Wholly aromatic liquid crystal polyester resin, molded article, and electrical/electronic component

一种液晶聚酯、全芳香族的技术,应用在全芳香族液晶聚酯树脂领域,能够解决输出信号品质降低、传输损耗增大等问题,达到提高耐热性、提高膜制造性、耐热性以及加工性的平衡优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] Add 5 mol% of p-hydroxybenzoic acid (HBA), 48 mol% of 6-hydroxy-2-naphthoic acid (HNA), 23.5 mol% of 4,4-dihydroxybiphenyl (BP), 23.5 mol% of terephthalic acid (TPA), charged with potassium acetate and magnesium acetate as a catalyst, decompression-nitrogen injection of the polymerization vessel was performed 3 times, and after nitrogen replacement, acetic anhydride (1.08% relative to the hydroxyl group) was added. molar equivalent), the temperature was raised to 150° C., and the acetylation reaction was carried out under reflux for 2 hours.

[0133] After the acetylation, the polymerization container in the state where the acetic acid was distilled was heated up at 0.5°C / min. When the melt temperature in the tank reached 300°C, the polymer was taken out and cooled to solidify. The obtained polymer was pulverized to a size capable of passing through a sieve with a mesh size of 2.0 mm to obtain a prepolymer.

[0134] Next, in an oven manufactured by Yamato Scientific Co...

Embodiment 2

[0136] A liquid crystal polyester resin was obtained in the same manner as in Example 1 except that the charged amount of the monomers was changed to 3 mol % of HBA, 54 mol % of HNA, 21.5 mol % of BP, and 21.5 mol % of TPA, and it was confirmed in the same manner as above liquid crystallinity.

Embodiment 3

[0138] A liquid crystal polyester resin was obtained in the same manner as in Example 1 except that the charged amount of the monomer was changed to 6 mol % of HBA, 54 mol % of HNA, 20 mol % of BP, and 20 mol % of TPA, and it was confirmed in the same manner as above liquid crystallinity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

