Channel disc connector for open-end spinning device

A technology of open-end spinning and splicer, which is applied in spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve the problem of insufficient magnetic fixation of yarn guide nozzle, high price, complicated manufacturing, etc. problems, to achieve reliable connection, reduce manufacturing costs, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

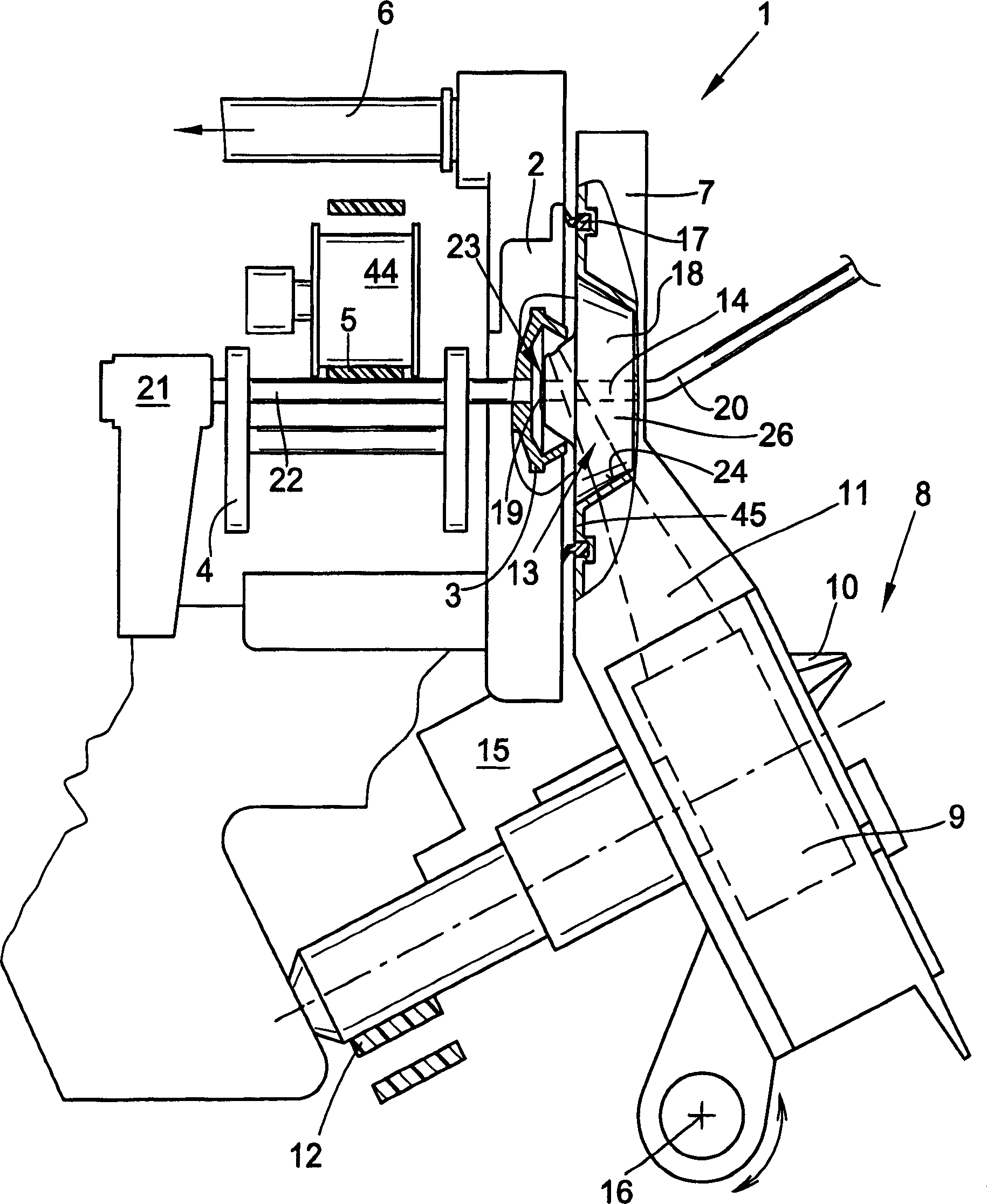

[0036] figure 1 The rotor spinning device 1 shown in the figure has a known rotor housing 2 in which a rotor 3 rotates at high speed during spinning production. The rotor 3 is supported with its rotor shaft 22 in the bearing wedge of the washer bearing 4 and is axially fixed by an axial bearing 21 , for example a permanent magnet.

[0037] The rotor 3 is usually driven by a tangential drive belt 5 which leans against the rotor shaft 22 by means of a support roller 44 .

[0038] The rotor housing 2, which is open to the front, is connected to a vacuum source (not shown) via a suction line 6 and is closed at the front by a so-called fiber channel disk 45 during spinning production.

[0039] The fiber channel disk 45 is mounted on a housing 7 which is rotatably mounted around the axis of rotation 16 and bears against the end face of the rotor housing 2 with a lip sealing element 17 .

[0040] Furthermore, a sliver feeding and opening mechanism 8 is integrated in the housing 7 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com