Open-end spinning device with an exchangeable twist congesting element

A holding element, rotor spinning technology, applied in the direction of continuous winding spinning machine, spinning machine, open-end spinning machine, etc., can solve problems such as uneven yarn, achieve high yarn quality and high flexibility performance, reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

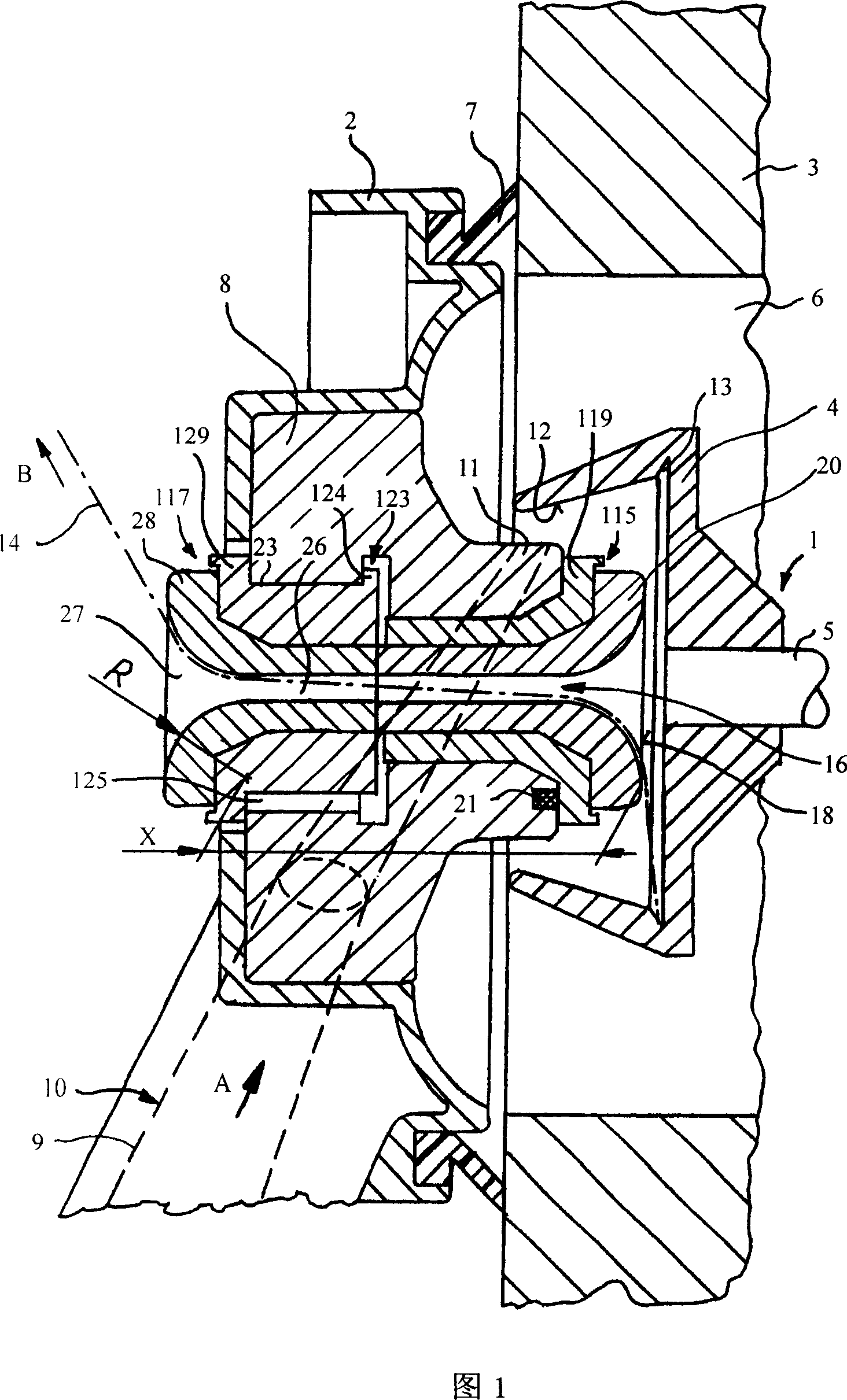

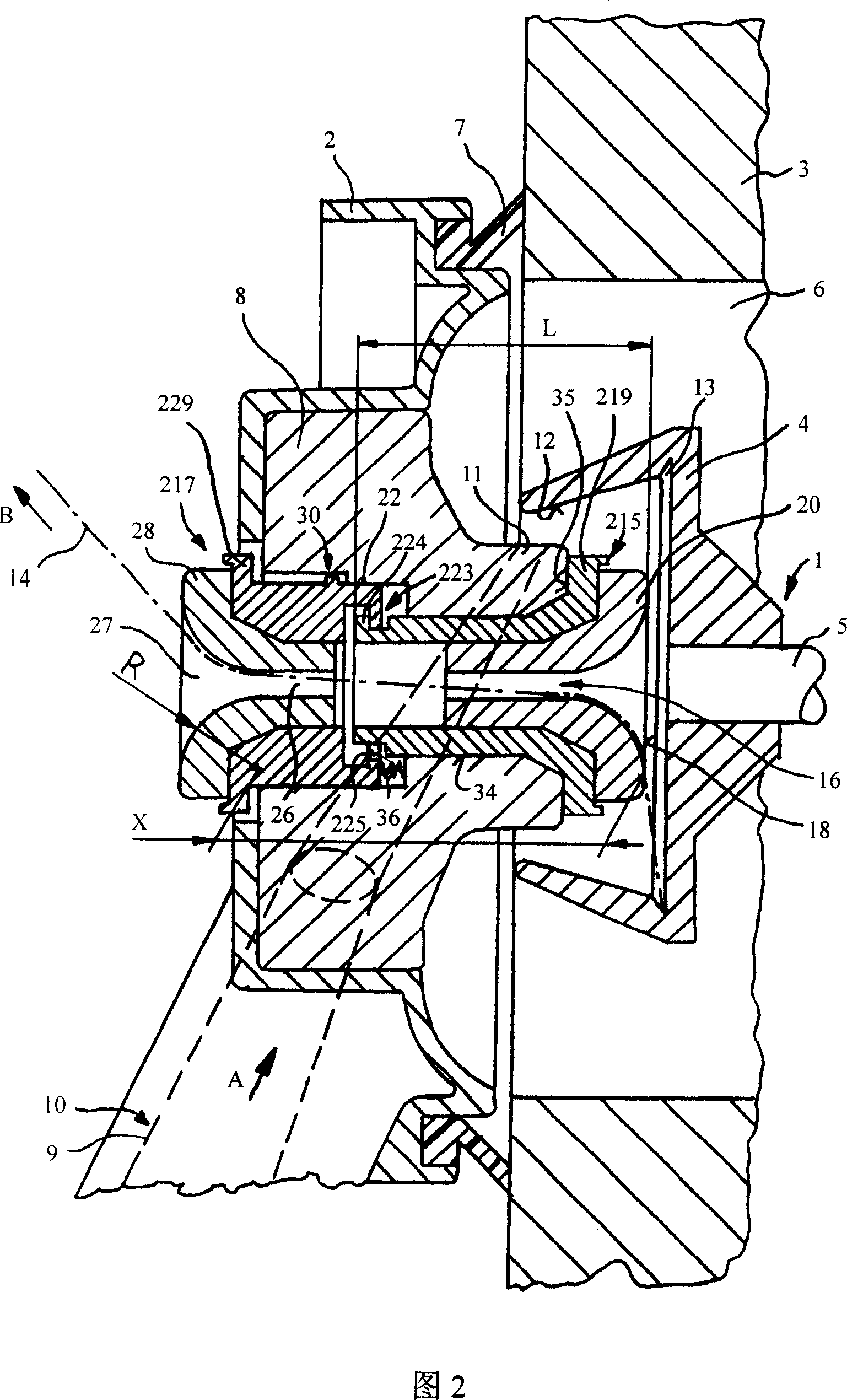

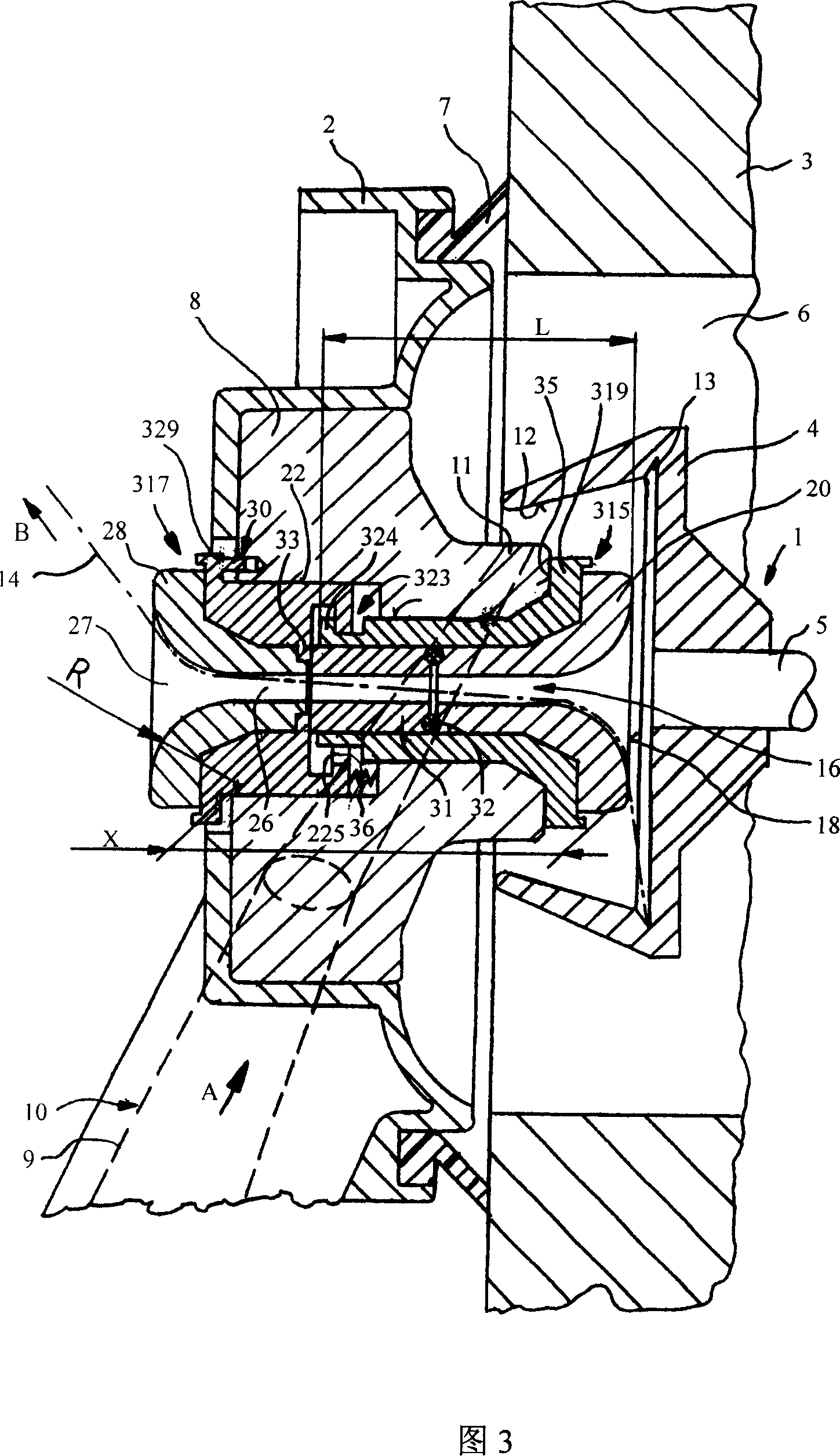

[0034] FIG. 1 shows a spinning rotor 1 enclosed in a rotor housing 3 by a cover 2 on a rotor spinning spinning device. The spinning rotor 1 is formed in a known manner from a rotor disk 4 and a shaft 5 supported and driven in a manner not shown in the figures.

[0035] In the operating state, the rotor disk 4 rotates in a known manner in a negative-pressure chamber 6 formed by the rotor housing 3 . During operation, the rotor housing 3 is closed with a cover 2 which can be removed for maintenance purposes. The sealing ring 7 is used for sealing between the cover 2 and the rotor housing 3 .

[0036] On the cover 2 , which is often designated as a bezel, a substantially rotationally symmetrical bezel adapter 8 is arranged as an exchangeable projection, which can protrude partially into the interior of the rotor disk 4 . A section 9 of a fiber feed trough 10 is arranged in the cover 2, the fiber feed trough 10 extends from the opening roller, not shown in the figure, to the rot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com