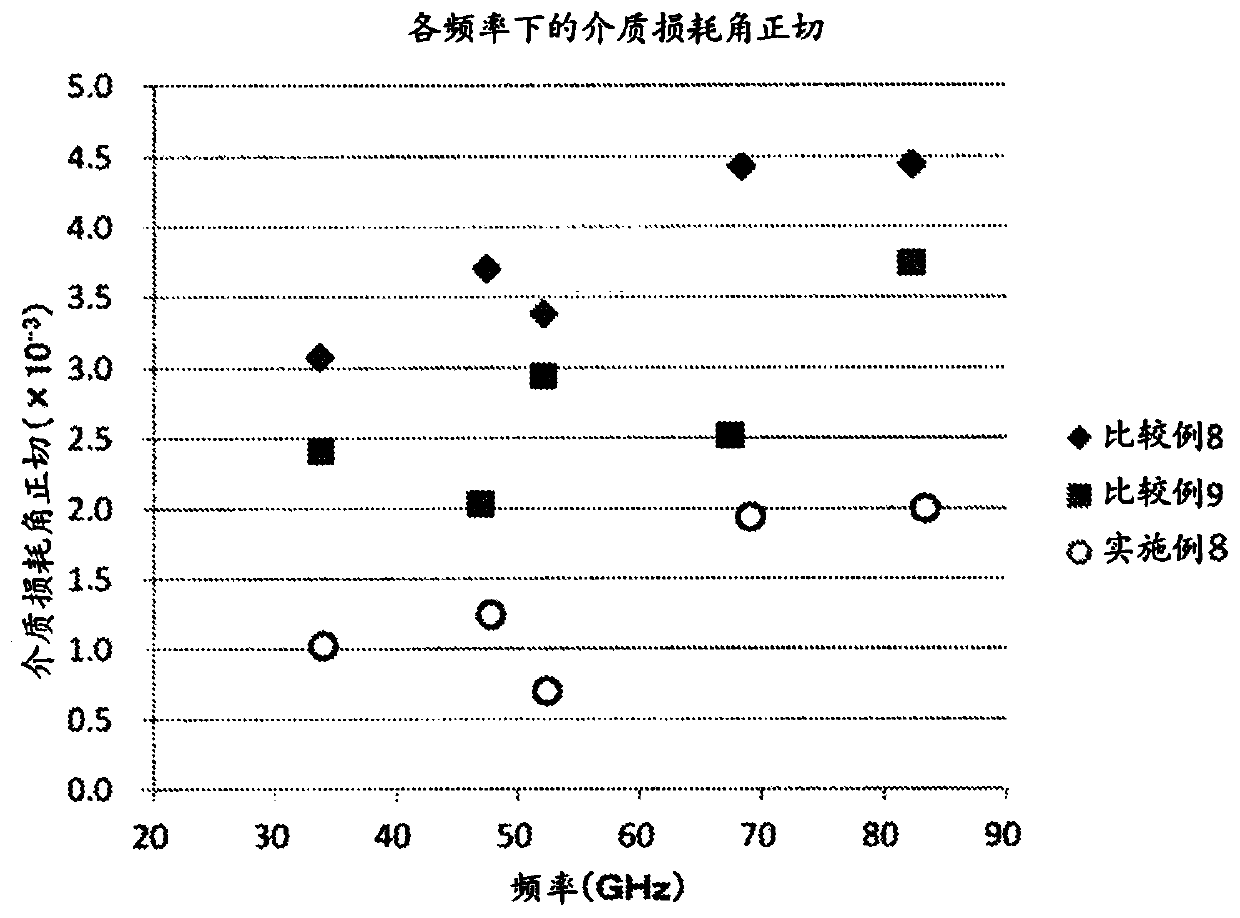

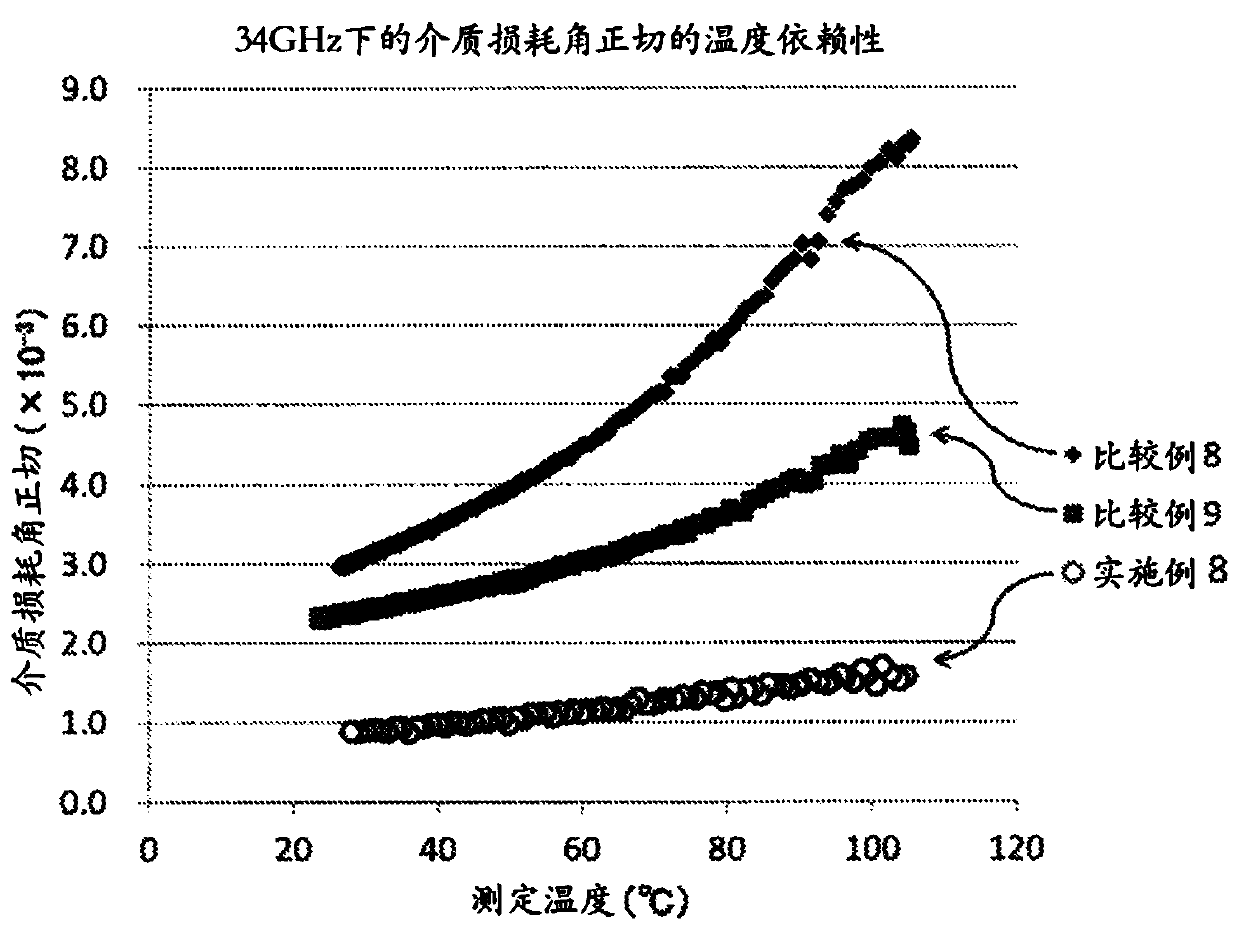

| loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com