Spinning device for air exhaust type rotor spinning machine

A technology of rotor spinning machine and spinning machine, which is applied in spinning machine, open-end spinning machine, continuous winding spinning machine, etc. Quality reduction and other problems, to achieve the effect of stable positioning, convenient installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

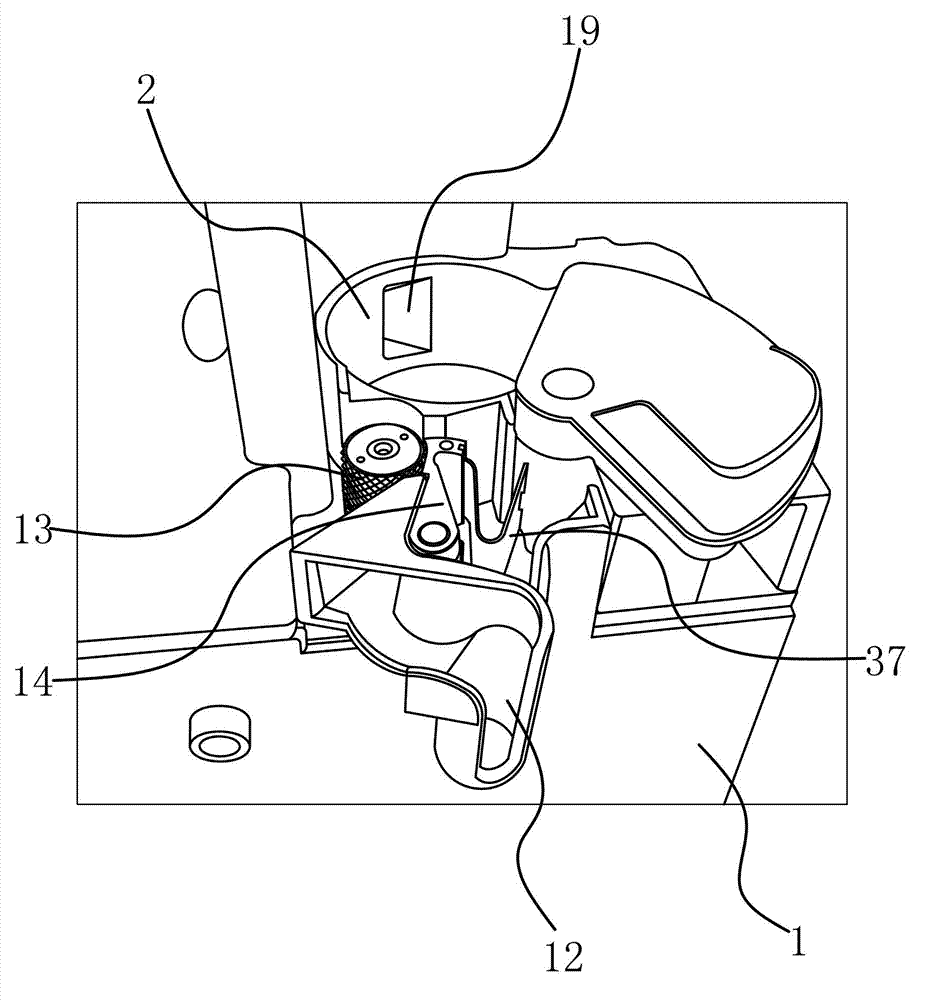

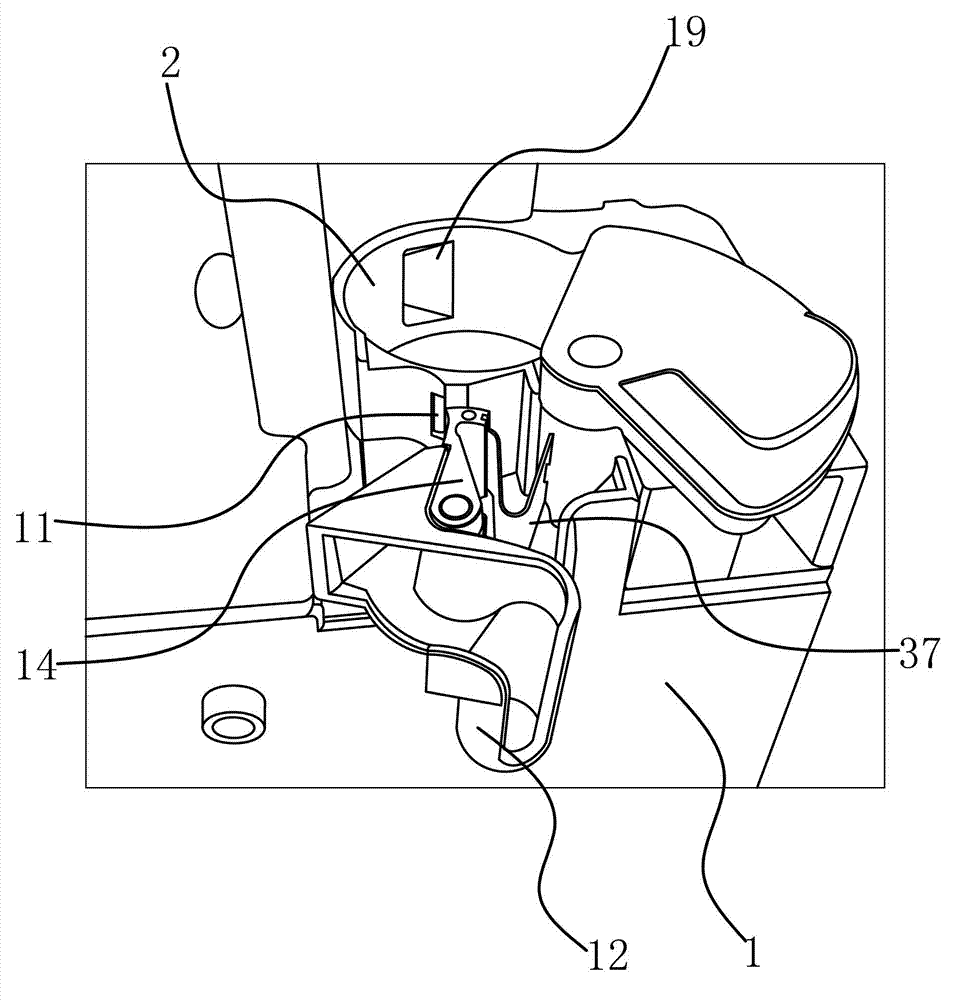

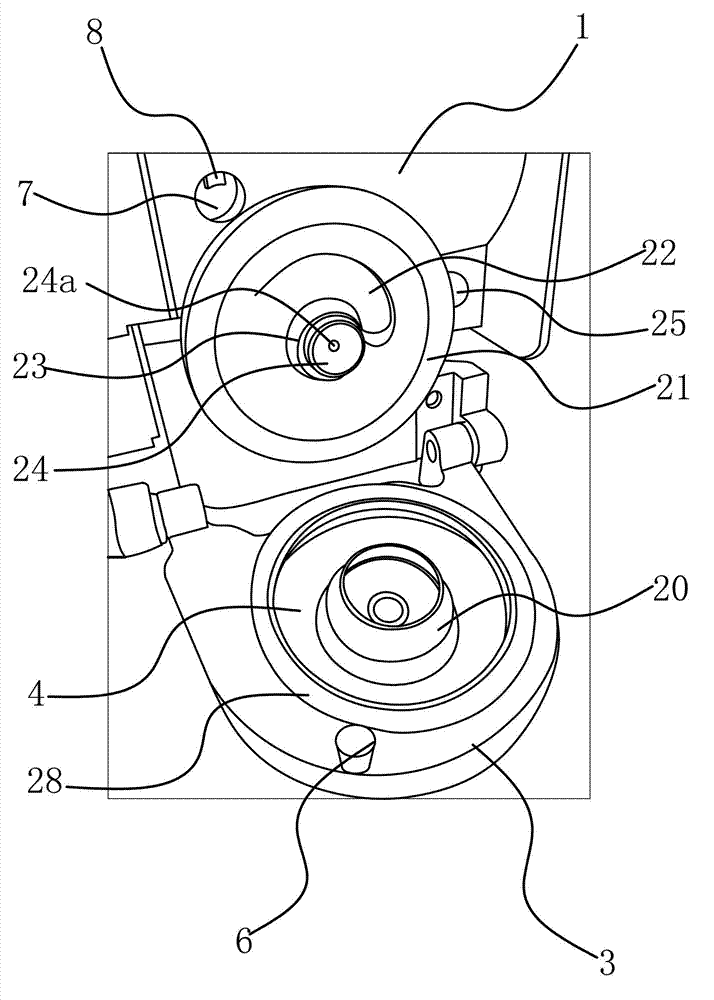

[0042] The spinning device of the air suction rotor spinning machine includes a housing 1, on which a cotton feeding device, a miscellaneous removal device, a rotor device, a rotor seat 3 and a yarn guide tube 5 are arranged. The cotton feeding device feeds the cotton sliver into the carding device, and the carding device combs the cotton sliver into single fibers. During the carding process, the impurities on the cotton sliver are discharged from the waste removal device, and the single fiber enters under the action of negative pressure. The rotor device forms a sliver in the rotor device and leads from the yarn guide tube 5 .

[0043] Specifically, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com