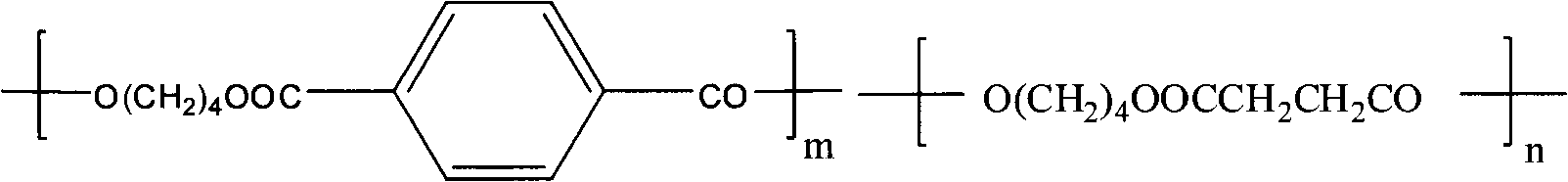

Method for preparing biodegradable copolyester fully-drawn yarns in one step

A technology of full-drawn yarn and copolyester, which is applied in the direction of single-component copolyester artificial filament, filament generation, melt spinning, etc., to achieve good evenness, good spinning stability, and increased strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

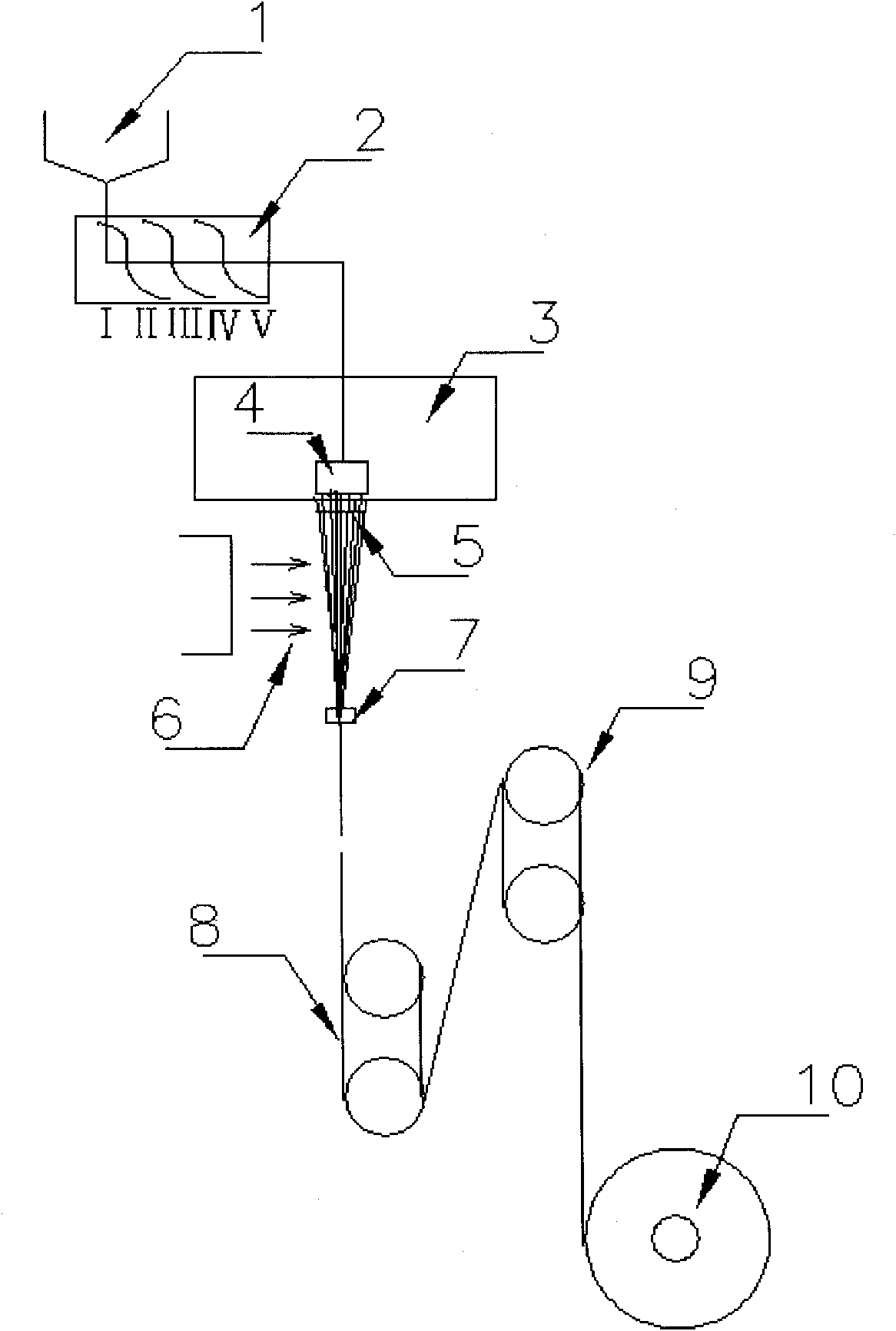

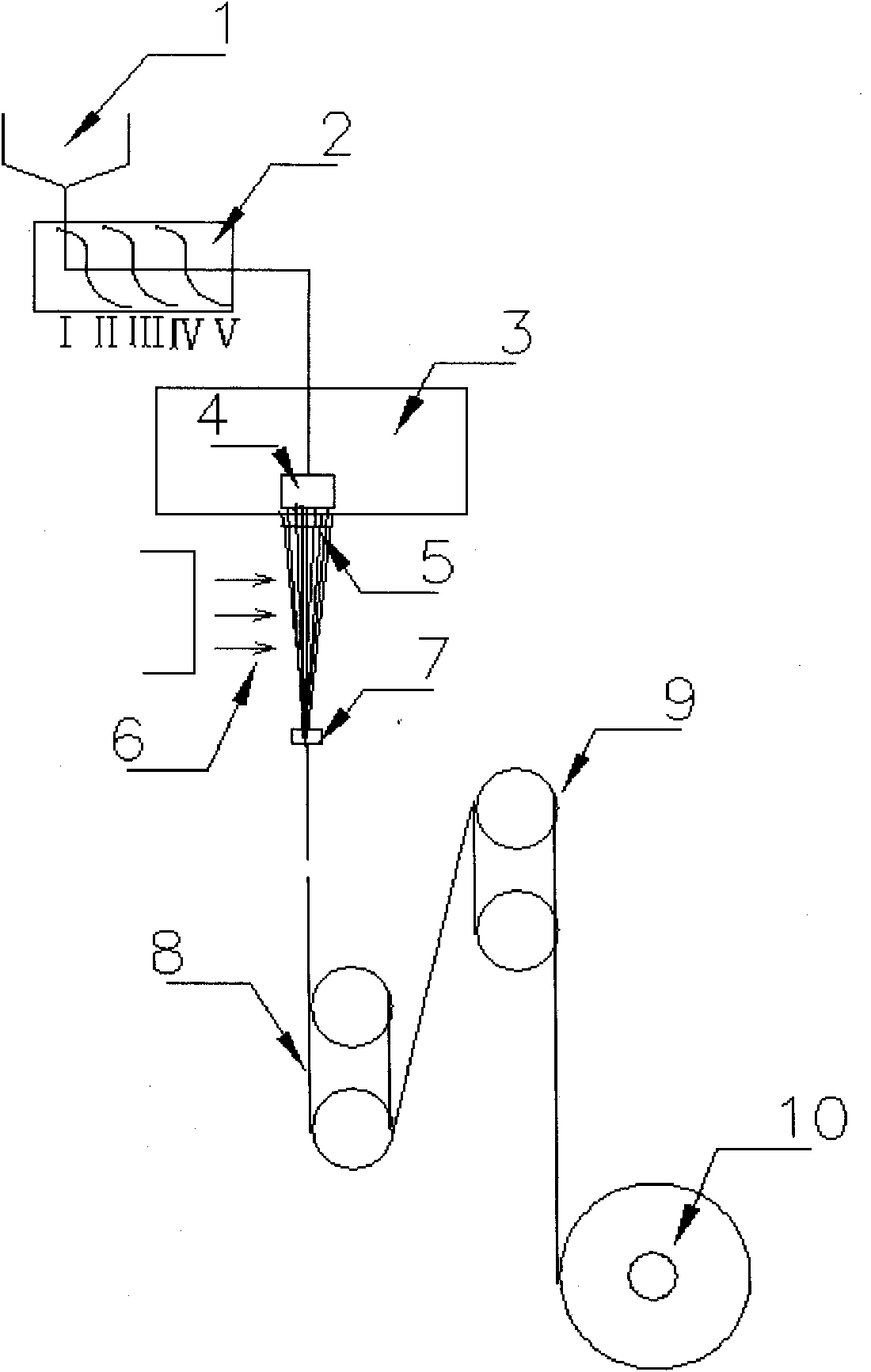

[0024] Chips of polybutylene terephthalate-co-butylene succinate (PBST) with an intrinsic viscosity of 0.85dL / g and a weight average molecular weight of 92,000 were dried in a vacuum oven at 110°C for 24 hours and then fed The hopper 1 of the one-step melt spinning machine is then extruded and heated through the five zones of the screw extrusion device 2. The temperature in zone I is 185°C, the temperature in zone II is 190°C, the temperature in zone III is 200°C, and the temperature in zone IV is 220°C, the temperature in the V zone is 240°C, and then enters the box 3, the temperature of the box 3 is 250°C, then the melt passes through the metering pump 4 and is ejected from the