and the fiber material prepared via the technology has good performance.

Owner:DUNHUANG XIYU MINING & CHEM

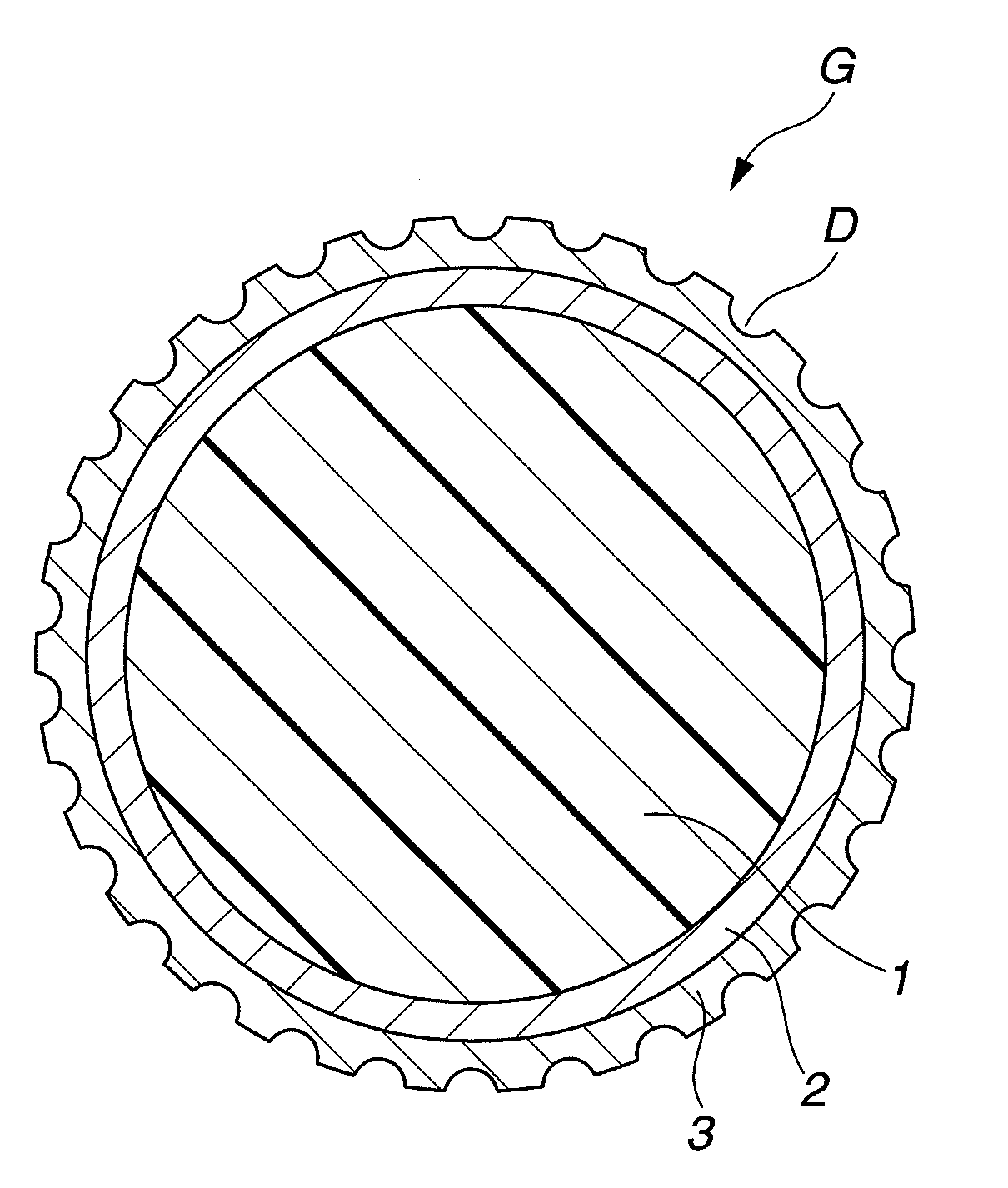

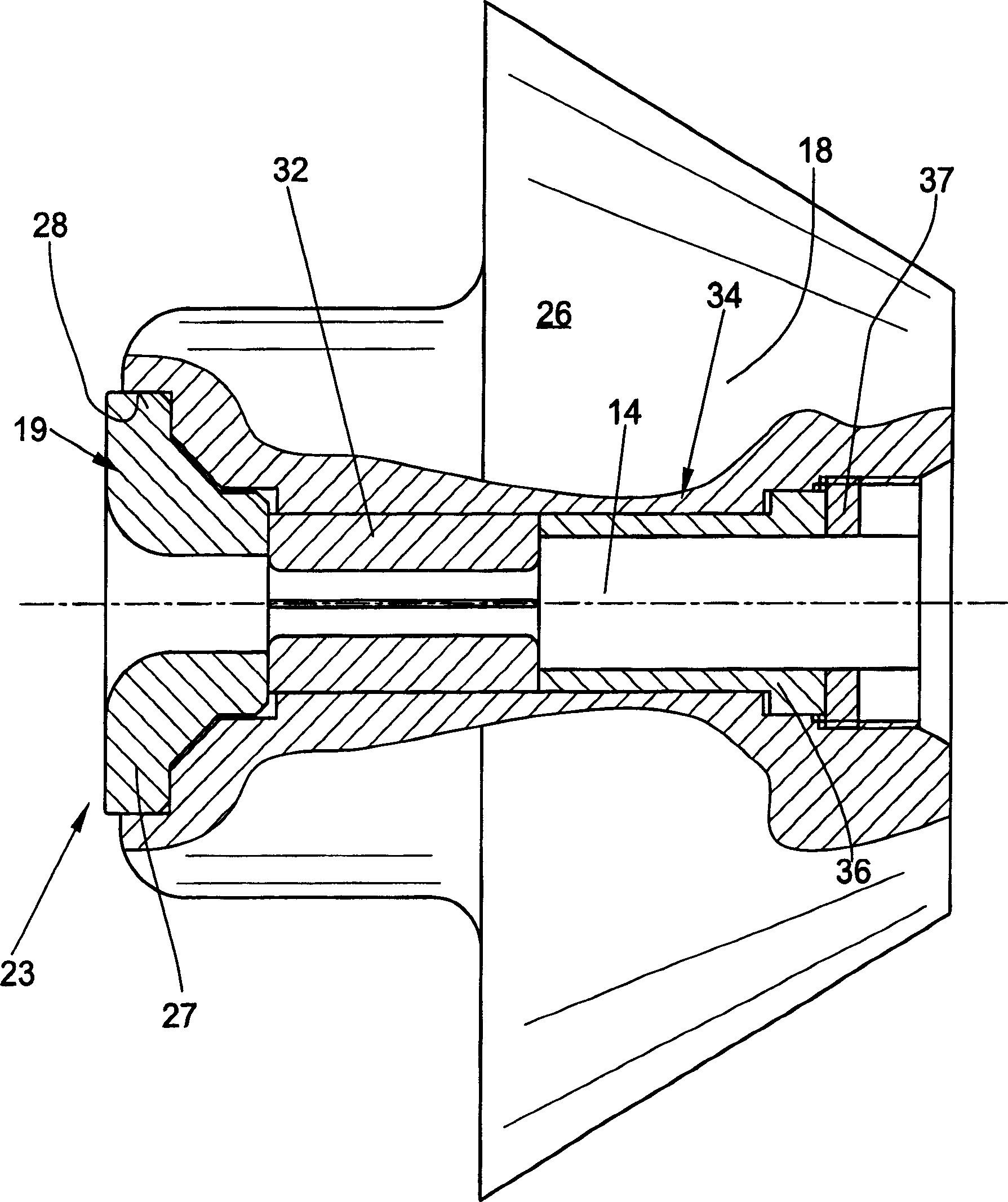

Multi-piece solid golf ball

The invention provides a multi-piece solid golf ball composed of a solid core, a cover, at least one intermediate layer interposed therebetween, and a plurality of dimples on a surface of the ball. The respective initial velocities (m / s) of the core, a sphere I composed of the core encased by the intermediate layer, and the golf ball satisfy formula A below, and the respective deflections (mm) of the core, the sphere I composed of the core encased by the intermediate layer, and the golf ball, when compressed under a final load of 130 kg from an initial load of 10 kgf, satisfy formula B below:(initial velocity of core−initial velocity of sphere I)2+(initial velocity of sphere I−initial velocity of golf ball)2<0.40; Formula A:0.30<(deflection of core−deflection of sphere I)2+(deflection of sphere I−deflection of golf ball)2<0.70. Formula B:The golf ball of the invention has a good feel, an excellent spin performance on approach shots and an excellent distance, in addition to which it has an excellent scuff resistance and durability.

Owner:BRIDGESTONE SPORTS

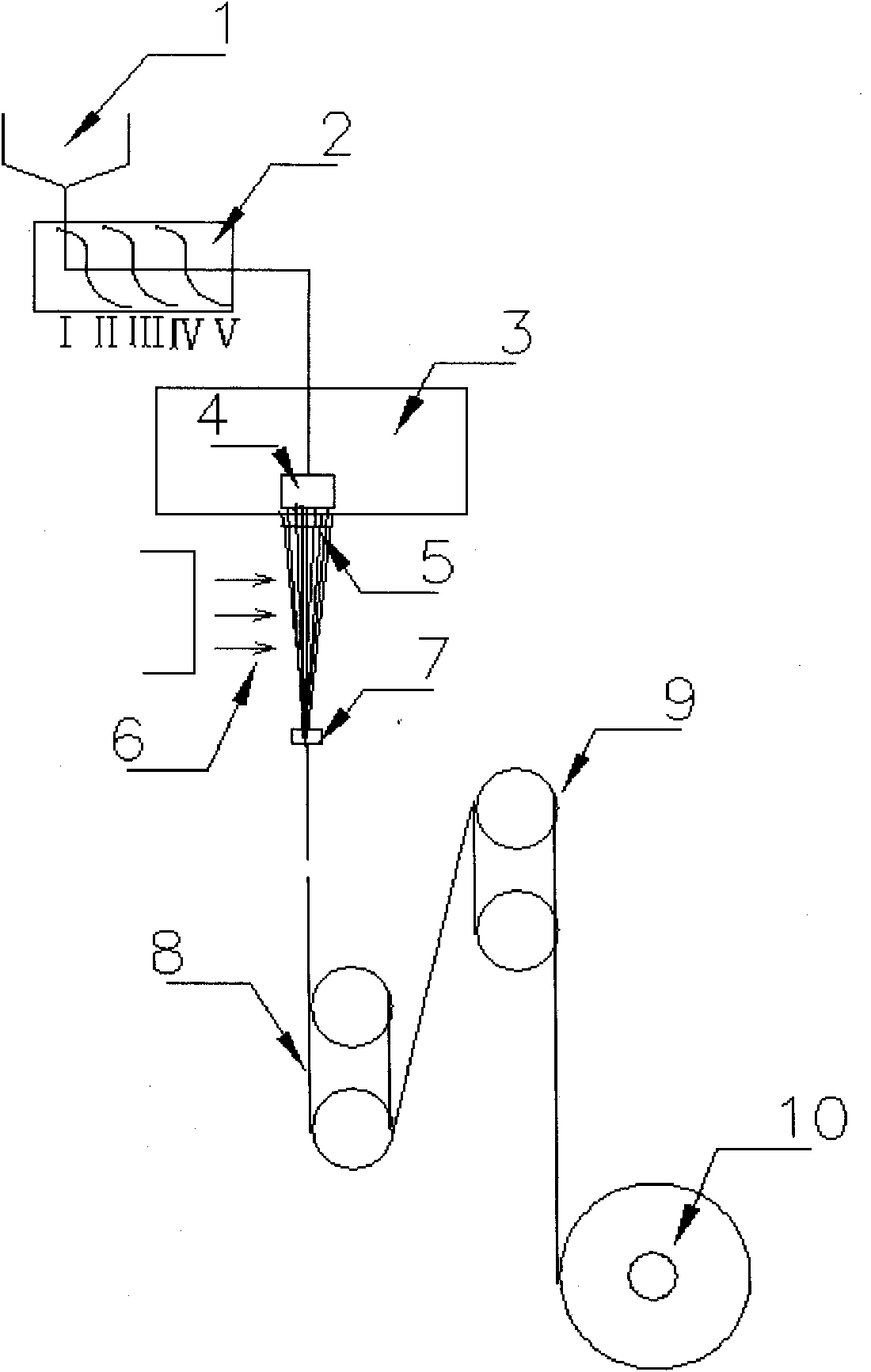

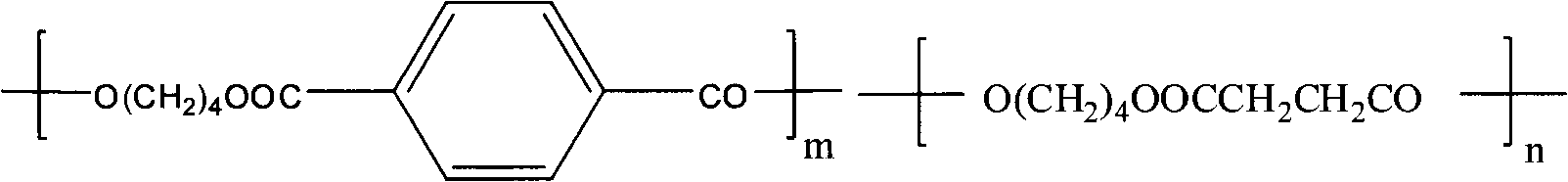

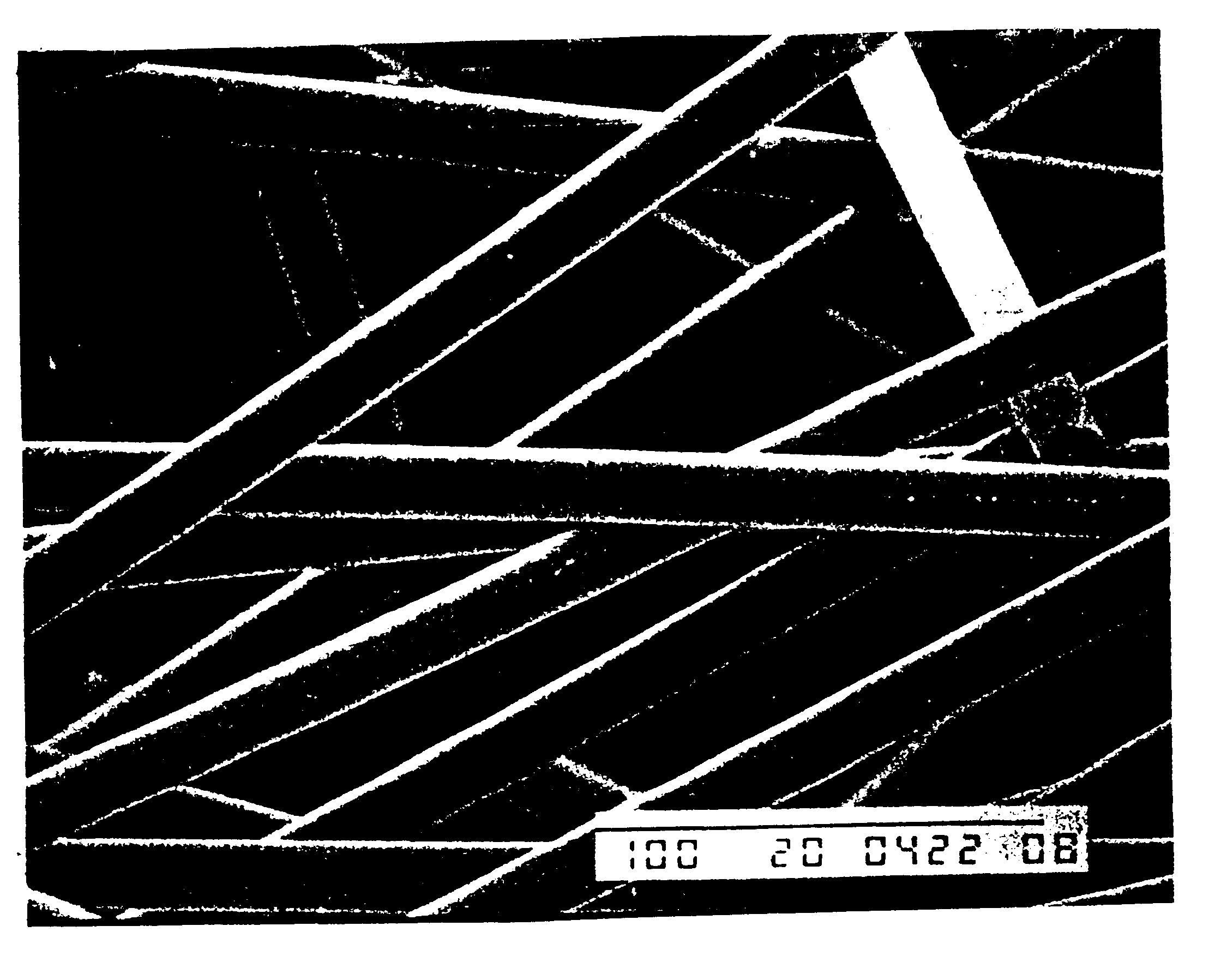

Method for preparing biodegradable copolyester fully-drawn yarns in one step

InactiveCN101781805AImprove spinning stabilityImprove evennessFilament manufactureMonocomponent copolyesters artificial filamentYarnEngineering

The invention belongs to the technical field of the melt-spinning manufacturing functional synthetic fibers, and provides a method for preparing biodegradable copolyester fully-drawn yarns in one step, which is specifically used for preparing the biodegradable polybutylene terephthalate-co-polybutylene succinate fully-drawn yarns by taking biodegradable polybutylene terephthalate-co-polybutylene succinate slices as raw materials and adopting a one-step melt-spinning process. The method has the advantages of high spinning stability, no broken filament, high yarn levelness, good winding property and high spinning speed; and by the method, the strength of the fully-drawn yarn is enhanced and production efficiency is improved.

