Start-stop control method of blowing and suction trolley of spinning machine

A start-stop control, blowing and suction technology, applied in textiles and papermaking, etc., can solve the problems of yarn drying and breakage, lower yield, no energy saving, etc., to achieve improved reliability, improved spinning stability, and reduced control cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

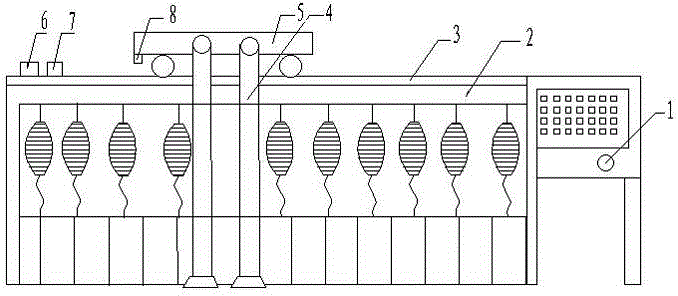

[0007] The method for controlling the start and stop of the blowing and suction trolley of the spinning frame includes the following steps. First, a blowing and suction switch 1 is added on the control panel on the motor box of the spinning frame, and a support frame 2 is arranged along the length direction of the spinning frame body. The support frame 2 is provided with a track 3 for the sliding of the blowing and suction trolley 5, and the blowing and suction ducts 4 are respectively arranged on both sides of the blowing and suction trolley 5. The wind trolley 5 starts to move towards the rear of the car at the front of the car, and the blowing and suctioning trolley 5 sucks the waste yarn and fluff on the ground into the blowing and suctioning duct 4 through the blowing and suctioning duct 4 during the moving process; A proximity switch 6 and an infrared detection delay switch 7 are added at the place, and a touch switch 8 is added on the air blowing and suction trolley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com