spinneret 5, the flow rate of the metering pump 4 is 30g / min, The aperture of the spinneret 5 is 0.32mm, the aspect ratio is 4.0, and the number of holes is 36 holes; the polybutylene terephthalate-co-butylene succinate melt ejected from the spinneret 5 Thin stream is drawn and formed through two pair...

Embodiment 2

[0027] Polybutylene terephthalate-co-butylene succinate chips with an intrinsic viscosity of 1.05dL / g and a weight average molecular weight of 124,000 were dried in a vacuum oven at 110°C for 24 hours and then fed into one-step melting The hopper 1 of the spinning machine is then extruded and heated through the five zones of the screw extrusion device 2. The temperature in zone I is 190°C, the temperature in zone II is 200°C, the temperature in zone III is 215°C, and the temperature in zone IV is 230°C. The temperature in the V zone is 245°C, and then enters the box body 3, the temperature of the box body 3 is 255°C, then the melt passes through the metering pump 4 and is ejected from the spinneret 5, the flow rate of the metering pump 4 is 38g / min, and the spinneret The aperture of 5 is 0.32mm, aspect ratio is 4.0, and number of holes is 36 holes; The polybutylene terephthalate-co-butylene succinate melt stream that sprays out from spinneret 5, Carry out draft forming through...

Embodiment 3

[0030]Polybutylene terephthalate-co-butylene succinate chips with an intrinsic viscosity of 1.15dL / g and a weight average molecular weight of 140,000 were dried in a vacuum oven at 110°C for 24 hours and then fed into one-step melting The hopper 1 of the spinning machine is then extruded and heated through the five zones of the screw extrusion device 2. The temperature in zone I is 200°C, the temperature in zone II is 210°C, the temperature in zone III is 220°C, and the temperature in zone IV is 235°C. The temperature in the V zone is 255°C, and then enters the box 3, the temperature of the box 3 is 265°C, then the melt passes through the metering pump 4 and is ejected from the spinneret 5, the flow rate of the metering pump 4 is 30g / min, and the spinneret The aperture of 5 is 0.32mm, aspect ratio is 4.0, and number of holes is 36 holes; The polybutylene terephthalate-co-butylene succinate melt stream that sprays out from spinneret 5, Carry out draft forming through two pairs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com