Owner:DONGHUA UNIV +1

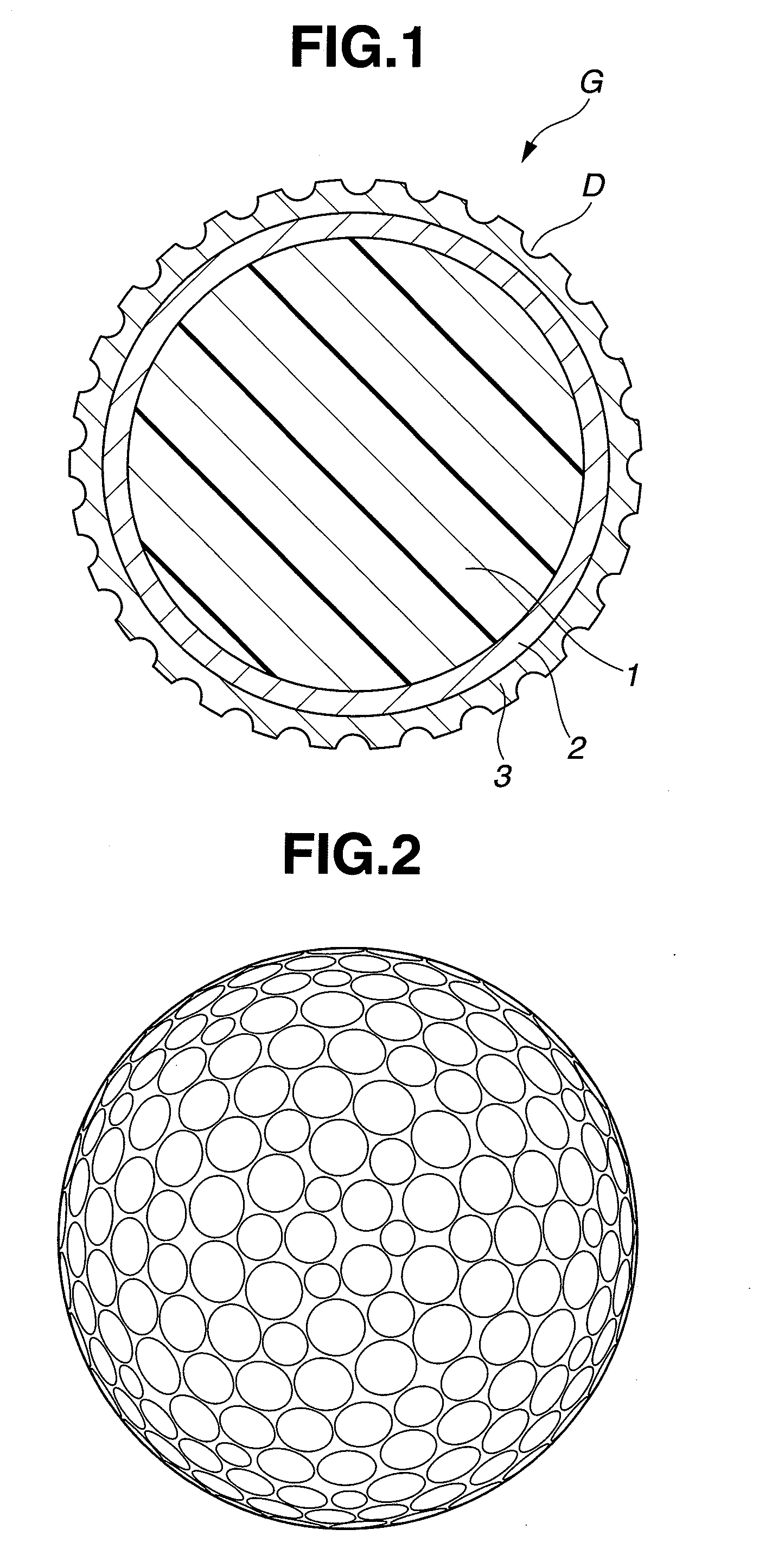

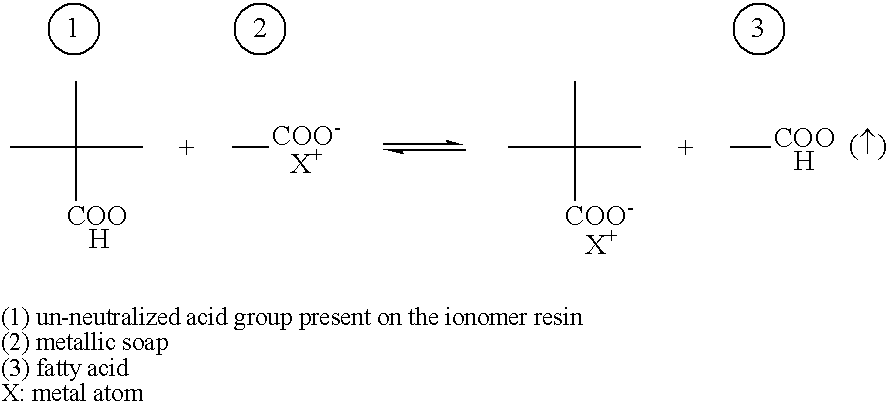

Golf ball

InactiveUS20090105012A1Improve spinning stabilityThickness minimizationGolf ballsSolid ballsEngineeringGolf Ball

Golf ball 2 of the present invention has core 4, cover 10 situated on the external side of the core 4, and paint layer provided to cover this cover 10. The base polymer of the cover 10 is a urethane resin. The base polymer of the paint layer 16 is a urethane resin. The cover 10 has a thickness Tc of 0.1 mm or greater and 0.7 mm or less. The paint layer 16 has a thickness Tp (mm) of 0.015 mm or greater and 0.040 mm or less. The ratio (Tp / Tc) is 0.021 or greater and 0.40 or less. Preferably, the paint layer 16 is formed with two or more layers 18 and 20. Preferably, the base polymer of the paint layer 16 is a two-pack type urethane resin or a two-pack type epoxy resin.

Owner:DUNLOP SPORTS CO LTD

Titania fiber, method for producing the fiber and method for using the fiber

InactiveUS6409961B1Improve spinning stabilityHigh mechanical strengthPhysical/chemical process catalystsOther chemical processesPhysical chemistryPolymer chemistry

A continuous fiber of titania are made having an average diameter per a monofilament of from 5 to 50 mum, which has a BET specific surface area of 10 m2 / g or more, a pore volume of 0.05 cc / g or more, a volume of pores having a pore diameter of not less than 10 angstroms being 0.02 cc / g or more and an average tensile strength per a monofilament of 0.1 GPa or more, or which has an average tensile strength per a monofilament of 0.5 GPa or more.

Owner:SUMITOMO CHEM CO LTD

Process for polyurethane crosslinking agent for melting spandex fiber

InactiveCN101070370AImprove spinning stabilityHigh breaking strengthMonocomponent polyurethanes artificial filamentArtifical filament manufactureFiberBreaking strength

A production method of melt-spun polyurethane fiber by polyurethane crosslinker, polyesterdiol or polyetherdiol or mixture of polyesterdiol and polyetherdiol is vacuum dewatered under 100-140 degree C for 1-3 hours, and cooled to 50-60deg.C, added with diisocyanate under the protection of nitrogen. They react under 70-80deg.C for 1-5 hours to form the polyurethane crosslinker. The molar ratio between the referred polyesterdiol or polyetherdiol or polyesterdiol and polyetherdiol's mixture and diisocyanate is 1:1.5-1:3. The advantages of this method are simple process, high productivity, short production cycle, low production costs, less equipment investment and applied to industrial production. The crosslinker formed by using this method can improve the spinning stability, breaking strength and heat resistance of melt-spun polyurethane fiber, through practical test, the breaking strength of the melt-spun polyurethane fiber can reach to 1.5-1.8CN / dtex, and the flexible response rates of the fiber are 94-96% of 300% response, and 98% of 100% response, and the heat resistance of the fiber can be general increased by 10-15degree C, with its maximum of 140degree C, moreover, the fiber has excellent stability.

Owner:SHANGHAI YITAN NEW MATERIAL CO LTD

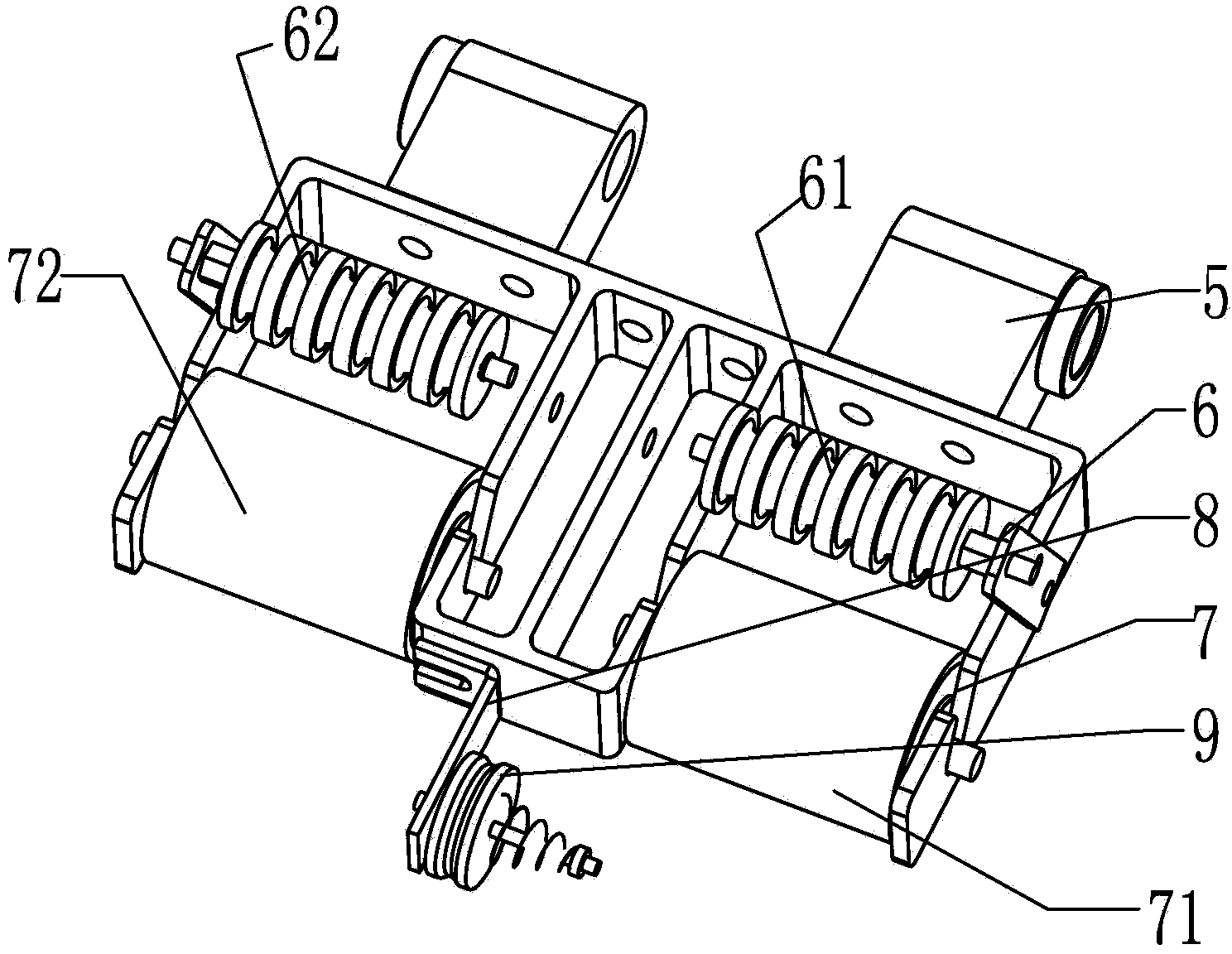

Chenille spinning machine

The invention discloses a chenille spinning machine for spinning chenille yarns. Firstly, knitting wools for spinning the chenille yarns wind an inverted triangle distance cutting sheet through a high-speed swiveling head, and the width of the neck portion of the distance cutting sheet depends on the length of pile yarns. Subsequently, a pressure roller is fed into a grey yarn rack, two core yarns are discharged, one of the core yarns forms a surface layer core yarn of the chenille yarns, and the other one of the core yarns forms a base layer core yarn of the chenille yarns. The knitting wools on the distance cutting sheet are pushed to blades through roller pieces, the blades move in the middle of the neck portion of the distance cutting sheet, and the knitting wools are cut by means of the blades. The cut knitting wools are sideward clamped between the surface layer core yarn and the base layer core yarn, and flaky knitting wools between the two core yarns are scattered towards all sides to form the chenille yarns through downward use of swiveling of reeling spindles. The chenille spinning machine has the advantages of being convenient to operate, high in production efficiency, large in reeling volume, safe, and reliable.

Owner:ZHEJIANG DONGXING TEXTILE MACHINERY

Processing method of high antibacterial towel yarn

The invention discloses a processing method of a high antibacterial towel yarn. The method comprises the steps of processing bamboo carbon fiber and long stapled cotton, pre-processing apocynum venetum fiber, mixing, drawing, roving and spinning yarns. The specific steps comprise the steps of (a) processing the bamboo carbon fiber and long stapled cotton, wherein the bamboo carbon fiber and the long stapled cotton are fully mixed, and card slivers A are obtained through opening, picking and carding the cottons; (b) pre-processing apocynum venetum fiber, wherein the pre-processing procedure is performed for the apocynum venetum fiber; (c) mixing, wherein the pre-processed apocynum venetum fiber and the long stapled cotton are mixed, and card slivers B are obtained through opening, picking and carding the cottons; (d) drawing, wherein the card slivers A and B are drawn out to obtain drawn slivers; (e) roving, wherein the roving procedure is performed for the obtained drawn slivers; (f) spinning yarns, wherein the spinning yarn procedure is performed for the obtained roves. The yarns processed by the method disclosed by the invention have good adsorbability, antibacterial property, comfort property, gas permeability and the like; the three kinds of fibers are mixed fully; after the processed fabrics are washed repeatedly, the yarns have durability and can be widely used for producing and processing antibacterial towels.

Owner:ZHEJIANG GRACE

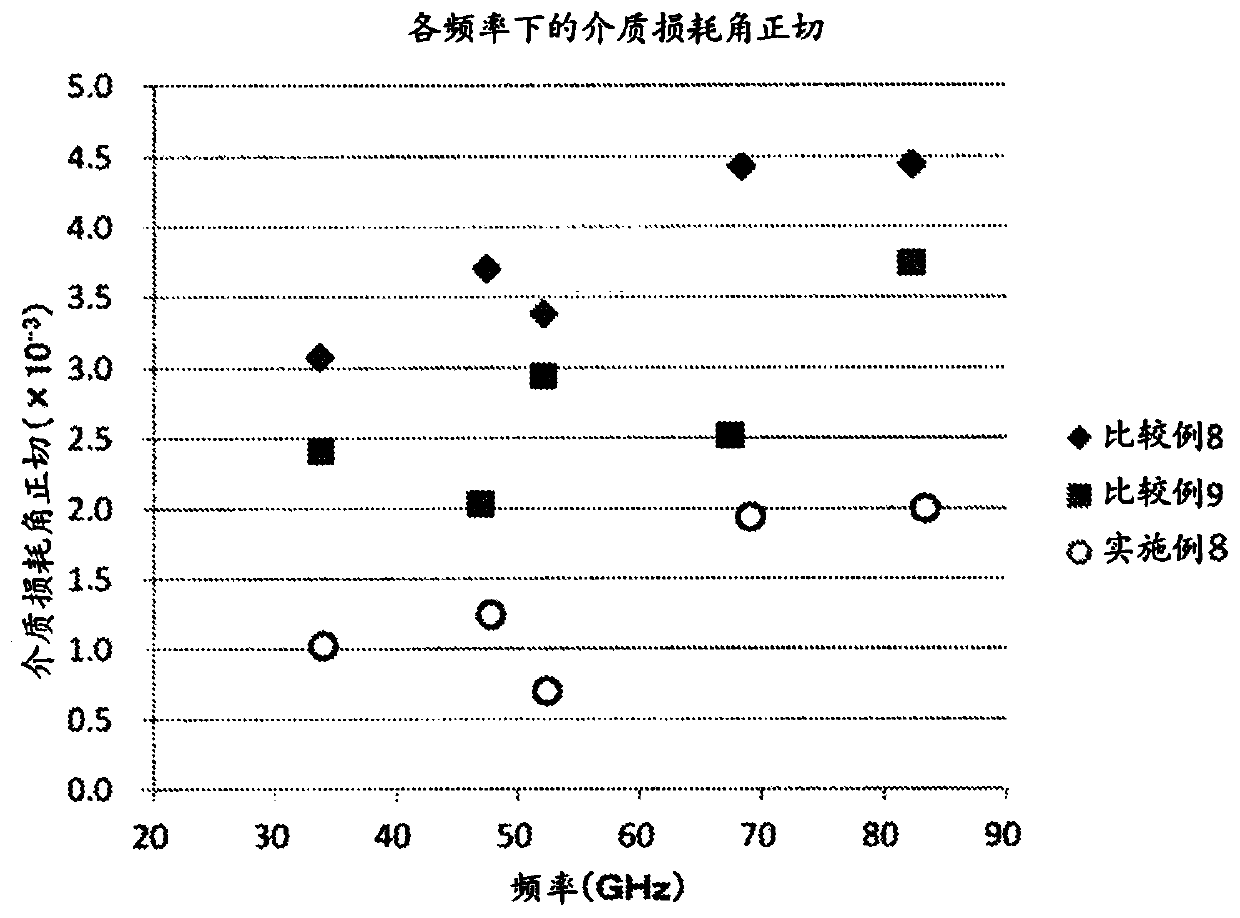

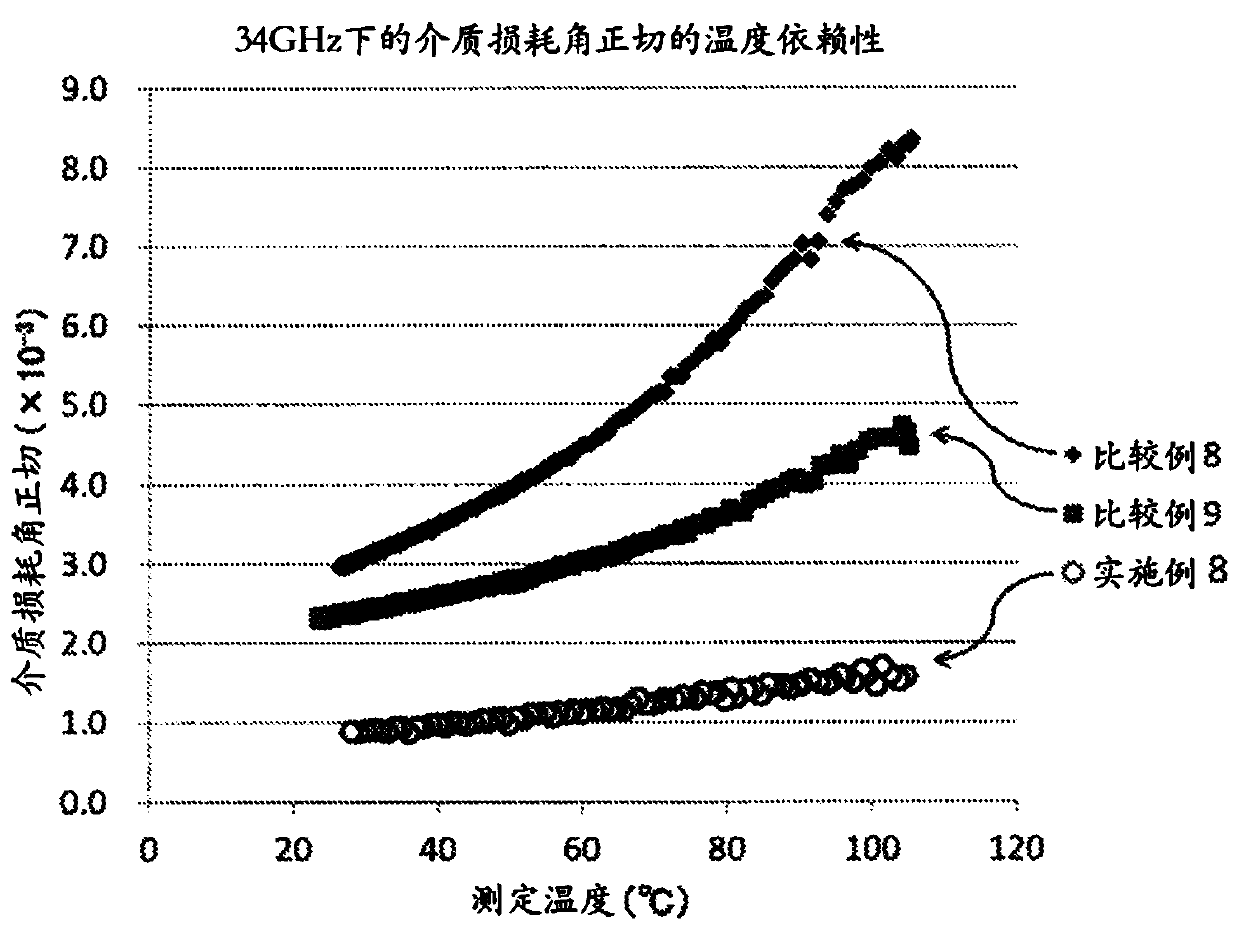

Wholly aromatic liquid crystal polyester resin, molded article, and electrical/electronic component

The invention provides a wholly aromatic liquid crystal polyester resin which achieves an excellent balance between heat resistance and processability and has a particularly low dielectric loss tangent. The wholly aromatic liquid crystal polyester resin according to the present invention is characterized by containing a constituent unit (I) derived from p-hydroxybenzoic acid, a constituent unit (II) derived from 6-hydroxy-2-naphthoic acid, a constituent unit (III) derived from an aromatic diol compound and a constituent unit (IV) derived from an aromatic dicarboxylic acid, and is also characterized in that the composition ratios (mol%) of the constituent units (I)-(IV) satisfy the following conditions: 2 mol% <= constituent unit (I) <= 9 mol%; 40 mol% <= constituent unit (II) <= 75 mol%; 9mol% <= constituent unit (III) <= 24 mol%; and 9 mol% <= constituent unit (IV) <= 24 mol%.

