Thread tube of open end spinning arrangement

A technology of air spinning and yarn guide, applied in the field of yarn guide, can solve problems such as poor strength and uniformity, achieve good yarn value, improve yarn quality, and improve spinning stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

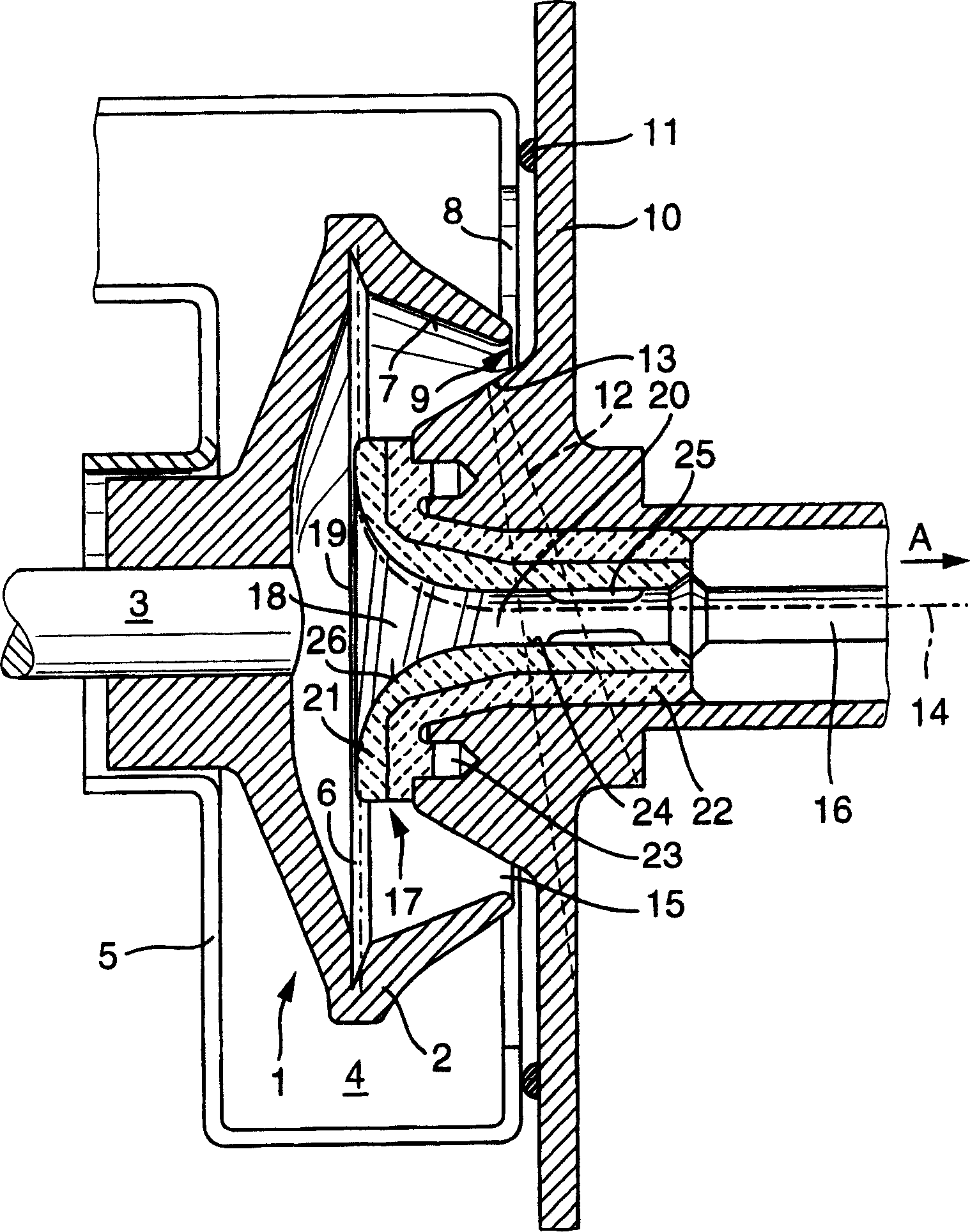

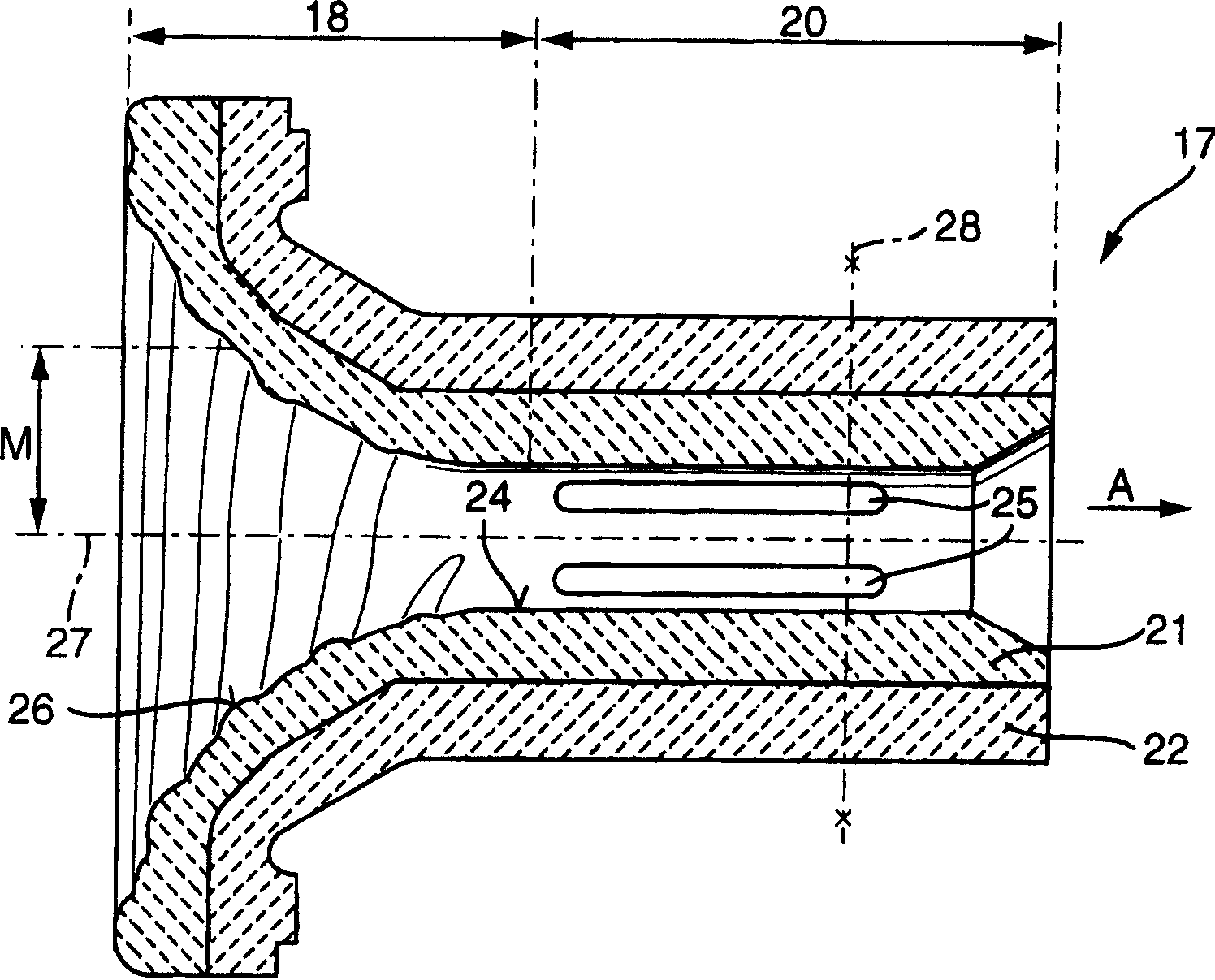

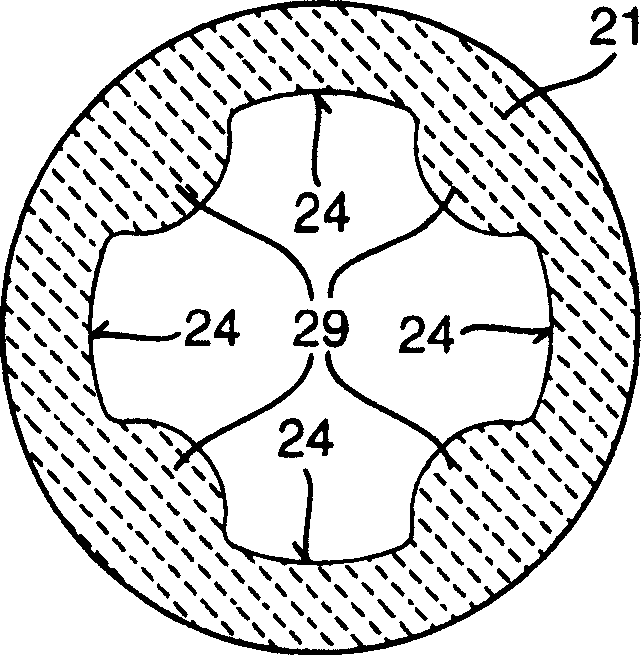

[0022] figure 1 The open-end rotor spinning device, shown only partially in , comprises a rotor 1 consisting of a cup disc 2 and a mandrel 3 pressed into it. The arbor 3 is supported and driven in a manner not shown. The cup and plate 2 rotate in the negative pressure chamber 4 formed by the cup shell 5 when working, and the cup shell is connected on the negative pressure source in a manner not shown.

[0023] The cup tray 2 has a fiber sliding surface 7 that expands conically toward the fiber collecting groove 6 . In the fiber collection groove 6, the diameter of the hollow cavity of the cup and tray 2 is the largest. The rotor 1 can be pulled out through the front opening 8 of the cup housing 5 towards the operating surface of the open-end rotor spinning device. In operation, this opening 8 of the cup shell 5 together with the open front 9 of the cup tray 2 is closed by a removable guard 10 . The guard plate 10 is tightly attached to the cup shell 5 by connecting an annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com