Owner:JXTJ NIPPON OIL & ENERGY CORP

Thread tube of open end spinning arrangement

InactiveCN1690269AQuality improvementIncrease contactContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention relates to a yarn guide tube for an open-end air spinning device. In the yarn deflection area, the yarn guide tube has a helical structure, which extends essentially continuously over the entire yarn deflection area without interruption. In addition, a further formation consisting of gentle elevations or gentle depressions follows the inner helical formation of the tube throat of the yarn guide tube. Both structures are constructed so that they can transmit forces to the yarn without damaging the yarn.

Owner:MASCHINENFABRIK RIETER AG

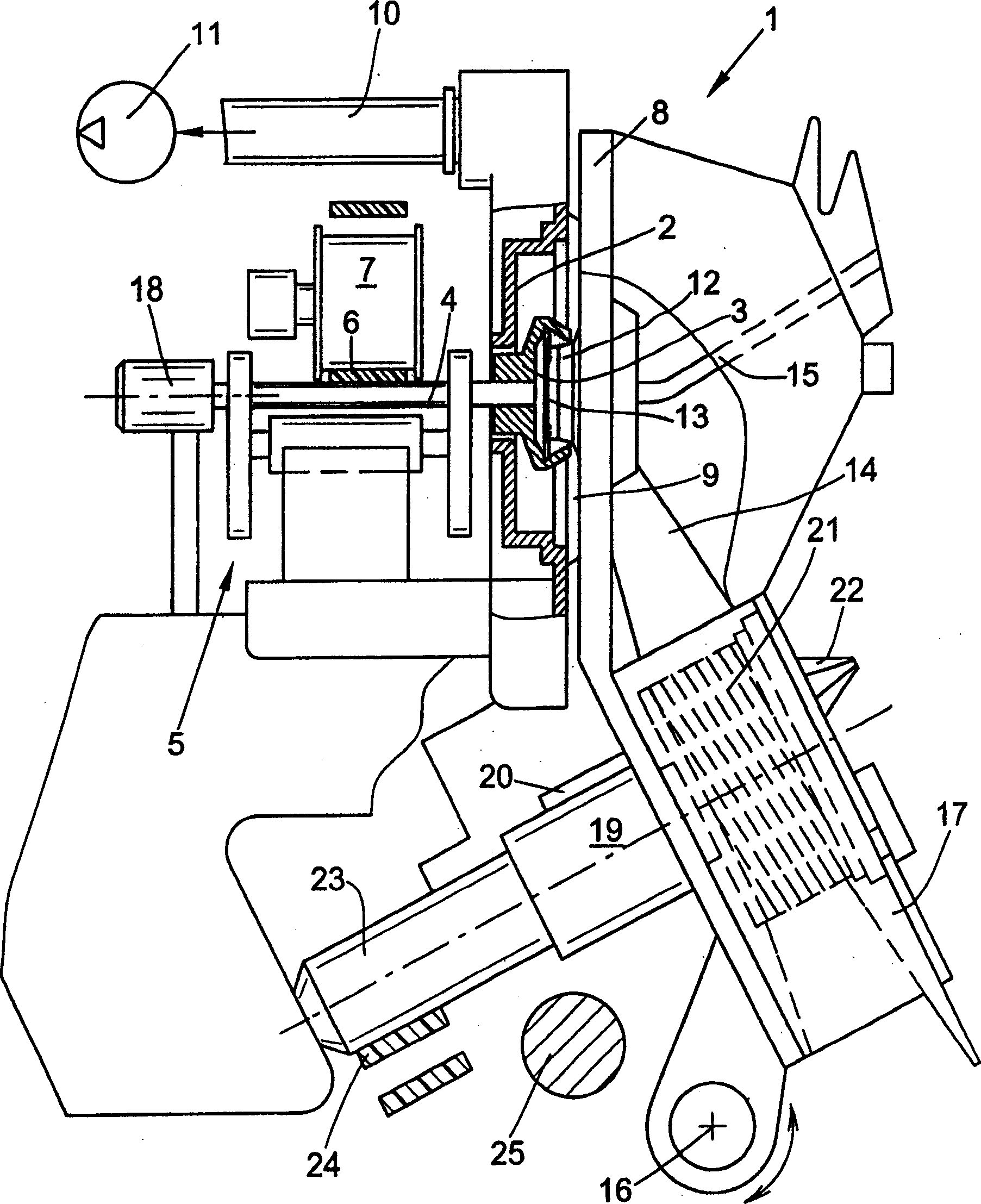

Channel disc connector for open-end spinning device

InactiveCN1461833AReduce manufacturing costsEasy to replaceContinuous wound-up machinesOpen-end spinning machinesCircular discEngineering

Owner:SAURER GERMANY GMBH & CO KG

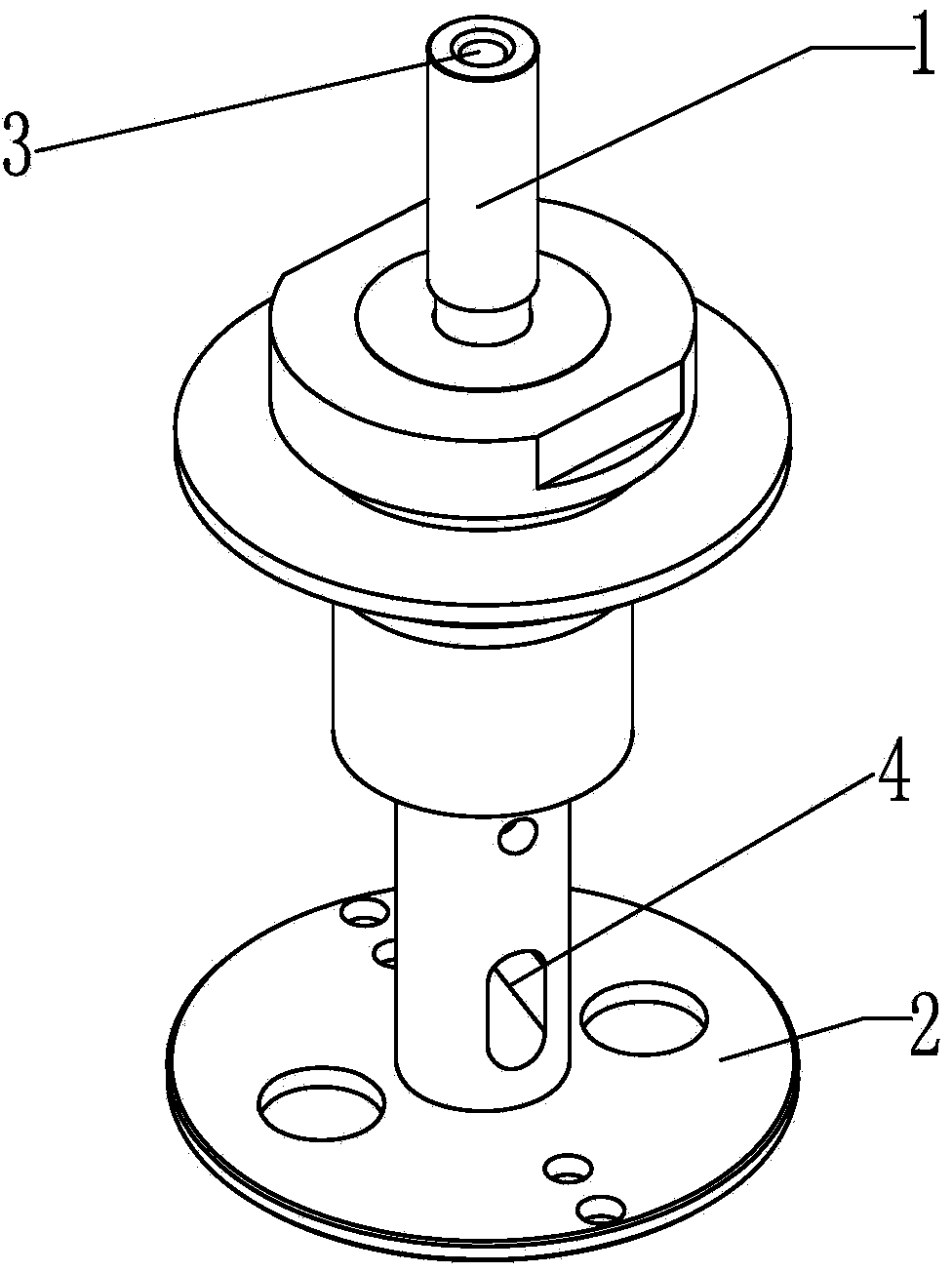

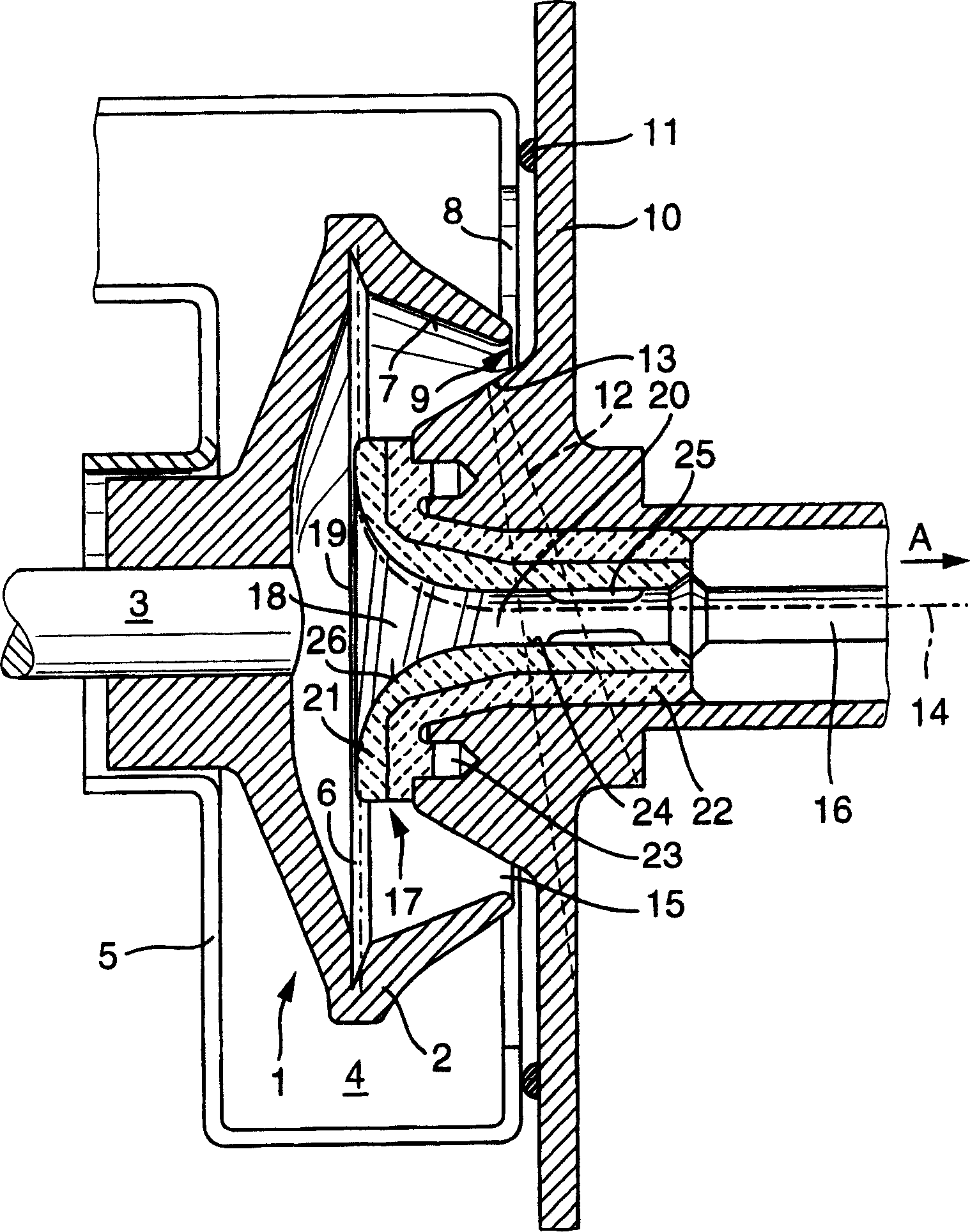

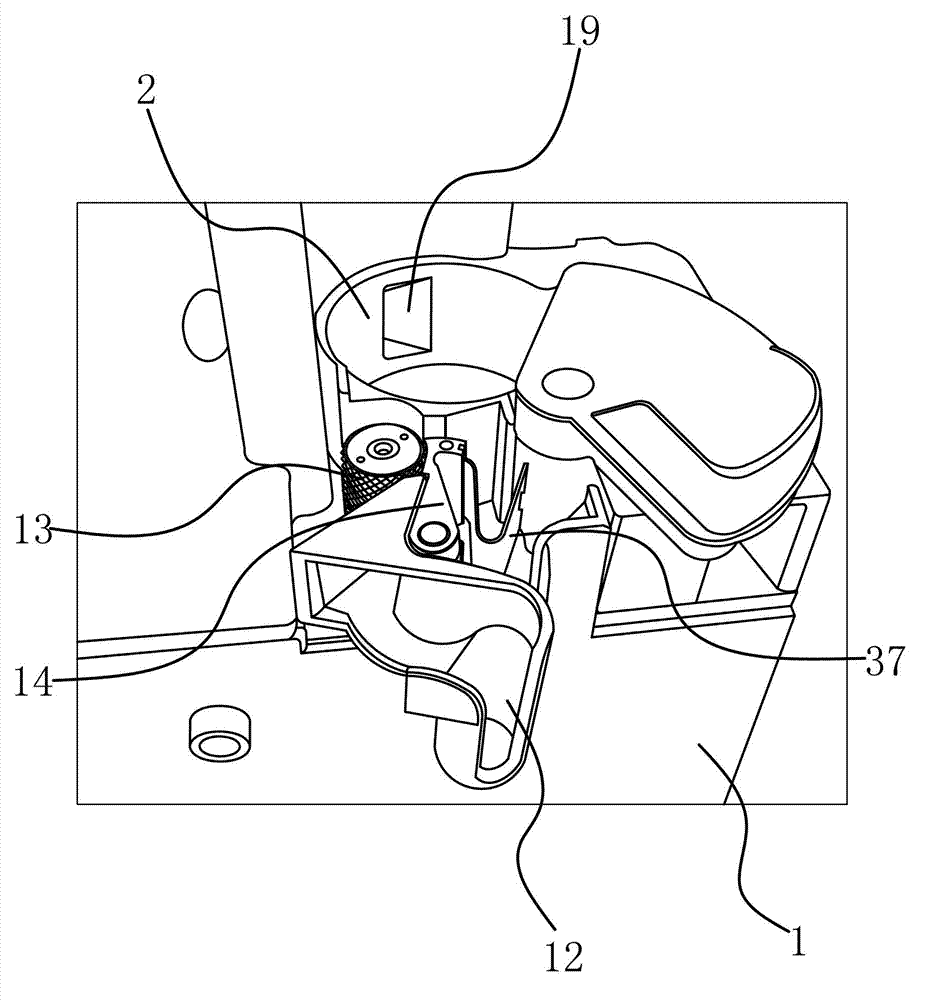

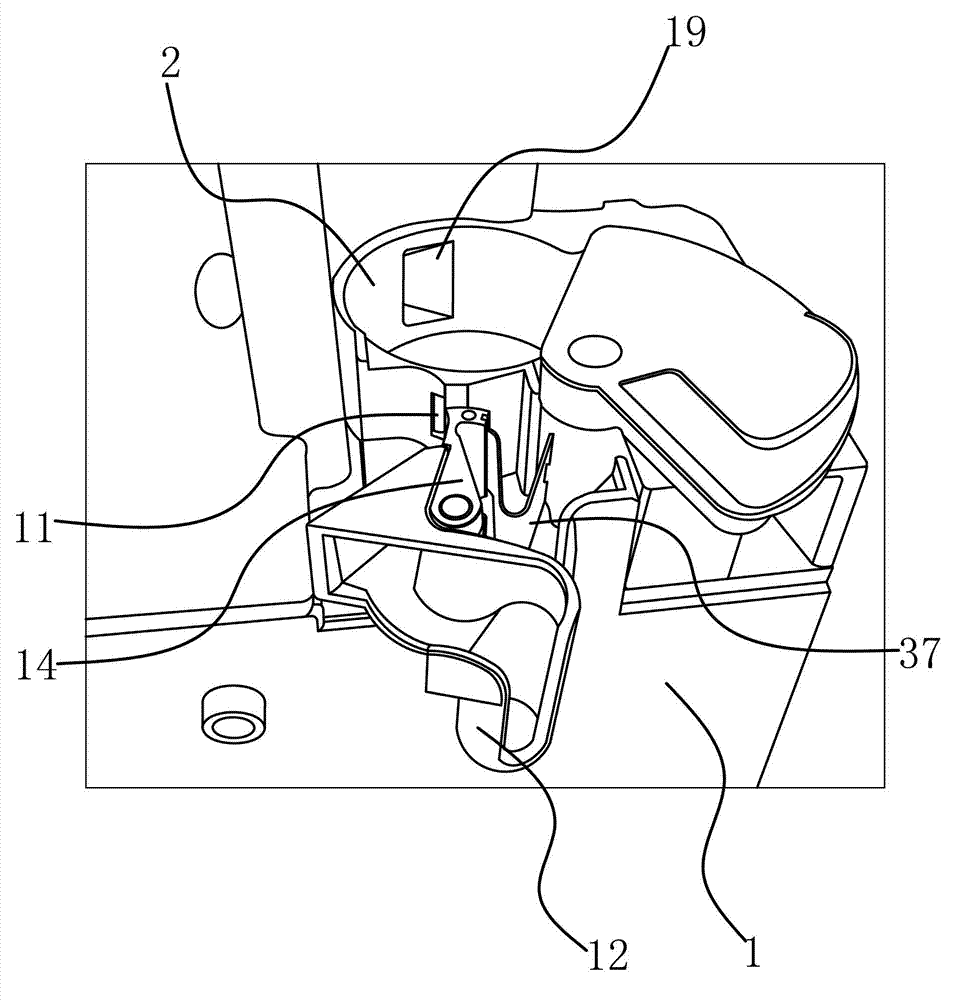

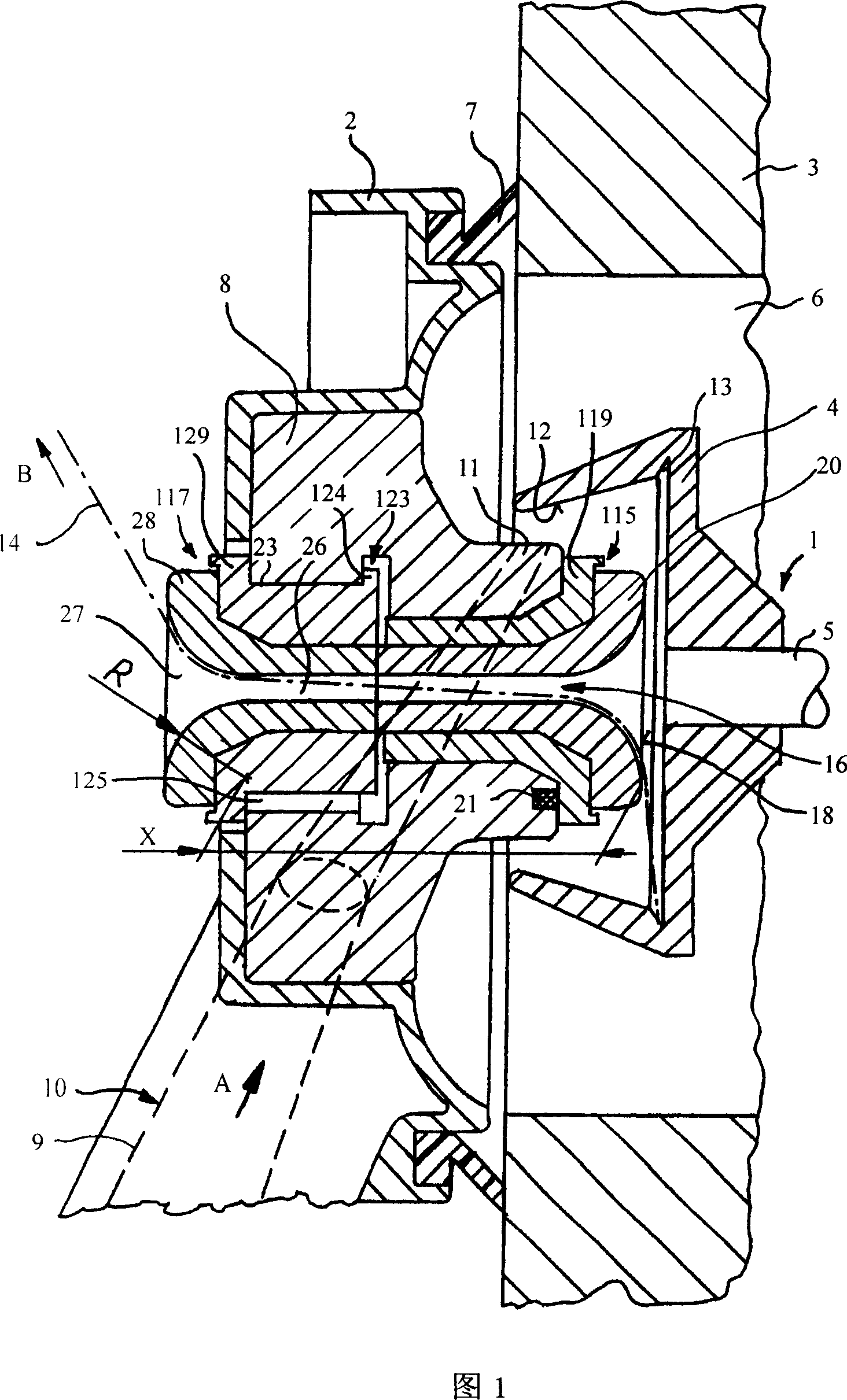

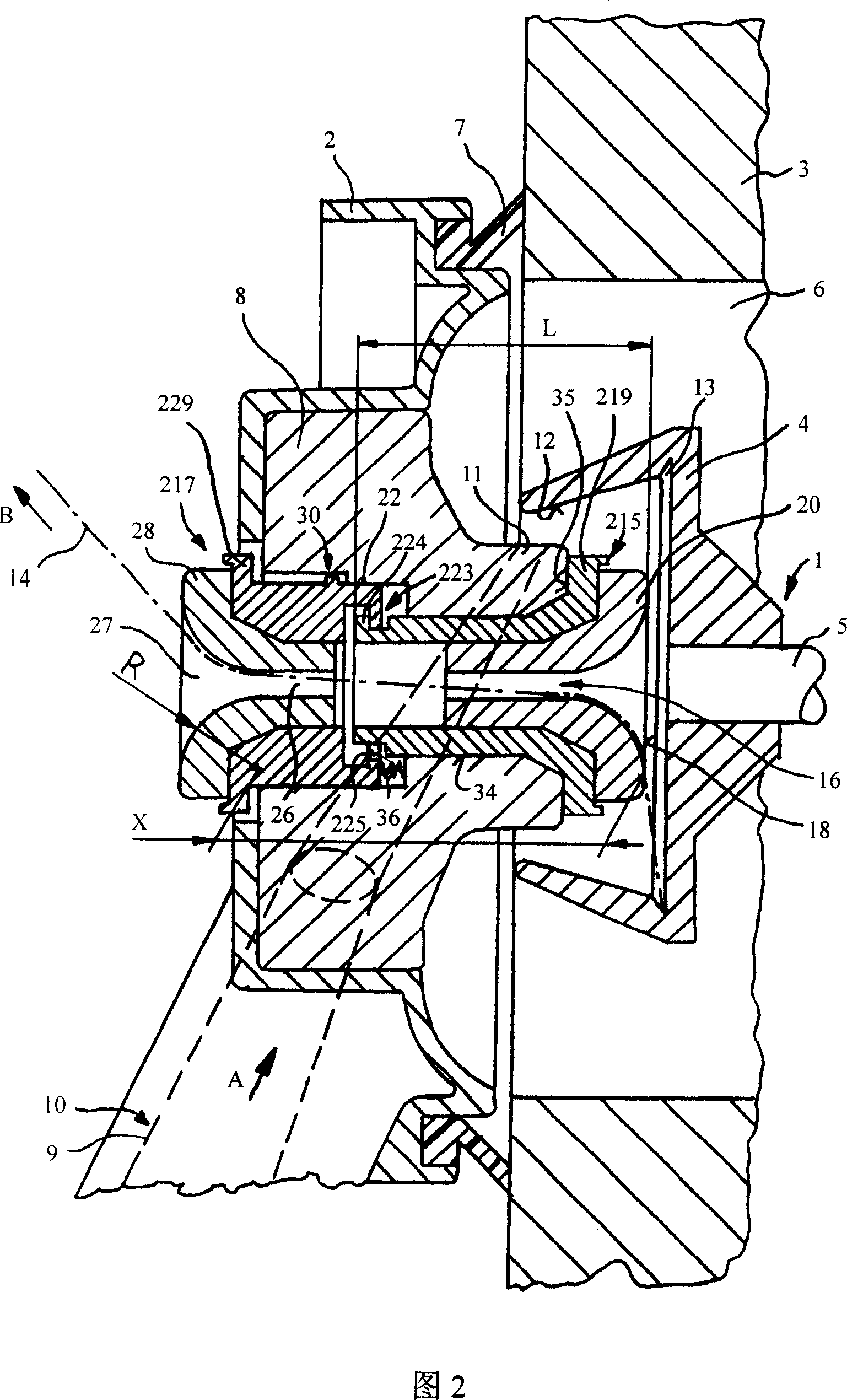

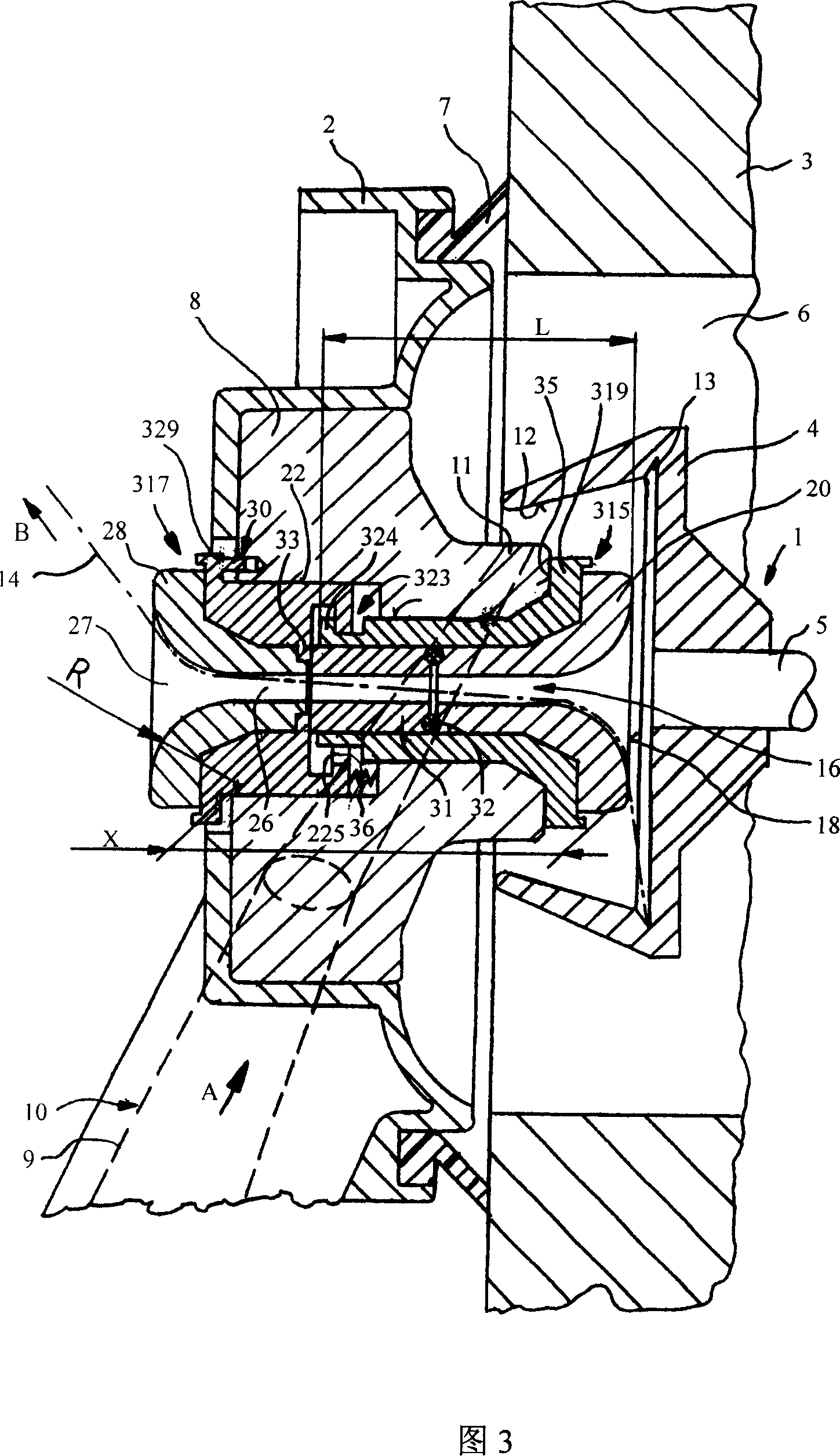

Spinning device for air exhaust type rotor spinning machine

ActiveCN102776618APrevent rotationPrecise positioningDrafting machinesContinuous wound-up machinesFiberYarn

The invention provides a spinning device for an air exhaust type rotor spinning machine, and belongs to the technical field of spinning machines, solving the technical problems of current spinning device for the air exhaust type rotor spinning machine that a spinning rotor holder cannot be firmly positioned, and the spinning device is inconvenient to use, etc. The spinning device for the air exhaust type rotor spinning machine comprises a housing body with a carding chamber, wherein a cotton feeding device, a cotton device and an inclusions removing device are arranged on the housing body; the spinning rotor holder is hinged on the housing body, and provided with a negative pressure chamber on the spinning rotor holder; the negative pressure chamber is communicated with the carding chamber; a rotor device for integrally twisting a plurality of single fibers is also arranged in the negative pressure chamber; and a yarn guiding pipe is arranged on the housing body; when the spinning rotor holder is clung to the housing body, the negative pressure chamber is communicated with the outside through the yarn guiding pipe, thus the fiber in the negative pressure chamber can be guided out of the housing body through the yarn guiding pipe; and a fixing device for adhering and fixing the spinning rotor holder to the housing body is arranged between the spinning rotor holder and the housing body. The spinning device for the air exhaust type rotor spinning machine has the advantages that the housing body is firmly fixed to the spinning cup holder, and the spinning device is stable in running, etc.

Owner:WENLING RISHENG MACHINERY

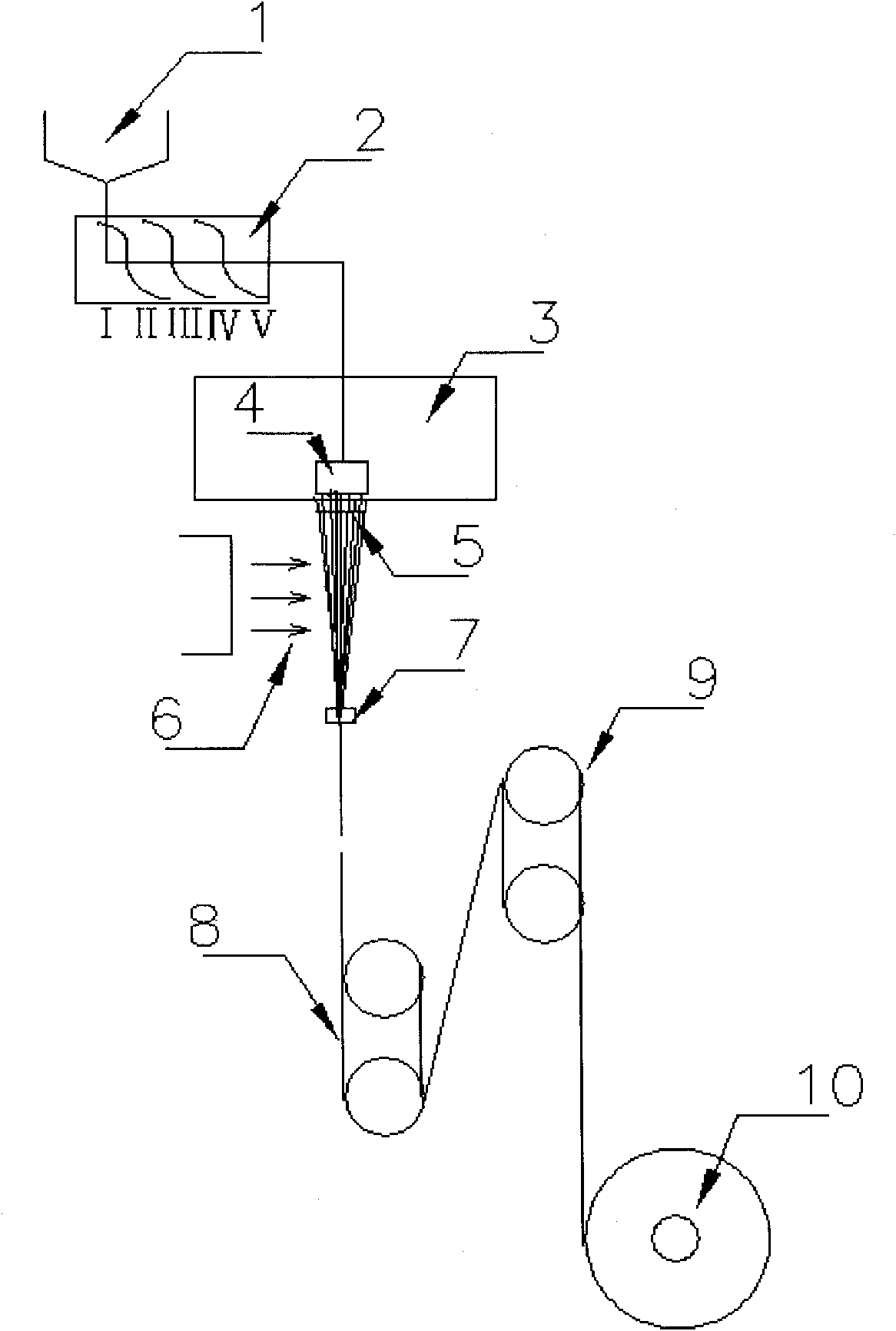

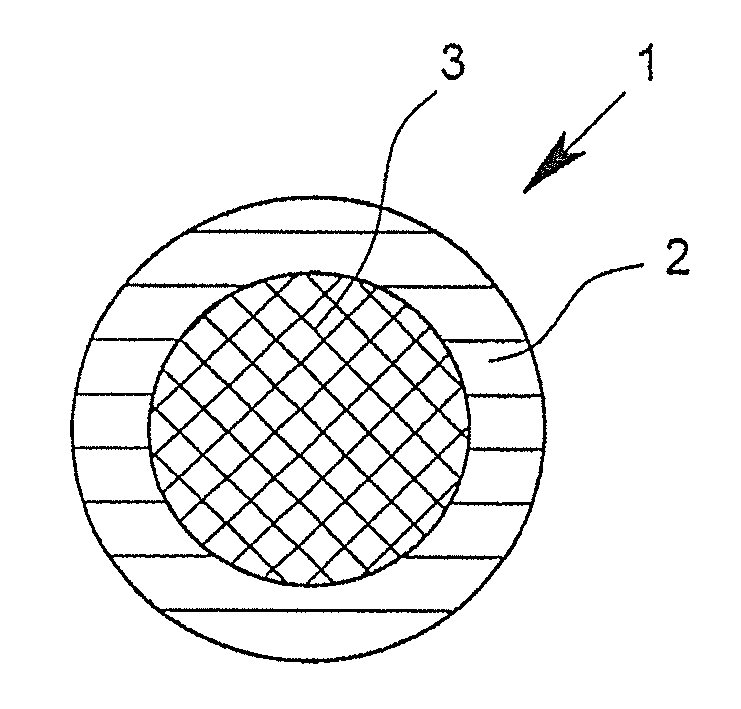

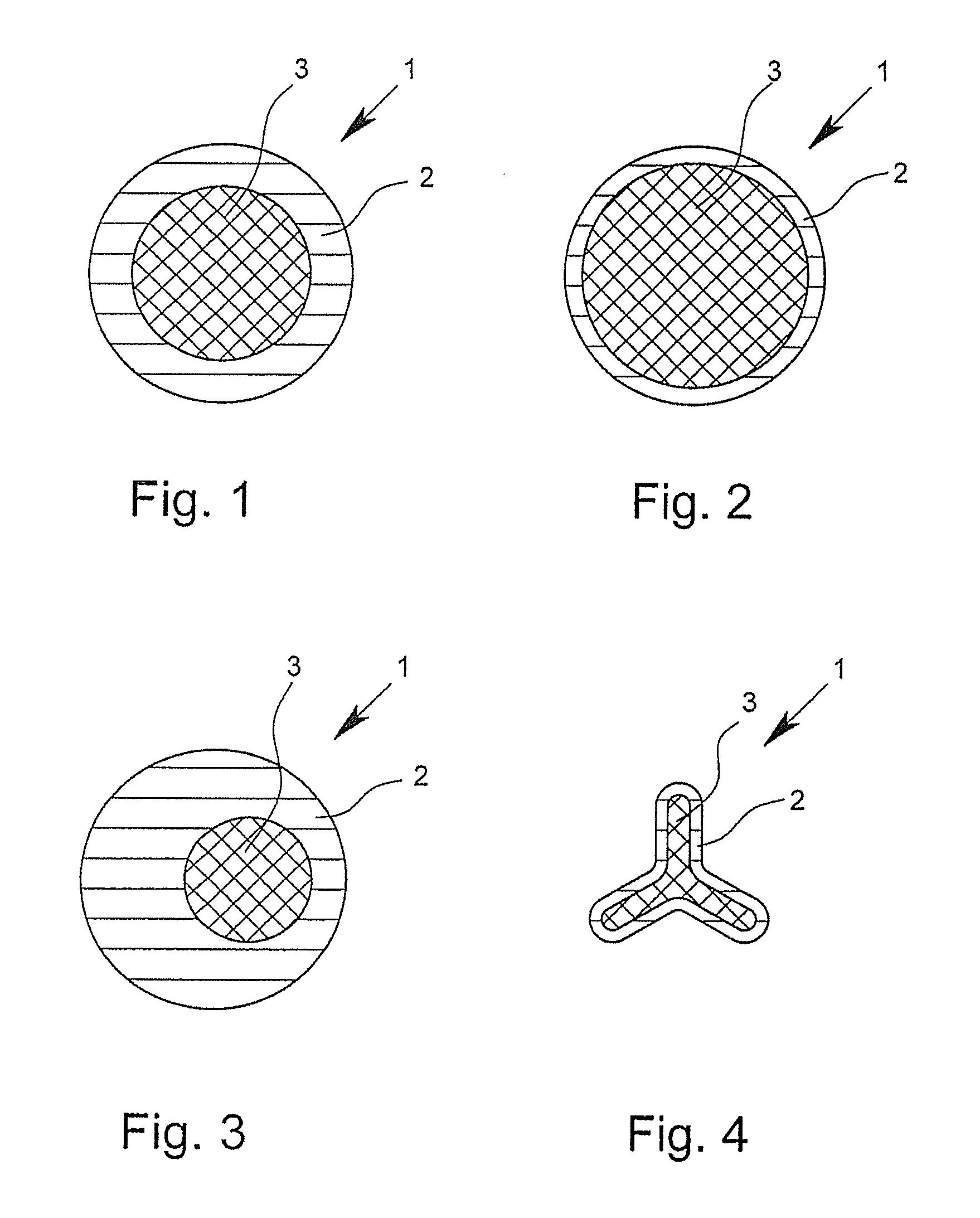

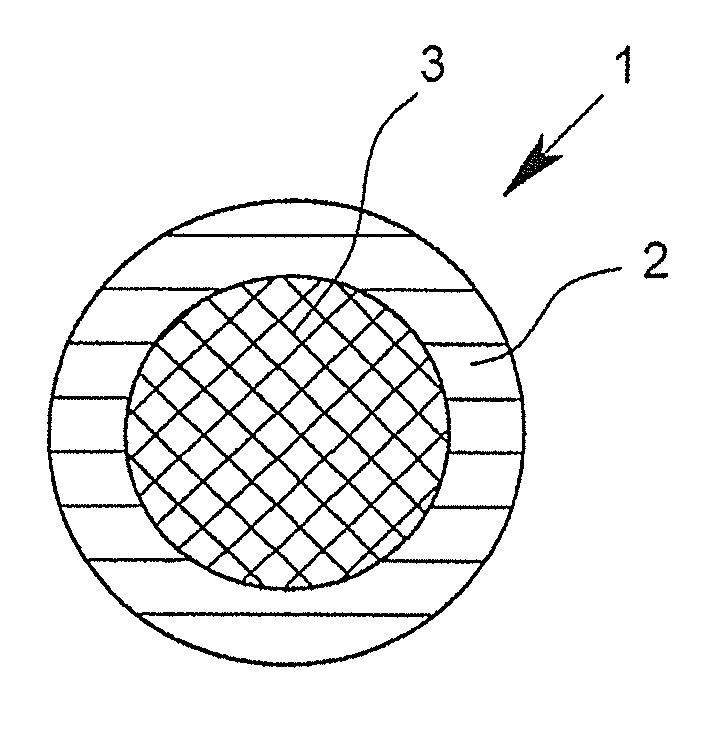

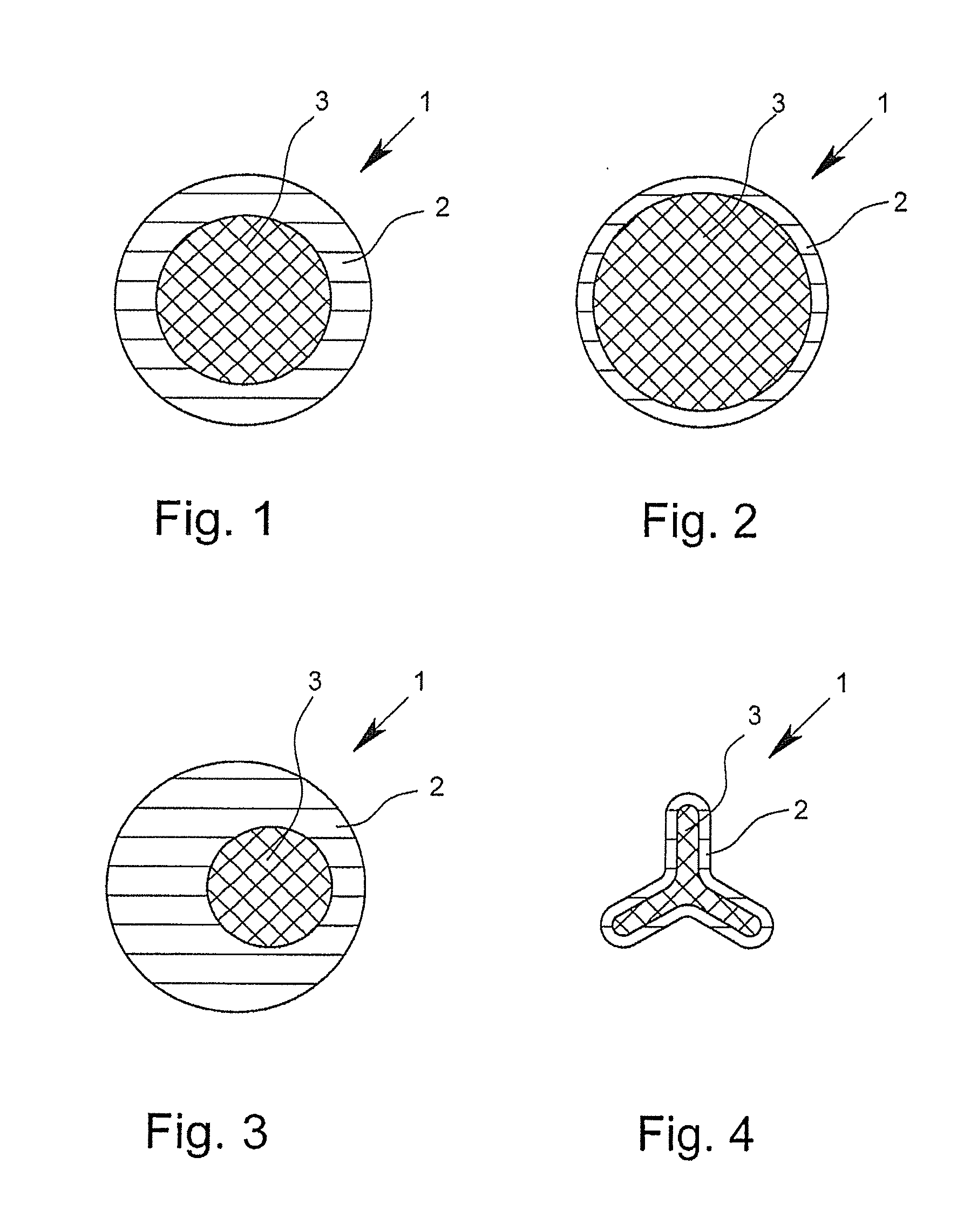

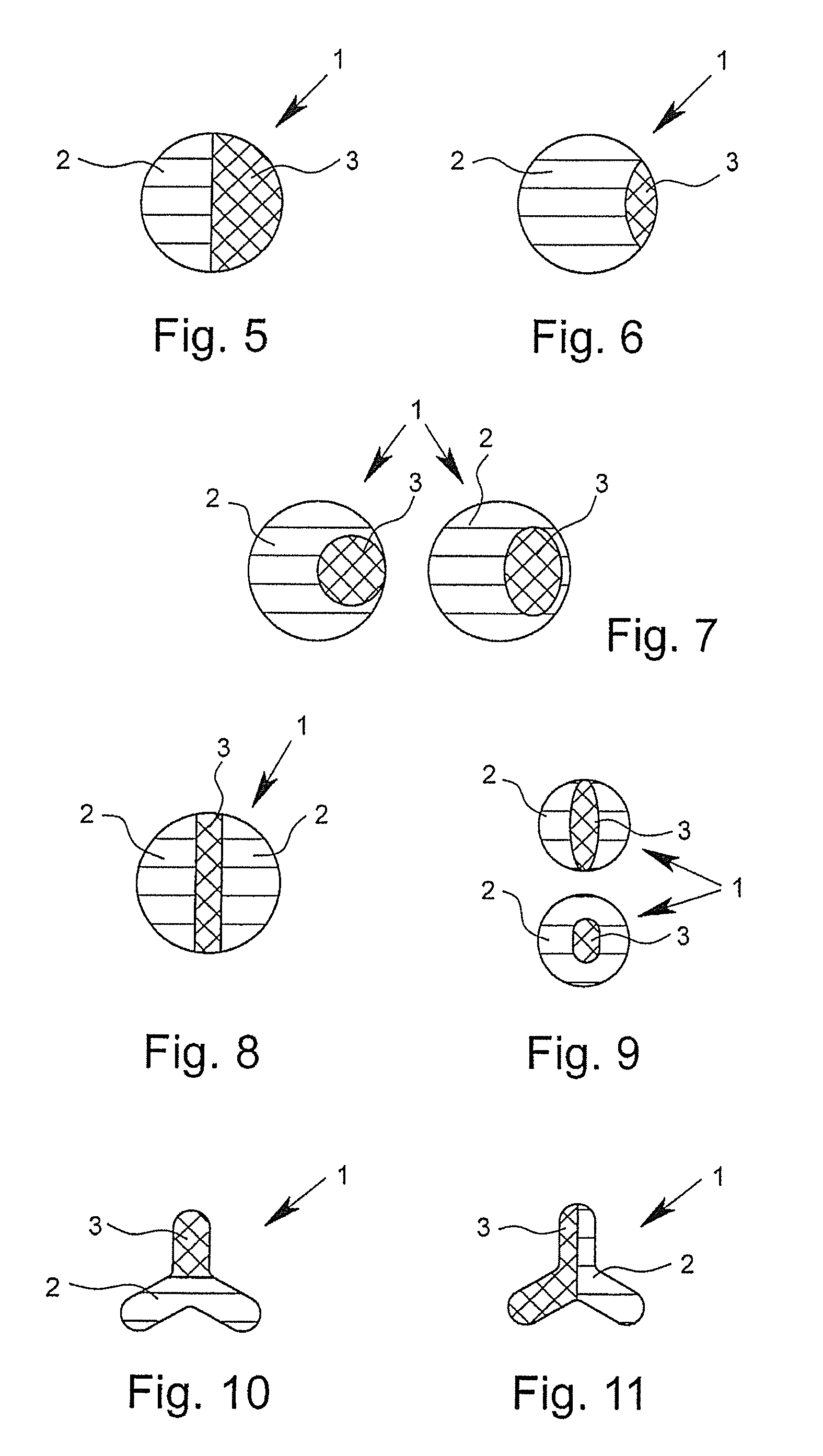

Bi-component fiber for the production of spunbonded fabric

InactiveUS20150017865A1Raise the ratioChange propertiesWoven fabricsConjugated synthetic polymer artificial filamentsFiberPolymer science

A bi-component fiber (1), in particular for the production of spunbond fabrics (4), with a first component (2) and a second component (3), whereby the first component (2) has a first polymer as an integral part and the second component has a second polymer as an integral part. The first component (2) has an additive, and the second component (3) has a percentage by weight of the additive that is smaller than that in the first component (2).

Owner:EWALD DORKEN

Si-Al-C-O fiber preparation method

ActiveCN109111574AHigh softening pointHigh average tensile strengthFibre chemical featuresFiber8-Hydroxyquinoline

The invention provides a Si-Al-C-O fiber preparation method, and discloses a polyaluminocarbosilane preparation method, which comprises: uniformly mixing a polycarbosilane solution and an 8-hydroxyquinoline aluminum solution, carrying out a reaction for 0.5-2 h at a temperature of 230-300 DEGC under a pressure of 0.5-2 Mpa, and distilling. The invention further discloses a method for preparing Si-Al-C-O fiber by carrying out further treatment on the polyaluminocarbosilane prepared by the method. According to the present invention, the prepared aluminum-containing precursor has advantages of uniformity, controlled aluminum content, simple synthesis process and high safety compared to the precursor obtained through the normal pressure solid phase synthesis; the prepared aluminum-containing precursor has advantages of high softening point, good spinnability, high spinning stability and high yield after high temperature firing; and the prepared Si-Al-C-O fibers are smooth, black and bright, have characteristics of small average diameter, high average tensile strength and stable performance, can be directly used as the reinforcing body in high-temperature-resistant materials, and can befurther subjected to ultrahigh temperature sintering to obtain polycrystalline Si-Al-C fibers.

Owner:SOUTHEAST UNIV

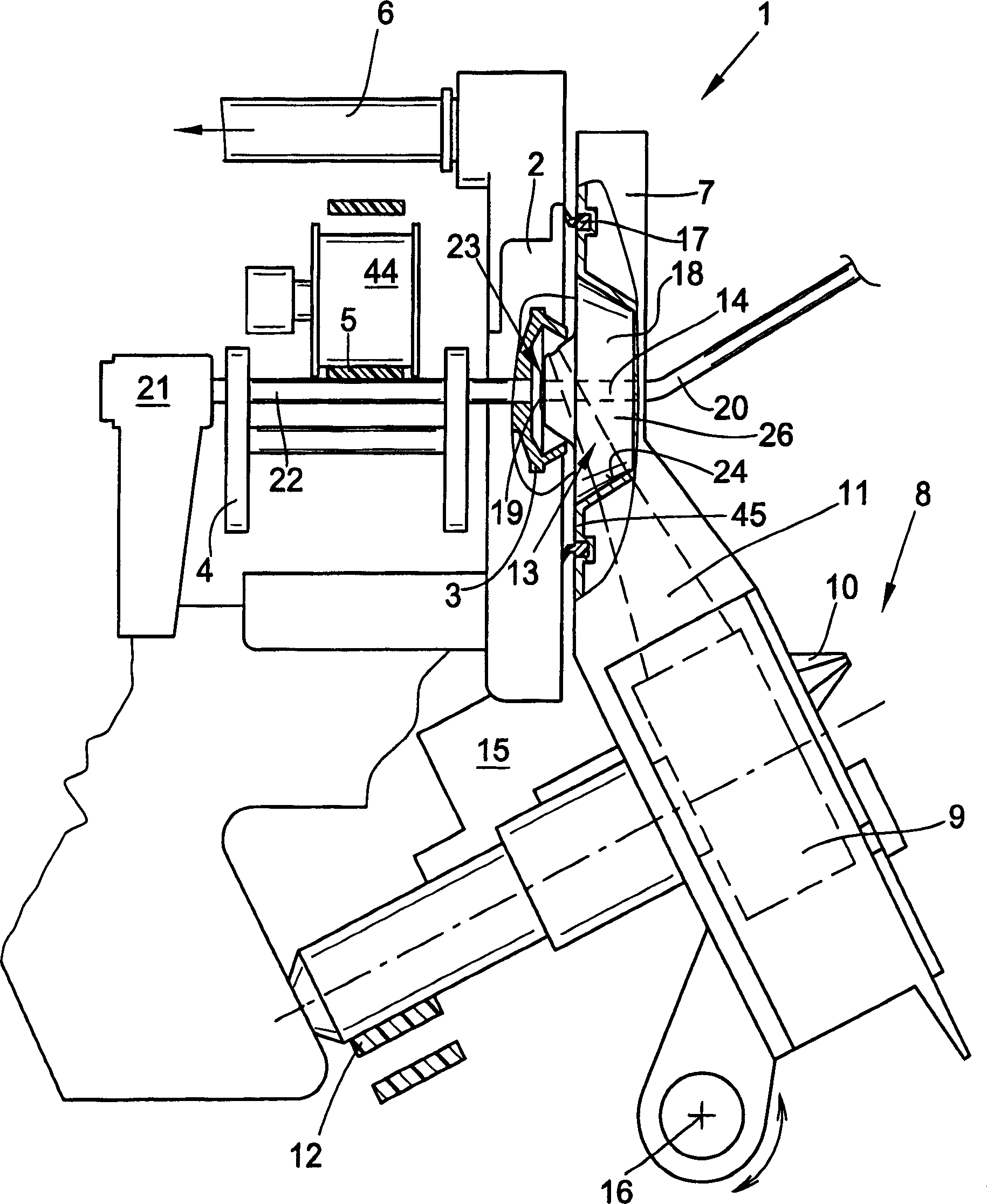

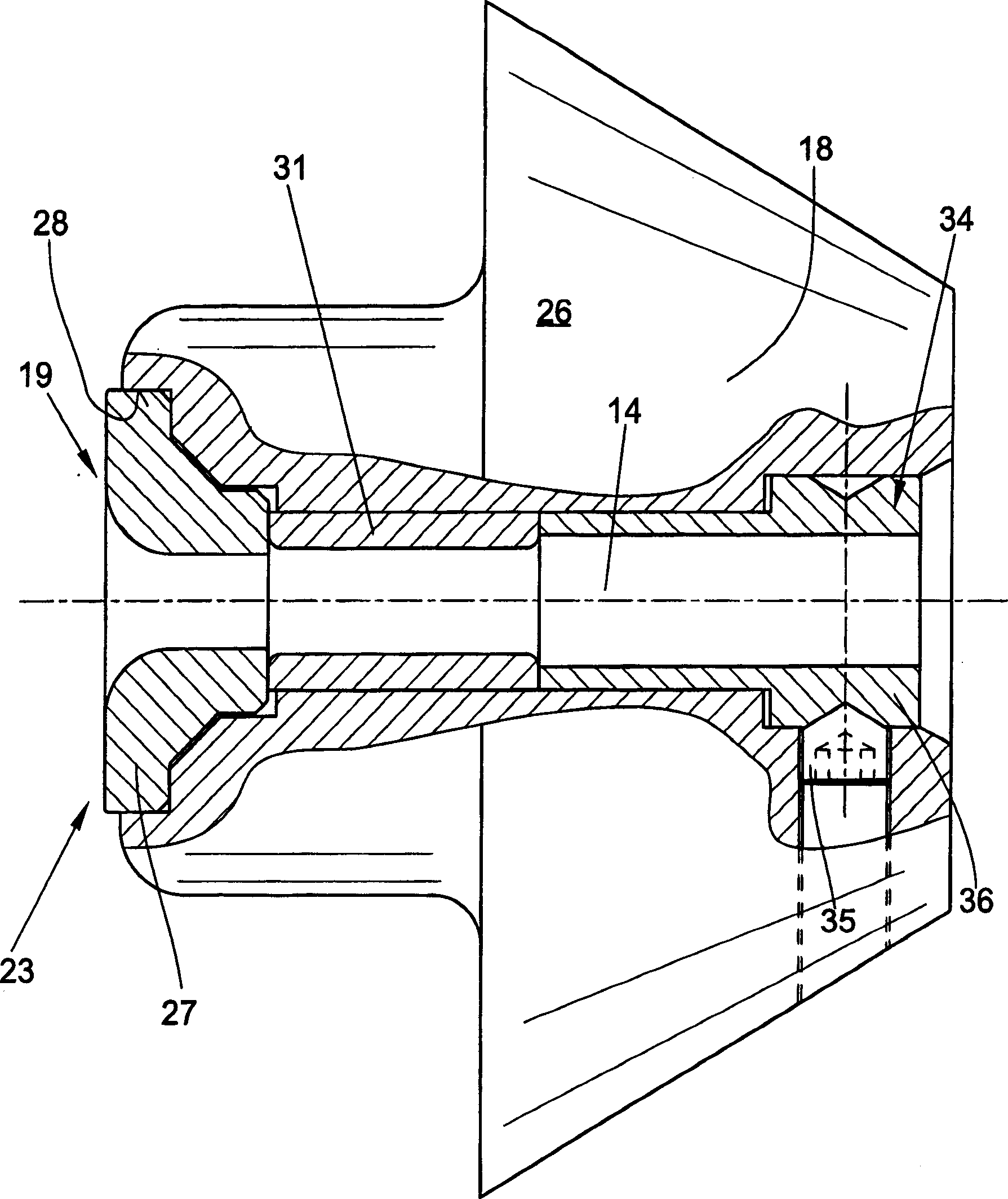

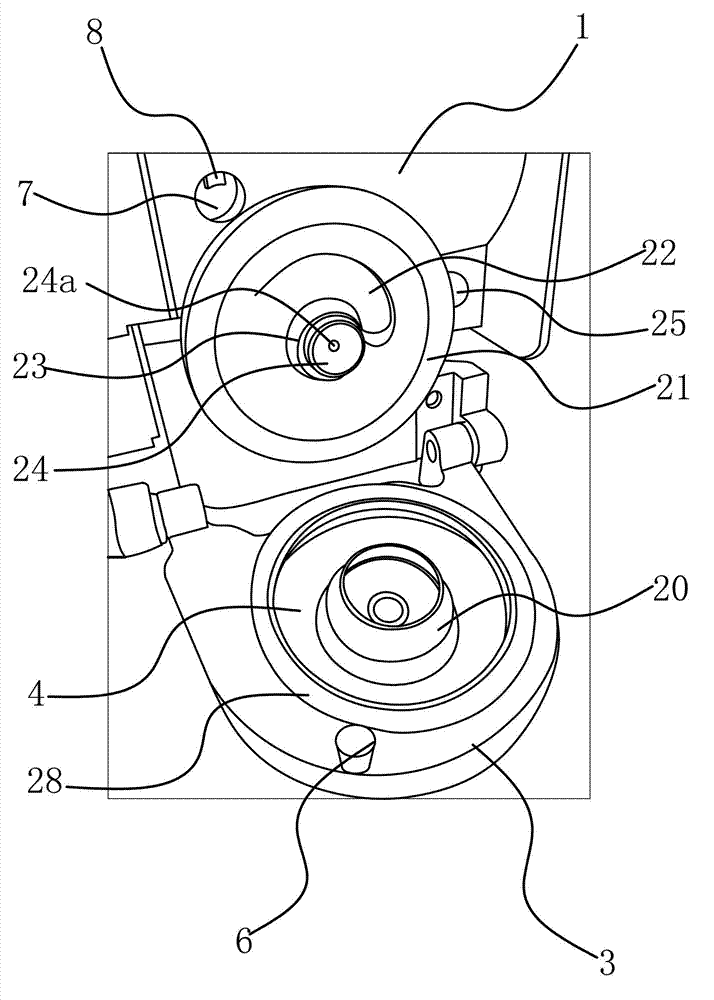

Open-end spinning device with an exchangeable twist congesting element

ActiveCN1978719AImprove stabilityImprove yarn qualityContinuous wound-up machinesOpen-end spinning machinesFiberNozzle

A rotor spinning spinning device including a cover encloses rotor housing. A replaceble groove plate adapter is arranged in the cover to feed fibre and doff. Doffing is processed by a doffing nozzle and at least a easily changed holder part which arranged in the rear. The twiddle rotate holder has a doffing hole basically in the centre. The twiddle rotate holder inserts directly in the groove plate adapter.

Owner:RIETER INGOLSTADT SPINNEREI

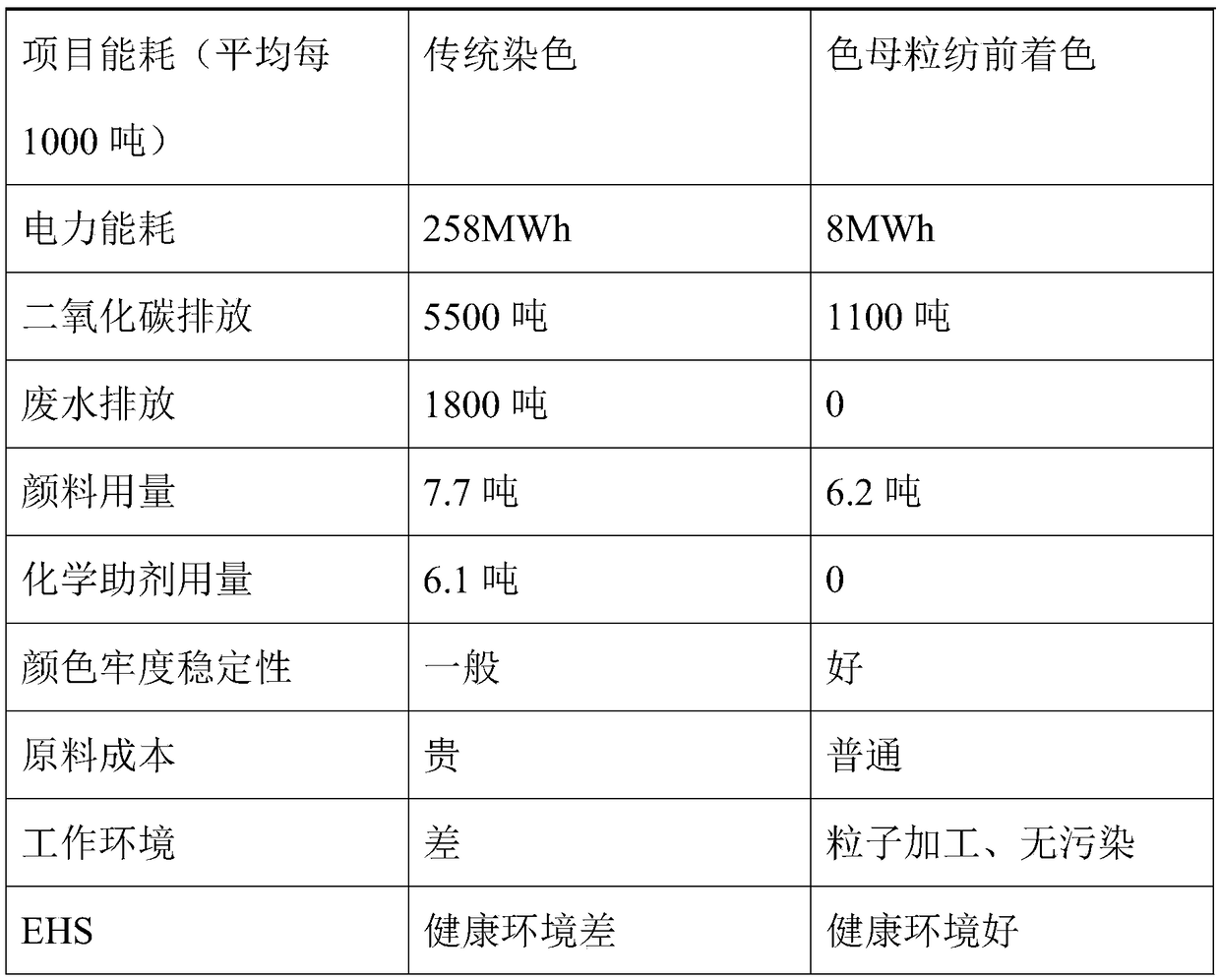

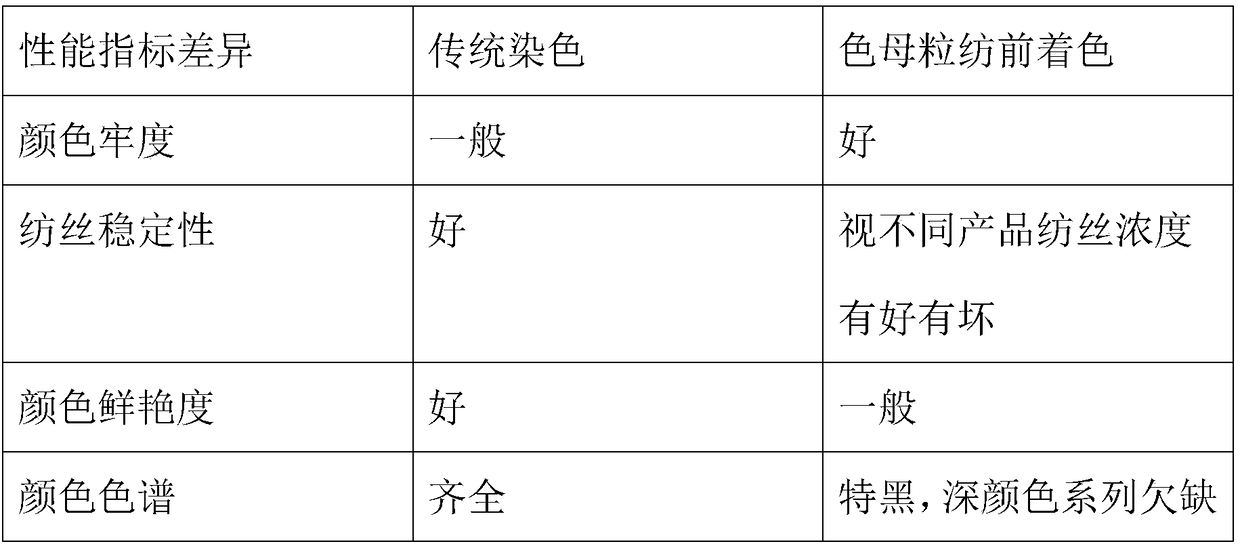

Method for improving brilliance and tinting strength of polyester fiber

InactiveCN108866672AImprove vividnessHigh tinting strengthPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses a method for improving brilliance and tinting strength of polyester fiber. The method comprises the following step: S1, preparing coloring master batch, wherein the prepared coloring master batch is prepared from 20 to 30% of pigment, 5 to 10% of ethylene acrylate copolymer, 2 to 5% of dispersing agent and the balance of carrier resin; S2, mixing the coloring master batch with PET slices and drying, wherein the weight proportion of the coloring master batch is 5 to 20%; S3, putting the coloring master batch and the PET slices which are evenly mixed into a spinning machine to be molten and extruding into silk by a spinneret plate to form polyester fiber. According to the method for improving brilliance and tinting strength of the polyester fiber disclosed by the invention, the coloring master batch containing pigment and the ethylene acrylate copolymer is used, so that brilliance and the tinting strength of the prepared polyester fiber is improved, and the brilliance of the polyester fiber is improved by 20%; meanwhile, spinning stability is improved, pressure is stable, and a spinning period is improved by 20%; furthermore, in an assembly cleaning process, residues are less, more convenience is brought to cleaning, and cost and energy consumption are obviously reduced.

Owner:浙江恒烨新材料科技有限公司

Method of preparing high performance polyvinyl alcohel fiber

ActiveCN100339519CPrevent evaporationAchieve superheatingMonocomponent synthetic polymer artificial filamentMelt spinning methodsPolymer sciencePolyvinyl alcohol

The invention relates to a method using melt spinning to manufacture high performance polyvinyl alcohol fiber. It adopts intermolecular hydrogen compound for nitrogen compound, hydrophilicity auxiliary additive, compound modifier and polyvinyl alcohol to make modified polyvinyl alcohol. The modified polyvinyl alcohol is practiced melt spinning by extruding-spinning equipment to make polyvinyl alcohol as-formed fiber. It is formed to high performance polyvinyl alcohol fiber by multi-stage stretching, drying, and hot forming. The technique is simple, economic, environmental protection, and easy to realize industrialization production.

Owner:SICHUAN UNIV +1

Bi-component fiber for the production of spunbond fabric

InactiveUS20150017864A1Raise the ratioChange propertiesWoven fabricsConjugated synthetic polymer artificial filamentsFiberMaterials science

A bi-component fiber (1), in particular for the production of spunbond fabrics (4), has a first component (2) and a second component (3), whereby the first component (2) has a first polymer as an integral part and the second component has a second polymer as an integral part. It is provided that the difference between the melting points of the first component (2) and the second component (3) is less than or equal to 8° C.

Owner:EWALD DORKEN

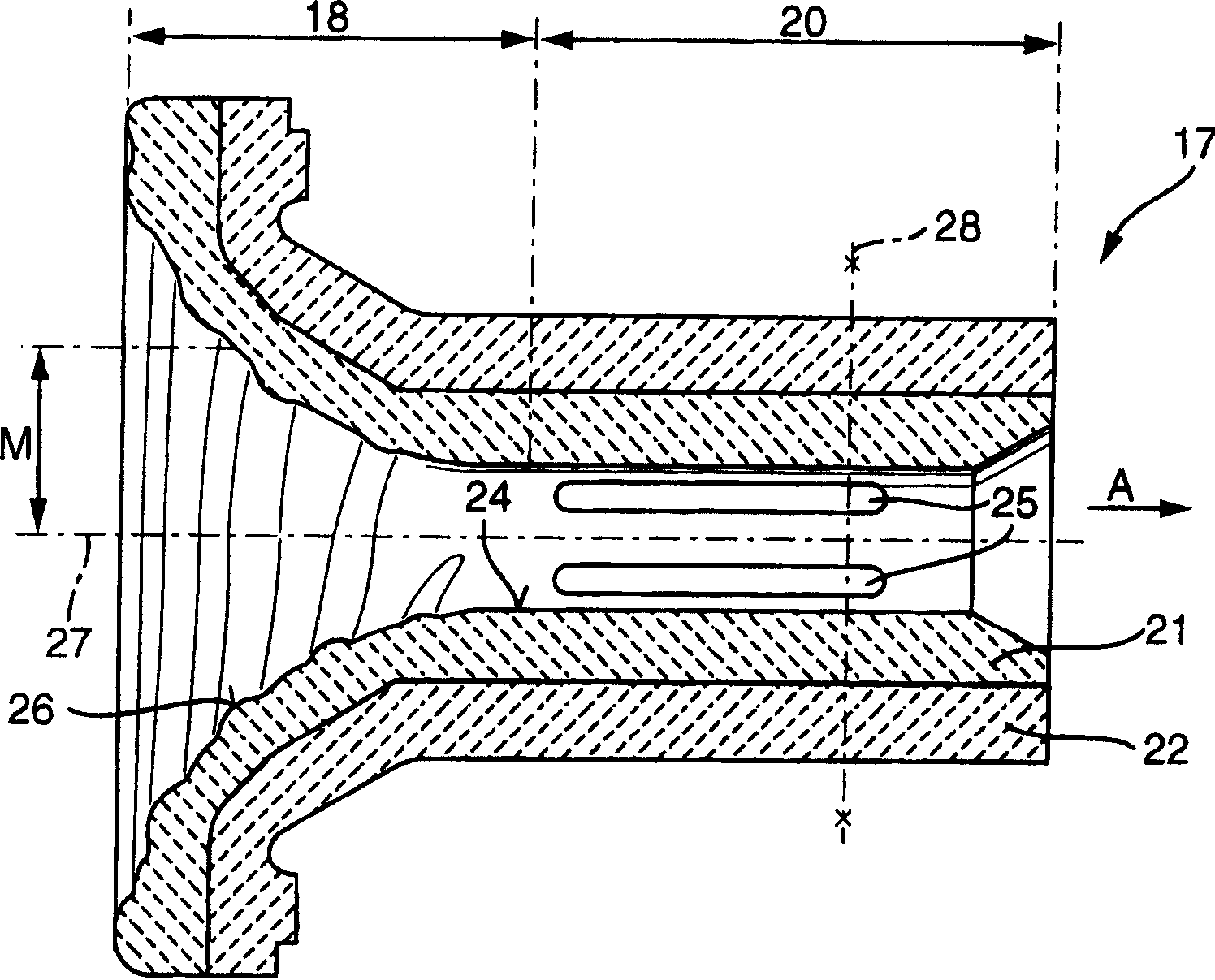

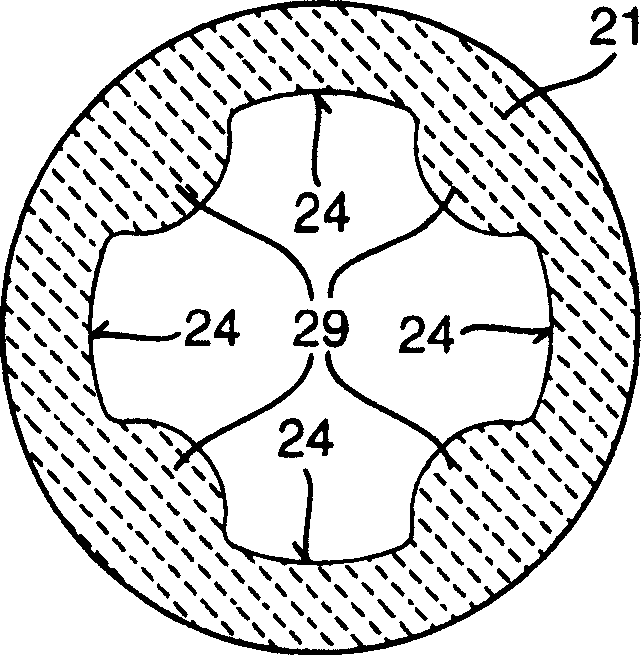

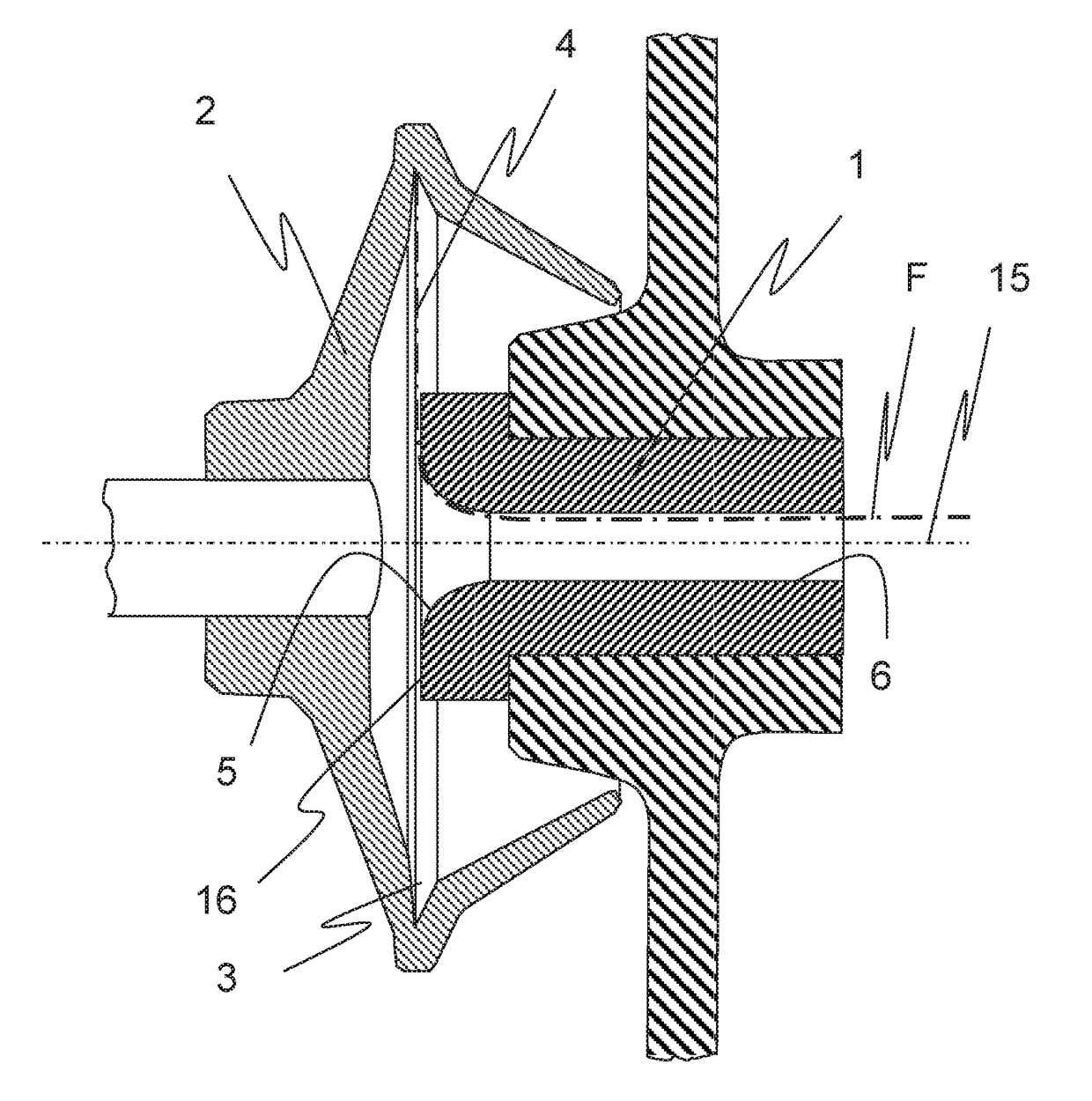

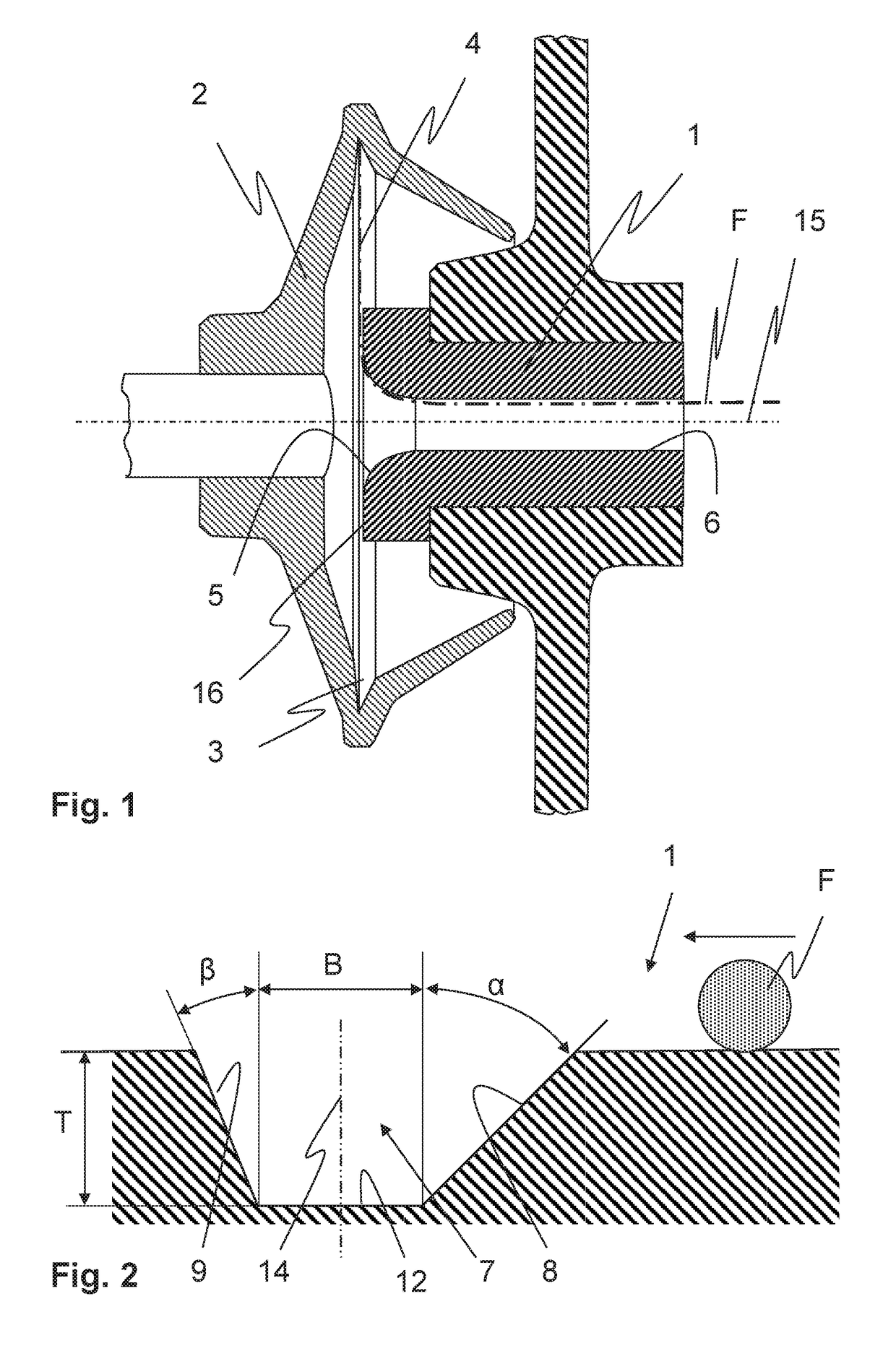

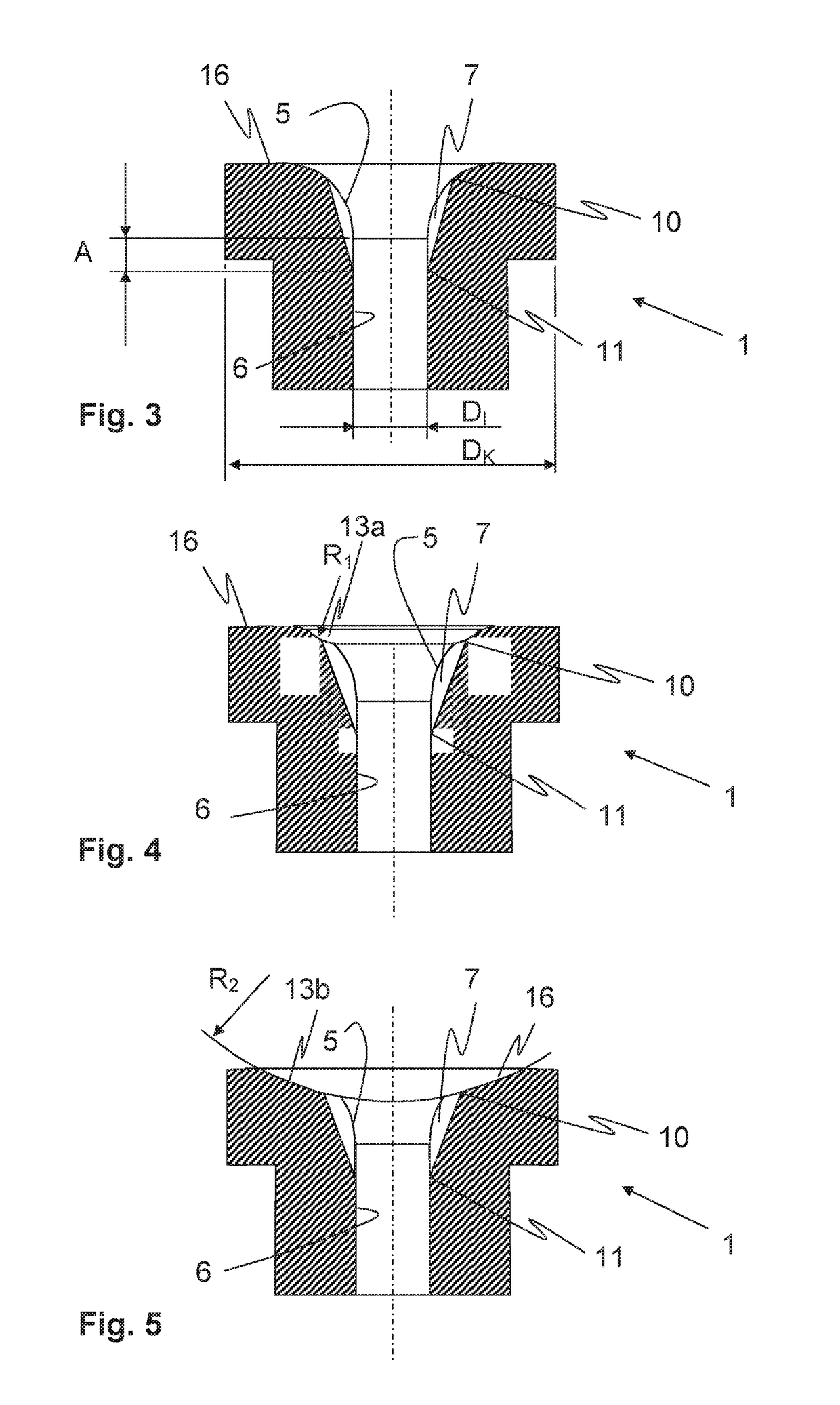

Thread Draw-Off Nozzle having Notches Extending Radially to the Nozzle Bore

ActiveUS20180320292A1Excellent yarn qualityReduce the impactContinuous wound-up machinesOpen-end spinning machinesNozzle

A thread draw-off nozzle for an open-end rotor spinning device includes an entrance-side nozzle funnel and an exit-side nozzle bore adjoining the nozzle funnel. A plurality of notches are arranged in the nozzle funnel and extend essentially radial to the nozzle bore. Each notch has an inlet wall, a baffle wall, a radially outer notch inlet, and a radially inner notch outlet. Each notch further includes an essentially flat notch bottom arranged between the inlet wall and the baffle wall.

Owner:MASCHINENFABRIK RIETER AG

Polyacrylonitrile-based copolymer, polyacrylonitrile-based precursor fiber for carbon fiber, carbon fiber bundles, process for producing stabilized fiber bundles, and process for producing carbon fiber bundles

ActiveUS10017881B2Significant valueImprove thermal stabilityFilament/thread formingMonocomponent synthetic polymer artificial filamentProduction rateCarbon fibers

Provided are: a polyacrylonitrile-based precursor fiber for the production of a carbon fiber having a large single-fiber fineness, said precursor fiber ensuring high heat stability of a spinning dope and excellent productivity; and a copolymer suitable for the production of said precursor fiber. Also provided are: high-quality carbon fiber bundles which have a large single-fiber fineness and excellent productivity; a process for producing the same; and a process for producing flameproofed fiber bundles suitable for the production of the carbon fiber bundles. A polyacrylonitrile-based copolymer which comprises 93.0 to 99.4 mol % of acrylonitrile units, 0.5 to 4.0 mol % of (meth)acrylamide-based units, and 0.1 to 3.0 mol % of unsaturated carboxylic acid hydroxyalkyl ester units and in which the (meth)acrylamide-based units are (meth)acrylamide units and / or (meth)acrylamide derivative units having a molecular weight of 105 or less; a precursor fiber comprising the copolymer; a process for producing flameproofed fiber bundles which uses precursor fiber bundles consisting of the precursor fiber; carbon fiber bundles; and a process for production thereof.

Owner:MITSUBISHI CHEM CORP

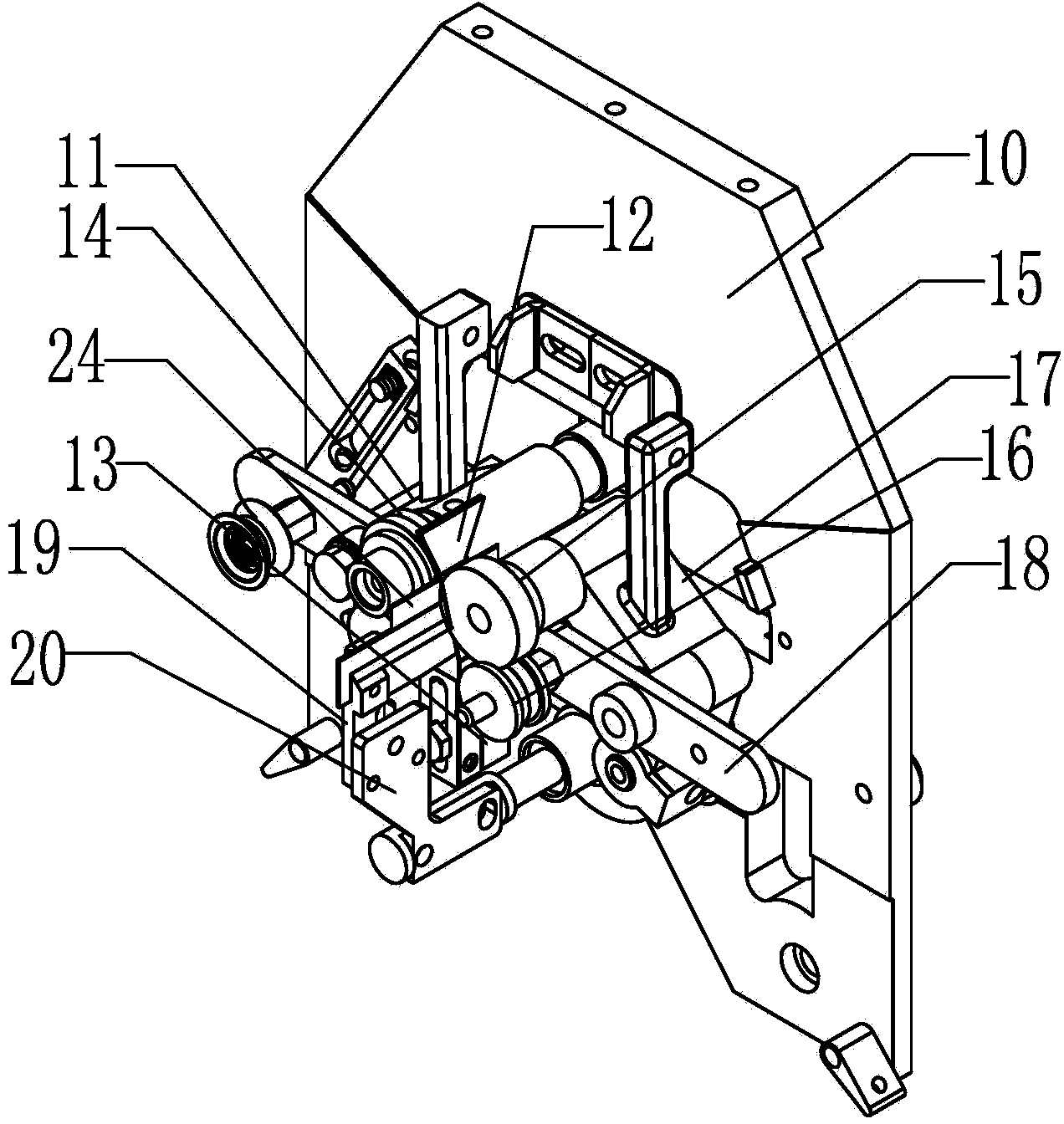

Start-stop control method of blowing and suction trolley of spinning machine

The invention relates to a start-stop control method of a blowing and suction trolley of a spinning machine. The method comprises the steps: firstly, a blowing and suction switch is additionally arranged on a control panel on a motor case of the spinning machine; a support frame is arranged on the spinning machine body along the length direction; a rail for the sliding of the blowing and suction trolley is arranged on the support frame; blowing and suction pipelines are respectively arranged at two sides of the blowing and suction trolley; secondly, the blowing and suction switch on the motor case of the spinning machine is started and the blowing and suction trolley during moving blows waste yarns and fluffs on the ground into the blowing and suction pipelines by using the blowing and suction pipelines; thirdly, a proximity switch and an infrared detection delay switch are additionally arranged at the tail of the blowing and suction trolley and a touch switch is additionally arranged on the blowing and suction trolley; when the blowing and suction trolley moves to the tail part, the touch switch contacts with the proximity switch and the blowing and suction trolley stops moving; after stopping for a certain time, the blowing and suction trolley slides to the head end under the action of the infrared detection delay switch. According to the start-stop control method of the blowing and suction trolley of the spinning machine, the spinning stability of the spinning machine is improved.

Owner:JINGWEI TEXTILE MASCH CO LTD

Oiling method of polyacrylonitrile precursor

ActiveCN111088536AIncrease oiling rateOil evenlyArtificial filament washing/dryingFilament/thread formingThermodynamicsSpinning

The invention relates to an oiling method of a polyacrylonitrile precursor, and mainly solves the problems of non-uniform oiling and low oiling rate in the prior art. Through the technical scheme, theoiling method of the polyacrylonitrile precursor comprises the steps of oiling, drying densification, steam drafting and heat setting. The oiling method is characterized in that at least two times ofoiling and at least two times of drying densification are performed, at least one time of oiling and at least one time of drying densification are performed before the steps of steam drafting and heat setting, and at least one time of oiling and at least one time of drying densification are performed after the steps of steam drafting and heat setting. Therefore, the problem is well solved, and the oiling method can be used in the spinning process of the polyacrylonitrile precursor.

Owner:CHINA PETROLEUM & CHEM CORP +1

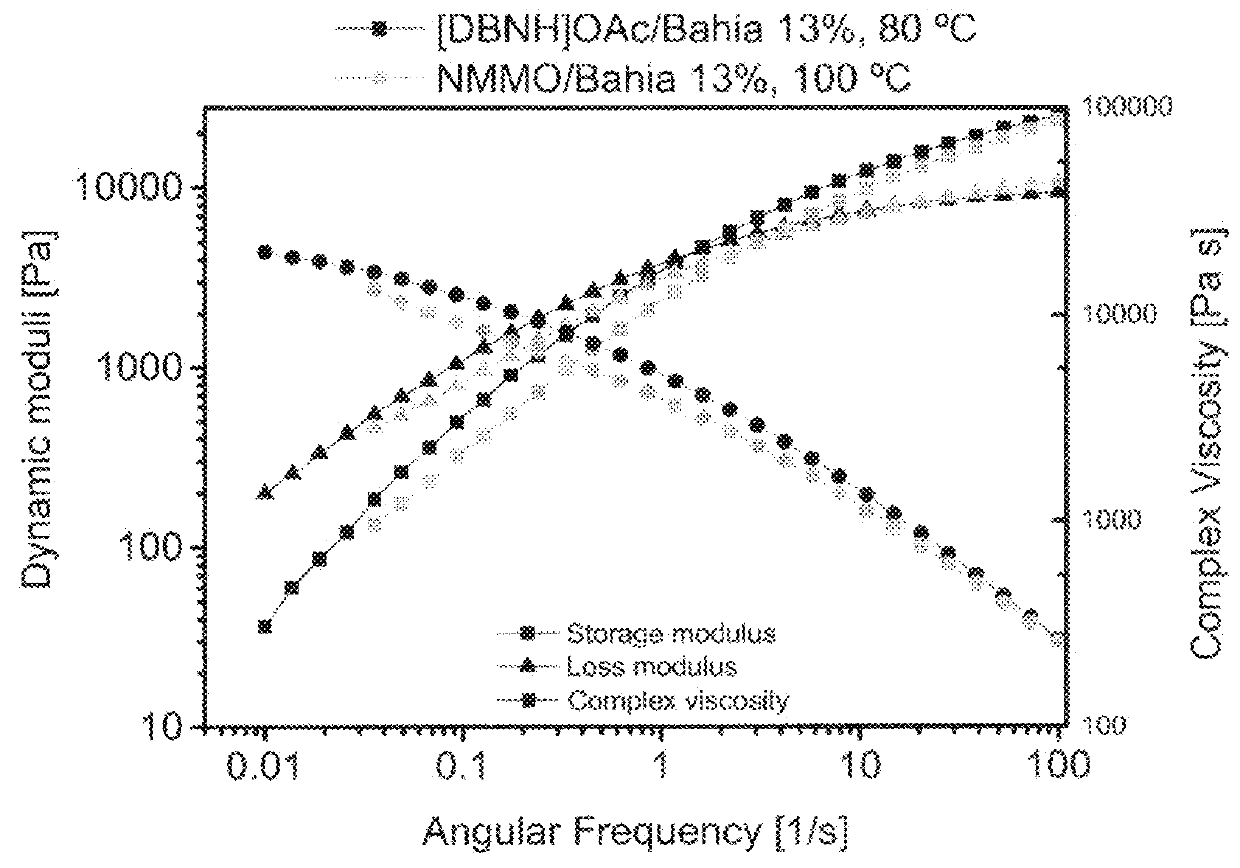

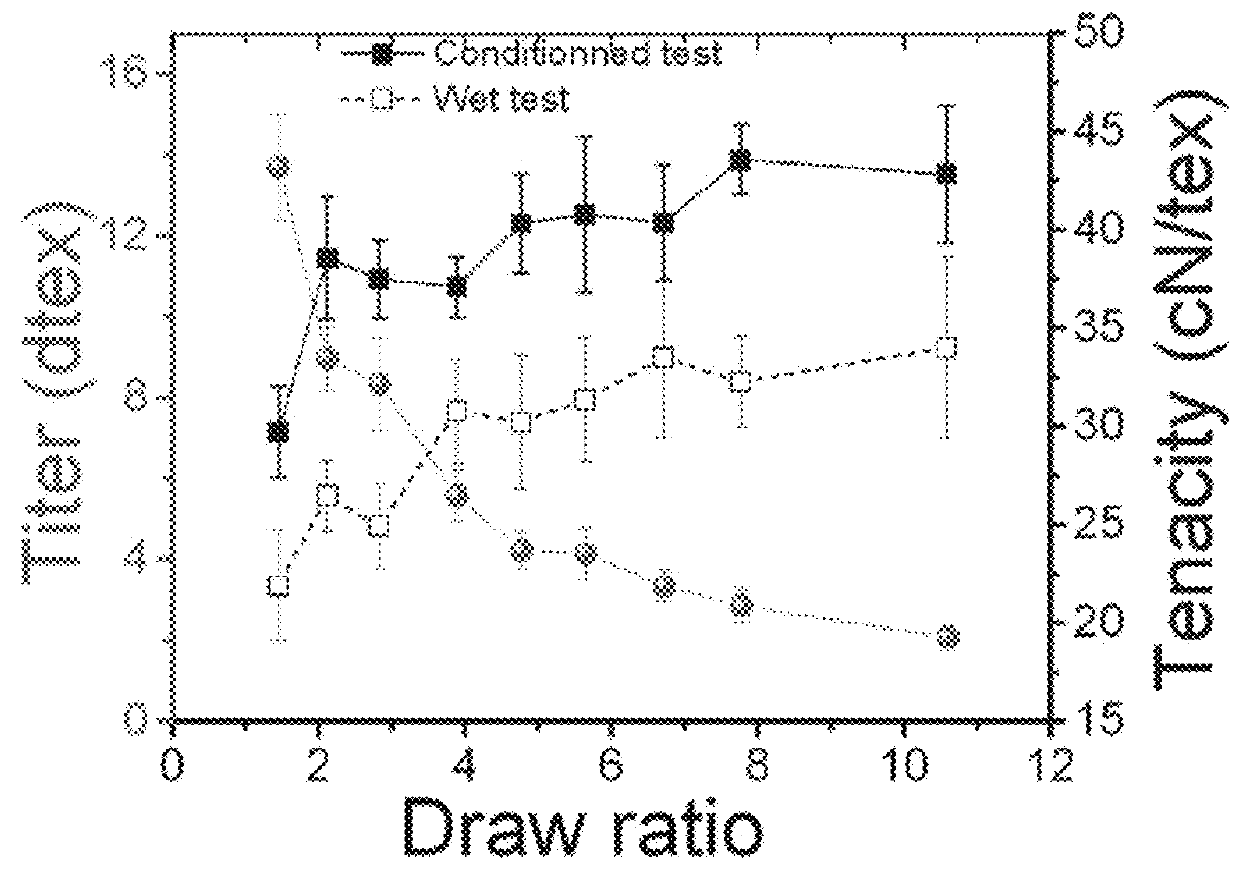

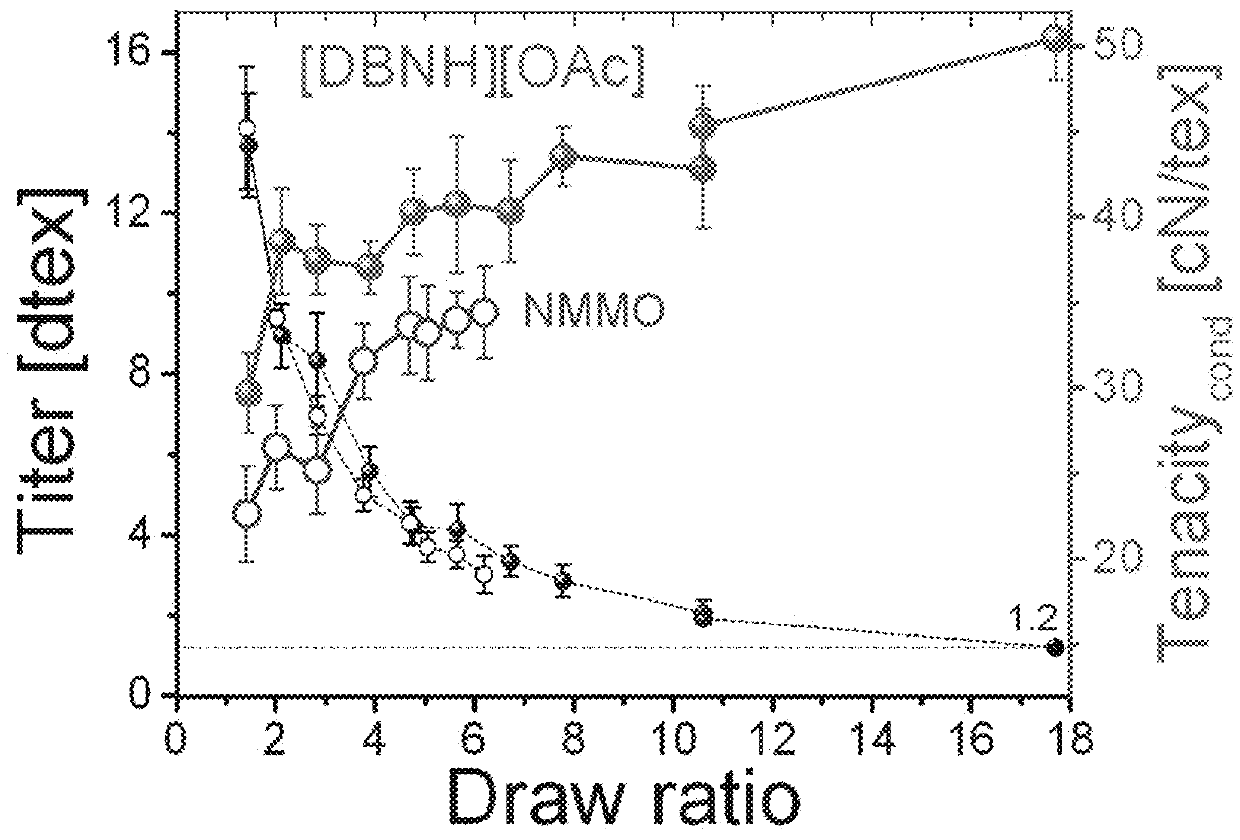

Process for the production of shaped cellulose articles

ActiveUS20160053407A1High viscosityLow viscosityArtificial filaments from cellulose solutionsOrganic non-macromolecular adhesiveCelluloseFiber

A method of manufacturing a cellulose-based shaped article. The method comprises subjecting a solution of lignocellulosic material, dissolved in a distillable ionic liquid, to a spinning method, wherein the ionic liquid is a diazabicyclononene (DBN)-based ionic liquid. DBN-based ionic liquids have good dissolution power, high thermal and chemical stability, lack runaway reactions and exhibit low energy consumption, due to low spinning temperatures. The shaped cellulose articles can be used as textile fibres, high-end non-woven fibres, technical fibres, films for packaging, and barriers films in batteries, as membranes and as carbon-fibre precursors.

Owner:AALTO UNIV FOUND

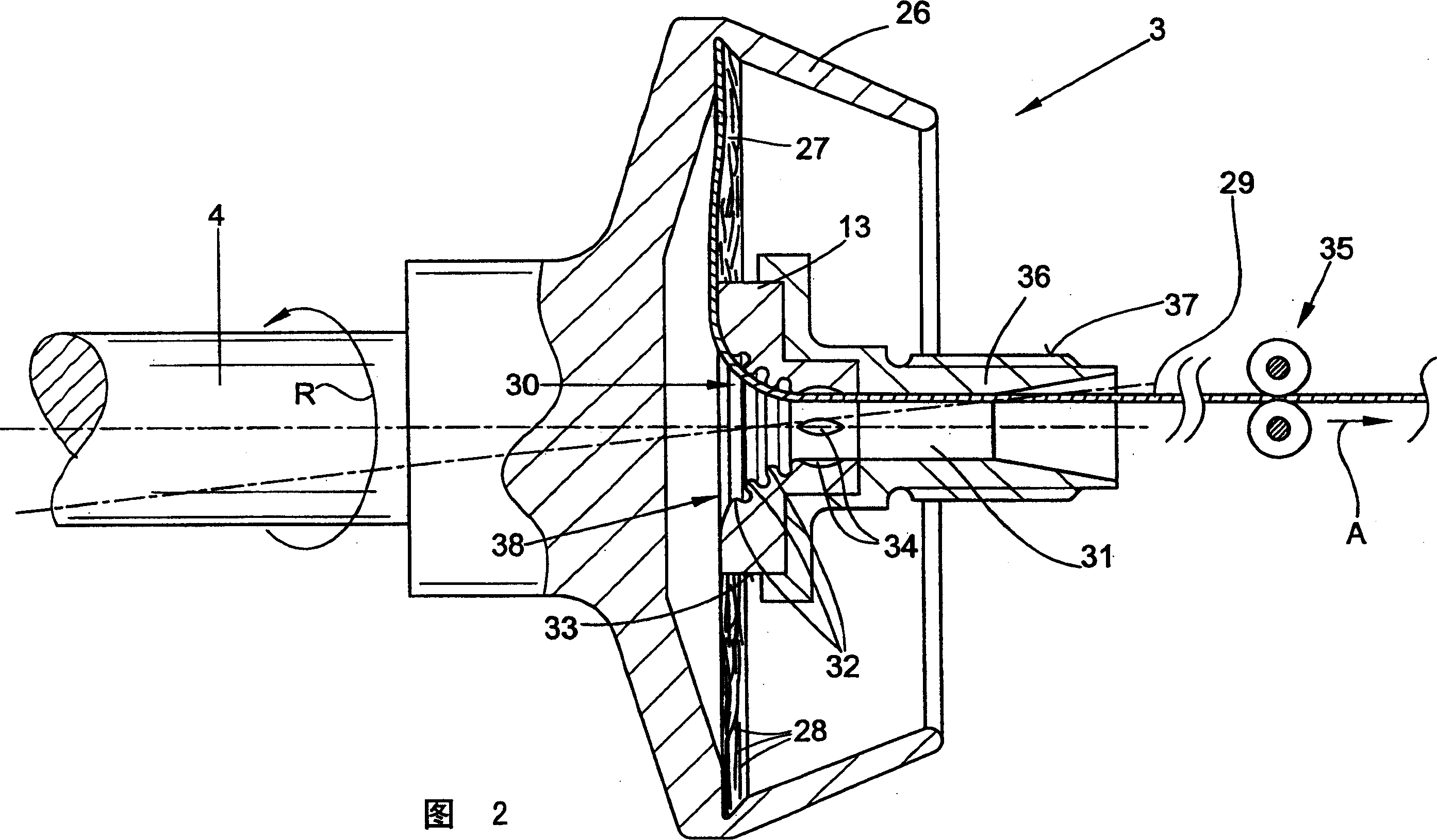

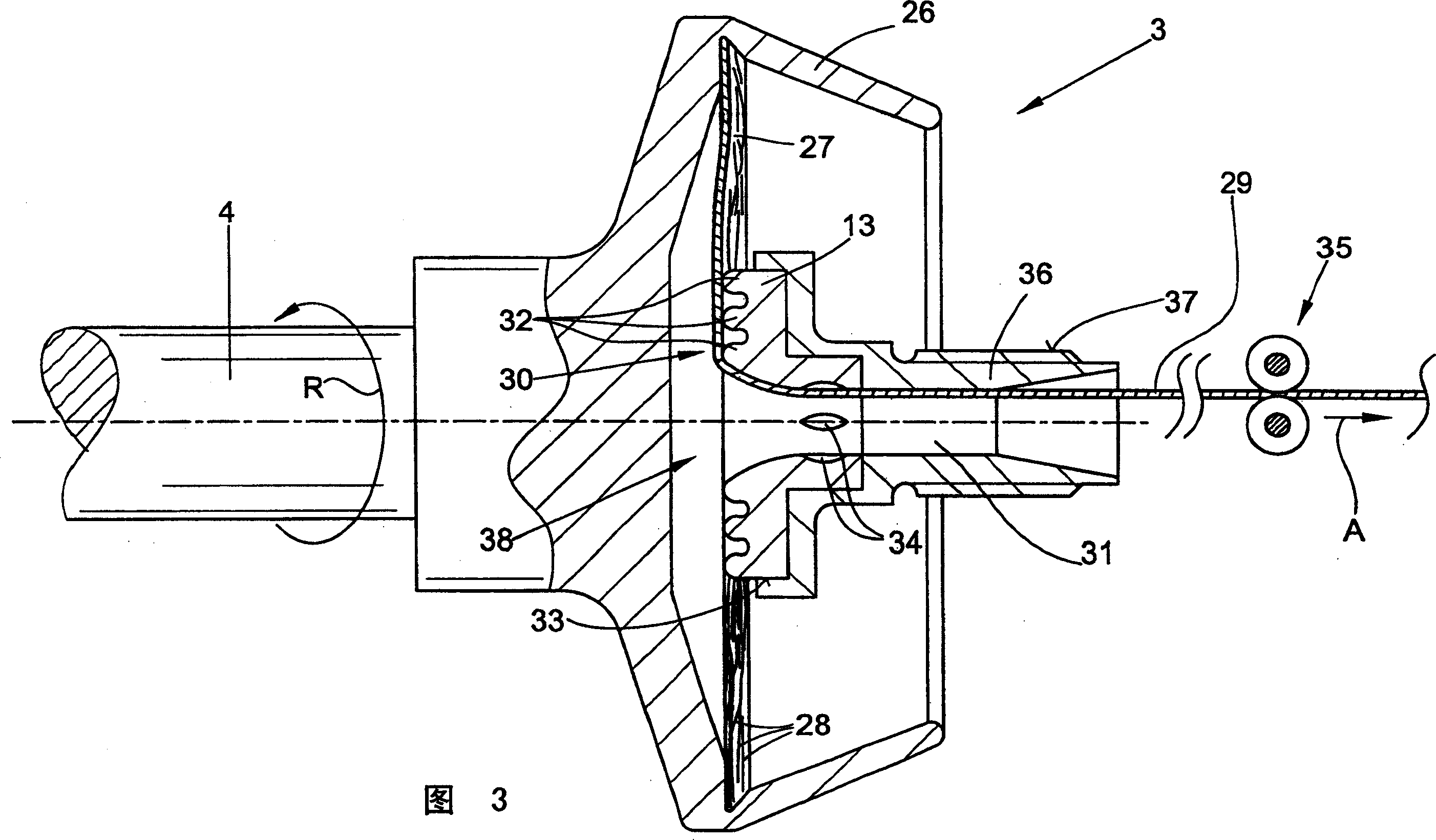

Yarn resistant twisting head

InactiveCN1570230AImprove spinning stabilityOptimize layoutContinuous wound-up machinesOpen-end spinning machinesYarnAirflow

This invention relates to the yarn navel which belongs to one kind of airflow spinning device.It includes a coaxial structure which arranges in the entrance funnel, and a slot is apart from the funnel in a certain distance.The slot, which goes along the yarn's movement direction ,is located in the downstream of the coaxial structure. According to this invention,the coaxial arrangement structure (30) constitutes through the different diameter circular bulges or the slots (32).

Owner:SAURER GERMANY GMBH & CO KG

Process for producing polyurethane elastomer and elastic filament

InactiveCN1261930ASuppress generationImprove spinning stabilityMonocomponent polyurethanes artificial filamentPolyurethane elastomerYarn

A process for producing a polyurethane elastic material or polyurethane elastic yarn from a first polymer diol having a molecular weight of 600 or more, a second polymer diol having a molecular weight of 600 or more, a first low molecular weight diol having a molecular weight of 500 or less, a second low molecular weight diol, a first diisocyanate and a second diisocyanate as main starting materials, the total amount of the first diisocyanate and the second diisocyanate in the starting materials being 0.95 to 1.25 times the total molar amount of the first polymer diol, the second polymer diol, the first low molecular weight diol and the second low molecular weight diol, comprising the step of: extruding continuously extruding from a nozzle a polyurethane polymer in fluid state obtained by continuously reacting a prepolymer having hydroxyl-terminal obtained by reacting the first polymer diol, the first low molecular weight diol and the first diisocyanate, with a prepolymer having isocyanate-terminal obtained by reacting the second polymer diol, the second low molecular weight diol and the second diisocyanate.

Owner:NISSHINBO IND INC

Spinning cellulose diacetate fiber preparation method

ActiveCN110685021AReduce viscosityIncrease concentrationSpinning solution de-aeratingArtificial filaments from cellulose derivativesFiberPolymer science

The invention discloses a spinning cellulose diacetate fiber preparation method which includes the steps: 1) preparing spinning pulp by a solid phase and a liquid phase, and uniformly stirring and mixing the solid phase and the liquid phase to obtain the spinning pulp; 2) primarily filtering the spinning pulp by a pressure filter and secondarily filtering obtained filtrate; 3) pressurizing and heating the filtrate obtained in the step 2) to reach 1.0Mpa and 59 DEG C or more, performing dry spinning on the filtrate after passing a candle filter and a precision metering pump, and applying a flash spinning technology in the spinning process with the draft ratio of 1.5-2.0; 4) crimping fibers formed after spinning to obtain cellulose diacetate fibers. The solid phase comprises cellulose diacetate and wood pulp fibers, the liquid phase is mixed solution of acetone, water and internal lubricants, and differential pressure is as low as 0.1-0.3MPa. By the aid of the method, the spinning cellulose diacetate fibers can be industrialized, and high-strength low-denier short fibers are produced.

Owner:HUBEI XINYANG SPECIAL FIBER CO LTD

Preparation method of PBAT short fiber

ActiveCN114717685ABiodegradableMeet the needs of environmental protectionBio-packagingConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention discloses a preparation method of a PBAT short fiber. The preparation method comprises the following steps: (1) preparing an antibacterial PBAT master batch: uniformly mixing the PBAT master batch with an antibacterial agent, and carrying out melt extrusion, water cooling and grain-sized dicing to obtain the antibacterial PBAT master batch; the antibacterial agent is porous nano zinc oxide loaded with sodium benzoate; (2) drying the raw materials: drying the PBAT master batch and the antibacterial PBAT master batch, and respectively taking the PBAT master batch and the antibacterial PBAT master batch as a core layer material and a skin layer material; (3) fore-spinning: after respectively melting and extruding the core layer material and the skin layer material, performing extrusion molding through a skin-core type composite spinning assembly, and performing circular blowing cooling and winding treatment; and (4) post-spinning: oiling the wound fibers, drafting, and cutting to obtain the PBAT staple fibers. The spinning stability of the PBAT fiber is improved and high-speed continuous spinning is realized by regulating and controlling the fiber components and the process in the spinning process.

Owner:浙江安顺化纤有限公司

Tinting master batch capable of improving polyester fiber brightness and tinting strength

ActiveCN109054310AImprove vividnessHigh tinting strengthPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses tinting master batch capable of improving brightness and tinting strength of polyester fibers. The tinting master batch is prepared from 20-30% of pigment, 5-10% of ethylene acrylate copolymer, 2-5% of dispersion agent and the balance of carrier resin. According to the tinting master batch capable of improving the polyester fiber brightness and tinting strength, the pigmentand the ethylene acrylate copolymer are used, so that the brightness and the tinting strength of the polyester fibers using the tinting master batch are improved, wherein the brightness of the polyester fibers is improved by 20%; meanwhile, the spinning stability is improved, pressure is stable, a spinning cycle is prolonged by 20%, moreover, in an assembly cleaning process, the tinting master batch is remained less, cleaning is more convenient, and the cost and energy consumption are obviously reduced.

Owner:汕头市科彩新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com